Page 1

Royal Sovereign LAMINATORS

OWNER'S MANUAL

RSH-1050/1650 ,RSR-685/1050

PLEASE READ AND SAVE INSTRUCTIONS

- 1 -

Page 2

-

-

-

-

-

-

-

-

-

-

-

-

-

-

TABLE OF CONTENTS

TOPICS PAGE

INSTRUCTION ----------------------------------------------------------------------- 3

SAFETY PRECAUTIONS ----------------------------------------------------------- 3

CHARACTERISTICS ----------------------------------------------------------------- 4

SPECIFICATIONS --------------------------------------------------------------------- 4

NAMES OF MAJOR PARTS OF MACHIN-------------------------------------------

HOW TO INSTALL THE REWINDER ---------------------------------------------

HOW TO INSTALL THE UNWINDER ------------------------------------------------ 8

SETTING UP FILM ------------------------------------------------------------------- 9

HANGING FILM ----------------------------------------------------------------------- 10

1.HOT FILM ----------------------------------------------------------------------------

2.COLD FILM --------------------------------------------------------------------------

CONTROL OF ROLLER PRESSURE ---------------------------------------------

INSTRUCTIONS FOR CONTROL PANEL ---------------------------------------

1.LCD WINDOW ---------------------------------------------------------------------

2.FUNCTIONS OF BUTTONS ----------------------------------------------------

3.HOW TO USE BUTTONS ----------------------------------------------------

LAMINATING STEPS ------------------------------------------------------------------ 20

1.HOT LAMINATING -------------------------------------------------------------

6~7

10

11

12

13

14

15

16~19

20~21

5

2.COLD LAMINATING --------------------------------------------------------------

TIPS FOR REMOTE CONTROL AND FOOT SWITCH ------------------------

METHOD FOR USING CUTTER -----------------------------------------------------

*.CROSS CUTTER -------------------------------------------------------------------

IMPORTANT SAFETY CONCERNS ---------------------------------------------- 24

MAINTENANCE --------------------------------------------------------------------------

IT'S NOT OUT OF ORDER ----------------------------------------------------------

SPARE PARTS ------------------------------------------------------------------------WARRANTY ----------------------------------------------------------------------------- 26

SPEED & TEMPERATURE ADJUSTMENT---------------------------------------- 27

22

23

23

23

24

25

25

- 2 -

Page 3

y

p

INSTRUCTION

Thank you for purchasing a Royal Sovereign Roll Laminator. It has been

designed and manufactured to provide years of continuous service in the

professional environment. To insure high quality lamination, please read

this instruction manual thoroughly. This manual will provide you with complete

operating and maintenance information. For additional product support or

factory-direct ordering information. Call Royal Sovereign Customer Service at

1-800-397-1025.

SAFETY PRECAUTIONS

The safet

understood and followed before operating machine.

Kee

following safety procedures could result in serious personal injury.

1. To prevent the possibility of electrical shock, do not immerse machine in water

2. Do not allow articles of clothing (neckties, scarves, papers, etc.) near front or

3. Do not insert sharp objects into front or rear machine openings. Do not place

4. Do not attempt to laminate items that exceed total recommended material

5. Do not operate machine for any other purposes than its intended use.

6. Do not operate machine if electrical plug or power cord is damaged.

this information for future reference. Failure to comply any of the

or permit liquids to spill inside.

rear machine openings as they could get caught by rollers and be pulled inside,

causing personal injury.

anything in feed tray openings of machine other than appropriate laminating

materials or pouches.

thickness.

recommendations outlined in this section are to be read,

7. Turn off the power when unattended or not in use. Unplug machine before

moving it or when it is not in use for an extended period of time.

8. This machine is intended for indoor use only.

9. Do not alter or extend electric plug. Plug is configured for appropriate electrical

supply.

10. The socket-outlet shall be installed near the equipment and shall be easily

accessible.

- 3 -

Page 4

g

g

y

CHARACTERISTIC

RS Roll Laminator Line is advanced laminators with time transcendental design,

utilizin

It is desi

machine remember

the latest in laminating technology.

ned for you to set temperature and speed as necessary and have the

our settings. Also, you can laminate anything at high speed,

regardless of thickness of material and type of film.

Remote control device allows for control of the machine from the front or rear.

Foot-Pedal Switch allows for hands-free operation.

It is also designed for convenient use by anyone through the simple procedure of

adjusting film tension in accordance with the thickness of film and materials to be

laminated.

SPECIFICATIONS

Description

Dimensions(w x d x h)

Weight

Voltage/Cycles

Power Consumption

Max. Laminating Speed

Max. Laminating Width

Max. Laminating Thickness

Film thickness

COLD and WARM Laminating

RSH-1650 RSR-685

1960x650x1210mm

(77.2x25.6x47.4in) (42.1x25.6x48.0in)

300Kg

(660lbs)

2m/min

6.5ft/min

(64.9inch)

15.0mm

(0.6inch)

Yes

RSR-1050 RSH-1050

1400x650x1220mm 1070x650x1220mm

(55.1x25.6x48.0in)

140Kg

(308.6lbs)

AC100~120V, 50/60Hz

AC220~ 240V, 50/60Hz

3000w

4m/min 2m/min 4m/min

13.1ft/min

(41.3inch)

32 - 250micron

(1.3-10mil)

6.5ft/min

1050mm1650mm

13.0mm

(0.5inch)

Yes

100Kg

(220.5lbs)

2000w3300w

13.1ft/min

685mm

(27inch)

Yes

3

Take-Up

Film Alignment

Cutter-Cross

Ass'y Stand

Switch-Foot

Wired Remote Control

No Yes

Yes Yes Yes

Yes

Yes Yes Yes

Yes Yes

- 4 -

2

YesYes

1Cooling Blowers

Yes

Yes

YesYes

Yes

Page 5

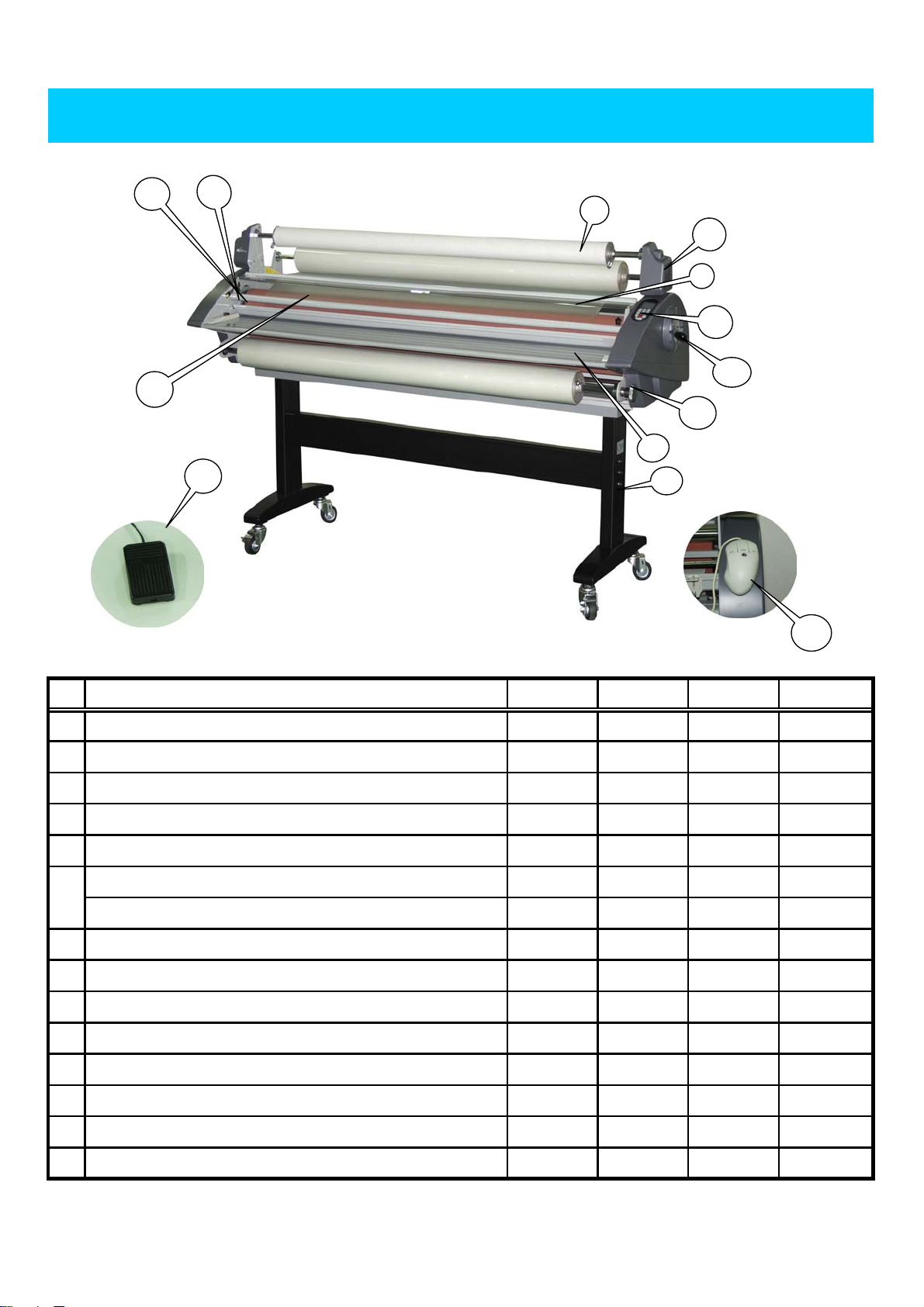

NAMES OF MAJOR PARTS OF MACHINE

1

14

6

3

2

4

10

11

12

5

8

7

9

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

PART NAME

FRAME-GUIDE,PAPER

TAKE-UP SWITCH

TAKE-UP BOBBIN

IDLE BAR

TABLE-FRONT

HOT ROLLER

HOT METAL ROLLER

ASS'Y-STAND

FOOT SWITCH

REMOTE CONTROL SWITCH

CONTROL PANEL

PRESSURE LEVER

TENSION CONTROL KNOB

FILM ALIGNMENT KNOB

RSH-1650

○

○

○

○

X

○

○

○

○

○

○

X

RSH-1050

○

○○

○

○

○

X

○

○

○

○

○○

RSR-1050 RSR-685

○○

○○

○○○

○

○

X

○

○○

○

○

○

○

○

○

○

X

○

○

○

○

○

○

○

○○○

14

SAFETY COVER

- 5 -

○

○○

○

Page 6

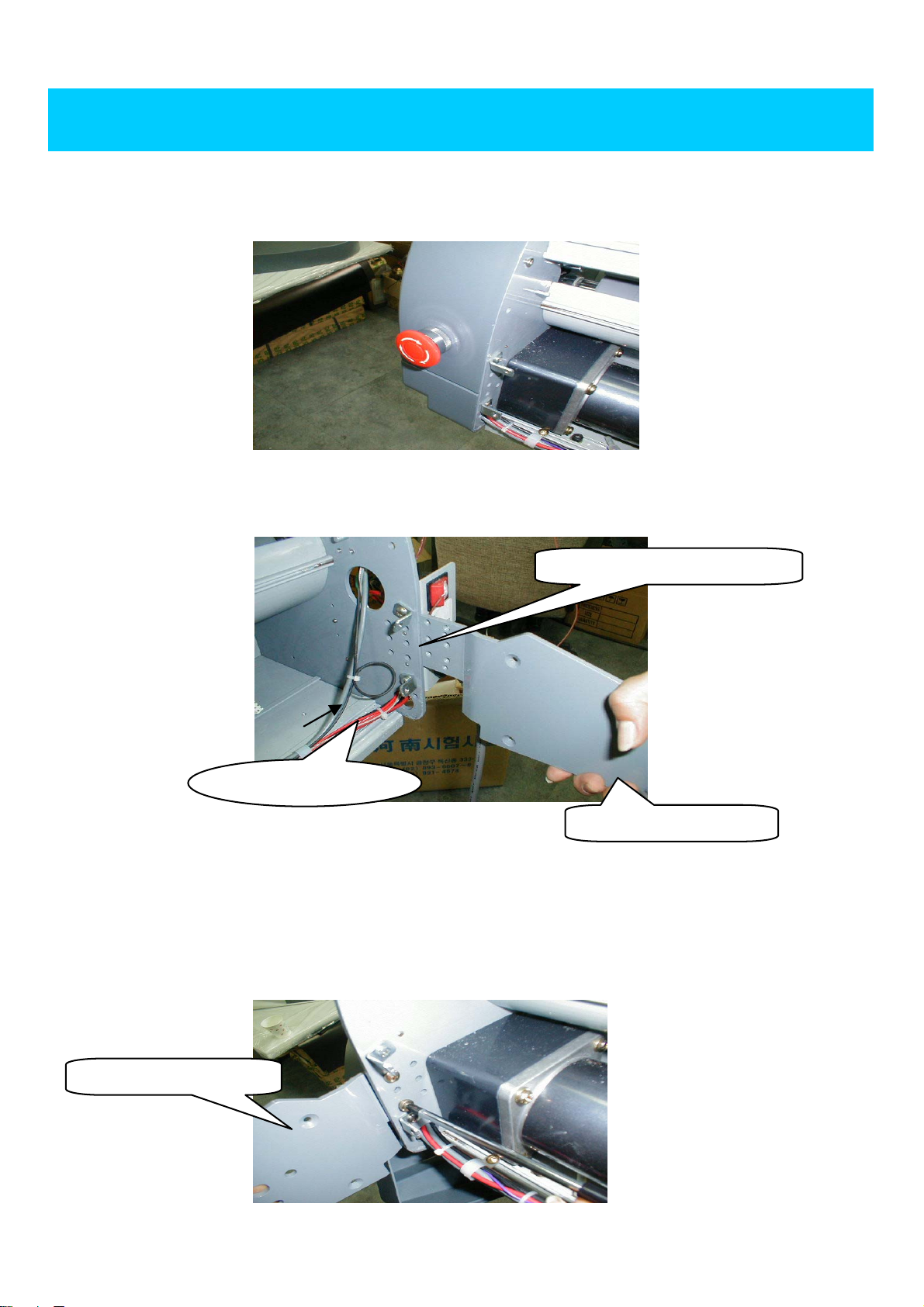

How to install the rewinder

1. Disassemble both the Right cover and the Left cover. (Note :Turn the fastening nut of the Emergency

switch counterclockwise and disaasemble the Emergency switch before disassembling the Right cover.)

2. Disassemble the Rear cover.

3. Disassemble the power switch bracket which is located at the left side of the machine.

Power switch bracket

M5 screw 6EA

Plate-Rewinder L

4. Put the Plate-Rewinder L on the outer side of the frame as shown in the following figure

and fasten it with six M5 screws.

5. Put the Plate-Rewinder R on the outer side of the frame as shown in the following figure

and fasten it with six M5 screws.

Plate-Rewinder R

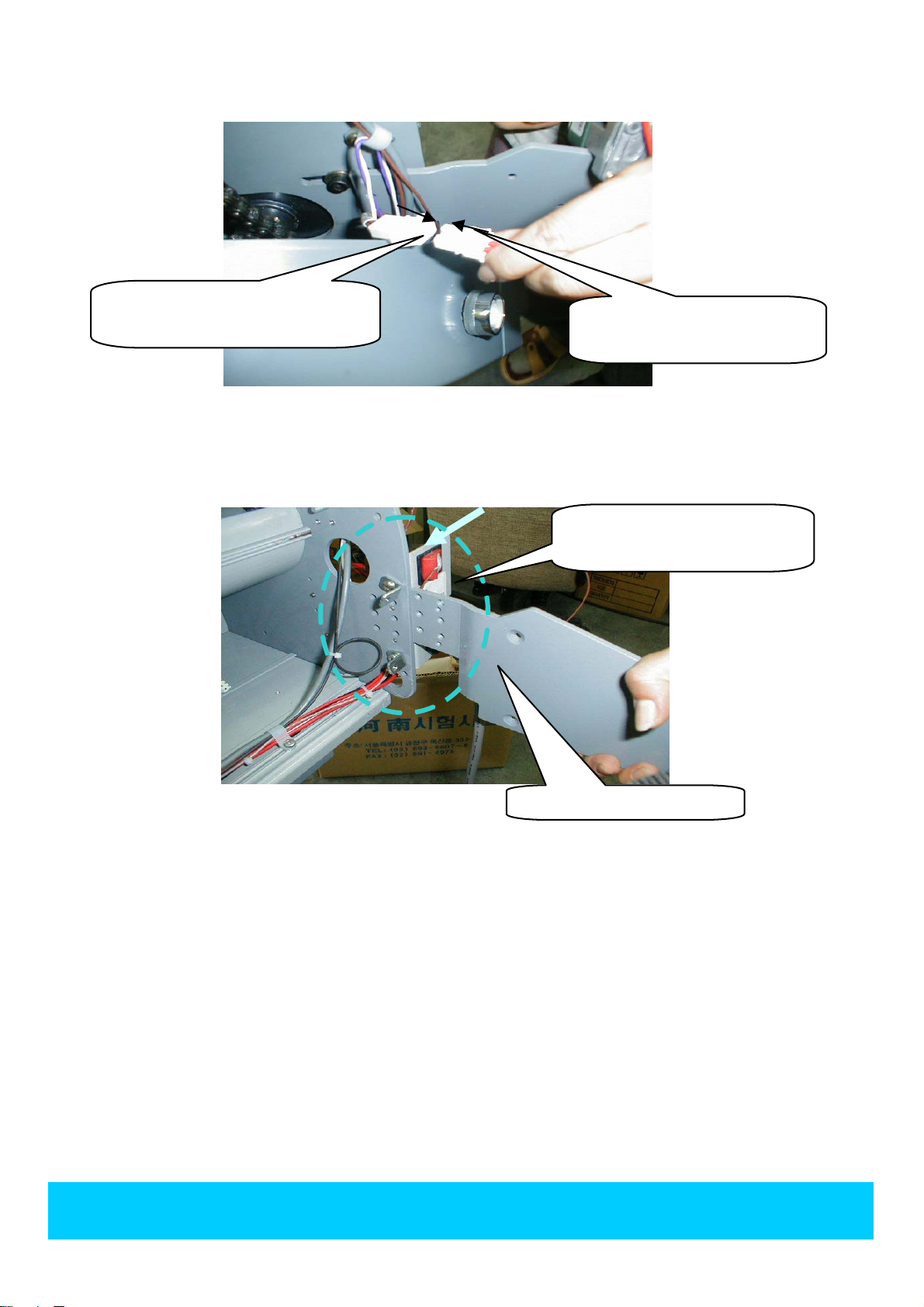

6. Insert the male connector from the Rewinder motor into the female connector from the

- 6 -

Page 7

take -up motor.

Female Connector from

Male Connector from

take-up motor

rewinder motor

7. Assemble the Right cover letting the wires go through the slot which is located at the rear side

of the Right cover.

8. Put the Power switch bracket on the Plate-Rewinder L and fasten it with two M4 screws.

Power switch bracket

How to install the unwinder

- 7 -

Plate-Rewinder L

Page 8

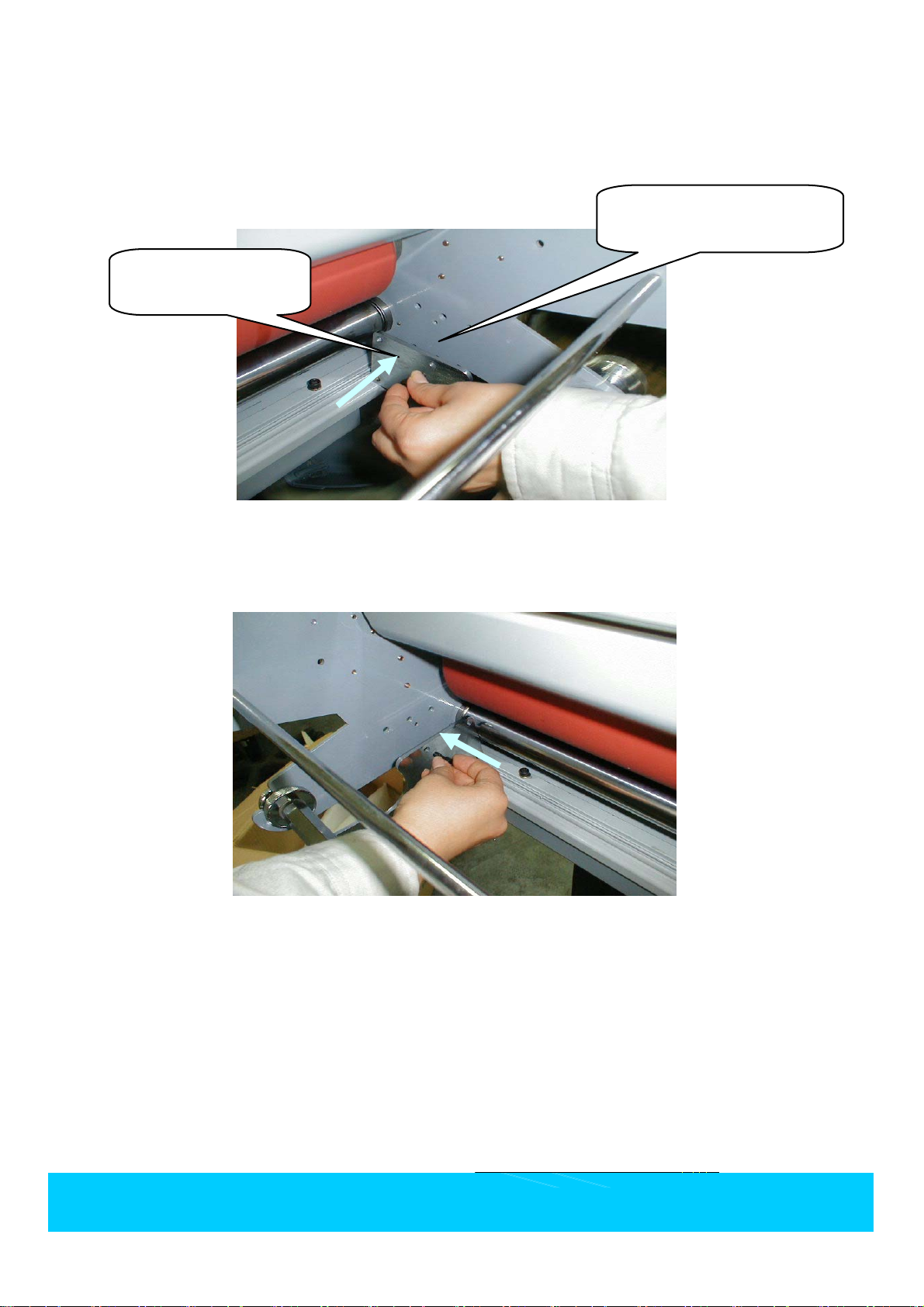

1. Put the Plate-Unwinder R on the inner side of the frame as shown in the following figure

주 름 방 지 부

열 판

주 름 방 지 부

열 판

C

표 시 창

버 튼 부

and fasten it with four M6 hexagonal bolts.

Plate-Unwinder R

M6 hexagonal

bolt

2. Put the Plate-Unwinder L on the inner side of the frame as shown in the following figure

and fasten it four M6 hexagonal bolts.

L

D

SETTING UP FILM

- 8 -

Page 9

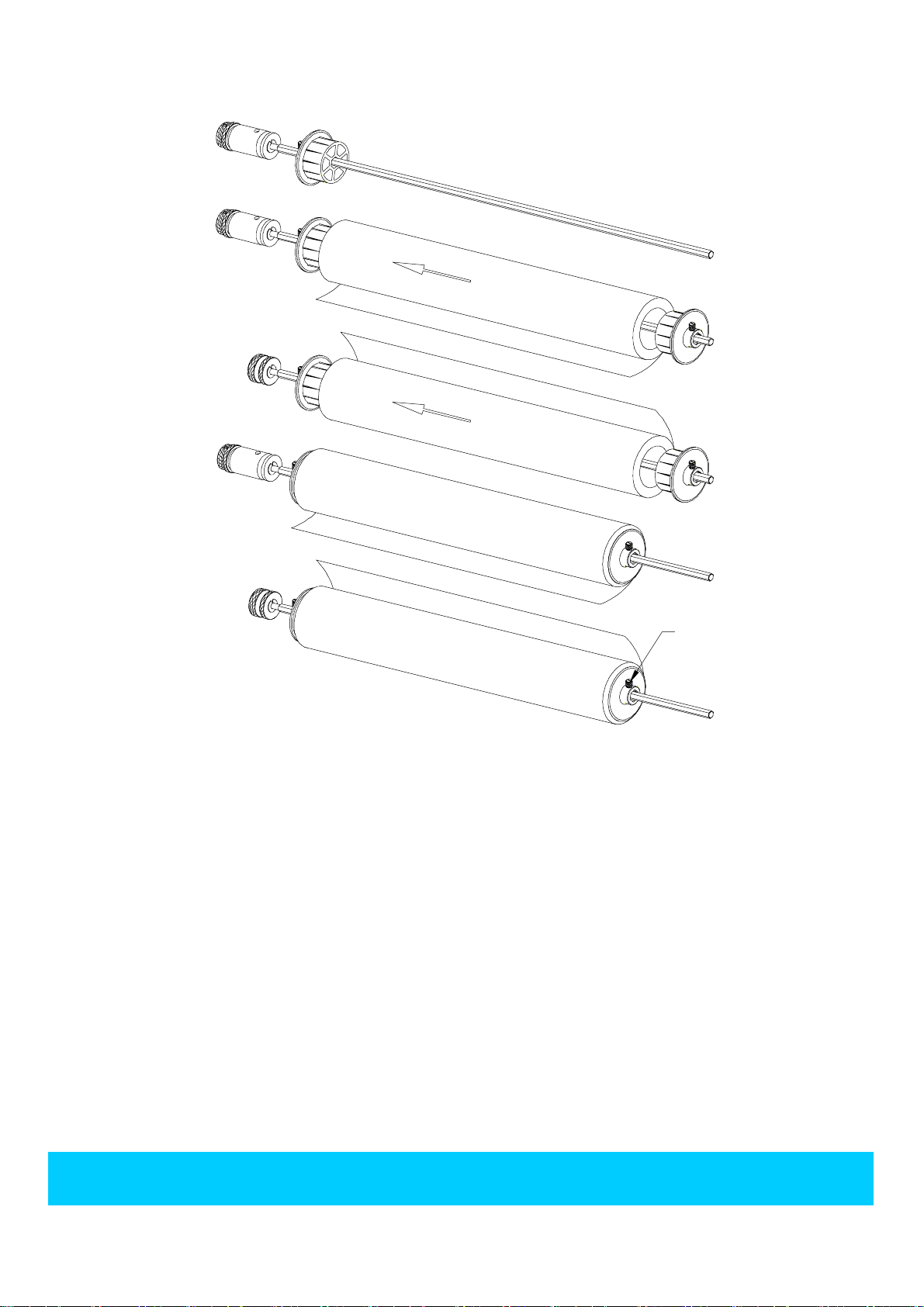

Picture 1

Picture 2

Picture 3

Picture 4

Upper Film

Lower Film

Upper Film

Picture 5

Core Fixing

Lower Film

Screw

1. Set the glossy side of upper/lower film to face the heat.

( Glossy side is PET film and matte side is thermal polymer laminating film.)

2. Like picture 1, insert core into the left side of upper/lower film shaft.

3. Like picture 2 and 3, insert core into the right side of upper/lower film.

4. Like picture 4 and 5, adhere core closely.

(Make the right/left direction of fixing screw consistent.)

5. Locate film in the middle, and then fasten core fixing screw.

HANGING FILM

- 9 -

Page 10

1. HOT FILM

R

UPPER ROLL FILM

UPPER IDLE BAR

HOT METAL ROLLER

HOT ROLLER

LOWER ROLL FILM

LOWER ROLL FILM

LOWER IDLE BA

UPPER ROLL FILM

UPPER IDLE BAR

RSH-1050/1650 RSR-685/1050

ROLLER

LOWER IDLE BAR

1. Insert bar into the core of the roll film then place the bar on the machine.

2. Place the Pressure Lever (on the right side of machine) to the open mode at 15mm.

3. Insert a piece of wide cardboard (guiding paper/carrier) between the rollers.

4. Pull the film from the upper roller passing over the upper idle bar to the upper roller

and put it on the roller.

5. When temperature reaches 80℃(176°F), resin starts melting and films turn to be

transparent.

6. Place the film from lower shaft beneath the film from the upper roller which is already

melting and unwind films of both rollers 30~40Cm(1~1.3ft) for loosing the tension.

7. Set the pressure Lever to the 1mm.

8. Set speed at 1 and press Run button. The films will be fed into the machine and will

come out from the rear site of machine.

9. Check the status of lamination and place the pressure lever at lamination mode.

2. COLD FILM

TAKE UP DEVICE

- 10 -

TAKE UP DEVICE

Page 11

TAKE UP DEVICE

COLD FILM

TAKE UP DEVICE

M

COLD FIL

PAPER BACK

HOT ROLLER

PAPER BACK

HOT METAL ROLLER

UPPER IDLE BAR

LOWER IDLE BAR

PAPER BACK

PAPER BACK

RSH-1050/1650 RSR-685/1050

1. Set up cold film below the upper bar of the machine

(Set the same as method of HOT film for protect paper of lower part)

2. Set the pressure Lever to the 15mm, open mode

UPPER IDLE BAR

ROLLER

LOWER IDLE BAR

3. Insert a piece of wide cardboard (guiding paper/carrier) between the rollers

4. Pull the film from the upper roller passing over the upper idle bar to the upper

roller and put it on the upper roller.

5. Put the paper back of the film to the bobbin at take-up bar to rewind

the paper back.

6. Allow some of the film with melted resin to stick to the Guiding Paper.

7. Place the film from lower shaft beneath the film from the upper roller which is

already melting and unwind films of both rollers 30~40Cm(1~1.3ft) for loosing

the tension.

8. Set the pressure Lever to the 1mm

9. Set speed at 1 and press Run button. The films will be fed into the machine and

will come out from the rear site of machine

10. Check the status of lamination and place the pressure lever at lamination mode

- 11 -

CONTROL OF ROLLER PRESSURE

Page 12

***Methods of controlling pressure of the roller**

1. For setting, pull the pressure lever out and turn the lever to following the indication

2. Open/15mm : for laminating 15mm(0.6") thick board (RSH-1050/1650)

3. 10~13mm : for laminating 10~13mm(0.4" to 0.5") thick board

4. 5~7mm : for laminating 5~7mm(0.2" to 0.27") thick board

5. 1mm : for laminating 1mm(40mil) thick board

6. LAMINATING : for laminating 32~250micron thick film

INSTRUCTIONS FOR CONTROL PANEL

We designed this machine standing by user’s convenience. You can manipulate

- 12 -

Page 13

speed and temperature of rollers each by each by the LCD controller.

And with memory function, you don’t need to set machine every time you laminate.

***Terms***

LCD DISPLY

1.LCD WINDOW

1. Initial display status.

- 13 -

BUTTON

Page 14

It displays you the last working condition

when turned on.

2.

Is displayed when the preset temperature

is reached.

3.

Blinking

Indicates to wait till blinking stops.

Current temperature is higher or lower than

the preset temperature.

4.

Saving electricity status.

5. Temperature

1) Shows the preset temperature

2) You can check the current temperature on

the heat shoe by pressing T-Check

6. Speed

*9 different speed option.

"RSH" type---(SPEED1->0.4m(1.3ft)/min.

SPEED9-> 2.0m(6.5ft)/min.)

"RSR" type---(SPEED1->0.8m(2.6ft)/min.

SPEED9-> 4.0m(13.1ft)/min.)

*You can choice from1to4 for Cold Function

7. PRGM

*9 different memory cell (address)

You can memorize 9 different working

conditions.

2. FUNCTIONS OF BUTTONS

UPPER

LOWER

UPPER SPEED

- 14 -

SPEED

: Upper roller temperature controller

: Lower roller temperature controller

Page 15

UPPER

SPEED

SPEED

: Speed controller

LOWER

COLD/HOT

REV

RESET

T-CHECK

STOP

FAN

MEMORY

ST/BY

RUN

MEAS

MEMORY

C/HOT

T-CHECK

: Choose memorized working condition

: ① Increase temperature

② Increase speed

③ Restore the memorized working

setting

: ① Decrease temperature

② Decrease speed

③ Restore the memorized working

setting

: Cold and Hot mode change

: Check current temperature

ST/BY

REV

REV

STOP

RUN

FAN

RESET

MEAS

: Saving electricity while the machine is

not being operated.

: Reverse function

Stay pressing reverse button to have

the roller run backward.

: Stop working

: Run the rollers.

: Run and stop the fans

:Count & Length Values Format

:Change Into Count & Length Mode

3.HOW TO USE BUTTONS

***Set the upper/ lower hot rollers***

1. Temperature available range from 0°C (32°F)

- 15 -

Page 16

to 160°C (320°F).

Button & Display

2. Temperature setting of upper roller

UPPER

LOWER

Press and you will see the LCD screen is

blinking 6 times. Before blinking is finished, press

UPPER

or to set the temperature

3. Set temperature of lower roller

Press and choose the arrow button

the same way to set temperature of upper roller.

4

it will change 1°C (2°F). If you press the button

more than 1 seconds, temperature will change

automatically until you press the button again.

5. Buzzer is ringing each time you press the button.

LOWER

Each time you press the button,

***Speed controls

1. The operator can use 9 different lamination speeds.

2. Press

is blinking 6 times

Before blinking finish, the operator can change the

speed with or

3. Each time you press the button, buzzer will ring.

SPEED

SPEED

button then speed display mode

***Memorizing Working condition and Using

the memorized working condition***

- 16 -

1) Memorize working condition

Page 17

1.Operator can memorize 9 working conditions.

2.Choose working condition by pressing and

UPPER

LOWER

SPEED

MEMORY

button after pressing button.

and speed, press button.

MEMOR

MEMORY

3.It is memorized if buzzer is ringing with blinking.

* If you change the temperature or speed when LCD

screen is still blinking, you have to press

MEMORY

button after changing.

4.When you memorize another working condition, you

can do above 2 and 3 operation over.

2) Use the memorized working condition.

1.Operator can choose one of 9 memorized working

conditions.

2.Press then or to select

MEMORY

a working condition. The display will blink.

3.After the blinking stops, it is set the working condition

MEMORY

you selected and shows the working condition on the

display.

***Check current temperature on the hot rollers.***

1.When you press button, the present

temperature will be shown on the screen and will

- 17 -

T-CHECK

Page 18

T-CHECK

blink five times.

2.After this, it automatically returns to the previous

state.

***Cold mode***

1.You can do cold lamination with this function.

C/HOT

SPEED

MEMORY

ST/BY

2.Press the button to show

C/HOT

"Cold" on the display.

3.Speed will always show 2.

4.Speed can be varied 1 or 4 by selecting

button.

5.You release the machine from cold mode by

pressing button.

C/HOT

6.Everytime you press the button, buzzer is ringing

7.ST/BY mode is not working at COLD mode.

***STND-BY (Saving Electricity while you are not operating for a while)***

1. When press button will display

on the screen and STND-BY mode is set at 80C.

2. When machine is in mode, machine

ST/BY

- 18 -

Page 19

condition wouldn’t work. Press the button and

ST/BY

it will revert to the previous working.

3. When machine runs, you can’t change it to the

mode.

ST/BY

In this case, press the button and turn the

machine to the mode.

STOP

***Check the laminating length & How many laminated papers***

1. When press button the present numbers of

length and papers laminated will be shown on

the screen.

2. When you want to return to working mode

Press button again.

MEAS

MEAS

RESET

FAN

MEAS

LAMINATING STEPS

1. HOT LAMINATING

3.Also, you can reset measure mode by pressing

RESET

button.(for 2 second)

1. Turn the power switch on the back side of the machine.

(Emergency Switch must be turned off)

- 19 -

Page 20

2. Set the pressure lever to the “Laminating mode”

3. Increase roller temperature. If you already memorized special working condition,

press button and choose right condition by using or

button.

4. When it’s ready, you will see ready sign on the screen and the buzzer will ring.

5. Press the button. If rollers don’t run, check the emergency switch whether

it is located at “ON” position or not.

6. To set film tension properly, use the Tension Control Knob.

Lower tension would make better operation.

7. Set document on the table. You should allow at least 5mm(1/4”) space on each side

for perfect laminations.

8. Press the button when your lamination is finished.

MEMORY

RUN

STOP

9. For your convenience, it would be better to set table guide in proper position.

10. When lamination is just finished, it is hot and easily bent. Try not to touch it until

it cools down.

11. After finishing your work, set the pressure lever to the “Hard Board/15mm

12. Turn the Power switch off

***Useful Information***

1. It would be easier for you to operate the machine next time if the

temperature and the speed are set at the best condition and memorized

by the using

MEMORY

function.

2

sign may appear on LCD window in the case continuous laminating.

- 20 -

Page 21

If it happens, the speed needs to be lowered by one speed level and started again

after

3. In case of wrinkling or rolling of film due to wrong position of document,

REV

to the front with buzzer sound.

4. When document is much smaller than film, you should place it in the middle of film

for preventing wrinkle

5. Use cooling fan when you laminate continuously without break and

document is too hot.

is needed to be keeping pushed in order that document could come out

signal on the LCD window.

***Laminating Speed at each level〔mm(ft)/min〕***

SPEED

1

2

3

RSR-685/1050

800mm(2.6ft)

1200mm(3.9ft)

1600mm(5.2ft)

RSH-1050/1650

400mm(1.3ft)

600mm(2ft)

800mm(2.6ft)

4

5

6

7

2000mm(6.56ft)

2400mm(7.9ft)

2800mm(9.2ft)

3200mm(10.5ft)

1000mm(3.3ft)

1200mm(3.9ft)

1400mm(4.6ft)

1600mm(5.2ft)

3600mm(11.8ft)8 1800mm(5.9ft)

9 2000mm(6.6ft)4000mm(13.1ft)

The above laminating speed numbers are at the condition on regular voltage with

almost no film tension. There might be the possibility for difference to the

above numbers due to the change of voltage or adjustment of tension.

2. COLD LAMINATING

1. Put cold roll film on upper bar.(Set the same as methord of HOT film for

protect paper of lower part)

2. Pull COLD film, and fix it so that backside protecting paper can be wound on

take-up mandrel clockwise. (Revolve core to make protectingpaper tight a little bit.)

3. Set pressure lever at the proper position following to your lamination condition.

- 21 -

Page 22

4. After pressing the button choose and set proper speed by using

C/HOT

the and button.

5. It is when ready is show on the screen and the buzzer rings three times.

6. Turn on the take up device and set the proper film tension by pressing the

button. Lower tension would make better operation.

RUN

SPEED

sound three times.

7. Set document on the table.

You should allow at least 5mm(1/4”)

space on each side for perfect laminations

8. Turn the switch “Run” and

“take up motor” at the same time.

The liner and film will be rolled at

the same time.

9. When lamination is finished, press the

button. For your convenience,

STOP

it would be better to set table guide in

proper position. And if needed,

cut documents with cross cutter.

10. Set pressure lever at the Hard board/15mm mode.

11. Turn off the power switch.

*** Reference ***

1. Set up the protection paper. Otherwise, glue form the film will be stuck on the face

of roller and it can be seriously damaged.

2. Turn the switch “Run” and “Take up motor” at the same time.

3. For worm lamination, set temperature from the hot mode.

TIPS FOR REMOTE CONTROL AND FOOT SWITCH

1. It is convenient to use the remote control in the back of machine while laminating.

2. It is also convenient if you use Foot Switch while laminating HARD BOARD.

3. "RUN", "STOP", "REV" buttons on Remote Control have same functions

with the ones on Control Panel.

- 22 -

Page 23

4. Press Foot Switch one time for "RUN", press one more time for "STOP".

(Don't keep pressing)

5. After use of Remote Control, attach it to the left side of rear of machine

METHOD FOR USING CUTTER

**Cross Cutter**

1. It is on the back side of the machine.

2. After lamination, move cutter to a point about

1/3 of the width of lamination

3. Grasp film with one hand and press the cutter

cutter downward and slide it to the direction

intending to cut with another hand.

4.Press the cutter and slide it the other way.

IMPORTANT SAFETY CONCERNS

1.Please be cautious that neck tie, necklace,

long hair, clothes are kept well away while operation.

2. Prevent children from accessing the machine

- 23 -

Page 24

Extreme Heat Will Cause Injury

q

3.Place the machines on the plated place so that

4.Make certain that the machine is connecterd to an ade

5.Do not use any other purposes other than

Lamination.

uate power souce.

MAINTENANCE

1.Do not allow the machine to run with only one roll of film installed. The

melted resin will adhere to one roller and ruin future laminations.

2.The width of film should be bigger than the material, and

Width of upper side and lower side of film should be same in order not to allow

melted resin to adhere to the rollers.

3.Be sure to adjust the film tension while in operation.

If the tension is too tight, it could cause the film to stretch.

4.After work, you should clean the resin from

the rollers before beginning the next operation.

5.Please check the lubricant after long operation

or you do not use for a long time.

6.Check the chain linking each gear is not loosened.

The limit tension allowed is 3mm.

It's not out of order

Cause Check pointSymptom

*Rollers do not operate 1. Power cord may not be plugged 1. Check the power cord

after press RUN button in. 2. Check the switch is on

2. Power switch is at OFF mode. 3. Check the emergency switch

3. Emergency switch may be at is off

ON mode. 4. Release STND-BY switch by

- 24 -

Page 25

4. It may stay at STAND-BY mode. press the STND-BY button

*Hot roller is not heater 1. It is set at the cold mode 1. Change the function to hot

up. 2. Memorized temp may be lower lamination.

than atmosphere temp. 2. Set proper temperature for the

work

*Wrinkled lamination 1. Film tension is not proper, too 1. Adjust film tension.

result tight.

*Result of lamination is 1. Temperature on the hot roller 1. Increase the temperature on the

not clear is too low or lamination is too hot roller or decrease the

speedy. speed.

SPARE PARTS

PART NAME EA MODEL PART NAME

Core(76mm)

Bolt(M8X65)

6

Washer(Φ8)

FUSE(50T)

RSH-1650

(AC250V 6.3A)

1

RSH-1050

RSR-1050

RSR-685

Nut(M8)

FUSE(65TS)

(AC250V 20A)

1

L-Wrench

EA MODEL

8

8

RSH-1650

RSH-1050

RSR-1050

RSR-685

4

1

WARRANTY

1. For six month from the date of purchase, Royal Sovereign International Corporation

or its authorized service center will repair this product free of charge if it is defective

in material or workmanship.

2. This Limited Warranty does not include cleaning, or damage caused by accident,

neglect, misuse or improper installation, operation or external scratch, any damage

caused from service, maintenance, modifications or tampering by anyone other than

- 25 -

Page 26

a Sovereign authorized service representative, or damage caused by a natural

calamity such as fire or earthquake and etc…

3. Customers will bear the expense of Transportation fee and delivery fee of the

damaged machine.

Speed & Temperature Adjustment

NO

Film thickness

Temp

38 micron

1

110 5 1

(1.5 mil)

- 26 -

Preset

Speed

Func'No

Temp

User

Speed

Remark

Page 27

2

75 micron

(3 mil)

115 4 2

3

4

5

6

7

8

9

80 micron

(3.2 mil)

100 micron

(4 mil)

125 micron

(5 mil)

150 micron

(6 mil)

175 micron

(7 mil)

200 micron

(8 mil)

250 micron

(10 mil)

120 5

120 4 4

125 5 5

125 3 6

130 4 7

135 3

140 3 9

3

8

- 27 -

Loading...

Loading...