INSTALLATION INSTRUCTIONS

4HP14/15 SPLIT SYSTEM HEAT PUMP

(R410A REFRIGERANT)

This manual must be left with the homeowner for future reference.

This is a safety alert symbol and should never be ignored. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury or death.

Table of Contents

Safety Precautions ......................................................2

Installation ...................................................................2

Electrical Connections ................................................. 5

Start-Up Procedure...................................................... 6

Operation .....................................................................7

Homeowner’s Information .........................................10

NOTE TO INSTALLING DEALER

These instructions and warranty are to be given to the

owner or displayed near the indoor air handler unit.

CAUTION

Improper installation, adjustment, alteration, service

or maintenance will void the warranty. The qualied

installer or agency must use factory-authorized kits

or accessories when added to this products. Refer to

the individual instructions included with the specic

accessory kit.

NOTE

These instructions are intended as a general guide and

do not supersede national, state or local codes in any

way.

WARNING

Installation or repairs made by unqualied persons can

result in hazards to you and others. Installation MUST

conform with local building codes and with the National

Electrical Code NFPA 70/ANSI C1-1993 or current

edition and Canadian Electrical Code Part 1 CSA C22.1.

WARNING

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out

and tag switch with a suitable warning label. Electrical

shock can cause personal injury or death.

215 Metropolitan Drive

West Columbia, SC 29170

Save these instructions for future reference

*P506318-03*

(P) 506318-03

Page 1 of 11506318-03 Issue 1850

These units are designed for use in residential and

light commercial type buildings. Heat Pumps may only

be installed with indoor combinations listed in the Air

Conditioning, Heating and Refrigeration Institute (AHRI)

Directory of Certied Products.

Inspect the unit for any damage before installation. If

damage is found, notify the transportation company

immediately and le a concealed damage claim.

Safety Precautions

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations.

Have re extinguisher available. Read these instructions

thoroughly and follow all warning or cautions attached to

the unit.

1. Always wear proper personal protection equipment.

2. Always disconnect electrical power before removing

panel or servicing equipment.

3. Keep hands and clothing away from moving parts.

4. Handle refrigerant with caution, refer to proper MSDS

from refrigerant supplier.

5. Use care when lifting, avoid contact with sharp edges.

Installation

NOTE: In some cases noise in the living area has been

traced to gas pulsations from improper installation of

equipment.

1. Locate unit away form windows, patios, decks, etc.

where unit operation sounds may disturb customer.

2. Ensure that vapor and liquid tube diameters are

appropriate to capacity of unit.

3. Run refrigerant tubes as directly as possible by

avoiding unnecessary turns and bends.

4. Leave some slack between structure and unit to

absorb vibration.

5. When passing refrigerant tubes through the wall, seal

opening with RTV or other silicon-based caulk.

6. Avoid direct tubing contact with water pipes, duct work,

oor joists, wall studs, oors, walls, and any structure.

7. Do not suspend refrigerant tubing from joists and

studs with a rigid wire or strap which comes in direct

contact with tubing.

8. Ensure that tubing insulation is pliable and completely

surrounds vapor tube.

When outdoor unit is connected to factory-approved indoor

unit, outdoor unit contains system refrigerant charge for

operation with indoor unit of the same size when connected

by 15 ft. of eld-supplied tubing. For proper unit operation,

check refrigerant charge using charging information

located on control box cover.

NOTE: Maximum liquid-line size is 3/8 in. O.D. for all

residential applications including long lines.

Outdoor Section

Zoning ordinances may govern the minimum distance the

condensing unit can be installed from the property line.

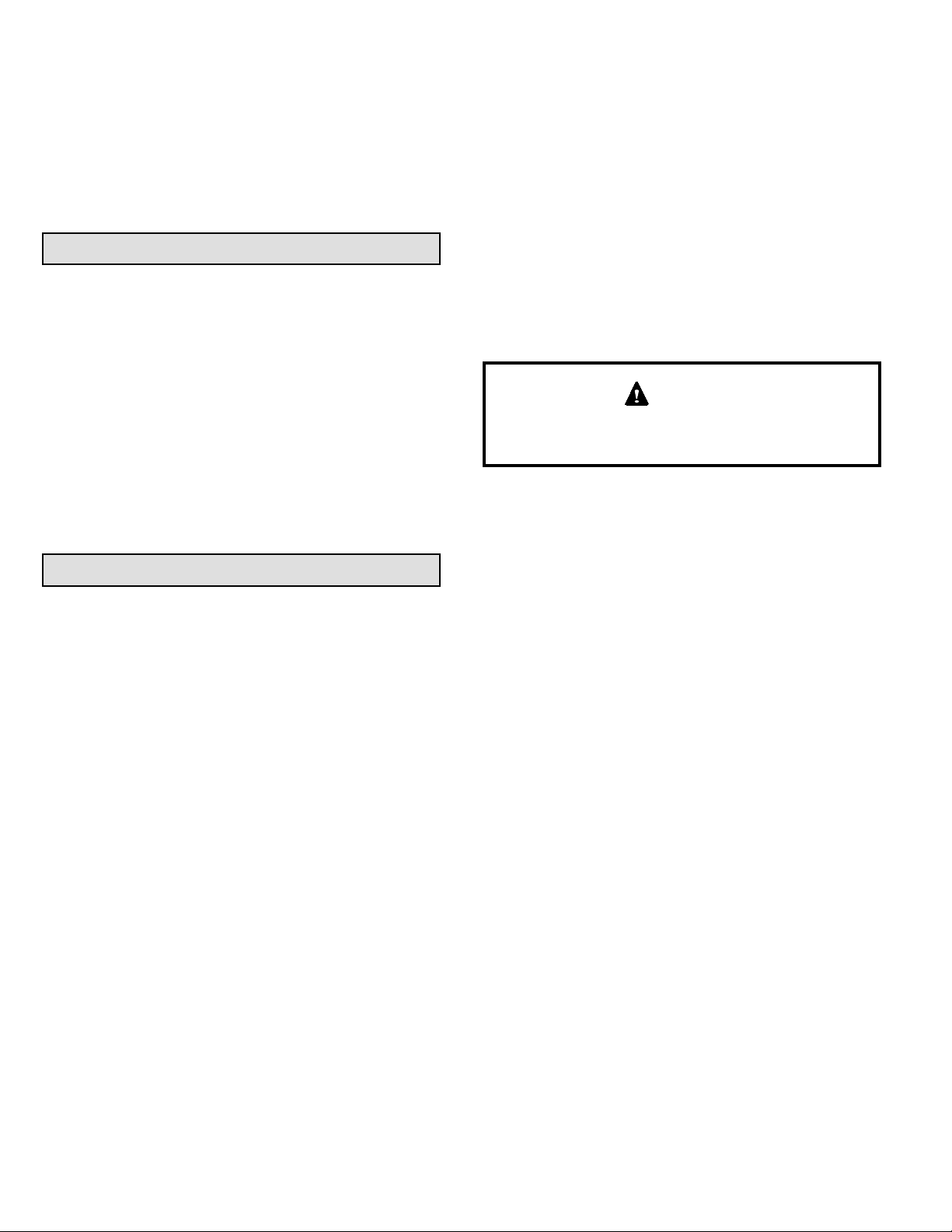

Install on a Solid, Level Mounting Pad

The outdoor section is to be installed on a solid foundation.

This foundation should extend a minimum of 2” (inches)

beyond the sides of the outdoor section. To reduce the

possibility of noise transmission, the foundation slab

should NOT be in contact with or be an integral part of the

building foundation.

Elevate Unit

CAUTION

Accumulation of water and ice in base pan may cause

equipment damage.

Elevate unit per local climate and code requirements to

provide clearance above estimated snowfall level and

ensure adequate drainage of unit. Use snow stand in areas

where prolonged freezing temperatures are encountered.

If conditions or local codes require the unit be attached to

pad or mounting frame, tie down bolts should be used and

fastened through knockouts provided in unit base pan.

Rooftop Installations

Mount on level platform or frame 6 inches above roof

surface. Place unit above a load-bearing wall and isolate

unit and tubing set from structure. Arrange supporting

members to adequately support unit and minimize

transmission of vibration to building. Ensure roof structure

and anchoring method is adequate for location. Consult

local codes governing rooftop applications.

Roof mounted units exposed to winds above 5 mph may

require wind bafes to achieve adequate defrost. A sheet

metal bafe should be spaced 6-1/2” from the fall of the

coil. The height should cover the face of the coil and the

length should be 6” from the access panel.

NOTE: Unit must be level to within ± 1/4 in./ft. per

compressor manufacturer specications.

Clearance Requirements

When installing, allow sufcient space for airow clearance,

wiring, refrigerant piping, and service. For proper airow,

quiet operation and maximum efciency. Position so water,

snow, or ice from roof or eaves cannot fall directly on unit.

506318-03Page 2 of 11 Issue 1850

Figure 1.

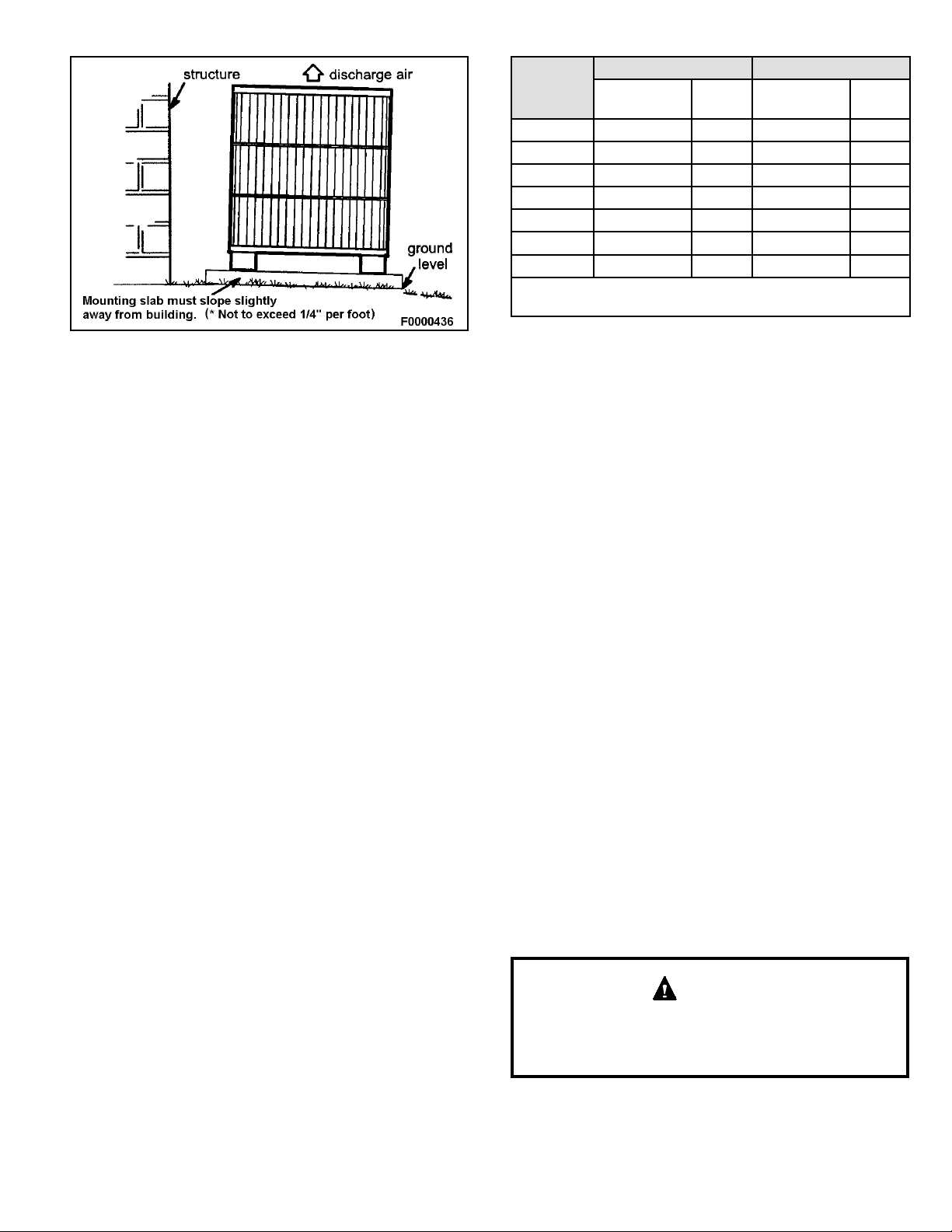

Liquid Vapor

Capacity

-018 3/8” 3/8” 3/4” 3/4”

-024 3/8” 3/8” 3/4” 3/4”

-030 3/8” 3/8” 3/4” 3/4”

-036 3/8” 3/8” 7/8” 7/8”

-042 3/8” 3/8” 7/8” 7/8”

-048 3/8” 3/8” 7/8” 7/8”

-060 3/8” 3/8” 7/8” *1-1/8”

* Field supplied 7/8 x 1-1/8 connector required on both ends

of vapor tubing.

Connections

Dia.

Tube

Dia.

Connections

Dia.

Tube

Dia.

Table 1. Recommended Liquid & Vapor Tube

Diameters (in.)

DO LOCATE THE UNIT:

• With proper clearances on sides and top of unit

• On a solid, level foundation or pad

• To minimize refrigerant line lengths

DO NOT LOCATE THE UNIT:

• On brick, concrete blocks or unstable surfaces

• Near clothes dryer exhaust vents

• Near sleeping area or near windows

• Under eaves where water, snow or ice can fall directly

on the unit

• With clearance less than 2 ft. from a second unit

• With clearance less than 4 ft. on top of unit

Operating Ambient

The minimum outdoor operating ambient in cooling mode

is 55°F, and the maximum outdoor operating ambient in

cooling mode is 125°F. The maximum outdoor operating

ambient in heating mode is 66°F.

Refrigeration Line Sets

Use only refrigerant grade copper tubes. Split systems

may be installed with up to 50 feet of line set (no more than

20 feet vertical) without special consideration (see long

line set guidelines).

It is important that no tubing be cut or seals broken until you

are ready to actually make connections to the evaporator

and to the condenser section. DO NOT remove rubber

plugs or copper caps from the tube ends until ready to

make connections at evaporator and condenser. Under no

circumstances leave the lines open to the atmosphere for

any period of time, if so unit requires additional evacuation

to remove moisture.

Be extra careful with sharp bends. Tubing can “kink” very

easily, and if this occurs, the entire tube length will have

to be replaced. Extra care at this time will eliminate future

service problems.

It is recommended that vertical suction risers not be upsized. Proper oil return to the compressor should be

maintained with suction gas velocity.

Filter Drier

The lter drier is very important for proper system operation

and reliability. If the drier is shipped loose, it must be

installed by the installer in the eld. Unit warranty will be

void, if the drier is not installed.

Installation of Line Sets

DO NOT fasten liquid or suction lines in direct contact with

the oor or ceiling joist. Use an insulated or suspension

type of hanger. Keep both lines separate, and always

insulate the suction line. Long liquid line runs (30 feet or

more) in an attic will require insulation. Route refrigeration

line sets to minimize length.

DO NOT let refrigerant lines come in direct contact with

foundation. When running refrigerant lines through the

foundation or wall, openings should allow for a sound

and vibration absorbing material to be placed or installed

between tubing and foundation. Any gap between

foundation or wall and refrigerant lines should be lled with

a vibration damping material.

CAUTION

If ANY refrigerant tubing is required to be buried by state

or local codes, provide a 6 inch vertical rise at service

valve.

Page 3 of 11506318-03 Issue 1850

Before making braze connections, be sure all joints are

clean. Before heat is applied for brazing, dry nitrogen

should be owing through the tubing to prevent oxidation

and scale formation on the inside of the tubing.

The following is the recommended method for making

braze connections at the refrigerant line connections:

1. Debur and clean refrigerant tube end with emery cloth

or steel brush.

2. Insert tubing into swage tting connection.

3. Wrap wet rags over valves to protect from heat.

4. Allow dry nitrogen to ow through refrigerant lines.

5. Braze joint, using a suitable brazing alloy for copper to

copper joints.

6. Quench the joint and tubing with water using a wet

rag. Leave rag on tting body and re-wet with water to

help cool area.

Leak Check

Refrigeration lines and indoor coil must be checked for leaks

after brazing and before evacuation. The recommended

procedure is to apply a trace amount of vapor refrigerant

(approximately two ounces or 3 psig) into the line set and

indoor coil, then pressurize with 150 psig of dry nitrogen.

Use a refrigerant leak detector to check all joints. The

system may also be checked for leaks using a halide torch

or pressure and soapy solution. After completion of leak

check, relieve all pressure from system before evacuation.

Evacuating and Charging Instructions

NOTE: Intentional release of CFC or HCFC refrigerant to

the atmosphere violates Federal Law. It may also violate

State and Local Codes. Check all Federal, State and Local

Codes before proceeding.

These outdoor units are pre-charged at the factory with

adequate refrigerant to handle 15 feet of refrigerant tubing.

NOTE: DO NOT use any portion of the charge for purging

or leak testing. It is mandatory that a thorough evacuation

of the refrigeration lines and indoor coil be performed.

The liquid line and suction line service valves have been

closed after nal testing at the factory. DO NOT disturb

these valves until the lines have been leak checked

and evacuated or the charge in the unit may be lost.

1. Connect the vacuum pump to the center hose of the

manifold gauge set, the low-pressure manifold gauge

to the vapor service valve and the high pressure

manifold gauge to the liquid service valve.

NOTE: Unnecessary switching of hoses can be

avoided and complete evacuation of all lines can

be achieved by also connecting a branch hose from

the manifold gauge center port to a cylinder of the

proper refrigerant. Provide a separate shut-off valve to

vacuum pump to avoid contaminating vacuum pump

oil with refrigerant.

2. The valves should be kept in the “front seated” (closed)

position. This will allow evacuation of the refrigeration

lines and the indoor coil, without disturbing the factory

charge in the outdoor unit.

3. Follow the vacuum pump manufacturer’s instructions.

Allow the pump to operate until the system has been

evacuated down to 300 microns. Allow the pump to

continue running for an additional 15 minutes. Turn

OFF the pump and leave the connections secured to

the two (2) service valves. After 5 minutes, if the system

fails to hold 500 microns or less, check all connections

for tight t and repeat the evacuation procedure.

4. Isolate the vacuum pump from the system by closing

the shutoff valves on the gauge-set. Disconnect the

vacuum pump.

Opening Service Valves

After evacuation of the connecting lines, remove the

service valve cap and fully insert the hex wrench into the

stem. A back-up wrench is required on the valve body to

open the valve stem. Back-out counterclockwise until the

valve stem just touches the coined edge.

Wrench sizes:

• 3/8 service valve: 3/16” Hex wrench

• 3/4 service valve: 5/16” Hex wrench

• 7/8 service valve: 5/16” Hex wrench

Replace service valve cap and torque to 8-11 ft-lb on

3/8” valves; 12-15 ft-lb on 3/4” valves; 15-20 ft-lb on 7/8”

valves. Use backup wrench on valve body when torquing

valve cap.

Install Electrical Accessories

Refer to the instructions packaged with the accessories.

506318-03Page 4 of 11 Issue 1850

Electrical Connections

Control Wiring

The control voltage is 24 VAC. NEC Class I insulated 18

AWG is required for control wiring. For lengths longer than

150 feet, contact your local distributor for technical service.

WARNING

Electrical Shock Hazard!

Turn OFF electric power before connecting

unit, performing any maintenance or

removing panels or doors. More than one

disconnect may be required to turn off all

power.

FAILURE TO DO SO COULD RESULT IN

BODILY INJURY OR DEATH.

Be sure to check all local codes to determine that the unit

is installed accordance with local requirements. Consult

the National Electric Code for wire size requirements. Use

60 C wire or higher. Always provide ground connections to

the outdoor unit. Power supply must agree with rating on

unit nameplate.

Provide line voltage power supply to unit from a properly

sized disconnect switch. Route power and ground wires

from disconnect switch to unit. Line voltage connections

are made at the line side of the contactor in the control box

of the outdoor unit. Follow the appropriate wiring diagram

attached to inside of the access panel.

Proper circuit protection recommendations are indicated

on Unit Rating Plate. Time delay fuses are required to

prevent blowing due to starting current (the current in rush

when equipment starts is referred to as the Locked Rotor

Amps or (LRA). A fuse of this kind properly sized will give

maximum equipment protection.

Ensure the room thermostat is properly installed per

instructions shipped with room thermostat. Generally the

thermostat should not be exposed to sunlight, drafts or

vibration and should not be mounted on exterior walls.

Low voltage control wire connections should be made

to the screw connection terminal board mounted on the

defrost control as shown. All low voltage control wiring

must be separated from incoming power leads.

Thermostat Air Handler Heat Pump

24 VAC HOT

RED

R

R

R

R

INDOOR FAN

24 VAC COM

GREEN

G

BLUE

C

G

G

B

C

C

HEAT

STAGE 2

EMERGENCY

HEAT

W

E

WHITE

W

W1

W2

W1

L

RVS

COOLING

COOL / HEAT

STAGE 1

O

Y

ORANGE

YELLOW

O

Y1

F0000453

Figure 2.

Use copper wire only between disconnect switch and unit.

Remove access panel to gain access to unit wiring. Extend

wires from disconnect through power wiring hole provided

and into unit control box. Flexible conduit is required for the

swing out control box feature.

WARNING

The unit cabinet must have an uninterrupted or unbroken

ground to minimize personal injury if an electrical fault

should occur. The ground may consist of electrical wire

or metal conduit when installed in accordance with

existing electrical codes. Failure to follow this warning

can result in an electric shock, re, or death.

Connect ground wire to ground connection in control box

for safety. Connect power wiring to contactor.

High voltage power connections to 3-phase models is made

to “Pig Tail” leads with eld supplied splice connectors.

Heat Pump Application with Electric Heat

Emergency Heat (Heating Heat Pump)

If selector switch on thermostat is set to the emergency

heat position, the heat pump will be locked out of the

heating circuit, and all heating will be electric heat ( if

applicable). A jumper should be placed between W and

E on the thermostat so that the electric heat control will

transfer to the rst stage heat on the thermostat. This will

allow the indoor blower to cycle on and off with the electric

heat when the fan switch is in the AUTO position.

* Add Jumper on Subbase (Optional)

Page 5 of 11506318-03 Issue 1850

Start-Up Procedure

1. Check to ensure:

• Service valve and gage port caps are installed and

tightened.

• Voltage supply at unit agrees with nameplate rating.

• Field wiring connections are tight and factory wiring

has not been disturbed and are tight.

• Indoor fan motor is on correct speed tap.

2. Set thermostat selector switch to OFF and fan control

switch to “Auto” is so equipped.

3. Close electrical disconnects to energize system.

4. Set room thermostat at desired temperature. Be sure

set point is below indoor ambient temperature.

5. Set the system switch of the thermostat on COOL

(or HEAT if applicable) and fan switch for continuous

operation (ON) or AUTO, as desired. There will be

a 5 minute short cycle compressor delay on startup.

Operate unit for 15-20 minutes, then check the system

refrigerant charge.

6. Adjust refrigerant charge per “Adjusting Charge”

section.

Adjusting Charge

Factory charge is shown on the rating label located on the

access panel.

All split system heat pumps are factory charged for 15

feet of connecting line set and matched indoor fan coil.

Nameplate refrigerant charge should initially be adjusted

for line set lengths other than 15 feet. For line sets shorter

than 15 feet in length, remove charge. For line sets longer

than 15 feet, add charge. Oil charge is sufcient for all line

lengths.

Refrigeration Charge Adjustment

Liquid Line Diameter Oz. Per Linear Foot

Before nal adjustment is made to the refrigerant charge,

it is imperative that proper indoor airow be established.

Airow will be higher across a dry coil versus a wet coil.

Blower charts are calculated with a dry or wet coil basis.

Recommended airow is 350-450 CFM per ton (12,000

Btuh) through a wet coil. Refer to indoor unit instructions for

methods of determining air ow and blower performance.

The optimum method for checking the charge is by

weight. However the following methods may be used

to conrm the proper charge:

Cooling Mode

1. Operate unit a minimum of 10 minutes before checking

charge.

2. Measure liquid service valve pressure by attaching an

accurate gage to service port. Determine saturation

temp. from T/P chart.

3. Measure liquid line temperature by attaching an

accurate thermistor type or electronic thermometer to

liquid line near outdoor coil.

4. Calculate subcooling (saturation temp. measured

temp.) and compare with table on back of central box

cover.

5. Add refrigerant if subcooling is lower than table.

Recover refrigerant if subcooling is high.

6. If ambient temp is lower than 60°F, check charge in

heating mode or weigh refrigerant according to name

plate data.

Heating Mode

Check charge in heating mode if ambient temp is below

60° F. Indoor temp must be between 65° and 75° F.

Follow steps (1) to (6) above and compare with heating

mode subcooling range on the table on back of central box

cover.

Charge must be rechecked again during the cooling

season.

3/8” 0.6

* Factory charge for series is for 15’ (ft.) line sets and

matched fan coil.

Table 2.

Cold Weather Application

A cold weather accessory kit may be required for heat

pumps operating at ambient conditions below 25°F.

Supplemental heat should be provided for these conditions

due to the expected performance degeneration.

506318-03Page 6 of 11 Issue 1850

Operation

The outdoor unit and indoor blower cycle on demand

from the room thermostat. When the thermostat blower

switch is in the ON position, the indoor blower operates

continuously.

Emergency Heat Function (Room Thermostat)

An emergency heat function is designed into some room

thermostats. This feature is applicable when isolation of

outdoor unit is required or when auxiliary electric heat is

staged by outdoor thermostats. When the room thermostat

is placed in the emergency heat position, the outdoor unit

control circuit is isolated from power and eld-provided

relays bypass the outdoor thermostats. An amber indicating

light simultaneously comes on to remind the homeowner

that he is operating in the emergency heat mode.

Emergency heat is usually used during an outdoor unit

shutdown, but it should also be used following a power

outage. If power has been off for over an hour and the

outdoor temperature is below 50°F (10°C). System should

be left in the emergency heat mode at least six hours

to allow the crankcase heater sufcient time to prevent

compressor slugging. This applies only to systems with

crank case heaters.

Defrost System

The defrost system includes two (2) components: a defrost

thermostat and a defrost control.

Defrost Thermostat

The defrost thermostat is located on the outdoor coil of

most models and on the liquid line between the check/

expansion valve and the distributor on R-410A TXV

equipped models. When defrost thermostat senses 29°F

(42 on R-410A TXV’s) or cooler, the thermostat contacts

close and send a signal to the defrost control board to start

the defrost timing. It also terminates defrost when the liquid

line warms up to 60°F.

Defrost Control

The defrost control board includes the combined

functions of a time/temperature defrost control, defrost

relay, diagnostic LEDs and terminal strip for eld wiring

connections.

The control provides automatic switching from normal

heating operation to defrost mode and back. During

compressor cycle, the control accumulates compressor run

times at 30-, 60-, or 90-minute eld-adjustable intervals.

If the defrost thermostat is closed when the selected

compressor run time interval ends (call for defrost), the

defrost relay is energized and defrost begins. The factory

setting is 90 minutes which is the optimum efciency

setting.

Figure 3. Outdoor Unit Defrost Control Board

Defrost Control Timing Pins

Each timing pin selection provides a different accumulated

compressor run time period for one defrost cycle. This

time period must occur before a defrost cycle is initiated.

The defrost interval can be adjusted to 30 (/T1), 60 (T2),

or 90 (T3) minutes. If the timing selector jumper is not in

place the control defaults to a 90-minute defrost interval.

The maximum defrost period is 14 minutes and cannot be

adjusted.

A TEST option is provided for troubleshooting. The TEST

mode may be started any time the unit is in the heating

mode and the defrost thermostat is closed or jumpered. If

the jumper is in the TEST position at power-up, the control

will ignore the test pins. When the jumper is placed across

the TEST pins for 2 seconds, the control will enter the

defrost mode. If the jumper is removed before an additional

5 second period has elapsed (7 seconds total), the unit will

remain in defrost mode until the defrost thermostat opens

or 14 minutes have passed. If the jumper is not removed

until after the additional 5 second period has elapsed, the

defrost will terminate and the test option will not function

again until the jumper is removed and re-applied.

Time Delay

The timed-off delay is 5 minutes long. The delay help to

protect the compressor from short-cycling in case the

power to the unit is interrupted or a pressure switch opens.

The delay is bypassed by placing the timer select jumper

across the TEST pins for 0.5 seconds.

Pressure Switch Circuit

The defrost control incorporates 2 pressure switch circuits.

The high pressure switch connects to the boards HI PS

terminals. The low pressure switch is factory installed.

Page 7 of 11506318-03 Issue 1850

During a single demand cycle, the defrost control will lock

out the unit after the fth time that the circuit is interrupted

by any pressure switch wired to the control board. In

addition, the diagnostic LEDs will indicate a locked-out

pressure switch after the fth occurrence of an open

pressure switch. The unit will remain locked out until power

to the board is interrupted, then re-established or until the

jumper is applied to the TEST pins for 0.5 seconds.

NOTE: The defrost control board ignores input from the

low-pressure switch terminals as follows:

• During the TEST mode,

• During the defrost cycle,

• During the 90 second start-up period,

• And for the rst 90 seconds each time the reversing

valve switches heat/cool modes. If the TEST pins are

jumpered and the 5 minute delay is being by-passed,

the LO PS terminal signal is not ignored during the 90

second start-up period.

Diagnostic LEDs

The state (Off, On, Flashing) of two LEDs on the defrost

board (DS1 [Red] and DS2 [Green]) indicate diagnostics

conditions that are described in Table 3.

Mode Green LED (DS2) Red LED (DS1)

No power to control Off Off

Normal operation /

power to control

Anti-short cycle

lockout

Low pressure switch

fault

Low pressure switch

lockout

High pressure switch

fault

High pressure switch

lockout

Simultaneous slow ash

Alternating slow ash

Off Slow ash

Off On

Slow ash Off

On Off

Table 3.

Defrost Board Pressure Switch Connections

The unit’s automatic reset pressure switches (LO PS - S87

and HI PS - S4) are factory-wired into the defrost board on

the LO-PS and HI-PS terminals, respectively.

Low Pressure Switch (LO-PS) — When the low pressure

switch trips, the defrost board will cycle off the compressor,

and the strike counter in the board will count one strike.

The low pressure switch is ignored under the following

conditions:

• during the defrost cycle and 90 seconds after the

termination of defrost

• when the average ambient sensor temperature is

below 15° F (-9°C)

• for 90 seconds following the start up of the compressor

• during “test” mode

High Pressure Switch (HI-PS) — When the high pressure

switch trips, the defrost board will cycle off the compressor,

and the strike counter in the board will count one strike.

Defrost Board Pressure Switch Settings

• High Pressure (auto reset) - trip at 590 psig; reset at

418.

• Low Pressure (auto reset) - trip at 25 psig; reset at 40.

5-Strike Lockout Feature

The internal control logic of the board counts the pressure

switch trips only while the Y1 (Input) line is active. If a

pressure switch opens and closes four times during a Y1

(Input), the control logic will reset the pressure switch trip

counter to zero at the end of the Y1 (Input). If the pressure

switch opens for a fth time during the current Y1 (Input),

the control will enter a lockout condition.

The 5-strike pressure switch lockout condition can be reset

by cycling OFF the 24-volt power to the control board or by

shorting the TEST pins between 1 and 2 seconds. All timer

functions (run times) will also be reset.

If a pressure switch opens while the Y1 Out line is engaged,

a 5-minute short cycle will occur after the switch closes.

Compressor Delay

The defrost board has a eld-selectable function to reduce

occasional sounds that may occur while the unit is cycling

in and out of the defrost mode. When a jumper is installed

on the DELAY pins, the compressor will be cycled off for

30 seconds going in and out of the defrost mode. Units are

shipped with jumper installed on DELAY pins.

NOTE: The 30 second compressor delay feature (known

as the quiet shift) must be deactivated during any unit

performance testing. The feature is deactivated by

removing the jumper located on the compressor delay pins

on the control board mounted inside the unit control box.

This feature is optional for the homeowner, but may impact

testing performance.

506318-03Page 8 of 11 Issue 1850

Figure 4. H/P 14/15 SEER Wiring Diagram

Page 9 of 11506318-03 Issue 1850

Homeowner’s Information

WARNING

ELECTRICAL SHOCK HAZARD!

Turn OFF electric power to unit before performing any

maintenance or removing panels or doors.

FAILURE TO DO SO COULD RESULT IN BODILY

INJURY OR DEATH.

Heat Pump Operation

Your new heat pump has several characteristics that you

should be aware of:

• Heat pumps satisfy heating demand by delivering large

amounts of warm air into the living space. This is quite

different from gas-or oil-red furnaces or an electric

furnace which deliver lower volumes of considerably

hotter air to heat the space.

• Do Not be alarmed if you notice frost on the outdoor

coil in the winter months. Frost develops on the outdoor

coil during the heating cycle when temperatures are

below 45°F. An electronic control activates a defrost

cycle lasting 5 to 15 minutes at preset intervals to clear

the outdoor coil of the frost.

• During the defrost cycle, you may notice steam rising

from the outdoor unit. This is a normal occurrence.

The thermostat may engage auxiliary heat during the

defrost cycle to satisfy a heating demand; however,

the unit will run to normal operation at the conclusion

of the defrost cycle.

In case of extended power outage...

If the outdoor temperature is below 50°F and power to your

outdoor unit has been interrupted for 6 hours or longer,

observe the following when restoring power to your heat

pump system.

• Set the room thermostat selector to the “Emergency

Heat” setting to obtain temporary heat for a minimum

of 6 hours. This will allow system refrigerant pressures

and temperatures enough time to return to a stabilized

condition.

• In Emergency Heat mode, all heating demand is

satised by auxiliary heat; heat pump operation is

locked out. After a 6 hour “warm-up” period, the

thermostat can then be switched to the “Heat” setting

and normal heat pump operation my resume.

• Heat pumps (in the cooling mode) remove humidity

from your home. Depending on the amount of moisture

in the air inside your home, water will trickle from the

condensate drain of the cooling coil.

Thermostat Operation

The wall-mounted thermostat controls your air conditioner.

The thermostat is available in various congurations from

different manufacturers. The information below is typical for

most thermostats. Ask your dealer for specic information

regarding the model of thermostat installed.

Temperature Setting Levers

Most heat pump thermostats have 2 temperature selector

levers: one for heating and one for cooling. Set the levers or

dials to the desired temperature set points for both heating

and cooling. Avoid frequent temperature adjustment;

turning the unit off and back on before pressures equalize

puts stress on the unit compressor.

On heat pump systems, increasing your thermostat setting

by more than 2 degrees may cause supplemental heaters

to turn on, reducing potential energy savings.

Fan Switch

In AUTO or INT (intermittent ) mode, the blower operates

only when the thermostat calls for heating or cooling. This

mode is generally preferred when humidity control is a

priority. The ON or CONT mode provides continuous indoor

blower operation, regardless of whether the compressor or

auxiliary heat are operating. This mode is required when

constant air circulation or ltering is desired.

System Switch

Set the system switch for heating, cooling or auto

operation. The auto mode allows the heat pump to

automatically switch from heating mode to cooling mode to

maintain predetermined comfort settings. Many heat pump

thermostats are also equipped with an emergency heat

mode which locks out heat pump operation and provides

temporary heat supplied by the auxiliary heat.

Indicating Light

Most heat pump thermostats have an amber light

which indicates when the heat pump is operating in the

emergency heat mode.

Temperature Indicator

The temperature indicator displays the actual room

temperature.

Fan Control

For fan control your thermostat may have a Fan Selection

Switch that allows you to run the fan continuously or cycle

it automatically with the heating or cooling system. Switch

the lever to ON for continuous operation and to AUTO for

automatic cycling.

For maximum comfort satisfaction and continual air

cleaning/ltering, constant fan operation is recommended.

On models without a fan Selection Switch, the fan will cycle

with the outdoor unit.

506318-03Page 10 of 11 Issue 1850

Important System Information

• Your system should never be operated without a clean

air lter properly installed.

• Return air and supply air registers should be free from

restrictions or obstructions to allow full ow of air.

of the air. Clogged condenser coils will lower the efciency

of your unit and could cause damage to the condenser.

Periodically, debris should be brushed from the condenser

coils.

Regular Maintenance Requirements

Your system should be regularly inspected by a qualied

service technician. These regular visits may include

(among other things) checks for:

• Motor operation

• Ductwork air leaks

• Coil & drain pan cleanliness (indoor & outdoor)

• Electrical component operation & wiring check

• Proper refrigerant level & refrigerant leaks

• Proper airow

• Drainage of condensate

• Air lter(s) performance

• Blower wheel alignment, balance & cleaning

• Primary & secondary drain line cleanliness

• Proper defrost operation (heat pumps)

There is some routine maintenance procedures you can do

to help keep your system operating at peak performance

between visits.

Air Filter

Inspect air lters at least monthly and replace or clean as

required. Disposable lters should be replaced. Washable

lters may be cleaned by soaking in mild detergent and

rinsing with cold water. Replace lters with the arrows

pointing in the direction of airow. Dirty lters are the most

common cause of poor heating / cooling performance and

compressor failures.

Indoor Coil

If the system has been operated with a clean lter in place,

it should require minimal cleaning. Use a vacuum cleaner

and soft brush attachment to remove any accumulation of

dust from the top and underside of the nned coil surface.

However, perform this maintenance only when the coil is

completely dry.

If the coil cannot be cleaned by this method, call your

dealer for service. It may need a detergent solution and

rinsing with water for cleaning, which may require coil

removal. You should not attempt this yourself.

WARNING

SHARP OBJECT HAZARD!

Condenser coils have sharp edges. Wear adequate

body protection on body extremities (e.g. gloves).

FAILURE TO FOLLOW THIS WARNING COULD

RESULT IN BODILY INJURY.

Use a soft bristle brush with light pressure only. DO NOT

damage or bend condenser coil ns. Damaged or bent ns

may affect unit operation.

Painted Surfaces

For maximum protection of the unit’s nish, a good grade

of automobile wax should be applied every year. In

geographical areas where water has a high concentration

of minerals (calcium, iron, sulfur, etc.). It is recommended

that lawn sprinklers not be allowed to spray the unit. In

such applications, the sprinklers should be directed away

from the unit. Failure to follow this precaution may result

in premature deterioration of the unit nish and metal

components.

In sea coast areas, special maintenance is required due

to the corrosive atmosphere provided by the high salt

concentration in ocean mists and the air. Periodic washing

of all exposed surfaces and coil will add additional life to

your unit. Please consult your installing dealer for proper

procedures in your geographic area.

IF YOUR SYSTEM DOES NOT WORK, BEFORE

REQUESTING A SERVICE CALL:

1. Ensure thermostat is set below (cooling) or above

(heating) room temperature and that the system lever

is in the “COOL”, “HEAT” or “AUTO” position.

2. Inspect your return air lter: If it is dirty your air

conditioner may not function properly.

3. Check indoor and outdoor disconnect switches.

Conrm circuit breakers are ON or that fuses have not

blown. Reset breakers/replace fuses as necessary.

4. Inspect the outdoor unit for clogged condenser coils,

(grass cuttings, leaves, dirt, dust or lint). Ensure that

branches, twigs or other debris are not obstructing the

condenser fan.

Condensate Drain

During cooling season check at least monthly for free ow

of drainage and clean if necessary.

Condenser Coils

Grass cuttings, leaves, dirt, dust, lint from clothes dryers,

and fall off from trees can be drawn into coils by movement

IF YOUR SYSTEM STILL DOES NOT OPERATE,

CONTACT YOU SERVICING DEALER.

Be sure to describe the problem, and have the model and

serial numbers of the equipment available.

If warranted replacements parts are required, the warranty

must be processed through a qualied distribution location.

Page 11 of 11506318-03 Issue 1850

Loading...

Loading...