Carburettor Version Model

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

1

PREFACE

“FIRST TIME RIGHT” is a very important element for enhancing Customer Satisfaction.

Royal Enfield is committed to upgrade the skills and knowledge of technicians so that they follow scientific repair

techniques to ensure “FIRST TIME RIGHT” practices and carry out repairs accurately so that customers will enjoy

trouble free performance at all times.

This manual will help in complete understanding of systematic procedures for dismantling, inspection, diagnosis and

reassembly for the new Royal Enfield Himalayan motorcycle, in a simple and scientific manner.

While this manual is updated with latest Information and Specifications at the time of going to print, due to continuous

improvements being done to improve performance, some of the data, illustrations etc., in this manual may be different

from some of the parts fitted in the motorcycle.

Please do feel free to write to us at support@royalenfield.com , if you have any queries, clarification, suggestions or

feedback.

With warm regards

SERVICE HEAD QUARTERS

Royal Enfield, A Unit of Eicher Motors Limited,

Thiruvottiyur High Road, Thiruvottiyur, Chennai - 600 019.

E-mail: Support@royalenfield.com

Website: www.royalenfield.com

Part No: 888435 / Jan. ’17

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

2

HIMALAYAN – VEHICLE VIEWS

VEHICLE VIEW LH

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

3

VEHICLE VIEW RH

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

4

VEHICLE VIEW FRONT

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

5

VEHICLE VIEW BACK

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

6

VEHICLE VIEW TOP

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

7

TABLE OF CONTENTS

SL.NO. DESCRIPTION PG.NO.

1. Technical Specifications ........................................ 8

2. Periodical Maintenance ......................................... 10

3. Special Tools Usage List ......................................... 11

4. Engine Dismantling from Frame & Reassembly . 12

5. Rider & Pillion Seat ................................................. 47

6. Control Cables ........................................................ 50

7. Air Filter.................................................................... 57

SL.NO. DESCRIPTION PG.NO.

12. Rear Suspension

12.1 Rear Wheel ..................................................... 110

12.2 Rear Sprocket / Drive Chain Adjustment .... 111

12.3 Rear Mudguard .............................................. 113

12.4 Mono Shockabs orber ................................... 114

12.5 Drag & Drop Links .......................................... 115

12.6 Swing Arm ...................................................... 116

13. Hydraulic Disc Brakes -Front & Rear ..................... 127

8. Pulse Air Valve ......................................................... 63

9. Fuel Tank .................................................................. 67

10. Exhaust Pipe & Silencer ......................................... 71

11. Front Suspension

11.1 Front Mudguard ............................................ 84

11.2 Front Wheel ................................................... 85

11.3 Front Fork ....................................................... 86

11.4 Handle Bar ...................................................... 89

11.5 Steering Stem ................................................. 9 0

14. Carburetor ............................................................... 161

15. Electrical Components ........................................... 175

16. Electricals ................................................................. 184

17. Wiring Harness ........................................................ 206

18. Trouble Shooting .................................................... 210

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

8

SECTION 01 - TECHNICAL SPECIFICATION

VEHICLE & VEHICLE SYSTEMS

A. ENGINE: LS 410

B. CHASSIS:

1. Frame Half duplex split cradle

2. Suspension

Front Telescopic, Hydraulic Damping,Fron t wheel travel:

200 mm

Front fork oil grade 2W 35

Capacity / leg 455ml/leg

Rear Swing arm with Linkage type Hydraulic damping Mono

shock, Rear wheel travel: 180 mm

3. Brakes

Front Disc 300mm Dia disc.

Rear Disc 240mm Dia disc.

Hydraulic oil Grade DOT3 / DOT4

Hydraulic oil reservoir capacity - Front & Rear 50ml.

4. Tyre size

Front 90 / 90 – 21

Rear 120 / 90 – 17

Solo With Pillion

5. Tyre Pressures

6. Steering lock In Built

7. Fuel Tank * Values below are approximate & actual capacity may

Front 25 PSI / 1.75Kg/cm2 27 PSI / 1.89Kg/cm2

Rear 32 PSI / 2.25 Kg/cm2 34 PSI / 2.39 Kg/cm2

vary with each fuel tank .

Low fuel warning - Fuel Gauge (Red zone) 5.5+0.50 litres approx.*

Dead stock (unusable fuel) 0.5 litre approx.*

Tank capacity 15+0.5 litres approx.*

Reserve 3.0 + 0.5 Litres approx.*

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

9

VEHICLE & VEHICLE SYSTEMS

C. ELECTRICALS:

Generation Alternator

System 12V - DC

Battery 12V - 8 AH MF

Head lamp Bulb H4 12V 60/55W

Tail lamp / Brake lamp 2V- 4/1W LED

License Plate illuminator 12V- LED

Front position lamp 12V- LED

Speedometer lamp 12V- LED

Hi beam indicator 12V- LED

Neutral lamp telltale 12V- LED

Turn signal telltale 12V- LED

Turn signal 12V – 10W

Horn 12V, 2.5 Amp

Starter Motor 12V. 0.7 KW

Instrument Cluster Digital cluster with LCD panel

Side Stand indicator LCD Indication

D. DIMENSIONS:

Length 2190mm

Width 840mm

Height 1360mm

Wheel base 1465mm

Ground clearance 220mm

Saddle Height 800mm

E. WEIGHTS:

Kerb weight with (90% fuel & oil) 182 Kg.

Max. permissible load. 183 Kg.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

10

SECTION 02 - PERIODICAL MAINTENANCE

The Periodical maintenance schedule detailed below is based upon average riding conditions and indicates the

Intervals at which regular inspections, adjustments, replacements and lubrications must be carried out to help maintain

your Himalayan motorcycle meticulously

If in case the motorcycle is used frequently in very dusty environment / severe climatic conditions / Poor Roads /

stagnant water etc., the maintenance will need to be done earlier as may be required.

Contact a nearest Royal Enfield Authorised Dealer / Service Center to carry out the periodical maintenance and for

any expert advice.

S.

No .

Months 1 6 12 18 24 30 36 42 48 54 60

1 HT leads for crack I I I I I R I I I I I

2 Air Filter Element C C R C R C R C R C R

3 Accelerator Cable I I R I R I R I R I R

4 Clutch Cable I I R I R I R I R I R

5 Clutch Free Play Adjust every 1000 Kms or earlier as required

6 Steering ball races # I & A I & A I & A I & A I & A I & R I & A I & A I & A I & A I & R

7 Front Fork oil I I I R I I R I I R I

8 Fuel Filter in Fuel Tap C C C C C C

9 Fuel Hose I I R I R I R I R I R

10 Battery terminals (apply petroleum jelly) C C C C C C C C C C C

11 Earth wire eyelet Tightness I I I I I

12 Hydraulic Brake Fluid - Front & Rear # I I R I R I R I R I R

13 Hydraulic brake hose & Washers - Front & Rear # I I I I R I I I R I I

14 Brake Pads - Front & Rear # I I R I R I R I R I R

15 Tyre wear pattern (Front & Rear)# I I I I I R I I I I R

16 Spokes tightness / Wheel rim run out front & rear # I I I I I I I I I I I

17 Front & Rear wheel bearings for play # I I I I I I & R I I I I I & R

18 Swing arm Pivot bearings # I I I & L I I & L I & R I I & L I I & L I & R

19 Rear Suspension Linkages # I I & L I & L I & R I & L I & L I & R I & L I & L I & R I & L

20 Rear Drive Chain # Clean, Lubricate & Adjust every 1000 Kms or earlier as required

21 Drive chain & Sprockets set # I I R I R I R I R I R

22 Rear wheel cushdrive rubbers# I I R I R I R I R I R

23 All Mounting Fasteners in vehicle for tightness # I I I I I I I I I I I

24 Hand levers, side stand, Rider & Pillion foot rest Pivots Lubricate every 1000 Kms or earlier as required

DESCRIPTION

whichever is earlier

Kms (X 1000) 0.5 5 10 15 20 25 30 35 40 45 50

Clean/ Replace more Frequently if motorcycle always used

in dusty / off Road conditions.

A : A dj u st C : C le a n I : I ns p ec t L : L ub ri c at e R : R ep la c e

* Refer Service Manual. # Check every time after vehicle is used for off road riding

NOTE:

For maintenance after 50,000 Kms, please repeat the same frequency levels specified above.

PAID SERVICEFREE SERVICE

whichever is earlier

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

11

SECTION 03 - SPECIAL TOOLS USAGE LIST

PART NO. DESCRIPTION PHOTOS APPLICATION

ST-26461-2 Front Fork Assembling & To hold pipe seat inside fork main

Dismantling Tool tube for loosening / tightening of

Allen bolt on bottom tube.

ST-26485-3 Front Fork Oil Seal Driver To drive slide bush and fork oil seals into

bottom tube

ST-25244-4 Special spanner adjuster To adjust rear shock absorber spring

pre tension

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

12

SECTION 04 - ENGINE DISMANTLING FROM FRAME &

REASSEMBLY

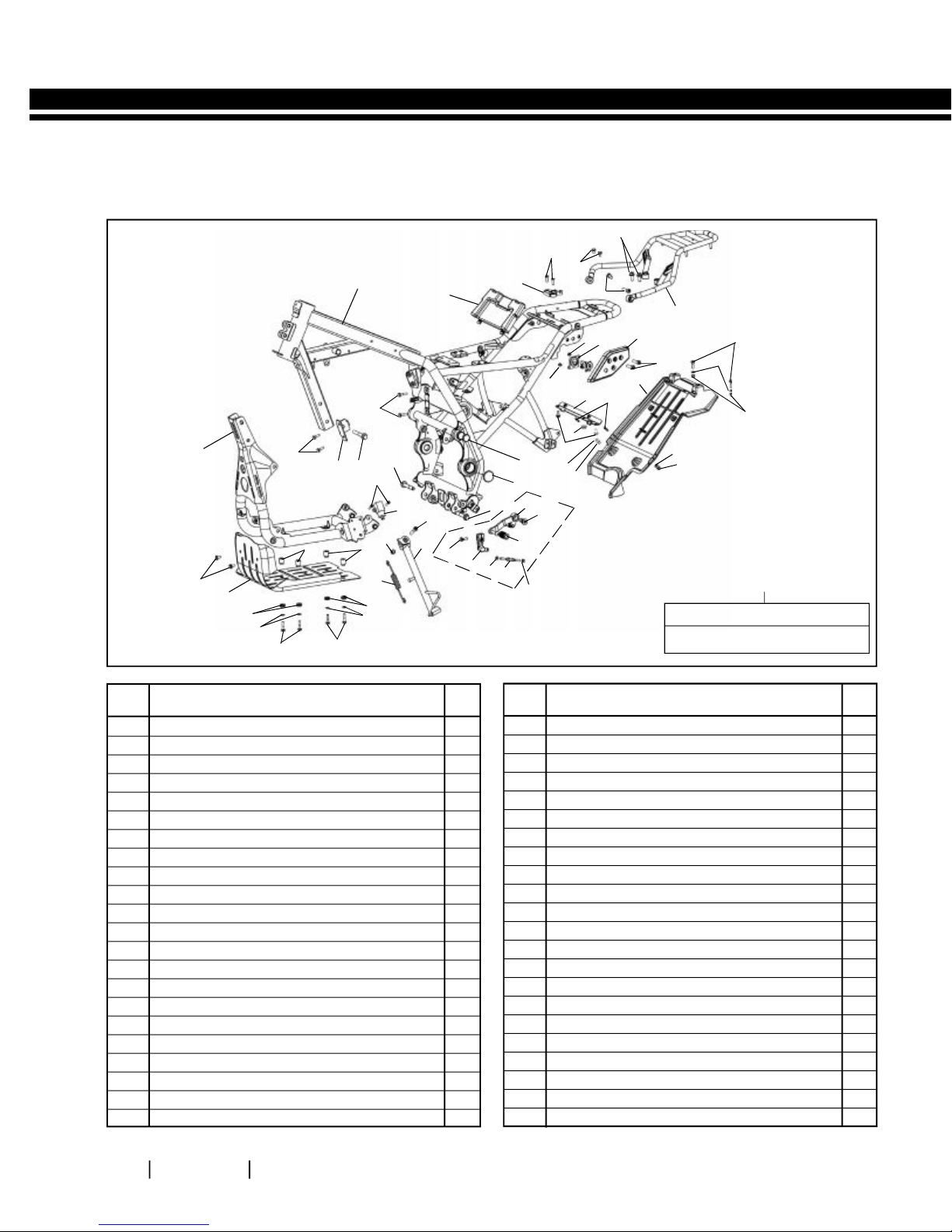

EXPLODED VIEWS

FRAME LH

7

4

5

28

22

27

3

9

20

21

23

24

25

26

6

8

10

11

6

12

18

14

15

9

19

17

16

14

15

13

14

15

A1

Key Nos.

13, 23, 24, 25, 25, 27, 28, 29

40

16

39

37

1

43

13

41

36

14

38

38

42

22

30

34

36

35

37

14

2

31

32

33

13

29

S. NO.

DESCRIPTION

A1 Gear Shift Lever Kit 1

1 Main Frame- Black 1

2 Utility Box 1

3 Seat Latch 1

4 Counter Sunk Screw M6 X 1 X 20 2

5 Flanged Hex Bolt M6 X 1 X 10 2

6 Hex Socket Head Screw M8 X 1.25 X 25 4

7 Flanged Hex Bolt M8 X 1.25 X 20 2

8 Grab Rail Black 1

9 Mushroom Head Screw M6 X 8 X 1 2

10 Plate Seat Lock 1

11 Saddle Bag Mtg - LH 1

12 Piece Mudguard 1

13 Flanged Hex Bolt M6 X 1 X 20 5

14 Plain Washer 8

15 Hex Nut with nylon insert 4

16 Flanged Hex Bolt, M6 X 1 X 14 6

17 Grommet 1

18 Stud 2

19 Crossbar Assy 1

20 Dust Cap-Frame Top 1

21 Dust Cap-Frame 1

QTY. S. NO.

22 Flanged Hex. Bolt M10 X 1.25 X 66 2

23 Toe Lever Comp 1

24 Pivot Pin- Gear Shifter 1

25 Sleeve, Gear Lever 1

26 Hex Nut 1

27 Link Rod 1

28 Hex Nut (LH Thread) 1

29 Gear Shift Lever Comp-Short 1

30 Hex Socket Head Cap Screw – M5 X 20 2

31 Switch-Side Stand 1

32 Hex Socket Head Screw M8 X 1.25 X 35 1

33 Side Stand Assy 1

34 Hex Nyloc Nut M8 X 9.5 1

35 Spring 1

36 Support Bush Skid Plate 4

37 Damper - Oil Cooler 4

38 Flanged Hex Bolt M6 X1 X 35 4

39 Skid Plate 1

40 Cradle Frame 1

41 Bracket Assy-Oil Cooler 1

42 Flanged Hex Bolt, M10 X 1.25 X 75 1

43 Flanged Hex Bolt M6 X1 X 27 2

DESCRIPTION

QTY.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

13

EXPLODED VIEWS

FRAME RH

27

26

17

S. NO.

25

24

21

20

19

6

18

16

DESCRIPTION

10

23

22

7

1 Connector Complete Black 1

2 Flanged Hex. Bolt M10 X 1.25 X 66 1

3 Plain Washer 1

4 Flanged Hex Bolt, M10 X 1.25 X 75 1

5 Flange Hex Bolt M10 X 1.25 X 165 1

6 Flange U Nut M10 X 1.25 6

7 Flange Hex Bolt M10 X 1.25 X 183 3

8 Clutch Clamp 1

9 Flanged Hex nut M10X1.25 1

10 Flanged Hex Bolt M8 X 1.25 X 16 2

11 Flanged Hex. Bolt M8 X 1.25 X 45 1

12 Steady Bracket Black 1

13 Flanged Hex. Nut M8 X 1.25 1

14 Flanged Hex Bolt M8 X 1.25 X 20 2

6

7

QTY. S. NO.

15 Flanged Hex Bolt M6 X 1 X 14 2

16 Brake Pedal Comp - RH 1

17 Pivot Pin-Brake Pedal 1

18 Spring-Pedal Return 1

19 Dust Cap-Frame 1

20 Hex Socket Button head Screw M6 X 1 2

21 Dust Cap-Frame Top 1

22 Hex.Socket Button Head Screw M6 X 1 X 16 1

23 plain washer M6 1

24 Flanged Hex Bolt M6 X 1 X 20 1

25 Bracket Assy. - Air Filter 1

26 Saddle Bag Mtg- RH 1

27 Hex Socket Head Screw M8 X 1.25 X 25 2

14

15

13

12

11

10

6

8

9

6

DESCRIPTION

5

1

2

3

4

6

6

QTY.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

14

COMPONENTS DISMANTLING SEQUENCE TO REMOVE ENGINE FROM FRAME

Skid Plate on Frame bottom

Engine oil (Drain when warm. Remove drain plug /

oil strainer cover on crankcase LH & Oil filter on Cover

RH)

Oil Cooler along with inlet & outlet pipes.

Fuel hose & Pulse Air valve connections

Battery connections

Magn eto / Gear posit ion / Side stand swit ch:

couplers dismantle

Starter motor connections

Spark plug suppressor cap

Engine steady bracket

Control Cables (Clutch / Accelerator)

Carburettor

Exhaust pipe & Silencer

Gear shift linkage

Starter motor

Cover LH

Gear position indicator sensor

Rear Chain (Remove from FD sprocket)

FD sprocket nut (loosen )

Cover RH

Oil pump gears / Oil pump

Crank shaft Nut (LEFT HAND THREADED)

Balancer shaft Bolt

Clutch center nut & Clutch assembly

Gear shift shaft assembly (Remove circlip & washer

on shift shaft from LH crankcase side first)

Cam shaft covers / Cylinder head cover

Automatic chain tensioner

Cam shaft gear & cam shaft Assembly

Cylinder Head Sub Assembly

Chain Tensioner Pads

Cylinder Barrel Sub Assembly

Cradl e frame top mountings (with connector)

mounting to frame

Cradle frame bottom mounting LH& RH on frame

Magneto rotor assembly including Starter clutch

Starter idler gears with bush & spindles

Rear top engine mounting on frame (support engine

from bottom suitably)

Four mounting studs of Engine to cradle frame

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

15

ENGINE DISMANTLING FROM FRAME

S.

Aggregate to Dismantle/

No.

Instructions

4.1 Skid plate

Fastener, Size, Tool Usage, Precautions, Photos

Loosen & remove 6

Flanged Hex screws (2 in

front & 4 in bottom.

Remove the spacers and

washers between the

skid plate and frame.

4.2 Oil Cooler

Remove Inlet & Outlet

Banjo union bolts from

LH & RH Crankcase

respectively & allow oil

to drain.

Flanged Hex Screw: M6

Socket Spanner: 10mm

NOTE:

Ensure the engine oil is

drained from the engine.

Banjo Union Bolts: M14

Socket spanner: 19mm

Ensure the 4 washers

are removed from the oil

pipes / banjo Union

Remove 2 Hex flange

bolts securing oil cooler

to the frame

Remove oil cooler along

with inlet & outlet pipes.

(Ensure the Oil pipe No 2

on RH s id e be tw een

engine & frame is taken

out caref ull y, whil e

dism antl ing the oil

cooler.)

Flanged Hex bolts: M6

Socket spanner: 8mm.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

16

S.

Aggregate to Dismantle/

No.

Instructions

4.3 Wind Shield

Assembly

Remove 4 Hex socket

head cap screws holding

the Wind shield

assembly to the top

frame.

Remove the 4 plastic

washers along with the

screws and remove wind

shield.

4.4 Trafficator front LH,

RH & cover cockpit

LH, RH.

Fastener, Size, Tool Usage, Precautions, Photos

Hex Soc Hd. Cap Screw:

M5

Allen Key: 4mm

NOTE:

Hold the rubber mounted

nuts from behind while

loosening screws.

Disconnect Trafficator

wiring couplers below

headlamp.

Remove hex socket

head screw mounting

the trafficators to the

top frames on LH & RH

sides.

Gently pull out Cover

cockpit LH & RH from the

rubber grommets in the

top frame LH & RH.

NOTE:

Couplers are color coded as:

LH side: Green

RH side: Red

Hex socket hd. Screw: M5

Allen key: M4

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

17

S.

Aggregate to Dismantle/

No.

Instructions

4.5 Headlamp

Assembly

Disconnect head lamp

wiring coupler below

head lamp.

Remove the dust caps

from the mounting

holes in top frame LH &

RH.

Fastener, Size, Tool Usage, Precautions, Photos

Remove 2 hex socket

head screws holding

headlamp assembly to

top frame LH & RH &

remove head lamp assy.

4.6 Top frame LH & RH

Remove 2 Flanged Hex

bolts holding the top

frame LH & RH to

Instrument cluster

bracket.

Remove the 2 dust caps

from the connector in

the frame.

Loosen 2 hex socket

head screw clamping

top frames LH & RH, to

connector tube.

Gently rotate & pull out

top frames LH & RH from

connector tube.

Hex Socket Hd. screw:

M5

Allen Key: 6mm

Flanged hex bolts: M8

Socket Spanner: 12mm

Hex Socket Hd. screws:

M6

Socket Spanner: 10mm

CAUTION

Take care not to damage

fuel tank while rotating &

removing the side support

brackets.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

18

S.

Aggregate to Dismantle/

No.

4. 7

Instructions

Pillion & Rider Seat

Unlock pillion seat by

turning key clockwise &

lift pillion seat from front

end to release rear tab &

remove.

Lift rider seat from rear

end to release front tab

& remove.

4.8 Fuel tank Dismantling

Fastener, Size, Tool Usage, Precautions, Photos

Remove Seat Assembly

Disconnect fuel hose

from carburetor end.

Remove 2 Hex screws

from the rear end of fuel

tank.

Disconnect fuel gauge

coupler wire by lifting the

tank slightly.

Slide fuel tank towards

rear to release front

clamp from frame

Remove tank along with

the overflow tube

carefully.

CAUTION:

Drain the fuel completely

from the fuel tank.

Hex Flange Bolt M6

Socket Spanner 10 mm

CAUTION :

Do not lift tank too high to

- Preve nt accidental

damage to the front

end of the fuel tank.

- Preve nt damage to

EVAP hose

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

19

S.

Aggregate to Dismantle/

No.

Instructions

4.9 Steady Engine

Bracket

Hold U nut at the

cylinder head mounting

area with a double end

spanner and loosen Hex

bolt at the front of the

steady engine bracket.

Fastener, Size, Tool Usage, Precautions, Photos

Flanged hex bolt: M10

Socket Spanner: 12mm

Flanged hex nut: M10

Remove the bolt and

nut.

Support steady engine

bracket, Loosen &

remove the 2 Flanged

hex bolts at the rear end

of the bracket and

remove the bolts and

steady engine bracket.

4.10

Throttle cable

Push rubber grommets

down and loosen hex

nuts completely.

Gently pull throttle cable

from bracket to release

the threaded position

from the bracket.

Socket Spanner: 12mm

Double End Spanner:

13mm

Remove inner cable

from the Carburetor.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

20

S.

Aggregate to Dismantle/

No.

4.11

Instructions

Clutch Cable

Fastener, Size, Tool Usage, Precautions, Photos

Loosen & remove outer

locknut from the rear of

the cable adjuster.

Loosen inner locknut

fully & push adjuster

fully into bracket.

Release inner cable from

the clevis in the clutch

shaft

Remove rubber grommet

& outer lock nut &

remove clutch cable

from the bracket.

Hex Nut: M8

D E Spanner: 12mm

NOTE:

Gently push the rubber

grommet away from the

adjuster while removing

nut.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

21

S.

Aggregate to Dismantle/

No.

4.12

Instructions

Side Panel LH

Fastener, Size, Tool Usage, Precautions, Photos

Remove 3 He x socket

Button head screws

(except left bottom

one).

Gently pull out to release

locater from frame

rubber Grommet.

4.13

Side Panel RH

Remove 3 He x socket

Button head screws

(except right bottom

one).

Hex. Socket Button Hd

Screw M6X12

Allen Key: M5

Hex. Socket Button Hd

Screw M6X12

Allen Key: M5

Gently pull out to release

locater from frame

rubber Grommet.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

22

S.

Aggregate to Dismantle/

No.

4.14

Instructions

Electrical connections

Fastener, Size, Tool Usage, Precautions, Photos

A. Battery

Remove negative terminal

scre w and disconnect

negative battery cable.

Remove positive terminal

screw and disconnect

positive battery cable.

B. Starter Motor

Remove the Hex nut

securing the wire eyelet

to starter motor terminal

and remove the wire.

Remove flanged hex

bolt securing the earth

wire eyelet to crankcase.

Philips Hd screw driver

Socket Spanner: 10mm

CAUTION

Ensure Ignition switch &

engine stop switch are in

OFF position before

disconnection battery &

wiring couplers.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

23

S.

Aggregate to Dismantle/

No.

4.14

Instructions

Electrical

connections

H. Magneto coupler

Disconnect white

coupler from LH side.

Disconnect small Black

coupler (Pulsar wire

connections from LH

Side.

Fastener, Size, Tool Usage, Precautions, Photos

I. Gear p osi tion s witch

coupler

Disconnect BIG & SMALL

Black coupler from LH

side.

J. Si de st an d sw it ch

coupler

Disconnect Red coupler

from LH side.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

24

S.

Aggregate to Dismantle/

No.

4.14

Instructions

Electrical

connections

K. Horn Terminals

Disconnect horn

terminals.

L. Spark plug suppressor

cap

Disconnect suppressor

cap from sparkplug.

Fastener, Size, Tool Usage, Precautions, Photos

4.15

Exhaust pipe &

Silencer

Remove 2 flanged Hex

nuts along with washers

at the cylinder head end.

Release the clamp from

the studs.

Remove 2 Hex bolts &

nuts at the silencer

mounting bracket end.

Support the silencer and

remove the bolt.

Gently pull out the

exhaust pipe from the

cylinder head and

remove exhaust pipe

with silen cer from the

vehicle.

Hex Nuts: M8X1.25

Tubular spanner - 12mm

NOTE

Remove copper washer in

cylinder head, exhaust

pipe seating area after

removing exhaust pipe.

Hex bolts: M8 X 1.25X45

Hex Nuts: M8 X1.25

Socket spanner -12mm

Double End Spanner: 12mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

25

S.

Aggregate to Dismantle/

No.

4.16

Instructions

Gear shifter/

linkage

Fastener, Size, Tool Usage, Precautions, Photos

Loosen Hex bolt on small

gear lever mounted on

gear shaft on LH side of

engine.

Slide out small lever from

shaft.

4.17

Rear Chain Link

Lock

Loosen rear wheel axle

nut sufficiently.

Loosen the chain adjuster

nuts on LH & RH sides of

the swing arm and push

the rear wheel inside, to

create sufficient slack in

the rear chain

Hex flange bolt: M6

Socket spanner: 10mm

Remove chain link lock

and remove chain from

the engine sprocket.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

26

S.

Aggregate to Dismantle/

No.

4.18

Instructions

Cradle frame with

Engine, separation

from Main frame

Support cradle frame /

engine suita bly at the

bottom such that it will not

drop of when mounting

bolts are removed.

Fastener, Size, Tool Usage, Precautions, Photos

Loosen Flanged Hex.,

holding cradle frame

top, to main frame.

Remove bolt & connector

complete. (Ensure the

top frame LH&RH and

horn connections are

removed from the

connector tube.)

Loosen Flanged Hex

bolt from the rear top

location of the engine.

DO NOT REMOVE THE

BOLT FROM THE FRAME.

Loosen & remove 2

flanged Hex bolts from

the cradle frame rear

bottom on both LH & RH

sides.

Remove the Flanged Hex

bolt (loosened earlier)

from the rear top

location of the engine.

Hex flange bolt: M10X66

Socket Spanner: 14mm

Hex flange bolt: M10X183

Socket Spanner: 14mm

Hex flange bolts: M10X65

Socket Spanner: 14mm

Loosen & remove

Flanged Hex bolt along

with oil cooler bracket,

holding oil cooler bracket

& cradle frame to main

frame.

Gently remove the support

from the bottom of the

cradle frame / engine

and simul taneously

remo ve cradle frame

with crankcase from

main frame.

Hex flange bolts: M10X75

Socket Spanner: 14mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

27

S.

Aggregate to Dismantle/

No.

4.19

Instructions

Engine separation

from cradle frame

Fastener, Size, Tool Usage, Precautions, Photos

Hold flanged Hex bolt on

Cradle frame top RH side,

and remove Flanged U

nut on the cradle frame

top LH side.

Hold flanged Hex bolt on

Cradle frame bottom RH

side, and remove

Flan ged U nut on the

cradle frame bottom LH

side,

Hold flanged Hex bolt on

Cradle frame rear RH

side, and remove

Flan ged U nut on the

cradle frame rear LH

side.

Remove the 3 studs from

the cradle frame & gently

lift up the engine away

from the frame.

Hex flange bolt: M10X165

Hex U Nut: M10X1.25

Socket Spanner: 14mm

Ring Spanner: 14mm

Hex flange bolts: M10X183

Hex U Nuts: M10X1.25

Socket Spanner: 14mm

Ring Spanner: 14mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

28

INSPECTION & PRECAUTIONS

Inspect all the studs & bolts for bends, distortion, thread wear , threads stripped off etc

Inspect all nuts for thread wear , threads stripped off etc

DO NOT REUSE Nylock Nuts and Hex U nuts, and Pre coated fasteners once they have been tightened and

removed. Replace them every time they have been removed.

DO NOT REUSE Washers, O Rings, Oil seals, Dust seals, rubber and plastic material rubber parts, plastic parts,

gaskets etc once they have been used and removed

Inspect all control cables for internal cables fraying / damage

Carefully inspect studs and nuts that are welded in the frame for any thread damage. If found damaged, use

suitable thread cleaning dies to repair the damages. If the threads are beyond repair, remove the damaged studs/

nuts and reweld new studs / nuts correctly.

Clean the threads in the frame carefully using suitable cleaning and solving agents to clean off dirt and scales

Apply suitable thread locking liquid as appropriate on non precoated fasteners before assembling and tightening

to torque.

Always tighten fasteners diagonally and evenly to the correct specified torque values

Clean, and repaint rusted areas in frame and other parts before assembly

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

29

TORQUE VALUES

S.

No.

Engine Mtg to Cradle Frame - Flanged Hex Bolt

1

front top M10X1.25X165

Engine Mtg to Cradle Frame - Flanged Hex Bolt

2

front Bottom M10 X1.25X183

Engine Mtg to Cradle Frame - Flanged Hex Bolt

3

Rear Bottom M10X1.25X183

4 Cradle frame Mtg to Frame top Flanged Hex Bolt M10X1.25X60 5 0 5. 0 42.5 4.3 57.5 5.8

Cradle frame Mtg to Frame Hex Flange Bolt

5

rear bottom M10X1.25X65

6 Oil Cooler Mtg to frame Hex Flange M6X1X20 10 1.0 8.5 0.9 11.5 1.2

Steady Bracket Mtg to Hex Flange Bolt

7

Cylinder head M10X1.25X47

8 Steady Bracket Mtg to Frame Hex Flange Bolt M8X1.25X20 25 2.5 21.3 2.1 28. 8 2.9

9 Skid Plate Mtg to Cradle frame Hex Flanged Bolt M6X1X10 10 1.0 8.5 0.9 11.5 1.2

10 Side Panels mounting to frame Hex Button Head M6X1X12 5 0.5 4.3 0.4 5. 8 0.6

11 Gear Shift Linkage Mtg to Frame M10X1.25 30 3.0 25.5 2.6 34.5 3.5

Aggregate Fastener

Torque

NM Kg.M

50 5.0 42.5 4.3 57.5 5 .8

50 5.0 42.5 4.3 57.5 5 .8

50 5.0 42.5 4.3 57.5 5.8

50 5.0 42.5 4.3 57.5 5 .8

50 5.0 42.5 4.3 57.5 5 .8

Min. Torque

(Nm) (Kg.M)

Max. Torque

(Nm) (Kg.M)

12 Gear Shift Linkage to Shift shaft M6X1 10 1.0 8.5 0.9 11.5 1.2

13 Fuel tank Mtg to frame Hex Flange M6X1X27 5 0.5 4.3 0.4 5.8 0.6

14 Exhaust Pipe Mtg to Cyl Head Flanged Hex Nut M8X1.25 1 0 1. 0 8.5 0.9 11.5 1.2

15 Silencer Mtg to Frame Hex Socket M8X1.25X25 25 2.5 21.3 2.1 28. 8 2.9

17 Rear Wheel Spindle Nut Hex U Nut M16X1.5 7 0 7.0 59. 5 6.0 80.5 8.1

18 Chain Adjuster Lock nut Hex Nut M8X1.25 25 2.5 21. 3 2.1 28. 8 2.9

Head Lamp Mtg to Support Hex Soc. Hd. screw

19

Brackets M8X1.25X25

Trafficators Mtg to Support

20

Brackets

Windshield Mtg to Support

21

Brackets

Button Head M6X1X20 5 0 .5 4.3 0.4 5.8 0.6

Hex Socket Head Screws M5X16 5 0.5 4.3 0.4 5.8 0.6

10 1.0 8.5 0.9 11.5 1.2

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

30

ENGINE ASSEMBLY TO FRAME

S.

Aggregate to Assemble/

No.

4.20

Instructions

Engine on Cradle

Frame

Locate Engine on cradle

frame & ensure the 3

mounting holes of the

cradle frame and th e

engine are aligned.

Insert Hex bolt M10X165

from RH side and

assemble U nut

M10X1.25. DO N OT

TIGHTEN FULLY.

Insert2 flanged Hex bolts

M10X183 from the front

& rear bottom RH side

and assemble U nut

M10X1.25. DO N OT

TIGHTEN FULLY.

Tighte n al l the

mo untings diagonally

to torque.

Hex flange bolts:

M10X165 & M10X183

Hex U Nuts: M10X1.25

Ring Spanner: 14mm.

Socket Spanner: 14mm.

Torque: 50 Nm (5.0 Kg.M)

Fastener, Size, Tool Usage, Precautions, Photos

4.21

Cradle frame with

engine, on Main

Frame

Locate cradle frame /

engine from underneath

main frame and lift up

with suitable support

under engine such that

the stud mounting holes

align as follows:

- Crankcase rear top hole

with frame mounting.

- 2 mounting holes of

cradle frame with 2 holes

in frame down tube.

- 2 mounting holes at the

rear bottom of cradle frame

with 2 holes in main frame.

Insert flanged Hex Bolt

M10X 183 at rear top of

engine and assemble U

nut.

DO NO T TIG HTE N

FULLY.

Hex flange bolts:

M10X183 & M10X165

Hex U Nuts: M10X1.25

Ring Spanner: 14mm.

Socket Spanner: 14mm.

Torque: 50 Nm (5.0 Kg.M)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

31

S.

Aggregate to Assemble/

No.

4.21

Instructions

Cradle frame with

engine, on Main

Frame

Locate 2 flanged Hex

bolts M10X65, at rear

bottom, LH & RH sides

and assemble U nuts DO

NOT TIGHTEN FULLY.

Position Oil cooler

mounting bracket in

frame with its small tab

resting on the frame

inside.

Align the mounting hole

with the low er

mounting hole in frame.

Locate Flanged Hex bolt

M10X75, over oil cooler

bracket and assemble U

nut. DO NOT TIGHTEN

FULLY.

Ti ghten all the

mo untings diagonally

to torque.

Fastener, Size, Tool Usage, Precautions, Photos

Hex flange bolt: M10X75

Hex U Nut: M10X1.25

Ring Spanner: 14mm.

Socket Spanner: 14mm.

Torque: 50 Nm (5.0 Kg.M)

4.22

Rear chain

assembly and chain

adjustment

Place vehicle on center

stand with the rear

wheel off the ground.

Ensure rear axle nut, lock

nuts & adjuster nuts on the

LH & RH chain adjusters

are loosened fully.

Push wheel fully inside.

Route rear chain through

final drive sprocket and

locate it on rear wheel

sprocket

Ensure ‘O’ rings are

located on the chain link

and Insert link from the

inside of the chain.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

32

S.

Aggregate to Assemble/

No.

4.22

Instructions

Rear chain

assembly and chain

adjustment

Assemble ‘O’ Rings on

the chain link and

assemble the link plate.

Assemble chain link lock

on the chain link,

ensuring the closed end

of the lock is towards the

normal direction of

rotation of the chain.

Fastener, Size, Tool Usage, Precautions, Photos

Tighten adjuster nuts on

LH & RH side evenly till

the chain has a slack of

20 to 25 mm on its top

run.

Ensure the reference

lines on the LH & RH chain

adjusters are matching

at the same reference

lines in the swing arm on

LH & RH sides.

Tighten rear wheel axle

nut to torque.

Tighten lock nuts against

the adjuster nuts on LH

& RH sides.

4.23

Gear Shifter /

Linkage

Locate small lever on

gear shift shaft, ensuring,

small lever is vertical to

ground and the gear

shift pedal is parallel to

rider footrest LH.

Hex U Nut: M17

Socket Spanner: 24mm.

Torque: 70-80Nm

(7.0-8.0Kg.M)

Hex Flange Bolt : M6X20

Socket Spanner : 10mm.

Torque: 10Nm(1.0Kg.M)

Assemble Hex bolt on

gear shift lever short

from the front side and

tighten to torque.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

33

S.

Aggregate to Assemble/

No.

4.24

Instructions

Pulse air valve

Connections

Fastener, Size, Tool Usage, Precautions, Photos

Braided hose (PAV to

Cylinder head)

Locate gasket on cylinder

head with a little grease

to hold it in position.

Locate PAV pipe flange

on the gasket. ENSURE

THE OPEN END OF THE

PIPE IS FACING

UPWARDS.

Tighten PAV pipe to

cylinder head with 2 hex

socket head cap screws.

Locate braided hose with

worm clip on the PAV outlet

pipe and tighten screw.

4.25

Exhaust pipe &

Silencer

Locate a new exhaust

pipe gasket on the

exhaust pipe.

Locate exhaust pipe

into the cylinder head,

position the clamp over

the studs on the cylinder

head & assemble 2 hex

nuts M8 DO NO T

TIGHTEN FULLY.

Position silencer

mounting bracket

against the frame at the

rear and insert flanged

hex bolt. Assemble hex

nut over bolt.

Tighten the 2 hex nuts

at the cyli nder head,

first an d t he n t he

silencer bracket nut.

Hd. Cap screws: M6X20

Allen Key: M5

Torque :

NOTE

Asse mble new exhaust

pipe gasket before locating

exhaust pipe in cylinde r

head.

Hex Nuts: M8X1.25

Socket spanner -12mm

Torque: 10Nm (1.0Kg.M.)

Hex bolts: M8 X 1.25X45

Hex Nuts: M8 X1.25

Socket spanner -12mm

Double End Spanner:

12mm

Torque: 25Nm (2.5Kg.M)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

34

S.

Aggregate to Assemble/

No.

4.26

Instructions

Throttle Cable

Ensure hex nut and

rubber grommet are

located on the inner

cable properly.

Locate inner cable in the

Carburetor.

Gently pull outer cable

upwards till the inner

cable can be located into

the brake t slot and

release slowly till the

threaded portion of the

outer cable isfully resting

on the bracket.

Tighten outer cable to

bracket using the hex

nut M6.

Slide the rubber

grommets over the

threaded sleeve on

outer cable.

Fastener, Size, Tool Usage, Precautions, Photos

Hex nut : M6

Double end spanner :

10mm

Adjust the throttle cable

free play correctly.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

35

S.

Aggregate to Assemble/

No.

4.27

Instructions

Steady engine plate

Position steady engine

plate such that the single

mounting hole aligns

with the cylinder head

mounting location & the

2 mounting holes align

with the welded nuts in

the frame.

Fastener, Size, Tool Usage, Precautions, Photos

Locate 2 Flanged Hex

Bolts over the steady

engine plate.

DO NO T TIG HTE N

FULLY.

Locate Flanged Hex Bolt

at the front end of the

steady bracket, through

the cylinder head &

assemble flange U Nut.

Tighten all the bolts to

torque.

4.28

Electrical

connections

A. St arte r Motor

Connections:

Position earth wire

eyelet on outer

mounting hole of starter

motor & tighten with

flanged hex bolt.

Locate Relay starter

cable on the starter

motor terminal & tighten

with Hex nut.

Flanged hex bolts:

M10X20

Socket Spanner: 12mm

Torque: 20Nm. (2.0Kg.M)

Flanged hex bolt: M10X47

Socket Spanner: 12mm

Flanged hex nut: M10X1.25

Ring Spanner: 12mm

Torque: 50Nm(5Kg.M.)

Socket Spanner: 10mm

Hex flange bolt: M6 X 30

Socketspanner: 8mm

Torque: 8-12Nm

(.8-1.2Kg.M)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

36

S.

Aggregate to Assemble/

No.

4.29

Instructions

Electrical

connections

Fastener, Size, Tool Usage, Precautions, Photos

G. Magneto

Connect white coupler

on LH side to wiring

harness

Connect small Black

coupler (Pulsar wire

connections on LH Side

to wiring harness.

H. Gear position switch

CAUTION

Ensure Ignition switch &

engine stop switch is in OFF

position before connecting

any wiring couplers.

NOTE

Connect BIG & SMALL

Black coupler to wiring

harness on LH side.

Ensure Protection

couplers are correctly slid

over the coupler after

connecting. Ensure wiring

harness is correctly

strapped to frame after

connecting couplers.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

37

S.

Aggregate to Assemble/

No.

4.29

Instructions

Electrical

connections

I. Si de st and switc h

coupler

Connect Red coupler to

wiring harness on LH

side.

J. Battery Connections

Connect Positive

terminal (Red) to the

positive terminal of the

battery.

Fastener, Size, Tool Usage, Precautions, Photos

Connect negative

terminal (Black) to

negative terminal of the

battery.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

38

S.

Aggregate to Assemble/

No.

4.30

Instructions

Fuel tank Assembly

Position fuel tank such

that the front mounting

clamps are correctly

located on the rubber

supports on the frame.

Gently push fuel tank

forward to lock in place.

Lift rear end of the tank

slightly and :

- Route the drain hose

between the frame

without any kinks.

- Connect blue coupler of

Low fuel sensor to wiring

harness

Ensure rubber grommets

are in place in the rear

mounting hole s and

align mounting holes to

the frame,

Locate 2 washers on the

hex flange bolts,

assemble the bolts and

tighten to torque.

Connect fuel hose to fuel

tap and carburetor and

lock the clips in place.

Fastener, Size, Tool Usage, Precautions, Photos

Hex Flange Bolt M6

Socket Spanner 10 mm

Torque 5 NM (0.5 Kg.M)

4.31

Side Panel LH & RH

Locate the tab of the

side panel in the rubber

grommet in frame and

press in gently.

Assemble 3 Hex socket

Button head screws over

the panel and tighten.

Hex. Soc Button Hd Screw:

M6X12

Allen Key: M5

Torque: 5Nm(0.5Kg.M)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

39

S.

Aggregate to Assemble/

No.

4.32

Instructions

Side Panel RH

Fastener, Size, Tool Usage, Precautions, Photos

Locate the tab of the

side panel in the rubber

grommet in frame and

press in gently.

Assemble 3 Hex socket

Button head screws over

the panel and tighten.

4.33

Rider & Pillion Seat

Locate the rider seat tab

under the fuel tank and

position the locking plate

centrally on the frame.

Locate rear seat tab in

the frame, align lock pin

with the seat latch and

gently press on seat to

lock.

Hex. Soc Button Hd Screw

M6X12

Allen Key: M5

Torque: 5Nm (0.5Kg.M)

Remove key after

locking pillion seat.

4.34

Connector tube &

Top frames

Position connector tube

from inside the frame

such that the horn

mounting bracket is on

the RH side.

Align mounting holes

with the upper

mounting hole in Frame.

Hex flange bolt: M10X75

Socket Spanner: 14mm.

Torque: 50 Nm (5.0 Kg.M)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

40

S.

Aggregate to Assemble/

No.

4.34

Instructions

Connector tube &

Top frames

Locate Flanged Hex bolt

from LH side & thread

into the welded nut

Ensure the 2 Hex socket

screws in top frames LH

& RH are loose & locate

on the connector tube

till they are flush with

the outer surface of the

connector tube.

Do not ti ghte n the

screws.

Fastener, Size, Tool Usage, Precautions, Photos

Hex Socket Hd. Cap

screws: M6

Allen Key: M5

Flanged hex bolts: M8

Socket Spanner: 12mm

Torque: 25Nm(2.5 Kg.M)

Align the mounting

holes of top frames LH &

RH with the holes in the

cockpit mounting

bracket assembly and

tighten using Hex bolts.

Tighten the 2 hex socket

head cap screws on the

top frame LH & RH to

clamp them against the

connector tube.

Ensure the dust caps are

fitted on the connector.

4.35

Horn

Locate horn in the

bracket and tighten.

Connect horn terminals

Flanged Hex Bolts: M8

Socket Spanner: 12mm

Torque: 25Nm(2.5Kg.M)

NOTE

Take care not to damage

fuel tank or fork legs while

assembling the top frames.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

41

S.

Aggregate to Assemble/

No.

4.36

Instructions

Trafficator front LH

Fastener, Size, Tool Usage, Precautions, Photos

Locate the front lug of

the cockpit cover into

the rubber grommet in

top frame LH.

Insert trafficator with

GREEN wire coupler into

cover cockpit on LH side.

Tighten trafficator to the

top frame with hex

socket button head

screw & hex nut.

Connect the wiring

coupler to the wiring

harness

4.37

Trafficator front RH

Hex Socket Hd. Cap

screws: M6X20

Allen Key: M5

Hex Nut: M6

Double end spanner:10mm

Torque: 10Nm.(1.0Kg.M.)

NOTE:

Couplers are color coded as:

LH side: Green

RH side: Red

Locate the front lug of

the cockpit cover into

the rubber grommet in

top frame RH.

Insert trafficator with

RED wire coupler into

cover cockpit on RH side.

Tighten trafficator to the

top frame with hex

socket button head

screw & hex nut.

Connect the wiring

coupler to the wiring

harness

Hex Socket Hd. Cap

screws: M6X20

Allen Key: M5

Hex Nut: M6

Double end spanner:10mm

Torque: 10Nm.(1.0Kg.M.)

NOTE:

Couplers are color coded as:

LH side: Green

RH side: Red

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

42

S.

Aggregate to Assemble/

No.

4.38

Instructions

Headlamp

Assembly

Fastener, Size, Tool Usage, Precautions, Photos

Position head lamp

assembly between top

frames LH & RH an d

ensure the mounting

holes are aligned.

Locate 2 Hex socket

head screws on either

sides of the top frame

and tighten.

Connect head lamp

wiring coupler.

Ensure the dust caps are

fitted in the slots on LH &

RH sides.

4.39

Windshield

Assembly

Locate 4 rubber nuts in

the top frame LH & RH.

Locate wind shield on

the top frame, ensure

the mounting holes are

aligned on both sides

and tighten using 4 Pan

head screws with plastic

washers..

Hex Socket Hd. Cap

screws: M8X25

Allen Key: M6

Torque: 10Nm.(1.0Kg.M.)

NOTE:

Ensure the head lamp beam

is properly aligned before

final torqueing

Pan Head screws: M8X25

Philips screw driver

Torque: 5Nm.(0.5Kg.M.)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

43

S.

Aggregate to Assemble/

No.

4.40

Instructions

Clutch Cable

Assembly

Ensure proper location

of inner cable in clutch

lever & outer cable in LH

bracket at handle bar

end.

Ensure proper routing

of cable along the frame

and in sert into the

bracket in cover RH.

Assemble outer lock nut

& larger end of rubber

grommet on the adjuster.

Lock inner cable in the

clevis on Cover RH, gently

pull cable outwards till

resistance is felt & thread

out inner lock nut so that

it rests against the bracket

Ensure 2–3 mm clutch

lever free play at handle

bar end by suitably

turning inner lock nut on

cable cable.

Tighten outer lock nut

against cable bracket.

Fastener, Size, Tool Usage, Precautions, Photos

NOTE:

Ensure the rubber grommet

is correctly positioned

between adjuster & clutch

lever on RH cover

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

44

S.

Aggregate to Assemble/

No.

4.41

Instructions

Oil Cooler

Insert Oil cooler pipe No

2 from the left side to the

Right side, between the

engine and the cradle

frame.

Fastener, Size, Tool Usage, Precautions, Photos

Position Oil cooler

mounting holes with the

bracket on LH side &

tighten with 2 flanged

Hex bolts

Position 1 each

aluminum washer on

either sides of the hose

banjo union of H os e

no.2 and tighten to

cover RH with Banjo

union bolt.

Position 1 each

aluminum washer on

either sides of the hose

banjo union ofHose no.1

and tighten to

crankcase LH with Banjo

union bolt.

Flanged Hex bolts: M6X20

Socket spanner: 8mm.

Torque: 10Nm.(1.0Kg.M.)

Banjo Union Bolts: M14

Socket spanner: 19mm.

Torque: 38Nm.(3.8Kg.M.)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

45

S.

Aggregate to Assemble/

No.

4.42

Instructions

Skid Plate

Assemble the 4 rubber

bushes in the bottom

mounting holes of the

Skid plate and locate 4

damper bushes on the

rubber bushes.

Position the Skid plate

under the cradle frame

and align the mounting

holes. Ensure the

damper bushes do not

fall off.

Assemble 4 Fl an ged

Hex Bolts M6 X1 X 35 at

the bottom of the Skid

plate.

Fastener, Size, Tool Usage, Precautions, Photos

Flanged Hex Screw: M6

Socket Spanner: 10mm

Torque: 10Nm (0.1 Kg.M)

Assemble 2 Flan ged

Hex Bolts, M6 X 1 X 14

at the front of the skid

plate.

Tig hte n all the 6 bolts

evenly and diagonally.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

46

SECTION 05 - RIDER & PILLION SEAT

EXPLODED VIEWS

RIDER & PILLION SEAT

1

2

3

4

5

S. NO.

DESCRIPTION

1 Pillion Seat Assy 1

2 Rider Seat Assy 1

QTY. S. NO.

4 Rubber Support - Rear 4

5 Tool Kit Strap 1

4

3

DESCRIPTION

QTY.

3 Rubber Support - Front 4

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

47

S.

Aggregate to Dismantle/

No.

Instructions

5.1 Rider & Pillion Seat

Dismantling

Unlock pillion seat by

turning key clockwise &

lift pillion seat from front

end to release rear tab &

remove.

Fastener, Size, Tool Usage, Precautions, Photos

Lift rider seat from rear

end to release front tab

& remove.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

48

S.

Aggregate to Assemble/

No.

Instructions

5.2 Rider & Pillion Seat

Assembly

Locate the rider seat tab

under the fuel tank and

position the locking

plate ce ntrally on the

frame.

Locate rear seat tab in

the frame, align lock pin

with the seat latch and

gently press on seat to

lock.

Fastener, Size, Tool Usage, Precautions, Photos

Remove key after

locking pillion seat.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

49

SECTION 06 - CONTROL CABLES

EXPLODED VIEWS

CONTROL CABLES

1

3

2

S. NO.

1 Clutch Cable Assy. 1

2 Throttle Cable Assembly 1

3 Seat Latch Cable Assy 1

DESCRIPTION

QTY.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

50

S.

Aggregate to Dismantle/

No.

Instructions

6.1 Clutch Cable

Removal from

Cover RH end

Fastener, Size, Tool Usage, Precautions, Photos

Loosen outer lock nut of

the cable adjuster on

Cover RH, completely.

Loosen inner locknut

sufficiently such that the

adjuster can be pushed

in to release inner cable

from clutch lever.

Release the inner cable

from the clevis in the

clutch lever on cover RH

Remove the rubber

grommet from the

clutch cable

Remove the outer lock

nut from the clutch cable

Hex Nut: M8

D E Spanner: 12mm

NOTE:

Gently pus h the rubbe r

grommet away from the

adjuster while removing

nut.

Pull out the clutch cable

from the front end of

the bracket.

Removal from Handle bar

end

Remove the outer cable

from the clutch lever

holder assembly at the

handle bar end.

Remove clutch cable

inne r from the clutch

lever

Remove the clutch cable

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

51

S.

Aggregate to Dismantle/

No.

Instructions

6.2 Throttle Cable

Removal from

Carburetor end

Loosen bottom hex nut

and unscrew till it is free

from the throttle cable

adjuster.

Loosen top lock nut till it

is resting against the top

of the adjuster.

Lift throttle rotor up till

cable becomes free from

the rotor, gently rotate

the cable and remove

from the rotor eyelet.

Remove the bottom lock

nut from the cable

Remove cable adjuster

and inner cable from the

bracket.

Removal from Handle bar

end

Loosen & remove

throttle cable stop plate

screw at the bottom of

the throttle rotor grip

housing on handle bar

RH

Loosen & remove 2

screws at the bottom of

the throttle rotor grip

housing on handle bar

RH.

Lower the housing and

release the inner cable

from the eyelet on the

throttle rotor

Remove the inner cable

on the throttle rotor

housing bottom

Fastener, Size, Tool Usage, Precautions, Photos

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

52

INSPECTION

Carefully inspect inner cable top and bottom ends for frayed strands, loose noipples on the cable and/ or uneven

wear of the nipple surfaces

Free movement of the inner cable inside outer cable.

Carefully inspect the outer cables for cuts / damages.

Brittleness of the cables and no flexibility.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

53

S.

Aggregate to Assemble/

No.

Instructions

6.3 Clutch Cable

Assembly at Handle

bar end

Locate inner cable nipple

in the slot in clutch lever

Locate outer cable in the

clutch lever bracket.

Route cable suitably

along the frame from the

LH side such that the

other end is towards the

clutch cover.

Assembly at Clutch cover

end:

Insert inner cable into

the clutch bracke t on

Cover RH till the inner

lock nut on threaded

adjuster is resting on the

bracket. (Ensure inner

locknut is fully threaded

into adjuster

Insert the outer lock nut

through the inner cable

and thread it on the

adjuster by 3 or 4 turns.

Insert larger end of the

rubber grommet on the

inner cable and position

it on the adjuster.

Locate the inner cable on

the clutch lever clevis.

Gently pull the cable

adjuster out of the

bracket - as far as possible

and tighten outer lock

nut against the bracket.

Check clutch lever free

play is between 2-3 mm

and tighte n /loosen

inner lock nut.

Tighten outer locknut

against clutch bracket.

Fastener, Size, Tool Usage, Precautions, Photos

NOTE:

Ensure proper seating of

rubber grommet on the

cable adjuster.

Hex Nut: M8

D E Spanner: 12mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

54

S.

Aggregate to Assemble/

No.

Instructions

6.4 Throttle cable

Assembly at Handle

bar end

Route throttle cable

inne r through the

bottom half of the

throttle rotor housing.

Fastener, Size, Tool Usage, Precautions, Photos

Insert throttle rotor on

handle bar RH and locate

inner cable in the rotor

eyelet

Support bottom half of

the throttle rotor

housing against handle

bar and ensure proper

resting of throttle rotor

on top of the housing.

Position top housing

over bottom housing,

ensuring the mounting

holes are matching and

the throttle rotor is

located in the slot in the

housing and rotates freely.

Locate long head screw

in front mounting hole

and the short screw in

rear mounting hole of

bottom housing and

tighten evenly till the

housing are firmly

tightened against

handle bar.

NOTE:

Ensure free rotation of the

throttle rotor in handle

bar.

NOTE:

Ensure free movement of

throttle rotor and cable

before tightening the

screws fully.

Philips head screw driver

Locate throttle cable

stop plate on outer cable

and tighten to bottom

housing with screw.

Route the throttle cable

below fuel tank and strap

properly to frame.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

55

S.

Aggregate to Assemble/

No.

Instructions

6.4 Throttle cable

Assembly on

carburetor end

Ensure top lock nut in

the cable adjuster is fully

threaded into adjuster

and insert cable into the

bracket on carburetor

end.

Assemble bottom lock

nut on cable adjuster.

Locate inner cable in the

throttle rotor eyelet .

Gently pull the adjuster

upwards and tighten

top lock nut against the

bracket

Fastener, Size, Tool Usage, Precautions, Photos

Ensure free play of 2 –

3mm at the throttle rotor

at the handle ba r end

and adjust top lock nut

accordingly.

Tighten bottom lock nut

against the bracket at

carburetor end

Hex Nut: M6

D E Spanner: 10mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

56

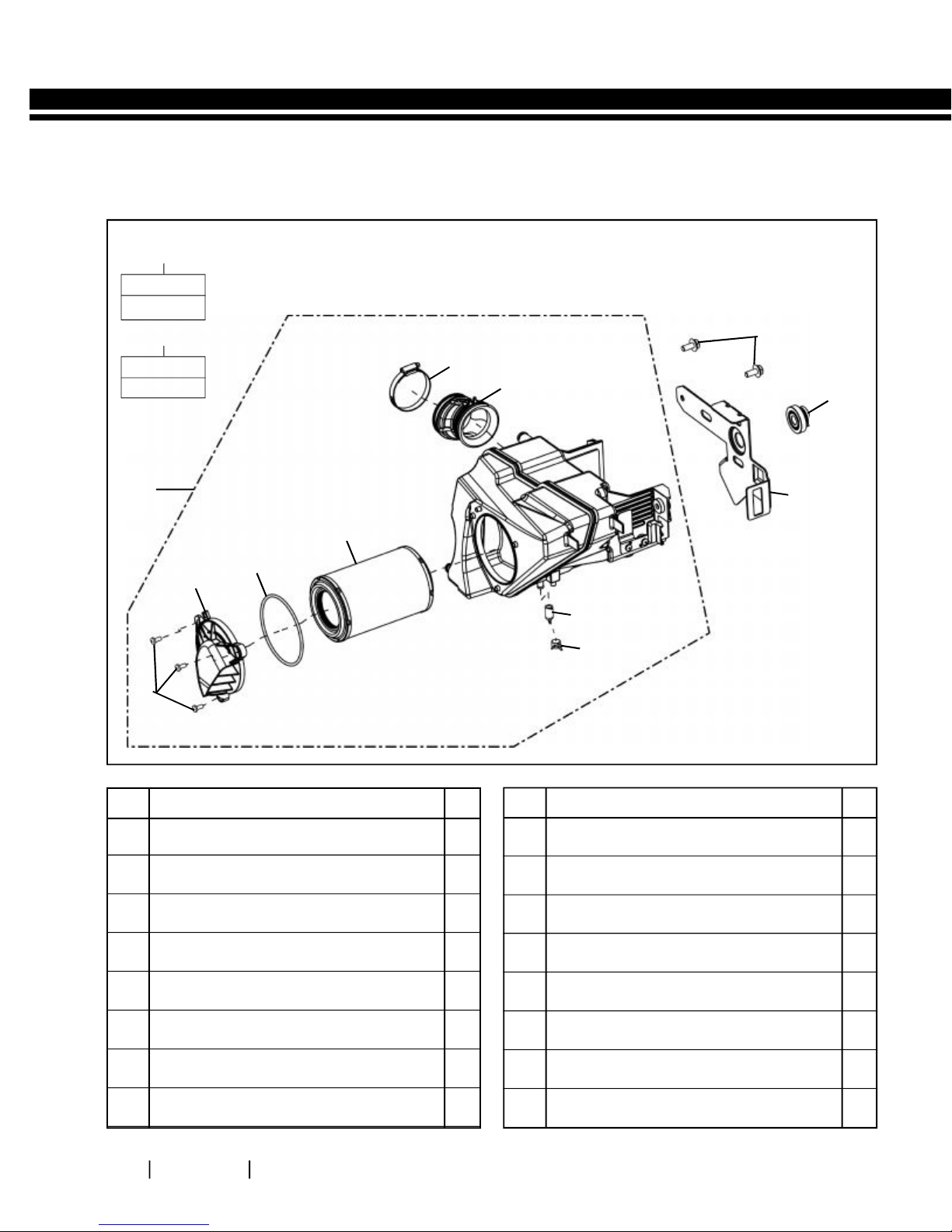

SECTION 07 - AIR FILTER

EXPLODED VIEWS

AIRFILTER

A1

Key Nos.

3 & 4

A2

Key Nos.

1 to 8

5

9

6

10

A2

4

2

1

S. NO.

3

DESCRIPTION

A1 A/F Element Kit 1

A2 Air Filter Box Assembly 1

1 Pan Head Screw M5 X12 3

QTY. S. NO.

7 Drain Tube 1

8 Clip 1

9 Hex Flange Bolt, M6 X 1 X 14 2

11

7

8

DESCRIPTION

QTY.

2 Inlet Cover 1

3 Seal 1

4 Element Air Filter 1

5 Clamp 1

6 Pipe Outlet 1

10 Rear Damper - Tank 1

11 Lid – Battery Carrier 1

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

57

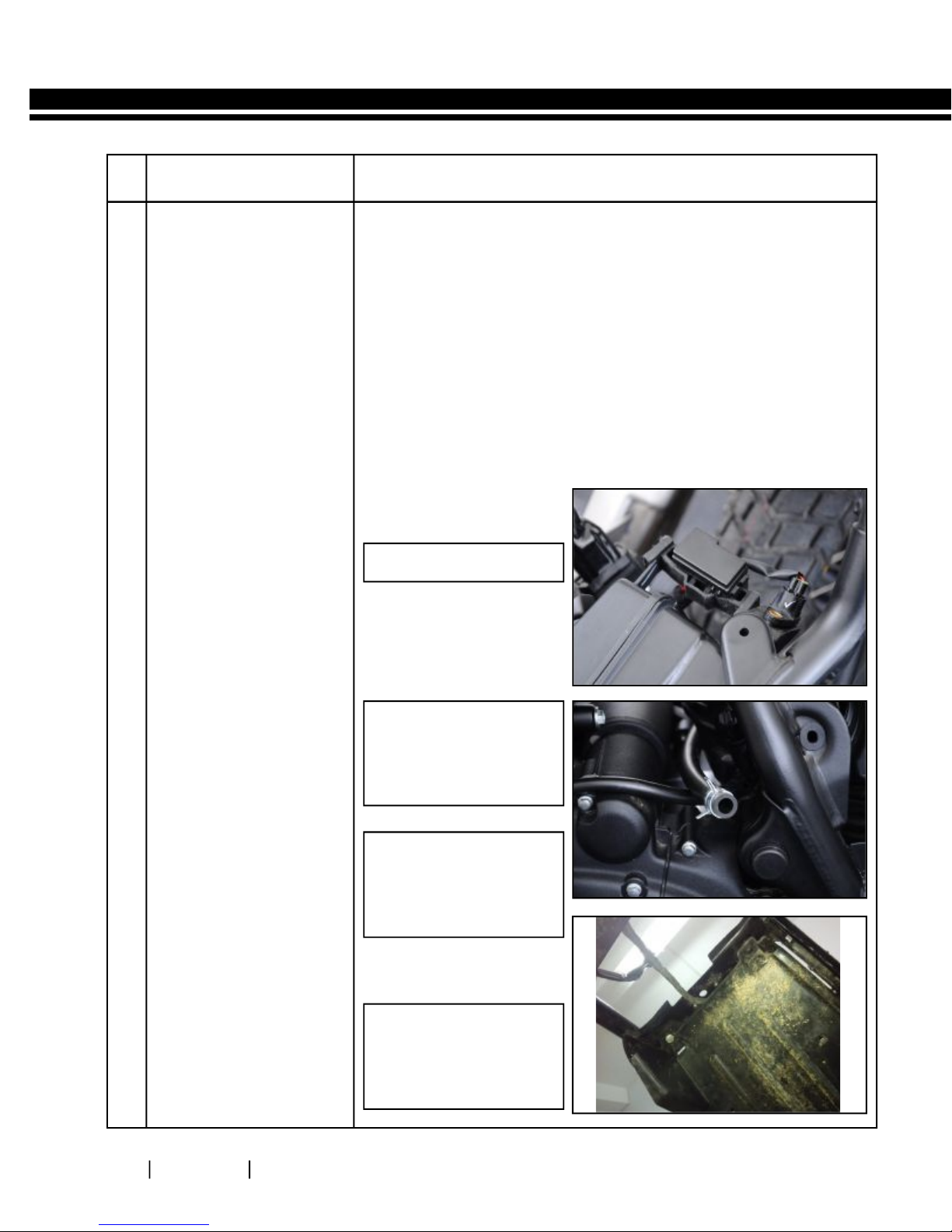

S.

Aggregate to Dismantle/

No.

Instructions

7.1 Air filter Element

from housing

Fastener, Size, Tool Usage, Precautions, Photos

Remove 2 hex socket

button head screws

from the LH side panel.

Pull out the side panel

gently to release from

the grommet in the

frame.

Loosen & Remove the 3

Pan head screws from

the air filter cover.

Remove Cover.

Pan head Screw M5

Allen Key 4mm

Pan head Screw M5

Allen Key 4mm

Remove air filter element

from housing.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

58

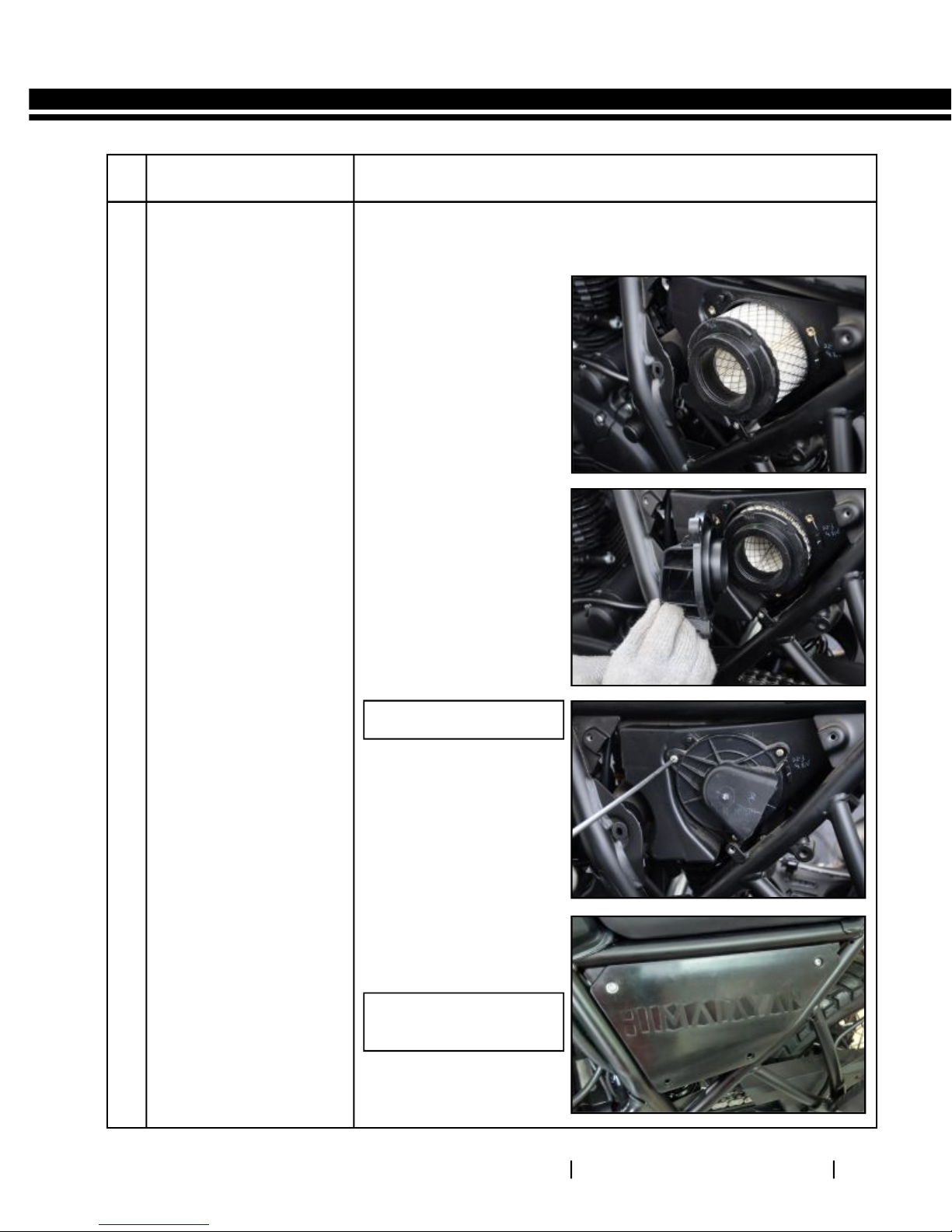

S.

Aggregate to Dismantle/

No.

Instructions

7.2 Air filter Housing

from frame

Fastener, Size, Tool Usage, Precautions, Photos

Disconnect battery

terminals and remove

from air filter housing.

(refer electricals section

for dismantling battery)

Remove 4 flanged hex

bolts and remove piece

mudguard.

Disconnect breather

hose from air filter

housing

Loosen carburetor

worm clip sufficiently.

Loosen & remove 2

flanged hex bolts,

holding air filter housing

to frame

Gently pull out Fuse box

along with its rubber

holder from air filter

housing

Remove RR unit with its

rubber holder from air

filter housing

Loosen and remove 3

flange hex bolts holding

the cross bar assembly

below air filter housing

to frame

Remove cross bar

assembly

Loosen flanged Hex

bolt, holding bracket air

filter to frame and

remove the bolt and

bracket air filter.

Remove air filter housing

from rear side of the

frame.

Hex Bolts: M6

Socket spanner: 8mm

Screw driver

Hex Bolts: M8

Socket spanner: 12mm

NOTE:

Ensure the wiring connections

are removed

Hex Bolts: M6

Socket spanner: 10mm

Hex Bolts: M8

Socket spanner: 12mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

59

INSPECTION & CLEANING

Inspect air filter element carefully for any deformation, damages, heavily clogged with dirt, soggy condition, and

/ or foreign particles embedded in the element. Replace if any of these conditions are observed.

Inspect rubber seals, hoses, for cuts, cracks, damages.

Clean Air filter element every 5,000 Kms OR more frequently if motorcycle is used in dusty / Off road conditions.

Gently Tap filter element with minimum force to dislodge heavy / embedded dust particles.

Use compressed air from the outside of the filter element to remove dust particles

Clean the element on the inside and outside using a soft cloth

Clean the insides of the air filter housing and cover using a soft cloth

Replace seals, ‘O’ Rings and rubber parts whenever the induction system is serviced.

Replace Air filter element every 15,000 Kms or earlier if motorcycle is used in dusty / off road conditions.

TORQUE VALUES

S.

No.

1 Bracket Assy-Airfilter top Flanged Hex Bolt M8 X 1.25 X 16 22.5 2.25

2 Bracket Assy-Airfilter bottom Flanged Hex Bolt M6 X 1 X 20 10 1.0

3 Crossbar Assy Flanged Hex Bolt, M6 X 1 X 14 10 1.0

4 Piece mudguard Flanged Hex Bolt, M6 X 1 X 20 1 0 1. 0

5 Lid battery carrier Flanged Hex Bolt, M6 X 1 X 14 10 1.0

Aggregate Fastener

Torque

NM Kg.M

Min. Torque

(Nm) (Kg.M)

20 2.0

8 0. 8

8 0. 8

8 0. 8

8 0. 8

Max. Torque

(Nm) (Kg.M)

25 2.5

12 1.2

12 1.2

12 1.2

12 1.2

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

60

S.

Aggregate to Assemble/

No.

Instructions

7.3 Air filter Housing

on frame

Position air filter

housing inside frame

from rear side with its

outlet hole facing

carburetor.

Ensure connecting is

correctly & fully seated

on both air filter and

carburetor & tighten hose

clip to prevent slipping

of the connection tube

Fastener, Size, Tool Usage, Precautions, Photos

Screw driver

Locate cross bar assembly

under air filter housing

and tighten to frame

using 2 flanged hex bolts.

Position bracket assembly,

air filter on frame RH side

and tighten using

flanged hex bolt M8 on

top and 2 M6 flanged

hex bolts at bottom.

Assemble piece mudguard

and tighten to frame

with flanged bolts,

washers and nylock nuts.

Assemble batter y,

connect terminals, locate

lid battery carrier in

housing and tighten with

hex bolts. (Refer electricals

section for battery

assembly)

Flanged Hex Bolts: M6

Socket spanner: 8mm

Torque:8-12Nm(0.8-1.2

KgM.)

Flanged Hex Bolt: M8

Socket spanner: 12mm

Torque:20-25Nm(2.0-2.5

KgM.)

Flanged Hex Bolt: M6

Socket spanner: 8mm

Torque: 8-12Nm(0.8-1.2

KgM.)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

61

S.

Aggregate to Assemble/

No.

Instructions

7.4 Air filter Element

into housing

Locate air filter element

in housing such that the

open end of the element

is facing outside.

Locate cover on the air

filter housing such that

the locating pegs and the

three mounting hole s

are aligned.

Fastener, Size, Tool Usage, Precautions, Photos

Tighten cover with 3

screws evenly and firmly

Locate side panel with its

bottom leg located in the

rubber grommet

Tighten side panel with

2 hex socket button

head screws

Philips head screw driver

Pan head screw M5

Allen Key 4mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

62

SECTION 08 - PULSE AIR VALVE

EXPLODED VIEWS

PULSE AIR VALVE

3

2

12

1

13

10

14

4

5

6

7

5

6

8

13

9

S. NO.

DESCRIPTION

1 PAV - Air Filter Hose 1

2 Clip 1

3 Flange Nyloc Type Nut M6 X 1 2

4 Pulse Air Valve 1

5 Damper - Oil Cooler 2

6 Spacer - Oil Cooler 2

7 Hex flange bolt M6 X 30 2

QTY. S. NO.

8 Clip – PAV Adaptor 2

9 PAV Adaptor Hose 1

10 Gasket Mounting Plate 1

11 Braided Hose assy 1

12 SS Hose Clip 1

13 Hex Socket Head Cap Screw M6 X 20 2

14 Clip - PAV air filter hose 1

DESCRIPTION

8

QTY.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

63

S.

Aggregate to Dismantle/

No.

Instructions

8.1 Pulse air valve pipe

connections

Remove fuel tank from

frame.

Gently expand the clip

and disconnect rubber

hose from inlet

manifold.

Disconnect air inlet hose

from pulse air valve.

Puls e a ir va lv e b ra id ed

hose:

Fastener, Size, Tool Usage, Precautions, Photos

Loosen screw on the SS

hose clip.

Loosen & remove 2 hex

socket head cap screws

holding braided hose

flange to cylinder head

on the exhaust end.

Gently pull out braided

hose from pulse air valve

bottom tube and

remove along with

gasket.

Pulse air valve from frame:

Holding the nuts on the

inside, loosen and

remove the 2 flanged

hex bolts from frame

Remove pulse air valve

from frame, taking care

not to drop the spacers

and dampers

Screw driver

Hex. Soc head cap screw:

M6X20

Allen Key 5mm

Hex bolts & nuts: M6

Double end spanner:

8mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

64

INSPECTION

Inspect the hoses for ageing, cuts and / or cracks. Replace as recommended.

Inspect braided hose for any leaks, cracks and proper sealing at cylinder head

TORQUE VALUES

S.

No.

1 Braided hose mtg to cyl head Hex Socket Head Cap Screw M6 X 20 10 1.0

2 PAV mtg to frame Hex flange bolt M6 X 30 10 1.0

Aggregate Fastener

Torque

NM Kg.M

Min. Torque

(Nm) (Kg.M)

8 0. 8

8 0. 8

Max. Torque

(Nm) (Kg.M)

12 1.2

12 1.2

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

65

S.

Aggregate to Assemble/

No.

Instructions

8.2 Pulse air valve on

frame

Locate pulse air valve in

the frame such that the

outlet is facing down, the

inlet from carburetor is

on the RH side and the

inlet from air filter is on

the Left side of the frame

Fastener, Size, Tool Usage, Precautions, Photos

Ensure the dampers and

spacers are in place in

the mounting locations

and tighten with 2 hex

flange bolts M6X30

Apply grease on the

gasket and locate it on

the cylinder head

Locate worm clip on the

braided hose and

assemble braided hose

on the outlet tube of the

pulse air valve

Position braided hose

flange over the gasket on

cylinder head , align the

holes and tighten with

two hex socket head cap

screws

Flanged Hex Bolts: M6

Socket spanner: 8mm

Torque:10-12Nm

(1.0-1.2 Kg.M)

Screw driver

Hex soc hd cap screws:

M6X20

Allen key: M5

Torque:10-12Nm

(1.0-1.2 Kg.M)

Tighten worm clip over

the braided hose.

Connect the rubber

hoses from airfilter and

inlet manifold

respectively and slide

the clips in place.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

66

SECTION 09 - FUEL TANK

EXPLODED VIEW

FUEL TANK

15

11

1

2

3

4

12

13

14

S. NO.

DESCRIPTION

1 Fuel Tank With Sticker 1

2 Flanged Hex Bolt M6 X 1 X 27 2

3 Bush - Fuel Tank 2

4 Rear Damper-Tank 2

5 Fuel Hose 1

6 Drain Hose 1

7 Fuel Tap Assy 1

8 Plain Washer 2

11

QTY. S. NO.

9 Fiber Washer 2

10 Hex socket head cap screw M6X16 2

11 Front Damper-Tank 2

12 O Ring-Fuel Gauge 1

13 Fuel Level Sensor Unit 1

14 Hex Flange Nut M5 X 0.8 4

15 Hex socket head cap screw M5X16 3

10

7

8

9

5

6

DESCRIPTION

QTY.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

67

S.

Aggregate to Dismantle/

No.

Instructions

9.1 Fuel tank -

Dismantling

Fastener, Size, Tool Usage, Precautions, Photos

Remove Seat Assembly

Disconnect fuel hose

from carburetor end.

Remove 2 Hex screws

from the rear end of fuel

tank.

Disconnect fuel gauge

coupler wire by lifting the

tank slightly.

Slide fuel tank towards

rear to release front

clamp from frame.

Remove tank along with

the overflow tube

carefully.

CAUTION:

Drain the fuel completely

from the fuel tank.

Hex Flange Bolt M6

Socket Spanner 10 mm

CAUTION :

Do not lift tank too high to

- Prevent accidental

damage to the front

end of the fuel tank.

- Prevent damage to

EVAP hose

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

68

INSPECTION

Carefully inspect fuel hose and vent hose for damage, cuts, cracks, holes, wear or general deterioration. Replace

if necessary.

WARNING

Gasoline is extremely flammable and highly explosive, which could result in serious injury.

Do not smoke or allow open flame or sparks in the vicinity.

Store the fuel carefully to avoid spillage.

TORQUE VALUES

Aggregate FastenerComponent

Torque Range

NM Kg-M

Fuel Tank Fuel tank Mounting Flanged Hex Bolt M6 * 1*27 5 0.5

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

69

S.

Aggregate to Assemble/

No.

Instructions

9.2 Fuel tank Assembly

Position fuel tank such

that the front mounting

clamps are correctly

located on the rubber

supports on the frame.

Gently push fuel tank

forward to lock in place.

Lift rear end of the tank

slightly and :

- Route the drain hose

between the frame

without any kinks.

- Connect blue coupler of

Low fuel sensor to wiring

harness

Fastener, Size, Tool Usage, Precautions, Photos

Ensure rubber grommets

are in place in the rear

mounting hole s and

align mounting holes to

the frame,

Locate 2 washers on the

hex flange bolts,

assemble the bolts and

tighten to torque.

Connect fuel hose to fuel

tap and carburetor and

lock the clips in place.

Hex Flange Bolt M6

Socket Spanner 10 mm

Torque 5 NM (0.5 Kg.M)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

70

SECTION 10 – EXHAUST PIPE & SILENCER

EXPLODED VIEWS

EXHAUST PIPE & SILENCER

1

3

1

2

4

5

6

7

1

5

13

8

12

9

11

10

9

1

5

S. NO.

DESCRIPTION

1 Flanged Hex. Nut M8 X 1.25 4

2 Exhaust Gasket 1

3 Exhaust Pipe Assy 1

4 Guard, Cat Pipe 1

5 Philips Pan Head Screw M6 X 6 6

6 Guard Exhaust Pipe 1

7 Clamp Silencer 1

QTY. S. NO.

8 Hex Flange Bolt M8 X 1.25 X 38 1

9 Pin Damper 2

10 Damper Bush 1

11 Silencer Assy 1

12 Hex Flange Bolt M8 X 1.25 X 55 1

13 Guard Silencer 1

DESCRIPTION

QTY.

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

71

S.

Aggregate to Dismantle/

No.

Instructions

10.1 Exhaust pipe &

Silencer

Fastener, Size, Tool Usage, Precautions, Photos

Remove 2 flanged Hex

nuts along with washers

at the cylinder head end.

Release the clamp from

the studs.

Remove 2 Hex bolts &

nuts at the silencer

mounting bracket end.

Support the silencer and

remove the bolt.

Gently pull out the

exhaust pipe from the

cylinder head and

remove exhaust pipe

with silen cer from the

vehicle.

Hex Nuts: M8X1.25

Socket spanner -12mm

NOTE:

Remove copper washer in

cylinder head, exhaust

pipe seating a rea after

removing exhaust pipe.

Hex bolts: M8 X 1.25X45

Hex Nuts: M8 X1.25

Socket spanner - 12mm

Double End Spanner: 12mm

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

72

INSPECTION

Inspect Silencer and Exhaust assembles for any damages / dents as it might cause damage to the internals.

Inspect silencer and exhaust pipe joint for any signs of exhaust gas leakage.

CAUTION :

Do not clean the silencer and exhaust internals with any solvents, gasoline etc as it will damage the catalytic

converters.

REPLACE

Copper gasket between exhaust pipe and cylinder head whenever exhaust pipe is dismantled from cylinder

head.

S No. Aggregate Fastener

1 Exhaust Pipe Mounting to Cyl.head Flanged Hex Bolt M8 X 1.25 X 16 10 1

2 Silencer Mounting to Frame Hex Socket M8X1.25X25 25 2.5

Torque Range

NM Kg-M

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

73

S.No.-

Aggregate to Assemble/

Instructions

10.2

Exhaust pipe &

Silencer

Locate a new gasket on

the exhaust pipe.

Locate exhaust pipe

into the cylinder head,

position the clamp over

the studs on the cylinder

head & assemble 2 hex

nuts M8 DO NO T

TIGHTEN FULLY.

Position silencer

mounting bracket

against the frame at the

rear and insert flanged

hex bolt. Assemble hex

nut over bolt.

Fastener, Size, Tool Usage, Precautions, Photos

Hex Nuts: M8X1.25

Socket spanner -12mm

Torque: 10Nm (1.0Kg.M.)

Tighten the 2 hex nuts at

the cylinder head, first

and then the silence r

bracket nut.

Hex bolts: M8 X 1.25X45

Hex Nuts: M8 X1.25

Socket spanner -12mm

Double End Spanner: 12mm

Torque: 25Nm (2.5Kg.M)

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

74

SECTION 11 - TOP BRACKET, HANDLE BAR,

FRONT MUDGUARD, FRONT WHEEL FRONT

SUSPENSION & STEERING STEM

ROYAL ENFIELD HIMALAYAN BS III VEHICLE SERVICE MANUAL

75

EXPLODED VIEWS

TOP FRAME, WINDSCREEN & COCKPIT BRACKET

A1

Key Nos.

11 (4 Nos.),