Page 1

MODEL:RSH-380SL

Roll Laminator Service Manual

Page 2

…

…

…

…

…

…

…

Table of Content

…

…

…

…

…

1.Safety Precautions ………………………………………………………………………

2.Troubleshooting ……………………………………………………………………………

2.1) Rollers Not Heating ………………………………………………………………………

2.2) Rollers Over Heating ………………………………………………………………………

2.3) Rollers Not Running ………………………………………………………………………

2.4) No Main Power ………………………………………………………………………………

2.5) Poor Lamination Quality …………………………………………………………………

3.Replacing Parts ………………………………………………………………………………

3.1) Right Cover …………………………………………………………………………………

3.2) Left Cover …………………………………………………………………………………

3.3) Rear Cover …………………………………………………………………………………

3.4) Main PCB ……………………………………………………………………………………

3 ~ 3

4 ~ 10

4 ~ 6

6 ~ 7

7 ~ 9

9 ~ 10

11 ~ 11

12 ~ 14

12 ~ 12

13 ~ 13

13 ~ 13

13 ~ 13

3.5) Sub PCB ………………………………………………………………………………………

3.6) Heaters ………………………………………………………………………………………

3.7) Cross Cutter …………………………………………………………………………………

4.Adjustments ……………………………………………………………………………………

5. Parts List …………………………………………………………………………………………

6.Exploded Drawings ………………………………………………………………………

7.Wire Diagram …………………………………………………………………………………

8.Backup ……………………………………………………………………………………………

13 ~ 13

13 ~ 14

14 ~ 14

15 ~ 16

17 ~ 19

20 ~ 25

26 ~ 29

30 ~ 33

Page 3

Failure to comply any of the following safety procedures could result in serious injury.

Please read the instructions carefully and keep for future reference.

1. Only a licensed electrician should install wiring and outlet for the laminator.

2. Ensure the unit is plugged into a properly grounded outlet with the correct

voltage.

3. Keep hands and clothing(ie.Neckties)away from rollers. The rollers are pinch points that

can trap body parts or clothing and cause serious injury .

Safety Precaution

4. Keep flammable and wet objects away from the machine .

5. Place machine on a level surface.

6. Avoid excessive sunlight, humidity and extreme temperatures.

1. Safety Precautions

7. Ensure the unit is turned off, cooled ,and unplugged from the outlet prior to moving

and/or repairing.

8. Keep out of reach of children.

9. Only Royal Sovereign authorized maintenance and service technicians should make

repairs.

10. Do not attempt to laminate items that exceed total recommended material thickness for

the unit.

11. When cleaning the machine, don't use flammable sprays or materials.

12. Do not touch the rollers when they are hot or place foreign objects inside the machine.

13. Do not cover the surface of the machine until the machine has completely cooled.

1

Page 4

2. Troubleshooting

Note: While repairing:

a. Make sure the power plug is unplugged from the power outlet.

b. Open both side covers and rear cover.

c. Be sure to follow the steps below in order.

2.1 Rollers Not Heating

CAUSES:

1. Improper laminating mode.

2. Heating wire is not connected to the main PCB.

3. Blown (burnt) upper and/or lower wire fuse (T/Fuse).

4. Defective Bi-Metal.

5. Defective heater.

6. Defective Main PCB.

MEASURE

1. Heating wire is not connected to the main PCB.

a. Connect the upper and lower heating wires to the main PCB.

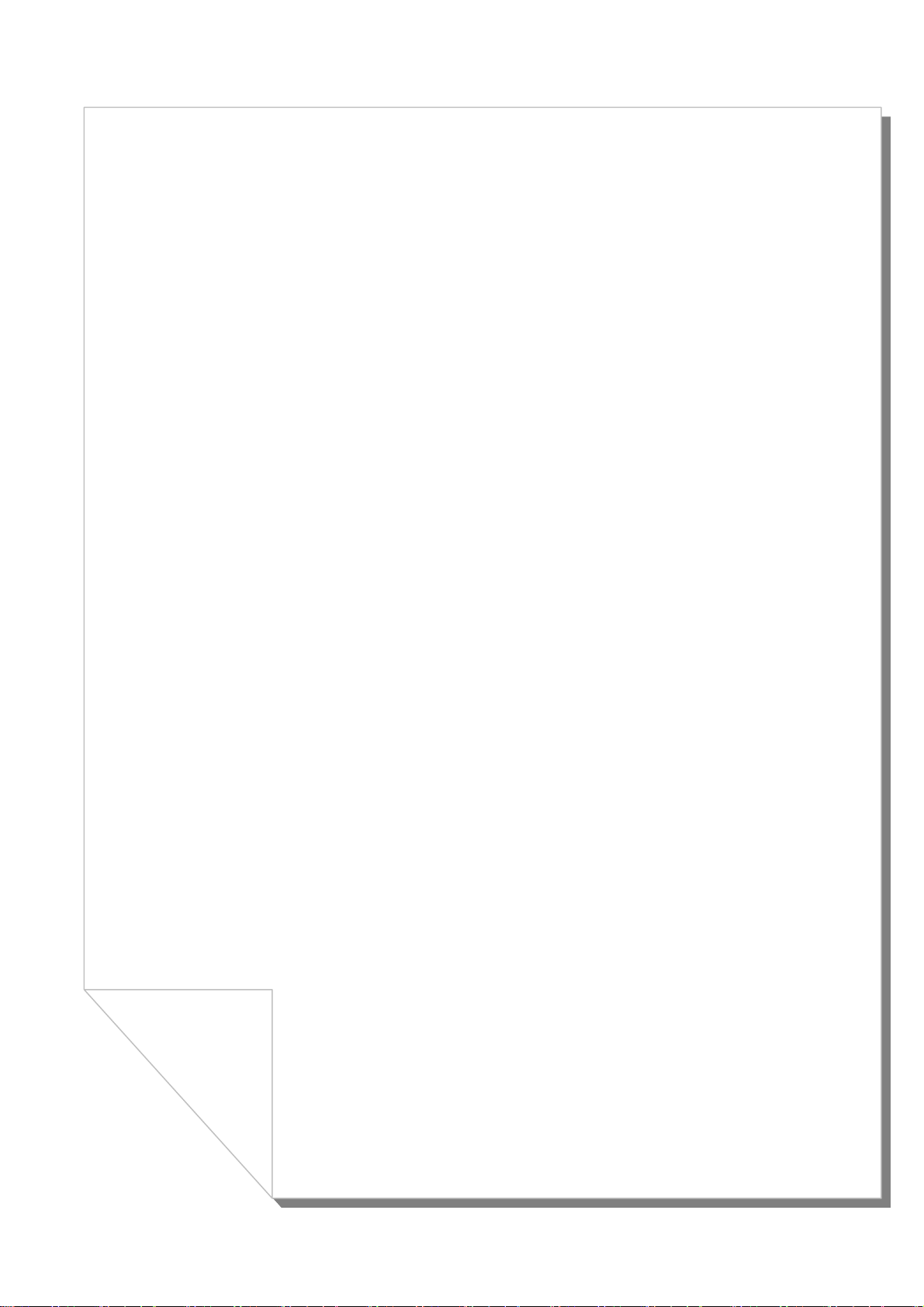

Wire-Heater

Wire-Heater

2

Page 5

2. Blown (burnt) wire fuse (T/Fuse).

a. Replace the T/Fuse wire located on the left-hand side.

3. Defective Bi-Metal.

a. Replace the Bi-Metal

Wire-Temp. Fuse

Bi-metal (135℃)

4. Defective heater.

a. Using the multi-meter, test the continuity of the heater. If it fails, replace the heater.

Multi-meter

b. Physically examine the heater assembly for breakage.

Broken

3

Page 6

5. Defective Main PCB.

a. Replace the PCB Main.

2.2 Rollers Over Heating

CAUSES

1. Heat sensor is reversed on the PCB Main.

2. Defective T/Fuse wire.

3. Defective heater.

4. Defective main PCB.

MEASURES

1. Wires for lower and upper heat sensors are reversed on the main PCB.

a. Reverse the heat sensors.

Connector-Wire Sensor

2. Defective T/Fuse wire.

a. Replace the T/Fuse wire located on the left-hand side.

Wire-T / Fuse

3. Defective heater.

a. Test continuity of the heater. If it fails, replace the heater.

b. Glass tube that surrounds heating coil is broken – replace the heating element.

4

Page 7

4. Defective Main PCB.

a. Replace the PCB Main.

2.3 Rollers Not Running

CAUSES

1. No power to the unit.

2. The main switch is close.

3. Opened safety cover.

4. Film is jammed on the rollers.

5. Disconnected motor wire.

6. Defective main motor.

7. Defective main PCB.

MEASURES

1. No power to the unit.

a. Make sure the power plug is connected to the proper source of outlet

2. The main switch is close.

Main Switch

3. Opened safety cover.

a. Close the safety cover and double check to insure that the safety cover switch

is engaged.

Note: By closing the safety cover, it engages the safety cover switch.

5

Page 8

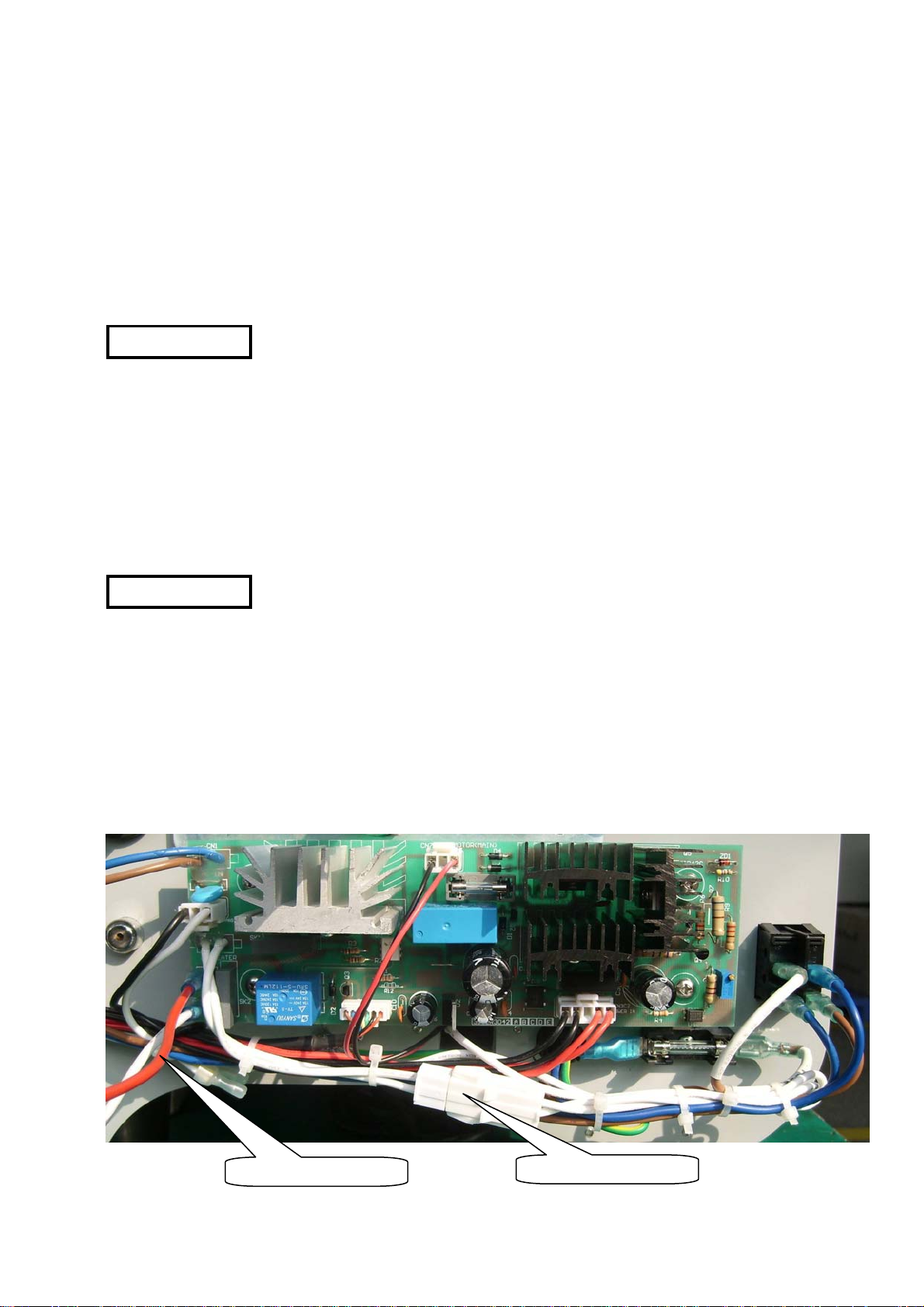

Switch is engaged

4. Film is jammed on the rollers.

a. Un-jam the film using a combination of the pressure lever and reverse button.

5. Disconnected motor wire.

a. Check the motor wire connection with PCB.

6. Defective main motor.

a. Replace the main motor.

Wire-motor

Motor

6

Page 9

7. Defective main PCB.

a. Replace the main PCB.

2.4 No Main Power

CAUSES

1. No electricity.

2. Blown main fuse.

3. Disconnected main power wires.

4. Defective transformer.

MEASURES

1. No Electricity.

a. Double check to insure that you have electricity from your outlet.

b. Check the circuit breaker.

c. Double check that source of power is 220V, 15Amp, and single phase.

2. Blown main fuse.

a. Replace the main fuse located above the main power switch.

3. Disconnected main power wires.

a. Check that the main power wires are properly connected.

Main Fuse

Main Power Wires

7

Page 10

4. Transformer is defective

a. Replace the transformer.

Transformer

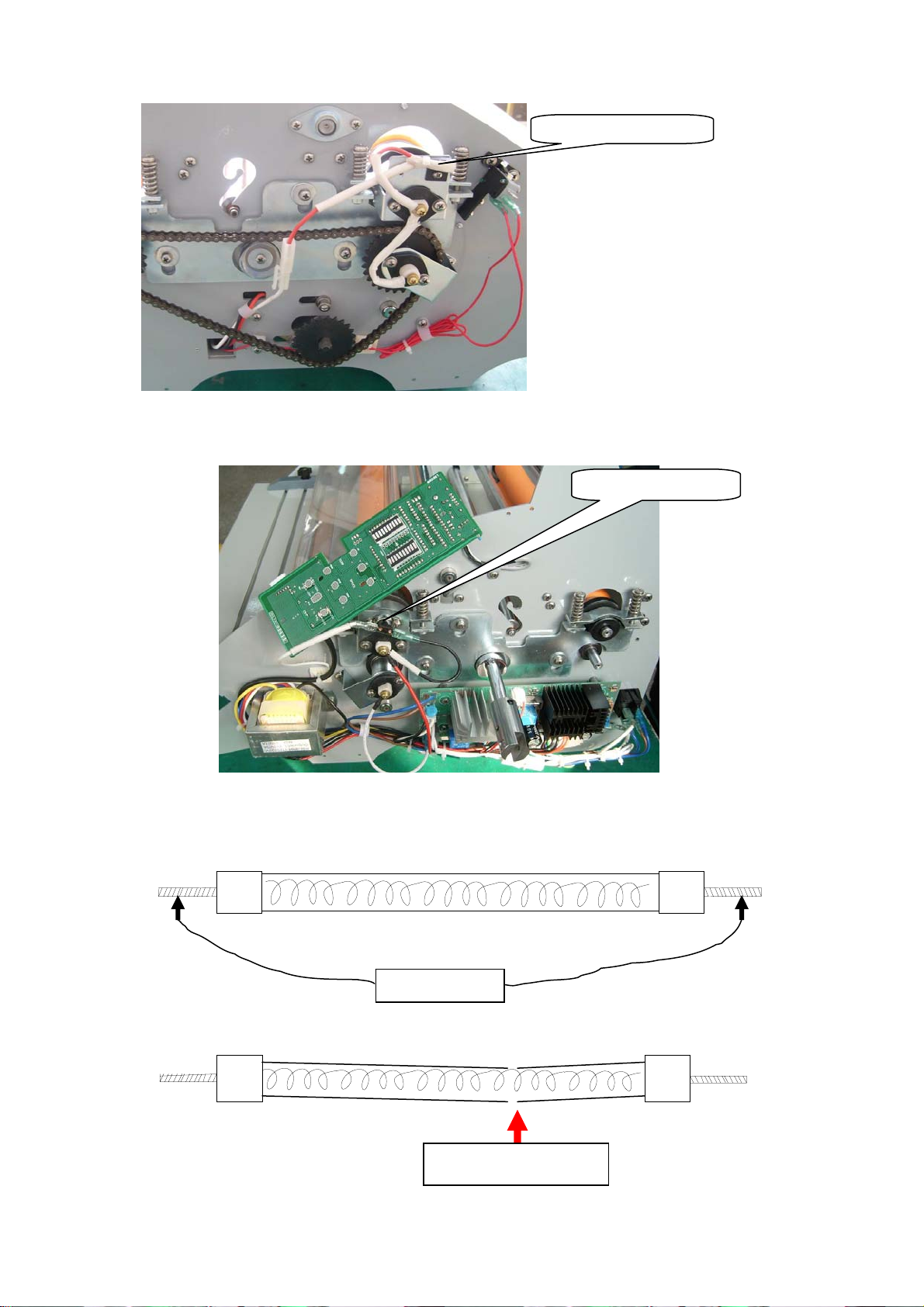

2.5 Poor Lamination Quality

Problem: Straight wave lines across the output.

Cause: Excessive front roller pressure.

Measure: Loosen the front roller pressure.

Problem: Concave waves in the lamination.

Cause: Excessive rear (pulling) roller pressure.

Measure: Loosen the rear back roller pressure.

Problem: Angled waves on both sides of the output.

Cause: Insufficient rear roller pressure.

Measure: Tighten the rear roller pressure.

Problem: Angled waves on one side of the output.

Cause: Insufficient rear left (or right) side roller pressure.

Measure: Tighten the rear left (or right) side roller pressure.

Problem: Straight waves in the output.

Cause: Excessive heat at the nip rollers.

Measure: Lower the roller temperature.

Problem: Wake waves.

Cause: Insufficient heat at the nip rollers.

Measure: Raise the roller temperature.

Problem: Curling.

Cause: 1.The film tension is very tight;

2.The decurling bar is not in the working location.

Measure: 1.Loose the tension;2.Adjust the decurling bar to working location.

8

Page 11

3. Replacing Parts

Note: While replacing parts:

a. Make sure the power plug is unplugged from the power outlet.

b. Open both side covers and rear cover.

3.1 Replacing the Right Cover.

a. Take out the pressure lever (Figure 1) and four cover screws using Phillips screw driver (Figure 2).

Figure 1

b. Pull out the male control panel connector from the Sub-PCB( Figure 3).

Figure

3.2 Replacing the Sub-PCB

a. Refer to “Replacing Right Cover”.

c. Loosen two screws from Sub-PCB , installed on to new Right Cover (Figure 4).

Figure

d. Follow the reverse order to assemble the Right Cover back.

Figure

3.3 Replacing the Main PCB

a. Remove the rear cover and label all the wires before unplugging from the Main PCB.

b. Detach the Main PCB from 6 white plastic holders ( Figure 7).

c. Replace the board with new PCB and connect all the wires.

Figure

9

Page 12

3.4 Replacing the Heaters

Note: Cotton or surgical gloves are recommended while handling the heater assembly.

a. Disassemble Right and Left Covers (Refer to “Replacing Right Cover” and “Replacing Left Cover”).

b. Take out the heater brackets on each side by loosening screws (Figure 8, 9).

Figure8

c. Take out the broken heater. Figure 10

Figure 1

Note:

a. When inserting the heater into the roller, rotate the heater slightly and push the rod in gently.

b. Use an air blower to blow out the broken pieces of heating rod.

(Please ensure that no one is standing on the other side.)

Figure9

3.5 Replacing the Cross Cutter

a. Disassemble the nut from the Frame-Cutter.

b. Unfasten the spring from the cutter.

c. Change the Cutter.

d. Assemble the Cutter by reversing the above steps.

10

Page 13

s

4. Adjustments

.2 Adjusting front and rear roller

Pressure

• Use Screwdriver

to adjust the roller pressure:

C.W – Increase pressure.

C.C.W – Decrease pressure.

1.Using Push-Pull Scale, measure

3 spots as shown on Figure B &C:

Front roller should be 5~6 and back

rollers should be 6~8.

2.Checking for over all tension –

C.C.W

C.W

Figure A

when the machine is running, check that

the top and the bottom films are fed in

without any wrinkles.

3.Pressure mark checking (Heat Line) –

stop the machine for 30 seconds to

create a heat line. Then check to see if

you have two even parallel lines from

one end to other. Note: A narrow parallel

lines indicate that it has less pressure

at that point.

4.Laminating Test – Laminate samples

with different thickness of substrates.

Figure B

5.Check above steps 2 through 4 with

3mil & 5mil films.

Figure C

11

Page 14

5.PART LIST

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Part No. RemarkPart Name Spec.

021LR0001A COVER-L ABS PA-765 UL94 V-0 PANTON 431

125LR4001A HANDLE-TENSION S45C Cu+Ni+Cr

138LR4012A SPRING-TENSION SWP Ф3.2

12200X022A BEARING-RADIAL 15*28

141LR4033A PLATE-PRESSURE,PULL SPCC 3.0T

138LR4015A SPRING-PRESSURE SWP Ф2

141LR4032A PLATE-PRESSDURE,LAMI SPCC 3.0T

141LR4035A PLATE-DU BUSH SECC T=2.0

141LR4019A BRACKET-HEATER,UP SPCC 1.6T

36400X014B MICRO SWITCH AC 250V/5A 50-60HZ

141LR4054A BRACKET-LIMIT SWITCH SPCC 2.0T

147LR4013A STOPPER-HEATER,UP SILICONE

141LR4020A BRACKET-HEATER,LOW SPCC 1.6T

141LR3039A PLATE-PRESSURE,L SPCC 3.0T

15

16

17

18

19

20

21

22

23

24

25

26

27

27-1

27-2

021LR4001A LAMIT-SWITCH COVER PP

122LR4044A BUSH-ROLLER LAMI,UP FTG70 CU 3-35

122LR4046A BUSH-ROLLER PULL,UP FTG70 CU 3-35

111LR4024A BOLT-GUIDE S45C

124LR4005A CAM S45C

122LR4050A

122LR4047A BUSH-ROLLER PULL,LO FTG70Cu3-35

136LR4001X CHAIN

013LR3142A FRAME-L SPCC 3.0T

147LR4002A PAD-TENSION LEATER 1.5T

140LR4036A HOLDER-SHAFT,FILM S45C Cu+Ni+Cr

120LR4002M SHAFT-FILM S45C N19

ASMLR1339A ASSY-AUTO GRIP CORE 2" RSH-380SL

ASMLR1339B ASM-AUTO GRIP CORE3" RSH-380SL

124LR4006A CORE-24 AL 6063

BUSH-ROLLER LAMI,LO

FTG70 CU 3-35

RS#25 P6.35 98节

28

29

30

31

32

33

34

RIV05018E8 BRINDER RIVET AL φ5*18

12200X029A DU-BUSH FLANGE Ф10*10

026LR4006A FOOT NBR 160g

141LR4064A BRACKET-TABLE SPCC 2.2T

013LR3146A FRAME-STAND 25*25*2.0 SQUARE TUBE

023LR4002A KNOB-BOLT GUIDE PHENOL BLK

145LR3002A GUIDE-DOCUMENT ABS PA-765 UL94V-0 431C

12

Page 15

35

141LR4043A FRONT TABLE SAFETY LEVER SPCC 1.5T

36

37

38

39

40

40-1

40-2

40-3

40-4

41

42

43

44

45

46

013LR4004A SAFETY FRAME SPCC

021LR3024A SAFETY-COVER PC 3.0T

014LR3001B TABLE-FRONT AL6063

133LR3001A ROLLER-LAMI STPG ORG

223LR3001H HEATER ASS'Y FCHW1 81Ω EU,KR,CH,EU(N),BR

223LR3001J HEATER ASS'Y FCHW1 96Ω AU,UK

223LR3001E HEATER ASS'Y FCHW1 24Ω CUL

223LR3001D HEATER ASS'Y FCHW1 20.2Ω TW

223LR3001F HEATER ASS'Y FCHW1 16.7Ω JOL,JAP

140LR4003A HOLDER-SAFETY COVER S45C

111LR4018A SCREW-H

131LR4027A SPROCKET-MOTOR S45 24Z

210004002A MOTOR-MAIN DC 24V

131LR4017A SPROCKET-LAMI FTG70Cu3-35 28z

120LR3031B SHAFT-CAM S45C Cu+Ni+Cr

SWRH MFZN-Y

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

013LR3143A PLATE-MIDDLE SPCC 0.5T

015LR2010A BAR-IDLE S45C Φ20

015LR3011C IDLE-BAR S45C Cu+Ni+Cr

015LR3012C SHAFT-DECURLING S45C Cr

131LR4018A SPROCKET PULL FTG70Cu3-35 20z

133LR3002A ROLLER-PULL S45C GRY

013LR3144A REAR-COVER SPCC 0.5T

013LR3145A TABLE-CUTTER SPCC 2.0T

013LR3002H FRAME-CUTTER AL6063

021CR3001A KNOB-CUTTER,C ABS PA-765 UL94 V-0 PANTON 431C

140LR3001A HOLDER-CUTTER,C ABS PA-765 UL94 V-0 PANTON 431C

213LR4001A CUTTER-CROSS STS420 J2 1T

34000S011A POWER TRANSFORMER AC110-120V,220-240V/50-60HZ

141LR3038A PLATE-PRESSURE,R SPCC 3.0T

144LR4001B CLAMPER-LEVER S45C Cu+Ni+Cr

62

63

64

65

66

66-1

67

023LR4010A KNOB LEVER NYLON BLK

125LR4003B LEVER-PRESSURE S45C Cu+Ni+Cr

120LR4009B SHAFT-COVER SAFETY S45C

350LR3042A PCB MAIN ASM ROHS

032LR3029A SHEET-FUNCTION PC 0.75T

032LR3029C SHEET-FUNCTION PC 0.75T

023LR3007B BUTTON-FUNC SILICON

13

Page 16

68

350LR3043A PCB-SUB ASSY FR-4

69

70

70-1

71

72

73

74

75

76

77

78

79

80

81

82

36600X001A FUSE-BLOCK FB66 LITTLE FUSE TRIAD INC

32500X0008 FUSE-MAIN 65TS AC250V 10A EU,AU,KR,CH,UK,EU(N),BR

32500X0005 FUSE-MAIN 65TS AC250V 20A TW,CUL,JOL,JAP

021LR3018A COVER-R ABS PA-765 UL94 V-0 PANTON 431

138LR4001A SPRING-CUTTER CROSS SWRH Φ0.3

KPS03012D2 KEY PLAIN 3*3*12 SUS27

138LR4018A SPRING-LEVER SUS 304-WPB

12200X027A DU-BUSH FLANGE Ф25*10

12200X028A DU-BUSH FLANGE Ф25*20

111LR4006A BOLT-GUIDE S45C SNC3 4*22.5

12200X030A DU-BUSH FLANGE Ф10*20

013LR3141A FRAME-R SPCC 3.0T

36400X002B SWITCH-MAIN 8216 B/R I/O SIGNAL-LUX SPA

013LR2012G FRAME-SENSOR AL6063

033LP4016A MICA-WASHER Φ4*Φ11 T=0.5

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

12200X032A DU-BUSH FLANGE Ф12*10

12200X040A DU-BUSH φ6*8 FLANGE

363LR4013A BIMETAL THERMOSTAL

141LP4018A BRACKET-FUSE EGI T=1

147CR4003A SILICON RUBBER SILICON Φ7*160

23300X001A BUSHING-CORD,EU 7NR32 DONG-A

111LR4004A BOLT-CORE S45C Φ15*42

ASMLR2023A ASM SENSOR RSH-380SL

381LR4020B WIRE-FUSE,EU UL1015 AWG#14

381LR4052A WIRE-MOTOR UL1007 AWG#20 BLK RED

381LR4115A WIRE-MAIN UL2464 AWG#24,BLE

381LR4062B WIRE-HEATER UL1015 AWG#16 WHITE

381LR4063A WIRE-TEMP FUSE

381LR4049A WIRE-BIMETAL UL1015 AWG#18, WHT

381LR4114A WIRE-HEATER LOW UL1015 AWG#16, WHT

135℃ 15A

SF133E,AC250V 15A 133℃ UL1015 AWG#14

98

99

99-1

99-2

99-3

99-4

99-5

381LR4051A WIRE-HEATER LINK UL1015 AWG#18, WHT

380LR4001A POWER CORD EU AC250V 15A 1.8M

380LR4003A POWER CORD AU AC250V 15A 1.8M

380CR4007A POWER CORD UK AC250V 10A 1.8M

380LR4001B POWER CORD KR AC250V 15A 1.8M

380CR4003A POWER CORD JAP AC125V 15A 1.8M

380CR4004A POWER CORD CUL AC125V 15A 1.8M

14

Page 17

No. Part No. Part Name

6.EXPLODE VIEW

24

25

1

2

3

4

6

6

86

9

11

10

2

3

22

33

77

34

38

24

25

31

26

31

27

89

87

12

12

13

14

4

36

35

32

30

6

6

7

8

16

15

20

75

37

28

18

76

29

30

5

23

21

78

17

19

18

18

41

39

29

41

43

45

41

83

40

31

31

42

31

31

39

40

48

36

83

48

50

49

84

90

81

44

47

73

46

32

31

83

41

91381LR4020B

381LR4115A

381LR4062B

381LR4063A

381LR4049A

381LR4114A

381LR4051A

380LR4001A

41

92381LR4052A

93

94

95

96

UP

97

LOW

98

99

51

83

42

31

41

1

2

52

31

31

J

J

52

84

80

79

30

6

59

88

26

54

53

32

30

6

7

16

76

20

13

17

60

18

18

73

75

27

29

28

55

31

31

6

6

5

62

78

21

18

19

29

9

1212

68

63

61

74

85

66

67

56

57

72

58

64

82

65

64

82

64

82

64

82

70

69

71

1 021LR0001A COVER-L

2 125LR4001A HANDLE-TENSION

3 138LR4012A SPRING-TENSION

4 12200X022A BEARING-RADIAL

5 141LR4033A PLATE-PRESSURE,PULL

6 138LR4015A SPRING-PRESSURE

7 141LR4032A PLATE-PRESSDURE,LAMI

8 141LR4035A PLATE-DU BUSH

9 141LR4019A BRACKET-HEATER,UP

10 36400X014B MICRO SWITCH

11 141LR4054A BRACKET-LIMIT SWITCH

12 147LR4013A STOPPER-HEATER,UP

13 141LR4020A BRACKET-HEATER,LOW

14 141LR3039A PLATE-PRESSURE,L

15 021LR4001A LAMIT-SWITCH COVER

16 122LR4044A BUSH-ROLLER LAMI,UP

17 122LR4046A BUSH-ROLLER PULL,UP

18 111LR4024A BOLT-GUIDE

19 124LR4005A CAM

20 122LR4050A BUSH-ROLLER LAMI,LO

21 122LR4047A BUSH-ROLLER PULL,LO

22 136LR4001X CHAIN

23 013LR3142A FRAME-L

24 147LR4002A PAD-TENSION

25 140LR4036A HOLDER-SHAFT,FILM

26 120LR4002M SHAFT-FILM

27 ASMLR1339A ASSY-AUTO GRIP CORE 2"

27-1 ASMLR1339B ASM-AUTO GRIP CORE3"

27-2 124LR4006A CORE-24

28 RIV05018E8 BRINDER RIVET

29 12200X029A DU-BUSH

30 026LR4006A FOOT

31 141LR4064A BRACKET-TABLE

32 013LR3146A FRAME-STAND

33 023LR4002A KNOB-BOLT GUIDE

34 145LR3002A GUIDE-DOCUMENT

35 141LR4043A FRONT TABLE SAFETY LEVER

36 013LR4004A SAFETY FRAME

37 021LR3024A SAFETY-COVER

38 014LR3001B TABLE-FRONT

39 133LR3001A ROLLER-LAMI

40 223LR3001H HEATER ASS'Y

40-1 223LR3001J HEATER ASS'Y

40-2 223LR3001E HEATER ASS'Y

40-3 223LR3001D HEATER ASS'Y

40-4 223LR3001F HEATER ASS'Y

41 140LR4003A HOLDER-SAFETY COVER

42 111LR4018A SCREW-H

43 131LR4027A SPROCKET-MOTOR

44 210004002A MOTOR-MAIN

45 131LR4017A SPROCKET-LAMI

46 120LR3031B SHAFT-CAM

47 013LR3143A PLATE-MIDDLE

48 015LR2010A BAR-IDLE

49 015LR3011C IDLE-BAR

50 015LR3012C SHAFT-DECURLING

51 131LR4018A SPROCKET PULL

52 133LR3002A ROLLER-PULL

53 013LR3144A REAR-COVER

54 013LR3145A TABLE-CUTTER

55 013LR3002H FRAME-CUTTER

56 021CR3001A KNOB-CUTTER,C

57 140LR3001A HOLDER-CUTTER,C

58 213LR4001A CUTTER-CROSS

59 34000S011A POWER TRANSFORMER

60 141LR3038A PLATE-PRESSURE,R

61 144LR4001B CLAMPER-LEVER

62 023LR4010A KNOB LEVER

63 125LR4003B LEVER-PRESSURE

64 120LR4009B SHAFT-COVER SAFETY

65 350LR3042A PCB MAIN ASM

66 032LR3029A SHEET-FUNCTION

66-1 032LR3029C SHEET-FUNCTION

67 023LR3007B BUTTON-FUNC

68 350LR3043A PCB-SUB ASSY

69 36600X001A FUSE-BLOCK

70 32500X0008 FUSE-MAIN

70-1 32500X0005 FUSE-MAIN

71 021LR3018A COVER-R

72 138LR4001A SPRING-CUTTER CROSS

73 KPS03012D2 KEY PLAIN

74 138LR4018A SPRING-LEVER

75 12200X027A DU-BUSH

76 12200X028A DU-BUSH

77 111LR4006A BOLT-GUIDE

78 12200X030A DU-BUSH

79 013LR3141A FRAME-R

80 36400X002B SWITCH-MAIN

81 013LR2012G FRAME-SENSOR

82 033LP4016A MICA-WASHER

83 12200X032A DU-BUSH

84 12200X040A DU-BUSH

85 363LR4013A BIMETAL THERMOSTAL

86 141LP4018A BRACKET-FUSE

87 147CR4003A SILICON RUBBER

88 23300X001A BUSHING-CORD,EU

89 111LR4004A BOLT-CORE

90 ASMLR2023A ASM SENSOR

91 381LR4020B WIRE-FUSE,EU

92 381LR4052A WIRE-MOTOR

93 381LR4115A WIRE-MAIN

94 381LR4062B WIRE-HEATER

95 381LR4063A WIRE-TEMP FUSE

96 381LR4049A WIRE-BIMETAL

97 381LR4114A WIRE-HEATER LOW

98 381LR4051A WIRE-HEATER LINK

99 380LR4001A POWER CORD

99-1 380LR4003A POWER CORD

99-2 380CR4007A POWER CORD

99-3 380LR4001B POWER CORD

99-4 380CR4003A POWER CORD

99-5 380CR4004A POWER CORD

15

Page 18

7. Wire Diagram

7654321

8

SRCLR

SRCLK

VCC_5V

23

Q102

1

C102M

RA103

330R 10 P

12

34

56

78

910

1112

1314

1516

1718

1920

SER

RCLK

G

VCC_5V

VCC_5V

BZ1

R101

BUZ ZER

330

10

SER2

14

SRCL K2

11

RCLK2

12

23

Q101

1

BUZ ZER

C102M

13

D4

FR10 5

T 6.3AL 250V

FUSE1

24V24V

YW396-03V

24V

R7

680 2w

Q4

HS?

A1271

HS-529

D3

1N4148

R8

2k

R9

220 1w

2

RY1A

FF/R EV Motor

IRF8 30

3

SK2

104 120 з

RY2A

CH1-MD12F

D5

FR10 5

5

4

CH2-MD12F

DOWN HE ATER

MG640598

CN4

31Q1

R10

ZD1

1W 15V

4.7K

MG640598

TAC 1

BTA2 4- 600 C

SK1

104 120 з

UP Heat er

12V

D1

1

1N4007

2

RY1-CH2MD12

23

REV

CN7

2

1

CN5

2

1

Q2

1

C102M

CNN7

YH396-03V

1

1

2

2

3

3

CNN4

MG610599

2

1

CNN5

MG610599

2

1

F

HEATER2

R12

3K

HEATER2 ASS'Y

1N4007

1

bimetal 70∩

HEATER ASS'Y

bimetal 70∩

24V

D2

RY2_CH1MD12

23

Q3

C102

+

DC

-

D

1

2

F

C

DC?

MOTOR DC

B

A

Title

Number RevisionSize

A2

Date: 6-Mar-2009 Sheet of

File: D:\PR OGRAM FILES\ EXAMPLES\RSL -38 2S CI\RS L-38 2S C I.D DBDrawn By:

MCLR/Vp p

RB0/INT

RA5/AN4/SS

OSC1/CLKIN

RB1

RB2

RB3

RB4

RB5

RB6

U2

KA7805/1A

VIGVO

VCC_5V

R104

10K

1

C106

3.3/50V

21

SRC LK1

22

RCLK1

23

SER1

24

SRC LK2

25

RCLK2

26

SER2

BUZ ZER

27

H/Disp lay Com

7

9

R102 1M

10

XTAL101

8Mhz

HS?

HS-529

C5

470/25V

QH1

QG1

QF1

QE1

QD1

QC1

QB1

QA1

GND_EARTH

15

LA10 1

LDQ- N5 1G

U102

74LS59 5

9

QH

7

QH

6

QG

5

QF

4

QE

3

QD

2

QC

1

QB

QA

C101

C6

104

104

CARB ON S/ W

SW1

SPEED_ UP SW

SW2

SPEED_ DO WN SW

D

SW3

TEMP_UP SW

SW4

TEMP_DOWN SW

SW5

REV_SW

SW6

STOP_ SW

SW7

RUN_SW

VCC_5V

R103

330

LED1

23

Q103

C102M

1

1

C

SENS_ASS 'Y

利寇急

s_ou t

SENS OR ASS ' Y

vccgnd

senso r_in

SMH025-05

CNN102

CN102

SMW02 5-0 5

1

2

3

4

5

SENSOR

B

VCC_5V

RA101 10K x 10

HEATER

PWM O UT

HEATER2

REV RELAY

SPEED _U P SW

SPEED _D OWN SW

TEMP_UP SW

TEMP_DO WN SW QC2

REV SW

STOP SW

RUN SW

RUN L ED

HEATE R2 LED

VCC_5V

TEMP SEN SOR

MAIN-S UB

C105

104

CN101

1

2

3

4

5

6

BD2

DB105G

VCC_5V

R103

330

LED4

LED3LE D2

23

Q104

C102M

1

2

5v

3

4

R103

5

C104

10K

104

470/ 25V

C107

U101

PIC16C72

12

13

11

28

15

16

17

18

3

5

14

4

6

2

VCC_5V

CN6

6

PWM- OU T

5

REV-RELAY

4

HEATER

3

HEATER2

2

1

-+

RC1/T1OSI

RC2/CCP1

RC 0 / T1 OS O/T 1 C KI

RB7

RC4/SDI/SDA

RC5/SDO

RC6

RC7

RA1/AN1

RA3/AN3/VREF

RC3/SCK/SCL

RA2/AN2

RA4/TOCKI

RA0/AN0

OSC2/CLKOUT

C4

1000/50 V

SRCLR

SRCLK

VCC_5V

H/Display Com

RA102

330R 10 P

12

34

56

78

910

1112

1314

1516

1718

1920

10

SER1

14

SER

SRCL K1

11

RCLK1

12

RCLK

13

G

HEATE R

VCC_5V

C102

C103

104

104

LA10 2

LDQ- N5 1R

QH2

QG2

QF2

QE2

QD2

QB2

QA2

GND_EARTH

74LS595

9

QH

7

QH

6

QG

5

QF

4

QE

3

QD

2

QC

1

QB

15

QA

PWM

R4

330

U4

1

2 3

PC81 7

U103

R6

1K 1w

R5

470 1w

4

24v_gn d

KA7824

C8

470/ 50V

HS?

HS-529

TAC 1

HS-501

24V

R2

R1

100

330

MOC30 43

12

U3

4 6

R3

10K 1/2W

C9

104

AC POWER S/W

CNN3

5

4

3

2

1

YH396-03

AC13V

AC24V

POWER TRANSF ORMER

A

AC_i n

FUSE1

T 15A 250V

CN3

P/T OU TPU T

5

4

3

2

P/T OU TPU T

1

BD1

BR-106

CN2

CNN2

YW396-03AV

1

1

2

2

3

3

P/T INPUT

CN1

BR-1103C02P

1

2

AC INPUT

C1

100nF/2 75V MKP

-+

C2

4700/10 0V

D6

1N4007

Q5

PNP

U1

R6

VIGVO

75 2w

C7

104

C3

104

1 2 3 4 5 6 78

16

Page 19

7

4

2

1

3

5

8

6

<Connect part>

1. Wire Main. 6. Wire Power Transformer In

2. Wire Power 7. Wires Power Transformer Output

3. Wire Heater,up 8. Wire Fuse

4. Wire Heater,low

5. Motor wires

17

Page 20

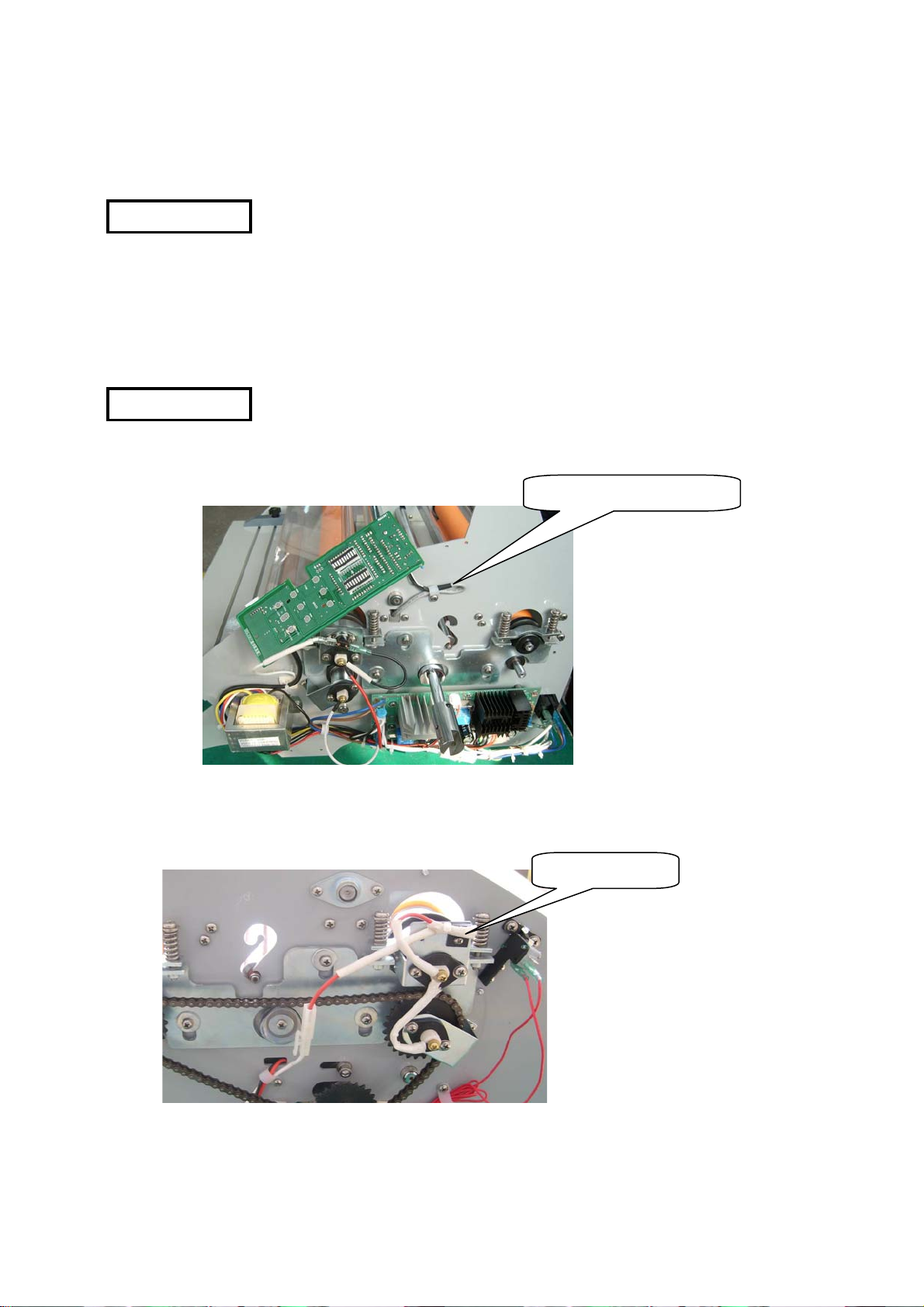

SUB PCB

Wire Lo Heater

Bimetal(135℃)

Wire Sensor

Fuse Main

Power Cord

Wire Bimetal

Motor

Wire Up Heater

18

Page 21

Wire T/Fuse (133℃)

Micro Switch

Wire Motor

Wire Safety S/W

19

Loading...

Loading...