Page 1

MODEL:RSL-2702S/RSL-382S

Roll Laminator Service Manual

451-8 24B/9L,Nonhyeon-dong,Namdong-Ku,Incheon city,KOREA

TEL:032) 822-0414 FAX:032)820-7105 A/S:080)262-8464

www.royalsovereign.com

Page 2

…

g

…

…

…

Table of Content

…

…

…

…

1.Safety Precautions ………………………………………………………………………

2.Troubleshooting ……………………………………………………………………………

2.1) Rollers Not Heating ……………………………………………………………

2.2) Rollers Over Heatin

…………………………………………………………

2.3) Rollers Not Running ……………………………………………………………

2.4) No Main Power …………………………………………………………………

2.5) Poor Lamination Quality ………………………………………………………

3.Replacing Parts ………………………………………………………………………………

3.1) Right Cover ………………………………………………………………………

3.2) Left Cover ………………………………………………………………………

3.3) Rear Cover ………………………………………………………………………

3.4) Main PCB …………………………………………………………………………

3 ~ 3

4 ~ 10

4 ~ 6

6 ~ 7

7 ~ 9

9 ~ 10

11 ~ 11

12 ~ 14

12 ~ 12

13 ~ 13

13 ~ 13

13 ~ 13

3.5) Sub PCB …………………………………………………………………………

3.6) Heaters ……………………………………………………………………………

3.7) Cross Cutter ………………………………………………………………………

4.Adjustments ……………………………………………………………………………………

5. Parts List …………………………………………………………………………………………

6.Exploded Drawings ………………………………………………………………………

7.Wire Diagram …………………………………………………………………………………

8.Backup ………………………………………………………………………………………………

13 ~ 13

13 ~ 14

14 ~ 14

15 ~ 16

17 ~ 19

20 ~ 25

26 ~ 29

30 ~ 33

Page 3

1. Safety Precautions

Failure to comply any of the following safety procedures could result in serious injury.

Please read the instructions carefully and keep for future reference.

1. Only a licensed electrician should install wiring and outlet for the laminator.

2. Ensure the unit is plugged into a properly grounded outlet with the correct voltage.

3. Keep hands and clothing(ie.Neckties)away from rollers. The rollers are pinch points that can

trap body parts or clothing and cause serious injury .

4. Keep flammable and wet objects away from the machine .

5. Place machine on a level surface.

6. Avoid excessive sunlight, humidity and extreme temperatures.

7. Ensure the unit is turned off, cooled ,and unplugged from the outlet prior to moving and/or

repairing.

8. Keep out of reach of children.

9. Only Royal Sovereign authorized maintenance and service technicians should make repairs.

10. Do not attempt to laminate items that exceed total recommended material thickness for the

unit.

11. When cleaning the machine, don't use flammable sprays or materials.

12. Do not touch the rollers when they are hot or place foreign objects inside the machine.

13. Do not cover the surface of the machine until the machine has completely cooled.

Safety Precaution

1

Page 4

2. Troubleshooting

Note: While repairing:

Make sure the power plug is unplugged from the power outlet.

a.

Open both side covers and rear cover.

b.

Be sure to follow the steps below in order.

c.

2.1 Rollers Not Heating

CAUSES:

1. Improper laminating mode.

2. Heating wire is not connected to the main PCB.

3. Blown (burnt) upper and/or lower wire fuse (T/Fuse).

4. Defective Bi-Metal.

5. Defective heater.

6. Defective Main PCB.

MEASURE

1. Improper laminating mode.

a. Ensure that the laminating mode is in the “Hot” mode, not the “Cold” mode.

Press “C/HOT” button on the control panel to change the mode.

2. Heating wire is not connected to the main PCB.

a. Connect the upper and lower heating wires to the main PCB.

2

Page 5

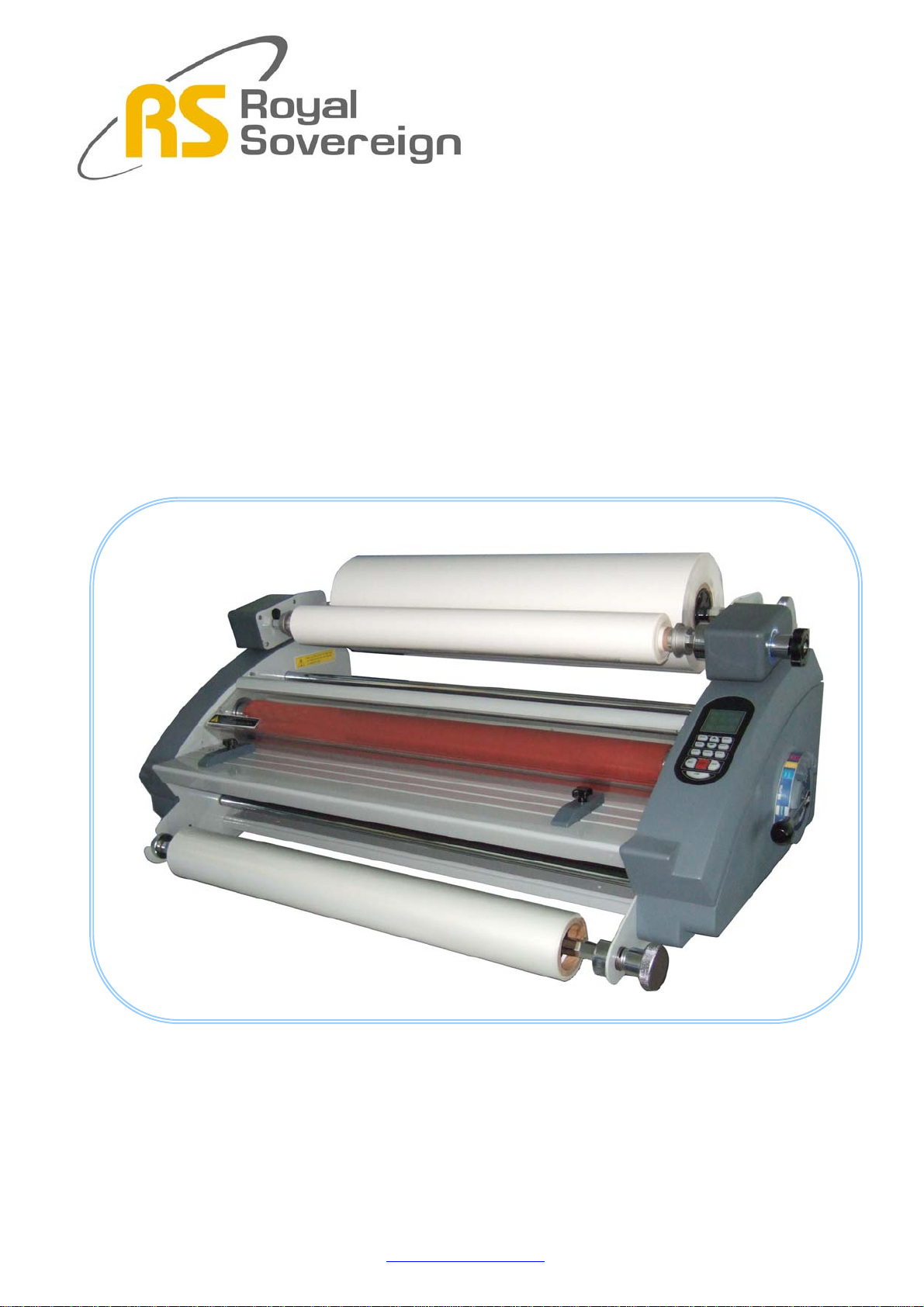

3. Blown (burnt) upper and/or lower wire fuse (T/Fuse).

r

a. Replace the T/Fuse wire located on the left-hand side.

WIRE-UP-T/FUSE

4. Defective Bi-Metal.

a. Replace the Bi-Metal

WIRE-LO-T/ FUSE

BIMETAL-L(130℃)

BIMETAL-R(145℃)

5. Defective heater.

a. Using the multi-meter, test the continuity of the heater. If it fails, replace the heater.

Multi-mete

b. Physically examine the heater assembly for breakage.

Broken

3

Page 6

6. Defective Main PCB.

a. Replace the PCB Main.

2.2) Rollers Over Heating

CAUSES

1. Lower and upper heat sensors are reversed on the PCB Main.

2. Defective T/Fuse wire.

3. Defective heater.

4. Defective main PCB.

MEASURES

1. Wires for lower and upper heat sensors are reversed on the main PCB.

a. Reverse the heat sensors.

Connector-Wire Sensor

2. Defective T/Fuse wire.

a. Replace the T/Fuse wire located on the left-hand side.

WIRE-UP-T/FUSE

WIRE-LO-T/ FUSE

4

Page 7

3. Defective heater.

a. Test continuity of the heater. If it fails, replace the heater.

b. Glass tube that surrounds heating coil is broken – replace the heating element.

4. Defective Main PCB.

a. Replace the PCB Main.

2.3) Rollers Not Running

CAUSES

1. No power to the unit.

2. Emergency switch is engaged.

3. Opened safety cover.

4.Opened Front Table Switch.

5. Film is jammed on the rollers.

6. Disconnected motor wire.

7. Blown motor fuse.

8. Defective main motor.

9. Defective main PCB.

MEASURES

1. No power to the unit.

a. Make sure the power plug is connected to the proper source of outlet

(220V, 15Amp, & single phase).

2. Emergency switch is engaged.

Switch is engaged

5

Page 8

3. Opened safety cover.

a. Close the safety cover and double check to insure that the safety cover switch

is engaged.

Note: By closing the safety cover, it engages the safety cover switch.

Switch is engaged

4. Opened Front Table Switch.

a. Properly position the front table to engage the switch.

5. Film is jammed on the rollers.

a. Un-jam the film using a combination of the pressure lever and reverse button.

6. Disconnected motor wire.

a. Check the motor wire connection with PCB.

Wire-motor

6

Page 9

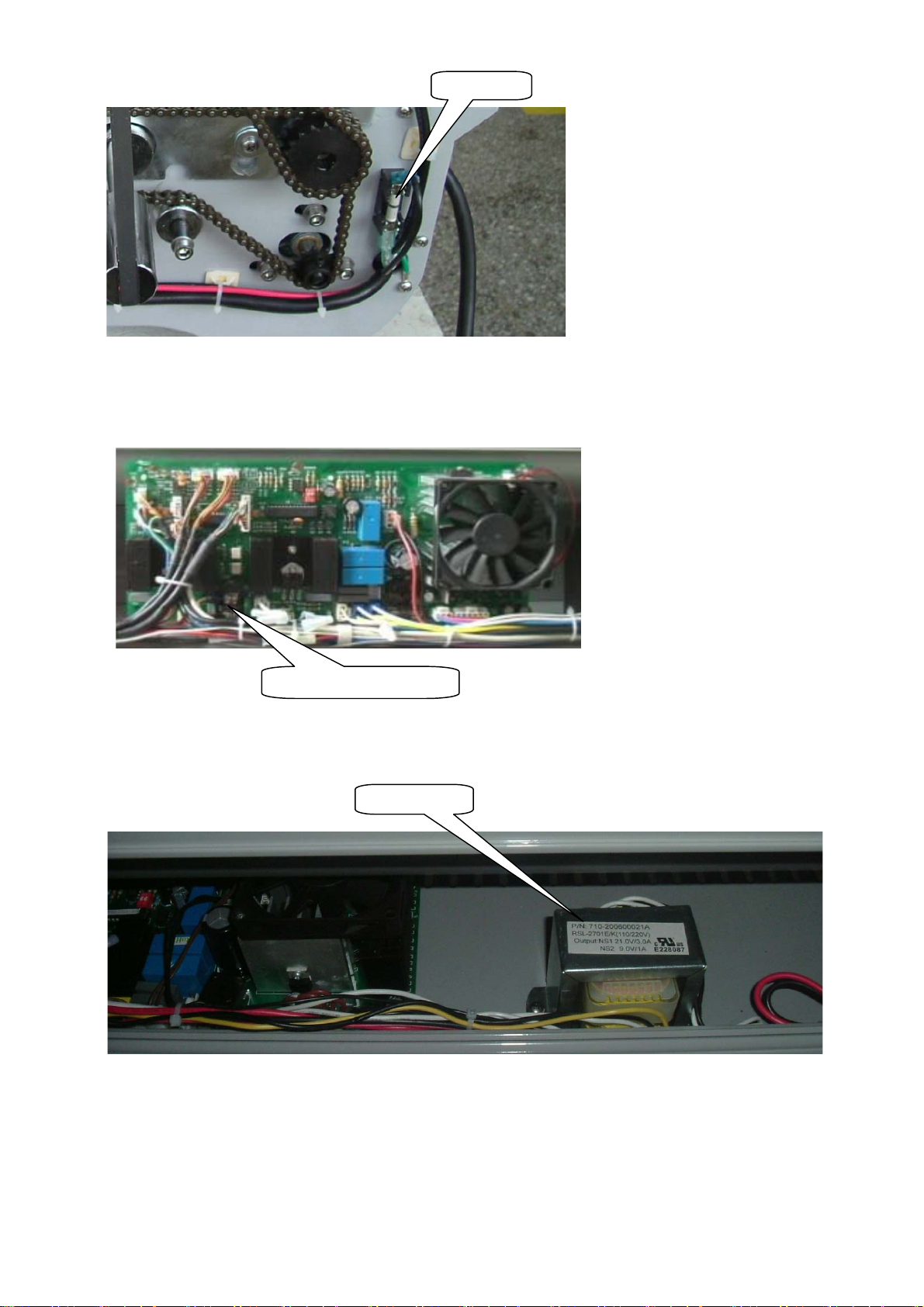

7. Blown motor fuse.

a. Replace the motor fuse located above the main power switch.

8. Defective main motor.

a. Replace the main motor.

9. Defective main PCB.

a. Replace the main PCB.

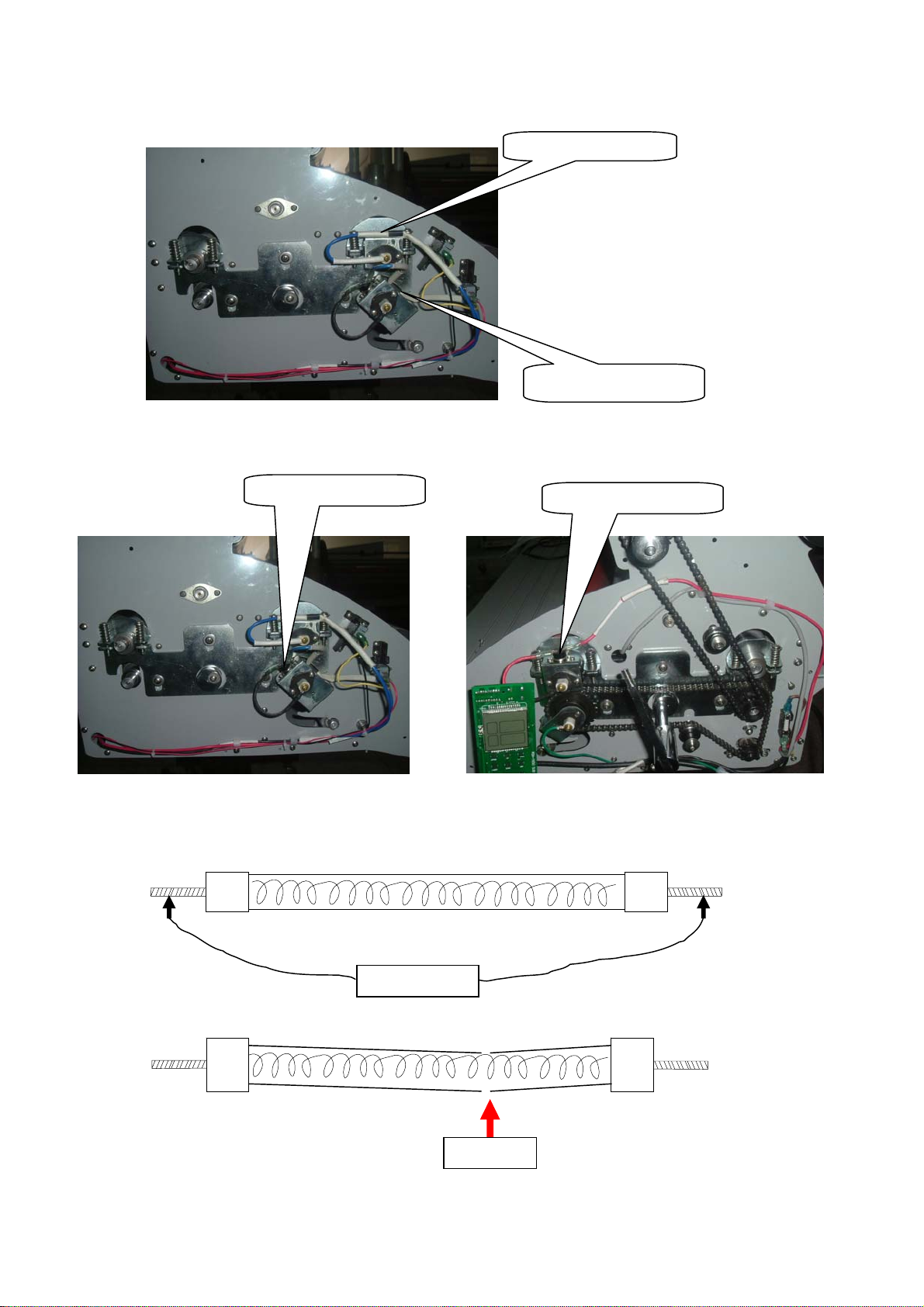

2.4) No Main Power

CAUSES

1. No electricity.

2. Blown main fuse.

3. Disconnected main power wires.

4. Defective transformer.

MEASURES

Motor Fuse

1. No Electricity.

a. Double check to insure that you have electricity from your outlet.

b. Check the circuit breaker.

c. Double check that source of power is 220V, 15Amp, and single phase.

2. Blown main fuse.

a. Replace the main fuse located above the main power switch.

7

Page 10

Main Fuse

3. Disconnected main power wires.

a. Check that the main power wires are properly connected.

Main Power Wires

4. Transformer is defective

a. Replace the transformer.

10

Transformer

8

Page 11

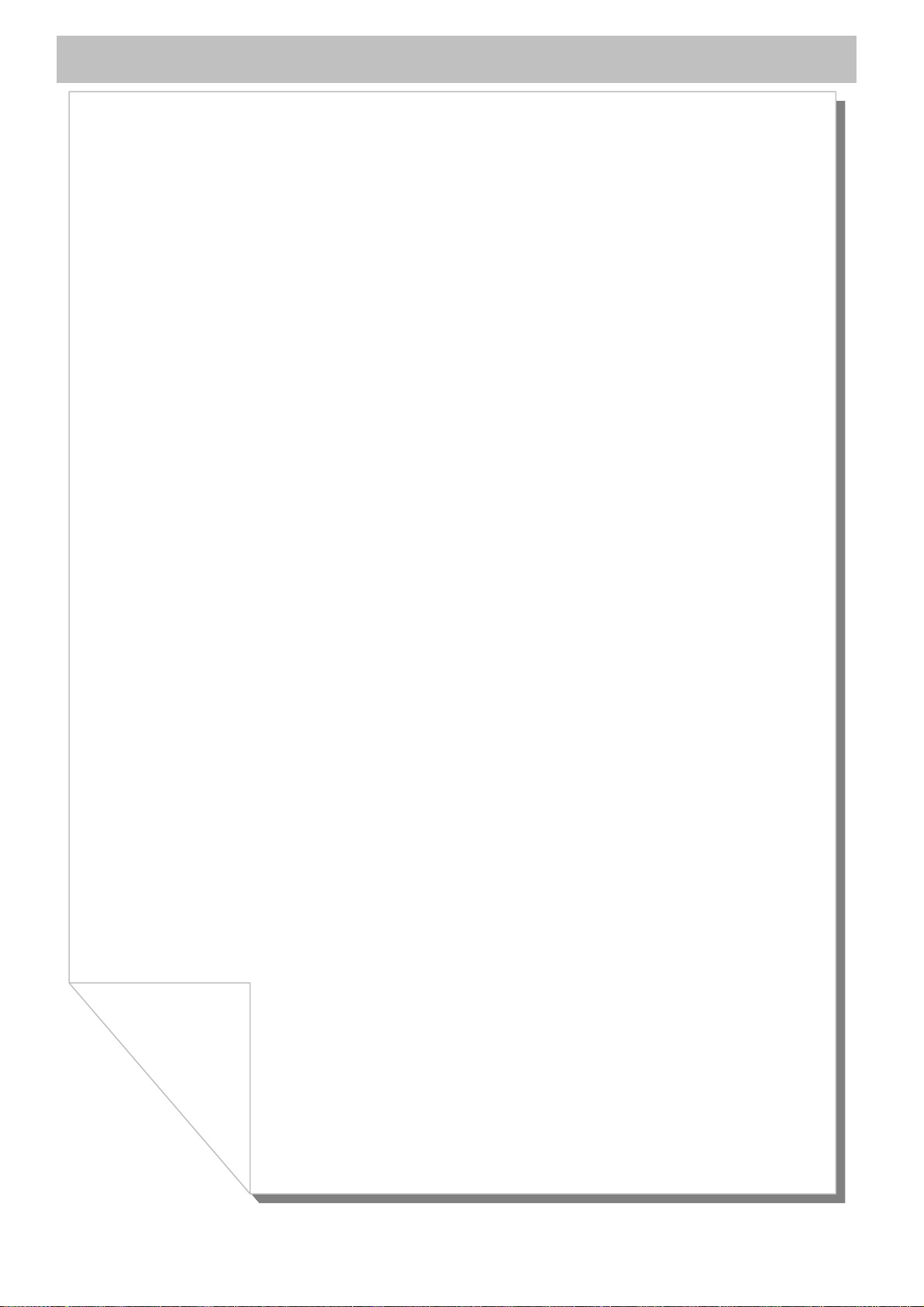

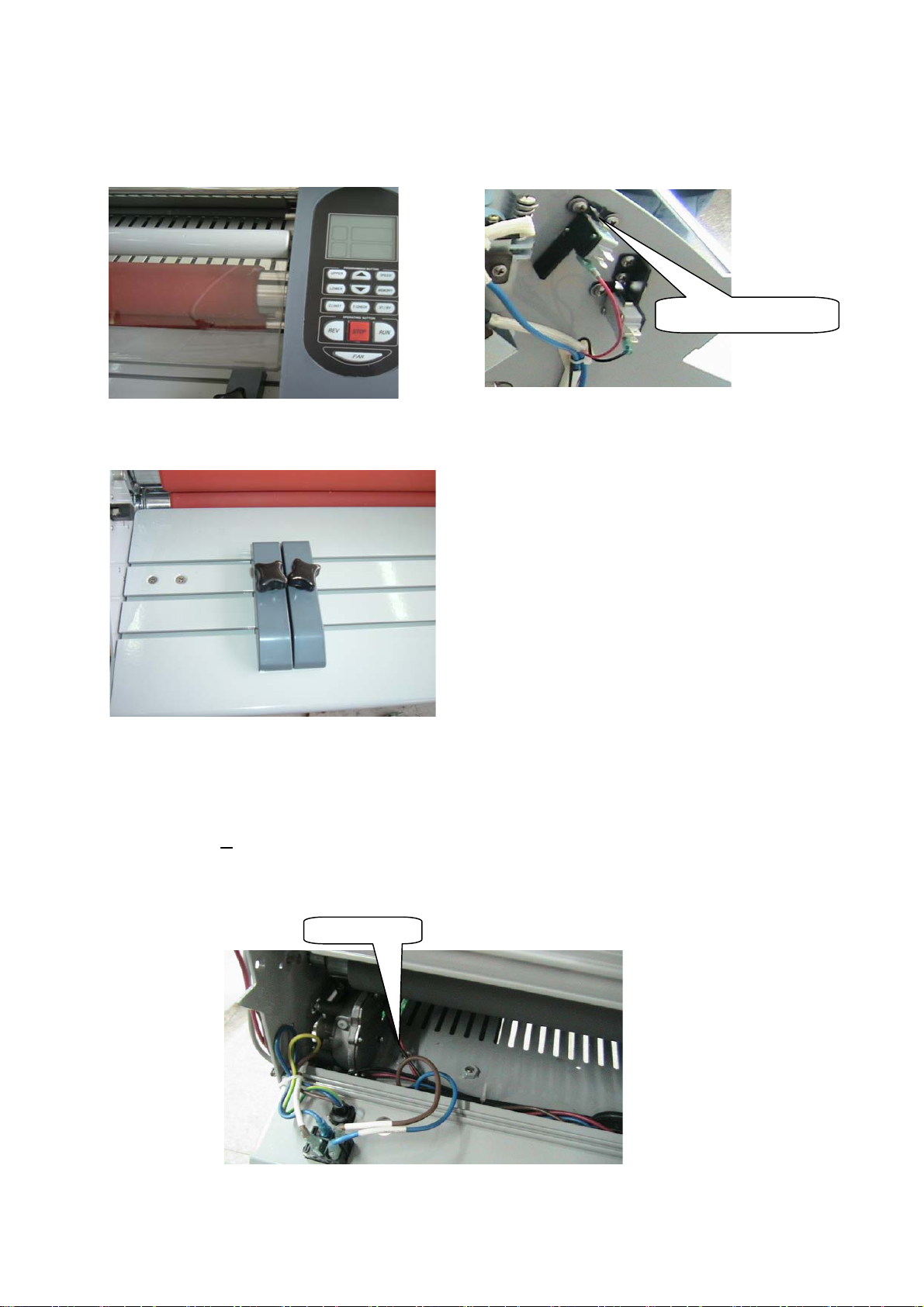

2.5 Poor Lamination Quality

Problem: Straight wave lines across the output.

Cause: Excessive front roller pressure.

Measure: Loosen the front roller pressure.

Problem: Concave waves in the lamination.

Cause: Excessive rear (pulling) roller pressure.

Measure: Loosen the rear back roller pressure.

Problem: Angled waves on both sides of the output.

Cause: Insufficient rear roller pressure.

Measure: Tighten the rear roller pressure.

Problem: Angled waves on one side of the output.

Cause: Insufficient rear left (or right) side roller pressure.

Measure: Tighten the rear left (or right) side roller pressure.

Problem: Straight waves in the output.

Cause: Excessive heat at the nip rollers.

Measure: Lower the roller temperature.

Problem: Wake waves.

Cause: Insufficient heat at the nip rollers.

Measure: Raise the roller temperature.

Problem: Curling.

Cause: 1.The film tension is very tight;2.The decurling bar is not in the

working location.

Measure: 1.Loose the tension;2.Adjust the decurling bar to working

location.

9

Page 12

.

3. Replacing Parts

Note: While replacing parts:

a. Make sure the power plug is unplugged from the power outlet.

b. Open both side covers and rear cover.

3.1 Replacing the Right Cover.

a. Take out the pressure lever (Figure 1) and four cover screws using Phillips screw driver (Figure 2).

Figure 1

b. Pull out the male control panel connector from the Sub-PCB( Figure 3).

Figure 3

c. Loosen two screws from Sub-PCB , installed on to new Right Cover (Figure 4).

Figure 2

Figure 4

d. Follow the reverse order to assemble the Right Cover back

3.2 Replacing the Left Cover

a. Replace the Left Cover by loosening four Left Cover screws.

10

Page 13

3.3 Replacing Rear Cover

r

a. Take off the left and right covers.

b. Take out the four screws from frames,two screws of each side(Figure 5,Figure 6)

Figure 5 Figure

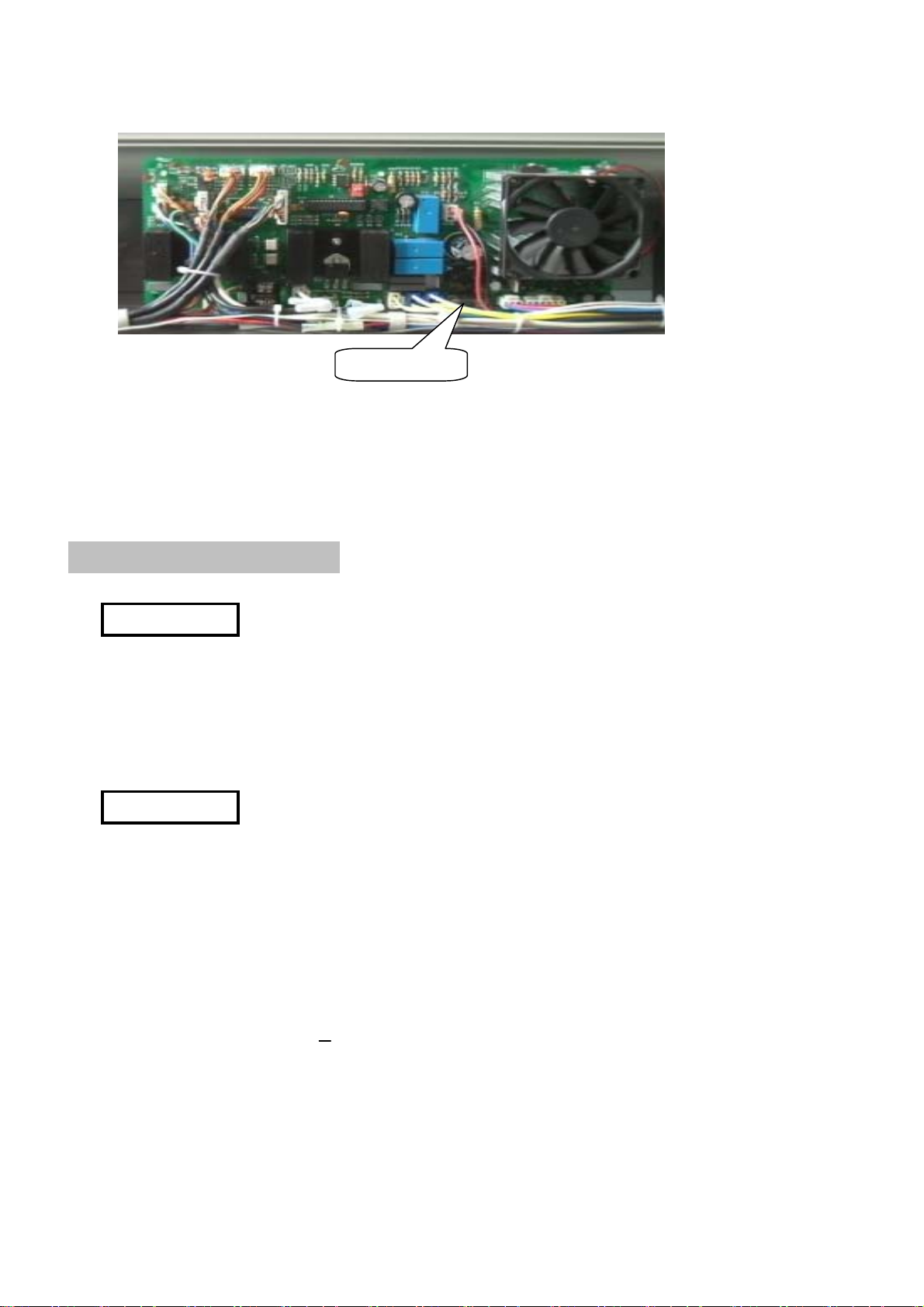

3.4 Replacing the Main PCB

a. Remove the rear cover and label all the wires before unplugging from the Main PCB.

b. Detach the Main PCB from 6 white plastic holders ( Figure 7).

c. Replace the board with new PCB and connect all the wires.

Figu

3.5 Replacing the Sub-PCB

a. Refer to “Replacing Right Cover”.

3.6 Replacing the Heaters

Note: Cotton or surgical gloves are recommended while handling the heater assembly.

a. Disassemble Right and Left Covers (Refer to “Replacing Right Cover” and “Replacing Left Cover”).

b. Take out the heater brackets on each side by loosening screws (Figure 8, 9, & 10).

Figure8

11

Figure

Figure10

Page 14

c. Take out the broken heater. Figure 11

Figure 11

Note:

a. When inserting the heater into the roller, rotate the heater slightly and push the rod in gently.

b. Use an air blower to blow out the broken pieces of heating rod.

(Please ensure that no one is standing on the other side.)

3.7 Replacing the Cross Cutter

a. Disassemble the nut from the Frame-Cutter.

b. Unfasten the spring from the cutter.

c. Change the Cutter.

d. Assemble the Cutter by reversing the above steps.

12

Page 15

t

4. Adjustments

4.1 Adjusting Take-up Shaft Speed

CAUSES:

1.Main rollers and take-up shaft speed is not synchronized.

MEASURES:

Adjust take-up shaft speed,by loosenning or tightenning the knob

According to label-take up.

C.W – Tighten.

C.C.W – Lossen.

.2 Adjusting front and rear rollers

Pressure

• Use Screwdriver

to adjust the roller pressure:

C.W – Increase pressure.

C.C.W – Decrease pressure.

1.Using Push-Pull Scale, measure

5 spots as shown on Figure B &C:

Front roller should be 5~6 and back

rollers should be 6~8.

2.Checking for over all tension –

when the machine is running, check tha

the top and the bottom films are fed in

without any wrinkles.

3.Pressure mark checking (Heat Line) –

stop the machine for 30 seconds to

create a heat line. Then check to see if

you have two even parallel lines from

one end to other. Note: A narrow parallel

lines indicate that it has less pressure

at that point.

C.C.W

C.W

Figure A

Figure B

13

Page 16

4.Laminating Test – Laminate samples

with different thickness of substrates.

5.Check above steps 2 through 4 with

3mil & 5mil films.

Figure C

14

Page 17

t

e

k

5. Part list

RSL-2702S Part lis

No. Part No. Part Nam

1 013LR2012F FRAME-SENSOR

2 013LR2087A FRAME-L

3 013LR2088A FRAME-R

4 013LR3002K FRAME-CUTTER

5 013LR3009A FRAME-REAR

6 013LR3021A PLATE-MIDDLE

7 013LR3075A BASE-FRONT

8 013LR3076A BASE-REAR

9 013LR4004A FRAME-COVER SAFETY

10 014LR3001A TABLE-FRONT

11 015LR2001B IDLE BAR LOW

12 015LR3011A IDLE-BAR

13 015LR3012A SHAFT-DECURLING

14 021CR3001A KNOB-CUTTER,C

15 021LR0001A COVER-L

16 021LR2008A COVER-TAKE UP,L

17 021LR2013A COVER-TAKE UP,R

18 ASMLR1602A ASM-SENSOR

19 ASMLR1608A ASM-SENSOR

20 021LR3018A COVER-R

21 021LR3024B COVER-SAFETY

22 021LR4001A LIMIT SWITCH COVER

23 023LR3005A BUTTON-FUNC

24 023LR4002A KNOB-BOLT GUIDE

25 023LR4004A KNOB-TENSION

26 023LR4007A KNOB-LEVEL

27 026LR4006A FOOT

28 032LR3002A SHEET-FUNC

29 111LR4004A BOLT-CORE

30 111LR4006A BOLT-GUIDE

31 111LR4018A SCREW-H

32 112004001D NUT

33 120LR3004G SHAFT-FILM,L

34 120LR3023A SHAFT-CAM

35 120LR4008A SHAFT-TABLE

36 120LR4014A SHAFT-TAKE UP

37 12200X005A BEARING-TRUST NEEDLE

38 12200X009A DU BUSH

39 12200X022A BEARING-RADIAL TRUST

40 12200X027A DU BUSH

41 12200X028A DU BUSH

42 12200X029A DU BUSH

43 12200X030A DU BUSH

44 12200X032A DU BUSH

45 12200X034A DU BUSH

46 12200X040A DU BUSH

47 122LR4024A BUSH-ROLLER LAMI,UP

48 122LR4026A BUSH-ROLLER PULL,UP

49 122LR4042A BUSH-ROLLER LAMI,LO-LEFT

50 122LR4047A BUSH-ROLLER PULL,LO

RSL-2702S

Remar

15

Page 18

51 122LR4050A BUSH-ROLLER LAMI,LO-RIGHT ASS'Y

52 124LR4005A CAM

53 124LR4006A 1"CORE

54 125LR4001A HANDLE-TENSION

55 125LR4003B LEVER-PRESSURE

56 125LR4004A SHAFT-TENSION 2

57 125LR4008A SUPPORT-SPRING

58 131LR4017A SPROCKET-LAMI

59 131LR4022B SPROCKET-DOUBLE

60 131LR4023A SPROCKET-TAKE UP

61 131LR4034A SPROCKET-MOTOR

62 133LR2021A ROLLER-LAMI,LO

63 133LR2021B ROLLER-LAMI,UP

64 133LR2022A ROLLER-PULL,LO

65 133LR2022B ROLLER-PULL,UP

66 134LR4001A PULLEY-CHAIN

67 134LR4003A BUSH-PULLEY

68 136LR4001C CHAIN

69 136LR4001G CHAIN-2(TAKE UP)

70 138LR4001A SPRING-CUTTER CROSS

71 138LR4012A SPRING-TENSION

72 138LR4015A SPRING-PRESSURE

73 138LR4018A SPRING-LEVER

74 140LR3001A HOLDER-CUTTER,C

75 140LR4001A HOLDER-SHAFT FILM

76 140LR4021A HOLDER-SHAFT,T

77 141LP4018A BRACKET-T/FUSE

78 141LR3017A PLATE-PRESSURE,L

79 141LR3018A PLATE-PRESSURE,R

80 141LR4005A PLATE-SHAFT FILM

81 141LR4020A BRACKET-HEATER,LO-R

82 141LR4035A PLATE-DU BUSH

83 141LR4040A PLATE-SLIP

84 141LR4041A BRACKET-FAN

85 141LR4043A FRONT TABLE SAFETY LEVER

86 141LR4054A BRACKET-LIMIT SWITCH

87 141LR4059A BRACKET-SENSOR

88 141LR4060A PLATE-PRESSURE,LAMI

89 141LR4061A PLATE-PRESSURE,PULL

90 141LR4081A BRACKET-HEATER,LO-L

91 141LR4087A BRACKET-HEATER,UP

92 143LR3001A SUPPORTER-SHAFT

93 144LR4001B CLAMPER-LEVER

94 145LR3002A GUIDE-DOCUMENT

95 147LR4002A PAD-TENSION

96 147LR4010A PAD-TAKE UP

97 147LR4013A STOPPER-HEATER,UP

98 210004002A MOTOR-MAIN

99 211003004A FAN

99-1 211003004B FAN

100 213LR4001A CUTTER-CROSS

101 223LR2007B HEATER ASS'Y

101-1 223LR2007C HEATER ASS'Y

101-2 223LR2007D HEATER ASS'Y

101-3 223LR2007F HEATER ASS'Y

16

RSL-2702S

Page 19

102 23200X002A SUPPORT-PCB

103 23300X001A BUSHING-CORD

104 32500X0005 FUSE-MAIN

104-1 32500X0008 FUSE-MAIN

105 34000S011A POWER TRANSFORMER

106 350LR3022A PCB-SUB ASS'Y

107 350LR3036C PCB-MAIN ASS'Y

108 363LP3001A BI-METAL LO

109 363LR4001F BI-METAL UP

110 36400X002B SWITCH-MAIN

111 36400X014B MICRO S/W

112 36600X001A FUSE-HOLDER

113 380CR4003A POWER CORD

113-1 380CR4004A POWER CORD

113-2 380LR4001A POWER CORD

113-3 380LR4001B POWER CORD

113-4 380LR4003A POWER CORD

113-5 380LR4007A POWER CORD

114 381LR4013C WIRE-POWER S/W

115 381LR4020B WIRE-FUSE,EU

116 381LR4030D WIRE-UP HEATER1,EU

117 381LR4043A WIRE-SAFETY S/W

118 381LR4044A WIRE-MAIN

119 381LR4052A WIRE-MOTOR

120 381LR4054A WIRE-LO HEATER2,EU

121 381LR4055A WIRE-UP HEATER2,EU

122 381LR4084A WIRE-T/FUSE(UP)

123 381LR4091A WIRE-LO HEATER1,EU

124 381LR4092A WIRE-T/FUSE(LO)

125 443LR4001A L-WRENCH

126 ASMLR1339A ASM-AUTO GRIP FILM CORE 2"

126-1 ASMLR1339B ASM-AUTO GRIP FILM CORE3"

127 KPS03012D2 KEY-PLAIN

128 KPS05010D2 KEY-PLAIN

129 RE001000C8 E-RING

130 RC001200C8 SNAP-RING

131 RIV05018E8 RIVET

132 SKE04010D2 SET SCREW

132-1 SKE05006D2 SET SCREW

132-2 SKE05010D2 SET SCREW

132-3 SKE05015D2 SET SCREW

133

134

135

136

137

013LR4010A FRAME-GUIDE,R

013LR4011A FRAME-GUIDE,L

141LR4127A BRACKET-DECURLING BAR,R

141LR4128A BRACKET-DECURLING BAR,L

111LR4022A KNOB-GUIDE

RSL-2702S

17

Page 20

t

e

k

5. Part list

RSL-382S Part lis

No. Part No. Part Nam

1 013LR2012G FRAME-SENSOR

2 013LR2087A FRAME-L

3 013LR2088A FRAME-R

4 013LR3002H FRAME-CUTTER

5 013LR3035A FRAME-REAR

6 013LR3036A PLATE-MIDDLE

7 013LR3069A BASE-FRONT

8 013LR3070A BASE-REAR

9 013LR4004A FRAME-COVER SAFETY

10 014LR3001B TABLE-FRONT

11 015LR2010A IDLE BAR LOW

12 015LR3011B IDLE-BAR

13 015LR3012B SHAFT-DECURLING

14 021CR3001A KNOB-CUTTER,C

15 021LR0001A COVER-L

16 021LR2008A COVER-TAKE UP,L

17 021LR2013A COVER-TAKE UP,R

18 ASMLR1604A ASM-SENSOR

19 ASMLR1608A ASM-SENSOR

20 021LR3018A COVER-R

21 021LR3024A COVER-SAFETY

22 021LR4001A LIMIT SWITCH COVER

23 023LR3005A BUTTON-FUNC

24 023LR4002A KNOB-BOLT GUIDE

25 023LR4004A KNOB-TENSION

26 023LR4010A KNOB-LEVEL

27 026LR4006A FOOT

28 032LR3002A SHEET-FUNC

29 111LR4004A BOLT-CORE

30 111LR4006A BOLT-GUIDE

31 111LR4018A SCREW-H

32 112004001D NUT

33 120LR3004E SHAFT-FILM,L

34 120LR3031B SHAFT-CAM

35 120LR4008A SHAFT-TABLE

36 120LR4014C SHAFT-TAKE UP

37 12200X005A BEARING-TRUST NEEDLE

38 12200X009A DU BUSH

39 12200X022A BEARING-RADIAL TRUST

40 12200X027A DU BUSH

41 12200X028A DU BUSH

42 12200X029A DU BUSH

43 12200X030A DU BUSH

44 12200X032A DU BUSH

45 12200X034A DU BUSH

46 12200X040A DU BUSH

47 122LR4024A BUSH-ROLLER LAMI,UP

48 122LR4026A BUSH-ROLLER PULL,UP

49 122LR4042A BUSH-ROLLER LAMI,LO-LEFT

50 122LR4047A BUSH-ROLLER PULL,LO

RSL-382S

Remar

18

Page 21

51 122LR4050A BUSH-ROLLER LAMI,LO-RIGHT ASS'Y

52 124LR4005A CAM

53 124LR4006A 1"CORE

54 125LR4001A HANDLE-TENSION

55 125LR4003B LEVER-PRESSURE

56 125LR4004A SHAFT-TENSION 2

57 125LR4008A SUPPORT-SPRING

58 131LR4017A SPROCKET-LAMI

59 131LR4022B SPROCKET-DOUBLE

60 131LR4023A SPROCKET-TAKE UP

61 131LR4034A SPROCKET-MOTOR

62 133LR3001A ROLLER-LAMI

64 133LR3002A ROLLER-PULL

66 134LR4001A PULLEY-CHAIN

67 134LR4003A BUSH-PULLEY

68 136LR4001C CHAIN

69 136LR4001G CHAIN-2(TAKE UP)

70 138LR4001A SPRING-CUTTER CROSS

71 138LR4012A SPRING-TENSION

72 138LR4015A SPRING-PRESSURE

73 138LR4018A SPRING-LEVER

74 140LR3001A HOLDER-CUTTER,C

75 140LR4001A HOLDER-SHAFT FILM

76 140LR4021A HOLDER-SHAFT,T

77 141LP4018A BRACKET-T/FUSE

78 141LR3017A PLATE-PRESSURE,L

79 141LR3018A PLATE-PRESSURE,R

80 141LR4005A PLATE-SHAFT FILM

81 141LR4020A BRACKET-HEATER,LO-R

82 141LR4035A PLATE-DU BUSH

83 141LR4040A PLATE-SLIP

85 141LR4043A FRONT TABLE SAFETY LEVER

86 141LR4054A BRACKET-LIMIT SWITCH

87 141LR4059A BRACKET-SENSOR

88 141LR4060A PLATE-PRESSURE,LAMI

89 141LR4061A PLATE-PRESSURE,PULL

90 141LR4081A BRACKET-HEATER,LO-L

91 141LR4087A BRACKET-HEATER,UP

92 143LR3001A SUPPORTER-SHAFT

93 144LR4001B CLAMPER-LEVER

94 145LR3002A GUIDE-DOCUMENT

95 147LR4002A PAD-TENSION

96 147LR4010A PAD-TAKE UP

97 147LR4013A STOPPER-HEATER,UP

98 210004002A MOTOR-MAIN

100 213LR4001A CUTTER-CROSS

101 223LR3001H HEATER ASS'Y

101-1 223LR3001J HEATER ASS'Y

102 23200X001A SUPPORT-PCB

103 23300X001A BUSHING-CORD

104 32500X0008 FUSE-MAIN

105 34000S011A POWER TRANSFORMER

106 350LR3022A PCB-SUB ASS'Y

107 350LR3036C PCB-MAIN ASS'Y

108 363LP4013A BI-METAL UP

19

RSL-382S

Page 22

109 033LR4002A WASHER-BI METAL

110 36400X002B SWITCH-MAIN

111 36400X014B MICRO S/W

112 36600X001A FUSE-HOLDER

113 380LR4001A POWER CORD

113-1 380LR4003A POWER CORD

113-2 380LR4007A POWER CORD

114 381LR4013J WIRE-POWER S/W

115 381LR4020B WIRE-FUSE,EU

116 381LR4030D WIRE-UP HEATER1,EU

118 381LR4044B WIRE-MAIN

119 381LR4052A WIRE-MOTOR

120 381LR4054A WIRE-LO HEATER2,EU

121 381LR4055A WIRE-UP HEATER2,EU

122 381LR4084A WIRE-T/FUSE(UP)

123 381LR4091A WIRE-LO HEATER1,EU

124 381LR4092B WIRE-T/FUSE(LO)

125 443LR4001A L-WRENCH

126 ASMLR1339A ASM-AUTO GRIP FILM CORE 2"

126-1 ASMLR1339B ASM-AUTO GRIP FILM CORE3"

127 KPS03012D2 KEY-PLAIN

128 KPS05010D2 KEY-PLAIN

129 RC001200C8 SNAP-RING

130 RE001000C8 E-RING

131 RIV05018E8 RIVET

132 SKE04010D2 SET SCREW

132-1 SKE05006D2 SET SCREW

132-2 SKE05010D2 SET SCREW

132-3 SKE05015D2 SET SCREW

133

134

135

136

137

013LR4010A FRAME-GUIDE,R

013LR4011A FRAME-GUIDE,L

141LR4127A BRACKET-DECURLING BAR,R

141LR4128A BRACKET-DECURLING BAR,L

111LR4022A KNOB-GUIDE

RSL-382S

20

Page 23

6. Explode View

Explode View

Frame L

Frame R

Frame, Roller and Other View

Wire, Front Table ,Film Shaft and Control PCB

21

Page 24

RSL-2702S Expolde View

1 013LR2012F FRAME-SENSOR

2 013LR2087A FRAME-L

3 013LR2088A FRAME-R

4 013LR3002K FRAME-CUTTER

5 013LR3009A FRAME-REAR

6 013LR3021A PLATE-MIDDLE

7 013LR3075A BASE-FRONT

8 013LR3076A BASE-REAR

9 013LR4004A FRAME-COVER SAFETY

10 014LR3001A TABLE-FRONT

11 015LR2001B IDLE BAR LOW

12 015LR3011A IDLE-BAR

13 015LR3012A SHAFT-DECURLING

14 021CR3001A KNOB-CUTTER,C

15 021LR0001A COVER-L

16 021LR2008A COVER-TAKE UP,L

17 021LR2013A COVER-TAKE UP,R

18 ASMLR1602A ASM-SENSOR

19 ASMLR1608A ASM-SENSOR

20 021LR3018A COVER-R

21 021LR3024B COVER-SAFETY

22 021LR4001A LIMIT SWITCH COVER

23 023LR3005A BUTTON-FUNC

24 023LR4002A KNOB-BOLT GUIDE

25 023LR4004A KNOB-TENSION

26 023LR4007A KNOB-LEVEL

27 026LR4006A FOOT

28 032LR3002A SHEET-FUNC

29 111LR4004A BOLT-CORE

30 111LR4006A BOLT-GUIDE

31 111LR4018A SCREW-H

32 112004001D NUT

33 120LR3004G SHAFT-FILM,L

34 120LR3023A SHAFT-CAM

35 120LR4008A SHAFT-TABLE

36 120LR4014A SHAFT-TAKE UP

37 12200X005A BEARING-TRUST NEEDLE

38 12200X009A DU BUSH

39 12200X022A BEARING-RADIAL TRUST

40 12200X027A DU BUSH

41 12200X028A DU BUSH

42 12200X029A DU BUSH

43 12200X030A DU BUSH

44 12200X032A DU BUSH

45 12200X034A DU BUSH

46 12200X040A DU BUSH

47 122LR4024A BUSH-ROLLER LAMI,UP

48 122LR4026A BUSH-ROLLER PULL,UP

49 122LR4042A BUSH-ROLLER LAMI,LO-L EFT

50 122LR4047A BUSH-ROLLER PULL,LO

51 122LR4050A BUSH-ROLLER LAMI,LO-R IGHT ASS'Y

52 124LR4005A CAM

53 124LR4006A 1"CORE

54 125LR4001A HANDLE-TENSION

55 125LR4003B LEVER-PRESSURE

56 125LR4004A SHAFT-TENSION 2

57 125LR4008A SUPPORT-SPRING

58 131LR4017A SPROCKET-LAMI

59 131LR4022B SPROCKET-DOUBLE

60 131LR4023A SPROCKET-TAKE UP

61 131LR4034A SPROCKET-MOTOR

62 133LR2021A ROLLER-LAMI,LO

63 133LR2021B ROLLER-LAMI,UP

64 133LR2022A ROLLER-PULL,LO

65 133LR2022B ROLLER-PULL,UP

66 134LR4001A PULLEY-CHAIN

67 134LR4003A BUSH-PULLEY

68 136LR4001C CHAIN

69 136LR4001G CHAIN-2(TAKE UP)

70 138LR4001A SPRING-CUTTER CROSS

71 138LR4012A SPRING-TENSION

72 138LR4015A SPRING-PRESSURE

73 138LR4018A SPRING-LEVER

74 140LR3001A HOLDER-CUTTER,C

75 140LR4001A HOLDER-SHAFT FILM

76 140LR4021A HOLDER-SHAFT,T

77 141LP4018A BRACKET-T/FUSE

78 141LR3017A PLATE-PRESSURE,L

79 141LR3018A PLATE-PRESSURE,R

80 141LR4005A PLATE-SHAFT FILM

81 141LR4020A BRACKET-HEATER,LO-R

82 141LR4035A PLATE-DU BUSH

83 141LR4040A PLATE-SLIP

84 141LR4041A BRACKET-FAN

85 141LR4043A FRONT TABLE SAFETY LE VER

86 141LR4054A BRACKET-LIMIT SWITCH

87 141LR4059A BRACKET-SENSOR

88 141LR4060A PLATE-PRESSURE,LAMI

89 141LR4061A PLATE-PRESSURE,PULL

90 141LR4081A BRACKET-HEATER,LO-L

91 141LR4087A BRACKET-HEATER,UP

92 143LR3001A SUPPORTER-SHAFT

93 144LR4001B CLAMPER-LEVER

94 145LR3002A GUIDE-DOCUMENT

95 147LR4002A PAD-TENSION

96 147LR4010A PAD-TAKE UP

97 147LR4013A STOPPER-HEATER,UP

98 210004002A MOTOR-MAIN

99 211003004A FAN

99-1 211003004B FAN

100 213LR4001A CUTTER-CROSS

101 223LR2007B HEATER ASS'Y

101-1 223LR2007C HEATER ASS'Y

101-2 223LR2007D HEATER ASS'Y

101-3 223LR2007F HEATER ASS'Y

102 23200X002A SUPPORT-PCB

103 23300X001A BUSHING-CORD

104 32500X0005 FUSE-MAIN

104-1 32500X0008 FUSE-MAIN

105 34000S011A POWER TRANSFORMER

106 350LR3022A PCB-SUB ASS'Y

107 350LR3036C PCB-MAIN ASS'Y

108 363LP3001A BI-METAL LO

109 363LR4001F BI-METAL UP

110 36400X002B SWITCH-MAIN

111 36400X014B MICRO S/W

112 36600X001A FUSE-HOLDER

113 380CR4003A POWER CORD

113-1 380CR4004A POWER CORD

113-2 380LR4001A POWER CORD

113-3 380LR4001B POWER CORD

113-4 380LR4003A POWER CORD

113-5 380LR4007A POWER CORD

114 381LR4013C WIRE-POWER S/W

115 381LR4020B WIRE-FUSE,EU

116 381LR4030D WIRE-UP HEATER1,EU

117 381LR4043A WIRE-SAFETY S/W

118 381LR4044A WIRE-MAIN

119 381LR4052A WIRE-MOTOR

120 381LR4054A WIRE-LO HEATER2,EU

121 381LR4055A WIRE-UP HEATER2,EU

122 381LR4084A WIRE-T/FUSE(UP)

123 381LR4091A WIRE-LO HEATER1,EU

124 381LR4092A WIRE-T/FUSE(LO)

125 443LR4001A L-WRENCH

126 ASMLR1339A ASM-AUTO GRIP FILM CORE 2"

126-1 ASMLR1339B ASM-AUTO GRIP FILM CO RE3"

127 KPS03012D2 KEY-PLAIN

128 KPS05010D2 KEY-PLAIN

129 RE001000C8 E-RING

130 RC001200C8 SNAP-RING

131 RIV05018E8 RIVET

132 SKE04010D2 SET SCREW

132-1 SKE05006D2 SET SCREW

132-2 SKE05010D2 SET SCREW

132-3 SKE05015D2 SET SCREW

133 013LR4010A FRAME-GUIDE,R

134 013LR4011A FRAME-GUIDE,L

135 141LR4127A BRACKET-DECURLING BAR,R

136 141LR4128A BRACKET-DECURLING BAR,L

137 111LR4022A KNOB-GUIDE

22

Page 25

Frame - L

2 013LR2087A FRAME-L

15 021LR0001A COVER-L

16 021LR2008A COVER-TAKE UP,L

22 021LR4001A LIMIT SWITCH COVER

27 026LR4006A FOOT

32 112004001D NUT

38 12200X009A DU BUSH

41 12200X028A DU BUSH

47 122LR4024A BUSH-ROLLER LAMI,UP

52 124LR4005A CAM

72 138LR4015A SPRING-PRESSURE

77 141LP4018A BRACKET-T/FUSE

78 141LR3017A PLATE-PRESSURE,L

82 141LR4035A PLATE-DU BUSH

86 141LR4054A BRACKET-LIMIT SWITCH

88 141LR4060A PLATE-PRESSURE,LAMI

89 141LR4061A PLATE-PRESSURE,PULL

90 141LR4081A BRACKET-HEATER,LO-L

91 141LR4087A BRACKET-HEATER,UP

92 143LR3001A SUPPORTER-SHAFT

97 147LR4013A STOPPER-HEATER,UP

108 363LP3001A BI-METAL LO

111 36400X014B MICRO S/W

128 KPS05010D2 KEY-PLAIN

129 RE001000C8 E-RING

23

Page 26

Frame - R

3 013LR2088A FRAME-R

17 021LR2013A COVER-TAKE UP,R

20 021LR3018A COVER-R

23 023LR3005A BUTTON-FUNC

25 023LR4004A KNOB-TENSION

26 023LR4007A KNOB-LEVEL

27 026LR4006A FOOT

37 12200X005A BEARING-TRUST NEEDLE

39 12200X022A BEARING-RADIAL TRUST

41 12200X028A DU BUSH

47 122LR4024A BUSH-ROLLER LAMI,UP

52 124LR4005A CAM

54 125LR4001A HANDLE-TENSION

55 125LR4003B LEVER-PRESSURE

56 125LR4004A SHAFT-TENSION 2

57 125LR4008A SUPPORT-SPRING

58 131LR4017A SPROCKET-LAMI

59 131LR4022B SPROCKET-DOUBLE

60 131LR4023A SPROCKET-TAKE UP

61 131LR4034A SPROCKET-MOTOR

66 134LR4001A PULLEY-CHAIN

67 134LR4003A BUSH-PULLEY

68 136LR4001C CHAIN

69 136LR4001G CHAIN-2(TAKE UP)

71 138LR4012A SPRING-TENSION

72 138LR4015A SPRING-PRESSURE

73 138LR4018A SPRING-LEVER

79 141LR3018A PLATE-PRESSURE,R

81 141LR4020A BRACKET-HEATER,LO-R

83 141LR4040A PLATE-SLIP

88 141LR4060A PLATE-PRESSURE,LAMI

89 141LR4061A PLATE-PRESSURE,PULL

91 141LR4087A BRACKET-HEATER,UP

93 144LR4001B CLAMPER-LEVER

96 147LR4010A PAD-TAKE UP

97 147LR4013A STOPPER-HEATER,UP

98 210004002A MOTOR-MAIN

104 32500X0005 FUSE-MAIN

104-1 32500X0008 FUSE-MAIN

106 350LR3022A PCB-SUB ASS'Y

109 363LR4001F BI-METAL UP

112 36600X001A FUSE-HOLDER

125 443LR4001A L-WRENCH

127 KPS03012D2 KEY-PLAIN

128 KPS05010D2 KEY-PLAIN

130 RC001200C8 SNAP-RING

132 SKE04010D2 SET SCREW

132-1 SKE05006D2 SET SCREW

132-2 SKE05010D2 SET SCREW

132-3 SKE05015D2 SET SCREW

24

Page 27

Frame, Roller and Other View

1 013LR2012F FRAME-SENSOR

2 013LR2087A FRAME-L

3 013LR2088A FRAME-R

4 013LR3002K FRAME-CUTTER

5 013LR3009A FRAME-REAR

6 013LR3021A PLATE-MIDDLE

7 013LR3075A BASE-FRONT

8 013LR3076A BASE-REAR

9 013LR4004A FRAME-COVER SAFETY

10 014LR3001A TABLE-FRONT

11 015LR2001B IDLE BAR LOW

12 015LR3011A IDLE-BAR

13 015LR3012A SHAFT-DECURLING

14 021CR3001A KNOB-CUTTER,C

18 ASMLR1602A ASM-SENSOR

19 ASMLR1608A ASM-SENSOR

21 021LR3024B COVER-SAFETY

24 023LR4002A KNOB-BOLT GUIDE

27 026LR4006A FOOT

28 032LR3002A SHEET-FUNC

29 111LR4004A BOLT-CORE

30 111LR4006A BOLT-GUIDE

31 111LR4018A SCREW-H

32 112004001D NUT

33 120LR3004G SHAFT-FILM,L

34 120LR3023A SHAFT-CAM

35 120LR4008A SHAFT-TABLE

36 120LR4014A SHAFT-TAKE UP

37 12200X005A BEARING-TRUST NEEDLE

40 12200X027A DU BUSH

42 12200X029A DU BUSH

43 12200X030A DU BUSH

44 12200X032A DU BUSH

45 12200X034A DU BUSH

46 12200X040A DU BUSH

48 122LR4026A BUSH-ROLLER PULL,UP

49 122LR4042A BUSH-ROLLER LAMI,LO-LEFT

50 122LR4047A BUSH-ROLLER PULL,LO

51 122LR4050A BUSH-ROLLER LAMI,LO-RIGHT ASS'Y

53 124LR4006A 1"CORE

62 133LR2021A ROLLER-LAMI,LO

63 133LR2021B ROLLER-LAMI,UP

64 133LR2022A ROLLER-PULL,LO

65 133LR2022B ROLLER-PULL,UP

70 138LR4001A SPRING-CUTTER CROSS

74 140LR3001A HOLDER-CUTTER,C

75 140LR4001A HOLDER-SHAFT FILM

76 140LR4021A HOLDER-SHAFT,T

80 141LR4005A PLATE-SHAFT FILM

84 141LR4041A BRACKET-FAN

85 141LR4043A FRONT TABLE SAFETY LEVER

87 141LR4059A BRACKET-SENSOR

94 145LR3002A GUIDE-DOCUMENT

95 147LR4002A PAD-TENSION

99 211003004A FAN

99-1 211003004B FAN

100 213LR4001A CUTTER-CROSS

101 223LR2007B HEATER ASS'Y

101-1 223LR2007C HEATER ASS'Y

101-2 223LR2007D HEATER ASS'Y

101-3 223LR2007F HEATER ASS'Y

102 23200X002A SUPPORT-PCB

103 23300X001A BUSHING-CORD

105 34000S011A POWER TRANSFORMER

107 350LR3036C PCB-MAIN ASS'Y

110 36400X002B SWITCH-MAIN

124 381LR4092A WIRE-T/FUSE(LO)

126 ASMLR1339A ASM-AUTO GRIP FILM CORE 2"

126-1 ASMLR1339B ASM-AUTO GRIP FILM CORE3"

131 RIV05018E8 RIVET

133 013LR4010A FRAME-GUIDE,R

134 013LR4011A FRAME-GUIDE,L

135 141LR4127A BRACKET-DECURLING BAR,R

136 141LR4128A BRACKET-DECURLING BAR,L

137 111LR4022A KNOB-GUIDE

25

Page 28

Wire, Film Shaft,Ass'y-Auto

29 111LR4004A BOLT-CORE

36 120LR4014A SHAFT-TAKE UP

45 12200X034A DU BUSH

53 124LR4006A 1"CORE

113 380CR4003A POWER CORD

113-1 380CR4004A POWER CORD

113-2 380LR4001A POWER CORD

113-3 380LR4001B POWER CORD

113-4 380LR4003A POWER CORD

113-5 380LR4007A POWER CORD

114 381LR4013C WIRE-POWER S/W

115 381LR4020B WIRE-FUSE,EU

116 381LR4030D WIRE-UP HEATER1,EU

117 381LR4043A WIRE-SAFETY S/W

118 381LR4044A WIRE-MAIN

119 381LR4052A WIRE-MOTOR

120 381LR4054A WIRE-LO HEATER2,EU

121 381LR4055A WIRE-UP HEATER2,EU

122 381LR4084A WIRE-T/FUSE(UP)

123 381LR4091A WIRE-LO HEATER1,EU

125 443LR4001A L-WRENCH

126 ASMLR1339A ASM-AUTO GRIP FILM CORE 2"

126-1 ASMLR1339B ASM-AUTO GRIP FILM CORE3"

131 RIV05018E8 RIVET

132 SKE04010D2 SET SCREW

132-1 SKE05006D2 SET SCREW

132-2 SKE05010D2 SET SCREW

132-3 SKE05015D2 SET SCREW

26

Page 29

RSL-382S Expolde View

27

1 013LR2012G FRAME-SENSOR

2 013LR2087A FRAME-L

3 013LR2088A FRAME-R

4 013LR3002H FRAME-CUTTER

5 013LR3035A FRAME-REAR

6 013LR3036A PLATE-MIDDLE

7 013LR3069A BASE-FRONT

8 013LR3070A BASE-REAR

9 013LR4004A FRAME-COVER SAFETY

10 014LR3001B TABLE-FRONT

11 015LR2010A IDLE BAR LOW

12 015LR3011B IDLE-BAR

13 015LR3012B SHAFT-DECURLING

14 021CR3001A KNOB-CUTTER,C

15 021LR0001A COVER-L

16 021LR2008A COVER-TAKE UP,L

17 021LR2013A COVER-TAKE UP,R

18 ASMLR1604A ASM-SENSOR

19 ASMLR1608A ASM-SENSOR

20 021LR3018A COVER-R

21 021LR3024A COVER-SAFETY

22 021LR4001A LIMIT SWITCH COVER

23 023LR3005A BUTTON-FUNC

24 023LR4002A KNOB-BOLT GUIDE

25 023LR4004A KNOB-TENSION

26 023LR4010A KNOB-LEVEL

27 026LR4006A FOOT

28 032LR3002A SHEET-FUNC

29 111LR4004A BOLT-CORE

30 111LR4006A BOLT-GUIDE

31 111LR4018A SCREW-H

32 112004001D NUT

33 120LR3004E SHAFT-FILM,L

34 120LR3031B SHAFT-CAM

35 120LR4008A SHAFT-TABLE

36 120LR4014C SHAFT-TAKE UP

37 12200X005A BEARING-TRUST NEEDLE

38 12200X009A DU BUSH

39 12200X022A BEARING-RADIAL TRUST

40 12200X027A DU BUSH

41 12200X028A DU BUSH

42 12200X029A DU BUSH

43 12200X030A DU BUSH

44 12200X032A DU BUSH

45 12200X034A DU BUSH

46 12200X040A DU BUSH

47 122LR4024A BUSH-ROLLER LAMI,UP

48 122LR4026A BUSH-ROLLER PULL,UP

49 122LR4042A BUSH-ROLLER LAMI,LO-LEFT

50 122LR4047A BUSH-ROLLER PULL,LO

51 122LR4050A BUSH-ROLLER LAMI,LO-RIGHT ASS'Y

52 124LR4005A CAM

53 124LR4006A 1"CORE

54 125LR4001A HANDLE-TENSION

55 125LR4003B LEVER-PRESSURE

56 125LR4004A SHAFT-TENSION 2

57 125LR4008A SUPPORT-SPRING

58 131LR4017A SPROCKET-LAMI

59 131LR4022B SPROCKET-DOUBLE

60 131LR4023A SPROCKET-TAKE UP

61 131LR4034A SPROCKET-MOTOR

62 133LR3001A ROLLER-LAMI

64 133LR3002A ROLLER-PULL

66 134LR4001A PULLEY-CHAIN

67 134LR4003A BUSH-PULLEY

68 136LR4001C CHAIN

69 136LR4001G CHAIN-2(TAKE UP)

70 138LR4001A SPRING-CUTTER CROSS

71 138LR4012A SPRING-TENSION

72 138LR4015A SPRING-PRESSURE

73 138LR4018A SPRING-LEVER

74 140LR3001A HOLDER-CUTTER,C

75 140LR4001A HOLDER-SHAFT FILM

76 140LR4021A HOLDER-SHAFT,T

77 141LP4018A BRACKET-T/FUSE

78 141LR3017A PLATE-PRESSURE,L

79 141LR3018A PLATE-PRESSURE,R

80 141LR4005A PLATE-SHAFT FILM

81 141LR4020A BRACKET-HEATER,LO-R

82 141LR4035A PLATE-DU BUSH

83 141LR4040A PLATE-SLIP

85 141LR4043A FRONT TABLE SAFETY LEVER

86 141LR4054A BRACKET-LIMIT SWITCH

87 141LR4059A BRACKET-SENSOR

88 141LR4060A PLATE-PRESSURE,LAMI

89 141LR4061A PLATE-PRESSURE,PULL

90 141LR4081A BRACKET-HEATER,LO-L

91 141LR4087A BRACKET-HEATER,UP

92 143LR3001A SUPPORTER-SHAFT

93 144LR4001B CLAMPER-LEVER

94 145LR3002A GUIDE-DOCUMENT

95 147LR4002A PAD-TENSION

96 147LR4010A PAD-TAKE UP

97 147LR4013A STOPPER-HEATER,UP

98 210004002A MOTOR-MAIN

100 213LR4001A CUTTER-CROSS

101 223LR3001H HEATER ASS'Y

101-1 223LR3001J HEATER ASS'Y

102 23200X001A SUPPORT-PCB

103 23300X001A BUSHING-CORD

104 32500X0008 FUSE-MAIN

105 34000S011A POWER TRANSFORMER

106 350LR3022A PCB-SUB ASS'Y

107 350LR3036C PCB-MAIN ASS'Y

108 363LP4013A BI-METAL UP

109 033LR4002A WASHER-BI METAL

110 36400X002B SWITCH-MAIN

111 36400X014B MICRO S/W

112 36600X001A FUSE-HOLDER

113 380LR4001A POWER CORD

113-1 380LR4003A POWER CORD

113-2 380LR4007A POWER CORD

114 381LR4013J WIRE-POWER S/W

115 381LR4020B WIRE-FUSE,EU

116 381LR4030D WIRE-UP HEATER1,EU

118 381LR4044B WIRE-MAIN

119 381LR4052A WIRE-MOTOR

120 381LR4054A WIRE-LO HEATER2,EU

121 381LR4055A WIRE-UP HEATER2,EU

122 381LR4084A WIRE-T/FUSE(UP)

123 381LR4091A WIRE-LO HEATER1,EU

124 381LR4092B WIRE-T/FUSE(LO)

125 443LR4001A L-WRENCH

126 ASMLR1339A ASM-AUTO GRIP FILM CORE 2"

126-1 ASMLR1339B ASM-AUTO GRIP FILM CORE3"

127 KPS03012D2 KEY-PLAIN

128 KPS05010D2 KEY-PLAIN

129 RC001200C8 SNAP-RING

130 RE001000C8 E-RING

131 RIV05018E8 RIVET

132 SKE04010D2 SET SCREW

132-1 SKE05006D2 SET SCREW

132-2 SKE05010D2 SET SCREW

132-3 SKE05015D2 SET SCREW

133 013LR4010A FRAME-GUIDE,R

134 013LR4011A FRAME-GUIDE,L

135 141LR4127A BRACKET-DECURLING BAR,R

136 141LR4128A BRACKET-DECURLING BAR,L

137 111LR4022A KNOB-GUIDE

Page 30

Frame - L

2 013LR2087A FRAME-L

15 021LR0001A COVER-L

16 021LR2008A COVER-TAKE UP,L

22 021LR4001A LIMIT SWITCH COVER

27 026LR4006A FOOT

32 112004001D NUT

38 12200X009A DU BUSH

41 12200X028A DU BUSH

47 122LR4024A BUSH-ROLLER LAMI,UP

52 124LR4005A CAM

72 138LR4015A SPRING-PRESSURE

77 141LP4018A BRACKET-T/FUSE

78 141LR3017A PLATE-PRESSURE,L

82 141LR4035A PLATE-DU BUSH

86 141LR4054A BRACKET-LIMIT SWITCH

88 141LR4060A PLATE-PRESSURE,LAMI

89 141LR4061A PLATE-PRESSURE,PULL

90 141LR4081A BRACKET-HEATER,LO-L

91 141LR4087A BRACKET-HEATER,UP

92 143LR3001A SUPPORTER-SHAFT

97 147LR4013A STOPPER-HEATER,UP

108 363LP4013A BI-METAL UP

111 36400X014B MICRO S/W

128 KPS05010D2 KEY-PLAIN

129 RC001200C8 SNAP-RING

28

Page 31

Frame - R

3 013LR2088A FRAME-R

17 021LR2013A COVER-TAKE UP,R

20 021LR3018A COVER-R

23 023LR3005A BUTTON-FUNC

25 023LR4004A KNOB-TENSION

26 023LR4010A KNOB-LEVEL

27 026LR4006A FOOT

37 12200X005A BEARING-TRUST NEEDLE

39 12200X022A BEARING-RADIAL TRUST

41 12200X028A DU BUSH

47 122LR4024A BUSH-ROLLER LAMI,UP

52 124LR4005A CAM

54 125LR4001A HANDLE-TENSION

55 125LR4003B LEVER-PRESSURE

56 125LR4004A SHAFT-TENSION 2

57 125LR4008A SUPPORT-SPRING

58 131LR4017A SPROCKET-LAMI

59 131LR4022B SPROCKET-DOUBLE

60 131LR4023A SPROCKET-TAKE UP

61 131LR4034A SPROCKET-MOTOR

66 134LR4001A PULLEY-CHAIN

67 134LR4003A BUSH-PULLEY

68 136LR4001C CHAIN

69 136LR4001G CHAIN-2(TAKE UP)

71 138LR4012A SPRING-TENSION

72 138LR4015A SPRING-PRESSURE

73 138LR4018A SPRING-LEVER

79 141LR3018A PLATE-PRESSURE,R

81 141LR4020A BRACKET-HEATER,LO-R

83 141LR4040A PLATE-SLIP

88 141LR4060A PLATE-PRESSURE,LAMI

89 141LR4061A PLATE-PRESSURE,PULL

91 141LR4087A BRACKET-HEATER,UP

93 144LR4001B CLAMPER-LEVER

96 147LR4010A PAD-TAKE UP

97 147LR4013A STOPPER-HEATER,UP

98 210004002A MOTOR-MAIN

104 32500X0008 FUSE-MAIN

106 350LR3022A PCB-SUB ASS'Y

109 033LR4002A WASHER-BI METAL

112 36600X001A FUSE-HOLDER

125 443LR4001A L-WRENCH

127 KPS03012D2 KEY-PLAIN

128 KPS05010D2 KEY-PLAIN

130 RE001000C8 E-RING

132 SKE04010D2 SET SCREW

132-1 SKE05006D2 SET SCREW

132-2 SKE05010D2 SET SCREW

132-3 SKE05015D2 SET SCREW

29

Page 32

Frame, Roller and Other View

1 013LR2012G FRAME-SENSOR

2 013LR2087A FRAME-L

3 013LR2088A FRAME-R

4 013LR3002H FRAME-CUTTER

5 013LR3035A FRAME-REAR

6 013LR3036A PLATE-MIDDLE

7 013LR3069A BASE-FRONT

8 013LR3070A BASE-REAR

9 013LR4004A FRAME-COVER SAFETY

10 014LR3001B TABLE-FRONT

11 015LR2010A IDLE BAR LOW

12 015LR3011B IDLE-BAR

13 015LR3012B SHAFT-DECURLING

14 021CR3001A KNOB-CUTTER,C

18 ASMLR1604A ASM-SENSOR

19 ASMLR1608A ASM-SENSOR

21 021LR3024A COVER-SAFETY

24 023LR4002A KNOB-BOLT GUIDE

27 026LR4006A FOOT

28 032LR3002A SHEET-FUNC

29 111LR4004A BOLT-CORE

30 111LR4006A BOLT-GUIDE

31 111LR4018A SCREW-H

32 112004001D NUT

33 120LR3004E SHAFT-FILM,L

34 120LR3031B SHAFT-CAM

35 120LR4008A SHAFT-TABLE

36 120LR4014C SHAFT-TAKE UP

37 12200X005A BEARING-TRUST NEEDLE

40 12200X027A DU BUSH

42 12200X029A DU BUSH

43 12200X030A DU BUSH

44 12200X032A DU BUSH

45 12200X034A DU BUSH

46 12200X040A DU BUSH

48 122LR4026A BUSH-ROLLER PULL,UP

49 122LR4042A BUSH-ROLLER LAMI,LO-LEFT

50 122LR4047A BUSH-ROLLER PULL,LO

51 122LR4050A BUSH-ROLLER LAMI,LO-RIGHT ASS'Y

53 124LR4006A 1"CORE

62 133LR3001A ROLLER-LAMI

64 133LR3002A ROLLER-PULL

70 138LR4001A SPRING-CUTTER CROSS

74 140LR3001A HOLDER-CUTTER,C

75 140LR4001A HOLDER-SHAFT FILM

76 140LR4021A HOLDER-SHAFT,T

80 141LR4005A PLATE-SHAFT FILM

85 141LR4043A FRONT TABLE SAFETY LEVER

87 141LR4059A BRACKET-SENSOR

94 145LR3002A GUIDE-DOCUMENT

95 147LR4002A PAD-TENSION

100 213LR4001A CUTTER-CROSS

101 223LR3001H HEATER ASS'Y

101-1 223LR3001J HEATER ASS'Y

102 23200X001A SUPPORT-PCB

103 23300X001A BUSHING-CORD

105 34000S011A POWER TRANSFORMER

107 350LR3036C PCB-MAIN ASS'Y

110 36400X002B SWITCH-MAIN

124 381LR4092B WIRE-T/FUSE(LO)

126 ASMLR1339A ASM-AUTO GRIP FILM CORE 2"

126-1 ASMLR1339B ASM-AUTO GRIP FILM CORE3"

131 RIV05018E8 RIVET

133 013LR4010A FRAME-GUIDE,R

134 013LR4011A FRAME-GUIDE,L

135 141LR4127A BRACKET-DECURLING BAR,R

136 141LR4128A BRACKET-DECURLING BAR,L

137 111LR4022A KNOB-GUIDE

30

Page 33

Wire, Front Table, Film Shaft

29 111LR4004A BOLT-CORE

36 120LR4014C SHAFT-TAKE UP

45 12200X034A DU BUSH

53 124LR4006A 1"CORE

113 380LR4001A POWER CORD

113-1 380LR4003A POWER CORD

113-2 380LR4007A POWER CORD

114 381LR4013J WIRE-POWER S/W

115 381LR4020B WIRE-FUSE,EU

116 381LR4030D WIRE-UP HEATER1,EU

118 381LR4044B WIRE-MAIN

119 381LR4052A WIRE-MOTOR

120 381LR4054A WIRE-LO HEATER2,EU

121 381LR4055A WIRE-UP HEATER2,EU

122 381LR4084A WIRE-T/FUSE(UP)

123 381LR4091A WIRE-LO HEATER1,EU

125 443LR4001A L-WRENCH

126 ASMLR1339A ASM-AUTO GRIP FILM CORE 2"

126-1 ASMLR1339B ASM-AUTO GRIP FILM CORE3"

131 RIV05018E8 RIVET

132 SKE04010D2 SET SCREW

132-1 SKE05006D2 SET SCREW

132-2 SKE05010D2 SET SCREW

132-3 SKE05015D2 SET SCREW

31

Page 34

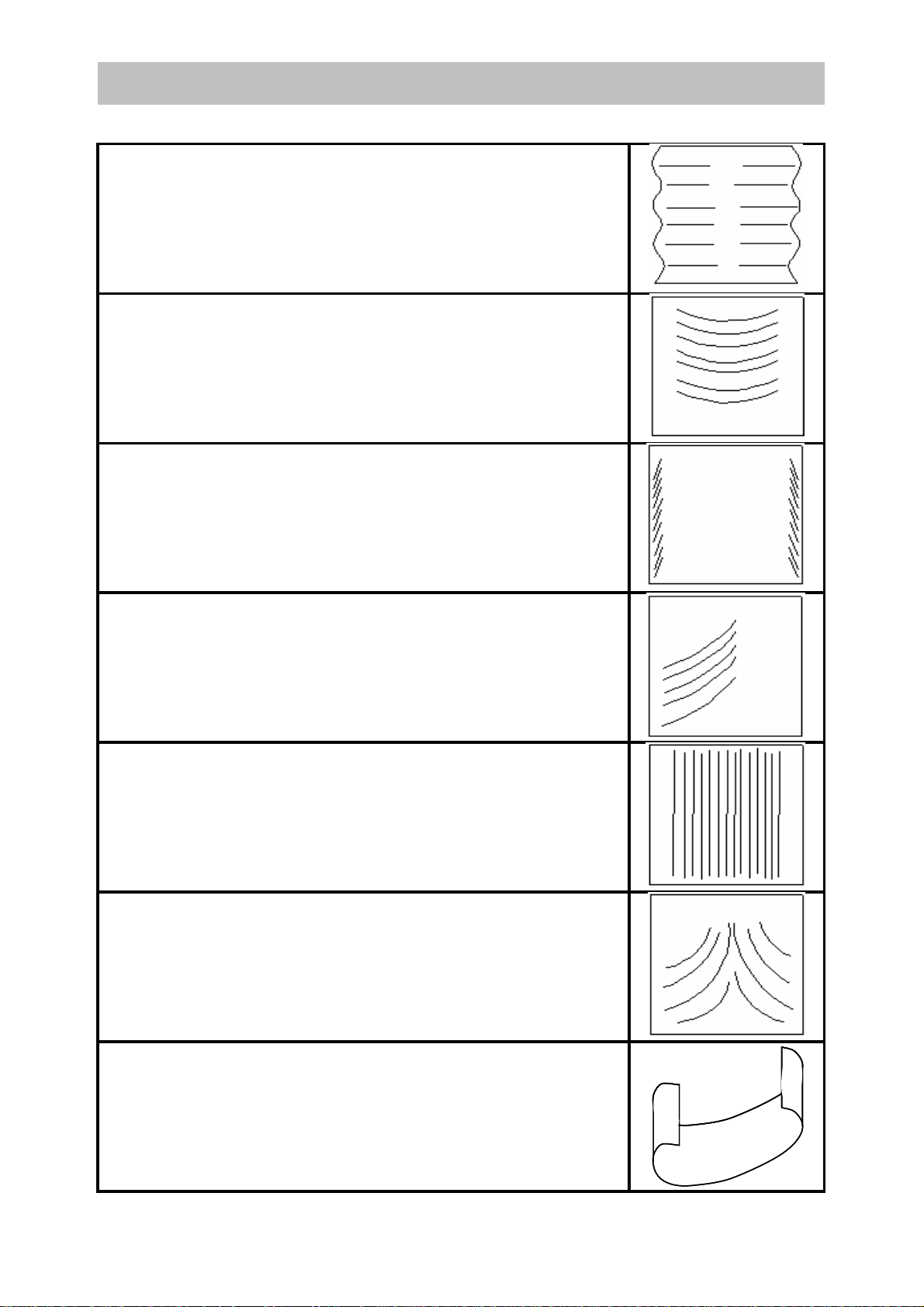

7. RSL-2702S,RSL-382S Wire Diagram

32

Page 35

③

②

①

⑨

④

<Connect part>

1. Wire Main. 6. Wire Up Heater.

2. Wire Sensor Up 7. Wire Fan(2EA)

3. Wire Sensor Low 8. Wire Power Transformer In

4. Wire Power 9. Motor wires

5. Wire Low Heater 10. Wires Power Transformer Output

⑤⑥

33

⑦⑧

⑩

Page 36

<SUB PCB and Frame-R Heater Layout>

Bimetal(145℃)

Wire Bimetal

SUB PCB

Wire Up Heater

Wire Up Sensor

Power Cord

Fuse Main

Wire Lo Heater

Motor

34

Power cord

Wire-Fuse

Wire power

Page 37

<MICRO SWITCH and Frame-L Heater Layout>

Wire Bimetal

Wire Motor

Wire Safety S/W

Bimetal (130℃)

Wire F/Fuse (133℃)

Wire F/Fuse (133℃)

Safety Cover Micro S/W

35

Front Table Micro S/W

Loading...

Loading...