Foreword

The Royal Enfield Continental GT is our lightest, fastest, and most powerful motorcycle in production. It’s a machine

with a story, a nod to motorcycling’s finest hour, the best expression yet of a cultural phenomenon that has simply

refused to fade away - the cafe racer.

And now you have one of your own. Congratulations!

Your meticulously re-engineered Continental GT debuts a twin downtube cradle frame chassis developed by the

renowned Harris Performance from UK. A new engine displaces 535cc and dollops of torque, when you need it. With

gas-c harged rear s hock absorbers from Paoli and Brembo disc brakes, you stay in charge. W ith an aerodynamic

seating position, Pirelli Sports Demon tyres and a remapped ECU, the new Continental GT is part homage, part

engineering tour-de-force.

This manual will help you to operate your motorcycle and guide you to wholly maintain it. We have also provided tips

on safe riding and on minor adj ustments for the care of your motorcycle. Please avail the four free s ervices at the

nearest Authorised Service Point at the appropriate time to maintain your motorcycle in top riding condition. We

request you to carefully read the terms and c onditions of warranty and other useful information given in this manual

before starting to use your C ontinental GT. Log on to the exciting world of Royal Enfield on www.royalenfield.com to

get to know more about the company, its products and news from time to time.

Welcome to the world of the Rockers, and enjoy your burn-ups atop this spectacular machine.

1

Notice

All information in this manual is based on the latest product information available at the time of publication. Due to

continuous improvements or other changes, there may be discrepancies between information in this manual and your

vehicle. Royal Enfield reserves the right to make production changes at any time without prior notice and without

incurring any obligation to make same or similar changes to vehicles previously built or sold.

All images shown are for reference to explain and need not to be exactly the same on the model you own. Technical

specifications are subject to change without prior notice.

© Copyright 2013 Royal Enfield (A unit of Eicher Motors Ltd.). All Rights Reserved. No part of this manual shall be copied,

distributed or otherwise dealt without the express permission in writing from Royal Enfield.

Part No. 585441/A / Revision 1.0 / Qty. 500 / Nov. 2013

2

Contents

3

PERSONAL & VEHICLE INFORMATION....... 6

FREE SERVICE RECORD ............ ............... 7

SAFETY DEFINITIONS ........ ... ............... .. 8

TECHNICAL SPECIFICATIONS ....... ........ ..... 9

Engine .... .................. .. .................. ...... 9

Ignition System ............................ ... .. .. 10

Transmi ssion ......... ..... ........................ 10

Elec tr ic als .... ..................... .. ... ............. 11

Chass is ........... ... ............................ .. .. 12

Dimensions .................................. ..... .. 13

Weigh ts ....................... .. ... .................. 13

SAFE RIDING TIPS/GUIDELINES ........ ........ 14

SAFE & HAPPY RIDING ........ ... .. ............... 18

RULES OF THE ROAD .................. ............. 19

VEHICLE IDENTI. NUMBER-DETAILS .... .. .... 21

KEY PARTS LOCATION ........................... .. 22

Righ t Side View ...... ... .. ..... .................. 22

Lef t Side View...... .. ............... ... .......... 23

Top View .... ... ..... ................................ 24

OPERATION OF CONTROLS ............. .. .... 25

Igniti on Switch ............... .. ............... .... 25

Steerin g Lock ....................... ... .. ... ...... 26

Steering Unlock ............. ... .. ... ............. 26

Fuel Tank Cap.... ... .. ... ..... ..................... 27

Side Panel LH / Battery Cover . ........... 27

Utility Box ................. .. ............... ........ 27

Side PANEL RH ........ ............... .......... 27

Alpha-Numer ic display unit. ............ ..... 28

Head Lamp Switc h............. ..... .. ........... 30

Head Lamp Day Flash.... ..... ... .. ... ......... 30

Dip Switc h ......................................... 30

Engine Start Switch ............. .. ............. 31

Engine Stop Switch ............. ............... 31

Turn Signal Swit ch ............................. 3 1

Horn ............................... ..... ..... ......... 32

Contents

4

Manual Bi Starter (choke) ............... .... 32

PRE OPERATIONAL CHECKS .................... 33

RUNNING IN PERIOD.................................. 3 4

ELECTRONIC FUEL INJECTION (EFI) ... ...... 35

EFI .... ....................... ..... .................. .. 35

The Advantages of EFI .... ..... ... .. ......... 35

Malfunction Indicator Lamp (MIL) ......... 35

ROLL OVER SENSOR .... .. ... .. .................. .. 36

STARTING ........ .................. .. ... ................. 37

GEAR SHIFTING ................. ..... ............... .. 40

PARKING ................ ..... ..... ... ..... ................ 41

Center Stand .... ..... ... .. ... ..................... 4 1

Side Stand .... ... .. ... ..... ........................ 41

TOOLS & FIRST AID KIT.... ..... .................. .... 42

RECOMMENDED LUBRICANTS .... ............... 43

PERIODICAL MAINTENANCE ...... .......... .. ... 4 4

MINOR MAINTENANCE TIPS .................. .... 48

Control Cables, Hand lever,

Center / Side Stand Pivots ............. ..... 48

Oil Level Inspection ................. ... .. ...... 48

Engine oil change ...... ..... .. ... ............... 49

Spark Plug ............................. ........ .... 50

Brake fluid (Front & Rear) .. ............... .. 51

Inspection of tyres and wheels .... ...... 51

Tyre pres sure ....................... ..... ... ...... 52

Front W heel removal .............. ........ .... 52

Front Wheel reassembly .......... ........... 53

Rear wheel removal .. .. ............... ........ 54

Rear wheel reas s emb ly........... .. ... ...... 55

Adjustments-Clut ch lever f ree play .... 57

Rear brake light switch adjus tment. ..... 57

Drive Chain free play ................... ..... .. 58

Chain lock f itment .... .. ... .................... .. 59

Adj . of gas filled shockabs orber ... ...... 60

Removal of Battery from th e Vehicle..... 61

Contents

5

Battery Maintenanc e ........................... 61

Reassembly of Battery on Vehicle . .... . 62

CHANGING ELECTRICAL COMPONENTS .... 64

Head Lamp Bulb Replacement ......... ... 6 4

Tail Lamp bulb Replacement .... .. .......... 65

Trafficator bulb Replacement .... ... ..... .. 65

Fuse .... ..... ... .. .................................. .. 66

Blade fuse usage list .............. ..... ... .. .. 66

Air Filter Paper element........... ..... ... .. .... 67

WASHING PROCEDURE............................. 6 8

Pr ecautions .. .................... ... .. ............. 68

Af t er wash ing.... ..... ..... ..... .................. 68

STORAGE PRECAUTION ................. .. ........ 70

Prepari ng the motorcyc le for re-use . .. 7 1

LONG TRIP PRECAUTIONS ....................... 72

COMPLET E WIRING DIAGRAM (Domestic) . 73

TROUBLE SHOOTING .................... ..... ...... 74

Engine f ails to start .... .................. .. .... 74

Engine mis firing .... .. ............... .. .......... 75

Poor pickup ........ ..... ............... ..... ...... 75

White / Blue smoke ................. ... ........ 7 6

Eng ine overheating ...... ..... ............... .. 76

Excess ive f uel consumption........ .. ...... 76

Brakes Poor .. .................... ... .. ............. 77

Vehic le wobbl es.... .. ... ....................... .. 77

Elec tr ic als .... ............... .. ............... ...... 77

Electronic Fuel Injection (EFI) .............. 7 8

WARRANTY ........ .. ... ............... .. ............... 79

EMISSION WARRANTY........ ............ .......... 81

REGIONAL & AREA OFFICES ...... ............ ... 8 5

FREE SERVICE COUPONS ......... ..... ........... 86

PAID SERVICE/MAINTENANCE RECORD... .. 95

ALL INDIA ROAD SIGNS .. .......... ..... .......... 103

LOG BOOK .... ... .. ..... .......................... ....... 10 4

NOTES ..... .. ... ............... .. ... .................... .. 108

Personal & Vehicle Information

Name

Door No./St.

Locality

City State Pin

Contact Nos.

Engine N o. Battery No.

Frame No. Battery make

Reg. No. Licence No.

Date of Sale Valid till dt.

Model Key No.

Tyre make Colour

Sold by Dealer Code

Vehicle Installation Form (VIF) No.

Res: Off: Mobile: Email:

6

Free Service Record

It is our endeavour to provide excellent service to your CONTINENTAL GT at all times. Towards this we provide 4 free

services at specific Intervals.

Please avail these services at the specified time, in any of the Royal Enfield Authorised Dealer / Service Point nearest to you

and as a token of satisfactory services, kindly return the free service coupon duly filled in and signed, to the service outlet.

Availing the free services in the specified time is a prerequisite for warranty consideration. The cost of fuel, oil, grease etc.

used for all free services are chargeable to the customer.

7

st

1

Service 4th Service2nd Service

Date of Service

Kms Covered

Servicing ASP /

Dealer’s Name

Address

Dealer / ASP

Rubber Stamp

NOTE : Please ensure that the free service details are recorded in this sheet immediately after the service is carried out.

Dealer / ASP

Rubber Stamp

rd

Service

3

Dealer / ASP

Rubber Stamp

Dealer / ASP

Rubber Stamp

Safety Definitions

The information given under the titles: Warning, Caution and Note are for your safety and for the care and safety to

your motorcycle and others. Please read these carefully and if disregarded it may result in injury to yourself or others

and damages to the motorcycle

Statement in this manual preceded by the following words are with special significance.

Warning

Indicates a potentially hazardous situati on, which if not avoided, could result in s erious injury or damage.

CAUTION :

Indic ates a potentially hazardous situation , if not avoided, may result in minor or moderate injury or d amage.

NOTE :

Indicates important and useful messages for clear understanding.

8

Technical Specification

ENGINE

Engine ....................................................... 4 Stroke, air cooled, single cylinder, OHV, SI Engine

Capacity .................................................... 535 cc

Bore .......................................................... 87 mm

Stroke........................................................ 90 mm

Compression ratio ..................................... 8.5 : 1

Max. Power @ RPM ................................... 29.1 BHP (21.4 kw) @ 5100 rpm

Max. Torque @ RPM .................................. 44 Nm @ 4000 rpm

Air Filter Element ....................................... Paper Element Filter

Engine Oil Capacity (dry fill) ....................... 2.75 Litres.

Lubrication ................................................ Forced Lubrication, W et Sump

Engine Oil Grade........................................ Royal Enfield 15 W 50 API SL Grade Engine Oil (JASO MA)

Fuel System .............................................. Electronic Fuel Injection Programmed (PGM-EFI)

9

Technical Specification

10

IGNITION SYSTEM

Ignition system .......................................... Electronic Ignition

Spark plug Electrode gap.......................... 0.80 - 0.90 mm

Spark plug ................................................ WQR8DC (Bosch Super)

TRANSMISSION

Clutch ....................................................... W et Multiplate (7 Plates)

Primary drive ............................................ Duplex Chain

Primary Drive Ratio ................................... 2.15 : 1

Gear box .................................................. Constant Mesh 5 Speed

Gear shift pattern ..................................... 1 - N - 2 - 3 - 4 - 5

Gear Ratios .............................................. 1st-3.063:1, 2nd-2.013:1, 3rd-1.522:1, 4th-1.212: 1, 5th-1.000:1

Secondary Drive (F.D. Sprocket) ............. 18 Teeth

Final Drive Ratio ....................................... 2.00:1

Drive Chain Links ...................................... 100 Links

Technical Specification

ELECTRICALS

11

Generation ................................................ Alternator

System ..................................................... 12V DC

Battery ...................................................... 12V - 14 AH

Head lamp................................................. 12V, H4 - 60/55 W,

.......................................................... Halogen Bulb

Brake / Tail lamp ....................................... 21/5 W

Turn signal................................................ 12V, 10W - 4 nos.

Instrument Cluster .................................... Digital instrument Cluster with LCD

High beam indicator .................................. 12V, 0.2W (L.E.D.)

Neutral Telltale Bulb .................................. 12V, 1.12W

Horn (Dual) ............................................... 12V, 2.5A (dual tone - LT, HT)

Starter Motor ............................................ 12V, 0.9 KW

gadgets other than specified rating may

lead to ove r loading / erratic be haviour /

prema ture failure o f electrical system.

Modific ations on the bike which are not

approved by Royal Enfield may not only

dis qualify for warran ty, but also affec ts

performance of the bike.

WAR N IN G

Usin g bul b s / ot her ele c t r ic al

Technical Specification

CHASSIS

Frame ....................................................... Tubular steel double cradle

Tyre size .................................................. Front: 100/90-18 M/C 56H

.......................................................... Rear: 130/70-18 M/C 63H

Tyre pressure ........................................... Front - Solo: 1.41 Kg/cm2 (20 PSI)

.......................................................... Pillion: 1.55 Kg/cm2 (22 PSI)

.......................................................... Rear- Solo: 2.11 Kg/cm2 (30 PSI)

.......................................................... Pillion: 2.25 Kg/cm2 (32 PSI)

Fuel tank capacity .................................... 13.5 Litres***

Low fuel warning ..................................... 3.00 Litres***

Suspension .............................................. Front: Telescopic, Stroke 110mm

.......................................................... Rear: Gas Charged, Stroke 80 mm

Front fork oil capacity .............................. 430 ml per leg

Front fork oil ............................................. Gabriel Fork Oil 2W 35

Hydraulic Brakes ...................................... Front: 300 mm dia floating disc, t win piston floating caliper

.......................................................... Rear: 240 mm dia disc, single piston floating caliper

Brake oil grade ......................................... DOT 3 or DOT 4

Brake oil capacity ..................................... Front : 50 ml

.......................................................... Rear: 100 ml

Note :

***F uel tank c ap aci ty give n

he re is ap pr o ximat e. It ca n

v ary m a rgin a lly fr om th is

spec ified value.

12

Technical Specification

13

DIMENSIONS

Length ...................................................... 2060 mm

Width ........................................................ 760 mm

Height ....................................................... 1070 mm

Wheel base .............................................. 1360 mm

Saddle height ........................................... 800 mm

Ground clearance .................................... 140 mm

NO TE : B S II I

Th is vehicl e meets Emiss ion Nor ms Bhara t (T rem) Stage - III

WEIGHTS

Kerb W eight (with 90% Fuel) ................... 185 Kg

Gross vehicle weight ............................... 365 Kg

NOTE :

1. Values / Dimens ions given above are for your guidanc e only.

2. In view of continuous improvements being done on our products, the specifications are subject to change without notice.

Safe Riding Tips / Guidelines

14

Befor e operating your new mot or cyc l e, we

request you to carefully read and follow the

operating and maintenanc e instructions detailed

in this manual for the safety of your own, your

motorcycle, and also that of others.

Know and respect the rules of the road. Please

be a safe rider for your own safety and for others

in road.

Before starting t he motorcycle, check for proper

operation of brakes, c lutch, gear shifter, handle

bar controls, tyre pressures, fuel and oil levels.

Use only genuine Royal Enfield spare parts and

ap p r o v ed ac c es s or ies . U se o f other

manufac turer ’s performanc e parts may affect

the performance of your motorcycle and render

the motorcycle void of warranty. See your Royal

Enfield dealer for details.

W henever ref uelling your motor cyc le, please

exercise utmost caution and carefully observe

the following rules.

DO NOT smok e and please ens ur e that

there are no open flames or sparks near the

motorcycle, when refuelling OR servicing

the fuel system.

Switch OFF mobile phones and other hand

held electronic devices. Open the fuel filler

cap slowly.

Ref uel in a well ven t ilat ed area with the

engine turned off.

DO NOT fill the tank to its brim. Please fill

fuel only till the bottom of the filler nec k

insert, so as to leave air space in the fuel

tank to allow for fuel expansion.

Warning

Royal Enfield c autions you against the use of certain

nons tandar d parts suc h as aftermarket and custom

made extended f ront forks or suspensions , which may

adversely aff ect performance and handling. Removing

or al t e ring or igin al p art s may advers ely af f e c t

performance and could result in to an accident.

Safe Riding Tips / Guidelines

15

A new motorcycle must be operated acc ording

t o t h e sp ec ial r u n n i n g - i n - p r oc e d u r e . S ee

running-in-procedure mentioned in Page No. 34.

Operate motorcycle only at moderate speeds and

out of traffic until you have become thoroughly

f am il i ar w i t h i t s op er at io n and han d l in g

characteristics under all conditions.

DO NOT exceed the legal speed limit or drive too

fast for existing conditions. Always reduce speed

when poor driving conditions exist. High speed

increases the influ ence of any other condition

affecting stability and increases the possibility of

loss of control.

NOTE :

If you are an inexperienced rider we recommend that

you obtain formal training on correct motorcycle riding

techniques and b ecome t horoughly familiar with the

oper ati on of your partic ular motorc ycle. N ew r iders

should gain experience under various conditions while

driving at moderate speeds.

Pay st ric t att ent ion to road sur f ac es and wi nd

conditions. Any two wheeled vehicle may be subject

to the following upsetting forces:

Wind blasts from passing trucks.

Rough uneven road surfaces.

Slippery road surfaces.

Thes e f or c e s m ay aff ec t t he h an dl i n g

characteristics of your motorcycle. If this happens,

reduce speed and guide the motorcycle relaxed to

a controlled condition. Do not brake abruptly.

Oper a t e you r mot or c y c le d ef en sivel y.

Remember that, a motorcycle does not afford

the sam e protect ion as an aut omobile in an

acc ident. One of the most common accident

situations occurs when the driver of the other

vehicle fails to see or recognize a motorcyc le

and turns into the oncoming motorcyclist.

Safe Riding Tips / Guidelines

16

Wear an approved helmet, clothing, and foot

gear suited for riding a motorcycle. Bright OR

light colou rs are bes t for greater vis ibility in

traffic , specially at night. Avoid loose, flowing

garments and scarves.

W hen c a r r yi n g a p illi o n rider, i t i s y our

responsibility to instruct them on proper riding

procedur es.

DO NOT allow other individuals , under any

cir cumst anc es, t o operat e your motor c ycle

unless you know they are experienced, licensed

rider s and ar e thor ou g hl y familiar wit h th e

operating conditions of your motorcycle.

Warning

Regularly inspect shock absorbers and front f orks

and look for leaks. Replace worn out parts. Worn

out parts can adversely affect stability and handling.

Warning

For your pers onal welfare, all the listed service and

mai n t e n an ce r ec om m e n dation s s h ould b e

per f or med. Lac k of regular maint en ance at the

suggested intervals may affect the safe operation

of your motorcycle.

Warning

Avoid any contact with the exhaust system. Wear

clot hing that will completely cover the legs while

riding. The exhaust system gets very hot when the

engine is running and remains too hot, even after the

engine is turned off. Failure to wear proper or protective

clothing could result in serious injury.

Warning

Exh aus t gas es c ontains p oisono u s c ar bon

monoxide and chemicals, known to cause Cancer,

Birth defects or other reproductive defects.

Safe Riding Tips / Guidelines

17

Warning

Mot or c ycle b at t e r i es c o n t a in le ad and l ea d

components, acids and chemicals known to cause

cancer, birth defects or other reproduc tive harm.

Exercise extreme c aution while handling a battery.

Was h hands th or ou ghly when ev er a bat t er y is

handled.

Warning

Consult your Royal Enfield Dealer regar din g any

questions or problems that occur in the operation

of your motorcyc le. Failure to do so may aggravate

an initial problem, cause costly repairs & jeopardize

your personal safety.

Warning

DO NOT tow a disabled motorcycle. The st eering

and handling of the disabled motorcycle will be

impaired due to the force of the towline. If a disabled

motorcycle must be trans ported, use a truck or a

tr ailer. Towing a motorcy cle may cau se loss of

control of the motorcycle in the front, leading to an

acc ident.

Warning

DO NOT pull a trailer behind a motorcycle. Towing

a trailer may cause reduced braking efficiency, tyre

overloading and unstable handling. Towing a trailer

may cause loss of control of the motorcycle in the

front, leading to an accident.

Safe & Happy Riding

18

RIDING DRESS

Please wear proper riding apparel.

A pair of riding boots or shoes.

Soft leather gloves.

Goggles or spectacles to safe guard eyes.

An approved helmet. Affixed with light reflecting

strips of radium s tickers at the front and rear.

NOTE :

A light coloured shirt enables greater visibility to other

road us ers specially during nights.

CAUTION :

Loos e clothing may get caught on moving parts of

your mot orcycl e.

SITTING POSTURE

Correct sitting posture is a pre-requisite for stable

and safe riding

Sit in lean forwarded position.

Keep your elbows close t o your body

Hold the handle bar grips, close to its inner end

Look extensively ahead, incl ud ing rear view

mirrors, without turning the head.

BRAKING

Ap pl y f r on t a nd r ea r br ak es gen t l y an d

simultaneously for maximum braking efficiency.

WARNING

Applying any one of the brakes suddenly may cause

the vehicle to sk id. T he hydraulic disc brakes fitted

on your motorcycle require very less effort. High eff ort

or sudden application may lock the wheel. Please use

utmost caution while applying the b rakes .

While riding on wet or bad road conditions use

brakes cautiously.

Rules of the Road

19

Be sure your number plate is installed in the

position specified by law and it is clearly visible

at all times.

Ride at a safe speed that is consistent with the

type of road su rface you are on. Pay str ict

attention to whether the surf ace is :

Dry

Oily

Icy

Wet

Watch for loose debris, such as leaves, slippery

substances or loose gravel that can hamper the

stability of your vehicle.

DO NOT exceed the legal speed limit or drive

too fast for existing conditions. Always reduce

speed when poor driving conditions exist. High

sp eed incre ases th e influence of any other

condition affecting stability and inc reases the

possibility of loss of control.

Keep to the correct side of the r oad center line

when meeting oncoming vehicle.

Actuate your turn signals and exercise caution

when passing other vehicles going in the same

direct ion. Never try to pas s another vehic le

goi n g in t he s am e di r e c t i on at st r ee t

intersections, on curves, or when going up/or

down a hill.

At st reet intersection give the right-of-way to

the vehic le on your lef t or rig ht . DO NO T

presume you have the r ight-of-way.

Always signal when preparing to stop, tur n or

pass .

W h il e tu rning eit her rig ht or lef t, watch for

pedestrians, animals, as well as vehicles.

All tr affic signs , including manual controls at

in t ersec t i ons, sh oul d be obeyed prom p t ly.

SLOW DOWN at traffic signs near schools and

CAUTION signs at railroad crossings.

Rules of the Road

20

When intending to turn, signal at least 100 feet

(30.5 meters ) before reaching the turning. Be

close to the cen ter line (unles s local ru les

require otherwis e), slow down and then tur n

carefully.

Never jump a traffic light. W hen a

change is imminent from GO to

ST O P (or vic e ve r s a) at

intersections, slow down and wait

for th e light to change to green.

Never run through a yellow or red

traffic light.

DO NOT leave the curb or parking area without

signalling. B e sure your way is clear to enter

moving traffic. A moving line of traffic always

has the right-of -way.

When parking the motorcycle, park on a f irm

and flat surface to prevent it from falling over.

Prot ec t your mot orc ycle agai nst theft. After

parking your motorcycle, ensure that steering

head is locked and then remove the Ignition key.

Red

Yellow

Green

SIDE VIEW MIRRORS

Your motorcycles is equipped with convex mirrors

and have a curved surface. This type of mirror is

designed to give a much wider view of the rear than

a norm al flat mir r or. Howev er, car s and other

objects seen in this type of mirror will look smaller

and farther away than when seen in a flat mirror.

Us e care when judging the siz e or dist ance of

objects seen in these mirrors.

NOTE :

To hel p you to es t abl is h the relativ e di s tan c e of

vehicles b ehind your motorc ycle, adjust eac h mirr or

in such a way, that a small portion of your s houlder is

visible and a l arge portion behi nd your motorcycle is

seen c learly.

Vehicle Identification Number - Details

21

CHASSIS NUMBER

Punched on the steering head tube RH side

ENGINE NUMBER

Punched on top of the Engine LH side.

Key Parts Location

22

RIGHT SIDE VIEW

7

1. RH Trafficator front

2. Brake Pedal

3. Kick Start Lever

4. Starter Motor

5. Horn

6. RH Side Panel

1

7. RH Tr affic ator Rear

2

6

43

5

Key Parts Location

23

LEFT SIDE VIEW

1

1. Trafficator front LH

2. Spark plug

6

2

3

4

5

3. Gear Change Pedal

4. Centre stand

5. Side Stand

6. Side Panel LH / Battery Cover

7. Trafficator rear LH

7

Key Parts Location

5 6

TOP VIEW

3

4

24

10

8

97

11

2

1. Turn signal switch

2. Horn button

3. Clutch lever

4. Day flash switch

5. Head lamp dip switch

1

6. Manual Bistarter / Choke

7. Speedometer

8. Ignition switch

9. Malfunction Indicator Lamp

10. Tacho Meter

12

13

14

11. Engine Kill switch

12. Park / head light switch

13. Electric Start Switch

14. Fuel tank cap

Operation of Controls

IGNITION SWITCH

25

OFFON

Insert ignition key and turn clockwise direction

to “ON”. Once you turn on the ignition key all the

indicating lights in ins trum ent cluster starts

glowing on for few seconds and the engine will

get ready to start. The key cannot be removed

from “ON” possition.

Turn the ignit ion key in anticlockwise direction

to “OFF”. Once you turn off, all the electrical

s ys t e m s g oes o ff . N ow t h e k ey c an b e

removed.

Operation of Controls

26

STEERING LOCK

Turn the handle bar to extreme left or right position.

Pus h the key inside in “OFF” position, press

and furt her turn to anticlockwis e direc t ion to

lock the s teering system.

The key can be removed from the lock in this

position.

CAUTION :

Protect your motorc ycle against thef t. Af ter parkin g

your Motorc yc le and lock t he steering , then remove

the key from combination swit ch.

STEERING UNLOCK

Push the key in steering lock Position, and turn

clock wise direction to unlock the steering.

The key can be removed from the lock in this

position.

CAUTION :

Do not lubricat e barrel locks wit h petroleum based

lubricants or graphite. Inoperative locks may result in

damage to your vehicle.

Operation of Controls

27

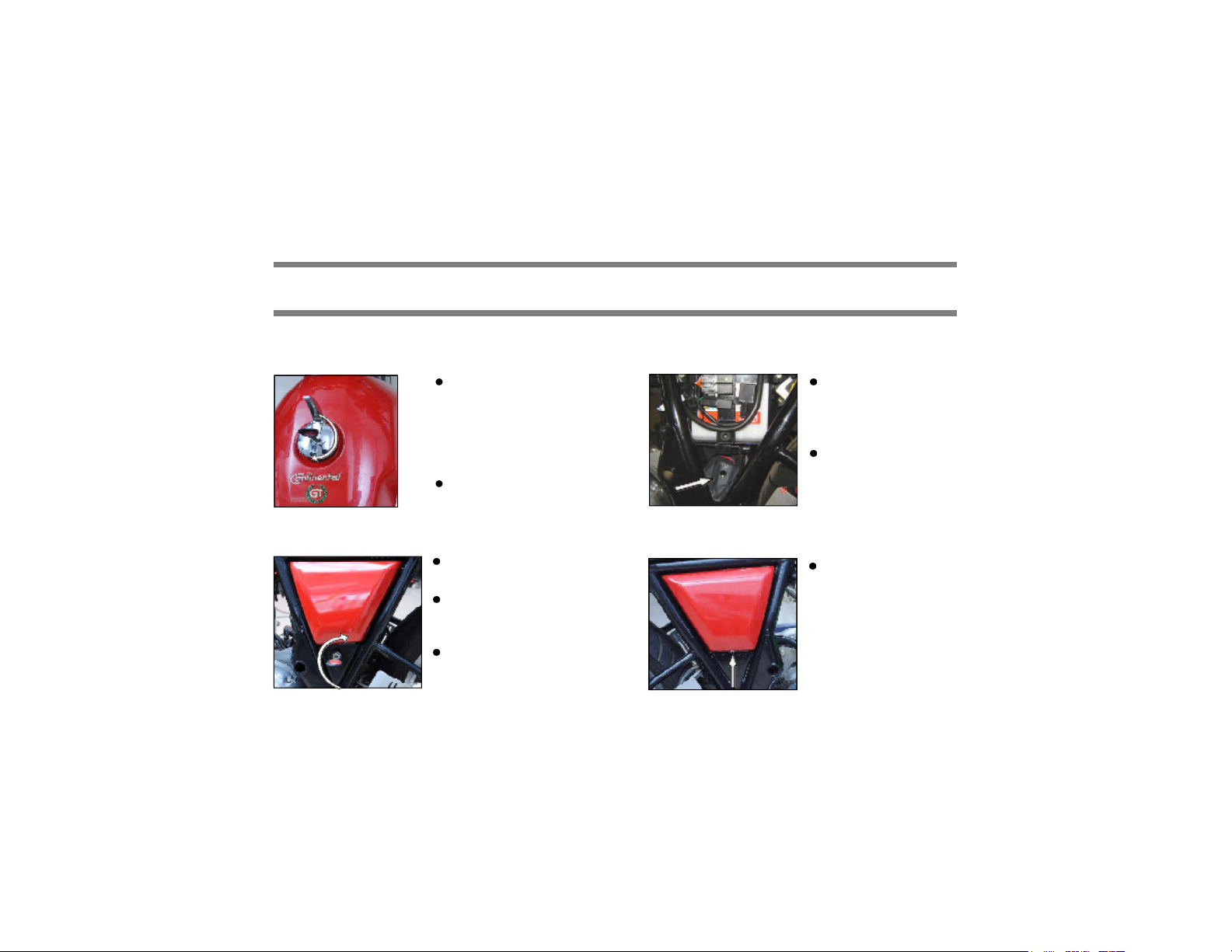

FUEL TANK CAP

Turn key clockwise

to open. Press the

cap to lock with key

in position.

NOTE :

Key can be removed

only in locked position.

SIDE PANEL LH / BATTERY COVER

Turn key clockwise to

unlock the side panel.

Pu ll th e s i de pan el

outside for opening

the same.

Ke y cann ot b e

remo v ed in t his

position.

UTILITY BOX

Utility box i s

pr ov i d ed at t h e

bot tom ar ea of

battery carrier.

It is c ov e r ed wit h

side panel LH

SIDE PANEL RH

Unscrew the indicated

screw and then pull

t he side pane l f or

opening the same.

Operation of Controls

28

ALPHA-NUMERIC DISPLAY UNIT

This unit in the

speedometer consists

of

1. Odometer

Alpha Nume ric Display

Push Bu tton

Sw itch

2. Trip A

3. Trip B

4. Fuel level indicator

ODOMETER MODE

Odomet er mode is t he

initial display mode of

this un i t . It di s p lays

od om e t er read i ng by

def ault.

NOTE :

Once you turn “ON” the ignition key, whatever was the

last selec tion mode will get displayed.

TRIP METER MODE

A light push for les s

tha n one sec o n d on

the “PUS H” but t o n

switch will change the

display from odometer

to Trip meter (TRIP A)

Again another press on the “PUSH” button switch

will change the display f rom “TRIP A to “TRIP B”.

NOTE :

For resetting the Trip Meter

1. Set the display as TRIP A or B as a current mode.

2. Press the “PUSH” button f or more than 3 Seconds.

3. Automatically the display will become zero.

Warning

Do not attempt to change any setting while riding the

motorcycle. It may cause loss of control leading to an

acc ident .

Operation of Controls

29

FUEL LEVEL INDICATOR

The fuel level in dic ator

indicates the level of fuel

in the fuel tank.

The display bar s of the fu el met er di sappears

t ow ar d s t h e E m p t y ( E ) w h en t he f ue l leve l

decreases .

when last bar start blinking (less than 3 litres), refuel

the bike at the earliest.

NOTE :

If the last bar of the fuel meter is blinking continuously

after fueling, visi t a Royal Enfield authorised dealer

and check the same.

BATTERY LOW VOLTAGE INDICATOR

Battery low voltage indicator

If the battery voltage is less than 12 volts, the low

voltage indicator will s tart glowing continuously.

W hile the ignition is “ON” , low voltage indicator

symbol will glow until engine reaches 700 RPM.

In running condition if the battery voltage is below

12 Volts for more than 3 seconds continuously, the

low voltage indicator will start glowing.

Operation of Controls

HEAD LAMP SWITCH

30

HEAD LAMP OFF

PRESS FOR HEAD LIGHT FLASH

POSITION LAMP

DIP SWITCHHEAD LAMP DAY FLASH

LOW BEAM

HEAD LAMP ON

HIGH BEAM

Operation of Controls

31

ENGINE START SWITCH

TURN SIGNAL SWITCH

OFF (PUSH TO OFF)

PRESS

ENGINE STOP SWITCH

ENGINE ON

LEFT RIGHT

ENGINE OFF

Operation of Controls

32

HORN

MANUAL BI STARTER (CHOKE)

PRESS

Apply choke in cold start condition while starting the Bike

Pre Operational Checks

33

A careful check of the following must be carried out

every time before riding and specially after long periods

of storage to determine if any additional maintenance

is necessary.

1. Adequate fuel in the tank.

2. Tyres for correct pressure, abrasions or cut s.

3. Rear chain for proper tension and suffic ient

lubrication.

4. Brakes, s t eer ing a nd t hr ot t le f or pr oper

responsivenes s.

5. Cable for fraying or crimping and free operation.

6. Engine oil level.

7. W heel spokes for proper tigh tnes s and no

breakage.

8. Headlamp, tail lamp, brake lamp and indicator

lamps for proper functioning.

Warning

For your pers onal welfar e and saf ety, all the point s

mentioned above should be perf or med periodi cally.

Failure t o do so may affec t saf e operation, d amage

your mo tor c yc le and co uld res ult in an ac c ide nt

caus in g serious injury.

Running In Period

34

Proper ru nni ng-I n is very imp or t an t for obtain ing

maximum life and performance of a new motorcycle.

The following guid elines explain p roper runnin g- in

pr oc edu res .

Since the engine is brand new, it should not be loaded

excess ively for the first 2 ,000 kilometers. During the

fir st few hundred kilometers, the mating parts in the

engine will wear and polish themselves to the c orrect

operat ing cl ea ran ces . Dri vin g wit h prolonged ful l

throttle operat ion, or in any hig h speed cond it ions

migh t result in excess ive heating of the engine and

cause abnormal wear of the moving parts and hence

the same must be avoided.

1. 0-500 Kms :

T h e rec om m ende d s p eed s f or t he fi r s t 5 0 0

Kilometer s is below 50 to 60 Kmph. During this

per iod avoid operat in g the motorc yc le wit h ful l

throttle opening. Stop the motorc ycle f or about 5

to 10 minutes to let it cool down, after every hour

of ru nni ng. Vary th e sp eed of the motorcycle

reg ular l y du ring r unni n g but avoid us i n g th e

motorcycle above 1/2 throttle opening p osition.

2. 501-2000 Kms :

The recommended s peed is below 80 – 90 kmph.

Avoid drivi ng the motor c yc le wi th ful l throttl e

op enin g . Vary t h e s p eed o f t h e m ot o r c yc l e

reg ularly but avoid using the motorcyc le above

th

3/4

t hrottle opening position.

3. 20 01 Kms and above

Avoi d pr ol on g ed f ul l - th r ott l e ope r ation. Var y

sp eed occasi onall y.

CAUTION :

After covering the first 500 kilometers, Please replace

the engine oil and oil filter element.

Roy al E nf i eld engi ne s ar e air-c oo l ed and

conseq uently requir e forc ed air coo lin g over th e

cyl in der an d he ad to ma i ntai n pr oper op er at i ng

tem perature. Ext ended periods of idling may over

heat the engine, resulting in serious engine damage.

DO NOT run the engine at extremely high RPM with

cl ut ch disengag ed or trans mis s ion in neutral as it

can caus e serious engine d amage.

An engine runni ng for long distanc es at high speed

must be given clos e attention to avoid overheati ng

and possi ble engine damage

Electronic Fuel Injection (EFI)

35

ELECTRONIC FUEL INJECTION (EFI)

An electronic control unit (ECU) monitor s engine

performance and provides exact requirement of Air

/ Fuel mixture to the engine, through the fuel injector

by taking inputs from various sensors provided in

the motorcycle.

THE ADVANTAGES OF EFI ARE

Faster response of the engine to suit road/load

condit ions.

Better power output

Lower emission

Bett er reliability

Excellent cold Startability

Engine Diagnost ic capabilit ies

Maintenance f ree

MALFUNCTION INDICATOR LAMP (MIL)

A M alfunc t i onin g

Indicator Lamp (MIL)

is provid ed in the

RPM meter which is

located on the right

side of the Cluster

unit.

1. EFI Mal Funct i on Indicator : W hen bot h the

Ignition & Engine kill switch is “0N”, the MIL will

glow for fe w sec onds and will go “OFF ”. This

indicates that all the func tions of Electronic Control

Unit (ECU) and other sens ors are working perfectly

and the motorcycle can be used.

In case of any malfunctioning of the ECU or other

sensors etc., the MIL will glow continuously. In the

event of any such phenomenon, it is recommended

to take the vehicl e to a near est Royal En field

authorised service point for inspection and further

neces sary action.

Rollover Sensor

36

ROLLOVER SENSOR

Your motorcycle is fitted with a unique “Roll Over

Sensor” under the seat. T his is a safety feature.

In the event of an accident OR if the motorcycle

falls over on any side with the eng ine run ning

condit ion, The “Roll Over Sensor” will switch off

Ignit ion and cut off fuel su ppl y to pr event the

motorcycle from moving suddenly, while it is in gear.

To re-activate the system after the motorcycle has

been made upr igh t, please sw itc h off both the

Ignition & Engine kill swit ch, wait for a few s econds

and switch “ON” again.

This will help to RESET the “Roll Over Sensor” and

the engine can be started/ run.

Starting

37

Warning

Before starting engine, always shift gears into neutral.

CAUTION :

Do not force the gear lever while attempting to shift to

ne u t r al . Move th e motor c yc l e ba c k & for th and

simult aneously press gear lever to come to neutral.

Ensure neutral Indicator light glows in the Speedometer.

NOTE :

If the engine does not start on the first attempt

in cold climate, release the starter button, wait

for 30 seconds before pr es s ing the starter

button again.

Press starter button and release starter switch

once the engine starts.

A clutc h swit ch is provided in the sys tem for

the safety of the rider. This is to prevent the

vehicle from starting when the vehicle is in gear.

To start the engine when it is in gear, pull clutch

lever, press th e st arter but t on and releas e

slowly after the engine starts.

Tu r n ignit io n

switch ‘ON’

Ensure the side

and main stands

are in releas ed

pos ition

Ensure that gears

are in neutral and

neutral lam p is

glowing

Starting

38

Ensur e Engin e

stop switch is in

“RUN” position

Press Clutch

Lever.

Press Starter

Button and

release as soon

as engine starts

CAUTION :

Never acc elerate the engine immediately after a cold

start. The engine should be allowed to run slowly f or

15-30 seconds. This will allow the engine to warm up

and let oil reach all sur f ac es n eed ing lubri c ation.

Failure to adhere may result in damage to the Engine.

Manual bi

Starter (choke)

NOTE :

It may be necessary to operate and hold the manual

bi starter, when starting the engine f or the first time in

cold mornings , temper atures below 10°C or at high

altitudes, to prevent the stalling and to keep the idling

RPM steady.

Starting

39

As so on as the engin e at t ains t h e oper at ing

temperature, the RPM will raise, at which time the

manual Bi Starter should be released.

Warm up engine for 2 minutes - till idling is

cons is tent.

Prior to st arting, check to see the f uel level from

the fuel gauge.

If the last bar is blinking refuel immediately.

CAUTION :

Please ens ure the motor cycle is not used with the

low fuel indic ator bar blinking continuously. It may not

only result in the motorcycle running out of fuel. But

will also cause s er ious damage to the f uel pu mp.

Please ensure f uel is filled up as s oon as the low fuel,

last bar start blinking.

CAUTION :

Air cooled engin e req ui r es air movement over the

cylinder head and exhaust pipe to maintain proper

oper ati ng temperature.

Never accelerate the engine abnormally in stand still

condition of the motorcycle. Failure to adhere this may

res ult in damag e to exhaust pipe / si lenc er of the

engine due to over heating.

Gear Shifting

40

Warm up engine

for 2 minutes t ill id ling i s

consistent/stable

GEAR SH IF T PAT T E R N

1 N 2 3 4 5

Press clutc h lever towards the hand grip.

Press gear pedal with toe toward s down to

engage 1st gear.

Gen t l y op en t hr ot t l e a n d r el eas e c lu t c h

simultaneously. If clutch is released suddenly,

the engine may stall and cause a jerky s tart.

CAUTION :

The clutch must be fully disengaged before attempting

a gear shift. Failure to fully disengage the clutch may

cause a jerk y start OR stallin g the engin e besides

caus ing damage to transmi ssion parts.

Press the gear

pedal upwards

wi t h t oe t o

en g ag e 2n d

and gear.

Follow the same procedure for 3rd, 4th and 5th

gear.

NOTE :

Always start motorcycle with gear in neutral position.

Always move the motorcycle in f irs t gear position only.

W hen engin e speed decreases or while c li mbing a

gradient or running at a reduced s peed, shift to the

appropria te lower gear to prevent the eng ine fr om

stalling or straining to pull.

Parking

41

PARKING VEHICLE ON CENTER STAND

Select a firm, flat surface

Hold handle bar straight

Lower center stand, and ensure that both the

legs of the stand are resting evenly on firm ground.

Apply pres s ure on the fulcru m lever on the

center stand and pull vehicle upwards, gently.

PARKING VEHICLE ON SIDE STAND

Select a firm, flat surface

Lower Side Stand and gently tilt motorcycle to

the left till it rests firmly on the side s tand.

Warning

Always park the m otor c ycle on a firm and flat surface. Parking in a soft ground may cause stand to s ink and the

motorcycle to f all, c ausing injury to you or to others and damage t o the motorcycle parts.

Tools & First Aid Kit

42

2 3 4 5

1

S.No. Description Qty.

1. Tool Bag 1

2. Screw Driver O6 X 160 1

3. Tommy Bar 1

4. Box Spanner 21 X 24 1

5. Double End Spanner 14 X 15 1

6. Double End Spanner 10 X 13 2

7. Double End Spanner 8 X 10 1

8. Allen Key 5 MM 1

9. Allen Key 3 MM 1

10. Tyre Removal Lever 2

6 7

8

9

10

5

4

S.No. Description Qty.

1. Antiseptic cream 5 gms 1

2. Gauze bandage 5 cm x 2 cm 1

3. Elastic Gauze bandage 8 cm x 1 mtr. 1

4. Wash proof plaster 1.9 c m x 7.2 cm 2

5. Sterilized Gauze Swab 5 cm x 5 cm 2

6. Sterilized elastic plaster 7 cm x 6 cm 1

7. First aid kit pouch 1

3

6

1

7

2

NOTE :

This Tool Kit is kept in Utility box. Refer Page No. 27.

Recommended Lubricants

43

Engine Oil

Grade Royal Enfield 15 W 50 API SL Grade

Engine Oil

(JASO MA)

Capacity 2.75 Ltrs. (for dry fill)

2.50 Ltrs. (during oil & filter element

replacement)

Front Fork Oil

Grade Royal Enfield

Front Fork Oil

(or Gabriel Fork

Oil 2W 35)

Capacity 430 ml / leg

ISO 14001 – EMS

Operation Control Process

1. All customers are advised timely replacement of Engine Oil,

Fork Oil & Brake Oil at the dealership /ASP. In case done

privately, it is advise to reach old/used Oil to our authorised

vendor through RE Dealer/ASP

2. Similarly we advise for disposal of old/used Battery, Tube &

Tyres as mentioned in above point No.1.

Grade DOT 3 or DOT 4

Capacity

Warning

DO NO T swit ch oil brands indiscriminat ely because s ome oil i nteract chemic ally when mixed.

Use of i nferior oils or non- deter gent oils can damage the engine.

DO NOT Mix DOT 3 & DOT 4 brake fluid together.

Brake Fluid

Front : 50 ml

Rear : 100 ml

Periodical Maintenance

The maintenance schedule detailed here will help you to maintain your Royal Enfield motorcycle meticulously and to

get a long trouble free service. The schedule provided herein is based upon average riding conditions and indicates

the mileage at which regular inspections, adj ustments, replacements and lubrications must be carried out.

The frequency of the maintenance must be shortened depending upon the severity of the Riding condition OR if the

motorcycle is used in a very dusty environment, severe climatic cold and hot conditions, bad roads, stagnant water

etc., Contact a nearest Royal Enfield Authorised Dealer / Service Point for expert advice and to carry out the

periodical maintenance.

44

Warning

For your personal welf are, all the listed service and maintenance recommendations should b e performed. Lack of

reg ular mai nt en ance at the s u gges t ed intervals m ay aff ec t t he safe operati on of your motorcycl e cau s in g the

motorc ycle to malf unc tion and st all abruptly resulting in an accident and cause s erious injur y.

A : Adjust C : Clea n D : D e-c arbonise I : Ins pect L : Lubr ica te R : Rep lace

NOTE :

For maintenance after 30,00 0 Kms, pleas e repeat the s ame frequency levels specif ied ab ove, in consultation wit h a

Royal Enfield Authoris ed Dealer / Service Point.

Do not mix DOT 3 and DOT 4 brake fluid together.

*Carbo cleaner / Carbclik or Fuel Line Cleaner Spray. (Make - Wurth or ITW Chemin)

Periodical Maintenance

45

S.

No.

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Months 1.5 3 6 9

1 Engine Oil

2 Engine oil filter element R C R R R R R

3 Engine sump filter (oil strainer) C C C C C C C

Magnetic drain plug under gear box and secondary

4

drain plug under

5 Spark plug C&A C&A C&A C&A C&A R C&A C&A C&A C&A R

6 HT lead for crack I I I I I I I I I I I

7 Fuel hose & clip / Injector ‘O’ Ring / Seal Ring I I I I R I I I R I I

8 Fuel Pump Check for screw tightness in all services

9 Accelerator & Throttle pully cable free play A A A A A A A A A A A

10 Rubber hose, Air filter to Throttle body I I I I R I I I R I I

11 Rubber hose, Inlet manifold I I I I R I I I R I I

DESCR IPTION

cranksharft in

crankcase RH

FREE SERVICE

whi chever is ea rlier

R R R R R R

Check level at every 1000 Kms or earlier as required

C C C C C C C

PAID SERVICE

Periodical Maintenance

46

S.

No.

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Months 1.5 3 6 9

12 Air filter paper element C C C C R C C C R C C

13 Inlet / Exhaust valve seating I I

14 Cylinder head (Combustion chamber) D

15 Exhaust pipe D

16 Clutch lever free play Adjust every 1000 Kms or earlier as required

17 Rear brake pedal pivot L L L L L L L L L L L

18 Battery terminals (apply petroleum jelly) C C C C C C C C C C C

19 Battery Electrolyte level I I I I I I I I I I I

20 Earth wire eyelet contact (below ECU Mounting) I I

21 Rear Wheel Drive Chain

22 Front Fork oil / leak I I I R I I I R I I I

23 Steering ball races / play adjustment A L A R A L A R A L

DESCR IPTION

FREE SERVICE

whi chever is ea rlier

Adjust every 1000 Kms or earlier as required

Lubricate every 3000 Kms or earlier as required

PAID SERVICE

Periodical Maintenance

47

S.

No.

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Months 1.5 3 6 9

24 Spokes tightness / Wheel rim run out front & rear I I I I I I

25 Rear wheel cush rubbers I & R I & R

26 Tyre wear front & rear I I I I I I I I I

27 Hand levers & Kick starter pivot Lubricate every 1000 Kms or earlier as required

28 Brake Oil level check / Replacement I I I I I I I I R I I

29 Pivot-Side Stand / Center Stand pivot L L L L L L L L L L L

30 Rider & Pillion Foot rest pivot L L L L L L L L L L L

31 Swing arm needle bearings and spindle L L

32 Vent Pipe under air filter box I & C I & C I & C I & C I & C I & C I & C I & C I & C I & C

33 Throttle body - cleaning spray* C C C C C

34 PAV pipes & hose clip I I I I I I I I R I I

35 Front & Rear brake hose and Banjo Bolt I I I I I I I I I I R

DESCRIPTION

FREE SERVICE

whi chever is ea rlier

PAID SERVICE

Minor Maintenance Tips

48

The following minor maintenance can be carried

out easily with simple tools. However, In case, if it

is felt that the adjustments are best done by an

expert, we recommend that the motorcycle be taken

to a nea res t Royal Enfi eld Aut horis ed Dealer /

Service Point.

CONTROL CABLES, HANDLE BAR LEVER, PIVOTS,

CENTER / SIDE STAND PIVOTS

Main Stand Pivot

Lever Pivot

Lubricate after using the motor cycle in rain,

after waterwash or if us ed in dusty conditions.

Wipe the area free of dirt / grease.

Apply a few drops of oil on the pivots.

Side Stand

Pivot

OIL LEVEL INSPECTION

MAX

MIN

Place motorcycle on its center stand on a firm

surface.

Warm up engine for a few minutes & switch off.

The level is correct if the oil level is in the middle

of the oil level window.

Top up with recommended oil if required.

Minor Maintenance Tips

ENGINE - OIL CHANGE

Place motorcycle on its centre stand on a firm

flat surface.

Start engine and warm up for 2 minutes.

Keep a clean tray below the engine

49

TILT VEHICLE RH & LH

Prim ary

Drai n

Plug

(Refer Periodical Maintenance Chart for frequency)

Remove primary drain cap, to drain oil & clean

suction filter, magnet.

Then remove secondary drain plug to drain oil &

clean the magnet.

Finally remove primary drain bolt to d rain the

complete oil.

Prim ary

Fil ter Cap

Sec ond ary

Drai n P lug

Remove the oil filter paper elem ent on the

Crankcase Cover RH.

Allow the oil to drain by tilting the motorcycle to

both sides.

Wash the primary and secondary drain plugs

along with suction filter thoroughly and refit on

the crankcase after all the oil is drained out.

Minor Maintenance Tips

50

Soak a new oil filter paper element in the oil and

refit on the Crankcase Cover RH.

Assembly 3 bolts and tighten them. Ensure ‘O’

Ring and gaskets are taken seat properly.

Fill recommended

oil to engine till the

oil lev el is upt o

“MAX” level mark in

the oil window in

Crankcase Cover

RH.

Max

NOTE :

Replace oil filter paper element whenever oil is being

repl ac ed.

Min

CAUTION :

Do not f ill oil over “MAX” mark. It may cause the engine

to smoke and result in loss of power. Do NOT use the

motorc ycle if the oil is below the “MIN” mark. Doing

so will caus e serious damage to the movin g par ts

inside the engine and result in an engine lock up.

SPARK PLUG

Gap 0.80 to 0.90 mm.

Cl ean ing an d adj usting gap ( Ref er Periodic al

Maintenance Chart f or frequency)

Remove HT Lead and the spark plug from the

cyl inder head usin g the plug sp anner and

Tommy bar.

Clean the insulator tip and electrodes of the plug

carefully using a pointed sc raper or spark plug

cleaner.

Set the gap between 0.80 to 0.90 mm.

Refit the spark plug on the cylinder head and

connect H.T. Lead.

Minor Maintenance Tips

51

BRAKE FLUID

MAX

MIN

MIN

FRONT BRAKE REAR BRAKE

Check if oil is below ‘MIN’ level. To top Up, remove

cover and diaphragm, then top up with DOT 3 or

DOT 4 as specified.

CAUTION :

Brake fluid is highly corrosive and can caus e damage

to painted parts. Please ensure that brake fluid does

not spill on any part of the motorcycle. In the event of

a spill, please c lean the area immediately with a soft

cloth ( preferably a wet cloth) to avoid damage.

Don’t mix DOT 3 & DOT 4 Brake fluid together.

INSPECTION OF TYRES AND WHEELS

Inspect the tyre periodically for

tread wear, cracks and cuts.

Minimum tread depth

Front tyre : 1.00 mm

Rear tyre : 2.00 mm

Check and remove stone, splinters, nails or other

particles embedded in the tyre treads.

Bald spots / swelling may be caused by internal

damage. Replace the tyres, if defective.

Replace tyres when the tread depth has reached

the minimum as specified.

Periodically ins pect wheels for spokes breakage

and wheel rim run out.

Check proper s eating of the tyre beading on the

rim whenever the tyre is reassembled.

Whenever a new tyre is installed, ensure rim

and s pokes do not get damaged on account of

wrong handling.

Minor Maintenance Tips

52

Us e only stand ard tyres & tubes inflated to

correct pressure.

TYRE PRESSURE

Front Rear

Solo 1.41 kg/cm2 2.11 kg/cm2

(20 PSI) (30 PSI)

With Pillion 1.55 kg/cm2 2.25 kg/cm2

(22 PSI) (32 PSI)

Warning

Tyres, rims and air valves must be correctly matched

to w hee l r i m s . S ee your Roy al E n f i eld D ealer.

Mismatching tyre, tubes, rims and air valves may result

in damage to the tyre bead during mounting, allow

tyre slippage on the rim and cause tyre failur e.

FRONT WHEEL REMOVAL

Place the vehicle on center stand

Place a wooden block

t he f r ont e nd of

engine to support the

vehicle.

Loosen the pinch bolt

on the RH fork guide

by 6 mm allen key.

Hold the axle head by

dou ble end span ner

wh ile loosenin g th e

axle nut.

Remove the axle nut

along with washer.

Minor Maintenance Tips

53

Tap and remove the

front wheel spindle.

Tilt the vehicle to RH

Locating

TAB

Side and take out the

wheel alo n g w it h

wheel speed sensor

and LH side spacer.

CAUTION :

Do not pres s the fron t brake lever when wheel is

removed as this will result in the brake pads c oming

too f ar out of the brake caliper.

Place a 4 mm thick wooden piece or cardboard

sheet between the brake pads to avoid pads

activation in the event the front brake lever is

accidently pressed.

FRONT WHEEL REASSEMBLY

Remove the wooden piece / card board sheet

placed between the brake pads

Place the wheel speed

sensor in position.

Ensure slot on hub

and speedo sensor is

matched correctly.

Ins ert th e whee l

al ong wi t h w h eel

speed sensor and LH

spacer between the

fr ont f ork en d s

ens uring the brake

di s c i s lo c a t e d

between the br ak e

pads.

In s ert and tap th e

f r ont w h eel axl e

gently inside.

Refit the washer and

tighten the nut firmly.

Minor Maintenance Tips

Tighten the pinch bolt on the RH fork guide.

Rotate the wheel and check for smooth rotation.

REAR WHEEL REMOVAL

Index mark

54

Place the vehicle on

cen t er st an d on a

firm and flat surface.

Observe and mar k

the alignment index

ma r k s in the both

sides of swing arm.

Remove axle nut on

the RH side.

Ensure wheel speed sensor wire coupler is being

connected to c lus ter unit and then check for

proper working of speedo meter.

Press brake lever 2 or 3 times to check front

brake efficiency.

Remove wheel spindle

from LH side along

with wheel collar and

LH side spacer.

Minor Maintenance Tips

55

Remove the calip er

ass emb ly by pulling

out from the swing

arm slot.

Remove the distance collar.

Tilt the motorcycle towards RH side and take out

the rear wheel assembly conveniently.

CAUTION :

Do not press the r ear brake pedal when wheel is

removed as this will result in the brake pads c oming

too far out of the brake c aliper.

Place a 4 mm thick wooden piece or cardboard

sheet between the brake pads to avoid pads

activation in the event the rear br ake pedal is

accident ly pressed.

REAR WHEEL REASSEMBLY

Ensure the four Cush rubbers are in position

inside the rear wheel hub.

Tilt vehicle to right and

insert wheel assembly

be t w een the swin g

arms.

Po s i t i on t h e r ea r

wh eel with c u s h

rubber on t he r ear

dr iven f l a nge /

adaptor.

Fix the LH side spacer

in rear wheel hub.

Remove the wooden

pi ec e / card b oar d

sheet placed between

the brake pads.

Minor Maintenance Tips

In s er t the c al i per

assembly by pushing

in th e pr o j e c t io n

giv en i n s id e t he

swin g ar m. Ensur e

the br a ke d isc is

locat ed in bet ween

the brake pads.

Align the caliper brack et, wheel and swing arm

holes in-line and ensur e dis t an ce collar is

placed in hub dus t seal.

Insert and tap the rear

wheel axle gently.

CAUTION :

Do not force the spindle into

the wheel as the thr ead s

may get damaged. Tap it

through the wheel gently.

Ensure the index marks alignments on both sides

of the swing arm are in same position for proper

wheel alignment.

56

Adjuster End Plate

Index mark

Adjuster Lock nut

Tight en the axle nut

firmly.

Ensure that swing arm

end plate is seated

prope r l y and th e

ch ain adj u s ter nut s

ar e correc t ly tight -

Warning

Ensure the vehicle do not c ome out of center s tand

wh i l e d i s m antlin g an d as sem b l i ng the whe el

assemb ly.

ened and Locked.

Minor Maintenance Tips

57

ADJUSTMENTS - CLUTCH LEVER FREE PLAY

2 to 3 mm

Clutc h Lever (free play 2 - 3 mm)

Loosen the cable outer lock nut (A).

Turn the Nut (B) Clockwise to reduce the play

or Anticlockwise to increase the free play.

Check free play 2 to 3 mm at Clutc h lever pivot

on handle bar end.

Tighten lock nut (A) after adjustment is done.

B

REAR BRAKE LIGHT SWITCH ADJUSTMENT

The brake light glows once

you press the brake pedal.

If brake light is not glowing,

check the brake light switch

A

If above are alrig ht , then do the adjustm ent as

mentioned below:

1. Turn the brake light switch adj ustment nut while

holding the rear brake light sw it ch bod y in

position.

2. If the brake light do not glows after press ing

th e pedal for approxim at ely 25mm , tur n the

adjusting nut in clockwise direction by 2 to 3

threads and check for brake light function.

3. If the b rak e light continuous ly glows,turn the

adjusting nut in anti clockwis e direction by 2

to 3 threads so as to get the positions in which

the light goes off.

wire for proper connection

and the brake light Switch

sp ring f or any bend,

breakage or disconnection.

Minor Maintenance Tips

58

DRIVE CHAIN FREE PLAY (PLAY 20 - 25 MM)

Plac e m ot or -

Dri ve c hain slack

adjusting nut

Ind ex mark

Swing Arm

reference m ark

1. If the drive chain free play is incorrect adjust

as follows:

a. Loosen the axle nut of the rear wheel axle.

Ad ju st e r

Lock nut

c yc l e o n its

center stand on

a fi r m & f l at

surface.

Sh ift the gear

into t he neutral

pos ition

Me as u r e t h e

drive chain free

play as shown.

The drive chain

free play is 20 to

25 mm

b. L oosen the Q D

sprocket spindle nut.

c. Loosen the locknut at

bo t h end o f the

swing arm.

d. To reduc e the free

play, turn the drive

chain slack adjusting

nut i n cl oc k w i s e

direction.

e. To increase the free

play, turn the drive

chain slack adjusting

nut in anticlockwise

direction and pus h

t h e r e a r w h e e l

for war d .

Minor Maintenance Tips

59

f. Later adjust the nut on LH side by matching

the index mark with respect to RH side index.

g. Ensure that both the sides are in same index

marks.

h. Finally torque the spindle and axle nuts to 7

kgm.

i. Tighten the adjuster locknut by 13mm spanner

against chain slack adjusting nut.

Warning

Ch ai n slacknes s beyond 30m m w ill lead to ch ai n

slippage.

Main tai n drive ch ain s lacknes s wit hin the spec if ied

limits at every 1000 kms interval.

Please Check the front and rear wheels are correctly

aligned, after the c hain adjustment.

CHAIN LOCK FITMENT

The open end of the chain master link lock should

face opposite to normal direction of chain rotation.

Warning

The f itment of loc k in wrong directi on other than

shown above can lead to its falling off, and thus can

caus e the sudden disconnection of the c hain during

the drive.

Minor Maintenance Tips

60

ADJUSTMENT OF GAS FILLED SHOCKABSORBER

Th e rear gas f i lle d shoc k ab s or ber is an

adjus t ab le type.T he sp ring tension can be

increased or decreased.

Reduce the spring tension for low load operation

by turning the adjuster nut in the direction as

shown above by using a suitable C - spanner.

In c r eas e th e sp r ing tens ion for hi gh load

operation by turning the adj uster nut in oposite

direction.

Adjust both the rear shock absorbers to the same

thread possitions.

Recommended = 10 mm height adj ustment only

from factory setting.

Warning

Rid ing th e motor c yc l e wit h the sh ock ab s or b er s

adju ste d in diff erent pos i tions can ca us e l os s of

contr ol.

Regularly inspect s hock absorbers and front forks for

any leaks.

NOTE :

Ens ure acc essories, f itted if any, do not foul with

rear shoc k ab s orbe r s . Ch eck fo r su f f i c i ent gap

between the shock absorbers and the attachment s

in a condition that the rear end of the Motorcycle is

fully loaded and the shock absorbers are maximum

compressed .

Minor Maintenance Tips

61

REMOVAL OF BATTERY FROM THE VEHICLE

Battery Carrier bracket screw

(-)

TERMINAL TERMINAL

Unlock (turn the key clockwise) and remove

the Left side panel.

Disconn ect both the ter minal wires (negative

first and positive next respectively)

Rem o v e th e batt ery c ar rier b r a c k et b y

loosening the two screws

Take out the battery.

BATTERY MAINTENANCE

(+)

The Motorcycle is provided with 12V - 14 AH

battery.

The battery must be periodically checked for

Cleanliness and corrosion free terminals.

Electrolyte level.

I f elect r oly t e level is low, top up with

distilled water only.

NOTE :

The poor contact or loose fitment of Battery terminals

may cause ECU failure.

Minor Maintenance Tips

62

Warning

Always d isc on ne c t the neg at ive (-) batt ery cab le

fi r s t and th en th e Red pos iti ve (+) c abl e wh i l e

removing the battery connecti ons .

NOTE :

For chec k ing the batt er y vol tag e a nd elec trolyt e

sp ec if ic gravity, co nt act aut h orised Roy al Enf ield

Dealer / service point or battery service centre.

CAUTION :

Do not use battery with low electr olyt e level as

the battery internal cells will get damaged.

Do not overf ill the battery electr olyte level as it

will s pill out through the overflow pipe and cause

corrosion to vehicl e parts.

Use only distilled water meant for use in batteries

to avoid damage to battery.

REASSEMBLY OF BATTERY ON MOTORCYCLE

Position the battery in the battery carrier such

that negative terminal of the battery is towards

the fuel pump side.

Ensure ignition swit ch is

in “OFF” condition.

Con n e c t t he p os it iv e

terminal (Red wire) first

Con n e c t t h e n egat iv e

terminal (Black wire) next.

Smear the term inals with petroleum jelly. (Do

not use grease in the battery terminals).

Place the terminal boot / cap properly.

Refit the carrier bracket.

Refit LH side panel & lock it.

NOTE :

Clean t he wire terminal s free of corros ion and keep

the terminals coated with petroleum jelly.

CAUTION :

Keep the +ve and -ve cables f irmly conneted t o the

res pective bat tery t erminals . Failur e to do so may

result in damage to the motorcycle electrical system.

Minor Maintenance Tips

63

CHANGING ELECTRICAL COMPONENTS

HEADLAMP BULB REPLACEMENT

Loo s en the r i m

holdi ng sc r ew on

top and tak e ou t

the h ead l amp

dom e.

Disconnect electrical connections.

Thumb push and

remo v e th e bu lb

ho ld ing c lam p

gently.

Remove the bulb.

Po s i t i on new b u l b

in s id e the reflec t or

such that the three

project ions o n t h e

bulb align with the slot

on the reflector.

Refix the bulb holding

clamp.

Connect the Electrical

connections.

Position head lamp doom onto the head lamp

shell and tighten the mounting screw on top.

NOTE :

Never touc h t he bulb with your

fi n gers . Finger pr ints will etc h

the glass and decrease bulb life.

Always hold the bul b with paper or clean dr y cloth

during handling as s hown in f ig.

X

Minor Maintenance Tips

64

TAIL LAMP BULB REPLACEMENT

Unlock the bat tery

cover

Re m o ve t he s eat

assembly by pulling

seat lock cable.

Re m o ve t he t a i l

lig h t g la s s by

uns cr ew ing i t s

mounting screw

Hol d t h e b u l b , press insi de and r ot at e

anticlockwise to remove the tail light bulb from

its holder.

Replace the bulb 12V 21 / 5W.

A s s e m b l e

back the tail

light in th e

r e v e r s e

or der of

disman tling

process.

Minor Maintenance Tips

65

TRAFFICATOR BULB REPLACEMENT

Remove t he scr ew

from the trafficator

housing back side.

Open the Indicator

hous ing.

Take out the bulb

holder with help of

is screw driver.

Take out the bulb

an d r eplac e th e

same.

Ref it the h older

fitt ing it s l o c k in

proper position.

Fix the rubber gasket

cover.

Assemble back the

in d ic at or hous i ng

cover.

Minor Maintenance Tips

66

FUSE

1

2

3

4

5

8

7

6

Warning

Electronic Cont rol U ni t (ECU) may fail due to loose

elect rical connections, loose bat tery t erminal s etc.

Henc e, it is very important to keep all the Electrical

connec tions intact .

BLADE FUSE USAGE LIST

Fuse

Color

No .

1 Blue 15A RR Fuse

2 Blue 15A MAIN Fus e

3 Re d 10A EC U Fuse

4 Re d 10A

5 Re d 10A Head Lam p Fuse

6 Re d 10A Instrument Cluster / Horn

7 Blue 15A Spare Fuse

8 Re d 10A Sp are Fuse

Amps

Gene ra l illu mina t io n / Tail / Tra f fi c at or

Application

Warning

Please get the electrical system of your Motorcycle checked

th ro ug ht ly and get the faul ts corr ected im media tly aft er

experiencing any fuse failure. Not doi ng this c an result in to

repeated fuse failures.

Usage of fuses other than spcified rating will damage the complete

electrical system.

Warning

While doing Arc welding any where in motorcycle,the battery

terminals and the Electronic Control Unit (ECU) coupler are to be

completely disconnected. Failure to do so many cause damage to

the Electrical system of the Motocycle.

Minor Maintenance Tips

67

AIR FILTER PAPER ELEMENT

CLEAN AND REFIX : EVERY 3000 KMS

Remove the screw from the side cover bottom

side and then take out RH side cover.

Remove the air filter

cover sc rews and

then takeout air filter

box cover.

Takeout air filt er pap er element and check

for dirt. Gently tap it as shown in fig and fix it

back.

NOTE :

It is adviceable to replace air filter paper element once

in 10,000 KMS. In case of vehicle running in dusty /

mud road condition it may be r eplaced as earlier as

req uired.

Us age of h i gh pres sure c om p r es sed ai r is not

recommended to clean air f ilt er paper element.

Fitment of air filter paper element is reverse order of

removal p rocess .

Washing Procedure

68

PRECAUTIONS

Wash vehicle when t he engine is cold.

Cover the silencer tail end and contr ol switches

with suitable plastic bags and tie it firmly to prevent

water entry into them.

Remove ignition key and seal k ey hole using

adhesive tape.

Do not rem ove RH side cover (panel) while

washing to avoid water entry into air filter box

assembly.

X

Use a suitable engine degreaser, available with

your local parts store, to remove dirt or grease

from the engine external parts if required. Follow

the directions in the label carefully before using

the degreaser.

Use low pressure jet of water to clean the entire

vehicle.

Never spray water with great force on head lamp,

Meter/cluster unit, trafficator lights, front and rear

wheel hubs, electrical connections and w ires,

control cables, EFI components, spark plug ,

battery,air fillter cover etc.

Use Luke warm water and mild detergent on the

painted components to remove dirt, etc.

Rinse vehicle thor oughly with plain water to

remove the detergent and wipe vehicle dry.

If possible, use compressed air and blow off

water par t icles fr om the obs c ure ar eas of

t he v ehic le, e lec tr i c al c o n n e c t i o ns , EF I

components etc.

Washing Procedure

69

AFTER WASHING

Ensure the vehicle is thoroughly dry by wiping

with a clean soft water absor bent cl ot h or

chamois leather.

Remove all plastic bags and adhesive tapes.

Lubricate control cables, pivots for footrest, side

st and, cent re stand, brake and gear shifter

linkages, rear c hain etc.with lube oil.

Polish the painted and plated surfaces using

polishing wax.

Start the bike and allow engine to idle & warm up.

Drive the motorcycle slowly, applying both brakes

intermittently to dry up the brake pads.

Test brakes for full efficiency.

Warning

Observe war nings and cau tions given on labels of

cleaning compounds before it is used.

When washing your motorcycle, be careful not to get

the brakes , engine, muff lers or air cleaner et c. , too

wet. Wet brake pad and / or disc can aff ect braking

eff ic ie nc y. En gine can be star ted after was h i ng.

Ensure brakes and engine are working properly bef ore

riding in the traffic and / or in highways at high speeds.

Storage Precautions

70

Incase your Motorcycle is not going to be used for

a m onth o r m or e, w e advise t h e foll o w ing

precautions to be taken

Carryout required repair/adj ust ments on the

motorc ycle.

Wash the motorcycle t horoughly and lubricate

as per the maintenance chart.

Start the engine, warm up f or a few minutes

and switch off.

Drain out the fuel completely from the fuel tank

and fuel lines.

Remove the spark plug. Pour in about 20ml of

clean engine oil through spark plug hole. Close

the hole and crank engine few times and refit

the sparkplug.

Clean the rear chain thorough ly and apply

lubrication oil on it.

Re m ove bat t e r y from th e bi k e . Clean i t s

terminal s and apply petr oleum jell y on the

terminals to avoid c orrosion.

Maintain electr olyte level between max and

min marks, by adding distilled water and wipe

the battery dry.

Stor e the bat t ery in a cool , dry and wel l

ventilated place.

Do not place the battery in direct sun light, near

open flame or where temper at ur e is above

40°C or below 0°C

Cover the silencer with plastic bags to prevent

moisture entry. Set the motorcycle on its center

stand.

Apply anti rust solution on all chrome plated

parts. Take care not to apply this solution on

rubber or painted parts .

Store motorcycle in a clean covered area free

of moisture and keep it covered to prevent dust

settling on it.

Storage Precautions

71

PREPARING THE MOTORCYCLE FOR REUSE

Remove anti rust solut io n from all ch rome

plated parts and clean the motorc ycle.

Inflate the tyres to the correct tyre pressure.

Ensure battery is fully charged and electrolyte

level is properly maintained.

Connect the bat tery.

Lubricate all control cables and pivots.

Ch eck level of oil in engi ne and top up if

necess ary.

Fill fuel tank with fresh petrol.

Check fuel line for any cracks or cuts.