Royal Sovereign RSS-685, RSS-1050, RSS-1200 User Manual

Royal Sovereign LAMINATORS

OWNER'S MANUAL

RSS-1200,1050 ,685

PLEASE READ AND SAVE INSTRUCTIONS.

- 1 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

A

-

TABLE OF CONTENTS

PAGETOPICS

INTRODUCTION --------------------------------------------------------------------------------

SAFETY PRECAUTIONS --------------------------------------------------------------------

CHARACTERISTICS -----------------------------------------------------------------------------

SPECIFICATIONS ---------------------------------------------------------------------------------

NAMES OF MAJOR PARTS OF MACHINE ------------------------------------------------

DJUSTMENT OF FILM TENSION AND LOCATIONS --------------------------------

SETTING UP FILM -------------------------------------------------------------------------------

HANGING FILM -----------------------------------------------------------------------------------

1.HOT FILM -----------------------------------------------------------------------------------------

2.COLD FILM ---------------------------------------------------------------------------------------

CONTROL OF ROLLER PRESSURE ------------------------------------------------------

INSTRUCTIONS FOR CONTROL PANEL ------------------------------------------------

1.LCD WINDOW ----------------------------------------------------------------------------------

2.FUNCTIONS OF BUTTONS ----------------------------------------------------------------

3.HOW TO USE BUTTONS -------------------------------------------------------------------

LAMINATING STEPS ---------------------------------------------------------------------------

1.HOT LAMINATING ----------------------------------------------------------------------------

2.COLD LAMINATING --------------------------------------------------------------------------

TIPS FOR REMOTE CONTROL AND FOOT SWITCH ----------------------------------

METHOD FOR USING CUTTER --------------------------------------------------------------

1.CROSS CUTTER -------------------------------------------------------------------------------

2.SLITERS -------------------------------------------------------------------------------------------

IMPORTANT SAFETY CONCERNS. -------------------------------------------------------

MAINTENANCE ------------------------------------------------------------------------------------

IT'S NOT OUT OF ORDER. --------------------------------------------------------------------

SPARE PART ----------------------------------------------------------------------------------------

MEMO ----------------------------------------------------------------------------------------------

3

3

4

4

5

6

7

8

8

9

10

11

12

13

14~17

18

18~20

21

22

22

22

23

24

24

25

25

26WARRANTY --------------------------------------------------------------------------------------

27

- 2 -

INTRODUCTION

Thank you for purchasing a Royal Sovereign Roll Laminator. It has been designed and

manufactured to provide years of continuous service in the professional environment.

To insure high quality lamination, please read this instruction manual thoroughly.

This manual will provide you with complete operating and maintenance information.

For additional product support or factory-direct ordering information.

Call Royal Sovereign Customer Service at (800) 397-1025.

SAFETY PRECAUTIONS

The safety recommendations outlined in this section are to be read, understood and

followed before operating machine. Keep this information for future reference. Failure

to comply any of the following safety procedures could result in serious personal injury.

1. To prevent the possibility of electrical shock, do not immerse machine in water or permit

liquids to spill inside.

2. Do not allow articles of clothing (neckties, scarves, papers, etc.) near front or rear

machine openings as they could get caught by rollers and be pulled inside, causing

personal injury.

3. Do not insert sharp objects into front or rear machine openings. Do not place anything

in feed tray openings of machine other than appropriate laminating materials or pouches.

4. Do not attempt to laminate items that exceed total recommended material thickness.

5. Do not operate machine for any other purposes than its intended use.

6. Do not operate machine if electrical plug or power cord is damaged.

7. Turn off the power when unattended or not in use. Unplug machine before movig it or

when it is not in use for an extended period of time.

8. This machine is intended for indoor use only.

9. Do not alter or extend electric plug. Plug is configured for appropriate electrical supply.

10. The socket-outlet shall be installed mear the equipment and shall be easily accessible.

- 3 -

CHARACTERISTICS

RS Roll Laminator Line are advanced laminators with time transcendental design, utilizing

the latest in laminating technology. It is designed for you to set temperature and speed as

necessary and have the machine remember your settings. Also, you can laminate anything

at high speed, regardless of thickness of material and type of film.

Remote control device allows for control of the machine from the front or rear.

Foot-Pedal Switch allows for hands-free operation. It is also designed for convenient use

by anyone through the simple procedure of adjusting film tension in accordancs with the

thickness of film and materials to be laminated.

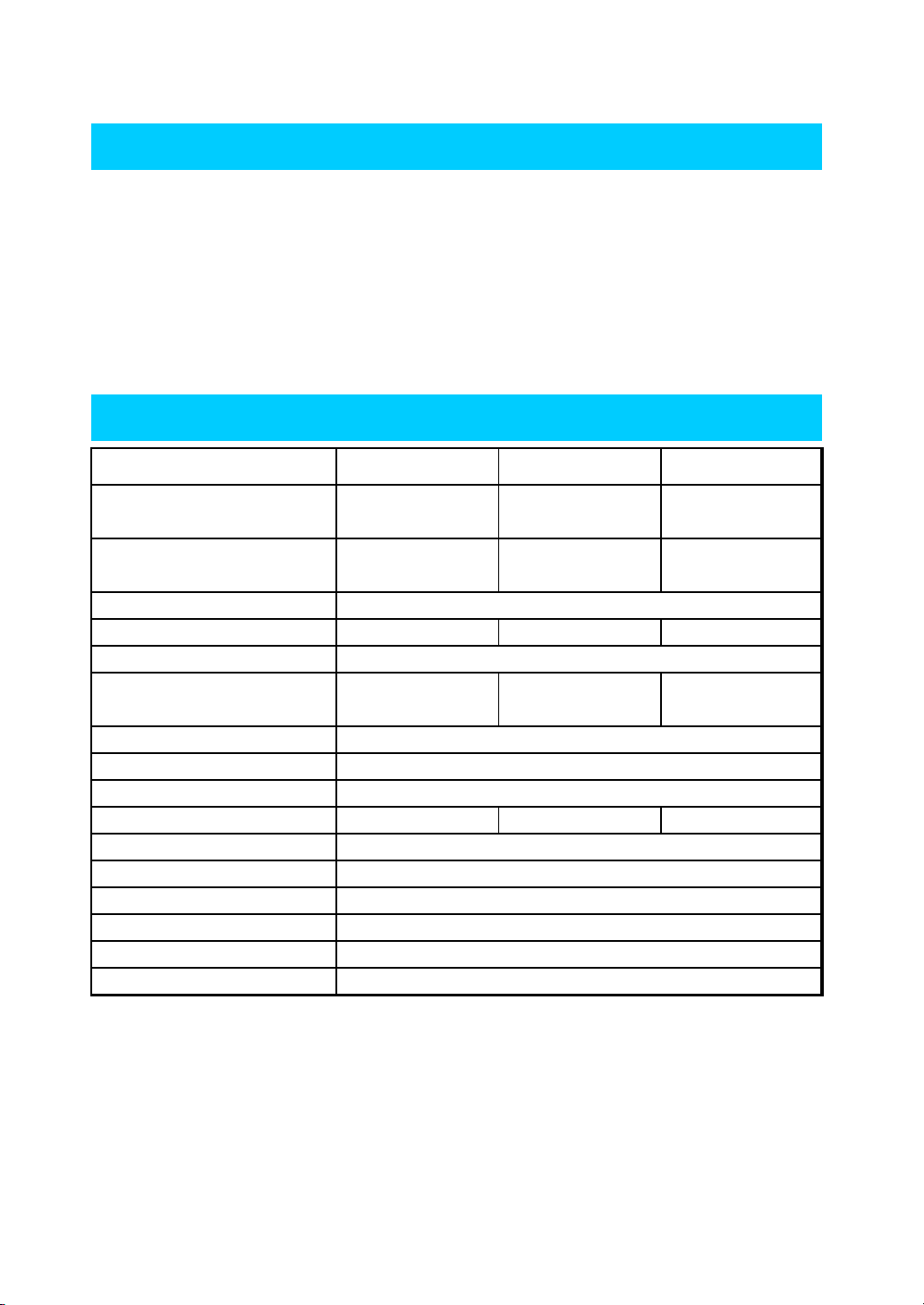

SPECIFICATIONS

Unit Dimensions

Unit Weight

Voltage/Cycles

Power Consumption

Max.Laminating Speed

Max.Laminating Width

Max.Laminating Thickness

Cold and Hot Laminating

Cooling Blower

Paper Counting

Length Measurement

Take Up

Film Alignment

Cutter-Cross

Foot-Switch

RSS-1200

1550*650*1210(mm)

61*25.6*47.4(in)

190(Kg)

418(lbs)

RSS-1050 RSS-685Description

1400*650*1210(mm)

55.1*25.6*47.4(in)

140(Kg)

308(lbs)

1070*650*1205(mm)

AC 100~120/ 200~240V 50~60Hz

3000W 3000W 2000W

6m/min (19.7ft/min)

1200(mm)

47.2(in)

1050(mm)

41.3(in)

13mm ( 0.5in)

25~250mic (1 ~ 10mil)Film Thickness

Yes

221

Yes

Yes

Yes

Yes

Yes

Yes

42.1*25.6*47.4(in)

100(Kg)

220(lbs)

685(mm)

27(in)

- 4 -

.

.

.

.

.

NAMES OF MAJOR PARTS OF MACHINE

13

4

3

1

14

6

10

5

11

12

9

2

7

8

1. FILM-UPPER 8. FOOT SWITCH

2. FILM-LOWER 9. REMOTE CONTROL SWITCH

3. TAKE-UP (ASS'Y-TAKE-UP) 10

4. IDLER BAR (UPPER) 11

5. TABLE-FRONT 12

6. SHOE-HEATER,UPPER 13

7. ASS'Y-STAND 14

- 5 -

CONTROL PANEL

PRESSURE LEVER

TENSION CONTROL KNOB

ALIGNMENT KNOB

TAKE-UP SWITCH

T

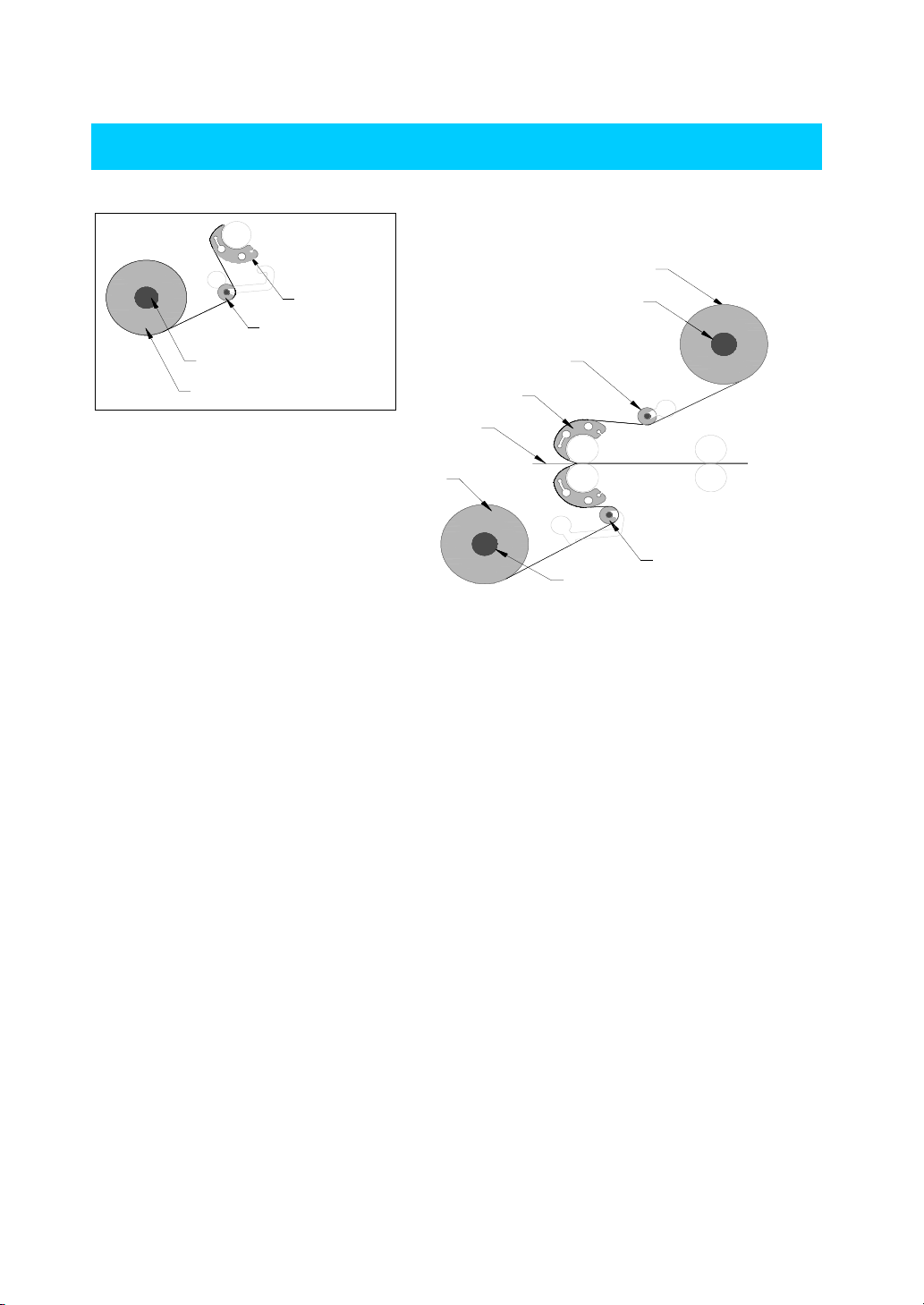

ADJUSTMENT OF FILM TENSION AND LOCATIONS

Alignment Knob.

Locking Nut

Tension Control Knob

Film

필름

열판

Shoe-Heater

Anti-Wrinkle

주름방지부

device

Film

필름

1. HOW TO CONTROL TENSION

Tension of film can be controlled depending on the state of lamination, but basically you

can adjust it, to some extent, and make wrinkles straighten from Anti-Wrinkle Part of the

heat shoe. To increase the tension on the film, turn the knob clockwise.

To lower the tension, turn the handle counter clockwise. If lamination is curved upward,

it means that tension of upper film is high. In this case, it can be controlled by raising

tension of lower film or lowering tension of upper film. If lamination is curved downward,

apply the method in reverse.

2. HOW TO ADJUST ALIGNMEN

Location control device is used when the edges of the lamination are unjustified.

As the drawing shows, when the alignment knob is turned clockwise, the upper film is

moved to right. On the contrary, when the handle is turned counter-clockwise, it is moved

to left. Once proper alignment is reached, turn the Locking Nut tight against the Alignment

knob so the adjustment is set.

- 6 -

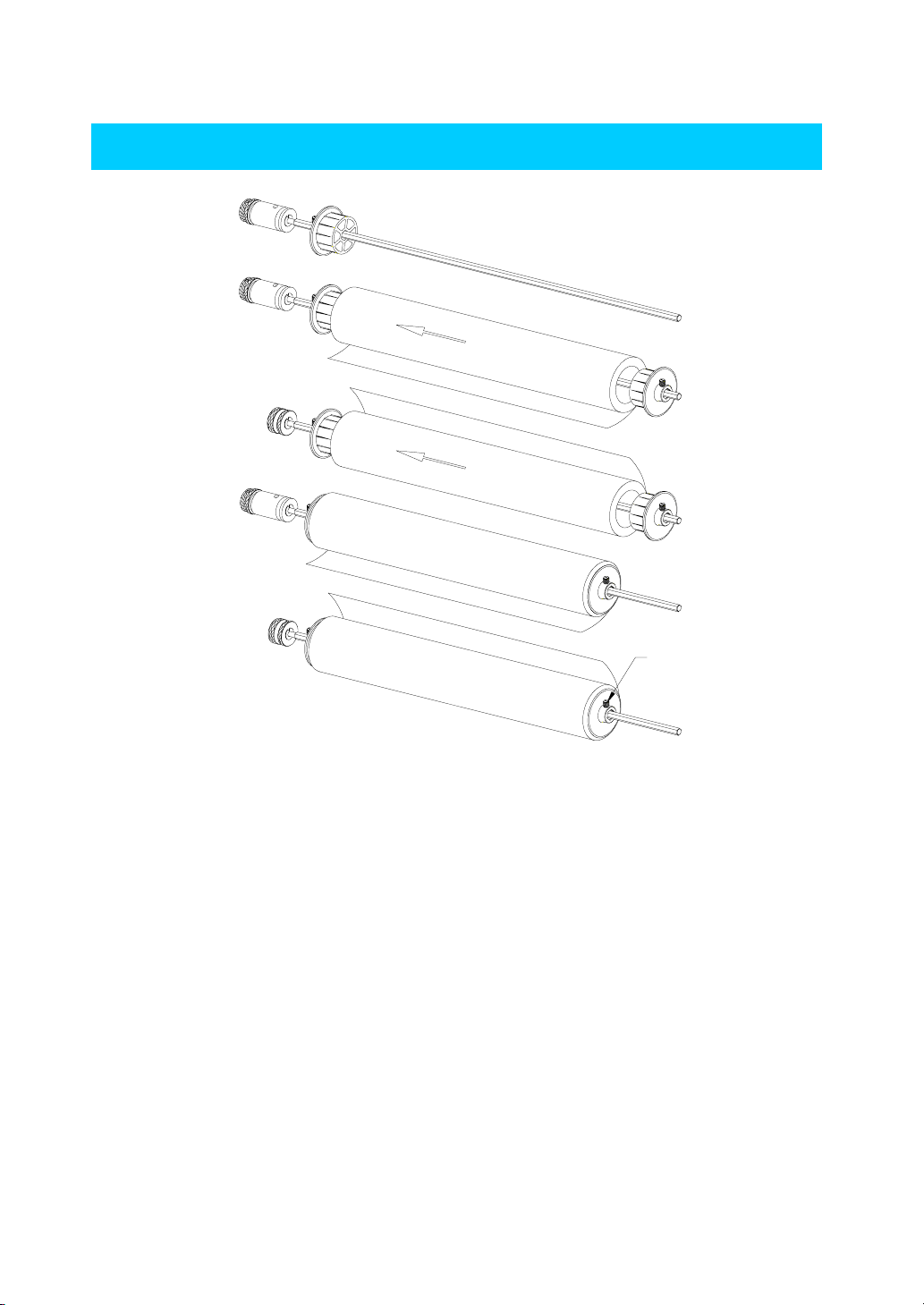

Picture 1

Picture 2

Picture 3

Picture 4

Picture 5

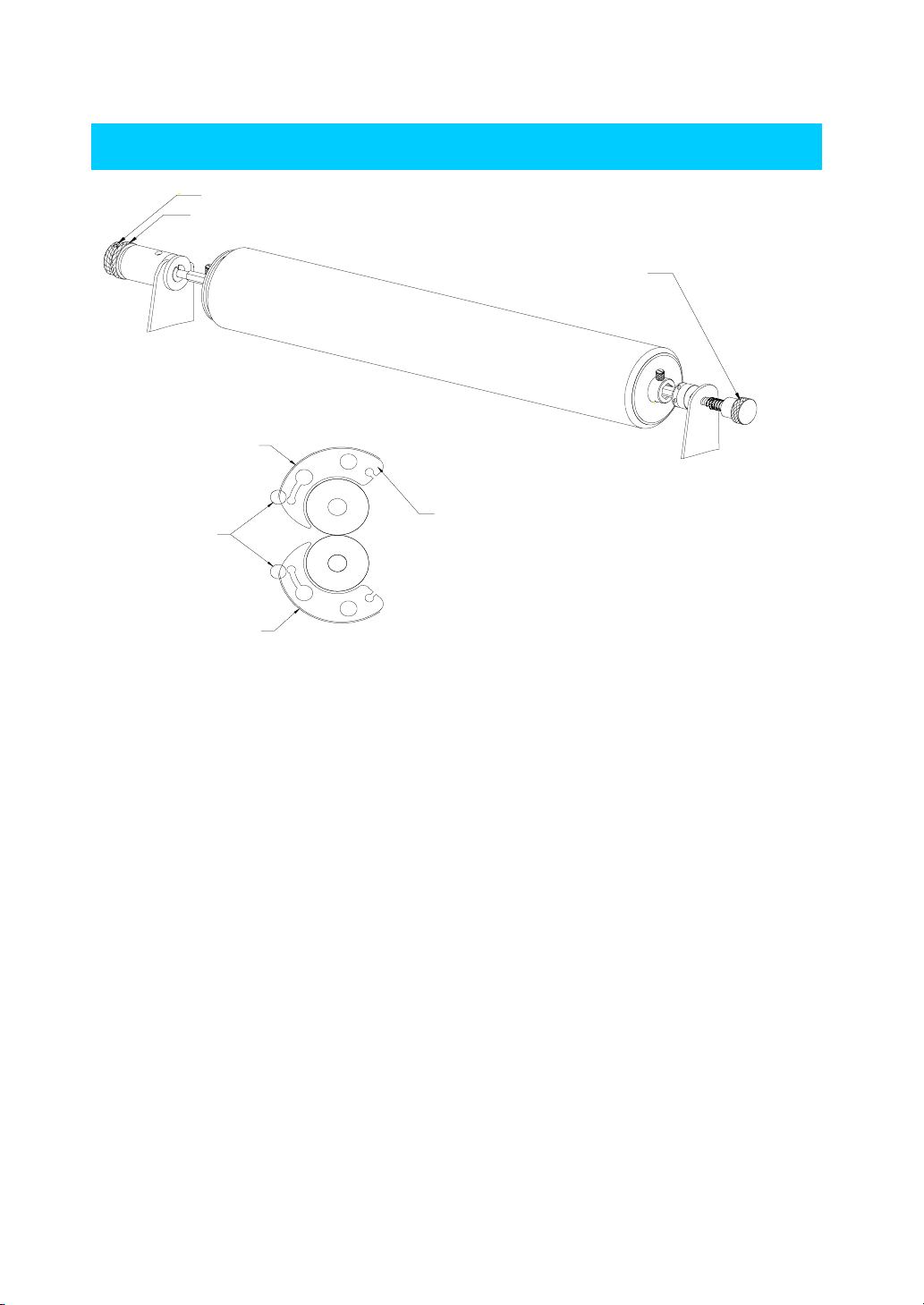

SETTING UP FILM

Upper Film

Lower Film

Upper Film

Lower Film

Core Fixing

Screw

1. Set the glossy side of upper/lower film to face the heat.

( Glossy side is PET film and matte side is thermal polymer laminating film.)

2. Like picture 1, insert core into the left side of upper/lower film shaft.

3. Like picture 2 and 3, insert core into the right side of upper/lower film.

4. Like picture 4 and 5, adhere core closely.

(Make the right/left direction of fixing screw consistent.)

5. Locate film in the middle, and then fasten core fixing screw.

- 7 -

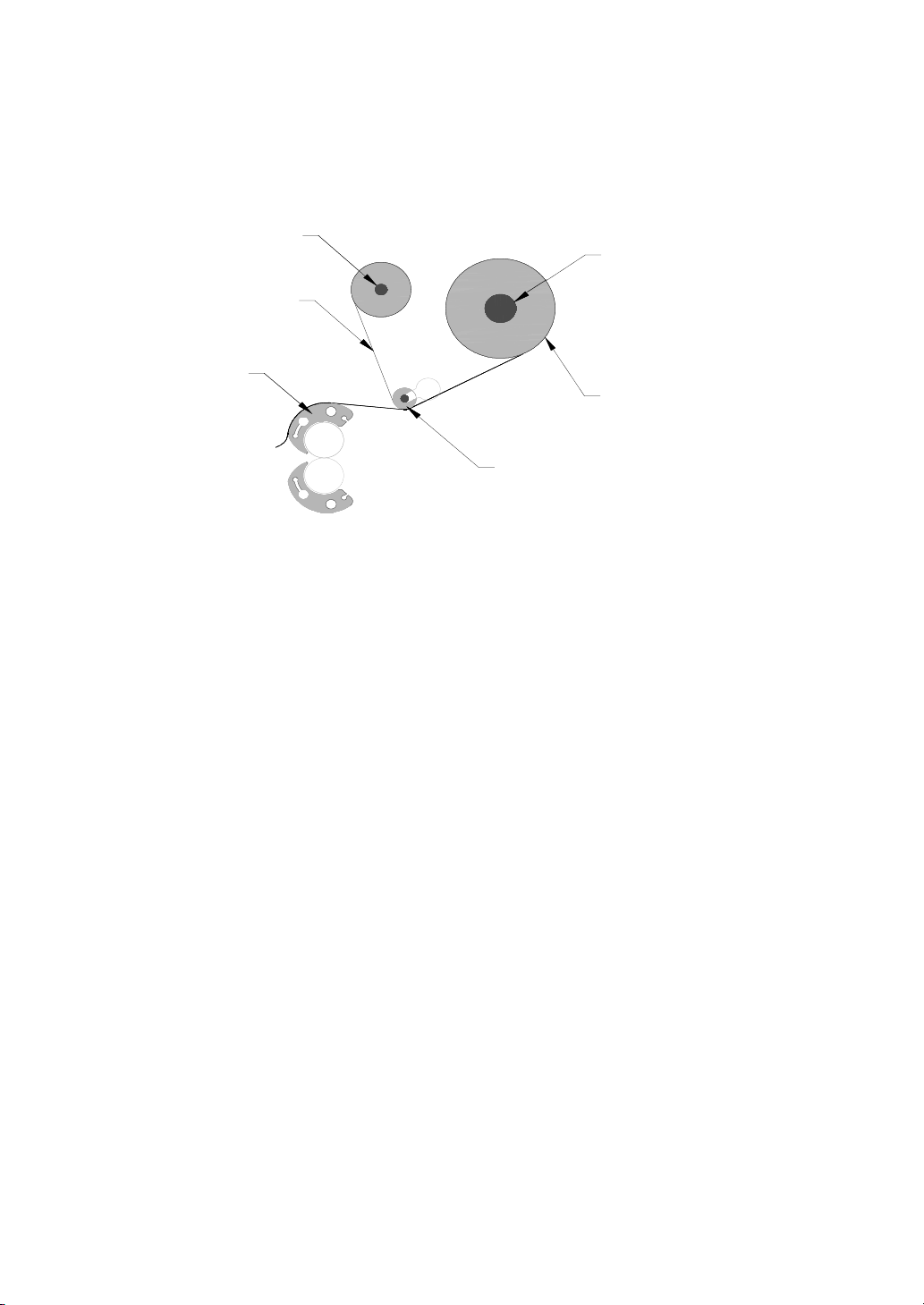

1. HOT FILM

HANGING FILM

HEAT SHOE

LOWER IDLE BAR

UPPER ROLL FILM

SHAFT

UPPER IDLE BAR

HEAT SHOE

LOWER IDLE BAR

SHAFT

Picture 1

SHAFT

LOWER FILM

GUIDING PAPER

LOWER ROLL FILM

1. Insert the bar into the core of roll film then place the bar on the machine.

2. Place the Pressure Lever to the open mode (10~13mm).

3. Insert a piece of lightweight cardboard (Guiding Paper) between the rollers, through to

beyond the second set of rollers.

**IMPORTANT : It should reach beyond the second set of rollers. It should stick out

5cm (2") in front of front roller.

4. Pull the upper film around the upper idler bar to the anti-wrinkle device and stretch out

the film on the upper heat shoe.

5. When the temperature reaches 80°C (176°F), the resin is melting, stick the film on the

shoe.

6. Allow some of the film with melted resin to stick to the Guiding Paper.

7. Repeat step 5 with lower roll film then stick it to the Guiding Paper.

8. Unwind 30~40cm(1~1.3ft) of both rolls of film, to loosen the film tension. This should be

fed through to the rear roller without tension.

9. Set speed at 1 and press the "RUN" button to feed film into the machine.

10. After checking the status of lamination, Place the pressure lever at the proper

lamination mode.

- 8 -

2. COLD FILM

TAKE UP DEVICE

PAPER BACK

HEAT SHOE

1. Take out the guiding table.

2. Put the shaft of roll film in each hole exactly.

UPPER FILM SHAFT

COLD FILM

UPPER IDLE BAR

3. Set the pressure lever to the proper lamination mode.(1mm/5mm/10~13mm)

4. Pull the film around the idler bar to the Anti-wrinkle device.

5. Put the paper back of the film to the bobbin at take-up bar to rewind the paper back.

**It is to be stuck on to roll up clock wise.

6. Place the sticky part of film on the upper shoe and get ready to laminate.

- 9 -

Loading...

Loading...