Rpb Nova 3 User Manual

0194

INSTRUCTION MANUAL

CONTENTS

Read all instructions and warnings before using this product.

Keep this manual for future reference.

INTRODUCTION 3

APPARATUS COMPONENT CONCEPT 4

WARNINGS 5

APPARATUS OPERATION 7

SPECIAL OR CRITICAL USER INSTRUCTIONS - BREATHING AIR PRESSURE TABLE 9

APPARATUS SETUP AND USE 10

CLEANING, DISINFECTING & STORAGE 15

PARTS AND ACCESSORIES 20

RPB® Safety Global Headquarters 2807 Samoset Rd, Royal Oak, MI 48073, USA.

T: 1-866-494-4599 F: 1-866-494-4509 E: sales.us@rpbsafety.com rpbsafety.com

RPB® Safety Asia Pacic Headquarters 652 Halswell Junction Road, Hornby South 8042 New

Zealand. T: +64-3-357-1761 F: +64-3-357-1763 E: sales.nz@rpbsafety.com rpbsafety.com

RPB®, Advancing Your Safety, Radex, Zytec, Nova and NOVA 3 are registered trademarks of RPB®

Safety LLC

For technical assistance contact our Customer Service Department

on 1-866-494-4599 or email: customerservice@rpbsafety.com

2

Form #: 7.20.525

Rev: 2

INTRODUCTION

The RPB® NOVA 3 is approved in two

categories as follows:

• COMPRESSED AIRLINE

BREATHING APPARATUS

EN14594 - When used with RPB®

Supplied Air Hose and Flow

Device System. This provides

respiratory protection during

Abrasive Blasting.

• Powered Air Purifying Respirator

- When used with the RPB® PX⁴

AIR PAPR unit.

The Nova 3 has been

designed for use in atmospheres NOT

IMMEDIATELY DANGEROUS TO LIFE OR

HEALTH, and from which a user can

escape without the aid of the breathing

apparatus, or that do not exceed the

concentrations allowed by Government

regulations and recommendations.

The RPB® NOVA 3 is tested and approved

to EN14594:2005 and AS/NZS 1716:2003

to provide breathing protection in

abrasive blasting applications. The cape

is designed to protect the wearer’s

upper body from rebounding abrasive.

03-101 Constant Flow Valve

NV2016 Flow Control Valve

4000-01 Cold Air Tube

4000-20 Hot Air Tube

03-501 Climate Control Device

03-901 RPB® PX⁴ AIR Powered Air

Purifying Respirator (refer to

PAPR Instruction Manual for

instructions on setting up for

use with the PAPR.)

WARRANTY

All RPB® Safety products are covered by

a manufactures warranty of 3 months.

The manufacturer warranty covers

defects in material, workmanship and

does not cover damage caused by misuse

or abuse. RPB® Safety’s only obligation

and your exclusive remedy shall be to

repair , replace or refund the purchase

price of such parts or products upon

the presentation of proof of purchase.

Maximum liability is in no case to exceed

the value of the RPB® Safety Product

involved.

The RPB® NOVA 3 provides an assigned

protection Factor of greater than

APF1000. Due to the high noise levels

experienced during abrasive blasting,

hearing protection must always be

worn.

The RPB® NOVA 3 is CE approved for use

with the following devices:

3

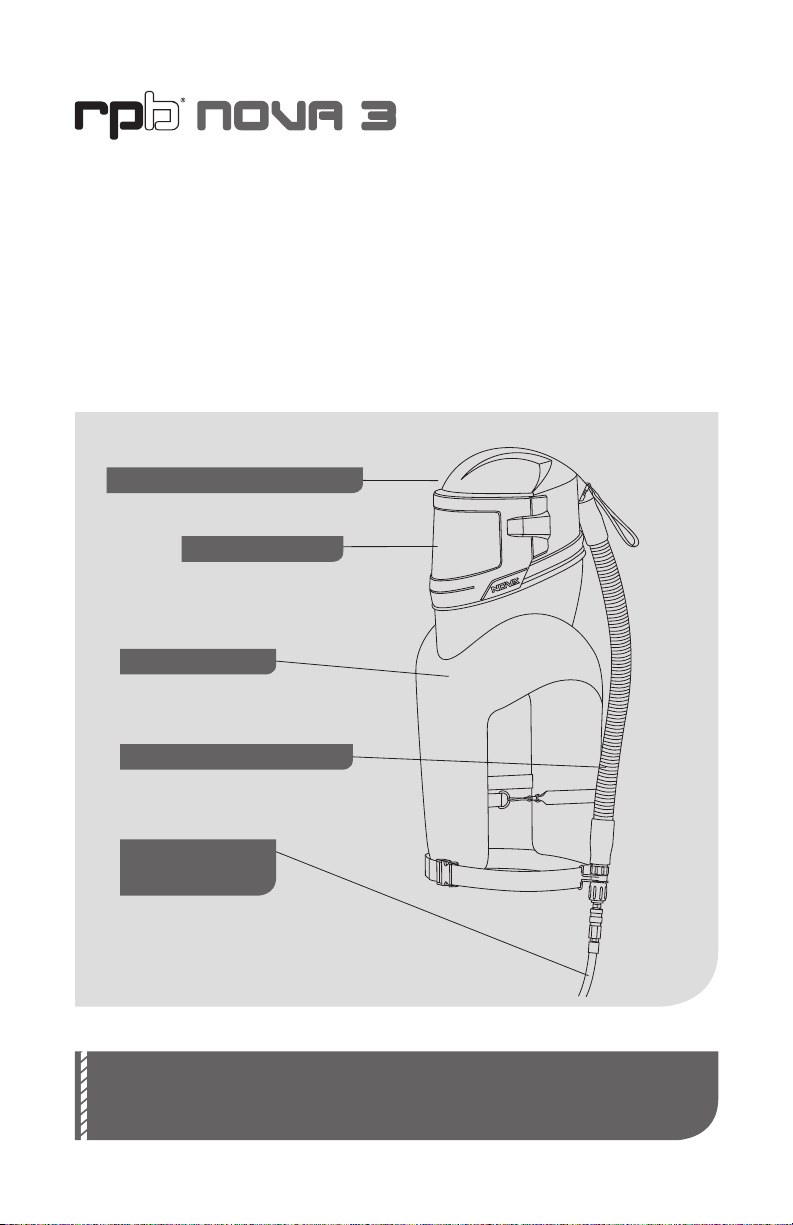

APPARATUS COMPONENT CONCEPT

The RPB® Nova 3 consists of 3 main components: Helmet assembly, breathing tube

and air supply hose illustrated in Fig1.1. All 3 components must be present and

properly assembled to constitute a complete EN14594, EN14 and AS/NZS 1716

approved Compressed Airline Breathing Apparatus. When congured with a PX⁴

PAPR the breathing tube will connect to the PX⁴ PAPR.

1. Apparatus Helmet Assembly

Inner & Outer Lens

2. Apparatus Cape

3. Breathing Tube Assembly

4

4. Air Supply Hose

or PX⁴ AIR PAPR

Figure 1.1

!WARNING! Failure to use genuine parts and components that are part of

the

EN14594, EN12941 and AS/NZS 1716 approved apparatus assembly will void

the approval of the entire apparatus assembly.

!WARNINGS!

1. Do not use this apparatus until you

have been trained in the apparatus

use, maintenance and limitations by

a qualied individual (appointed

by your employer) who has

extensive knowledge of the RPB®

NOVA 3 Series. All training must

be in accordance with this Users

Instruction Manual.

2. Before using this apparatus ensure

your employer has determined

that airborne contaminant

concentrations do not exceed those

allowed by applicable Government

Regulations and recommendations

for a Compressed Air line Breathing

Apparatus. It is required that the

employer measures and monitors

airborne contaminant levels in the

work area.

3. Do not wear this apparatus if any of

the following conditions exist

- Atmosphere is immediately

dangerous to your life or health

- You CAN NOT escape without

the aid of the apparatus

- Atmosphere contains less than

19.5% oxygen

- Work area is poorly ventilated

- Contaminants are in excess of

regulations or recommenda-

tions

4. Do not modify or alter this apparatus.

Use only parts and components that

are part of the EN14594 and AS/NZS

1716 approved apparatus assembly.

The use of non RPB® parts voids the

EN14594 and AS/NZS 1716 approvals

of the entire apparatus assembly.

5.

Inspect all components of the

apparatus daily for signs of damage

or wear and tear that may reduce

the level of protection originally

provided.

6

. Do not use silica sand or abrasives

containing silica, lead, arsenic or

sharp glass particles - use of abrasive

containing these elements could

result in serious injury or death.

7.

Do not wear this apparatus until

you have passed a complete

physical exam including a lung X-ray

conducted by qualied medical

personnel.

8.

Improper use of this apparatus or

use not in accordance with this User

Instruction Manual may cause injury

or death. Improper use may also cause

life threatening delayed lung diseases

such as silicosis, pneumoconiosis or

asbestosis.

9.

This apparatus, when properly tted

and used, signicantly reduces but

does not completely eliminate the

breathing of contaminates by the

apparatus wearer.

10.

Be certain your employer has

determined that the breathing air

source provides at least EN12021,

AS/NZS 1715 breathable air. The

apparatus must be supplied with

clean breathable air at all times. For

supplied air it is recommended that

a carbon monoxide monitor be used

5

at all times. Contact your RPB® Safety

distributor for a Radex 08-200 CO

Monitor.

11. RPB® Safety cannot accept any liability

of whatsoever nature arising directly

or indirectly from the use or misuse

of RPB® Safety products, including

purposes that the products are not

designed for. RPB® Safety is not liable

for damage, loss or expense resulting

from the failure to give advice or

information or the giving of incorrect

advice or information, whether or not

due to RPB® Safety’s negligence or

that of its employees, agents or subcontractors.

12.

Do not connect the apparatus’s air

supply hose to nitrogen, oxygen,

oxygen enriched air, toxic gases, inert

gases or other nonbreathable non

EN12021, AS/NZS 1715 breathable air

source. Check the air source before

using the apparatus. This apparatus is

not designed for use with compressed

air cylinders, i.e. SCBA cylinders.

Failure to connect the supply hose to

the proper air source could result in

serious injury or death.

13. DO NOT use this apparatus in poorly

ventilated areas or conned spaces

unless the area is well ventilated and

that the contaminant concentrations

are below those recommended for

this apparatus. Follow all procedures

for conned space entry, operation

and exit as dened in applicable

regulations and standards.

14.

DO NOT wear this apparatus if the

ambient usage temperature is below

-10˚C or above +60˚C. Moisture

content of breathable air should be

controlled when the apparatus is to

be used in temperatures below +4˚C

to avoid freezing the apparatus.

15. Leave work immediately if:

- Any apparatus component

becomes damaged.

- Airow stops or slows down

- Breathing becomes dicult

- You become dizzy, nauseous,

too hot, too cold or ill.

- Vision is impaired.

- When the warning alarm

sounds.

16. NOVA 3 apparatus does not provide

hearing protection. Approved ear

plugs must be properly tted when

exposed to noise levels that exceed

Government permissible exposure

levels.

RECOMMENDATION:

When using a NOVA 3 as a Supplied Air

apparatus. It is recommended to use a

Radex Airline Filter (04-900) and a carbon

monoxide monitor (08-200)

APPROVALS

This apparatus meets the requirements

of the European Community Directive

89/686/EEC, (Personal Protective

Equipment Devices).

6

APPARATUS OPERATION

AIR QUALITY

This Apparatus must be supplied with

clean breathable air, EN12021, AS/NZS

1715 or better, at all times. The NOVA 3

does not purify air or lter contaminants.

Breathable air must be supplied to the

point of attachment of the EN14594

approved NOVA 3 air supply hose.

Supplied breathing air must at least meet

the requirements for EN12021, AS/NZS

1715 and local Government Regulations.

When using the PX⁴ PAPR with the NOVA

3, always make sure to use a clean lter

cartridge to ensure the air is clean.

AIR SOURCE

Supplied AIr

Locate the air source in a clean air

environment, always use a lter on the

inlet of your air source. Do not park

vehicles beside your air inlet as this will

cause carbon monoxide to be drawn into

your air supply.

Use suitable aftercoolers / dryers with

lters and carbon monoxide alarms to

assure clean breathable air is supplied at

all times.

The air should be regularly sampled to

ensure that it meets EN12021, AS/NZS

1715 requirements.

POWERED AIR

Check that the contaminated area is

within the limits of the use of a Powered

Air Purifying Respirator and determine

the type of contamination. Once the

contamination level has been conrmed

then you can determine the lter

cartridge to be used for the application,

to make sure that you are suciently

protected. Make sure that the area is well

ventilated and that regular air samples

are taken to conrm the atmosphere

stays within the levels recommended by

OSHA and other governing bodies.

TESTED AND CERTIFIED BY:

Certied under Article 10, the QA

systems are approved under Article 11b

and approved as an EN14594 Respirator:

INSPEC International (0194)

56 Leslie Hough Way

Salford M6 6AJ

United Kingdom

Approved as an EN12941 Respirator:

Apave Sudeurope SAS (0082)

8 rue Jean-Jacques Vernazza

CS 60193

13322 Marseille Cedex 16

France

BREATHING AIR SUPPLY

HOSES AND FITTINGS

EN14594, AS/NZS 1716 approved

NOVA 3 airline hoses must be used

between the point of attachment and

the apparatus breathing air connection

at the wearer’s belt. EN14594, AS/NZS

1716 approved NOVA 3 quick disconnect

ttings must be used to connect the

hose lengths together. The hose sections

must be within the approved length and

the amount of sections must be within

the number specied in the Breathing

Air Pressure Table.

7

BREATHING AIR PRESSURE

The air pressure must be continually

monitored at the point of attachment

while the air is owing to the apparatus.

Air pressure must be read from a reliable

pressure gauge whilst the apparatus has

air owing through it.

!WARNING!

Failure to supply the apparatus with the

minimum required pressure at the point

of attachment for the length of airline

hoses used could result in contaminants

being inhaled as the pressure in the

helmet may become negative due to

peak inhalation ow when working

at very high work rates. The NOVA 3

BREATHING AIR PRESSURE TABLE on

Page 9 denes the air pressure ranges

needed to provide the apparatus with a

volume of air which falls in the required

range of 235-425 lpm.

!WARNING!

Make sure you understand the Breathing

Air Pressure table before using this

apparatus, as a compressed airline

breathing apparatus.

1. Determine your air source (column 1)

2. Identify your breathing tube

assembly (column 2)

3.

Be sure your air supply hose is

EN14594, AS/NZS 1715 approved

NOVA 3 breathing air hose.

4. Check your NOVA 3 air supply hose

is within the EN14594, AS/NZS 1715

approved length in column 4.

5. Set the air pressure at the point of

attachment within the range

specied in column 6 for your

breathing tube assembly, hose

length and amount of hose sections.

Make sure air is owing through your

apparatus when setting the pressure.

8

Loading...

Loading...