Royalton R32BRTO Service Manual

ROYALTON

R32BRTO OVEN

9981 York-Theta Drive, North Royalton, Ohio 44133

440-237-0806 FAX: 440-237-1694 1-800-662-8765

WARRANTY

ROYALTON FOODSERVICE EQUIPMENT COMPANY WARRANTS TO THE

ORIGINAL PURCHASER THAT ANY ORIGINAL PART FOUND TO BE DEFECTIVE

IN MATERIAL OR WORKMANSHIP WILL BE REPLACED AT OUR DISCRETION

WITHIN ONE (1) YEAR FROM DATE OF SHIPMENT.

IF AUTHORIZED BY OUR SERVICE DEPARTMENT, REPLACEMENT PARTS ARE

PROVIDED F.O.B. FACTORY. THIS WARRANTY ALSO PROVIDES ONE (1) YEAR

LABOR, FROM DATE OF SHIPMENT. END-USER OR RESPONSIBLE PARTY MUST

NOTIFY ROYALTON FOOD SERVICE EQUIPMENT CO. FIRST WITH A MODEL

AND SERIAL NUMBER AND WHAT TYPE OF PROBLEM IS OCCURRING. AT THAT

TIME AUTHORIZATION WILL BE GIVEN AND PARTS WILL BE SENT TO THE

END-USER OR SERVICE AGENCY. IF THIS PROCEDURE IS NOT FOLLOWED,

END-USER WILL BE RESPONSIBLE FOR SERVICE LABOR & TRAVEL BILL.

OUR TUBULAR HEATERS HAVE A WARRANTY OF FIVE (5) YEARS. WITHOUT

PRIOR AUTHORIZATION FROM OUR SERVICE DEPARTMENT, PARTS CANNOT

BE RETURNED TO US FOR CREDIT. CREDIT IS SUBJECT TO APPROVAL BY

OUR SERVICE DEPARTMENT AFTER INSPECTION OF RETURNED PARTS.

THIS WARRANTY DOES NOT INCLUDE LABOR AND DOES NOT APPLY TO:

DAMAGED EQUIPMENT CAUSED BY SHIPPING ACCIDENTS, IMPROPER

STORAGE, INADEQUATE MAINTENANCE, NEGLECT, MISAPPLICATION,

UNAUTHORIZED ALTERATIONS, LOSSES OR DAMAGES RESULTING FROM

MALFUNCTIONS, INCLUDING LOSS OF PRODUCT, IMPROPER INSTALLATION -

NO FRYERS, BROILERS, COOK TOPS, OR ANY KIND OF HEAT SOURCE SHOULD

BE PLACED ON THE RIGHT SIDE OF THE EQUIPMENT. GLASS, LIGHT BULBS,

DOOR AND BODY GASKETS, AND MEAT PROBES ARE NOT COVERED UNDER

OUR WARRANTY.

THIS WARRANTY IS IN LIEU OF ALL WARRANTIES EXPRESSED OR IMPLIED.

FOR WARRANTY SERVICE, PLEASE CONTACT CUSTOMER SERVICE AT

ROYALTON FOODSERVICE EQUIPMENT COMPANY @ 800-662-8765

440-237-0806 FAX: 440-237-1694 1-800-662-8765

9981 York-Theta Drive, North Royalton, Ohio 44133

CARE AND CLEANING

The unit should be wiped down, inside and out, after each use. The control

module should be checked for dust, grime, or grease around the vent

louvers and wiped on a regular basis. Because the roasting is done at low

temperatures, there is very little grease build-up. Over time, however, grease

will begin to stick to the walls and floor of the unit. Hot soapy water with a

non-abrasive pad or oven cleaner for stainless steel is best for cleaning the

interior. For the exterior, we recommend hot soapy water with a nonabrasive pad, or stainless steel cleaner and polish. Always wipe with the

grain. Failure to remove greasy build-up can cause bacterial growth within

the oven cavity. It can also impair the accuracy of the temperature sensors

that keep the heat cycling properly.

ο

DO NOT

Avoid getting water inside the control module, because it ruins

the electrical components and

ο

NEVER

equipment such as deep fryers or griddles.

ο DO NOT block louvers or cooling fans in the control module.

Doing so will cause the unit to overheat and shut down the oven.

CLEANING PROCEDURE

use a pressure washer or water under pressure.

VOIDS THE WARRANTY.

locate your Royalton unit next to grease emitting

1. Press power switch off

2. Turn off circuit breaker

3. Clean interior and exterior.

4. Turn on circuit breaker

INSTATLATION

LEVELING THE

To level the

1. Screw the adjustable feet

2.

oven, screw the leg feet in or out.

the front, back and sides; ifnot

After

close to

Note: This measurement

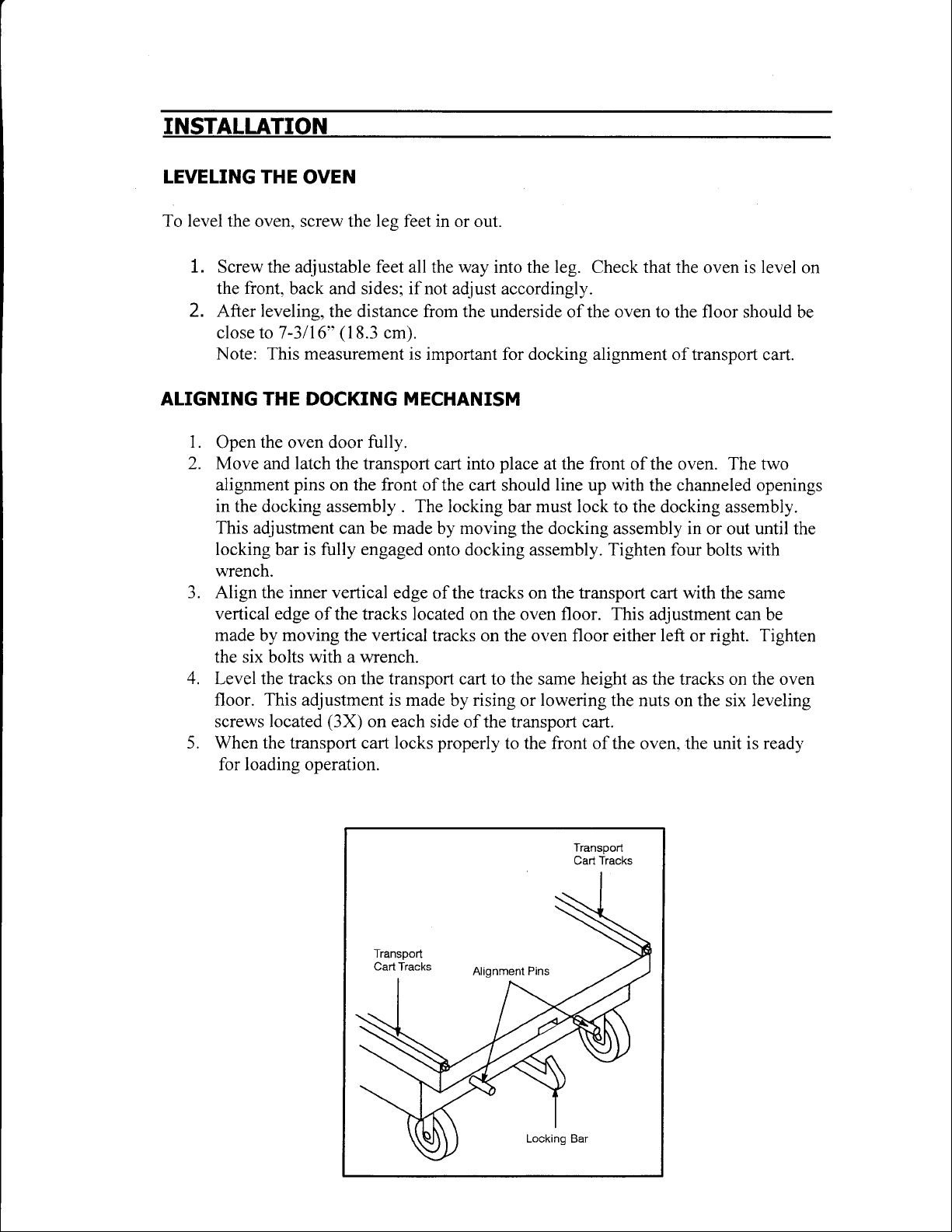

ALIGNING THE DOCKING

1.

Open

2. Move

alignment

in

the docking assembly . The locking

This adjustment

locking

wrench.

3. Align the inner vertical

vertical edge

made by moving the vertical

the six bolts with a wrench.

4.

Level the tracks on the transport cart

floor. This adjustment is made

screws located

5. When the transport cart locks

for loading operation.

OVEN

leveling,

7-3/16"

the

and

bar

the distance from the

(18.3

oven door

latch

the transport cart into

pins

on the front

can be made by moving the

is fully engaged

of the tracks located on

(3X)

cm).

MECHANISM

fully.

edge of the tracks on the transport

on

each side of the transport cart.

all the

is important for docking alignment

way

into the leg. Check that the

adjust accordingly.

underside of the oven to the floor should

place

at the

front of the oven. The two

of the cart should

bar

onto docking assembly. Tighten four

the

tracks on the oven floor either left

to the same height as the tracks on the oven

rising

by

properly

to the front of the

line

up with the channeled openings

must lock to

docking assembly in or out until the

oven floor. This

lowering

or

the docking assembiy.

cart

adjustment can be

the nuts on the six leveling

oven,

is level

oven

of transport cart.

with

bolts

with

the same

right. Tighten

or

the

unit

is ready

on

be

Transport

Cart Tracks

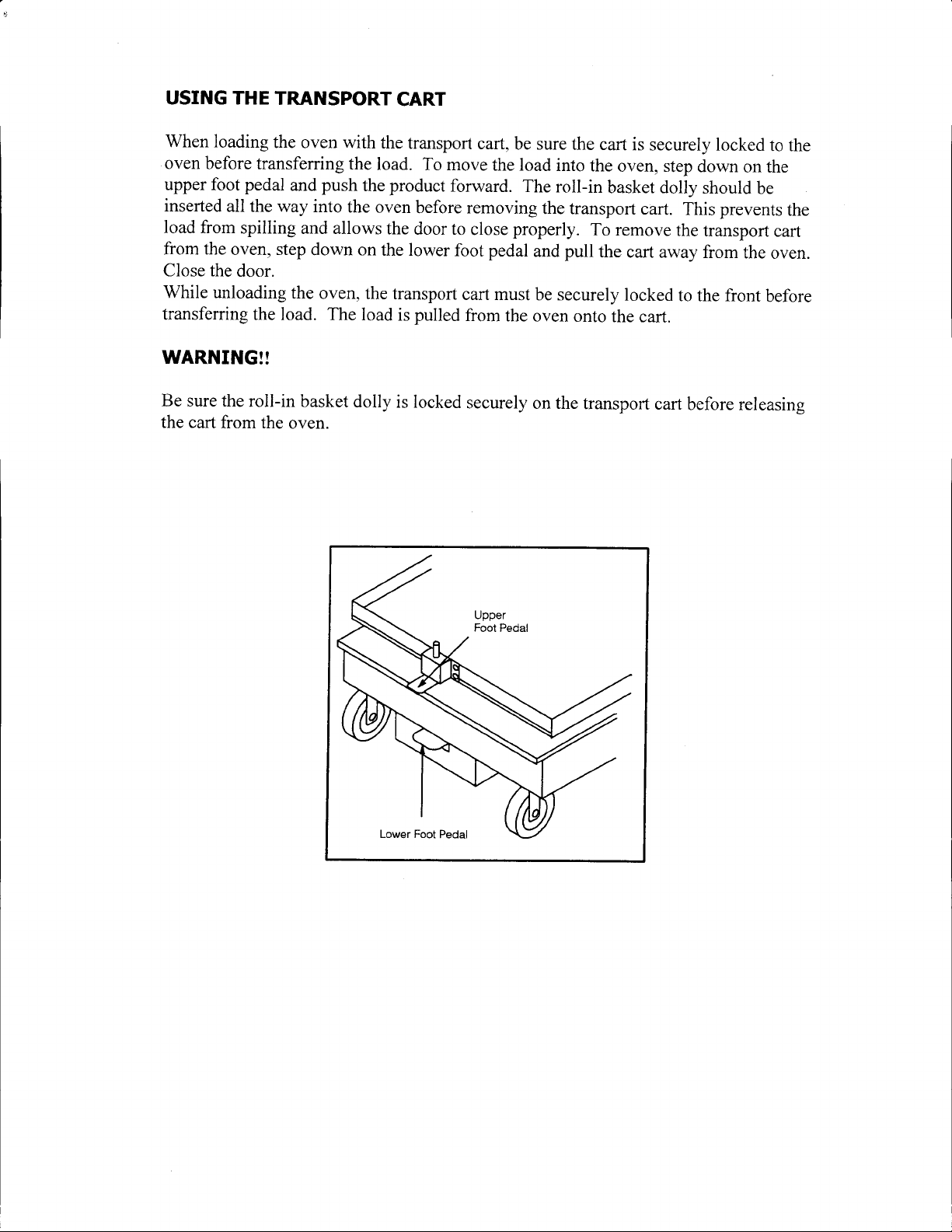

USING THE

TRANSPORT

CART

When loading

oven

before transferring

upper foot

inserted

load from

from the

Close the

While unloading

transferring

WARNING!!

Be sure the roll-in basket

the cart

from the

the oven with

pedal

and

all the

way into

spilling

oven, step

door.

the

the load. The

oven.

push

the

and allows

down on

oven,

the

transport

the

load.

To move

product

the

oven

before removing

the

door to

the lower

the transport

load

dolly

pulled

is

is locked

cart,

the load

forward.

close

pedal

foot

cafi must

from

the

securely

be sure

The

properly.

the cart

into

roll-in

the transport

pull

and

be securely

oven onto

on the

is

securely locked

the

oven, step

basket dolly

cart.

To

remove

the

cart away

locked

the cart.

transport

down

should

prevents

This

the

transport

from

to the front

carl

before releasing

to the

on the

be

cart

the

oven.

before

the

Loading...

Loading...