Page 1

Instruction Leaflet

RS stock no. 437-648

Issued August 1997 9778

Advantage 6 Alarm Panel

Introduction

The control panel is designed to be simple to install,

programme, and to use. The 16 button keypad allows you to

select, change,or inhibit the many facilities available in the unit.

A remote ke ypad is a v ailable separ atel y for arming ,part arming

and disarming the unit

The control panel is programmed using either the user code

(factory set 1234) or the engineer code (factory set 9999). It is

advisable to change both code numbers to a personally

selected code, using any combination from 0000 to 9999, when

the installation is complete.

The engineer programmes are protected by a non volatile

memory (NVM). This means that when all power has been

removed and then reconnected any previously programmed

information remains operative. The NVM facility also protects

the control panel microchip from mains surges and spikes.

The control panel provides 6 detector zones, a personal attack

circuit and two tamper circuits. All zones are capable of

operation with normally open and normally closed detectors. A

bank of 10 LED indicators will indicate the status whilst

programming or whilst in use.

An integral battery charge circuit will enable a rechargeable

battery such as RS stock no. 597-813 to provide power during

mains failure. Outputs are provided for bell/sounder, and

strobe.

The 6 detector zones are active only when the control panel is

armed. The personal attack circuit, 24hr circuits are active 24

hours a day even if the control panel is disarmed.

The advantage keypad

The advantage keypad uses ICONS to picture the key function,

a list of key functions follows in figure 1:

The control panel is factory set to be armed without the need to

enter the user code. It is possible to programme the control

panel so a user code is required to arm the system. If this mode

is selected the user code can only be changed by either,

programming under the engineer mode or, returning the

control panel to symbol arming mode then the user selecting a

new code and returning to control panel to user code arming

code.

Note: Please ensure you read this document completely

before you begin your installation.

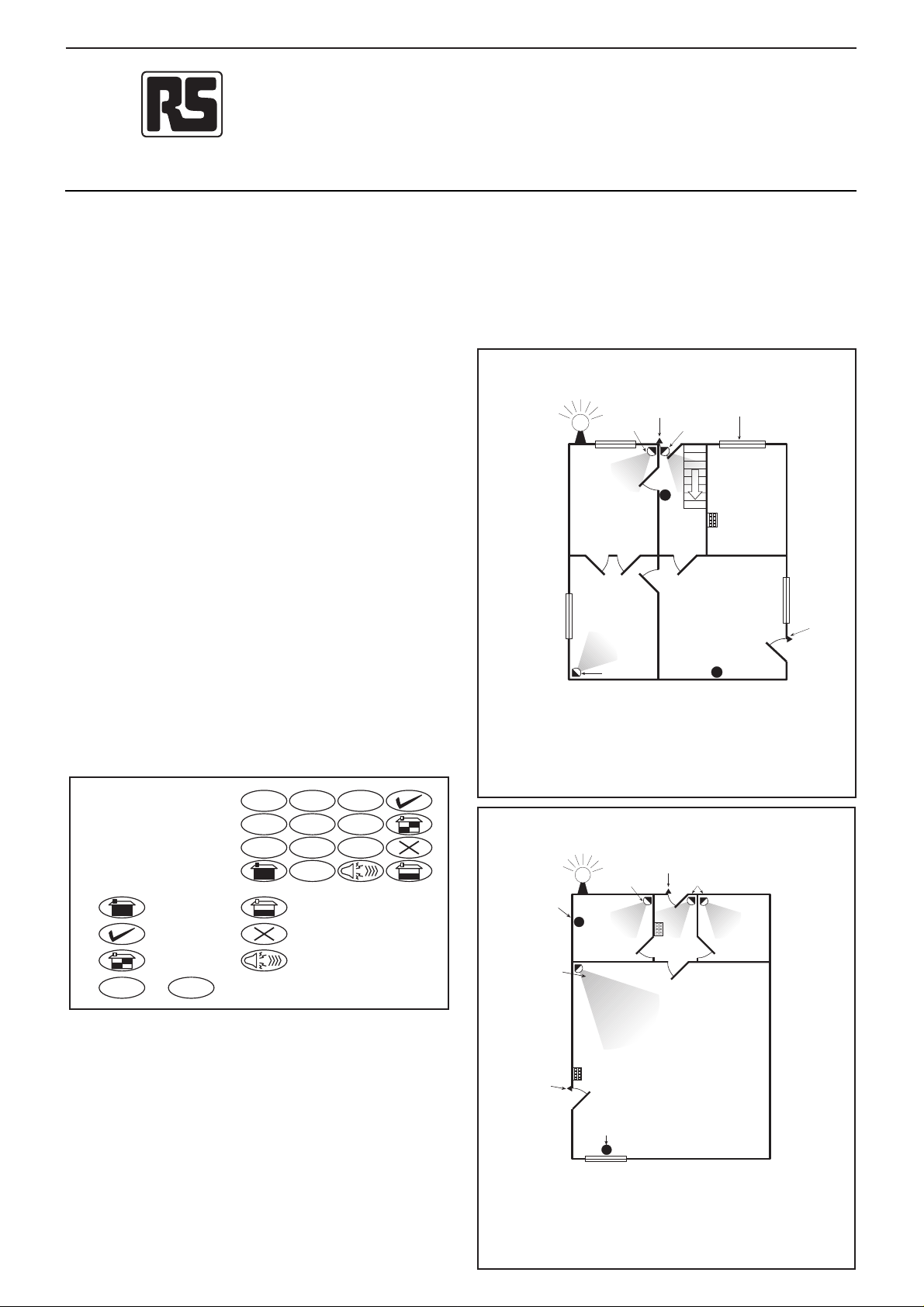

System planning

T o ensure the installation pr oceeds smoothly it is best to plan the

work before you begin. Start by drawing a plan of the building

(see figure 2 and 3). You will need to divide the building into

zones. Zone 1 is always used as the final exit zone with the

advantage panel and zone 2 is factory programmed as walk

through (this may be altered).

Office

Factory

Lobby

Accounts

A

B

C

D

E

F

GG

H

I

J

K

A

Figure 1

Full set

Arm

Zone omit

Part set

Reset

Event replay

to Numeric keys

Figure 2 Ground floor view

A. Magnetic contact zone 1

B. Zone 2

C. Zone 3

D. Magnetic contact zone 4

E. Zone 5

F. PIR

G. Siren

H. Personal attack switch

I. Vibration detector

J. Control panel

Note: Alarm control panel should

be located within the

protected area

Note: Zone 6 may be a PIR on the

first floor landing

Figure 3 Ground floor view of a commercial premises

A. Magnetic contact zone 1

B. Zone 2

C. Dual tech zone 3

D. Vibration detector zone 4

E. Zone 5

F. Zone 6

G. PIR

H. Siren

I. Personal attack switch

J. Control panel

K. Additional keypad

09

0

G

A A

FF

BC

Lounge

Dining

Room

CC

F

H

Hall

321

654

987

Garage

K

Kitchen

D

E

I

Page 2

9778

2

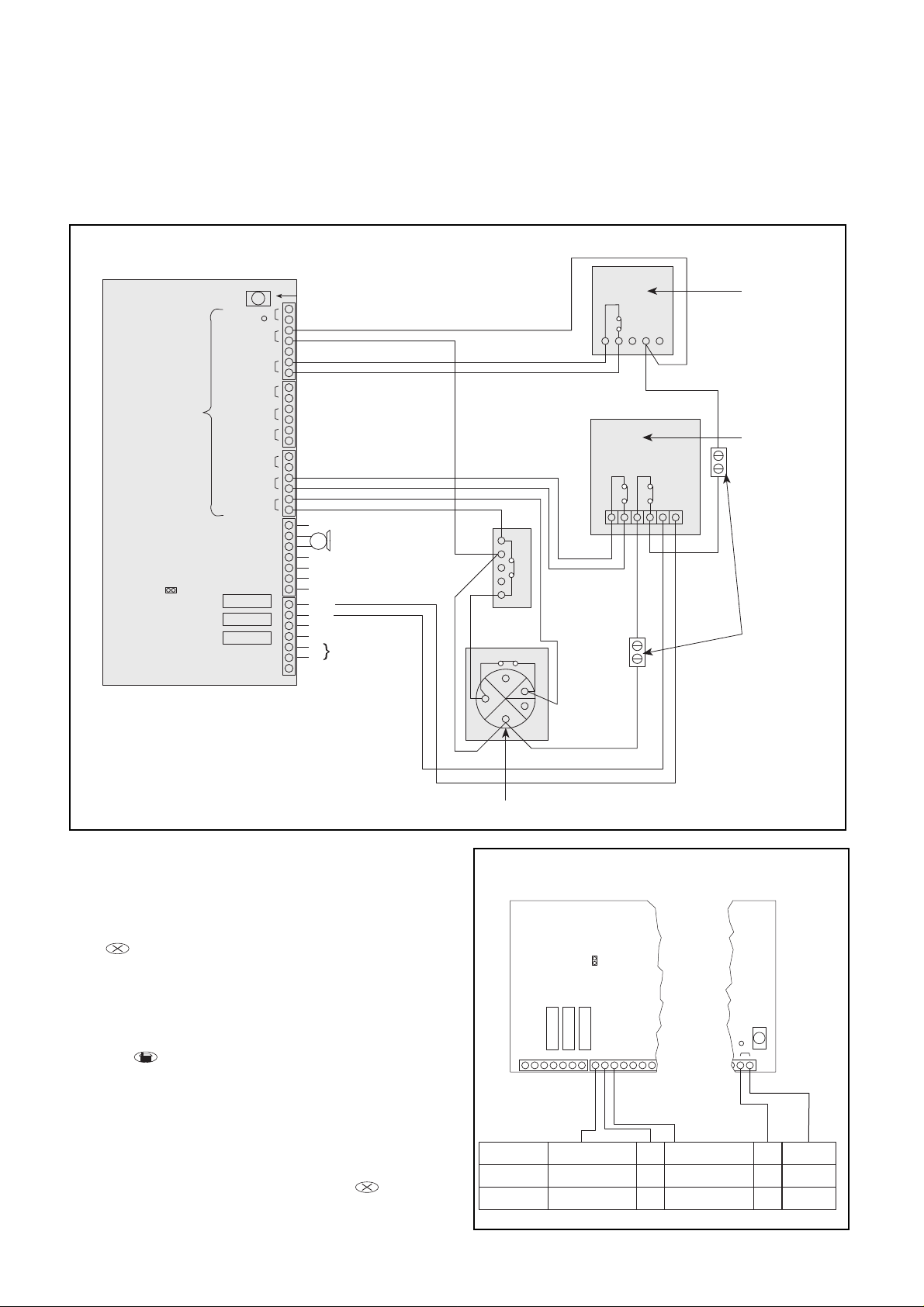

System layout

The system layouts shown are a guide to typical positions of the

system components. This will obviously vary depending on the

premises and level of protection to be afforded. However the

general rules given cover all installation layouts.

General rules

1. Final exit doors should have magnetic contact switches fitted

to ensure that the premises cannot be vacated with the doors

left open and also to protect against forced entry.

2. PIR detectors are best fitted where an intruder has to pass

through an area to gain access (i.e.halls and landings) or to

protect specific valuable items (i.e. lounge). Care should be

taken in siting to avoid direct sunlight, strong lighting and

heat sources (hence the vibration detector s in the kitchen) as

these may cause nuisance tripping. They are best sited so

the intruder cuts across the field of view, see figure 2 (some

products are specif ically designed for long corridors in this

instance this rule does not apply),hence a corner position is

usually adopted.

3. PIR, ultrasonic, vibration detectors, etc. all have complex

electronics. These are best given their own zone as in the

event of a fault occurring isolating the fault will be quicker

and nuisance tripping quickly eliminated. Magnetic door

contacts tend to be very reliable if installed well within their

magnetic actuation limit. Hence these can be put in ser ies

together on a loop if appropriate. They are also easier to test

if faulty.

4. Wir ing is best concealed where possible to prevent damage

and tampering. Try to avoid running alongside mains cables

as interference may occur.

5. The sounder/SAB unit should be fitted well above head

height to avoid tampering. The wiring should pass directly

through the wall behind the unit to make it inaccessible.

6. The control panel requires a 240V power source. An

unswitched fused spur preferably direct from the consumer

unit on its own fuse wired in accordance with the current IEE

regulations should be provided.

Using the above general rules you should plan your installation

on your sketched drawing considering the panel siting,how the

cable runs can be minimised, where different types of detector

will be fitted and which zone they will be on. When you have

finalised your plan you can begin installation.

Installation

The following instructions should be followed in sequence to

ensure trouble free installation. To begin with, the alarm panel

should be tested.

The control panel

Printed circuit board (PCB) is clearly marked with each output,

input, and the relevant polarity. Wire links are f itted to each of

the 6 zones and the three 24 hour circuits, to simulate closed

circuits. The wire links are removed during installation as each

zone/circuit is connected. Wire links should never be fitted

where no link is depicted across the terminals on the PCB. Most

of the detectors in the security industry are normally closed

contacts these must be wired in series,normally open detectors

such as pressure mats can also be used, wire them between the

zone and the 24 hour terminal.

Testing the control panel

The control panel is fitted with the factory fitted wire links, to

enable the panel to be tested prior to installation.

1. Remove the two front cover screws (located behind the LED

flap) and the front cover, and place safely to one side in the

box provided to eliminate the chance of damage.

2. Check that the 9 factory fitted links (see figure 4) are

positioned across each pair of the 6 zone inputs, PA,

24 hour and SCB terminals. Press down the lid tamper

spring. (It is important that this spring is depressed

throughout the test to avoid the control panel activating). Or

to temporarily defeat the lid tamper connect a wire between

the SCB 0 terminal and the left 24 hour terminal. Do not

forget to remove this wire before commissioning the

system.

3. Fit the 12V battery (

RS stock no. 597-813) to the unit using

battery connecting wires provided. Observe the correct

polarity, red wire to red (+) terminal, black wire to black (-)

terminal. The panel is now ready to test.

4. Press (full guard),the clear LED will illuminate.

5. Remove a factory fitted link wire from zone 1 and the

respective zone LED will light and a tone indication will be

heard. Ref it the link and the zone LED will extinguish.

6. Repeat step 5 for all other zones. For each of the zones

opened a tone indication will be heard,the number of bleeps

will depend on what zone is open i.e. 1 bleep for zone 1, 2

bleeps for zone 2 and so on.

7. Test the lid tamper by releasing the tamper spring, the

internal sounder will activate, replace tamper spring, and

enter user code (1,2,3,4). The 24 hour LED will be

illuminated and the sounder will cease. Press the (reset)

key to return to standby.

8. To test the 24 hour SCB and PA circuit repeat the above

sequence removing and replacing the wire link in each

circuit in turn. After each test enter user code (1,2, 3, 4) then

press reset to return to standby. Disconnect the battery when

you have finished testing.

Siting the control panel

Site the panel in a position which is above the accessible height

of small children. Try to site the control panel close to a mains

electricity supply.

Mark the two fixing holes on the left and right-hand sides of the

bottom and the hole in the top centre on the wall, and fix the

panel loosely. Only secure tightly once installation is complete.

Wiring

Detectors

The exact positioning of the detection devices should now be

decided and the detectors wired. Typically for passive infrared

detectors (PIR) 6-core cable will be required (RS stock no.365-

587) and for door/window contacts 4-core cable (RS stock no.

365-571). If only a limited number of magnetic contacts are

used wire 6-core throughout. Wire the correct cable to each

position. Connect the detectors as shown in figure 5.

Connecting to the mains supply

WARNING - ELECTRICITY CAN KILL

Before connecting the control panel to the mains supply ensure

that the supply is disconnected at the consumer unit.

The ideal mains supply is direct from the consumer unit, on its

own fused spur, wired in accordance with the latest IEE

regulations. You will require 5A 3-core cable suff icient in length

to connect the control panel to the mains power supply.

Figure 4

Cable clamp

Page 3

9778

3

Figure 4 shows the location of the cable clamp. To secure the

cable,use the cable clamp located in the back of the advantage

case. Break off the cable clamp fr om the case. Feed one end of

the 3-core cable through the back of the control panel and

connect as follows to the transformer terminal block.

Live (L) red or brown. Neutral (N) black or blue. Earth (E)

green or green and yellow. Secure the cable clamp over the

cable using the screws provided.

Connecting the sounder unit

Disconnect the mains supply. Run a 6-core cable to the sounder

from the panel.

Connect the sounder unit to the panel as shown in figure 6.

Testing should be carried out in accordance with the

instructions included with the sounder unit.

RT

SWITCHED POSITIVE

STROBE +

STROBE BELL +

BELL -

SPEAKER

NVM RESET

BELL/STROBE F3

SPEAKER

AUX. F2

BATTERY F1

AUX +

AUX BATTERY + RED

BATTERY - BLACK

AC

AC

TRANSFORMER

SCB

24 hour

KEYSWITCH

PA

ZONE 6

ZONE 5

ZONE 4

ZONE 3

ZONE 2

ZONE 1

N/C

N/C

N/C

N/C N/C

- +

These will be

factory supplied

with links as

shown on the

PCB

Figure 5 Control panel detector connections

A

B

C

D

A. Personal attack

B. Zone 2 PIR

C. The series 24 hour loop for each zone is best taken

back to the control panel and linked using a connector

block such as RS stock no. 423-655

D. Zone 1 door/window magnetic contacts

When the mains wiring is completed restore the mains supply,

the mains LED indicator and the keypad should be illuminated.

The panel will bleep replace the front cover. Enter user code

(1234) the 24 hour LED will be illuminated and bleeping will

cease.

Press (reset), the panel will return to standby.

At this stage it is worth checking the detectors for correct

operation.

Detector test

1. Press

2. Now walk around and activate each detector in turn. The

panel will bleep and the LED light as each detector is

activated.

Note: PIRs require a number of minutes setting time

before use.

3. When all detectors have been tested type

NVM RESET

BELL/STROBE F3

SPEAKER

AUX. F2

BATTERY F1

BELL -

BELL +

STROBE -

STROBE +

SW- +Ve

Strobe trig -Ve

Strobe trig -Ve

SW-Ve

RT

SCB

Ret Sig

Ret Sig

Return

0V

-Ve

0V

+Ve

+Ve

740-427

740-433

437-660

Siren trig -Ve

Siren trig -Ve

Figure 6 Sounder connections

Page 4

9778

4

System facilities

6 detector zones are provided, zone 1 is the entr y/exit zone,

activating this zone whilst the system is set will cause the entry

timer to begin and allow time for the panel to be disarmed. The

entry/exit tone will change tempo indicating there are 10

seconds left to disarm or ten seconds remaining to exit before

system is armed.

Part guard zones

The part guard feature allows you to select zones you wish to be

omitted when using the part guard option for arming. Please

note that a part guard zone cannot also be selected as a walk

through zone. If you wish to part guard with a remote key

switch/keypad then it will be necessary to program the control

panel (see remote part guard, under programming the

advantage in this manual).

Quick set

The quick set facility is provided to enable the exit time to be

shortened to a few seconds and avoid the exit tones continuing

when not required.

24 hour circuits

The 24 hour circuit is provided to protect all detector s connected

to this circuit and the control panel from unauthorised alteration

or tampering. All devices wired to the 24 hour terminals must

be wired in series. Activation of the 24 hour circuit when the

panel is disarmed will trigger the internal sounder, activation

when the system is armed will cause full alarm condition. If

tampering has been the cause of an alarm activation the 24

hour LED will illuminate after the user code has been entered.

The SCB terminals are for connection to bell box tamper

switches or RSCB if fitted.

Personal attack circuit (PA)

Any number of normally closed personal attack buttons can be

used in series with this circuit. A full alarm condition will occur

whether the control panel is armed or not.

Keypad tamper

When the control panel is armed, pressing any key on the

keypad will cause the entry timer to start, a full alarm condition

will occur if either the entry timer expires or if an incorrect user

code is entered 4 times.

Event replay

If an alarm condition has occurred,upon entering the user code

the 1st zone to be activated will be displayed. Press the EVENT

REPLAY button. The next LED to illuminate will show the

previous zone activated during this alarm duration. W ith each

subsequent press of EVENT REPLAY button the LEDs

illuminated will advance to the fir st zone that w as acti vated. If no

LED illuminates the next time the EVENT REPLAY button is

pressed it will display the last zone activated from the previous

alarm duration and with each subsequent press,advance to the

first activation of that alarm duration. Each time no LED

illuminates it shows the end/start of each individual alarm

duration. If no LED illuminates on two successive presses this

confirms the end.

Walk through zone

It is sometimes desirable to site the control panel in a position

which is guarded by an additional detector. A walk through

zone will be required, zone 2 is factory set to a walk through

zone.

A walk through zone allows a period of time similar to that

programmed for the entry/exit delay before going into alarm.

But only if the entry/exit zone is activated first. If the entr y/exit

zone is not first activated, an instant alarm will result. Any zone

other than the entry/exit zone may be programmed as a walk

through zone. If the walk through facility were not used then

once the PIR sensed the movement an alarm would occur

before the panel could be disarmed. Please note that a zone

selected for walk thr ough cannot also be selected as part guard

zone.

If the system is armed using part guard then any walk through

zones activated will start the entry timer, giving time to disarm

the system without activating the alarm.

Internal sounder

The control panel is fitted with an internal speaker this provides

a low volume entry/exit and high volume internal alarm.

Bell output

The bell output provides power to the external bell or siren.

Care should be taken not to exceed total current output, and

care should be taken when using motorised bells or sirens.

Strobe output

The strobe output will operate in every full alarm condition and

will continue to operate after the external sounder has stopped

and system has auto reset. The strobe output will also remain

active after the user code has been entered, and will not stop

until (reset) is pressed.

The negative strobe output ter minal can be used for PIRs or

other detectors that require a negative latch.

Aux.13V power supply

This 13V supply marked AUX. + - on main PCB is provided to

supply power for detectors which require a low voltage supply,

PIRs, break glass detectors, etc. This output is fuse protected

and is maintained at all times.

Switched positive output (SW+)

The SW+ terminal will go positive when the control panel is

armed and low when either a full alarm condition occurs or the

control panel is disarmed, use this connection for latching

detector circuits.

Battery backup

It is strongly recommended that the control panel is fitted with a

12V rechargeable batter y. The battery is kept fully charged by

the control panel,and will provide power in the event of a mains

failure . The battery supply is protected by a fuse.

Fuses

There are three fuses mounted on the left side of the PCB. The

fuse labelled F1 is the battery fuse and prevents excess current

being drawn from the battery. The fuse labelled F2 is to protect

the AUX.power supply, the fuse labelled F3 provides protection

for the bell, strobe and internal sounder.

Programming the advantage

The many facilities offer ed b y the control panel can be selected,

inhibited or changed by selecting engineer programming

mode.

To exit the programming mode after making your selected

function changes or if an incorrect function code has been

pressed,press (reset).

To select engineer programming mode

Enter ‘9999’(or current engineers code)

Clear LED will flash

The control panel is now in programming mode.

Note: Once a function code is pressed selections must be

entered within 10 seconds or the function code has to

be re-entered. The clear LED will continue to flash

throughout engineer programming.

Page 5

9778

5

Change engineer code

Function code LED indication

Press . Zone 1-4 LEDs illuminated.

Press (new engineer code).

As each key is pressed one zone LED will extinguish.

Press to store.

The control panel will bleep to confirm acceptance of the new

engineer code.

Exit time

Function code LED indication

Press . Zone 1-2 LEDs illuminated.

Enter exit time,i.e.

Press = 1 second.

Press = 99 seconds.

As each key is pressed one zone LED will extinguish. The

control panel will bleep to confirm acceptance of the new exit

time.

Entry time

Function code LED indication

Press . Zone 1-2 LEDs illuminated

Enter entry time, i.e.

Press = 1 second.

Press = 99 seconds.

As each key is pressed one zone LED will extinguish. The

control panel will bleep to confirm acceptance of the new entry

time.

Bell duration

Function code LED indication

Press . Zone 1-2 LEDs illuminated.

Enter bell time, i.e.

Press = 3 minutes.

Press = 30 minutes.

As each key is pressed one zone LED will extinguish. The

control panel will bleep to confirm acceptance of the new bell

duration.

Change user code

Function code LED indication

Press . Zone 1-4 LEDs illuminated.

Press (new user code).

As each key is pressed one zone LED will extinguish.

Press to store.

The control panel will bleep to confirm acceptance of the new

user code.

Select part guard zones

Function code LED indication

Press . Selected part guard zones illuminated.

Press appropriate zone keys to enable/disable part guard

zones.

Any zone LEDs which are lit will be par t guard zones.

Press to store.

The control panel will bleep to confirm acceptance of part

guard zones.

When a zone LED is lit it indicates the zone is now a part guard

zone.

Select walk through zones

Function code LED indication

Press . Selected walk through zones illuminated.

Press appropriate zone keys to enable/disable walk through

zones.

Any zone LEDs which are lit will be walk through zones.

Press to store.

The control panel will bleep to confirm acceptance of walk

through zones.

When a zone LED is lit it indicates the zone is now a walk

through zone.

Remote part guard

Function code LED indication

Press . If selected zone 1 LED illuminated.

Press to select/deselect remote part guard.

Press to store.

The control panel will bleep to confirm acceptance of the new

code.

Select code arming

Function code LED indication

Press If selected zone 2 LED illuminated.

Press to select/deselect code arming.

Press to store.

The control panel will bleep to confirm acceptance of the new

code.

System reset

Function code

Press .

The control panel is now reset back to factory settings, any

previous programming will now be lost.

Fault finding

1. Once a function code has been pressed the facility must be

programmed within 10 seconds or the panel will revert back

to programming mode. If a key has been pressed after this

time then you should press (reset) and re-enter the

function code.

2. The usual cause of a zone not responding is incorrect

wiring. Normally closed detectors must be connected in

series before connection to the control panel. Check

thoroughly that the correct wiring connections have been

made.

3. If a zone or 24 hour LED remains on, or the panel bleeps,

check that the unused zone/tamper circuits have a wire link

fitted and/or all tamper switches in PIRs,bell box and control

panel are fully depressed.

4. If you have difficulties in finding the cause of a fault, remove

all installation wires, leave the factory connected wires in

place. Refit all factory links. Never fit links across any of the

power outputs. It may be necessary to use the NVM reset to

recover the factory set condition. On power up follow the

test procedure detailed in the front of this manual.

5. If fuses are being tested or replaced, all power must be

removed. Fuses repeatedly failing are almost certainly the

result of a short cir cuit acr oss the AUX.output. Check for low

resistance readings, it is rare for blown fuses to be the result

of faulty equipment.

Advantage user information

If code arming has been selected then simply enter user code

before pressing the appropriate function symbol key.

Arming the system

Press Clear LED lit Press Leave via exit

route

If zone LED is lit Close all windows and

doors and check PIRs

1. Press (full guard).

2. If zone LED is on, check detectors on that zone i.e. open

door.

3. Once clear LED illuminates press (set).

4. Leave promptly via the exit route whilst the exit tone is

sounding. An increase in exit tone tempo indicates last 10

seconds before armed.

5. Once exit sound has stopped the system will be armed.

0

2

8

1

8

7

6

???

?

5

0

3

3

0

4

9

9

1

0

3

9

9

1

0

2

???

?

1

Page 6

9778

Part arming the system for night setting

Press Clear LED lit Press Press

Optional quick set

If zone Close all windows and

LED is lit doors and check PIRs

1. Press (part guard).

2. If zone LED is on, check detectors on that zone i.e. open

door.

3. Press (set).

4. It is possible to quick set the system and silence the exit tone

by pr essing the e xit tone (set) button again. The system

will arm within a few seconds.

5. Once the exit sound has stopped the system will be armed.

Disarming the system

Enter user code Two tone bleep standby confirmed

Entry sounder continues

1. Enter via the entry/exit route.

2. The entry tone will be heard. The entry tone will change

tempo to warn of the last 10 seconds before alarm is

activated.

3. Enter user code.

4. Two tone bleep will confirm system is disarmed and on

standby.

5. If the alarm has activated in your absence the zone(s)

activated will be sho wn and it will be necessary to press

(reset) after user code to stop the strobe.

Event replay

Enter user code Press (event replay)

1. Do not press (reset) after the alarm has been switched

off.

2. Press (event replay) up to 4 times to display past e vents.

3. Press (reset) twice to return to standby.

Disarming the system when on the premises

Enter user code Two tone bleep standby confirmed

Entry sounder continues

1. Go to the panel via the designated route.

2. Enter user code.

3. Two tone bleep will confirm system is disarmed and on

standby.

Temporary zone omit prior to arm

24Hr Enter zone

Press Press LED numbers to Press

(zone omit) Flashes be omitted

If a zone LED is lit then that zone will be

omitted when control panel is armed.

1. Press (full guard).

2. Press (zone omit). The clear LED will flash.

3. Press zone numbers to select or deselect for omit, the

omitted zone LED(s) will illuminate. Note that zone 1 (entry

/exit) cannot be omitted.

4. Press (arm).

Lost user/engineer code

In the event of a lost or forgotten engineer code or an

operational system:

1. Switch off mains power.

2. Disconnect the rechargeable batter y. (If an SCB is fitted the

external sounder will operate).

3. Place a screwdriver in a position able to short out the NVM

reset pins positioned on the left-hand side of the

microprocessor.

4. Reconnect either the mains or battery and wait three

seconds.

5. Remove the screwdriver, the control panel is now reset to

factory set and will require reprogramming with all previous

requirements.

6. In the event of a lost or forgotten user code or an operational

system:

a. Enter engineers code .

b. Press then (reset).

c. The panel has returned to factory set and will require

reprogramming with all previous requirements.

Installation log

This log may be filled in, detached from the manual and

retained as a record of the installation.

0

999

9

Installation address

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact name

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T elephone no.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation date

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zone Area protected Detector

1

2

3

4

5

6

24 Hr

PA

Page 7

9778

7

Technical specification

Dimensions H-186mm W-249mm D top-40mm bottom-60mm

Cabinet construction 3mm polycarbonate

LED indicators Mains, PA, 24Hr and zones 1-6 with keypad illumination

Detection zones Zone 1-6 negative loop, 24Hr negative loop, PA positive loop

Max. zone loop resistance 5000½

Zone input delay <200µs

Extension speaker Wired in series 8-30½

SW+ output Source 12V @ 12mA

Bell output 12V timer adjustable from 1 to 99 minutes

Strobe output 12V continuous

Control panel current consumption Standby 137mA.Alarming 170mA (inter nal only)

AUX. output 13.4V

Battery charge voltage 13.4V

Battery type 1.2 - 2.1Ah 12V lead acid

Fuses all 20mm 1A quick blow

Total current output 1A absolute max.

Mains supply 220-245V~ double insulated

Factory set defaults

User code 1234

Engineer code 9999

Exit time 30 seconds

Entry time 30 seconds

Bell time 20 minutes

Walk through zone Zone 2

Entry/exit Zone 1 (not programmable)

Arming mode Symbol arming (speed arming)

Page 8

9778

The information provided in RS technical literature is believed to be accurate and reliable; however, RS Components assumes no responsibility for inaccuracies or

omissions, or for the use of this information, and all use of such information shall be entirely at the user’s own risk.

No responsibility is assumed by RS Components for any infringements of patents or other rights of third parties which may result from its use.

Specifications shown in RS Components technical literature are subject to change without notice.

RS Components, PO Box 99,Corby, Nor thants, NN17 9RS Telephone: 01536 201234

An Electrocomponents Company © RS Components 1997

Loading...

Loading...