Rpb Z-link User Manual

INSTRUCTION MANUAL

0086

EN1 294 1: 19 98 +A1: 2 003 +A 2: 2008

EN14594: 2005

Employers: Read this manual and the flow control device Instruction

Manual and carry out the Employer Responsibilities (page 10).

Product users: Read this manual and the flow control device Instruction

Manual and follow the Product User Safety Instructions (page 11).

Manuals are regularly updated. Make sure this manual is available to all

users for reference.

Current version of manual and other languages:

www.rpbsafety.com/product/zlink/

Protecting you for Life’s best moments

®

CONTENTS

WARNING

DANGER

EXPLANATION OF SIGNAL WORDS AND SYMBOLS 2

INTRODUCTION 3

IMPORTANT SAFETY INFORMATION

PROTECTION PROVIDED AND LIMITATIONS 4

RESPIRATORY COMPONENT DIAGRAMS - NIOSH CAUTIONS & LIMITATIONS 7

AIR SOURCE, FITTINGS, AND PRESSURE 9

EMPLOYER RESPONSIBILITIES 10

PRODUCT USER SAFETY INSTRUCTIONS 11

BREATHING AIR PRESSURE TABLE 15

SETUP AND CARE

STANDARD CONFIGURATION 16

®

Z-LINK+

DONNING AND DOFFING 35

STORAGE 35

COMMUNICATIONS

COMMS-LINK

RADIO CONNECTOR COMPATIBILITY 38

PARTS AND ACCESSORIES 40

WARRANTY AND LIABILITY STATEMENT 46

(WELDING) CONFIGURATION 26

™

COMMUNICATION SYSTEM 36

EXPLANATION OF SIGNAL WORDS AND SYMBOLS

The following signal word and safety symbols are used in this manual and product labeling:

WARNING indicates a hazardous situation that, if not avoided, could

result in death or serious injury.

DANGER Indicates a hazardous situation that, if not avoided, will result

in death or serious injury.

Read the Instruction Manual.

Additional copies of RPB

®

manuals can be found at www.rpbsafety.com.

CERTIFIED BY:

BSI Group (NB00 86), K itemark Court, Knowlhill, Milton Keynes MK 5 8PP United Kingdom

®

Safety LLC is an ISO9001 certified company.

RPB

2

INTRODUCTION

The Z-LINK® is a multiuse respirator for a number of different applic ations where there is a

need for protection from airborne contaminants, eye/fac e protection and head protection;

such as welding, grinding, construction and other industrial applications. The optional

Quiet-Link™ Ear Defender earmuff system can add hearing protection. The Z-LINK+® is an

optional welding visor attachment. It allows the user to quickly switch bet ween the standard

configuration and the welding configuration. Additionally, the Vision-Link® light attachment

is available to provide light to the work area and the Comms-Link™ in-helmet communication

system allows for hands free radio communication.

This product must be inspected and maintained in accordance with this inst ruction manual at

all times.

See PROTECTION PROVIDED AND LIMITATIONS (page 4) for details.

RPB® SAFET Y - GLOBAL HEADQUARTERS

2807 Samoset Rd, Royal Oak , MI 48073, USA.

T: 1-866-494-4599 F: 1-866- 49 4-4509 E: sales.us@rpbsafety.com rpbsafety.com

®

RPB

SAFET Y - APAC

1 Ivan Jamieson Place, Christchurch Airport, Christchurch 8053 New Zealand.

T: +64-3-357-1761 F: +64-3-357-1763 E: sales.nz@rpbsafety.com rpbsafety.com

®

RPB

SAFET Y - EMEA

Unit 2, Teardrop Industrial Park, London Road, Swanley, BR8 8TS, United Kingdom

T: +44-800-689-5031 E: sales@rpbsafety.co.uk rpbsafety.com

Copyright ©2019 RPB Safety, LLC. All rights reserved. All materials contained on this

website are protected by United States copyright law and may not be reproduced, distributed,

transmitted, displayed, published or broadcast without the prior written permis sion of RPB

Safety, L LC. You may not alter or remove any trademark, copyright or other notice from

copies of the content.

All trademarks, service marks, and logos used in this public ation, both registered and

unregistered, are the t rademarks, ser vice marks, or logos of their respective owners. All

right s in the RPB Intellectual Property contained in this publication, including copyright,

trademarks, ser vice marks, trade secret, and patent rights are reserved. RPB Intellectual

Property means any patent, patented articles, patent applications, designs, industrial designs,

copyrights, software, source code, database right s, moral rights, inventions, techniques,

technical data, trade secrets, know-how, brands, trademarks, trade names, slogans, logos,

and any other common law and proprietary rights, whether registered or unregistered

anywhere in the world, that are owned by, developed in whole or in part by, or licensed by

RPB Safety, LLC.

For technical assistance contact our Customer Service Department at 1-866-494-4599 or

email: customerservice@rpbsafety.com

Form #: 7.20.542

Rev: 4

3

IMPORTANT SAFETY INFORMATION

WARNING

Improper selection, fit, use, or maintenance of this product can result in

injury; life threatening delayed lung, skin or eye disease; or death.

This product is intended for occupational use in accordance with applicable standards or

regulations for your location, industry, and activity (see Employer Responsibilities, page 9).

Familiarity with standards and regulations related to the use of this protective equipment is

recommended, even if they do not directly apply to you. If self-employed or if used in a nonoccupational setting, refer to Employer Responsibilities and Product User Safety Instructions. Go

to rpbsafety.com/importantsafetyinformation/ for helpful links to CE standards and other content.

Employers: Read this manual and the air supply device Instruction Manual and carry out the

Employer Responsibilities (page 9).

Product users: Read this manual and the air supply device Instruction Manual and follow the

Product User Safety Instructions (page 10).

Check website for updates. Product manuals are regularly updated.

Visit www.rpbsafety.com/resources/for the most recent version of this manual before using the

product.

PROTECTION PROVIDED AND LIMITATIONS

RESPIRATION

The RPB

Powered Air

The RPB

including t he Breathing Tube Assembly and the 03-90 1 RPB® PX4 AIR® Powered Air

Purifying Respirator, is an EN129 41: 1998 + A1: 2003 + A2: 2008 TH2 P R SL approved

powered air purifying respirator with an As signed Protection Factor of 40 (Nominal Protection

Factor of 1000). As such, it significantly reduces, but doe s not completely eliminate, the

breathing of contaminates by the respirator wearer. Specific protection depends on the filter

selected for use in the RPB® PX4 AIR® PAPR (see PX4 AIR® Instruction Manual).

Supplied Air

The RPB

including t he Breathing Tube Assembly, 03-102 Constant Flow Valve, and RPB® Breathing

Air Line is an EN 14594: 2005 Class 3B approved respirator with a nominal protection factor

of 500. As such, it significantly reduces, but does not completely eliminate, the breathing of

contaminates by the respirator wearer. Use with an airline filter, such as the 04-900 RPB®

RADEX® Airline Filter. Specific protection depends on the setup of the airline filter (see the

RPB® RADEX® Instruction Manual).

®

Z-L I NK® is approved in the categories as follows:

®

Z-L I NK® Respirator, when properly fitted and used with all required components,

®

Z-L I NK® Respirator, when properly fitted and used with all required components,

4

HAZARD LIMITATIONS

The RPB

FACE AND EYES:

HEAD:

HEARING:

®

Z-L I NK® Respirator is NOT FOR USE if:

In atmospheres immediately dangerous to life or health (IDLH).

Wearer cannot escape without the aid of the respirator.

Atmosphere contains less than 19.5% oxygen.

In abrasive blasting applications.

For protection against hazardous gases (e.g., carbon monoxide).

Contaminants are in excess of regulations or rec ommendations.

Contaminants or contaminant concentrations are unknown.

Work area is poorly ventilated.

The temperature is outside the range of -10°C to +60°C (14°F to 140°F ).

Used with systems including electrical parts, PX4 AIR®, Vision-Link

Link™ or 09-913 PT T, do not use when a flammable or explosive atmosphere is present.

The Z-LINK® Visor with Safety Lens is approved to EN 166:2001 (AS/NZS 1337.1:2010)

requirements and is designed for grinding, painting, and other industrial applications.

The Z-LINK® Welding Visor with Impact Lens and Auto-Darkening Welding Protection Filter

(ADF) is approved to EN 166:200 1 (AS/NZS 1337.1:2010) requirement s and is designed to

protect the operator’s face and head against sparks and hazardous ultraviolet and infrared

rays emitted during the welding proces s. See “Auto-Darkening Welding Protection Filter”

(page 31) for information about ADF capabilities and use. Use an approved RPB® welding

cape for adequate protection from sparks, debris, and light flashes.

The Z-LINK® is not designed or tested to provide protection against molten metals or

corrosive liquids.

Note: the Z-L INK® does not protect against the potential transfer of impact to glasses worn

underneath the Visor. Z-LINK® visors do not provide complete eye and face protection

against severe impact and penetration and are not a substitute for good safety practices

and engineering controls.

The Z-LINK® is approved to EN 397:2012+A1:2012 ( AS/NZS 1801:1997) requirements for

physical head protection as a hard hat. The helmet is designed to provide limited head

protection by reducing the force of falling objects striking the top of the head. Ensure the

helmet is adjusted to properly fit the user by adjusting the head harnes s and sidepads or

Quiet-Link™ if installed.

When used with the Z-LINK®, the Quiet-Link™ Ear Defender system provides a Noise

Reduction Rating (NRR) of 25db. Refer to the Quiet-Link™ instruction manual to ensure

proper installation and fit .

™

, 16-922 Comms-

5

PROTECTION PROVIDED AND LIMITATIONS

If Quiet-Link™ is not used, other hearing protection, such as earplugs, must be properly

fitted and worn where noise levels exceed the OSHA permissible exposure levels.

PPE REGULATION:

The Z-LINK® conforms to the PPE Regul ation (EU) 2016/425.

The Declaration of Conformity can be found at rpbsafety.com/resources/

See the Storage section for information on packaging and protection required for

transportation.

6

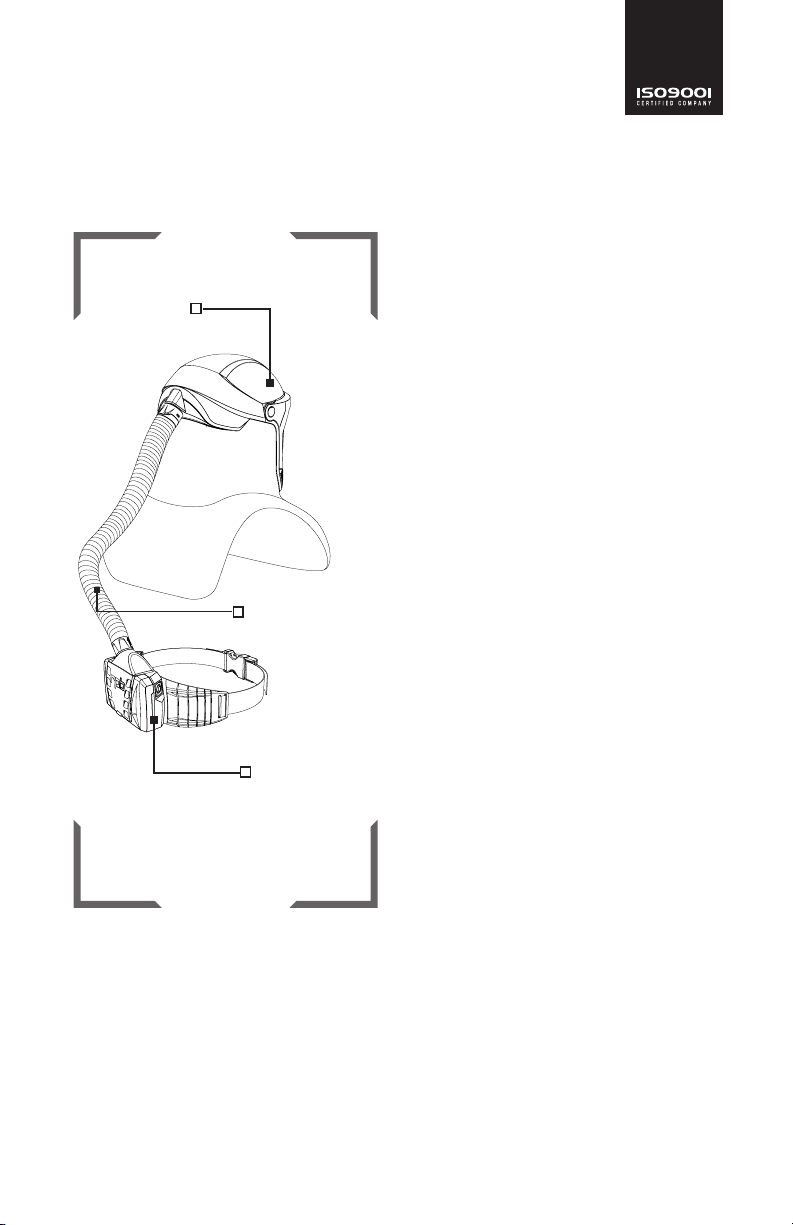

RESPIRATOR COMPONENT DIAGRAM - PAPR

F. Do not use Powered Air-Purifying

1. R ESP IR ATOR

HELMET

ASSEMBLY

2. BREATHING

TUBE

ASSEMBLY

3. AIR SUPPLY

PX4 AIR

FIGURE 1.1

®

CAUTIONS AND LIMITATIONS

POWERED AIR

A. Not for use in atmospheres containing

less than 19.5 percent oxygen.

B. Not for use in atmospheres immediately

dangerous to life or health.

C. Do not exceed maximum use

concentrations established by regulatory

standards.

Respirators if airflow is less than 115 lpm

(4 cfm) for tight fitting face pieces or 170

lpm (six cfm) for hoods and/or helmets.

H. Follow established cartridge and canister

change schedules or observe ESLI to

ensure that cartridge and canisters are

replaced before breakthrough occurs.

I. Contains electrical parts that may cause

an ignition in flammable or explosive

atmospheres.

J. Failure to properly use and maintain this

product could result in injury or death.

L. Follow the manufacturer’s User’s

Instructions for changing cartridges,

canister and/or filters.

M. All approved respirators shall be

selected, fitted, used and maintained in

accordance with applicable regulations.

N. Never substitute, modify, add or omit

parts. Use only exact replacement parts

in the configuration as specified by the

manufacturer.

O. Refer to User Instructions, and/or

maintenance manuals for information

on use and maintenance of these

respirators.

P. The Z-Link® is not evaluated as a

respirator for use as a surgical mask.

S. Special or Critical User Instructions and/

or specific limitations apply. Refer to

“S-Special or Critical User Instructions”

in the PX4 Air® Instruction Manual

before donning.

7

RESPIRATOR COMPONENT DIAGRAM - SAR

1. R ESP IR ATOR

HELMET

ASSEMBLY

2. BREATHING

TUBE

ASSEMBLY

AND FLOW

CONTROL

DEVICE

3. BREATHING

AIR LINE

FIGURE 1.2

CAUTIONS AND LIMITATIONS

SUPPLIED AIR

A. Not for use in atmospheres containing

less than 19.5 percent oxygen.

B. Not for use in atmospheres immediately

dangerous to life or health.

C. Do not exceed maximum use

concentrations established by regulatory

standards.

D. Air-line respirators can be used only

when the respirators are supplied with

respirable air meeting the requirements

of EN 12021 ( AS/NZS 1715) or higher

quality.

E. Use only the pressure ranges and

hose lengths specified in the user’s

instructions.

J. Failure to properly use and maintain this

product could result in injury or death.

L. Follow the manufacturer’s User’s

Instructions for changing cartridges,

canister and/or filters.

M. All approved respirators shall be

selected, fitted, used and maintained in

accordance with applicable regulations.

N. Never substitute, modify, add or omit

parts. Use only exact replacement parts

in the configuration as specified by the

manufacturer.

O. Refer to user’s instructions, and/or

maintenance manuals for information

on use and maintenance of these

respirators.

S. Special or Critical User Instructions and/

or specific limitations apply. Refer to

“S-Special or Critical User Instructions”

on page 14 before donning.

8

AIR SOURCE, FITTINGS, AND PRESSURE

DANGER

AIR SOURCE

Powered Air

Check that the contaminated area is within the limit s of use for a Powered Air Purifying

Respirator and determine the type of cont amination. Once the contamination level has

been confirmed you can then determine the filter cartridge to be used for the application,

to make sure that you are sufficiently protected. Make sure that the area is well ventilated

and that regular air samples are taken to confirm the atmosphere stays within the levels

recommended by governing bodies. Follow t he PX4 AIR

details. The Manufacturer Minimum Designed Flow is 170 l/min, Speed 1 - 10 to 13 hours,

Speed 2 - 7 to 10 hours, and Speed 3 – 6 to 8 hours.

Supplied Air

Locate the air source in a clean air environment, always use a filter on the inlet of your air

source. Make sure the air sourc e is somewhere that vehicles, forklift s, and other machinery

are not running near the air inlet, as t his will cause carbon monoxide to be drawn into your

air supply. Always use suitable after coolers /dryers with filters and carbon monoxide alarms

to ensure clean breathable air is supplied at all times. A Radex

a GX4® Gas Monitor (08- 400) are recommended. The air should be regularly sampled to

ensure that it meets EN 12021 (AS/NZS 1715) requirements.

AIR QUALITY

This respirator must be supplied with clean breathable air at all times. Breathable air must at least

meet the requirements for EN 12021 ( AS/NZS 1715). The RPB

filter contaminants. A carbon monoxide monitor must be used at all times.

Do not connect the respirator’s air supply hose to nitrogen, toxic gases,

inert gases or other unbreathable non-EN 12021 (AS/NZS 1715) air

sources. Check the air source before using the respirator. This apparatus is not designed for use

with mobile air supply systems i.e. cylinders. Connecting the supply hose to a non-breathable air

source will result in serious injury or death.

BREATHING AIR SUPPLY HOSES AND FITTINGS

®

RPB

air supply hoses and fittings must be used between the point of attachment and the

respirator breathing air connection at the wearer’s belt. The hose sect ions must be within

the correct lengt h and the amount of sections must be within the number specified in the

breathing air pressure table on page 15.

BREATHING AIR PRESSURE

The air pressure must be continually monitored at the point of attachment . Air pressure must

be read from a reliable pressure gauge whilst the respirator has air flowing through it.

®

PAPR Instruction Manual for more

®

Airline Filter (04-900) and

®

Z-LINK® does not purify air or

9

EMPLOYER RESPONSIBILITIES

Your specific responsibilities may vary by location and industry, but in general RPB® expects that

employers will:

Follow all applicable standards and regulations for your location, industry, and activity.

Depending on your location and industry, a number of standards and regulations may

apply to your selection and use of respirators and other personal protective equipment.

These may include such things as federal, local, or military standards and regulations and

consensus standards such as EN and AN/NZS. There are also requirements specific to

particular contaminants, e.g. silica (see rpbsafety.com/importantsafetyinformation/ for more

information), asbestos, organic pathogens, etc. Know which requirements apply to your

location and industry.

Have appropriate safety programs in place.

Have and follow:

A workplace safety program.

A written respiratory protection program in accordance with applicable standards and

regulations.

In accordance with the above,

Perform a hazard analysis and select appropriate equipment for each activity. A hazard

analysis should be performed by a qualified person. Controls should be in place as

appropriate and a qualified person should determine what kind of respiratory, face

and eye, head, and hearing protection is appropriate for the intended activities and

environments of use. (For example, select a respirator appropriate to the specific airborne

hazards, with consideration of workplace and user factors and with a Nominal Protection

Factor that meets or exceeds the required level for employee protection, select welding

face and eye protection appropriate to the type of welding to be done, etc.)

As applicable, check your workplace safety program, respiratory protection program, and

standards and regulations for your activity or industry for related protection requirements,

and see this manual (Protection Provided and Limitations, page 4) and the PX4 AIR®

PAPR or flow control device Instruction Manual for product specifications.

Be sure employees are medically qualified to use a respirator.

Have a qualified physician or other licensed health care professional (PLHCP) perform

medical evaluations using a medical questionnaire or an initial medical examination.

Train employees in the Z-LINK®’s use, maintenance, and limitations.

Appoint a qualified individual who is knowledgable about the RPB® Z-LINK® to provide

training:

Qualifications of the Respirator Trainer. Anyone providing respirator training shall:

a) be knowledgable in the application and use of the respirator(s);

b) have practical knowledge in the selection and use of respirator(s) and work practices

at the site;

c) have an understanding of the site’s respirator program; and

d) be knowledgable of applicable regulations.

10

Train each Z-LINK® user in the product’s use, application, inspection, maintenance, storage,

fitting, and limitations in accordance with the content of this Instruction Manual and the

approved flow control device Instruction Manual and standard or regulatory requirements.

Ensure that each intended user reads both these manuals.

Ensure that equipment is properly set up, used, and maintained.

Make sure that equipment is properly set up, inspected, fitted, used, and maintained,

including selection of the appropriate air filter cartridge and, when applicable, welding

filter shade adjustments, for the application.

Measure and monitor airborne contaminants in the work area.

Measure and monitor airborne contaminant levels in the work area in accordance with

applicable requirements. Make sure work area is well ventilated.

If you have any questions, contact RPB®.

Call Customer Service Department at:

Tel: 1-866-494-4599

Email: customerservice@rpbsafety.com

Web: rpbsafety.com

PRODUCT USER SAFETY INSTRUCTIONS

BEFORE INITIAL USE - BE TRAINED AND MEDICALLY QUALIFIED

Do not use this respirator until you have read this manual and the PX4 AIR

control device Instruction Manual (additional copies available at www.rpbsafety.com) and been

trained in the respirator’s use, maintenance, and limitations by a qualified individual (appointed by

your employer) who is knowledgable about the RPB® Z-LINK® Respirator.

Do not wear this respirator until you have passed a medical evaluation using a medical

questionnaire or an initial medical examination by a qualified physician or other licensed health

care professional (PLHCP).

Allergens: No known common allergens are used in this product.

Some materials could cause an allergic reaction in susceptible individuals. If you have a known

allergy or develop irritation, inform your employer. Irritation may occur from lack of cleaning.

Following all cleaning and care instructions provided in the instruction manuals for this and any

other RPB

®

products you are using.

MAKE SURE THE SYSTEM IS READY FOR USE

Make sure you have a complete system. Verify that you have all required components for the

®

Z-LINK

to serve as a complete approved respirator:

Respirator Helmet Assembly (Z-LINK®)

®

PAPR or the flow

11

PRODUCT USER SAFETY INSTRUCTIONS CONTINUED

Breathing Tube Assembly

Flow Cont rol Device (PX4 AIR® or Constant Flow Valve)

Breathing Air Line (Supplied AIr)

See Respirator Component Diagram (page 6-7). The RPB

with the RPB® PX4 AIR® PAPR or the RPB® Constant Flow Valve. Use only authentic RPB®

brand parts and components that are part of the approved respirator assembly. Using incomplete

or inappropriate equipment, including the use of counterfeit or non-RPB® parts, can result in

inadequate protection and will void the approval of the entire respirator. Do not modify or alter any

part of this product.

Inspect all components daily for signs of damage or wear and tear that may reduce the level

of protection originally provided. Remove any damaged component or product, including any

helmet or visor that has been subject to impact, from service until repaired or replaced. Scratched

or damaged safety lenses or other components should be replaced with genuine RPB

replacement parts. When safety and impact lenses are replaced, make sure to remove any

additional protective film from both sides of the lens. If the film is left in place, it could affect the

optical clarity of the lens and cause eye strain. Inspect the inside of the respirator for respirable

dust or other foreign objects. Keep the inside of the respirator clean at all times.

Make sure that the helmet is correctly assembled in the configuration that suits your application.

Never use the respirator without all lenses in place. This includes the Safety Lens and for the

®

Z-LINK+

this includes the Impact Lens, the ADF, and the rear ADF Lens. These lenses, when

installed properly, are part of the respiratory seal to prevent toxic or hazardous gases, liquids

or dust from entering the helmet. An incomplete or improperly installed lens system could

provide inadequate impact and respiratory protection. See Respirator Setup and Care - Standard

Configuration (page 16) or Respirator Setup and Use - Z-LINK+® Welding Configuration (page 26).

See Donning (page 35) for fit information.

VERIFY THAT YOU HAVE THE APPROPRIATE EQUIPMENT FOR YOUR ACTIVITY

Verify that the Z-LINK

®

provides appropriate protection for your activity. As applicable, check your

workplace safety program, respiratory protection program, and standards and regulations for your

activity or industry. (See PROTECTION PROVIDED AND LIMITATIONS, page 4.)

®

BEFORE DONNING THE Z-LINK

:

Verify airborne contaminants are within recommended limits for respirator use:

Determine the type and level of contamination. Verify that airborne contaminant

concentrations do not exceed those allowed by applicable regulations and

recommendations for powered air purifying respirators or supplied air respirators.

Filtering the breathing air:

PAPR : Once the contamination level has been confirmed, determine the correct filter

cartridge to be used for the application, to make sure that you are sufficiently protected.

Follow the PX4 AIR® PAPR Instruction Manual.

®

Z-LINK® is only approved to be used

®

brand

12

SAR: Once the contamination levels have been confirmed, check to make sure the airline

filter is working correctly. Follow the Radex® Airline Filter Instruction Manual.

Make sure the area is ventilated and monitored:

Make sure that the area is well ventilated and that regular air samples are taken to

confirm the atmosphere stays within the levels recommended by governing bodies. For

Supplied Air, it is recommended to use a GX4® Gas Monitor. Follow the GX4® Gas Monitor

Instruction Manual.

If you have any questions, ask your employer.

DO NOT ENTER THE WORK AREA if any of the following conditions exist:

Atmosphere is immediately dangerous to life or health.

You cannot escape without the aid of the respirator.

Atmosphere contains less than 19.5% oxygen.

Contaminants are in excess of regulations or recommendations.

Contaminants or contaminant concentrations are unknown.

Work area is poorly ventilated.

The work area is a confined space (unless proper measures are taken for confined spaces).

The temperature is outside the range of -10°C to +60°C (14°F to 140°F).

Used with systems including electrical parts, PX4 AIR®, Vision-Link

Link™ or 09-913 PT T, do not use when a flammable or explosive atmosphere is present.

LEAVE THE WORK AREA IMMEDIATELY IF:

Any product component becomes damaged.

Vision is impaired.

Airflow stops or slows down, or alarm sounds. Do not use Powered Air Purifying Respirators if

airflow is less than 170 lpm (6 cfm).

Breathing becomes difficult.

You become dizzy, nauseous, too hot, too cold, or ill.

Your eyes, nose, or skin become irritated.

The work area is a confined space (unless proper measures are taken for confined spaces).

You taste, smell, or see contaminants inside the helmet.

You have any other reason to suspect that the respirator is not providing adequate protection.

PRODUCT CARE

Never place the helmet on hot surfaces. Do not apply paints, solvents, adhesives or selfadhesive labels except as instructed by RPB

chemicals.

See the “Respirator Setup and Care” section for more specific cleaning instructions.

®

. This product may be adversely affected by certain

™

, 16-922 Comms-

13

WARNING

PRODUCT USER SAFETY INSTRUCTIONS CONTINUED

INSTRUCTIONS FOR SPECIFIC USES OR ENVIRONMENTS

Welding

See Operator Setup and Use - Z-LINK+

(page 31) for important safety-related use and care information. Check the prescribed shade level

for your welding application and adjust your auto-darkening filter accordingly (see table with

recommended shade levels, page 33). Never place the auto-darkening welding filter (ADF) on hot

surfaces. Do not expose the ADF to liquids and protect it from dirt. See ADF storage, maintenance,

and cleaning information (page 32). Make sure the helmet completely blocks any accidental

light. Make sure light can only enter the front of the helmet through the viewing area of the autodarkening welding filter.

Welding and Grinding

For welding and grinding applications that produce sparks, be sure to use the FR (Fire Retardant)

specific model of the PX4 AIR

Instruction Manual. Use a RPB® Zytec® face seal or shoulder cape for protection from sparks,

debris, and light flashes. Make sure all skin, such as the neck, is covered to prevent UV radiation

and burns.

Confined Spaces

If this respirator is used in confined spaces, ensure the area is well ventilated and that all

contaminant concentrations are below those recommended for this respirator. Follow all

procedures for confined space entry, operation, and exit as defined in applicable regulations and

standards.

Welding in Confined Spaces

Welding in a confined space can present an atmospheric hazard due to the generation of

contaminants and displacement of oxygen. A pressure-demand SCBA or a multifunctional

pressure-demand supplied-air respirator with self-contained air supply shall be used during

welding in confined spaces when welding can reduce the ambient oxygen level and supplemental

ventilation and atmospheric monitoring are not provided.

®

®

Welding Configuration (page 26) and ADF Operation

with the FR belt and spark arrestor in place, see the PX4 AIR®

Do not use the Z-LINK® for welding without the Auto Darkening

Protection Filter in place. Do not weld with only the grinding lens. Improper use may

cause blindness or other permanent eye damage.

14

BREATHING AIR PRESSURE TABLE

WARNING

WARNING

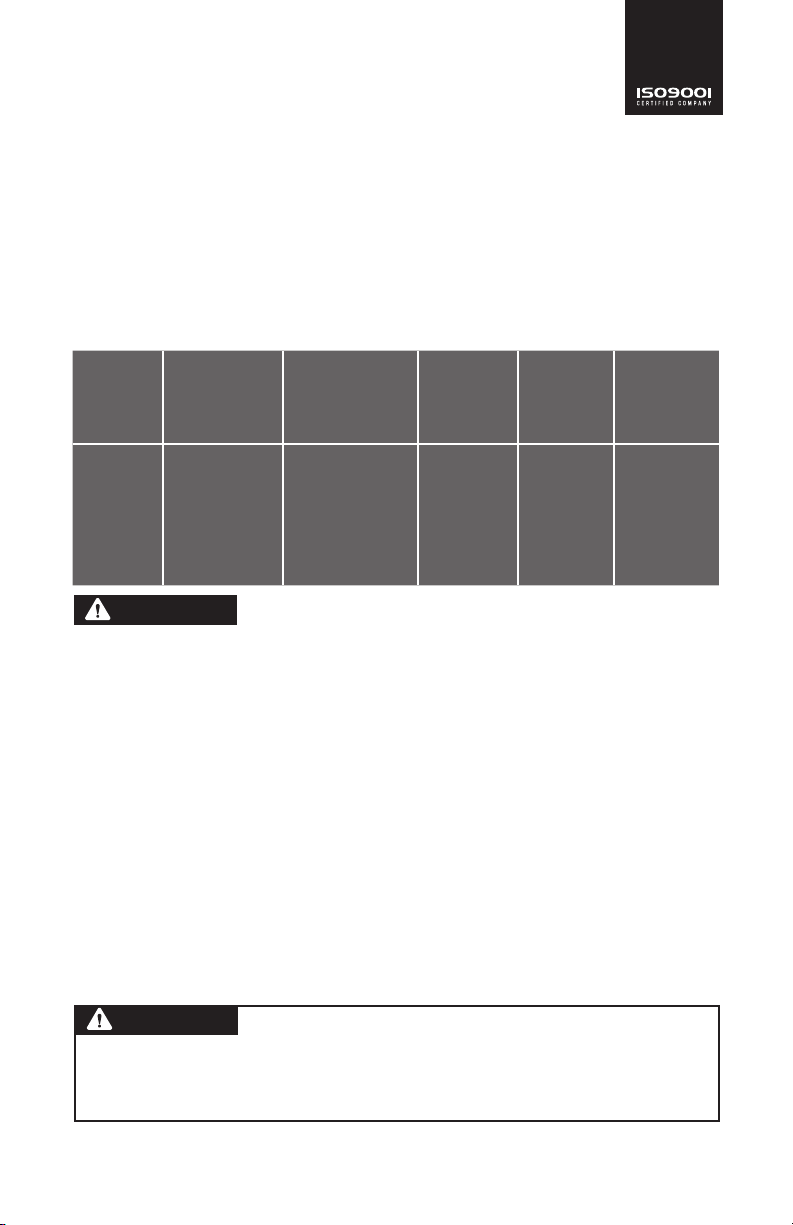

S - SPECIAL OR CRITICAL USERS INSTRUCTIONS - SAR TABLE 1.1

This t able lists Air pressure ranges needed to provide the RPB

of air that falls within the required range of 170 - 425 slpm (6 -15 cfm) according to

GOVERNMENT REGULATIONS. Maximum working pressure of the compressed air supply

tube is 20.7 BAR.

®

Z-L I NK® with the volume

1. AIR

SOURCE

Portable

or Stationary

Compressor

2. AIR

SUPPLY HOSE

04 -3 22 -25 (7. 5m )

04-322 -50 (15m)

04-322 -100 (30m)

04-422-15 (4.5m)

04-422-25 (7.5m)

3. FLOW CON TROL

DEV ICE USE D WITH

04- 835 BR EATHI NG

TUBE ASSEMBLY

03-10 2

Constant Flow

Valve Assembly

4. S UPPLY

HOSE LENGTH

(METERS)

7.5

15

30

45

60

75

90

5. MA X

NUMB ER OF

SECTIONS

1

1

2

3

4

5

6

6. PRESSURE

RA NGE (BAR )

0.65 - 0. 72

0.76 - 0.90

0.97 - 1.24

1.17 - 1. 52

1.45 - 1.72

1.70 - 2.00

1.90 - 2.17

Make sure you understand the Breathing Air Pressure table before

using this respirator.

1. Use the correct air source. Do not use an ambient air pump, as it does not supply enough

pressure (column 1).

2. Confirm the part number of the air supply hose (column 2) and the flow control device

(column 3) you are using.

3. Check your RPB® Safety Air Supply Hose is within the correct length (column 4) and the

correct number of hose sections (column 5).

4. Set the air pressure at the point of attachment within the range specified (column 6).

Make sure air is flowing through your respirator when setting the air pressure.

Failure to supply the minimum required air pressure at the point of attachment for the length

of air supply hose will decrease the level of protection provided. Check that the capacity

of the air supply systems can provide sufficient air to all users, with a maximum of 5 users

connected simultaneously per air supply unit. In addition, could result in contaminants being

inhaled as the pressure in the helmet may become negative due to peak inhal ation flow when

work ing at very high work rates. Low airflow will decrease the level of protection provided.

ALWAYS WEAR EAR PLUGS WHEN WEARING THIS APPAR ATUS.

The Apparatus must be supplied with respirable air meeting the

requirements of EN 12021, AS/NZS 1715 or Higher Quality. The moisture content of the

breathable air should controlled within the limit s in accordance with EN 12021, to avoid

the air freezing the apparatus. Do not use oxygen enriched air.

15

Loading...

Loading...