Rpb PX4 AIR User Manual

®

®

PX4 AIR

INSTRUCTION MANUAL

®

Employers: Read this manual and the respirator head-top Instruction

Manual and carry out the Employer Responsibilities (page 7).

Product users: Read this manual and the respirator head-top

Instruction Manual and follow the Product User Safety Instructions

(page 9).

Manuals are regularly updated. Make sure this manual is available to

all users for reference.

Current version of manual and other languages:

www.rpbsafety.com/product/px4-air/

Protecting you for life’s best moments

®

®

WARNING

PX4 AIR

CONTENTS

EXPLANATION OF SIGNAL WORDS AND SYMBOLS 2

INTRODUCTION 3

IMPORTANT SAFETY INFORMATION

PROTECTION PROVIDED AND LIMITATIONS 4

RESPIRATORY COMPONENT DIAGRAM - NIOSH CAUTIONS & LIMITATIONS 6

EMPLOYER RESPONSIBILITIES 7

PRODUCT USER SAFETY INSTRUCTIONS 9

RESPIRATOR SETUP AND CARE 12

ALARMS 22

INSPECTION AND CLEANING 25

PRODUCT SPECIFICATIONS AND DATA 27

PARTS AND ACCESSORIES 28

WARRANTY AND LIABILITY STATEMENT 30

EXPLANATION OF SIGNAL WORDS AND SYMBOLS

The following signal word and safety symbols are used in this manual and product labeling:

WARNING indicates a hazardous situation that, if not avoided, could

result in death or serious injury.

Read the Instruction Manual.

Additional copies of RPB

®

manuals can be found at www.rpbsafety.com.

RPB® Safety LLC is an ISO9001 certified company.

2

INTRODUCTION

The RPB® PX4 AIR® is approved by NIOSH as a Powered Air Purifying Respirator Fan Unit

designed to be used in conjunction with the approved RPB® head-tops for different applications

where there is a need for protection from airborne contaminants such as welding, grinding,

painting, and other construction and industrial applications, depending on the selected headtop. For applications such as welding or grinding that produce sparks or high heat, a FR (Fire

Retardant) specific model is available, with a FR belt and spark arrester to prevent sparks from

entering the PAPR and igniting the filter material.

This product must be inspected and maintained in accordance with this instruction manual at all

times.

See PROTECTION PROVIDED AND LIMITATIONS (page 4) for details.

RPB® SAFET Y - GLOBAL HEADQUARTERS

2807 Samoset Rd, Royal Oak , MI 48073, USA.

T: 1-866-494-4599 F: 1-866- 49 4-4509 E: sales.us@rpbsafety.com rpbsafety.com

®

RPB

SAFET Y - APAC

1 Ivan Jamieson Place, Christchurch Airport, Christchurch 8053 New Zealand.

T: +64-3-357-1761 F: +64-3-357-1763 E: sales.nz@rpbsafety.com rpbsafety.com

®

SAFET Y - EMEA

RPB

Unit 2, Teardrop Industrial Park, London Road, Swanley, BR8 8TS, United Kingdom

T: +44-800-689-5031 E: sales@rpbsafety.co.uk rpbsafety.com

Copyright ©2018 RPB Safety, LLC. All rights reserved. All materials c ontained on this

website are protected by United States copyright law and may not be reproduced, distributed,

transmitted, displayed, published or broadcast without the prior written permis sion of RPB

Safety, L LC. You may not alter or remove any trademark, copyright or other notice from

copies of the content.

All trademarks, service marks, and logos used in this public ation, both registered and

unregistered, are the t rademarks, ser vice marks, or logos of their respective owners. All

right s in the RPB Intellectual Property contained in this publication, including copyright,

trademarks, ser vice marks, trade secret, and patent rights are reserved. RPB Intellectual

Property means any patent, patented articles, patent applications, designs, industrial designs,

copyrights, software, source code, database right s, moral rights, inventions, techniques,

technical data, trade secrets, know-how, brands, trademarks, trade names, slogans, logos,

and any other common law and proprietary rights, whether registered or unregistered

anywhere in the world, that are owned by, developed in whole or in part by, or licensed

by RPB Safety, LLC.For technical assistance contact our Customer Ser vice Department at

1-866-494-4599 or email: customerservice@rpbsafety.com

Form #: 7.20.524

Rev: 6

3

®

WARNING

PX4 AIR

IMPORTANT SAFETY INFORMATION

Improper selection, fit, use, or maintenance of this product can result in

injury; life threatening delayed lung, skin or eye disease; or death.

This product is intended for occupational use in accordance with applicable standards or

regulations for your location, industry, and activity (see Employer Responsibilities, page 7).

Familiarity with standards and regulations related to the use of this protective equipment is

recommended, even if they do not directly apply to you. If self-employed or if used in a nonoccupational setting, refer to Employer Responsibilities and Product User Safety Instructions. Go

to rpbsafety.com/importantsafetyinformation/ for helpful links to OSHA and other content.

Employers: Read this manual and the respirator head-top Instruction Manual and carry out the

Employer Responsibilities (page 7).

Product users: Read this manual and the respirator head-top Instruction Manual and follow the

Product User Safety Instructions (page 9).

Check website for updates. Product manuals are regularly updated.

Visit www.rpbsafety.com/resources/for the most recent version of this manual before using the

product.

PROTECTION PROVIDED AND LIMITATIONS

RESPIRATION

The RPB

Powered Air

The RPB

including t he Breathing Tube Assembly and the approved head top, is part of a NIOSH

approved powered air purifying respirator. As such, it signific antly reduces, but does not

completely eliminate, the breathing of contaminates by the respirator wearer. See the

instruction manual and approval label for the selected head top for NIOSH approval with the PX4

AIR®and the as signed protection factor. Specific protection depends on the filter selected for

use in the RPB® PX4 AIR® PAPR. It is approved to be used with the 03-985 High Efficiency

(HE) Filter and the 03-995 Organic Vapor/Acid Gas/High Efficiency (OV/AG/HE) Cartridge.

HAZARD LIMITATIONS

The RPB

®

PX4 AIR® is approved by NIOSH in the categorie s as follows:

®

PX4 AIR® PAPR, when properly fitted and used with all required components,

®

PX4 AIR® PAPR is NOT FOR USE if:

In atmospheres immediately dangerous to life or health (IDLH).

Wearer cannot escape without the aid of the respirator.

Atmosphere contains less than 19.5% oxygen.

In abrasive blasting applications.

For protection against hazardous gases (e.g., carbon monoxide).

Contaminants are in excess of regulations or rec ommendations.

Contaminants or contaminant concentrations are unknown.

4

Work area is poorly ventilated.

The temperature is outside the range of 14°F to 131°F (-10°C to +55°C). If the internal battery

temperature reaches 140°F (60°C) the unit will completely shut down.

Flammable or explosive atmosphere is present. This system contains elect ric al parts that

are not suitable for use in such environments. The PX4 AIR® is not intrinsically safe.

AIR SOURCE

Powered Air

Check that the contaminated area is within the limits of use for a Powered Air Purifying Respirator

and determine the type of contamination. Once the contamination level has been confirmed

you can then determine the filter cartridge to be used for the application, to make sure that you

are sufficiently protected. Make sure that the area is well ventilated and that regular air samples

are taken to confirm the atmosphere stays within the levels recommended by OSHA and other

governing bodies.

5

®

PX4 AIR

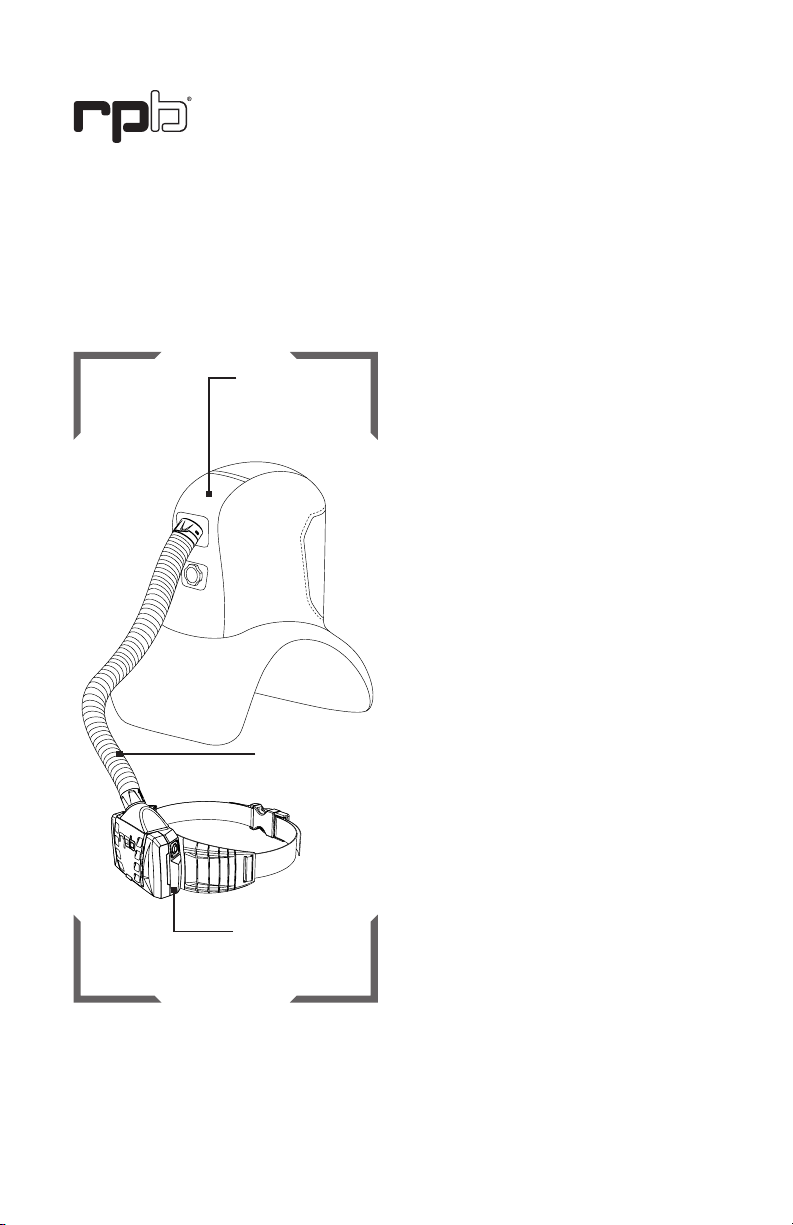

RESPIRATOR COMPONENT DIAGRAM

The RPB® PX4 AIR® is part 3 of the 3 main

components that constitute a powered air

purifying respirator. (Note the T-Link® has

been used in the above diagram as an

example.)

1. R ESPIR ATOR

HELME T/

HOOD

ASSEMBLY

2. BREATHING

TUBE

ASSEMBLY

3. AIR SUPPLY

PX4 AIR

FIGURE 1.1

®

NIOSH - CAUTIONS AND LIMITATIONS

Powered Air

A. Not for use in atmospheres containing

less than 19.5 percent oxygen.

B. Not for use in atmospheres immediately

dangerous to life or health.

C. Do not exceed maximum use

concentrations established by regulatory

standards.

F. Do not use powered air-purifying

respirators if airflow is less than four

cfm (115 lpm) for tight fitting face pieces

or six cfm (170 lpm) for hoods and/or

helmets.

I. Contains electrical parts that may cause

an ignition in flammable or explosive

atmospheres.

J. Failure to properly use and maintain this

product could result in injury or death.

L. Follow the manufacturer’s User’s

Instructions for changing cartridges,

canister and/or filters.

M. All approved respirators shall be

selected, fitted, used and maintained

in accordance with MSHA, OSHA, and

other applicable regulations.

N. Never substitute, modify, add or omit

parts. Use only exact replacement parts

in the configuration as specified by the

manufacturer.

O. Refer to user’s instructions, and/or

maintenance manuals for information

on use and maintenance of these

respirators.

P. NIOSH does not evaluate respirators for

use as surgical masks.

S. Special or Critical User Instructions and/

or specific limitations apply. Refer to

“S-Special or Critical User Instructions”

on page 15 before donning.

6

EMPLOYER RESPONSIBILITIES

Your specific responsibilities may vary by location and industry, but in general RPB® expects that

employers will:

Follow all applicable standards and regulations for your location, industry, and activity.

Depending on your location and industry, a number of standards and regulations may apply

to your selection and use of respirators and other personal protective equipment. These may

include such things as federal (e.g., OSHA, MSHA, Canadian Occupational Health and Safety),

local (e.g., state, provincial), or military standards and regulations and consensus standards

such as ANSI and CSA. There are also requirements specific to particular contaminants, e.g.

silica (see rpbsafety.com for more information), asbestos, organic pathogens, etc. Know which

requirements apply to your location and industry.

Have appropriate safety programs in place.

Have and follow:

A workplace safety program.

A written respiratory protection program in accordance with applicable standards and

regulations (e.g., OSHA 29 CFR 1910.134; ANSI/ASSE Z88.2; CSA Z94.4, etc.).

In accordance with the above,

Perform a hazard analysis and select appropriate equipment for each activity. A

hazard analysis should be performed by a qualified person. Controls should be in

place as appropriate and a qualified person should determine what kind of respiratory,

face and eye, head, and hearing protection is appropriate for the intended activities

and environments of use. (For example, select a respirator appropriate to the specific

airborne hazards, with consideration of workplace and user factors and with an Assigned

Protection Factor (APF) that meets or exceeds the required level for employee protection,

select welding face and eye protection appropriate to the type of welding to be done, etc.)

As applicable, check your workplace safety program, respiratory protection program, and

standards and regulations for your activity or industry for related protection requirements,

and see this manual (Protection Provided and Limitations, page 4) and the head top

Instruction Manual for product specifications.

Be sure employees are medically qualified to use a respirator.

Have a qualified physician or other licensed health care professional (PLHCP) perform

medical evaluations using a medical questionnaire or an initial medical examination per

OSHA 29 CFR 1910.134.

Train employees in the PX4 AIR®’s use, maintenance, and limitations.

Appoint a qualified individual who is knowledgable about the RPB® PX4 AIR® per ANSI/

ASSE Z88.2 guidelines to provide training:

8.1 Qualifications of the Respirator Trainer. Anyone providing respirator training shall:

a) be knowledgable in the application and use of the respirator(s);

b) have practical knowledge in the selection and use of respirator(s) and work practices

at the site;

7

®

PX4 AIR

EMPLOYER RESPONSIBILITIES CONTINUED

c) have an understanding of the site’s respirator program; and

d) be knowledgable of applicable regulations.

Train each PX4 AIR® user in the product’s use, application, inspection, maintenance, storage,

fitting, and limitations in accordance with the content of this Instruction Manual and the

approved head top Instruction Manual and standard or regulatory requirements. Ensure that

each intended user reads both these manuals.

Ensure that equipment is properly set up, used, and maintained.

Make sure that equipment is properly set up, inspected, fitted, used, and maintained,

including selection of the appropriate air filter cartridge for the application.

Measure and monitor airborne contaminants in the work area.

Measure and monitor airborne contaminant levels in the work area in accordance with

applicable requirements. Make sure work area is well ventilated.

Exposure limits for mixtures:

The American Conference of Government Industrial Hygienists (ACGIH) publishes a Guide

to Occupational Exposure Values and also documentation for Threshold Limit Values and

Biological Exposure Indices.

The information supplied by ACGIH provides formulas and information to calculate the

exposure level of the atmosphere. This helps to determine the appropriate respirator category

required for protection against all contaminants present. Check the ACGIH publications to help

determine the right protection for your application.

If you have any questions, contact RPB®.

Call Customer Service Department at:

Tel: 1-866- 494- 4599 or

Email: customerservice@rpbsafety.com

Web: rpbsafety.com

8

PRODUCT USER SAFETY INSTRUCTIONS

BEFORE INITIAL USE - BE TRAINED AND MEDICALLY QUALIFIED

Do not use this device until you have read this manual and the approved head top Instruction

Manual (additional copies available at www.rpbsafety.com) and been trained in the respirator’s

use, maintenance, and limitations by a qualified individual (appointed by your employer) who is

knowledgable about the RPB

Do not wear this respirator until you have passed a medical evaluation using a medical

questionnaire or an initial medical examination by a qualified physician or other licensed health

care professional (PLHCP).

Allergens: No known common allergens are used in this product.

Some materials could cause an allergic reaction in susceptible individuals. If you have a known

allergy or develop irritation, inform your employer. Irritation may occur from lack of cleaning.

Following all cleaning and care instructions provided in the instruction manuals for this and any

other RPB

®

products you are using.

MAKE SURE THE SYSTEM IS READY FOR USE

Make sure you have a complete system. The PX4 AIR

approved respirator system. Verify that you have all required components for the PX4 AIR® to

serve as a complete NIOSH approved respirator:

Respirator Head-top Assembly

Breathing Tube Assembly

PX4 AIR® PAPR

See Respirator Component Diagram (page 6). See the instruction manual and approval label for

the selected head top for NIOSH approval with the PX4 AIR

Use only authentic RPB® brand parts and components that are part of the NIOSH approved

respirator assembly. Using incomplete or inappropriate equipment, including the use of counterfeit

or non-RPB® parts, can result in inadequate protection and will void the NIOSH approval of the

entire respirator. Do not modify or alter any part of this product.

Inspect all components daily for signs of damage or wear and tear that may reduce the level

of protection originally provided, see Inspection and Cleaning (p. 24) for details. Remove any

damaged component or product, including any belt, breathing tube, or front cover of the PAPR,

from service until repaired or replaced. Damaged components should be replaced with genuine

®

brand replacement parts. Replace HE filter when they are visually dirty, filter media is

RPB

damaged, or the airflow is reduced. Inspect the prefilter and the spark arrestor for damage or

blockage. Inspect the inside of the respirator for respirable dust or other foreign objects. Keep the

inside of the respirator clean at all times.

Make sure that the PAPR is correctly assembled in the configuration that suits your application.

Never use the respirator without a HE filter in place depending on the application. It is

recommended that a prefilter always be used. For applications that produce sparks or high heat,

®

PX4 AIR® PAPR.

®

is only one component of a NIOSH

®

and the as signed protection factor.

9

Loading...

Loading...