EURO IV - VEHICLE SERVICE MANUAL

Continental GT

Bullet EFI

Classic Bullet EFI

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

1

PREFACE

“FIRST TIME RIGHT” is a very important element for enhancing Customer Satisfaction.

Royal Enfield is committed to upgrade the skills and knowledge of technicians so that they follow scientific repair

techniques to ensure “FIRST TIME RIGHT” practices and carry out repairs accurately so that customers will enjoy

trouble free performance at all times.

This Maintenance and service manual is specifically for the following EURO IV Regulation models being currently sold

only in UK & European countries.

BULLET EFI

BULLET CLASSIC EFI

CONTINENTAL GT

This Manual is intended for use primarily by a person who is well versed with basic repair technique of a motorcycle

& usage of general purpose tools and special service tools & diagnostic tools, while basic & routine service maintenance

may be in the event of not having possibility in carrying out using basic tools, required tools it is recommended that

the motorcycle may please be get inspected and serviced through an Authorized Royal Enfield Service Station.

This manual will help in guide in the basic servicing, periodical maintenance, systematic disassembly, Parts inspection

and assembling procedures of various mechanisms / systems of the motorcycle which has to be carried out in Royal

Enfield Authorised Dealership or Service Station.

While this manual is updated with latest Information and Specifications, at the time of going to print, due to continuous

improvements being done to improve performance, some of the data, illustrations etc., in this manual may differ

from the actual parts fitted in the engine.

Subsequent & continuous improvement that may be done on the motorcycles to enhance customer satisfaction, will

be uploaded also in the RMI portals & also available with Royal Enfield Authorised dealer & Service Station.

Please do feel free to write to us at support@royalenfield.com, if you have any queries, clarification, suggestions or

feedback.

With warm regards

SERVICE HEAD QUARTERS

Royal Enfield, A Unit of Eicher Motors Limited,

Thiruvottiyur High Road, Thiruvottiyur, Chennai - 600 019.

E-mail: Support@royalenfield.com

Website: www.royalenfield.com

Part No: 888569 / Feb. ’17

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

01

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VE HICLE SERVICE MANUAL - EURO IV

2

EURO IV BIKES – VEHICLE VIEWS

ROYAL ENFIELD VE HICLE SERVICE MANUAL - EURO IV

02

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

3

TABLE OF CONTENTS

SL.NO. DESCRIPTION PG.NO.

SL.NO. DESCRIPTION PG.NO.

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

03

1. Technical Specifications ............................................ 4

2. Periodical Maintenance ............................................. 6

3. Special Tools Usage List ............................................. 8

4. Engine Removal from Frame ..................................... 9

5. Vehicle Aggregagetes

5.1 Cables ............................................................... 11

5.2 Airfilter Paper Element .................................. 16

5.3 Fuel Tank .......................................................... 23

5.4 Seat Assembly ................................................. 30

5.5 Exahust Pipe & Silencer ................................. 39

6. Front Suspension

6.1 Front Wheel ..................................................... 46

6.2 Front Mudguard .............................................. 54

6.3 Handle Bar ....................................................... 60

6.3 Front Fork ........................................................ 70

6.4 Steering Stem .................................................. 87

7. Rear Suspension

7.1 Rear Wheel ....................................................... 103

7.2 Rer Sprocket / Drive Chain Adjustment ....... 111

7.3 Rear Shockers .................................................. 113

7.4 Rear Mudguard / Rear Number Plate ........... 119

7.5 Swing Arm ........................................................ 126

8. ABS ........................................................................... 133

9. EVAP ........................................................................... 167

10. EM S ........................................................................... 174

11. NACS II DIAGNOSIS ..................................................... 213

12. Electricals

12.1 Battery .............................................................. 233

12.2 Bulbs ................................................................. 239

12.3 Electrical Components ................................... 261

12.4 Wiring Diagram ............................................... 277

13. Trouble Shooting ........................................................286

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

4

SECTION 01 - TECHNICAL SPECIFICATION

TECH SPEC POINT

BULLET

CLASSIC EFI

CONTINENTAL GT

BULLET EFI

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

04

ENGINE

Engine 4 Stroke, air cooled, single cylinder 4 Stroke, air cooled, single cyl., OHV, SI

Capacity 499 cc (Displacement) 535 cc

Bore 84 mm 87 mm

Stroke 90 mm 90 mm

Compression ratio 8.5 : 1 8.5 : 1

Max. Power @ RPM 20.3 Kw @ 5250 RPM 21.4 kw @ 5100 RPM

Max. Torque @ RPM 41.3 Nm @ 4000 RPM 44 Nm @ 4000 RPM

Air filter Element Paper Element Paper Element

Lubrication Forced Lubrication, Wet Sump Forced Lubrication, Wet Sump

Fuel Supply Electronic Fuel Injection Electronic Fuel Injection

IGNITION SYSTEM

Ignition system Digital Electronic Ignition Electronic Ignition

Spark plug gap 0.8 mm 0.8 - 0.9 mm

Spark plug WQR8DC (Bosch) WQR8DC (Bosch)

TRANSMISSION

Clutch Wet Multiplate Wet Multiplate (7 Plates)

Drive Chain links 102 pitch 101 pitch 101 Pitch

Primary drive Duplex Chain drive 3/8” pitch Duplex Chain

Gear box 5 Speed Constant Mesh Constant Mesh 5 Speed

Gear Ratios

I - 3.063 : 1 I - 3.063 : 1

II - 2.013 : 1 II - 2.013 : 1

III - 1.522 : 1 III - 1.522 : 1

IV - 1.212 : 1 IV - 1.212 : 1

V - 1.000 : 1 V - 1.000 : 1

Primary Drive Ratio 2.15 : 1 2.15 : 1

Secondary Drive Chain Drive 18 Teeth (F.D. Sprocket)

Secondary ratio 2.235:1 2.12:1

ELECTRICALS

Generation Alternator Alternator

System 12V DC 12V DC

Battery 12V - 14 AH 12V - 14 AH

Head lamp 12V, 60/55 W 12V, 60/55 W, Halogen Bulb

Tail / Brake lamp 12V, 5/21 W 5/21 W

Turn signal 12V, 10W X 2 Nos. 12V, 10W X 4 Nos.

Pilot lamp 12V, 2 W X 2 Nos. / 12V, 4 W X 1 No. NA

Instrument Cluster NA Digital instrument Cluster with LCD

High beam indicator NA 12V, 0.2W (LED)

Neutral Indicator NA 12V, 1.12W

Horn 12V, 2.5 Amp (Max.) 12V, 2.5A (Dual tone-LT, HT)

Starter Motor NA 12V, 0.9 KW

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

5

Values / Dimensions mentioned above are for reference only.

In view of continuous improvements being done on our motorcycles, the specifications are subject to change

without prior notice.

CHASSIS

Frame Tubular Frame Tubular steel double cradle

Tyre size

Fr : 90 / 90-19”-52 V 3.25 X 19” 110/90-18 M/C 56H

Rr : 110 / 80-18”-58 V 3.50 x 19" 130/70-18 M/C 63H

Tyre pressure

Front-Solo: 18 PSI Front- Solo:1.41 Kg/cm2 (20 PSI)

Pillion: 20 PSI Pillion:1.55 Kg/cm2 (22 PSI)

Rear-Solo: 28 PSI Rear- Solo:2.11 Kg/cm2 (30 PSI)

Pillion: 30 PSI Pillion:2.25 Kg/cm2 (32 PSI)

Fuel tank capacity 14.5 + 1 Litres 13.5 Litres***

Suspension

Front: Telescopic, Hydraulic Damping Front:Telescopic, Stroke 110mm

stroke 110 mm

Rear: Swing arm with gas filled shockabsorbers

Rear:Twin - Gas Charged,

with adjustable 5 step spring tension load. Stroke 80 mm

Front fork oil capacity 430 ml per leg 430 ml per leg

Front fork oil Gabriel Fork Oil 2W 35 Gabriel Fork Oil 2W 35

Hydraulic Disc Brakes Front & Rear Hydraulic Disc Brakes Front & Rear

with ABS System with ABS System

Brakes Front: 300 mm dia disc with twin Front:300 mm dia floating disc,

piston caliper twin piston floating caliper

Rear: 240 mm dia disc with single piston & Rear:240mm dia disc, single piston

floating caliper floating caliper

Brake oil grade DOT 4 or above DOT 4 or above

Brake oil capacity Front:60 ml Rear: 100 ml Front:50 ml Rear: 100 ml

Speedometer lamp 12V, 3.4 W X 1 No. NA

Turn signal /

12V, 1.7 W each NA

High beam indicator

Neutral Indicator 12V, 1.7 W X 1 No. NA

DIMENSIONS

Length 2140 mm 2060 mm

Width 800 mm 760 mm

Height 1080 mm 1070 mm

Wheel base 1360 mm 1360 mm

Saddle height 805 mm 790mm 810 mm

Ground clearance 140 mm 140 mm

WEIGHTS

Mass of motorcycle in running order 270 Kg 267 Kg

Max pay load 95 Kg 98 Kg

Max technical permissible mass 365 Kg 365 Kg

PERFORMANCE

Maximum Speed 128 kmph 137 Kmph

TECH SPEC POINT

BULLET

CLASSIC EFI

CONTINENTAL GT

BULLET EFI

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

05

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

6

The Periodical maintenance schedule detailed below is based upon average riding conditions and indicates the Intervals at which

regular inspections, adjustments, replacements and lubrications must be carried out to help maintain your motorcycle meticulously.

If in case the motorcycle is used frequently in very dusty environment / severe climatic conditions / Poor Roads / stagnant water etc.,

the maintenance will need to be done earlier as may be required.

Contact a nearest Royal Enfield Authorized Dealer / Service Center to carry out the periodical maintenance and for any expert advice.

A : Ad just C : Cle an D : De-carboni se I : Inspec t L : Lubri cate R : Replace

S.

No.

DESCRIPTION

SCHEDULE

SECTION 02 - PERIODICAL MAINTENANCE

NOTE :

For maintenance after 30,000 Kms, (18,750 miles) please repeat the same frequency levels specified above, in consultation with a

Royal Enfield Authorized Dealer.

BULLET CLASSIC EFI & BULLET EFI

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Miles (x 1000) 0.3 2 3.75 6 7.5 9.5 11.25 13 15 17 18.75

1 Engine Oil

R R R R R R

Check level every 500 Kms or earlier as required

2 Engine oil filter element R R R R R R

3 Engine sump filter (oil strainer) C C C C C C

4

Magnetic drain plug under gear box and secondary C C C C C C

drain plug under crankshaft in crankcase right

5 Spark plug A A A A A R A A A A R

6 HT lead I I I I I I I I I I I

7 Fuel hose I I I I R I I I R I I

8 Fuel Pump Check for screw tightness in all services

9 Accelerator cable play A A A A A A A A A A A

10 Rubber hose, Air filter to Throttle body I I I I R I I I R I I

11 Rubber hose, Inlet manifold / Adaptor I I I I R I I I R I I

12 Airfilter paper element C C C C R C C C R C C

13 Inlet/Exhaust valve seating (compression/vaccum test) I I

14 Cylinder head D

15 Exhaust system D

16 Clutch free play Adjust every 1000 Kms or earlier as required

17 Rear brake pedal pivot L L L L L L L L L L L

18 Battery terminals (apply petroleum jelly) C C C C C C C C C C C

19 Battery Electrolyte level I I I I I I I I I I I

20 Earth wire eyelet (behind battery carrier) I I

21 Rear Wheel Drive Chain

Lubricate & Adjust every 1000 Kms/Clean, Lubricate &

Adjust every 3000 Kms or earlier as required

22 Front Fork oil R R R

23 Rear brake play Adjust every 1000 Kms or earlier as required

24 Rear brake cams L L L L L

25 Steering ball races play I A L A L A L A R A L

26 Spokes tightness / Wheel rim run out front & rear I I I I I I

27 Pivot-Side Stand, Center Stand, Pillion Foot Rest L L L L L L L L L L L

28 Tyre wear pattern (Front & Rear) I I I I I I I I I I I

29 Hand levers pivot Lubricate every 1000 Kms or earlier as required

30 Front Disc Brake Oil level check I I I I I R I I I I R

31 Evaporative Emission Equipment rubber hoses I I I I R I I I R I I

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

06

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

7

CONTINENTAL GT

The Periodical maintenance schedule detailed below is based upon average riding conditions and indicates the Intervals at which

regular inspections, adjustments, replacements and lubrications must be carried out to help maintain your motorcycle meticulously.

If in case the motorcycle is used frequently in very dusty environment / severe climatic conditions / Poor Roads / stagnant water etc.,

the maintenance will need to be done earlier as may be required.

Contact a nearest Royal Enfield Authorized Dealer / Service Center to carry out the periodical maintenance and for any expert advice.

A : Ad just C : Cle an D : De-carboni se I : Inspec t L : Lubri cate R : Replace

NOTE :

For maintenance after 30,000 Kms, (18,750 miles) please repeat the same frequency levels specified above, in consultation with a

Royal Enfield Authorized Dealer.

S.

No.

DESCRIPTION

SCHEDULE

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Miles (x 1000) 0.3 2 3.75 6 7.5 9.5 11.25 13 15 17 18.75

1 Engine Oil

R R R R R R

Check level every 500 Kms or earlier as required

2 Engine oil filter R R R R R R

3 Engine sump filter C C C C C C

4 Magnetic drain plug under gear box on crankcase right C C C C C C

5 Spark plug C&A C&A C&A C&A C&A R C&A C&A C&A C&A R

6 HT lead I I I I I I I I I I I

7 Fuel hose I I I I R I I I R I I

8 Fuel Pump Check for screw tightness in all services

9 Accelerator cable play A A A A A A A A A A A

10 Rubber hose, Air filter to Throttle body I I I I R I I I R I I

11 Rubber hose, Inlet manifold I I I I R I I I R I I

12 Airfilter element C C C C R C C C R C C

13 Inlet / Exhaust valve seating I

14 Cylinder head D

15 Exhaust pipe D

16 Clutch free play Adjust every 1000 Kms (600 Miles) or earlier as required

17 Rear brake pedal pivot L L L L L L L L L L L

18 Battery terminals (apply petroleum jelly) C C C C C C C C C C C

19 Battery Electrolyte level I I I I I I I I I I I

20 Earth wire eyelet contact I I

21 Rear Chain

Adjust every 1000 Kms (600 Miles) or earlier as required

Lubricate every 3000 Kms (1800 Miles) or earlier as required

22 Fork oil R R

23 Steering ball races A L A L A

24 Spokes tightness I I I I I I

25 Wheel rim run out I I I I I

26 Tyre wear I I I I I I I I I I

27 Hand levers & Kick starter pivot Lubricate every 1000 Kms or earlier as required

28 Brake Oil level check / Replacement I I I I I I I R I I I

29 Pivot-Side Stand L L L L L L L L L L L

30 Center Stand pivot L L L L L L L L L L L

31 Pillion Foot rest pivot L L L L L L L L L L L

32 Swing arm bearings L L

31 Evaporative Emission Equipment rubber hoses I I I I R I I I R I I

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

07

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

8

SECTION 03 - SPECIAL TOOLS USAGE LIST

ST-25834-2

Front fork Dismantling tool To hold pipe seat of front fork while

dismantling & tightening of front fork

main tube with bottom case (fork end

assy.).

ST-2511 4-4 Extractor for fork oil seal

To remove oil seal in front fork bottom

case.

ST-2511 3-4 Mandrel for oil seal

Fitment of oil seal into front fork

bottom case.

ST-2511 2-4 Expander for front fork Oil

Expanding the oil seal lip while

seal inserting main tube into bottom case

of front fork

ST-25110-3 Gauge plate for tightening

Alignment of Swing Arm while

chain stay mounting tightening into chassis.

ST-25244-4 Special spanner adjuster To adjust gas filled shockabsorber

spring load.

ST-25833-4 Front Fork Tool 1/2 SD To Loosen and tightening of front fork

assembly from the head lamp casing.

ST-26461-2 Front Fork Assembling & To hold pipe seat of front fork while

Dismantling Tool dismantling & tightening of front fork

main tube with bottom tube (fork end).

ST-26485-3 Front Fork Oil Seal Driver Fitment of slide bush and fork oil seal

(Dia 41mm) into front fork bottom case.

PART NO. DESCRIPTION PHOTOS APPLICATION

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

08

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

9

SECTION 04 - ENGINE REMOVAL FROM FRAME

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

09

Bullet Classic EFI / Bullet EFI / Continental GT

Disconnect alternator leads.

Disconnect the spark plug suppressor cap.

Disconnect the fuel pipe.

Remove throttle body along with throttle cable.

Remove the air filter assy.

Remove the exhaust pipe and silencer.

Disconnect the engine steady bolt.

Remove the rear chain.

Remove the LH Foot rest.

Support the engine on a suitable box or wooden block.

Remove the center stand and the stand stop.

Remove the front engine plates and the small bolt fixing the stand spring bracket.

Remove the stud securing the rear engine plate to the frame Slide out the engine.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

10

SECTION 05 - VEHICLE AGGREGATES

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

11

SECTION 5.1 CABLES

1

2 3

S. NO.

DESCRIPTION

QTY.

1 Throttle Cable Assembly (Twin Cable) 1

2 BI Starter Cable 1

3 Clutch Cable Assembly 1

EXPLODED VIEWS

BULLET CLASSIC EFI / BULLET EFI / CONTINENTAL GT

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

12

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

5.1 Clutch Cable

Assembly

Bullet Classic EFI/

Bullet EFI/

Continental GT

Dismantling

5.1 Throttle Cable

Assembly (Twin

Cable)

Bullet Classic EFI/

Bullet EFI/

Continental GT

Dismantling

Slacken the adjusters at

the throttle body end for

both cables.

Gently remove t he

Throttle cable assembly.

Slacken the adjuster at

the clutch cover end and

disconnect t he cable

from the lever.

Gently pull out part of

the clutch cable from the

cover.

Remove the clutch cable

from the clutch lever at

handle bar end.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

13

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

5.1 Bi Starter Cable

Bullet Classic EFI/

Bullet EFI/

Continental GT

Dismantling

Slacken the adjuster at

the Bi starter cable end

and disconnect the

cable from the lever.

Gently pull out the part

of Bi starter cable.

Remove the Bi starter

cable from the clutch

lever at handle bar end.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

14

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

5.1 Clutch Cable

Assembly

Bullet Classic EFI/

Bullet EFI/

Continental GT

Assembling

5.1 Throttle Cable

Assembly (Twin

Cable)

Bullet Classic EFI/

Bullet EFI/

Continental GT

Assembling

Locate the clutch cable in

clutch lever at handle bar

end.

Loca te pa rt of clutch

cable in the cover.

Slacken the adjuster at

the clutch cover end and

Connect the cable in the

lever.

Loca te the Throttle

cable assembly.

Slacken the adjusters at

the throttle body end for

both cables.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

15

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

5.1 Bi Starter Cable

Bullet Classic EFI/

Bullet EFI/

Continental GT

Assembling

Loca te the Bi start er

cable in the clutch lever at

handle bar end.

Loca te the pa rt of Bi

starter cable.

Slacken the adjuster at

the Bi starter cable end

and Connect the cable in

the lever.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

16

EXPLODED VIEWS

BULLET EFI, BULLET CLASSIC EFI

SECTION 5.2 - AIR FILTER PAPER ELEMENT

4

20

19

18

3

2

11

5

6

7

5

6

7

1

16

11

12

13

14

15

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Air Filter Box Assembly with sticker 1

2 Air filter element 500cc 1

3 Cover Filter element 1

4 Hex Nylock Nut M8X9.5 1

5 Hex Screw M6 X 14 2

6 Lock Washer M6 3

7 Plain Washer M6 1

8 Plain Washer M6 1

9 Hex Nut M6 X 1 X 7 1

10 Hex.Bolt M6 X 1 X 12 1

11 Inlet Bellow 1

12 Clip Hose - Inlet Bellow 1

13 Hexagon Socket Head Cap screw-M5X.8X20 2

14 TA Sensor 1

15 Gasket - Air Temp Sensor 1

16 Rubber Tube - Air Filter 1

17 Beading Box Cover 1

18 Beading Cover Air Filter 1

19 Cover Assembly - Air (Plastic) 1

20 Washer - Cover M10 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

17

1

11

10

9

8

8

8

8

6

7

2

3

A1

4

5

CONTINENTAL GT

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Air Filter Box 1

2 Clamp 1

3 Pipe Outlet 1

4 TA Sensor 1

5 Hex Socket Head Cap Screw M5 X 16 2

6 Drain Pipe 1

7 Clip 1

8 Pan Head Screw M5 X 12 4

9 Inlet Cover 1

10 Seal 1

11 Element Air Filter 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

18

5.2 Air Filter Element

Bullet Classic EFI/

Bullet EFI

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

S.

No.

Hex Nyloc Nut M8

Loosen hex Nylock nut

Gently pull out the cover

assembly.

Re move cover filter

element.

Remove the Air filter

Element.

Un lock and open the

Filter box RH.

CAUTION:

Ensure the pillion footrest is

in extended pos ition to

avoid damage to filter box lid

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

19

S.

No.

5.2 Air Filter Element

Continental GT

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

Pan Head Screw M5 X 12

Screw Driver

NOTE:

Remove rubber seal from

the cover.

Pan Head Screw M5 X 1

Screw Driver

CAUTION:

Ensure Purge valve is

placed safely to preven t

from damage.

Remove airfilter element

from the housing.

Remove the side panel

from the frame.

Remove the 4 pan head

scre ws on the airfilter

cover.

Loosen and remove the

pan head screw in side

panel RH bottom.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

20

CAUTION :

Do not wash filter element using water, gasoline or any solvents as it will damage the paper element.

INSPECTION

Inspect air filter element carefully for any deformation, damages, heavily clogged with dirt, soggy condition, and

/ or foreign particles embedded in the element. Replace if any of these conditions are observed.

Inspect rubber seals, hoses, for cuts, cracks, damages. Replace seals and rubber parts whenever the induction

system is serviced.

FOR CONTINENTAL GT MODELS

Inspect air filter housing and cover forany damages, cracks etc and replace entire assembly if damaged.

CLEANING

Gently Tap filter element with minimum force to dislodge heavy / embedded dust particles.

Using low pressure compressed air :

- blow air from INSIDE to OUTSIDE for Bullet EFI, Bullet Classic EFI Models.

- blow air from OUTSIDE to INSIDE for Continental GT Models.

to remove the fine dust particles. DO NOT WASH THE ELEMENT IN WATER, GASOLINE OR ANY SOLVENTS.

Clean Airfilter element every 3,000 Kms OR more frequently if motorcycle is used in dusty / Off road conditions.

Clean the airfilter housing internals, retainer plate etc, with a soft damp cloth to remove the dust.

REPLACE

All ‘O’ rings, rubber beadings, seals, gaskets, rubber parts etc, whenever the airfilter assembly is serviced.

Airfilter element evedry 12,000 Kms (7,500 Miles) or earlier if motorcycle isused in dusty / Off road conditions.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

21

5.2 Air Filter Element

Bullet Classic EFI/

Bullet EFI

Loca te the Air filte r

element inside filter box

RH.

Loca te Cove r filter

element over filter

element.

Ensure rubbe r rin g is

located in plastic cover

assembly.

Loca te Plastic cover

assembly over air filter

element in filter box RH.

Position washer on the

mounting stud.

Locate nyloc nut on stud

and tighten sufficiently

till it is completely resting

on the washer and

resi stan ce to tighten

further is felt.

Ensure beading is

correctly located on the

filter box lid.

Close filter box lid and

lock in place.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

S.

No.

Hex Nyloc Nut M8

CAUTION:

Ensure the pillion footrest

is in extended position to

avoid damage to filter box

lid.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

22

S.

No.

5.2 Air Filter Element

Continental GT

Locate Filter inside air

filter box.

Ensure rubbe r rin g is

correctly seated in the

cover air filter.

Ensure cover air filter is

located properly on the

filter box and the cover

is correctly located at the

mounting peg in the

housing.

In stal l the 4 pan head

screws on the cover and

tighten evenly.

Ensure the rubber

grommets are in place in

the side panel RH.

Locate side panel RH in

the frame, ensuing the

pegs in the frame are

seated in the grommets.

Tighten the RH side

pane l at the bottom

using pan head screw.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

Pan Head Screw M5 X 12

Allen Key 4mm

Pan Head Screw M5 X 12

Allen Key 4mm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

23

16

15

14

13

11

19

18

9

8

7

6

5

4

3

2

1

17

17

12

11

10

11

10

12

12

10

10

12

11

11

12

20

10

SECTION 5.3 - FUEL TANK ASSEMBLY

EXPLODED VIEWS

BULLET EFI, BULLET CLASSIC EFI

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Fuel Tank With Sticker - Black 1

2 Cap-Fuel Tank 1

3 Thigh Pad R H 1

4 Flanged Hex Bolt M6X1X27 2

5 Washer-Tank 2

6 Sleeve-Tank Mtg Rear 2

7 Rear Damper-Tank 2

8 Thigh Pad L H 1

9 PA Tube Assembly 1

10 Hex Socket Button Head Cap Screw M6X12 5

11 Washer 5

12 Washer 5

13 Clamp Plate - Fuel Pump 1

14 Fuel Pump 1

15 O Ring 1

16 Low Fuel Sensor 1

17 Front Damper-Tank 2

18 Quick Connector 1

19 Fuel Hose (Pa Tube) 1

20 Cap,Injector 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

24

CONTINENTAL GT

19

18

20

12

11

10

10

11

13

13

10

10

13

13

11

10

11

9

8

7

6

14

15

15

14

16

17

3

4

5

4

5

2

1

3

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Cap-Fuel Tank 1

2 Fuel Tank Assy With Sticker (Red) 1

3 Front Damper-Tank 2

4 Flanged Hex Bolt M6 X 1 X 27 2

5 Bush - Fuel Tank 2

6 Rear Damper-Tank 2

7 O Ring 1

8 Fuel Pump 1

9 Clamp Plate - Fuel Pump 1

10 Washer 5

11 Washer 5

12 Fuel Hose Assembly 1

13 Hex Socket Head Cap Screw M6 X 16 5

14 Hex Screw M6 X 12 4

15 Punched Washer-Fuel Gauge Mtg 4

16 Fuel Gauge Unit 1

17 O’ Ring-Fuel Gauge 1

18 Quick Connector 1

19 Fuel Hose (PA Tube) 1

20 Cap, Injector 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

25

5.3 Fuel tank -

Dismantling

Bullet Classic EFI/

Bullet EFI

Remove Seat Assembly.

Disconn ect f uel hose

from the Fuel tank.

Remove 2 Hex bolts from

the rear end of fuel tank

along with washers,seals

and rear dampers.

Ensure the handle bar is

held at stra ight ahead

position.

Place a piece of cloth

betw een handle bar

clamp bolt and fuel tank.

Gently lift up fuel tank at

the rear end to:

- Disconnect low fuel

sensor coupler.

- Discon nect EVAP

hose from the Fuel

tank.

Slide fuel tank towards

rear to release fron t

locking clamp from the

rubber supports in

frame.

Remove fuel tank from

frame carefully.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

CAUTION:

Drain the fuel completely

from the fuel tank.

S.

No.

Hex Flange Bolt M6

Socket Spanner 10 mm

CAUTION:

Do not lift tank too high to

- Pr even t accidental

damage to the fron t

end of the fuel tank.

- Prevent damage to

low fuel sensor

coupler

- Prevent damage to

EVAP hose

CAUTION:

Ensure Ignition switch and

Kill switch is in OFF Position

before disconnecting hose

from fuel ta nk or before

draining the fuel.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

26

5.3 Fuel tank Dismantling

Continental GT

Remove Seat Assembly.

Disconn ect f uel hose

from the Fuel tan k by

removing the quick

connector from the fuel

pump end

Remove 2 Hex bolts from

the rear end of fuel tank.

Ensure the handle bar is

held at stra ight ahead

position.

Place a piece of cloth at

the front end of the fuel

tank to prevent damage

whil e lifting a nd

removing tank.

Gently lift up fuel tank at

the rear end to:

- Disconnect low fuel

sensor coupler.

- Discon nect EVAP

hose from the Fuel

tank.

Slide fuel tank onwards

rear to release fron t

locking clamp from the

rubber supports in

frame. Remove tank

from frame carefully.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

CAUTION:

Drain the fuel completely

from the fuel tank.

S.

No.

Hex Flange Bolt M6

Socket Spanner 10 mm

CAUTION:

Do not lift tank too high to

- Pr even t accidental

damage to the fron t

end of the fuel tank.

- Prevent damage to

low fuel sensor

coupler.

- Prevent damage to

EVAP hose.

CAUTION:

Ensure Ignition switch and

Kill switch is in OFF Position

before disconnecting hose

from fuel tank or before

draining the fuel.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

27

INSPECTION

Carefully inspect fuel hose and vent hose for damage, cuts, cracks or general deterioration. Replace if necessary.

WARNING

Gasoline is extremely flammable and highly explosive, which could result in serious injury.

Do not smoke or allow open flame or sparks in the vicinity.

Store the fuel carefully to avoid spillage.

Aggregate Component Fastener

Torque Range

NM Kg-M

Fuel Tank Fuel tank Mounting Flanged hex bolt M6 * 30 5 0.5

TORQUE CHART

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

28

5.3 Fuel tank Assembly

Bullet Classic EFI/

Bullet EFI

Ensure t he handle bar is

held at straight ahead

position.

Position fuel tank on

frame such that the front

mounting locate on the

rubber supports in the

frame.

Gently lift up fuel tank at

the end to:

- Con nect low fuel

sensor coupler wire.

- Connect EVAP hose

to the Fuel tank.

Connect fuel hose to the

fuel tank.

Ensure the two dampers

and mounting sleeves

are properly located in

the mounting slots.

Ensure the mounting

are aligne d and

asse mble 2 h ex bolts

with large washers.

Tighten the two bol ts

evenly.

Assemble Seat.

Fill fuel in the tank.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

Place a piece of cloth on the

top, front portion of the

fuel tank to avoid damage

due to touching of t he

handle bar clamp on fuel

tank.

S.

No.

Hex Flange Bolt M6

Socket Spanner 10 mm

Torque 5 Nm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

29

5.3 Fuel tank Assembly

Continental GT

Loca te over flow tube

carefully into the Fuel

tank.

Install the fuel tank

towards front to mount

into front locking clamp

into the frame.

Place a piece of cloth

betw een handle bar

clamp bolt and fuel tank.

Gently lift up fuel tank at

the end and

- Con nect low fuel

sensor coupler wire.

- Connect EVAP hose

into the Fuel tank.

- Con nect fuel hose

into the Fuel tank.

Install 2 Hex bolts at the

rear end of fuel tank

along with washers,seals

and rear dampers.

Assemble Seat.

Fill fuel sufficiently.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

S.

No.

Hex Flange Bolt M6

Socket Spanner 10 mm

Hex Flange Bolt M6

Socket Spanner 10 mm

Torque 5 Nm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

30

SECTION 5.4 - SEAT ASSEMBLY

EXPLODED VIEWS

BULLET EFI

6

2

2

3

5

5

6

7

7

10

8

9

9

8

4

4

1

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Complete Seat Assy 1

2 Flanged Hex. Bolt M 6 X 20 4

3 Pillion Handle 1

4 Hex Nut With Nylon Insert, M6 4

5 Flanged Hex. Bolt M8 X 20 2

6 Hex Nut With Nylon Insert, M8 2

7 Flanged Hex Nut M8 X 7.7 X 8 2

8 Stud M8 2

9 Plain Washer M8 4

10 Rubber Support Seat Front 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

31

BULLET CLASSIC EFI

1

4

3

2

4

13

12

14

16

17

18

15

22

21

20

19

20

16

22 17

23

9

10

11

4

5

7

6

4

8

4

9

10

124

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Split Seat Assy-Rider 1

2 Silent Block Bracket Assy 1

3 Silent Block Seat 1

4 Hex. Nut with Nylock insert, M8 X 9.5 8

5 Seat Hinge Mounting Assembly 1

6 Spring Washer M8 4

Spring Washer M8 - Special 4

7 Flanged Hex. Bolt M8 X 60 1

8 Stud - Seat Mounting 1

9 Hexagonal Bolt M8 X 45 2

Domed Cap Bolt M8 X 45 (chrome) 2

10 Washer (Classic Models) 2

Plain Washer (Chrome) 2

11 Spring Bush 2

12 Bush - Seat Spring 4

13 Spring 2

14 Split Seat Assy. Pillion 1

15 Sub Frame - Black 1

16 Flanged Hex Bolt M6 X 1 X 35 2

17 Flanged Hex Bolt M6 X 1 X 27 2

18 Flanged Hex Bolt M8 X 170 1

19 Hex. Nut With Nylon Insert M8 X 9.5 1

20 Plain Washer 2

Spring Washer 2

21 Flanged Hex Bolt M8 X 1.25 X 16 2

22 Hexagonal Nut M6 X 1 X 7 2

23 Pillion Handle for Rear Seat - Black 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

32

CONTINENTAL GT

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Single Seat Assembly with Cowl - Red 1

2 Plain Washer 3

3 Cross Recessed Pan Head Screw M6X14 3

4 Rubber Support-Rear 2

5 Rubber Support-Middle 2

6 Rubber Support-Front 2

1

2

3

3

3

2

2

4

4

6

6

5

5

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

33

5.4 Seat - Dismantling

Bullet Classic EFI

Rider Seat Removal

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

S.

No.

Hex Nut with Nyloc

Insert M8

Socket Spanner 13 mm

Hex Flange Bolt M8

Socket Spanner 13 mm

Flange Hex Bolt M8

Socket Spanner 13 mm

Hold n ut and remove

long mounting bolt from

the sub frame.

Rear Seat Removal

Gently remove the rider

seat from the frame.

Remove the seat spring

mounting bolts on LH &

RH side.

Loosen hex bolt at the

front end of the seat.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

34

Bullet EFI

Remove front Hex nut

mounted on LH & RH side

of the seats.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

S.

No.

Hex Flange Bolt M8

Socket Spanner 13 mm

Remove rear hex bolt on

LH & RH side of the seats.

Gently lift the seat from

the rear end.

Domed Hex Nut M8

Double end ring spanner

17 mm

Flange hex Bolt M8

Socket Spanner 13 mm

Remove Rear shockers

mounting Domed h ex

nut from LH & RH side

and loosen the bolt.

Hex Flange Bolt M8

Socket Spanner 13 mm

Loos en the 2 hex bolt

under the rear seat to

remove seat from Sub

frame.

5.4 Seat - Dismantling

Bullet Classic EFI

Rider Seat Removal

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

35

5.4 Seat -Dismantling

Continental GT

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

S.

No.

Remove the seat

assembly.

Gently pull seat latch to

release seat.

SEAT LATCH

Unlock & Remove Side

panel LH.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

36

5.4 Seat - Assembling

Bullet Classic EFI

Rider Seat Assembly

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

S.

No.

Hex Nut with Nyloc

Insert M8

Socket Spanner 13 mm

Hex Flange Bolt M8

Socket Spanner 13 mm

Flange Hex Bolt M8

Socket Spanner 13 mm

Rear Seat Assembly

Tighten the 2 hex bol t

under the rear seat to

assemble seat into Sub

frame.

Tighten the seat spring

mounting bolts on LH &

RH side.

Tighten hex bolt at the

front end of the seat.

Position the rider seat on

the frame.

CAUTION:

Please take care not to

damage the fuel tank

while assy

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

37

Bullet EFI

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

S.

No.

Hex Flange Bolt M8

Socket Spanner 13 mm

Remove front Hex nut

mounted on LH & RH side

of the seats.

Flange Hex Nut M8

Double end ring spanner

17 mm

Hex Flange Bolt M8

Socket Spanner 13 mm

Locate nut and tighten

long mounting bolt into

the sub frame.

Flange hex Bolt M8

Socket Spanner 13 mm

Loca te the seat in to

front end tighten rear

hex bolt on LH & RH side

of the seats.

Tighten Rear shocker s

mounting Domed h ex

nut & Bolt from LH & RH

side.

5.4 Seat - Assembling

Bullet Classic EFI

Rider Seat Assembly

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

38

5.4 Seat -Assembling

Continental GT

Locate front end of the

seat tab in the bracket in

the frame. Ensure th e

lock pin is posi tion on

the cente r of the se at

latch.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

S.

No.

Locate the Side panel LH

and lock in the seat.

Gently press the seat

rear end to lock the seat.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

39

EXPLODED VIEWS

BULLET EFI, BULLET CLASSIC EFI, CONTINENTAL GT

SECTION 5.5 - EXHAUST PIPE & SILENCER

3

3

3

3

6

3

3

2

5

4

4

9

17

4

4

16

8

10

11

12

13

14

1

1

7

1

13

7

3

3

15

4

4

9

5

10

11

3

4

1

14

12

Bullet & Classic EFI

Continental GT

3

6

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Flanged Hex. Nut M8 X 1.25 2

2 Exhaust Pipe -Guard 1

3 Philips Pan Head Screw M6 X 6 5

4 Flanged Hex. Bolt M8 X 20 4

Flanged Hex. Bolt M8 X 20 2

Flanged Hex. Bolt M8 X 20 3

5 Flanged Hex. Bolt M6 X 35 1

6 Combined Heat Shield/Silencer Guard 1

7 Silencer CAT Assy. 1

8 Bracket front silencer 1

9 Bracket -Silencer Mounting /Bracket Silencer 1

10 Gasket - Exhaust pipe & Silencer 1

11 Hex. Nut M6 1

12 Clamp -Silencer 1

13 Exhaust Pipe Assy. 1

14 Exhaust Gasket (Copper) 1

15 Hex. Nut with Nylon Insert, M8 1

16 Flange Hex. Bolt M10 X 1.5 X 35 1

17 Hex. Screw M8 X 16 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

40

5.5 Exhaust System

Bullet Classic EFI/

Bullet EFI

Disconnect HEGO sensor

connector from the

exhaust pipe by loosening the nut.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

Hex Flange Bolt M8

Socket Spanner 10 mm

S.

No.

Hex Flange Bolt M8

Socket Spanner 10 mm

Flange Hex Nut M8

Socket Spanner 10 mm

Remove the c enter

silencer bracket mounting scre w with plain

washer.

Remove the rear mount-

ing nut at the pillion foot

rest end mounte d on

silencer.

Remove the flange hex

nuts from cylinder head.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

41

5.5 Exhaust System

Continental GT

Disconnect HEGO

sensor connector from

the exhaust pipe.

Re move silence r

mounting bolt & nut

from the frame.

Remove the 2 Hex flange

nuts holding exhaust

pipe to cylinder head.

Gently remove t he

silencer assembly with

Exhaust pipe.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

S.

No.

Hex Flange Bolt M8

Socket Spanner 10 mm

Flange Hex Nut M8

Socket Spanner 10 mm

NOTE :

Ensure the copper gasket is

removed from the cylinder

head / exhaust pipe.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

42

INSPECTION

Inspect Silencer and Exhaust assembles for any deep scoring / damages / dents as it might cause damage to the

internals and the catalytic converters.

Inspect silencer and exhaust pipe joint for any signs of exhaust gas leakage.

CAUTION :

Do not clean the silencer and exhaust internals with any solvents, gasoline etc as it will damage the catalytic

converters.

REPLACE

Gasket between the silencer and exhaust pipe joint whenever the silencer / exhaust pipe are dismantled.

Copper gasket between exhaust pipe and cylinder head whenever exhaust pipe is dismantled from cylinder

head.

Copper gasket in HEGO sensor whenever exhaust pipe / hego sensor is dismantled.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

43

5.5 Exhaust SystemAssembling

Bullet Classic EFI/

Bullet EFI

Loca te g asket o n

Exhaust pipe.

Position exhaust pipe

on the cylinder head

assembly.

Tighten two flange hex

nuts on e xhaust pipe

into cylinder head.

Tighten the rear Mount-

ing nut at the pillion foot

rest end.

Tighten the center

silencer bracket mounting scre w with plain

washer.

Connect HEGO sensor

connector to the exhaust

pipe.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

S.

No.

Hex Flange Bolt M8

Socket Spanner 10 mm

Torque 25 Nm

Hex Flange Bolt M8

Socket Spanner 10 mm

Torque 25 Nm

Hex Flange Bolt M8

Socket Spanner 10 mm

Torque 25 Nm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

44

5.5 Exhaust SystemAssembling

Continental GT

Loca te g asket o n

exhaust pipe.

Position exhaust pipe

on the cylinder head

assembly.

Tighten two flange hex

nuts on e xhaust pipe

into cylinder head.

Tighten the rear

Mounting nut at the

pillion foot rest end.

Connect HEGO sensor

connector from the

exhaust pipe.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

S.

No.

Hex Flange Bolt M8

Socket Spanner 10 mm

Torque 25 Nm

Hex Flange Bolt M8

Socket Spanner 10 mm

Torque 25 Nm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

45

SECTION 06 - FRONT SUSPENSION

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

46

1

2

3

4

4

6

7

8

9

10

5

12

11

13

14

15

16

20

19

18

8

7

17

EXPLODED VIEWS

BULLET EFI, BULLET CLASSIC EFI

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Hex Socket Button Head Screw M6*1.0 4

2 Toner Front Wheel 1

3 Spindle 1

4 Socket Button Head Cap Screw 6

5 Disc Front 1

6 Spacer, Disc Side 1

7 Grease Seal, 25 X 40 X 7 2

8 Wheel Bearing 6203 (17 X 40 X 12 ) 2

9 Spacer Assy 1

10 Front Hub 1

11 Brass Nipples 40

12 Spokes Front 40

13 90/90 - 19 52 V Front Tyre Import 1

14 Tube(Tyre) 3.25X19 1

15 Wheel Rim (1.85 X 19'’ -1.5 Thk) 1

16 Rim Tape 1

17 Spacer Speedodrive 1

18 Speedo DrIve Assy Disc Brake 1

19 Plain Washer,M16 1

20 Hex U Nut M16 X 1.5 1

SECTION 6.1 - FRONT WHEEL

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

47

1

2

3

4

5

4

6

7

8

9

10

8

12

11

13

14

15

16

17

18

CONTINENTAL GT

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Hex U Nut M16 X 1.5 1

2 Washer 1

3 Spacer Disc Side 1

4 Hex Flange Bolt M8 X 25 6

5 Toner-Front Wheel 1

6 Front Disc 1

7 Grease Seal,25 X 40 X 7 1

8 Deep Groove Ball Bearing 6203 (17X 40 X12) 2

9 Bearing Spacer Assy 1

10 Hub-Front 1

11 Spokes Front 36

12 Nipple 3.6 mm 36

13 Tyre-Front 100/90-18" 1

14 Tube -Front 100/90-18" 1

15 Rim Front Aluminium(2.5X18") 1

16 Rim Tape 1

17 Spindle-Front Wheel 1

18 Wheel Speed Sensor Assy 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

48

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.1 Front Wheel

Dismantling

Bullet Classic EFI/

Bullet EFI /

Continental GT

Place the motorcycle on

its center stand on a firm

and flat surface.

Provide a suitable

support below the front

end of the engine such

that the front wheel is

about 4 inches (10 cms)

above the ground.

Disconn ect spee do

cable at speedo drive.

Disconnect wheel speed

sensor coupler near

head lamp housing.

Hex Bolt M8, Hex Nut M8

Ring Spanner 13 mm

Double end Ring Spanner

13 mm

Loosen the pinch bolt on

the right side fork end.

Hold the axle on the right

side and loosen the axle

nut on the left side.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

49

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.1 Front Wheel

Dismantling

Bullet Classic EFI/

Bullet EFI /

Continental GT

Hex Socket Screw M8

Allen Key 6mm

Torque 25 Nm (2.5 Kg-m)

Hex Nut M16

Double end Spanner–

24mm

Remove the axle nut and

washer.

Tap the axle out gently

from the left side and

remove completely from

the right side.

Slide out the wheel from

the fork legs.

Remove the speedo

drive after removing

wheel from the fork legs.

Remove the wheel

speed sensor and spacer

afte r removing w heel

from the fork legs.

CAUTION:

Do not depress the front

brake lever when wheel is

removed as this will result in

the brake pads coming too

far out of the brake caliper.

NOTE:

Place a 4 mm thick wooden

pie ce or cardboard sheet

between the brake pads to

avoid pads activation in the

event the front brake lever

is Accidently depressed.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

50

INSPECTION

Inspect tyres for any side wall crack stone hits, bulge, proper seating in rim.

Tyres button to be above the tyre wear indicator mark on the side walls.

Inspect spokes for any loosening / breakage.

Inspect hub or any damage.

Inspect Toner ring for any damage.

Axle & nut for thread damage.

Inspect wheel rim for run out / “jump” it should not exceed 2 mm.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

51

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

6.1 Front Wheel

Assembling

Bullet Classic EFI/

Bullet EFI /

Continental GT

Remove the wooden

piece / card board sheet

placed between the

brake pads.

Locate spacer & speedo

drive on the right side in

the hub.

Locate stepped spacer

in the left side (disc side)

of the hub with its larger

face outside.

Loca te front wheel

between the fork ends

duly ensuring the

spacers and the speedo

drive do not fall off and

the bra ke disc is

correctly positioned

betw een the brake

pads.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

52

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

6.1 Front Wheel

Assembling

Bullet Classic EFI/

Bullet EFI /

Ensure the peg in the

Speedo drive is correctly

positioned in the slot in

the right side fork end.

Continental GT

Position wheel s peed

sensor such tha t th e

wire coupler can be

connected and the wire

is not stretched.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

53

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

6.1 Front Wheel

Assembling

Bullet Classic EFI/

Bullet EFI

Hex nut M16

Double end spanner 17mm

Torque – 70 Nm

Ensure all the mounting

bolts are aligned.

Locate washer and nut

on the left side.

Hold the axle from the

right side and tighten

nut on left side.

Hold the pinch bolt and

tighten the nylock nut

on the right s ide fork

end. (Only Bullet Classic

EFI / Bullet EFI)

Tighten h ex socket

screw on fork end RH.

(Only for C ontinental

GT)

Rota te the whee l and

chec k for smoot h

rotation.

Connect the s peedo

cable to spe edo drive

and check for proper

working of speedo

meter.

Depress brake lever 2 or

3 times to chec k front

brake efficiency.

Torque 25Nm

NOTE:

Insert axle through the right

side fork end and gently tap it

in fully.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

54

SECTION 6.2 - FRONT MUDGUARD

3

4

2

8

7

6

9

10

10

2

8

7

6

12

9

6

7

8

9

10

5

5

6

7

9

10

6

7

8

2

15

14

13

1

8

7

6

11

2

10

LH side

RH side

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

1 Front Mudguard-Black 1

2 Mudguard Stay Front Black Mod 4

3 Mudguard Stay Center LH Black New 1

5 Hex Flanged Bolt M8 X 1.25 X 38 2

6 Phillips Round Head Machined Screw M6X 13 6

7 Lock Washer M6 6

8 Hex Nut M6 X 1 6

9 Flanged Hex Bolt M8 X 20 6

10 Spring Washer 6

11 Cable Guide 1

12 Clamp - Front Caliper Brake Hose 1

13 Cross Recessed Pan Head Screw M6 X 14 1

14 Plain Washer M6 1

15 Hex. Nut M6 X 1 X 5 1

EXPLODED VIEWS

BULLET EFI, BULLET CLASSIC EFI

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

55

CONTINENTAL GT

2

6

6

6

3

8

8

8

8

1

4

4

4

4

7

5

7

7

5

5

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

A1 Front Mudguard Mud Flap,Extension Kit 1

1 Front Mudguard 1

2 Mud - Flap Front 1

3 Fork Brace 1

4 Hex. Socket Button Head Screw M6X1 4

5 Lock Washer Internal Teeth 3

6 Pan Head Screw M5 X 0.8 X 12 3

7 Hex. Nut M8 3

8 Hex. Socket HD. Cap Screw M6X20

Stainless Steel 4

A1

Key Nos.

2, 5, 6 & 7

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

56

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.2 Front Mudguard

Bullet Classic EFI /

Bullet EFI

Re move Front whe el

as described in Fron t

Wheel section

Re lease B rake hose

grommet from the

holding clip in front

mudguard.

Loosen and remove the

4 flanged hex bolts along

with spring w ashers,

holding front mudguard,

front, centre & rear stays

to fork end RH.

Loosen and remove:

- 2 flange d hex bolts

along with spring

washers, holding front

mudguard centre stay

& front brake caliper to

fork end LH.

- 2 flange d hex bolts

along with spring

washers, holding front

mudguard front an d

rear stays to fork end

LH.

Loos en wheel spe ed

sensor screw and

remove sensor along

with screw.

Gently rotate th e

mudguard stays into the

mudguard and slide out

of the fork legs.

Flanged Hex bolt: M8

Socket Spanner: 12 mm

Flanged Hex bolt: M8

Socket Spanner: 12 mm

Socket head cap Screw:

M6

Allen Key : 5 mm

CAUTION:

Ensure mudguard does not

get scratched while tilting

and removing.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

57

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.2 Front Mudguard

Continental GT

Re move Front whe el

as described in Fron t

Wheel section

Loosen and remove the

4 socket head cap

screws on the fork brace

between the fork legs RH

& LH.

Gently lift up and

remove mudguard from

the fork legs.

Socket head cap Screw:

M6

Allen Key : 5 mm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

58

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

6.2 Front Mudguard

Bullet Classic EFI /

Bullet EFI

Locate Mudguard stays

along with mudguard

and slide into the fork

legs.

In stal l whe el speed

sensor screw and locate

sensor along with screw.

Install and locate:

- 2 flange d hex bolts

along with spring

washers, holding front

mudguard centre stay

& front brake caliper to

fork end LH.

- 2 flange d hex bolts

along with spring

washers, holding front

mudguard front an d

rear stays to fork end

LH.

Install and locate the 4

flanged hex bolts along

with spring w ashers,

holding front mudguard,

front, centre & rear stays

to fork end RH.

Loca te Brake hose

grommet in the holding

clip in front mudguard.

Assemble Front whe el

as described in Fron t

Wheel section.

CAUTION:

Ensure mudguard does

not get scratched w hile

assembling.

Socket head cap Screw:

M6

Allen Key : 5 mm

Torque : 25Nm

Flanged Hex bolt: M8 X

38 & M8 X 20

Socket Spanner: 12 mm

Torque : 10 Nm

Flanged Hex bolt: M8 X

20

Socket Spanner: 12 mm

Torque : 10 Nm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

59

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

6.2 Front Mudguard

Continental GT

Gently lift down and

locate mudguard on the

fork legs.

Socket head cap Screw:

M6

Allen Key : 5 mm

Install and locate the 4

socket head cap screws

on th e fork brace

between the fork legs RH

& LH.

Locate Front whee l as

described in F ron t

Wheel section.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

60

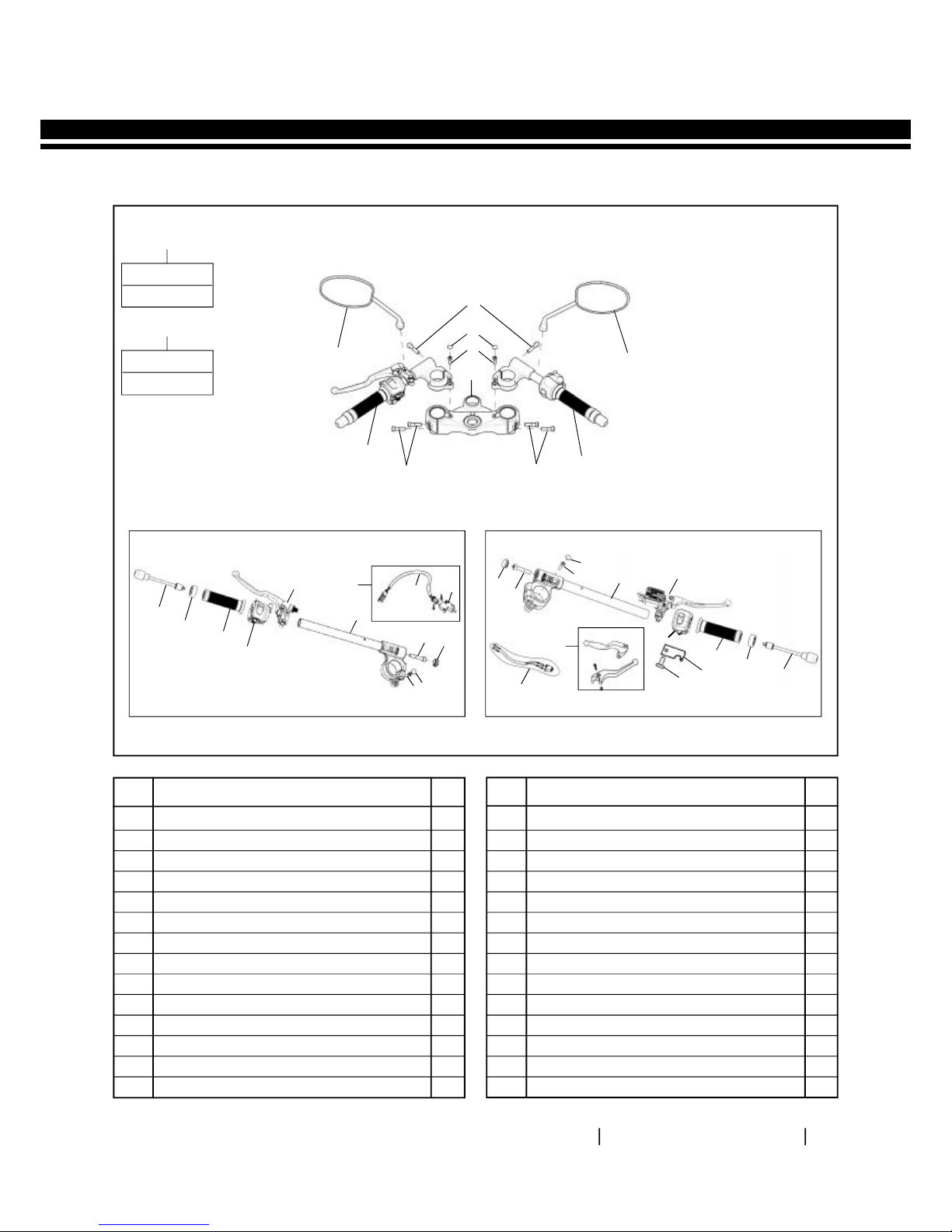

SECTION 6.3 – HANDLE BAR

7

5

10

9

12

13

14

8

2

1

3

2

1

17

18

4

ES

6

11

A1

16

15

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

A1 Handle Bar Assembly Complete 1

1 Hex Socket Head Screw M8 X 50 2

2 Damper Weight 2

3 Hand Grip LH 1

4 Cable Strap 6" 2

Cable Strap 8" 3

5 Handle Bar Complete 1

6 Rear View Mirror LH 1

7 Rear View Mirror RH 1

8 Grip Complete - Throttle RH 1

9 Lever & Holder Assy. LH 1

10 Clutch Lever 1

11 Switch Module LH 1

12 Switch Module RH 1

13 Rotor Plate 1

14 Pan Head Screw M5 X 10 1

15 Front Brake Lever kit 1

16 Add On Lead, Front Brake Switch 1

17 Add On Lead, Clutch Switch 1

18 Clutch Switch 1

EXPLODED VIEWS

BULLET CLASSIC EFI / BULLET EFI

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

61

CONTINENTAL GT

A1

Key Nos.

1 & 2

A2

Key Nos.

24 & 25

4

5

3

6

LH

8

3

3

2

1

7

9

10

11

12

13

14

A2

25

15

24

16

4

5

23

A3

16

15

17

4

5

18

19

20

10

9

21

22

RH

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

A1 Mirror Set OE - Continental GT 1

A2 Clutch Switch Repair Kit 1

A3 Clutch & Front Brake Lever Kit (Clear Coated) 1

1 Rear View Mirror - LH 1

2 Rear View Mirror - RH 1

3 Hex. Socket Head Screw M8 X 35 6

4 Grommet - Clip ON 2

5 Hex. Socket Head Cap Screw M6 X 20 4

6 Top Yoke 1

7 Handle Bar Assy. - LH 1

8 Handle Bar Assy. - RH 1

9 Counter Weight Assy. 2

10 Mirror Dummy Ring 2

11 Handle Grip - LH 1

12 Switch Module - LH 1

13 Lever & Holder Assy. - LH 1

14 Handle Bar Complete - LH 1

15 Hex. Socket Head Bolt M8 X 40 2

16 Rubber Sleeve - Handle Bar 2

17 Handle Bar Complete - RH 1

18 Master Cylinder - Front 1

19 Switch Module - RH 1

20 Grip Complete - Throttle RH 1

21 Rotor Plate - Throttle Cable 1

22 Pan Head Screw M5 X 10 1

23 Add On Lead, Brake Switch 1

24 Clutch Switch 1

25 Add On Lead, Clutch Switch 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

62

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.3 Handle Bar

Bullet Classic EFI /

Bullet EFI

Remove Headlamp from

the headlamp casing

and disconnect wire

terminals.

Philips head screw driver

Double end spanner

15mm

Disconnect wire couplers

from handle bar inside

the head lamp casing.

Remove Rear view

mirrors LH & RH.

Disconnect all control

cables from the handle

bar.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

63

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.3 Handle Bar

Bullet Classic EFI /

Bullet EFI

Remove the 2 hex bolts

on the clamp holding

Front brak e master

cylinder to handle bar.

CAUTION:

Ensure the brake lever is not

depressed while removing

from handle bar.

Hex SS Bolt : M12

Socket spanner: 14 mm

Hex bolts: M6

Socket spanner: 10 mm

Hex Nut: M8

Socket spanner: 12mm

Remove master cylinder

asse mbly from the

handle bar and support

suitably to prevent

hydraulic oil leak from

master cylinder.

Loos en and remove 2

Hex bolts along with

washers from the

handle bar clip top.

Loos en and remove 2

hex nuts along with

washers from the

handle bar clip bottom.

Remove handle bar clip

from the stu ds in the

headlamp casing and the

handle bar.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

64

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.3 Handle Bar

Continental GT

Remove Headlamp from

the headlamp housing

and disconnect wire

terminals.

Philips head screw driver

Double end spanner

15mm

Disconnect handle bar

LH & RH wire couplers

inside the he ad lamp

housing.

Remove Rear view

mirrors LH & RH.

Disconnect all control

cables from the handle

bar.

Remove the 2 hex bolts

on the clamp holding

Front brak e master

cylinder to handle bar.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

65

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.3 Handle Bar

Continental GT

Remove master cylinder

asse mbly from the

handle bar and support

suitably to prevent

hydraulic oil leak from

master cylinder.

Hex bolts: M6

Socket spanner: 10 mm

Hex. Socket Head Screw:

M8

Allen Key: 6 mm

Hex. Socket Head Screw:

M6

Allen Key: 5 mm

Loosen the hex socket

scre w clamping the

handle bar assemblies

LH & RH to the fork main

tubes.

Re move the 2 r ubber

grommets on top of the

handle bar LH & RH and

remove the 2 hex socket

head cap screws.

Remove handle bar LH &

RH form the fork main

tubes.

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

66

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

Locate handle bar clip on

the studs in the

headlamp casing and the

handle bar.

Install and locate 2 hex

nuts along with washers

on the handle bar clip

bottom.

Install and locate 2 Hex

bolts along with washers

on the handle bar clip

top.

Locate master cylinder

assembly on the handle

bar and support suitably

to prevent hydraulic oil

leak from ma ster

cylinder while locating.

Install the 2 hex bolts on

the clamp holding Front

brake master cylinder to

handle bar.

6.3 Handle Bar

Bullet Classic EFI /

Bullet EFI

Hex SS Bolt : M12

Socket spanner: 14 mm

Hex Nut: M8

Socket spanner: 12mm

CAUTION:

Ensure the brake lever is not

depressed while removing

from handle bar.

Hex bolts: M6

Socket spanner: 10 mm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

67

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

Connect all control

cables on the handle bar.

Locate Rear view mirrors

LH & RH.

Connect wire couplers

on handle bar inside the

head lamp casing.

Locate Headlamp in the

headlamp casing an d

connect wire terminals.

6.3 Handle Bar

Bullet Classic EFI /

Bullet EFI

Double end spanner

15mm

Philips head screw driver

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

68

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

Locate handle bar LH &

RH on the fork main

tubes.

Loca te the 2 rubber

grommets on top of the

handle bar LH & RH and

Install the 2 hex socket

head cap screws.

In stal l the hex socket

scre w clamping the

handle bar assemblies

LH & RH to the fork main

tubes.

Locate master cylinder

assembly on the handle

bar and support suitably

to prevent hydraulic oil

leak from ma ster

cylinder.

6.3 Handle Bar

Continental GT

Hex bolts: M6

Socket spanner: 10 mm

Hex. Socket Head Screw:

M8

Allen Key: 6 mm

Hex. Socket Head Screw:

M6

Allen Key: 5 mm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

69

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Assemble /

Instructions

Install 2 hex bolts on the

clamp holding Front

brake master cylinder to

handle bar.

Connect all control

cables from the handle

bar.

Locate Rear view mirrors

LH & RH.

Connect handle bar LH &

RH wire couplers inside

the head lamp housing.

Locate Headlamp on the

headlamp housing and

Connect wire terminals.

6.3 Handle Bar

Continental GT

Philips head screw driver

Double end spanner

15mm

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

70

SECTION 6.4 – FRONT FORK

22

21

20

19

18

17

16

12

10

13

14

15

11

24

23

26

27

28

25

24

1

2

A1

22

21

A2

4

3

5

6

7

8

9

A1

Key Nos.

1 to 3, 5 to 20

A3

Key Nos.

Qty 2 Nos. 2, 7, 9,

11, 15 & 20

A2

Key Nos.

1, 2, 4 to 20

A4

Key Nos.

Qty 2 Nos. 2, 7, 9,

15 & 20

A5

Key Nos.

Qty. 2 Nos. 16,

20 & 22

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

A1 Front Fork Assy - LH 1

A2 Front Fork Assy - RH 1

A3 Fork Pipe Spining Replacement Kit 1

A4 Fork Oil Seal, ‘O’-Ring & Piston Ring Kit 1

A5 Main Spring Front Fork Replacement Kit 1

1 Socket Headed Bolt 2

2 Copper Packing Washer 2

3 Outer Tube M/C - RH (Fork End) 1

4 Outer Tube M/C - LH (Fork End) 1

5 Guide Bush 2

6 Plain Washer Big 2

7 Oil Seal - LH & RH Front Fork 2

8 Oil Seal Stopper - LH & RH 2

9 Dust Seal - LH & RH 2

10 Slide Bush 1

11 Fork Pipe Spining - Inline Fork 2

12 Cap Oil Lock (Spindle Tapper) 2

13 Rebound Spring 2

14 Seat Pipe 2

15 Piston Ring - Front Fork 2

16 Main Spring 2

17 Washer - Fork Main Spring 2

18 Spacer Tube - Front Fork 2

19 Fork Bolt - Top 2

20 ‘O’ Ring - Fork Bolt Top 2

21 Plain Washer - Fork Bolt 2

22 Flange Bolt 2

23 Hex Nylock Nut M8 X 9.5 1

24 Punched Washer 2

25 Flanged Hex. Bolt M8 X 55 (Special) 1

26 Reflex Reflector (Amber) 2

27 Wheel Speed Sensor-ABS 1

28 Hex.Socket Button Head Screrw M6X1X16 1

EXPLODED VIEWS

BULLET CLASSIC EFI / BULLET EFI

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

71

CONTINENTAL GT

25

26

24

22

A2

2

A1

3

18

15

16

17

14

13

12

4

10

20

21

1

19

11

9

8

7

6

5

23

26

25

24

A2

Key Nos.

All Except 1 & 19

A3

Key Nos.

Each Qty. 2 Nos.

3, 7, 9, 11, 17 & 20

A1

Key Nos.

All Except 2

A4

Key Nos.

QEach Qty. 2 Nos.

7, 9, 11, 17 & 20

A5

Key Nos.

(Qty. 2 Nos. 13),

16 & 17

S. NO.

DESCRIPTION

QTY. S. NO.

DESCRIPTION

QTY.

A1 Fork End LH assy 1

A2 Fork End RH assy 1

A3 Fork Pipe Spinning Replacement Kit 1

A4 Fork Oil Seal, ‘O’ Ring & Piston Ring Kit 1

A5 Main Spring Fork Major Kit 1

1 Outer Tube - RH 1

2 Outer Tube - LH 1

3 Inner Tube Assy. 2

4 Piston - Front Fork 2

5 Bush (Outer Tube) 2

6 Bush Washer 2

7 Oil Seal 2

8 Circlip (Snap - Ring) 2

9 Dust Seal 2

10 Spindle Taper 2

11 Gasket 2

12 Bolt M10X1 2

13 Spring – 1 2

14 Washer Spring Top 2

15 Spacer 2

16 Bolt Cap 2

17 ‘O’ Ring 2

18 Washer - 2 2

19 Bolt M8 X 1.25 X 45 2

20 Piston Ring 2

21 Spring - 2 2

22 Cable Guide - Brake 1

23 Cable Guide - Speedo Cable 1

24 Hex. Bolt M6 X 12 2 2

25 Plain Washer 2

26 Lock Washer, M6 2

27 Reflex Reflector Amber 2

28 Wheel Speed Sensor-ABS 2

29 Hex.Socket Button Head Screrw M6 X1 X16 1

KS MOTORCYCLES - http://ksmotorcycles.com

ROYAL ENFIELD VEHICLE SERVICE MANUAL - EURO IV

72

S.

No.

Fastener, Size, Tool Usage, Precautions, Photos

Aggregate to Dismantle /

Instructions

6.4 Front Fork LH & RH

Bullet EFI / Bullet

Classic EFI

Remove Front wheel as

described in F ron t

Wheel section 6.1.

Remove front mud-

guard as deta iled in

Section 6.2.

Ensure wheel speed

sensor is removed from

the fork end LH.

Discon nect Trafficator

couplers LH & RH inside

headlamp casing.

Loosen Hex Nylock nuts

on steering stem pinch

bolt L H & RH remove

trafficator assembly

with bracket on LH & RH

side.

Hold the pinch bolts LH

& RH and loosen hex nut

Loosen nut by holding

fork pinch bolt in bottom

yoke (steering stem) on

RH & LH side.

Hex Nylock Nut: M8