Page 1

INSTALLATION INSTRUCTIONS

Gas Changeover Kit

Natural to Regulated LP/Propane (Kit #11K48)

For A802, 80G2, A952, A962 & 95G2 Units

This manual must be left with the homeowner for future reference.

This is a safety alert symbol and should never be ignored. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury or death.

WARNING

In the U.S., this conversion kit is to be installed

by a licensed professional service technician (or

equivalent) or other qualied agency in accordance

with the manufacturer’s instructions and all codes and

requirements of the authority having jurisdiction. If the

information in these instructions is not followed exactly, a

re, an explosion, or production of carbon monoxide may

result, causing property damage, personal injury or loss

of life. The qualied agency is responsible for the proper

installation of the kit. The installation is not proper and

complete until the operation of the converted furnace

is checked as specied in the furnace manufacturer’s

instructions supplied with the kit.

Application

Use natural to LP gas conversion kit 11K48 to convert

A802, 80G2, A952, A962 and 95G2 gas furnaces from

natural gas to regulated LP/Propane.

Installation

CAUTION

As with any mechanical equipment, personal injury can

result from contact with sharp sheet metal edges. Be

careful when you handle this equipment.

Shipping and Packing List

Package 1 of 1 contains the following:

2 - LP/Propane regulator springs (77W89)

12 -Main burner orices (0.034)

gas supply to the furnace, then turn off the electrical

power at the unit disconnect switch.

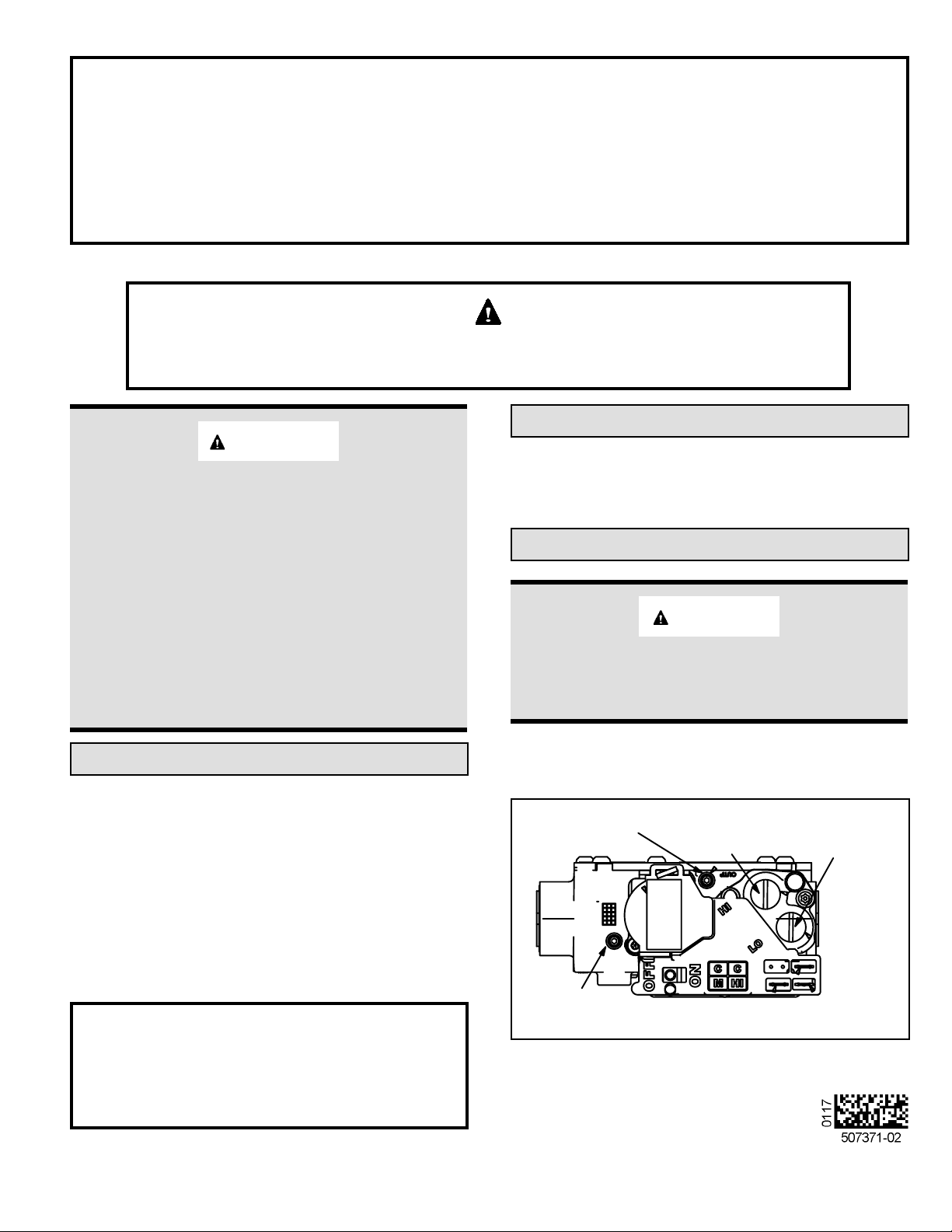

MANIFOLD

PRESSURE

POST

HIGH FIRE

ADJUSTMENT

SCREW

(under cap)

LOW FIRE

ADJUSTMENT

SCREW

(under cap)

1 - Gas converter sticker

1 - Nameplate conversion sticker

1 - Low gas inlet pressure switch

1 - Gas valve inlet brass tting

1 - Wire harness

1. Set the thermostat to the lowest setting. Shut off the

INLET

PRESSURE POST

Manufactured By

Allied Air Enterprises LLC

A Lennox International, Inc. Company

215 Metropolitan Drive

West Columbia, SC 29170

GAS VALVE SHOWN IN OFF POSITION

Figure 1. White Rogers Gas Valve

Save these instructions for future reference

507371-02 Issue 1706 Page 1 of 5

Page 2

2. Remove the access panel. Move the automatic gas

valve switch to OFF. See Figure 1.

3. Disconnect the gas supply from the gas valve.

Disconnect the wiring harness at the gas valve.

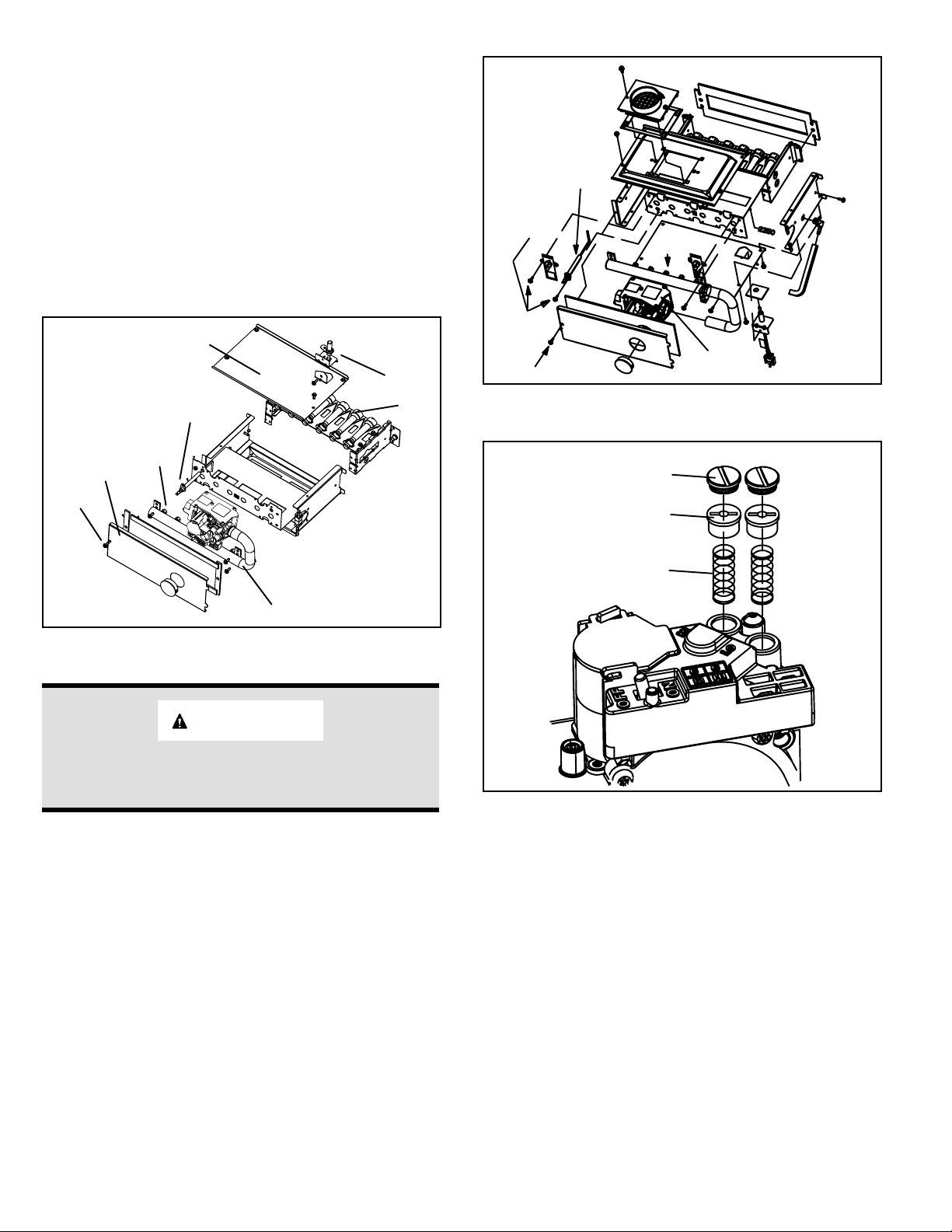

4. Remove the screw that secures the burner box front

cover and remove front cover. See Figure 2 or Figure

3.

5. Remove the four manifold securing screws. Remove

the manifold/gas valve assembly. Replace the main

burner orices with the provided orices. Torque to

approximately 35 in-lbs. See Figure 2 or Figure 3 .

NOTE: LP/Propane orices will be labeled (LP .034).

Burner

Box Top

Cover

Ignitor

Burners

Sensor

Sensor

Manifold

Securing

Screw

Screw

Gas

Orifices

Gas Valve

Figure 3. A952 & 95G2 Burner Box

Gas

Valve

Regulator

Vent

Hose

Ignitor

Burner Box

Front Cover

Screw

Orifice

Manifold

Figure 2. A802 & 80G2 Burner Box

IMPORTANT

DO NOT use pipe dope or any pipe sealant on gas orice

threads.

6. Gas Valve Conversion

a. Remove both high re and low re springs from

the gas valve. See Figure 4.

b. Replace both high re and low re springs with the

provided LP springs color-coded white.

c. Install the high re adjustment screw and adjust

approximately 12 turns.

d. Install the low re adjustment screw and adjust

approximately 8 turns.

e. Install both regulator screw covers.

High

Regulator

Cover Screw

Plastic Regulator

Adjustment Screw

Regulator Spring

Low

Figure 4.

7. A802 and 80G2 units with Nox inserts being converted

from natural to LP/Propane.

a. Remove the burner box assembly from the

vestibule panel.

b. Remove the screws which secures each of the

NOx inserts to the clamshell. Remove the NOx

inserts and reinstall the screws. See Figure 5.

c. Re-install burner box assembly.

507371-02Issue 1706Page 2 of 5

Page 3

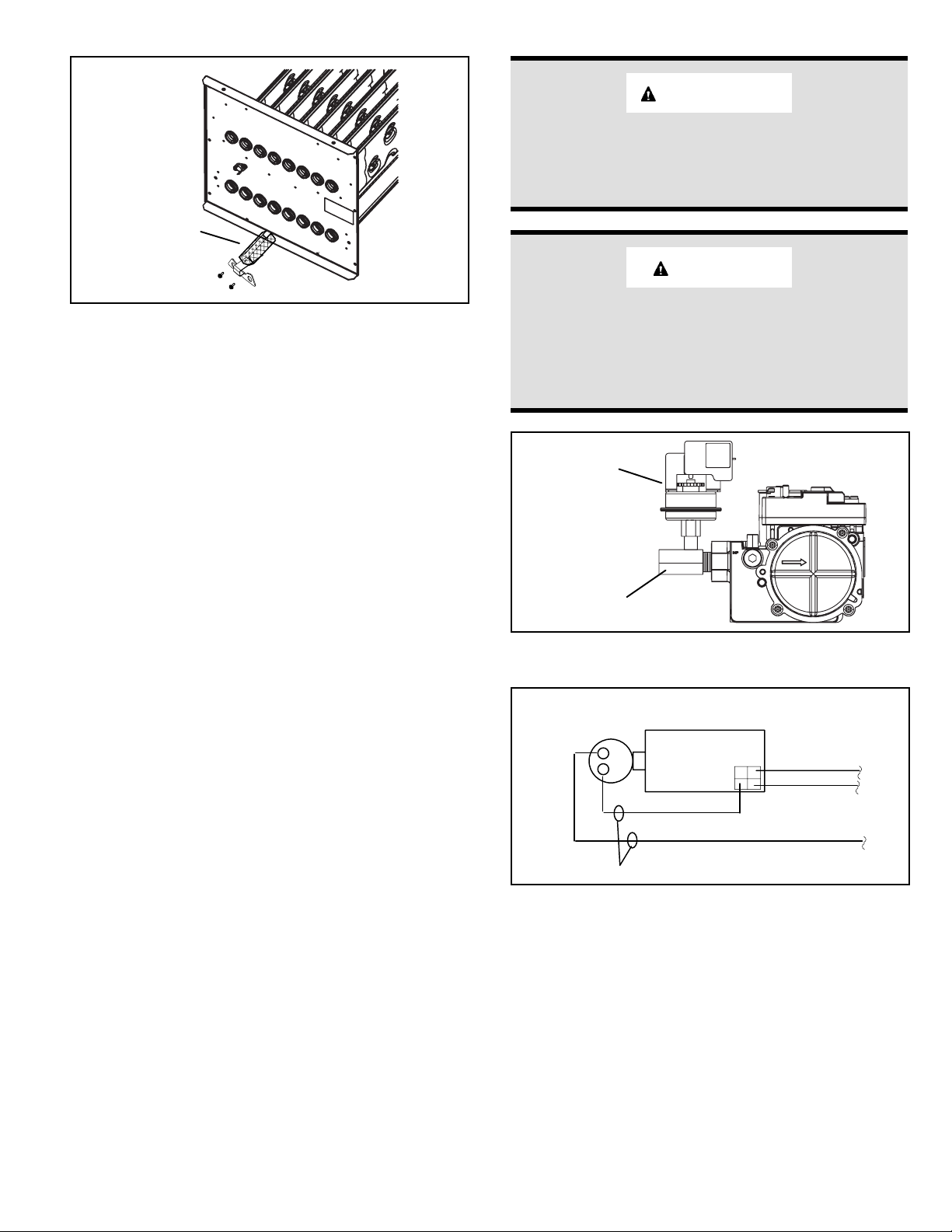

NOx Insert

IMPORTANT

Carefully check all piping connection for gas leaks. DO

NOT use matches, candles, open ames or other means

of ignition to check for gas leaks. Use a soap solution or

other preferred means.

Re-install

Screws

Figure 5. NOx Inserts

8. Re-install the manifold/valve assembly.

9. Thread provided brass tting to gas valve inlet until

hand tight. Using properly sized wrench, tighten tting

2 to 3 full turns being careful to position the side port to

allow clearance for the pressure switch and harness.

See Figure 6.

NOTE: Never use channel lock pliers or a pipe wrench

on the brass tting.

NOTE: Some installations may require the pressure

switch and tting assembly to be positioned differently

than shown in Figure 6.

10. Thread the gas supply to the brass tting until hand

tight. Using properly sized wrench to support brass

tting, tighten supply line into tting 2 to 3 full turns to

achieve leak free joint.

NOTE: Do not over tighten. (Maximum 3 full turns past

hand tight for ½” NPT per ASME B1.20.1-2013)

11. Thread pressure switch to brass tting 2 to 3 turns

past hand tight, then wire as shown in Figure 7.

12. Restore the electrical power to the unit.

13. Inspect all sides of assembly. Turn on gas supply.

Immediately check the entire tting surface and

assembly joints for gas leaks.

14. Afx nameplate conversion sticker next to unit

nameplate.

15. Complete the information required on the gas converter

sticker: date, name, and address. Afx sticker to the

exterior of the unit in a visible area.

16. Follow the steps given in the start-up and adjustment

section.

CAUTION

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly after

leak test has been completed. Do not use matches,

candles, ame or other sources of ignition to check for

gas leaks.

Low Inlet Pressure

Switch

Brass Fitting

Figure 6. Gas Valve with Low Inlet Pressure Switch

LOW INLET

PRESSURE

SWITCH

C

NO

PROVIDED HARNESS WIRES

Figure 7. Low Inlet Pressure Switch Wiring

Point-to-Point Wiring Diagram

GAS VALV E

WHITE

ORANGE

YELLOW

BROWN

ORANGE

507371-02 Issue 1706 Page 3 of 5

Page 4

Start-Up & Adjustment

BEFORE PLACING THE UNIT INTO OPERATION

Smell all around the appliance area for gas. Be sure to

smell next to the oor because LP/Propane gas is heavier

than air and will settle on the oor.

Use only your hand to move the gas control switch. Never

use tools. If the switch will not move by hand, do not try to

repair it. Force or attempted repair may result in a re or

explosion.

A - Placing the Unit into Operation

See Table 1 for supply line pressure. Following the supply

pressure check, turn off unit, remove manometer and

tighten post hex screw.

B - Measuring & Adjusting the Manifold Pressure

A952 & 95G2 Models

A manifold pressure post located on the gas valve provides

access to the manifold pressure. See Figure 1. Back out

the 3/32 hex screw one turn, connect a piece of 5/16

tubing and connect to a manometer to measure manifold

pressure. To correctly measure manifold pressure, the

differential pressure between the positive gas manifold

and the negative burner box must be considered. Furnace

should operate at least 5 minutes before checking manifold

pressure.

IMPORTANT

Follow the lighting instructions provided on the unit.

If lighting instructions are not available, refer to the

following section.

Units are equipped with a two-stage integrated ignition

system. The integrated ignition control automatically lights

the burners each time the thermostat calls for heat.

1. STOP! Read the safety information at the beginning

of this section.

2. Set the thermostat to its lowest setting.

3. Turn off all electrical power to the furnace.

4. Do not try to light the burners by hand.

5. Remove the unit access panel.

6. Move the switch on the gas valve to OFF. Do not force

the switch. See Figure 1.

7. Wait ve (5) minutes for any gas to clear out. If you

then smell gas, STOP! Immediately call your gas

supplier from a neighbor’s phone. Follow the gas

supplier’s instructions. If you do not smell gas, go to

the next step.

8. Move the switch on the gas valve to ON.

9. Replace the unit compartment access panel.

10. Turn on all electrical power to the unit.

11. Set the thermostat to desired setting.

12. If the furnace will not operate, see section E- “Turning

Gas Off to the Unit” and call the gas supplier.

Gas Pressure Measurement

A - Supply Pressure Measurement

An inlet pressure post located on the gas valve provides

access to the supply pressure. See Figure 1. Back out the

3/32 hex screw one turn, connect a piece of 5/16 tubing

and connect to a manometer to measure supply pressure.

Check the unit on high re. On multiple unit installations,

check the unit separately and with the other units operating.

1. Connect the test gauge positive side “+“ to manifold

pressure tap on gas valve as noted above.

2. Tee into the gas valve regulator vent hose and connect

to test gauge negative “-”.

3. Ignite unit on low re and let run for 5 minutes to allow

for steady state conditions.

4. After allowing unit to stabilize for 5 minutes, record

low re manifold pressure and compare to value given

in Table 1. If necessary, make adjustment. Figure 1

shows location of low re adjustment screw.

5. Repeat on high re and compare to value given in

Table 1. If necessary, make adjustment. Figure 1

shows location of high re adjustment screw.

A802 & 80G2 Models

A manifold pressure post located on the gas valve provides

access to the manifold pressure. See Figure 1. Back out

the 3/32 hex screw one turn, connect a piece of 5/16

tubing and connect to a manometer to measure manifold

pressure.

1. Connect test gauge to manifold pressure post (Figure

1) on gas valve.

2. Ignite unit on low re and let run for 5 minutes to allow

for steady state conditions.

3. After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

Table 1.

4. If necessary, make adjustments. Figure 1 shows

location of high re and low re adjustment screws.

5. Repeat steps 2, 3 and 4 on high re. See values in

Table 1.

Manifold Pressure in w.g. Gas Line Pressure in w.g.

Low Fire High Fire Minimum Maximum

4.9 10.0 11.0 13.0

Table 1. Manifold and Gas Line Pressure

507371-02Issue 1706Page 4 of 5

Page 5

C - Gas Flow (Approximate)

NOTE: To obtain accurate reading, shut off all other gas

appliances connected to meter.

Furnace should operate at least 5 minutes before checking

gas ow. Determine time in seconds for two revolutions of

gas through the meter. (Two revolutions assures a more

accurate time.) Divide by two and compare to time in

Table 2. If manifold pressure matches Table 1 and rate is

incorrect, check gas orices for proper size and restriction.

Remove temporary gas meter if installed.

% for LP

CO

Unit Capacity

-045 6.6 - 7.6 9.1 - 10.1

-070 6.5 - 7.5 8.6 - 9.6

-090 6.9 - 7.9 9.1 - 10.1

-110 7.3 - 8.3 9.5 - 10.5

The carbon monoxide reading should not exceed 100 ppm.

Low Fire High Fire

2

Table 4. A952 & 95G2 Downow Furnaces

Seconds for One Revolution

Unit Capacity

1 cu ft Dial 2 cu ft Dial

-045 200 400

-070 136 272

-090 102 204

-110 82 164

-135 68 136

2500 btu/cu ft

LP

Table 2. Gas Meter Clocking Chart

D- Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas ow rate before checking

combustion. Take combustion sample beyond the ue

outlet. See Table 3 through Table 5 .

NOTE: Shut unit off and remove manometer as soon as

supply line pressure, manifold pressure and combustion

sample have been obtained. Take care to replace pressure

tap plug.

All Models Firing Rate CO2% for Nat CO2% for LP

Upow/

Horizontal

Downow

The carbon monoxide reading should not exceed 100 ppm.

High Fire 6.8 - 7.4 7.5 - 9.0

Low Fire 4.2 - 5.7 5.0 - 6.0

High Fire 6.0 - 7.4 6.9 - 8.4

Low Fire 4.8 - 6.0 5.7 - 7.0

Table 5. A802 & 80G2

E - Turning Off Gas to the Unit

1. Set the thermostat to its lowest setting.

2. Turn off all the electrical power to the unit.

3. Remove the unit access panel.

4. Move the switch on the gas valve to OFF. Do not force

the switch.

% for LP

CO

Unit Capacity

-045 6.4 - 7.4 8.8 - 9.8

-070 6.3 - 7.3 8.7 - 9.8

-090 6.8 - 7.8 8.9 - 9.9

-110 7.1 - 8.1 9.3 - 10.3

-135 7.1 - 8.2 9.1 - 10.1

The carbon monoxide reading should not exceed 100 ppm.

Low Fire High Fire

2

Table 3. A952 & 95G2 Upow / Horizontal Furnaces

507371-02 Issue 1706 Page 5 of 5

Loading...

Loading...