Congratulations on becoming the proud owner of a legendary Royal Enfield motorcycle.

The new Bullet 500 is a motorcycle with the timeless handcrafted design of the legendary Bullet, now fitted with a

solid 500cc Unit Contruction Engine with twin-spark ignition for better combustion, superior power delivery and

improved fuel economy.

Do read this manual thoroughly before you begin riding to ensure that you operate your motorcycle the right

way, are aware of the terms and conditions of warranty, and know how to maintain it properly.

We ur ge you to avail of the fou r free se rvi c es we offer, at the righ t tim e, at any of our Au tho r ise d

Dealer / Service Point to keep your motorcycle in peak condition.

Pl e a s e log o n to ww w. r o yalen f i e l d . com to kn o w more ab o u t the h i s t o r y of t h e w o r ld’s o l d e st

motorcycle brand, our other products, and for exciting news of riding tours and events organised for Royal Enfield

motorcycle owners.

Welcome to motorcycling the Royal Enfield way. Ride safe and enjoy the trip!

2

IMP ORTAN T NOTICE

n Keep this manual in a convenient place for easy

referenc e.

n If any information is not understood in the manual

contact your Authorised Dealer / Ser vice Point for

assistance.

n If t he motorc ycle is being used by any friend,

relatives, or others it is responsibility of the owner

to make certain that the owner’s manual is read

and fully understood prior to usage and has been

instructed on it’s safe and proper use.

n The motorcycle is designed for normal on road

use only. Operation in off-road usage in some

areas may be ille gal and could be dangerous.

Obey local law and regulations.

n In the event of motorcycle being resold, it is the

responsibility of the owner of the motorcycle to

hand over the manual along with the motorcycle

and it’s documents.

n Becaus e of contino u s imp r o v e m e n t s in the

pr oduc t and ch ang es tha t may oc cur in the

manufacturing process, subsequent to printing of

th i s manual , it is po s sib l e som e inst r uct i ons ,

illustrations, pictures or designs found within this

ma n ual may di f fer fro m th ose foun d on th e

vehicle.

n However the technical information found within

this manual wa s correct at the ti m e it w a s

approved for publication.

n Roy a l E nfie l d re s e r ves t h e r i gh t t o m a k e

production changes at any time without prio r

notice and without i ncurring any obligation to

ma k e sam e or si milar chang e s to vehic l e s

previously built or sold.

“© Copyright 2013 Eicher Limited, Royal Enfield Unit. All Rights Reserved. No part of this manual shall be copied,

distributed or otherwise dealt without the express permission in writing of Eicher Motor Limited, Royal Enfield Unit.”

Part N o. 584639/a / Qty.1000 / Mar. ‘13

3

IMP ORTAN T NOTICE

SAFE TY DEFI NIT ION S

Statements in this manual preceded by the following

words are of special significance :

WARN ING

War n i ng in d icat e s a po tent i a lly ha zard o u s

situation, which if not avoided, could result in serious

injury.

CAUTIO N

Caution indicated a protentially hazardous situation,

which if not avoided, may result in property damage,

in minor or moderate injury.

NO TE

Indicates important and useful messages for clearer

understanding.

All Ima ges show n are for re fe re nc e to expla in and

need not to be e xac tly the sa me on t he mod el

you own.

Ho weve r if yo u hav e any qu eri e s, cla rif i cat i on,

suggestions/feedback, please write to us or e-mail at

“customerservice @royalenfield.com”.

SERVICE HEAD QUARTERS

Royal Enfield, A Unit of Eicher Motors Limited,

Thiruvottiyur High Road, Thiruvottiyur,

Chennai - 600 019.

Phone : 044 - 4223 0400, Fax : 044 - 4201 1719

E-mail : customerservice@royalenfield.com

Website : www.royalenfield.com

4

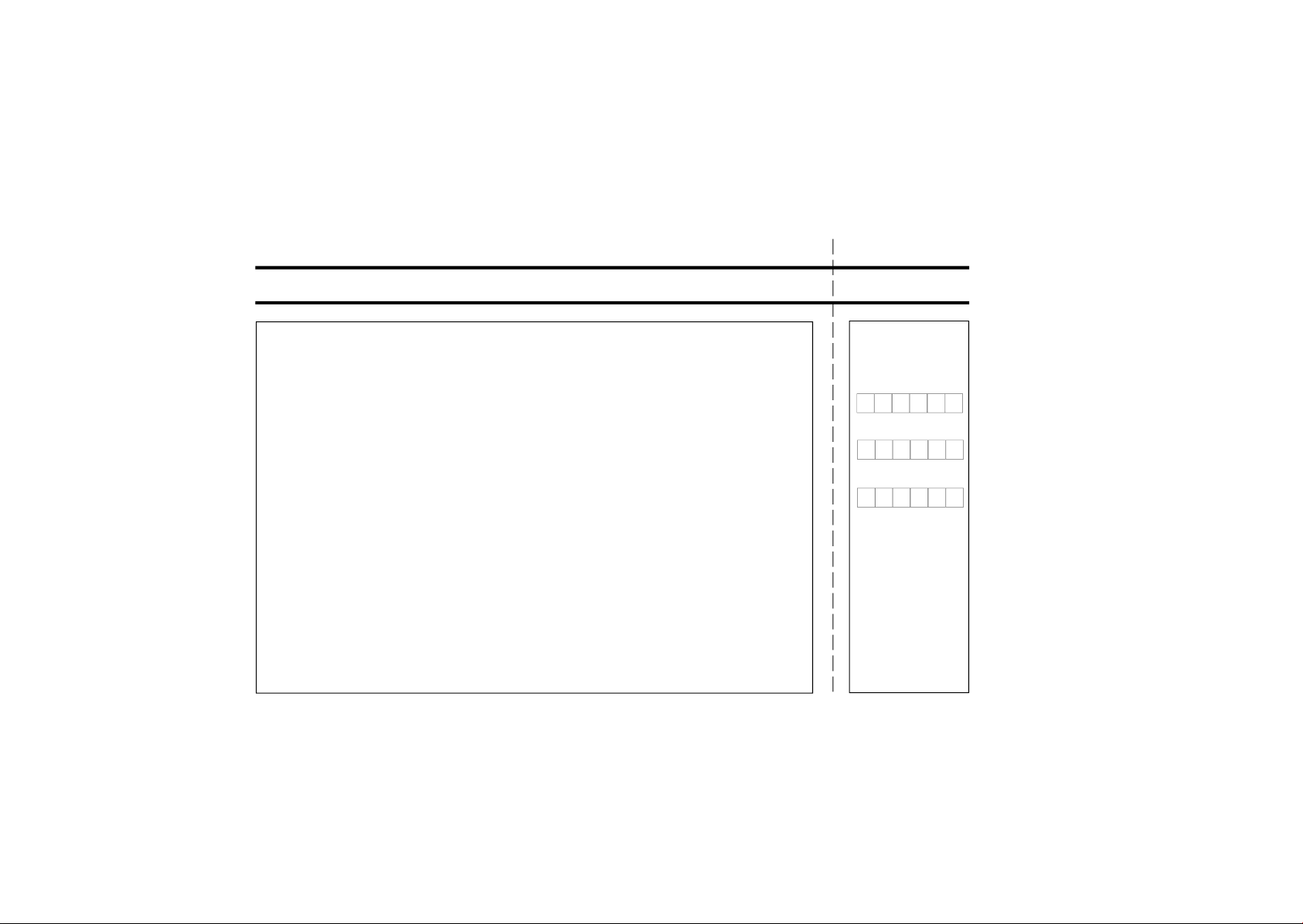

CONTENTS

PERSONAL & VEHICLE INFORMATI ON ........................ 7

FREE SERVICE RECORD .................................................. 8

SAFE OPERATING RULES ................................................ 9

RULES OF THE ROAD ...................................................... 15

TECHNICAL SPECIFICATIONS ....................................... 17

- Engine .................................................................... 17

- Ignition System ..................................................... 18

- Transmission ......................................................... 18

- Elec tricals .............................................................. 19

- Chassis ................................................................... 20

- Dimensions ............................................................ 21

- Weights ................................................................... 21

VEHICLE IDENTIFICATION NUMBER ............................ 22

KEY PARTS LOCATION .................................................... 23

- Top View ................................................................. 23

- Right Side View ..................................................... 24

- Left Side View ........................................................ 25

OPERATION OF CONTROLS ........................................... 26

- Ignition Switch ...................................................... 26

- Steering lock ......................................................... 26

- Fuel tank cap ........................................................ 27

- Side Box .................................................................. 27

- Head lamp switch ............................................... 28

- Dip Switch .............................................................. 28

- Head lamp Day flash ......................................... 28

- Engine Kill Switch ................................................ 29

- Horn ........................................................................ 29

- Turn Signal Switch ............................................... 29

- Engine Start Switch ............................................. 30

- Battery Box ............................................................. 30

- Fuel Tap ................................................................. 30

PRE OPERATIONAL CHECKS .......................................... 31

RUNNING IN .................................................................... 32

STARTING ......................................................................... 33

5

CONTENTS

GEAR SHIFTING ............................................................... 35

PARKING ........................................................................... 36

- Center Stand ......................................................... 36

- Side Stand ............................................................. 36

TOOLS AND FIRST AID KIT ............................................ 37

RECOMMENDED LUBRICANTS ...................................... 38

PERIODICAL MAINTENANCE ........................................ 39

MINOR MAINTEN ANCE TIPS ......................................... 43

- Control Cables, Handle bar lever,

Pivots, Ce nter / Side Stand Pivots ..................... 43

- Engine Oil Level Inspection .............................. 43

- Engine Oil Change .............................................. 44

- Spark Plug ............................................................. 45

- Brake fluid ............................................................. 46

- Inspection of tyres and wheels ........................ 46

- Tyre pressure ........................................................ 47

- Front Wheel removal ........................................... 47

- Front Wheel assembly ........................................ 48

- Rear wheel removal ........................................... 49

- Rear wheel assembly ......................................... 50

- Adjustment - Clutch ............................................. 51

- Drive Chain tension ...................................... 51

- Checking Rear Brake Pedal height .......... 52

- Rear Brake Pedal height Adjustment ....... 53

- Chain Lock Fitment ....................................... 53

- Adjustment of Gas Filled Shockabsorber ..... 54

- Removal of Battery on Vehicle ......................... 55

- Battery Maintenance .......................................... 55

- Assembly of Batte ry on Vehicle ........................ 56

- Changing Electric al Components ................... 57

- Head Lamp bulb r eplacement .................. 57

- Tail Lamp bulb replacement ..................... 59

- Trafficator bulb replacement .................... 59

- Fuse ................................................................... 60

- Blade Fuse usage List ................................... 60

- Air Filter element cleaning / replacement .... 61

6

CONTENTS

WASHI NG PROCEDURE .................................................. 62

- Precautions ........................................................... 62

- After Washing ....................................................... 62

STORAGE PRECAUTION ................................................. 63

- Preparing the motorcycle for reuse ................ 64

LONG TRIP PRECAUTIONS ............................................. 65

- Checks prior to the commencement .............. 65

- Checks after e very 1500 kms ............................ 65

- Items to be carried .............................................. 65

CARING FOR MILEAGE .................................................. 66

COMPLETE WIRING DIAGRAM - BULLET 500 ............. 68

TROUBLE SHOOTING ...................................................... 69

- Engine fails to start ............................................. 69

- Engine misfiring ................................................... 70

- Engine starts, but runs irregularly & stops .......... 71

- Poor pickup ........................................................... 71

- Whit e / blu e smoke .............................................. 72

- Engine over heating ........................................... 72

- Excessive fuel consumption .............................. 72

- Igni tion knock ...................................................... 73

- Brakes poor ........................................................... 73

- Vehicle wobbles ................................................... 74

- Elec tricals .............................................................. 74

- Electric Start .......................................................... 76

WARRANTY TERMS & CONDITIONS ............................. 77

EMISSION WARRANTY .................................................... 79

AL L INDIA RO AD SIG N S ... . .... . .... . ... . .... . ... . .... . ... . 83

FREE SERVICE COUPONS ............................................... 84

PAID SERVICE / MAINTENANCE RECORD ................... 93

REGIONAL & AREA OFFI CE S ... .. .. .. .. .. .. ...... .. .. .. .. .. .1 01

LOG BOOK ............................................................... 102

NO TES .... ... . ... ... ... ... ... ... . ... ... ... ... .... ... ... ... . ... ... ... .10 7

ANNE XU RES

- Vehicle Installat ion Form

- Pre-Delivery Inspection Report (PDI)

- Bike Installation Confirmation By Customer

- Form 22

7

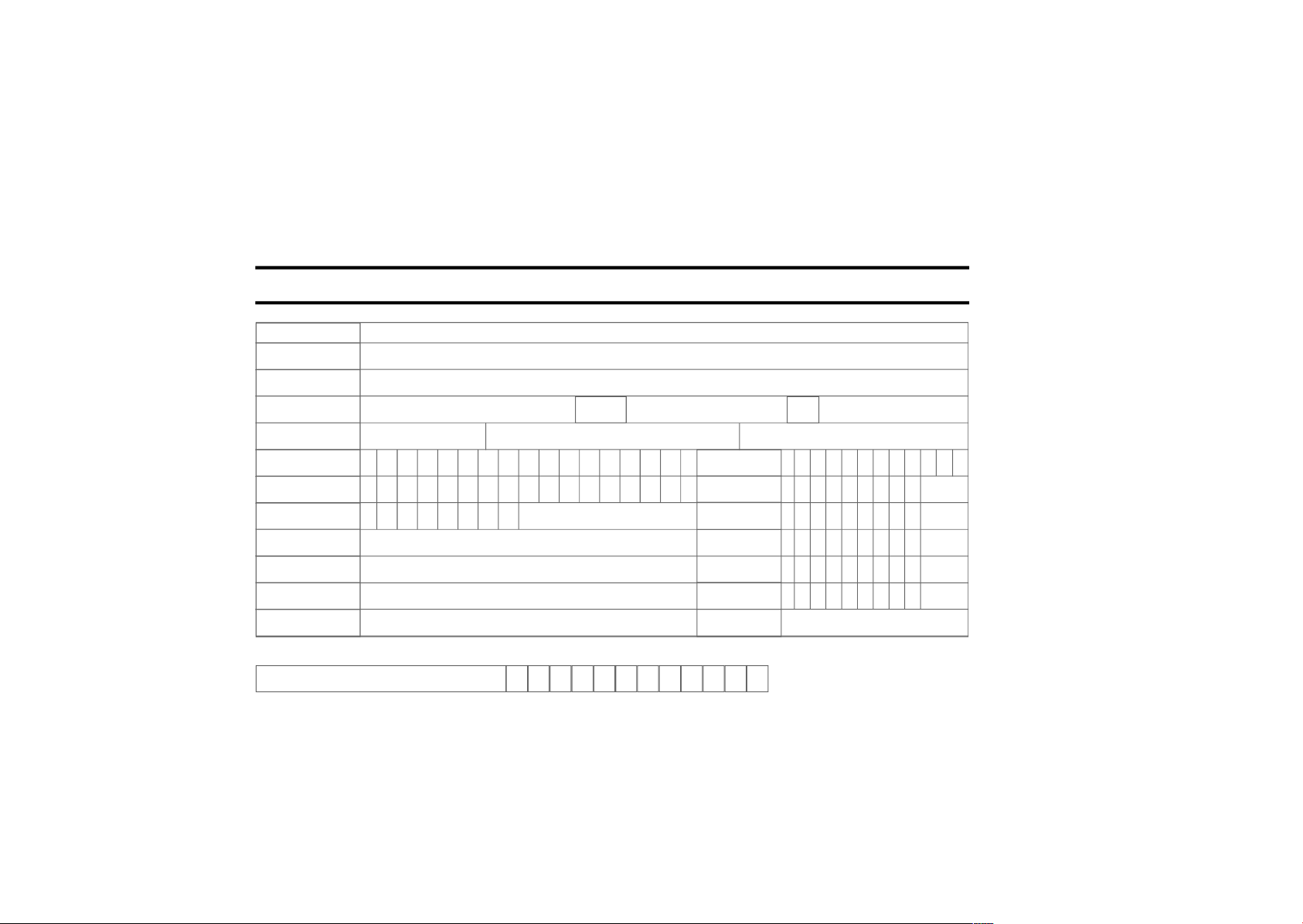

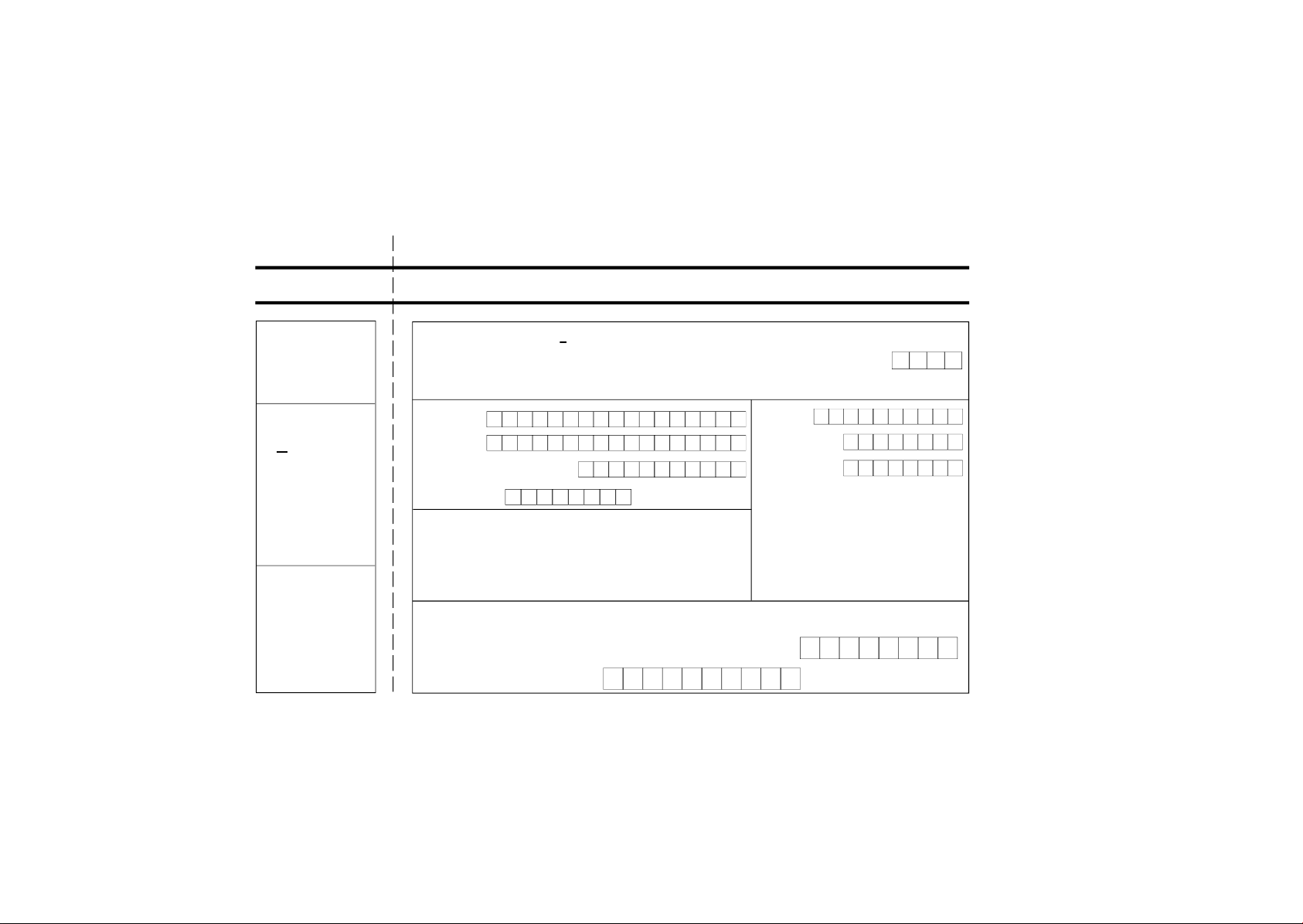

PERSONAL & VEHICLE INFORMATION

Name

Door No./Street

Locality

City State Pin

Contact Nos. Res: Off: Mobile: Email:

Engine No. Battery No.

Frame No. Battery make

Reg. No. Licence No.

Date of Sale Valid till dt.

Model Key No. :

Tyre make Colour

Sold by Dealer Code

Vehicle Installation Form (VIF) No.

8

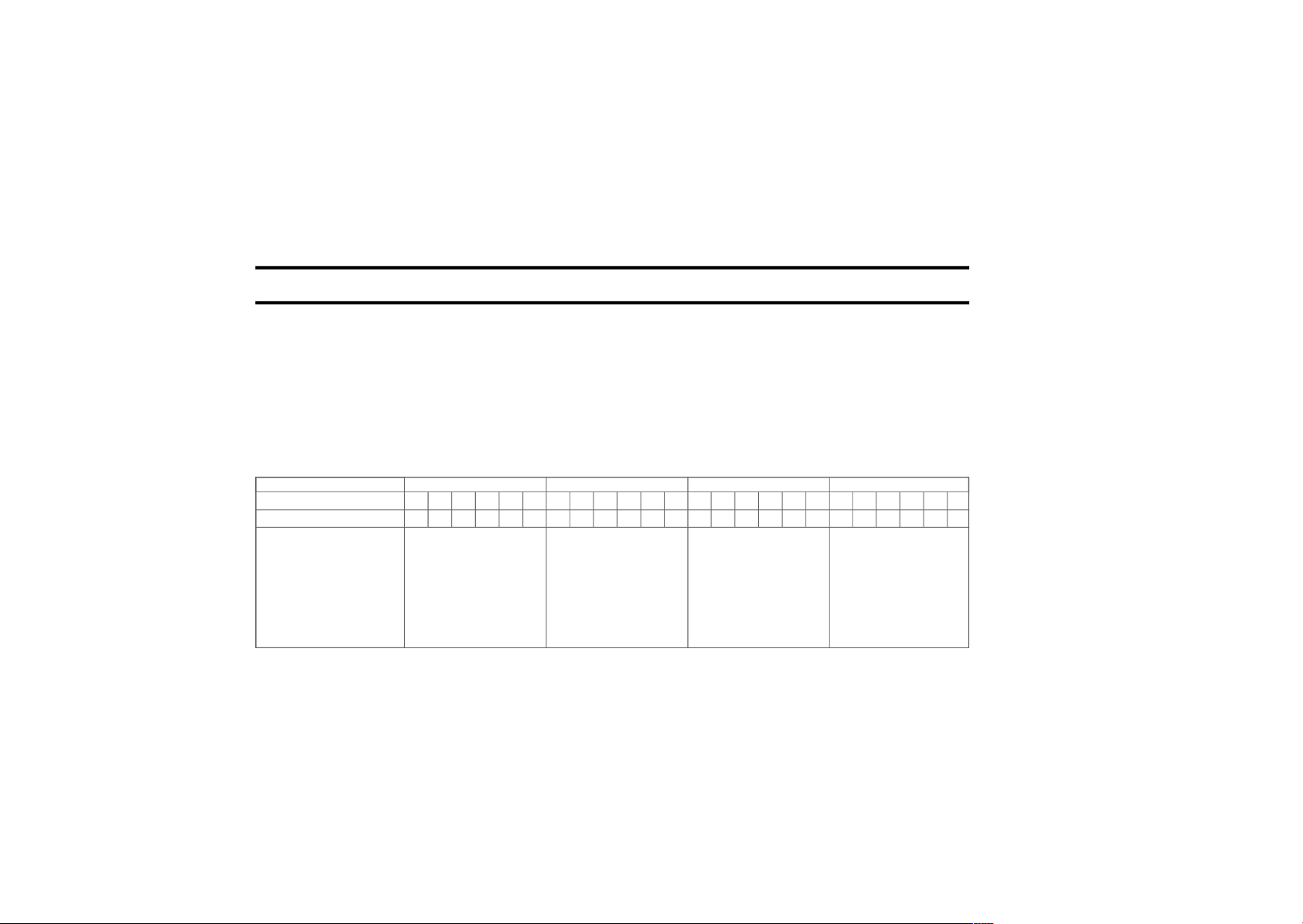

FREE SERVICE RECORD

It is our endeavour to provide excellent service to your Bullet 500 at all times. Towards this we provide 4 free

services at specific Intervals.

Please avail these services at the specified time, in any of the Royal Enfield Authorised Dealer / Service Point

nearest to you and as a token of satisfactory services, kindly return the free service coupon duly filled in and

signed, to the service outlet.

Availing the free services in the specified time is a prerequisite for warranty consideration. The cost of fuel, oil,

grease etc. used for all free services are chargeable to the customer.

1st Service 4th Service2nd Service 3rd Service

Date of Service

Kms Covered

Servicing

Dealer ’s / ASP

Name, Address

Dealer / ASP

Rubber Stamp

NO TE

Please ensure that the free service details are recorded in this sheet immediately after the service is carried out.

Dealer / ASP

Rubber Stamp

Dealer / ASP

Rubber Stamp

Dealer / ASP

Rubber Stamp

9

SAFE OPERATING RULES

n Before operating your new motorcycle, it is your

respons ib il it y to caref ul ly read and follow the

operating and mainte nance instr uctions detailed

in t h i s m an ua l f o r y o ur o w n s afe t y, y our

motorcycle and that of others.

n Know and respect the rules of the road. Be a safe

rider for your own safety and for other road users.

n Before starting the motorcycle, check for proper

operation of brakes, clutch, gear shifter, handle

bar controls, tyre pressu res, fuel and oil levels.

WARN ING

Royal Enfield cautions you against the use of

certain nonstandard parts such as aftermarket and

custom made extended front forks or suspensions,

whic h may ad ver sely af f e c t pe r f o r m a n c e an d

handling. Removing or altering original parts may

adversely affect perfo rmance and could result in an

accident causing serious injury.

n Use only genuine Royal Enfield spare parts and

approved accessories. Use of other manufacturer’s

performance parts may affect the performance of

your motorcycle and render the motorcycle void of

warranty. See your Royal Enfield dealer for details.

n Whene ve r ref uel lin g your moto rcyc le, ple ase

exercise utmost caution and carefully observe the

following rules :

H DO NOT smoke and please ensure that there

are no op e n f l a m e s o r sp a rks nea r t h e

motorcycle, when refuelling OR ser vicing the

fuel system.

H Switch OFF mobile phones and othe r hand

held electronic devices / gadgets.

H Open the fuel filler cap slowly.

H Refuel in a well ventilated area with the engine

turned off.

10

SAFE OPERATING RULES

H DO NOT fill the tank to its brim. Please fill fuel

only till the bottom of the filler neck insert, so

as to leave air space in the fuel tank to allow

for fuel expansion (for Spec. Ref. Page No. 20).

WAR NING

Pe t r o l is ex t r e m e l y f l a m mable an d hi ghly

explosive. Use care when handling Petrol. Always stop

the engi ne whe n refu ellin g or ser vicin g the fuel

system. Do not smoke or allow open flames or sparks

near Petrol. Do not store motorcycle with Petrol in

the tank, within the home or garage where open

flames , pilot light s, spark s or elec tric mot or s are

present. Inadequate safety precautions could cause

an explosion or fire which could result in damage to

property, serious injury.

n A new motorcycle must be operated according to

the special break-in-procedure. See BREAK-IN-THE

FIRST 500KM section.

n Operate motorcycle only at moderate speeds and

out of traffic until you have become thoroughly

fam i l i a r w i t h it s o p era t i o n a nd h andl i n g

characteristics under all conditions.

n DO NOT exc eed the legal speed limit or drive too

fast for existing conditions. Always reduce speed

when poor driving conditions exist. High speed

inc reases the influen ce of any other condition

affecting stability and increases the possibility of

loss of control.

NO TE

If you are an inexperienced rider we recommend that

you obtain formal training on correct motorcycle

riding techniques and become thoroughly familiar

with the operation of your particular motorcycle. New

ri d e r s s h o u ld ga in exp e r i e nce und e r v a r i o u s

conditions while driving at moderate speeds.

11

SAFE OPERATING RULES

WARN ING

Avoid overspeeding and never travel over the

speed limit. Excessive speed may cause loss of control

and coul d re su lt in an acciden t causing serious

injury.

n DO NOT exceed >110 km/h solo riding.

n DO NOT exceed >90 Km/h when carrying a pillion

or c argo.

n Pay strict attentio n to road surfaces and wind

co ndi t ion s. An y two wh eel e r veh icle may be

subject to the following upsetting forces :

H Wind blasts from passing trucks.

H Rough uneven road surfaces.

H Slippery road surfaces.

These forces may affec t the handling characteristics

of your motorcycle. If this happens, reduce speed and

gu i d e th e mo t o rcycl e wi t h a rela x e d gr i p to a

controlled condition. Do n ot brake abruptly or force

the handlebar.

n Operate your motorcycle defensively. Remember,

a motorcycle does not afford the same protection

as an automobile in an accident. One of the most

comm on acc ide nt situa tions occ urs when the

driver of the other vehicle fails to see or recognize

a mo t o r c yc le an d tu r n s into th e o n c o m i n g

motorcyclist.

n Wear an approved helmet, clothing, and foot gear

suited for riding a motorcycle. Bright OR light

colo rs are bes t fo r greater visibil it y in traffic ,

especially at night. Avoid loose, flowing garments

and scarves.

n Whe n ca r r y i n g a p i l l ion r ide r, i t i s y o u r

responsibili ty to instr uct them on proper riding

procedures.

n DO NOT allo w oth e r in d i v idual s , un d e r an y

circumstances, to operate your motorcycle unless

you know they are experienced, licensed riders

and are thoroughly familiar with the operating

conditions of yo ur motorcycle.

12

SAFE OPERATING RULES

WARN ING

Ma i n t ain t he re comme n d e d ty r e pre ss u r e .

En sure the fr o nt and re ar whee l s are corr e ctly

aligned and the tyres are seate d evenly & properly

in the rims. Check for correct tightness of the spokes

in the ri ms. Insp e ct yo u r tyr es per iod ical ly an d

replace tyres with approved tyres only. Failure to do

so can lead to improper balance, abnormal tread

we ar, poor hand li ng and could res ult in ser ious

injury.

WARN ING

Royal Enfield recommends replacement of any

tube / tyre punctured or damaged. In some cases

small punctures in the tread area may be repaired

from within the demounted tyre by your Royal Enfield

dealer. Speed should not exceed 60 km/h for the first

24 hours after repair and the repaired tyre should

Never be used over 90 km/h (applicable tube less tyre)

In emerg en cy situations, if a tem po rary repair is

made ride slowly with as light a load as possible until

the tyre is permanently repaired or replaced.

Failure to heed this warni ng could result in serious

injury.

n Safe motorcycle operation requires alert mental

judgement combined with a defens ive driv ing

attitude. DO NO T allow fatigue, alc ohol or drugs

to endanger your safety or that of others.

n Maintain your motorcycle in proper oper at ing

condition as per Periodical Maintenance Chart

(Re f Pa g e No.4 0 ) . Pa r t i c ular l y im por t a n t t o

motor c yc l e s t ability is pr o p e r tyre i n f l ation

pressure, tread condition. Pay strict attention to

loose and / or broken spokes, free movement of

steering system.

13

SAFE OPERATING RULES

WARN ING

DO NOT operate motorcycle with a loose, worn

or damaged steering system, including the front and

re ar susp ensio n syste m. Cont act you r deale r for

repair of steering or suspension system. Damaged

steering or suspension components may adversely

affect handling which c ould result in serious injur y.

WARN ING

Reg ul arly i ns pect rear shock absorbers and front

forks and look for leaks. Replace worn parts. Worn

parts c an adversely affect stability and handling.

WARN ING

For your personal welfare, all the liste d ser vice

an d maint e n anc e re c o mme n d atio n s shoul d be

pe rfo rme d . La ck of regula r maint ena nce at the

suggested intervals may affect the safe operation of

your motorcycle, which could resu lt in serious injury.

WARN ING

Avoid any contact with the exhaust system. Wear

clo th ing that w ill comp letely cover the legs whil e

riding. The exhaust system gets very hot when the

engine is running and remains too hot, even after

the engine is turned off (due to catalic converter).

Failure to wear proper or protective clothing could

result in serious injury.

WARN ING

Exhaust ga s e s contains poison o u s carbon

mo nox ide (CO.) and che mic als , known to cause

serious health hazards.

WARN ING

Mo to rcycle bat t er ies con tain lead and lea d

components, acids and chemicals known to cause

seriou s hea lt h hazards. Exe rcise extr em e caution

while h andling a battery. Wash hands tho rough ly

whenever a battery is handled.

14

SAFE OPERATING RULES

WARN ING

Consult your Royal Enfield Dealer regarding any

questions or problems that occur in the operation of

your motorcyc le. Failure to do so may aggravate an

initial problem, cause costly repairs, jeopardize your

personal safety and could result in serious injury.

WARN ING

Use only genu ine Royal Enfield replac ement

fasteners tightened to the proper torque. We caution

you against the use of certain non standard parts

such as after ma rket and cus to m made faste ne rs

which may not have specific strength, finish and type

req uirements to per form properly in the assembly

and its environment . The use of any nonstandard

parts, including faste ne rs , cou ld result in serious

injury.

WARN ING

DO NOT exceed the Gross Vehicle Weight Rating

of your motorcycle. The Gross Vehicle Weight Rating

(GVWR) is shown on the information plate, located

on the frame Down tube. (GVWR is the sum of the

we i g ht of the mo t o rcyc l e , ac cess o ries, an d th e

maximum weight of the rider, passenger and cargo

that may be safely carried.) Exceeding GVWR may

lea d to instab ility of the motorcycle, which could

cause an accident and result in se rious injury.

WARN ING

DO NOT tow a disabled motorcycle. The steering

and hand ling of the dis ab le d motorcycle will be

impaired due to the force of the towline. If a disabled

mot or cycle must be transported, use a truck or a

trailer. Towing a motorcycle may cause loss of control

of the motorcycle in the front, leading to an accident

resulting in serious injury .

WARN ING

DO NOT pull a tr ail er behi nd a mot o rcycl e.

Tow in g a t r a i l e r ma y c a u s e r e d u c ed br ak ing

efficiency, tyre overloading and unstable handling.

Towing a trailer may cause loss of control of the

mo torc ycle in the fr ont , lea ding to an ac cid e nt

resulting in serious injur y.

15

RULES OF THE ROAD

n Be sure front & rear nu mber plates is installed in

the position specified by law and is clearly visible

at all times.

n Ride at a safe speed that is consistent with the type

of road surface you are on. Pay strict attention to

whether the surface is :

H Dry H Oily

H Icy H Wet

n Watch for loose debris, such as leaves, slippery

substances or loose gravel that can hamper the

stability of your vehicle.

n DO NOT exceed the legal spe ed limit or drive too

fast for existing conditions. Always reduce speed

when poor driving conditions exist. High speed

inc reases the influen ce of any other condition

affecting stability and increases the possibility of

loss of control.

WARN ING

Avoid exce ssive speed and never travel at a

speed faste r than the speed limit. Excessive speed

may c au se los s of contr ol of vehicle, w hich could

result in death or serious injur y.

n Keep to the correct side of the road centre line

when meeting oncoming vehicle.

n Always sound your horn, actuate your turn signals,

and e x e r c i s e C A U T I O N w h e n pa s s i n g other

vehicles going in the same direction. Ne ver try to

pass another vehicle going in the same direction

at street inter sections, on curves, or when going

up/or dow n a hill.

n At street intersec tion giv e the right- of-way to the

vehicle on your left or right. DO NOT presume you

have the right- of-way.

n Alw ays signal when preparin g to stop , turn or

pass.

n Wh i l e tu r n i n g ei ther ri ght or le ft, watch fo r

pedestrians, animals as well as vehicles.

n All traff ic signs , inc luding man ua l cont ro ls at

intersections, should be obeyed promptly. SLOW

DOWN at traffic signs near schools and CAUTION

signs at railroad c rossings.

16

RULES OF THE ROAD

n When intending to turn, signal at least 100 feet

(30.5 meters) before reaching the turning. Be close

to th e cent er lin e (un l ess lo cal ru les re quir e

otherwise), slow down and then turn carefully.

n Never jump a traffic light. When a

change is imminent from GO to STOP

(or vice versa) at intersections, slow

Red

Yellow

down and wait for the light to change

to green. Never run through a yellow

Green

or r ed traffic light.

n DO NOT leave the curb or parking area without

si gna ling. Be sur e you r way is cl ear to ent er

moving traffic. A moving line of traff ic always has

the right-of-way.

n Park your motorcycle on a firm and flat surface to

prevent it from falling over.

n Pr o t e c t y our mo t o r c y c l e ag a i n s t the f t . Aft e r

parking your mot or cycle, rem ov e Ignition key

from switch and lock the stee ring head.

SIDE VIEW MIRRORS

Your motorcycle is equipped with convex mirrors and

have a curved surface. This type of mirror is designed

to give a much wider view t o the rear than a flat

mirror; however, c ars and other objects seen in this

type of mirror will look smaller and fart her away than

when se en in a flat mirror.

Use care when judging the size or distance of objects

seen in these mirrors.

NO TE

To help you establish the relative distance of vehicles

behind your motorcyc le, adjust each mirror in such

a way, that a small portion of your shoulder is visible

and a large portion behind your motorcycle is seen

clearly.

17

TECHNICAL SPECIFICATIONS

ENGINE

Engine ........................................................ Single Cylinder, 4 Stroke, Twinspark, Aircooled

Capacity ..................................................... 499 cc (Displacement)

Bore ............................................................. 84 mm

Stroke .......................................................... 90 mm

Compression ratio .................................... 8.5 : 1

Max. Power @ RPM ................................... 26.1 BHP @ 5100 rpm

Max. Torque @ RPM ................................. 40.9 Nm @ 3800 rpm

Air Filter Element ...................................... Corrugated Paper Element

Fuel Supply ................................................ Carburetor with Throttle Position Sensor (TPS)

Engine Start ............................................... Electric / Kick

Engine Oil Capacity ................................. 2.75 Litres.

Lubrication ................................................ Wet Sump, Forced Lubrication

Engine Oil Grade ...................................... Royal Enfield 15W50 API SL Grade Engine Oil (JASO MA)

Cooling system .......................................... Natural Air Flow

Carburetor ................................................ UCD 33

18

TECHNICAL SPECIFICATIONS

IGNITION SYSTEM

Ignition syste m ......................................... TCI Unit, Multi Curve (Variable Ignition Timing)

Spark plug ................................................ WQR8DC (Bosch Super) M14 & UR6DC (Bosch Super) M10

Spark plug Ele ctrode gap ..................... WQR8DC 0.80 to 0.90 mm

.............................................................. UR6DC 0.70 to 0.80 mm

TRANSMISSION

Clutch ......................................................... Wet Multiplat e (7 Plates Clutch)

Primary drive ............................................ Duplex Chain

Primary Drive Ratio ................................. 2.15 : 1

Gear box .................................................... 5 Speed Constant Mesh

Gear shift pat tern .................................... 1 - N - 2 - 3 - 4 - 5

Gear Ratios ............................................... 1st-3.06:1 2nd-2.01:1 3rd- 1.52:1 4th-1.21:1 5th-1:1

Secondary Drive (F.D. Sprocket) ........... 18 Teeth

Final Ratio ................................................. 2. 11 : 1

Drive C hain links ..................................... 102 links

19

TECHNICAL SPECIFICATIONS

ELECTRICALS

Generation ................................................ Alternator

System ........................................................ 12V DC

Battery ........................................................ 12V - 14 AH

Head lamp ................................................ 12V, 60/55 W, Halogen

Position lamp ............................................ 12V, 4W

Brake / Tail lamp ..................................... 12V, 21/5 W

Turn signal ................................................ 12V, 10W - 4 nos.

Pilot lamp .................................................. 12V, 2 W - 2 nos.

Speedometer lamp ................................. 12V, 3.4 W - 1 no.

Turn signal / High beam indicator ...... 12V, 1.7 W - 2 nos.

Neutral Indicator ..................................... 12V, 1.7 W - 1 no.

Horn (Dual) ............................................... 12V, 2.5 Amp (Max.) X2

Starter Motor ............................................. 12V, 0.9 KW

WAR NI N G

Using bul bs / other electrica l

gadgets other than specif ied r ating

may lead to over load in g / errati c

be h avi o ur / pre matu r e fai l ure of

electri cal sys tem.

Mod ific ations on the b ike which ar e

not approved b y Royal Enfield ma y

not only disqualify for warranty, but

also affects perf ormance of the bike .

20

TECHNICAL SPECIFICATIONS

CHASSIS

Frame ......................................................... Tubular Frame

Tyre size ..................................................... Front: 90 / 90 - 19” - 52 P Rear: 120 / 80 - 18” - 62 P

Tyre pressure ............................................ Front- Solo: 1.41 Kg/cm2 (20 PSI) Pillion: 1.55 Kg/cm2 (22 PSI)

.............................................................. Rear- Solo: 2.11 Kg/cm2 (30 PSI) Pillion: 2.25 Kg/cm2 (32 PSI)

Fuel tank capacity .................................. 13.5 Litres ***

Reserve capacity ..................................... 2 Litres (approx.)

Dead stock of petrol (unusable fuel) .. 0.75 Litres (approx.)

Suspension ................................................ Front: Telescopic, 130mm Travel

.............................................................. Rear: Twin gas charged shock absorbers, 80mm travel

Front fork oil capacity ............................ 195 ml per leg

Front fork oil .............................................. 1F Endurance (or Royal Enfield) fork oil

Brakes ......................................................... Front : Hydraulic 280 mm Ventilated Disc

.............................................................. Rear : Foot Operated 153mm Single Lead Internal expanding

Brake oil capacity ................................... 60 ml

Brake oil grade ........................................ DOT 3 or DOT 4

***Fu e l ta n k i s no t a me a s u r i n g

inst rument. The capacity of tank may

var y sl ightly from specifie d value.

21

TECHNICAL SPECIFICATIONS

DIMENSIONS

Length ........................................................ 2140 mm

Width .......................................................... 810 mm (Without Mirror)

Height ......................................................... 1110 mm (Without Mirror)

Wheel base ............................................... 1370 mm

Saddle height ........................................... 800 mm

Ground clearanc e ................................... 135 mm

WEIGHTS

Kerb Weight (with 90% Fuel) .................. 193 Kg

Max pay load ........................................... 172 Kg

NO TE

1. Values / Dimensions given above are for your guidelines only.

2. In view of continuous improvements being done on our products, the specifications are subject to change

without notice.

22

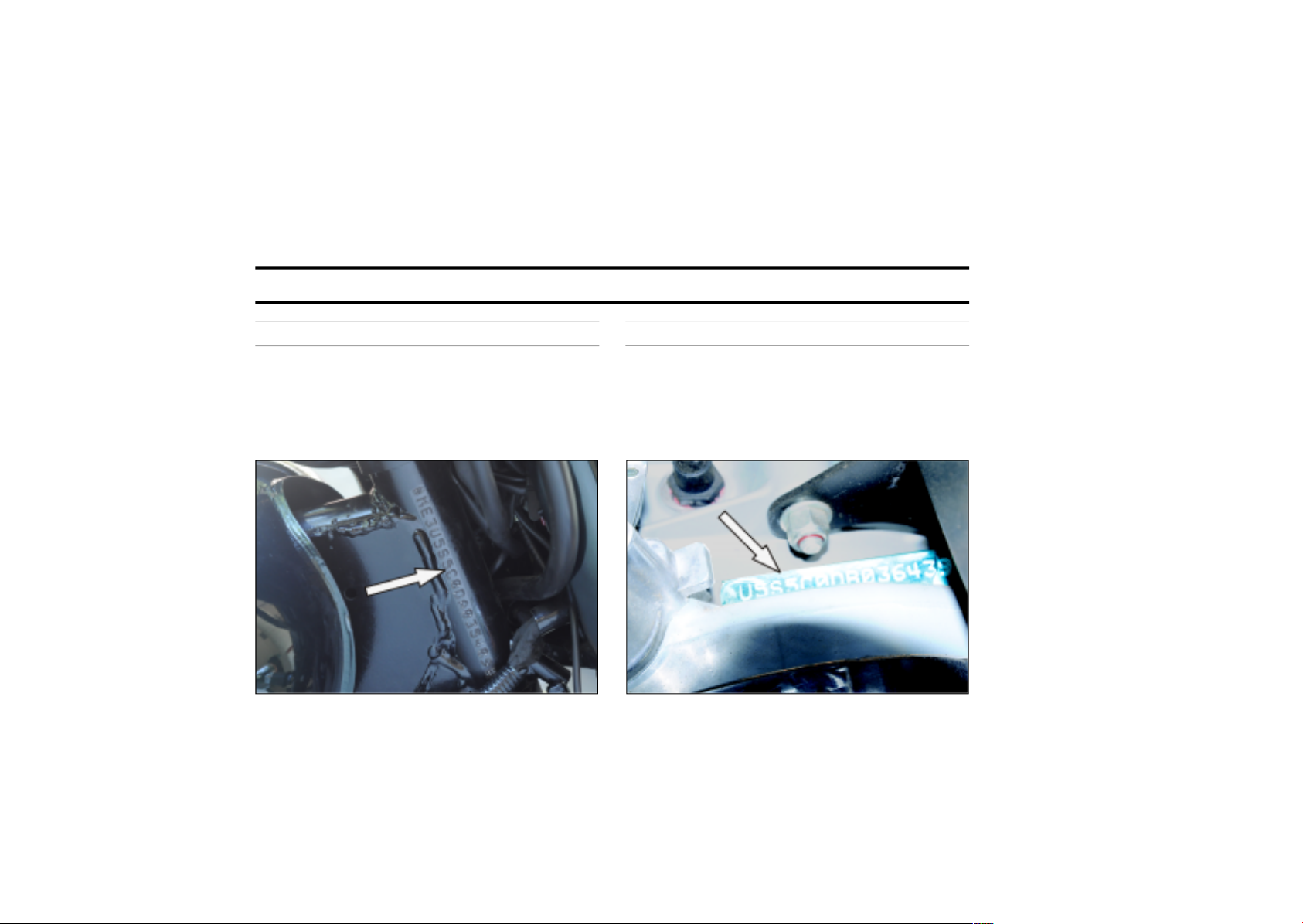

VEHI CLE IDENTIFICATION NUMBER - DETAILS

FRAME NUMBER

Punched on steering head tube RH side.

ENGINE NUMBER

Punched on top of the engine LH side.

23

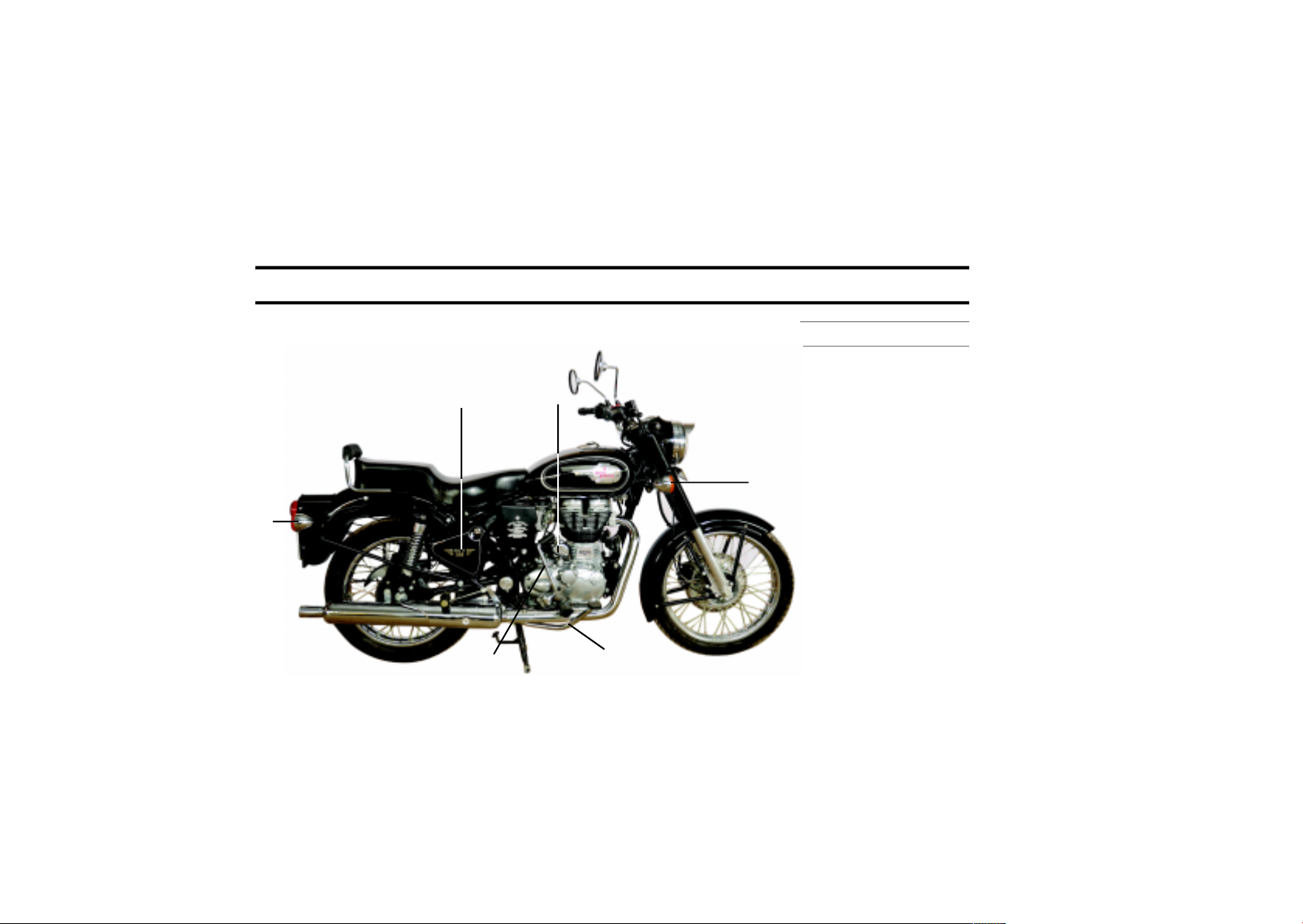

KEY PARTS LOCATION

12

12

7

4

3

6

TOP VIEW

1. Turn signal switch

2. Horn button

3. Clutch lever

4. Day flash switch

5. Head lamp dip switch

8

6. Ignition switch

7. Speedometer

8. Front brake lever

1

9. Accelerator

10

2

5

11

9

10. E-Start Switch

11. Fuel tank cap

12. Rear View Mirror

24

KEY PARTS LOCATION

5

6

RIGHT SIDE VIEW

1. RH Trafficator Front

2

2. Starter Motor

1

3. Brake Pedal

4. Kick Starter Lever

5. Airfilter Box

4

3

6. RH Trafficator Rear

25

KEY PARTS LOCATION

2

3 4 5

LEFT SIDE VIEW

1. Trafficator Front LH

2. Spark Plug

3. Battery Cover

1

9

10

8

7

4. Electricals Box LH

5. Rear Shock Absorber

6

6. Trafficator Rear LH

7. Side Stand

8. Centre Stand

9. Gear Change Lever

10. Horn

26

OPERATION OF CONTROLS

IGNITION SWITCH

OFF

ON

STEERING LOCK

Turn key clockwise to lock.

Lock the steering when leaving

bike parked.

Turn key ant i clockwise to u nlock.

CAUTIO N

Prot ect yo ur motorcycle against theft.

After parking your motorcycle, remove

the ignition key from switch and lock

the steering head.

Turn handle b ar to extreme left, before attem pting to lock

steering.

Do NOT lubricate barrel locks with petro leum based lubricants

or graphite. Inoperative locks may re sult in damage to your

vehicle.

27

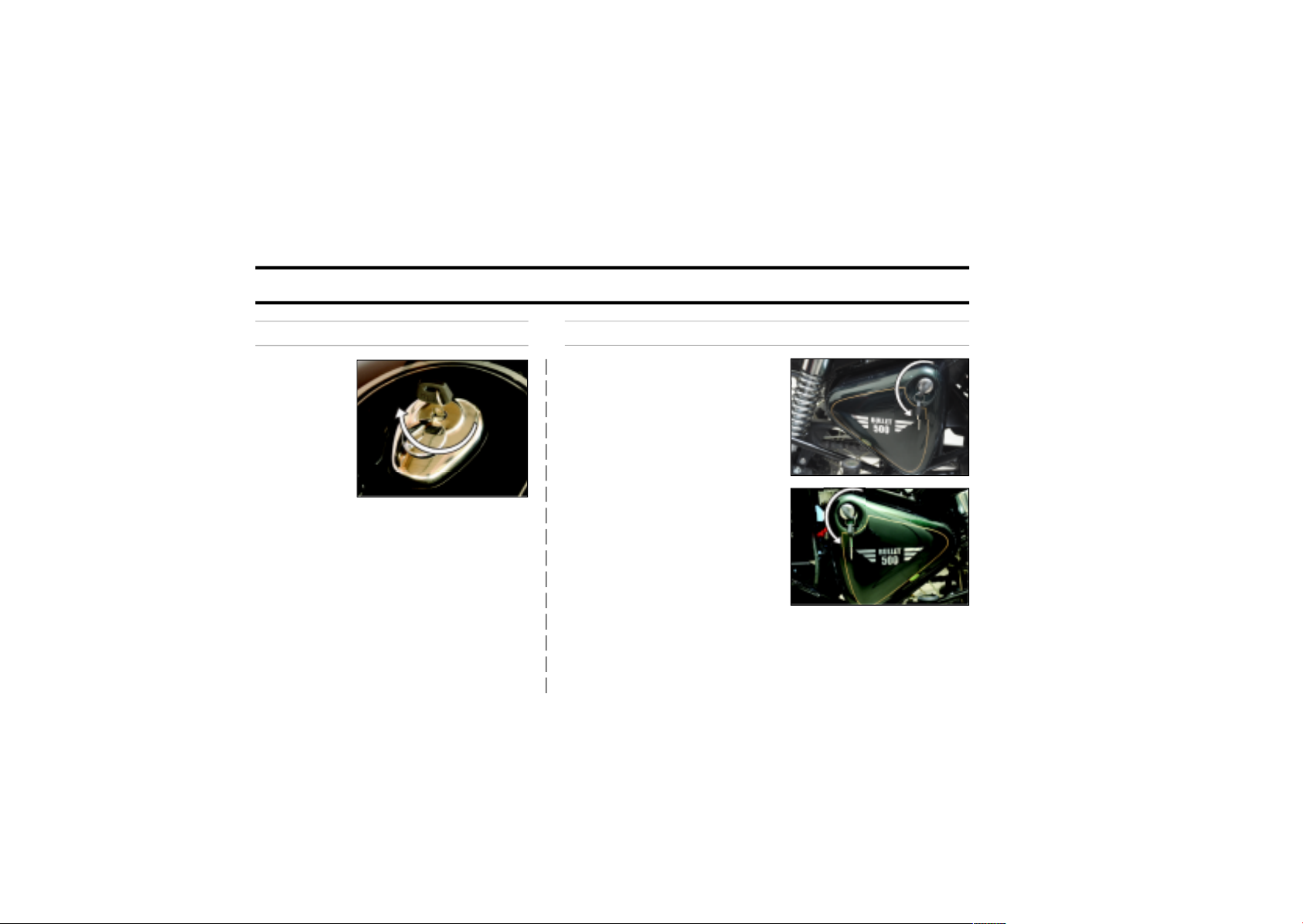

OPERATION OF CONTROLS

FUEL TANK CAP

n Turn key

clockwise

to open

n Press cap to lock with key in position

NO TE

Ke y c a n be remov e d onl y in l o c k e d

position.

SIDE BOX

AIR FILTER BOX RH

Turn Key anti-clockwise to open

SIDE BOX LH

Turn Key anti-clockwise to open,

it c ontains Tools Kit & Fuse

NO TE

n Key is common for ignitio n, petrol tank cap, steering lock,

side boxes and battery cover.

n Key for fuel tank and tool boxes can be removed from the

lock only in locked position.

28

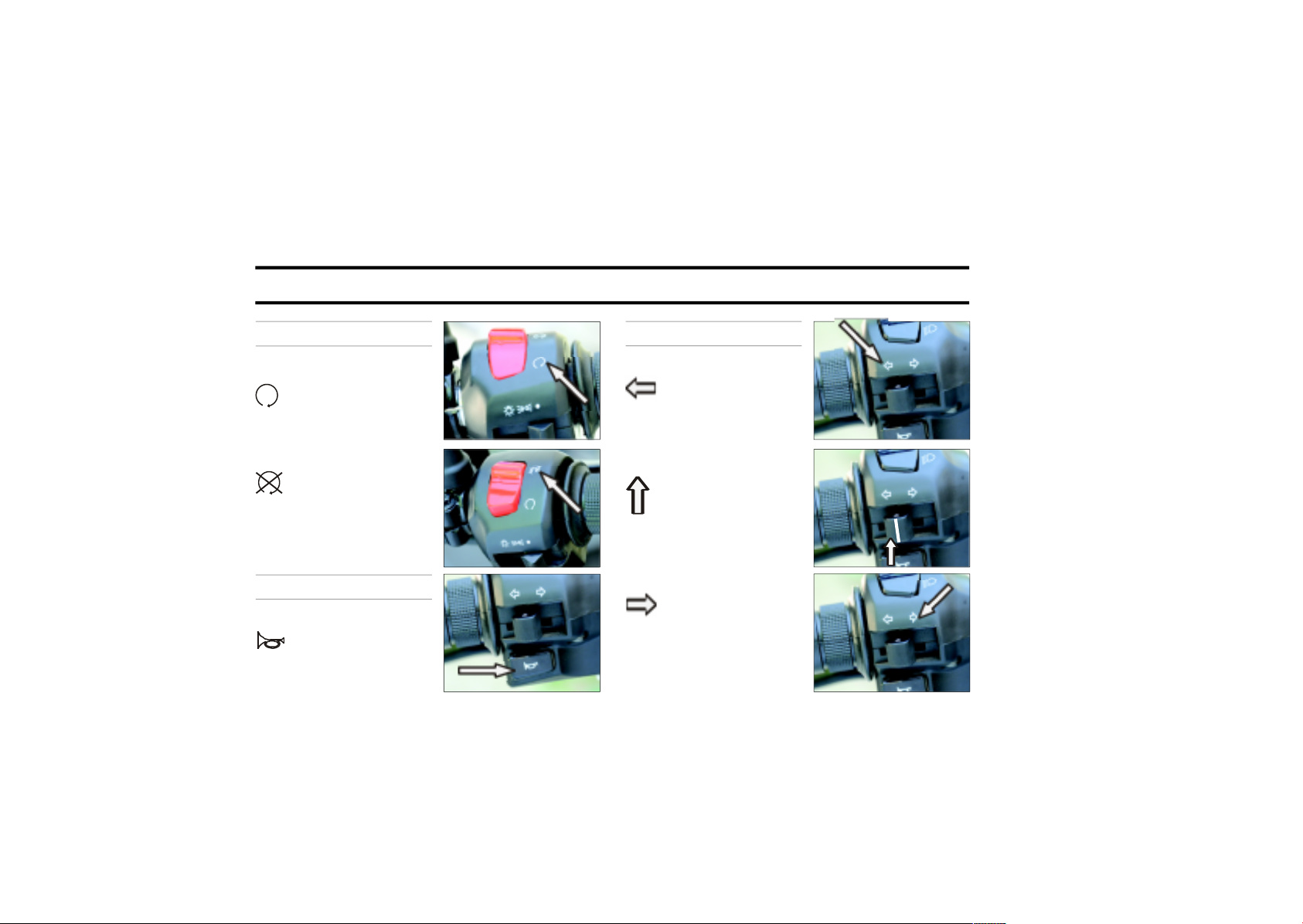

OPERATION OF CONTROLS

HEAD LAMP SWITCH

OFF

l

Pilot Light ON

Head Light ON

DIP SWITCH

Low beam

High Beam

HEAD LAMP DAY FLASH

Press for

Headlight Flash

29

OPERATION OF CONTROLS

ENGINE KILL SWITCH

Run

Stop

HORN

Press

TURN SIGNAL SWITCH

Left

OFF (Push to off)

Right

30

OPERATION OF CONTROLS

ENGINE START SWITCH

Press

BATTERY BOX

Turn ant i clockw is e

to open

FUEL TAP

OFF

Turn knob to

horizontal position

Main ON

Turn knob

downward position

Reserve ON

Turn knob upward

position

31

PRE OPERATIONAL CHECKS

A careful c heck of the following must be carried out

eve ry time before rid ing and speciall y after long

per i o d s o f sto r a g e to de t e r m i n e if ad d i t i o n a l

maintenance is necessary.

1. Tyres for cor rect pressure, abrasions or cuts.

2. Rear chain for proper tension.

Drive Chain

Clutch

3. B r a k e s , s t e e r in g

a n d t h r ot tl e f o r

responsiveness.

4. Cable for fraying or

cr im p i ng and fr e e

operation.

5. Engine oil level.

MAX

MIN

6. Wh e e l sp o k e f o r

proper tightness, no

breakage .

Spokes

7. Headlamp, tail lamp, brake lamp and indicator

lamps for proper operation.

WARN ING

For you r personal welfare and safety, all the

poin t s mentione d above sh o u l d be performed

per i o d i c a l l y. Fa i lure to do so, ma y af f e c t saf e

operation and damage you r motorcycle and could

result in an accident causing serious injury.

32

RUNNING IN

Proper running-in i s ver y important for obtaining

maximum life and performance of a new motorcycle.

The following guidelines explain proper running-in

procedures.

Since the engine is brand new, it should not be loaded

excessively for the first 2,000 kms. During the first few

hundred kms, the various parts in the engine wear and

polish themselves to the correct operating clearances.

Driving with prolonged full throttle operation, or any

high speed conditions might result in excessive heating

of the engine and cause abnormal wear of the moving

parts and hence must be avoided.

1. 0 - 500 Kms :

The reco mme nde d speeds for the first 500 Kms is

be l o w 5 0 K m p h . D u r ing this per i o d a v o i d

oper at i n g the mo t o r c ycle wi t h full t h r o t t l e

opening. Stop the motorcycle for about 5 to 10

minu tes to let it cool down, after every hour of

ru n n i n g. Var y th e sp e e d of the motorcycl e

regularly d uring running but avoid using the

motorcycle above ½ throttle opening position.

2. 501 - 2000 Kms.

The reco mm e nd ed spee d is below 80 Kmph .

Avoid d ri ving the motorcycle with full throttle

op e n i ng. Vary the speed of the mo t orcyc le

regularly but avoid using the motorcycle abo ve

3/4 throttle opening position.

3. 2,001 kms and above

Avoi d prolo ng ed fu ll- th rot t le ope r ati on. Vary

speed occasionally.

CAUTIO N

After cove ring the first 500 kms. please replace the

engine oil and oil filter element.

Royal Enf i e l d en g i nes are air- c o o l e d and

consequently require forced air cooling over the

cylinders and heads to maintain proper operating

temperature. Extended periods of idling may over

heat the engine, resulting in serious engine damage.

DO NOT run the engine at e xtremely high RPM with

clutch disengage d or transmission in neutral as it can

cause serious engine damage.

An engine running long distances at high speed must

be given close attention to avoid over heating and

possible engine damage.

33

STARTING

STARTING PROCESS (KS / ES)

n Turn fuel tap to

‘ON’

n Use ch o k e in co l d

condition

n Switch on ignition.

n En s u r e Engi n e st o p

sw i t c h is i n “RUN ”

position

n Ensu re the sid e and

main stands ar e in

released position

n Ensure that gears are

in neutral and neutral

lamp i s gl o w i ng i n

cluster box.

CAUTIO N

N

Do not force the gear lever while attempting to shift

to neutral . Move t he mot orcycle back & forth and

simultaneously press gear lever to c ome to neutral.

Ensure neutral indica to r light com es “ON”’ in the

Speedometer.

WARN ING

Before starting engine, always shift gears into

neutral.

34

STARTING

USING KICK START

n Sligh t l y c r a n k t h e

en gi n e f u r the r t i ll

compression ea s e s

over.

n Start the motorcyc le

wi t h a p ow e r f u l

swinging kick.

n Rele ase the choke, if

applied

USING ELECTRIC START

n Press Clutch Lever.

n Pr e ss St arter Bu t ton

and r elease as soon

as engine starts.

n Release the choke, if

applied

NO TE

n A clutch switch is provided in the system for the

safety of the rider. This is to prevent the vehicle from

starting when the vehicle is in gear. To start the

engine when it is in gear, pull clutch lever, press

starter button and release as soon as the engine starts.

n Pre ss starter button and rel ease starter switch

once the engine starts.

n If the engine does not start on the first attempt in

cold climate, release the star ter button, wait for

30 se co nds before pressi ng the star ter butto n

again.

35

GEAR SHIFTING

n Warm up engine

for 2 minutes - till

idling is consistent /

stable

GE A R SHI F T PATTER N

1 N 2 3 4 5

n Press clutch lever towards the hand grip.

n Press gear pedal with to e to engage 1st gear.

n Ge nt l y ope n th rot t l e and r ele a s e cl u t c h

simultaneously. If clutch is released suddenly, the

engine may stall and cause a jerky start.

CAUTIO N

The clu t c h m u st be fu l l y d i s e n g a g e d be f o r e

attempting a gear shift. Failure to fully disengage the

clutch may cause a jerky s tart and / OR stalling the

engi ne besi de s causing dam ag e to transmis sio n

parts.

l Press t h e g e a r

pedal with heel to

enga g e 2nd a nd

higher gear.

l Follow the same

procedure for 3rd, 4th

and 5th gear.

NO TE

Always move the motorcycle in first gear position only.

When engine spe ed decreases, whil e cli mbing a

gradient or running at a reduced speed, shift to the

appropriate lower gear to prevent the engine from

stalling or straining to pull.

36

PARKING

PARKING VEHICLE ON CENTER STAND

n Select a firm, flat surface

n Hold handle bar straight

n Lower center stand, and ensure that both the legs

of the stand are resting evenly on firm ground.

n Apply pressure on the fulcrum lever on the center

st and and pull vehi cle bac kwards , gently as

shown in pic.

PARKING VEHICLE ON SIDE STAND

l Select a firm, flat surface

l Lower Side Stand and gently tilt motor cycle to the

left till it rests firmly.

WARN ING

Always park the motor cycle on a firm and flat

surface. Parking in a soft ground may cause stand to

sink and the motorcycle to fall, causing injury to you

or t o others and damage to the motorcycle parts.

37

TOOLS & FIRST AID KIT

1

S.No. Description Qty.

1. Tool bag 1

2. Screw driver 1

3. Tommy bar 1

4. Tubular spanner 1

5. Tool Spark plug 1

6. Double end spanner 10 X 12 2

2

3 4 5 6

5 6

7

1

4

S.No. De scription Qty.

1. Antiseptic cream 5 gms 1

2. Gauze bandage 5 cm x 2 cm 1

3. Elastic Gauze bandage 8 cm x 1 mtr. 1

4. Wash proof plaster 1.9 cm x 7.2 cm 2

5. Sterilized Gauze Swab 5 cm x 5 cm 2

6. Sterilized elastic plaster 7 cm x 6 cm 1

7. First aid kit pouch 1

3

2

NO TE

This Tool Kit is kept in Tool box. Refer Page No. 27.

38

RECOMMENDED LUBRICANTS

Engine Oil

Grade Royal Enfield 15 W 50 API SL Grade

Engine Oil

(JASO MA)

Front Fork Oil

Grade Royal Enfield

Front Fork Oil

(or 1F Grade

Endurance)

Capacity 195 ml/leg

Brake Fluid

Grade DOT 3 or DOT 4

Capacity 60ml

ISO 14001 – EMS

Operation Control Process

1. All customers are advised timely replacement of

Engine Oil, Fork Oil & Brake Oil at the dealership

/ASP. In case done privately, it is advise to reach

old/used Oil to our authorised vendor through RE

Capacity 2.75 Ltrs. (with oil filter)

2.50 Ltrs. (during oil replacement)

Dealer/ASP

2. Similarly we advise for disposal of old/ use d

Battery, Tube & Tyres as mentioned in above point

No.1.

WARN ING

DO NOT sw itch oil br ands indis crim ina tel y bec a use some oil inter act ch emi cally wh en mix ed.

Use of inferior oils or non-detergent o ils can damage the engine.

DO NOT Mix DOT 3 & DOT 4 brake fluid together.

39

PERIODICAL MAINTENANCE

The maintenance schedule detailed here will help you to maintain your Royal Enfield motorcycle meticulo usly

and to get a long trouble free service. The sche dule provided herein is based upon average riding conditions

and indicates the mileage at which regular inspections, adjustments, replacements and lubrications must be

carried out.

The frequency of the maintenance must be shortened d epending upon the severity of the driving condition

OR if the motorcycle is used in a very dusty environment, severe climatic cold and hot conditions, bad roads,

stagnant water etc., Contact a nearest Royal Enfield Authorised Dealer / Service Point for expert advice and to

carry out the periodical maintenance.

WARN ING

For your personal welfare, all the listed service and maintenance recommendations should be performed.

Lack of regular maintenance at the suggested intervals may affe ct the saf e oper ation of your motorcycle

causing the motorcycle to malfunction and stall abruptly resulting in an accident and cause se rious injury.

40

PERIODICAL MAINTENANCE

S.

No.

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Months 1.5 3 6 9

1 Engine Oil R I R I R I R I R I R

2 Engine oil filter paper element R R R R R R

3 Engine suction filter & secondary drain magnetic plug C C C C C C

4 Spark plugs (2 nos.) C,A C,A C,A C,A C,A R C,A C,A C,A C,A R

5 HT leads for crack I I I I I I I I I I I

6 Carburetor

7 Fuel Tap / Filter C C C C C C

8 Fuel tank C C C C C

9 Fuel hose / pipe I I I R I I I R I I I

10 Accelerator & Carburetor cable play adjustment A A A A A A A A A A A

11 Rubbe r hose, Air filter to Carburetor I I I I R I I I R I I

A : Adj ust C : Cle an D : D e-c arb on ise I : Inspe ct L : Lubri cat e R : Re place

DESCRIPTION

FREE SERVICE

whichever is earlier

Check level every 1000 Kms or earlier as required

Clean, Inspect and Tune at every 6000 Kms. of run

PAID SERVICE

Replace with

minor kit

41

PERIODICAL MAINTENANCE

S.

No.

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Months 1.5 3 6 9

12 Rubber hose, Adaptor I I I I R I I I R I I

13 Exhaust system D

14 Air filter eleme nt C C C C R C C C R C C

15 Inlet / Exhaust valve seating I I

16 Clutc h lever free play Check & Adjust every 1000 Kms or earlier as required

17 Cylinder head (Combustion chamber) D

18 Hand levers & kick starter lever pivot Lubricate every 1000 Kms or earlier as requ ired

19 PAV pipes & hose clip I I C I C I C I C I C

20 Rear brake pedal pivot L L L L L L L L L L L

21 Battery terminals (apply petroleum jelly) C C C C C C C C C C C

22 Battery Electrolyte level I I I I I I I I I I I

23 Earth wire eyelet (behind batter y carrier) I I

24 Front Fork oil / leak I R I R I

A : Adj ust C : Cle an D : D e-c arb on ise I : Inspe ct L : Lubri cat e R : Re place

DESCRIPTION

FREE SERVICE

whichever is earlier

PAID SERVICE

42

PERIODICAL MAINTENANCE

S.

No.

Kms (x 1000) 0.5 3 6 9 12 15 18 21 24 27 30

Months 1.5 3 6 9

25 Rear Wheel Drive Chain

26 Rear brake pedal free play Adjust every 1000 Kms or earlier as required

27 Rear brake c am L L L L L

28 Steering ball races / play adjustment A L A L A

29 Spokes tightness & Wheel rim run out I I I I I I

30 Swing Arm pivot bush & spacer L L L R L

31 Tyre wear (Front & Rear) I I I I I I I I R I

32 Brake Fluid (Disc brake) I I I I R I I I R I I

33 Pivot-Side Stand, Center Stand, Pillion foot rest

A : Adj ust C : Cle an D : D e-c arb on ise I : Inspe ct L : Lubri cat e R : Re place

DESCRIPTION

Adjust for every 1000 Kms / Cle an, Lubricate &

FREE SERVICE

whichever is earlier

Adjustever y 3000 kms or earlier as required

L L L L L L L L L L L

PAID SERVICE

NO TE

For maintenance after 30,000 Kms, please repeat the same frequency levels specified above, in consultat ion

with a Royal Enfield Authorised Dealer / Service Point.

43

MIN OR MAINTENANCE TIPS

The following minor maintenance can be carried out

easily with simple tools. However, In case, if it is felt

that the adjustme nts are best done by an expert, we

recommend that the motorcycle be taken to a nearest

Royal Enfield Authorised Dealer / Service Point.

CONTROL CABLES, HANDLE LEVER, PIVOTS,

CENTER / SIDE STAND PIVOTS

Main & Side

Stand Pivot

Lever Pivot

n Lubricate after using the motorcycle in rain, after

water wash or if used in dusty c onditions.

n Wipe the area free of dirt / grease.

n Apply a few drops of oil on the pivo ts.

ENGINE OIL LEVEL INSPECTION

MAX

MIN

n Place motorcycle on its cent er stand on a firm

surf ace.

n Warm up engine for a few minutes & switch off.

n The level is correct if the oil level is in the middle

of the oil level window.

n Top up with recommended oil if required.

44

MIN OR MAINTENANCE TIPS

ENGINE OIL CHANGE

Seco nda ry

Drai n Plu g

Primary

Drai n C ap

Primary

Drai n Bol t

(Refer Periodical Maintenance Chart for frequenc y)

n Place motorcycle on its center stand on a firm flat

surf ace.

n Start e ngine and warm up for 2 minutes.

n Keep a clean tray below the engine.

n Remove primary drain cap, to drain oil & clean

suction filter, magnet.

n Then remove secondary drain plug to drain oil &

clean the magnet.

n Finally remove primay drain bolt to drain the

complete oil.

TILT VEHICLE

RH & LH

n Remove the oil filter element on the Crankcase

Cover RH.

n Assembly 3 bolts and tighten them. Ensure ‘O’ Ring

and gaskets are taken seat properly.

n Allow the oil to drain by tilting the motorcycle to

both sides.

45

MIN OR MAINTENANCE TIPS

n Wash the primary and sec ondary drain plugs

along with suction filter thoroughly and refit on

the crankc ase after all the oil is drained out.

n Soak a new oil filter element in the oil and refit

on the Crankcase Cover RH.

n Fill recommendedoil

to engine till the oil

le vel is upto “M AX”

level mark in the oil

win d o w i n C rankcase Cover RH.

Max

Min

NO TE

Re pla ce oil filt er el eme nt when eve r oil is bein g

replaced.

CAUTIO N

Filling up oil over MAX mark may cause smoke and /

or loss of power. Do NOT allow oil level to fall below

MIN m ark. Doing so may result in engine internal

damage or malf uncton.

SPARK PLUG

Clea n i n g and adjusting gap (R efer Periodic al

Maintenance Chart for frequency)

n Remove HT Lead and

th e spar k plu g from

M10

the c y l i n der h e a d

us i n g the pl ug

sp ann er an d tom my

bar as shown in pic.

n Clean the insulator tip

and elect rodes of the

M14

plug carefully using a

po i n t e d s c r a pe r o r

spark plug cleaner.

n Set the gap between

0.70 to 0.80 mm for

UR6DC & 0.80 to 0.90

mm for WQR8DC

n Refit the spark plug on

the cylinder head and

connect H.T. Lead.

46

MIN OR MAINTENANCE TIPS

MIN

MAX

BRAKE FLUID

Check if oil is above ‘min’ leve l. To top up, remove

cover with diaphragm and top up with either DOT 3

or D OT 4 as specified.

CAUTIO N

Please take care that it does not spill over any other

parts of the motorcycle. Please wipe the spille d brake

fluid immediately, if there is any spill over, using a

soft cloth (preferably a wet cloth) to avoid damage

to paint work or other parts.

Don’t mix DOT 3 & DOT 4 Brake fluid together.

INSPECTION OF TYRES AND WHEELS

n Insp ect the tyre pe rio dic all y for tre a d wea r,

cracks and cuts.

Minimum tread depth :

Front tyre : 1mm Rear tyre : 2 mm

n Check and remove stone, splinters, nails or other

particles embedded in the tyre treads.

n Bald spots / swelling may be caused by internal

damage. Replace the tyres, if defective.

n Replace tyres when the tread depth has reached

the minimum as specif ied.

n Periodically inspect wheels for spokes breakage

and wheel rim run out.

n Check prope r seating of the tyre beading on the

rim whenever the t yre is reassembled.

n Whenever a new tyre is installed, ensure rim and

spokes do not get damaged on acco unt of using

wrong levers.

47

MIN OR MAINTENANCE TIPS

n Use only standard tyres & tubes inflated to correct

pressure.

TYRE PRESSURE

Frontt

Solo 1.41 kg/cm2 2.11 kg/cm2

(20 PSI) (30 PSI)

With Pillion 1.55 kg/cm2 2.25 kg/cm2

(22 PSI) (32 PSI)

Rear

WARN ING

Tyres, rims and air valves must be corr ec tly

matched to wheel rims. See your Royal Enfield Dealer.

Mismatching tyre, tubes, rims and air valves may

result in damage to the tyre bead during mounting,

allow tyre slippage on the rim and cause tyre failure.

FRONT WHEEL REMOVAL

n Place the vehicle on center stand

n Place a wooden block

the f r o n t e n d o f

engine to support the

vehicle.

n Dis c o n n e ct s p e e d o

cable.

n Loosen the pinch bolt

on the RH fork guide.

n Ho l d f ron t a x l e b y

sp ann e r and loose n

axle nut then remove

nut along with washer.

48

MIN OR MAINTENANCE TIPS

n Tap and remove the fr ont wheel spindle

n Tilt the vehicle to RH Side and take out the wheel

along with speedo drive with bush & LH side spacer.

n Take out Speedo drive

and bush on the RH

side as shown in pic.

CAUTIO N

Do not press the front brake lever when wheel is

removed as this will re sult in the brake pads coming

too far out of the brake caliper.

n Place a 4 mm thick wooden piece or cardboard

sheet bet we en the bra ke pads to avoid pads

activation in the event the front brake lever is

accidently pressed.

FRONT WHEEL ASSEMBLY

n Remove t he woo den piece / card board sheet

placed betwe en the brake pads.

n Pl a c e the bu sh

sp e e d o d r i v e i n

po s iti o n and pl ace

speedo drive over it.

n Ins e r t t he w h e e l

al o n g wi t h sp e e d o

drive assembl y and

LH space r bet wee n

th e fr o n t fork end s

en sur ing the brak e

disc is lo c a t e d in

be t ween the bra ke

pads.

n Insert an d ta p t h e

fro n t wh e e l a x l e

gently inside.

n Refit the washer and

tighten the nut firmly.

49

MIN OR MAINTENANCE TIPS

n Tighten the pinch bolt on the RH fork guide .

n Rotate the wheel and che ck for smooth rotation.

n Connect the speedo cable t o speedo drive unit

and rotate the wheel to check for proper working

of speedo meter.

n Press brake lever 2 or 3 times to check front brake

efficiency.

NO TE

Ensure that the speedo drive is correctly located such

that the cable can be connected without dif ficulty.

REAR WHEEL REMOVAL

n Place the vehicle on center stand on a firm and

flat surface.

n Note and mark the position of the chain adjuster

but t i n g w i t h th e

stop per on the right

side.

n Remove split pin and

cas tle nut on the RH

side.

n Remove wheel spindle

fro m LH side al o n g

wi th chai n adjust er,

ta ki n g ca r e n o t t o

drop the wheel collar

and spacer from the

LH side of the wheel.

n Tilt vehicle to RH side

and s l ide o u t r e a r

wheel.

50

MIN OR MAINTENANCE TIPS

REAR WHEEL ASSEMBLY

n Ensure the four cush rubbers are in position inside

the rear wheel hub.

n Tilt vehicle to right

an d ins e r t wheel

assembly betwee n

the swing arms.

n Po s i t ion th e re ar

wh e e l wi t h cu s h

rubber on the rear

chain sprocket.

n Hold whe el coll ar

and s p a c e r i n

position.

n Ass e m b l e th e

whe e l sp i n d l e

al ong with ch a in

ad jus ter fro m the

LH side of veh icle

an d gent ly ta p it

through the wheel.

n Ensure that the chain adjuster knotch butts with

the stopper as appropriate when both the front

& rear w heels are aligned.

n Ti g hten the ca st le

nu t fi r m l y a nd

ensure that the hole

on ax l e sh a f t an d

the slot on castle nut

ar e al i g n e d to

enab l e s p lit p i n

fitment.

n Fix the split pin.

CAUTIO N

Do not force the spindle into the wheel as the threads

may get damaged. Tap it through the wheel gently.

WARN ING

Ensure the vehicle does not come off centre stand

wh i l e a s s e mbli n g / dis a s s e m b ling t he w h e e l

assembly. Failure to adhere could result in damage

or serious injur y.

51

MIN OR MAINTENANCE TIPS

ADJUSTMENTS - CLUTCH

2 to 3 mm

B

Clutch Lever (free play 2 to 3 mm)

A

CLUTCH FREE PLAY ADJUSTMENT

n Loosen the cable outer lock nut (A).

n Turn the Nut (B) Clockwise to reduce the play or

Anticlockwise to inc rease the free play.

n Check free play 2 t o 3 mm at Clutc h lever pivot

on handle bar end.

n Tighten lock nut ( A) after adjustment is do ne.

DRIVE CHAIN FREE PLAY (PLAY 25 - 30 MM)

n Remove rear wheel

split pin.

n Lo o sen cas t le nut,

spindle nut, anchor

nut and brake rod

nut.

n Turn the RH adjuster

cam a s a ppr o priately, t ill 25 to 30

mm s l a c k n e ss i s

achieved on the top

run of the chain.

52

MIN OR MAINTENANCE TIPS

n Check brake pedal free play, If necessary adjust.

n Check that the front

and rear wheels are

correc tly aligned.

n Turn the LH adjuster

cam appro pr iately,

to a l i g n b o t h t h e

wheels.

n Ch e ck an d ens u re

that the knotches on

the cam are resting

on t h e p i n i n the

swi ng arm on both

sides.

n Ap p l y b r ake a n d

tighten all nuts.

n Fi n all y Torq u e th e

anchor Nut.

CHECKING REAR BRAKE PEDAL HEIGHT

n Loosen the lock nut.

n Turn in or out the pedal stop pin bolt till the brake

pedal and front f ootrest are in the same he ight /

level as shown in above pic.

n Tighten the lock nut

n Check for free rotation of rear wheel.

53

MIN OR MAINTENANCE TIPS

REAR BRAKE PEDAL PLAY ADJUSTMENT

20 - 30 mm

l Turn in or out the adjuster nut at the brake rod end.

The recommended brake pedal travel is 20-30 mm.

l Check that the brake is not binding and the rear

wheel rotates freely.

WARN ING

Please ensure brakes are adjusted to their maximum

efficiency. Inefficient brakes can cause an accident.

Please ensure adequate caution while applying brakes.

Sudden application OR pressing the levers fully can caused

the wheels to lock. This may cause the motorcycle to skid

with possible los s of control and result in an accident

causing. Brake shoes must be inspected for wear every 4000

Kms. If you ride under adverse conditi ons, (steep hills,

heavy traffic, etc.) a more frequent inspection at 1600 Kms

or less, is required.

CHAIN LOCK FITMENT

The open end of the chain link master lock to face

opposite to normal direction of chain rotation as

shown pic.

WARN ING

The fitment in wrong dir ection lock can lead to

falling off of chain link thus disengaging the drive.

Th is will lead to pot e nti all y ha zar dou s sit u ati on

which, if not avoided, could result in serious injury.

54

MIN OR MAINTENANCE TIPS

ADJUSTMENT OF GAS FILLED SHOCKABSORBER

RH

LH

n The rear gas shock absorber is adjustable type i.e.,

the spring tension can be increased or reduced.

n Increase the spring tension for high load operation.

n Reduce the spring tension for low load operation.

n The adjuster provided on the bottom of the spring

has five knotches.

n Insert special ‘C ’ spanner on the bottom adjuster

and rotate to change knotch position.

n Turn the adjuster such that the adjuste r moves

up to increase the spring tension and vice versa

to reduce the spring tension.

n Ad just both le ft ha nd an d righ t han d sho c k

absorbers so that the same knotch rests on the

pin in both sides.

WARN ING

Ri d i n g t h e m o t o r cy c l e wit h t h e kn o t c h e s

ad ju sted in dif fer ent pos iti ons can cau se los s of

control and may lead to an accident.

Regularly inspect shock absorbers and front forks for

leaks. Replace worn parts. Worn parts can adversely

affect stability and handling.

NO TE

Ensure no fouling of any accessories with rear shock

ab s o r b er. Ch e c k for su ffici e n t ga p av ailab i l i ty

bet ween the shock absorber and the attachments

when the rear end of the motorcycle is fully loaded

and the shock absorbers are fully compressed.

55

MIN OR MAINTENANCE TIPS

REMOVAL OF BATTERY ON VEHICLE

n Th e ve h i c l e i s

provided with 12V 14 AH batt ery.

n Unlock (turn the key

anti clockwise) and

remove the battery

cover.

n Remove t he batter y

holding two rubber

straps gently.

n Pull out t he batte ry

and t urn , th e n

disconnect both the

te r m i n a l wire s

(neg a t i v e a n d

positive respectively)

n Take out the battery.

BATTERY MAINTENANCE

n The battery must be

periodically checked

for

H Cle anline ss and

co r r o s io n fr e e

terminals.

H Elec t r o l y t e level

mus t b e a b o ve

“MIN” level.

H If electrolyte level

is l o w, remo v e

caps and top up

with distilled water

only.

n Apply petroleum jelly

ove r t h e b a t ter y

terminals to avo i d

sulphation.

56

MIN OR MAINTENANCE TIPS

WARN ING

Always disconnect the negative (-) battery cable

fi r st and th e n the Re d po siti ve (+) ca ble whi l e

removing the battery connections.

NO TE

For chec king the batter y voltage and elec trolyte

specific gravity, contact author ised Royal Enfi el d

service or battery service centre.

CAUTIO N

n Do not use battery with low electrolyte level as

the bat tery internals cells w ill get damaged.

n Do not overfill the batter y elec trolyte level as it

will spill out through the overflow pipe and cause

corrosion to vehicle parts.

n Use only distilled water meant for use in batteries

to avoid damage to battery.

n Elec trolyte should not be filled when the level is

betwee n minimum & maximum levels indicated

in battery as “MIN” & “MAX”.

ASSEMBLY OF BATTERY ON VEHICLE

n Position the battery in the battery carrier such that

the negative terminal of the batter y is towards

fuel tap.

n Ensure ignition switch is in ‘OFF ’ condition.

n Connect the positive terminal (Red wire) first.

n Connect the negative terminal (Black wire) next.

n Smear the terminals with petroleum jelly. (Do not

use grease).

n Refit the rubbe r strap bracket to hold the battery.

n Refit LH side panel.

NO TE

Clean the wire terminals free of corrosion and keep

the terminals coated with petroleum jelly.

CAUTIO N

Connec t the +ve and -ve cables to the respective

batt e ry ter min als. Failu re to do so may result in

damage t o the motorcycle electric al system.

57

MIN OR MAINTENANCE TIPS

CHANGING ELECTRICAL COMPONENTS

HEAD LAMP BULB REPLACEMENT

n Loos e n th e he a d lam p

holdin g top scr ew. Then

pu l l o u t he a d l a m p

assembly.

n De tac h botto m lu g from

th e head lamp ho u sin g

body.

n Dis c o n n e c t he a d l a m p

wi r e co n n e c tors Green,

Ora n g e and Blue co l o r

terminals.

n Remove rubber grommet

from t h e r e f l e c t o r

Asse mb ly.

n Gent l y p r e s s t h e b u l b

holding ‘U’ clip from both

the sides downwards and

re lease it from refl ecto r

slot as shown.

n Pull out head lamp bulb

and inspect its filament for

fuse.

CAUTIO N

Ne ver to uch th e bul b with

your fingers, Finger prints will

etch the glass and decrease

bu l b li fe. Alway s ho ld th e

bulb with paper or clean dry

cloth during handling.

58

MIN OR MAINTENANCE TIPS

ASSEMBLING THE HEADLAMP

n Refix the new head lamp

halo g e n bulb in t o

reflector unit by locating

the wide protrude on top

side mounting.

n Fix bulb holding U clip into

re f l e c tor b o dy k n otc h ,

then press the both ends of

clip and lock in its slot.

n Fit the rubber grommet.

n Connect the wire couplers

as mentioned below.

TOP SIDE: GREEN COLOUR

RI G H T S I D E : B LU E C O LO UR

LEF T SIDE: ORANGE COLOUR

n Position the reflector ring

bottom lug into head lamp

ca sing slo t and sl ide it ,

the n t i g hte n t h e top

mounting screw.

NO TE

After connecting above said procedure, turn ignit ion

switch to “ON” condit ion and then check, ensure that

flash light w orking in HIGH BEAM mode.

If you use the bulb other than specified rating (12V

55/60W) may result in over loading electrical system

lead to premature fa i l u r e or fr e q u e n t batte r y

discharge.

59

MIN OR MAINTENANCE TIPS

TAIL LAMP BULB REPLACEMENT

n Remove the two nuts each

from RH & LH side of the

rear number plate holder.

n Pu l l o u t Ta i l L a m p

as se m b l y a l o n g wi t h

bracket and twist the bulb

holder in anticlockwise to

rem o v e bul b h old er

assembly.

n Turn old bulb to remove

and replace with a new

bulb.

n Refit the bulb holder and

turn clockwise to lock the

bulb holder.

n Re f i t t h e t ai l la mp

wi t h b r a c k e t on t he

reverse order of removal

process.

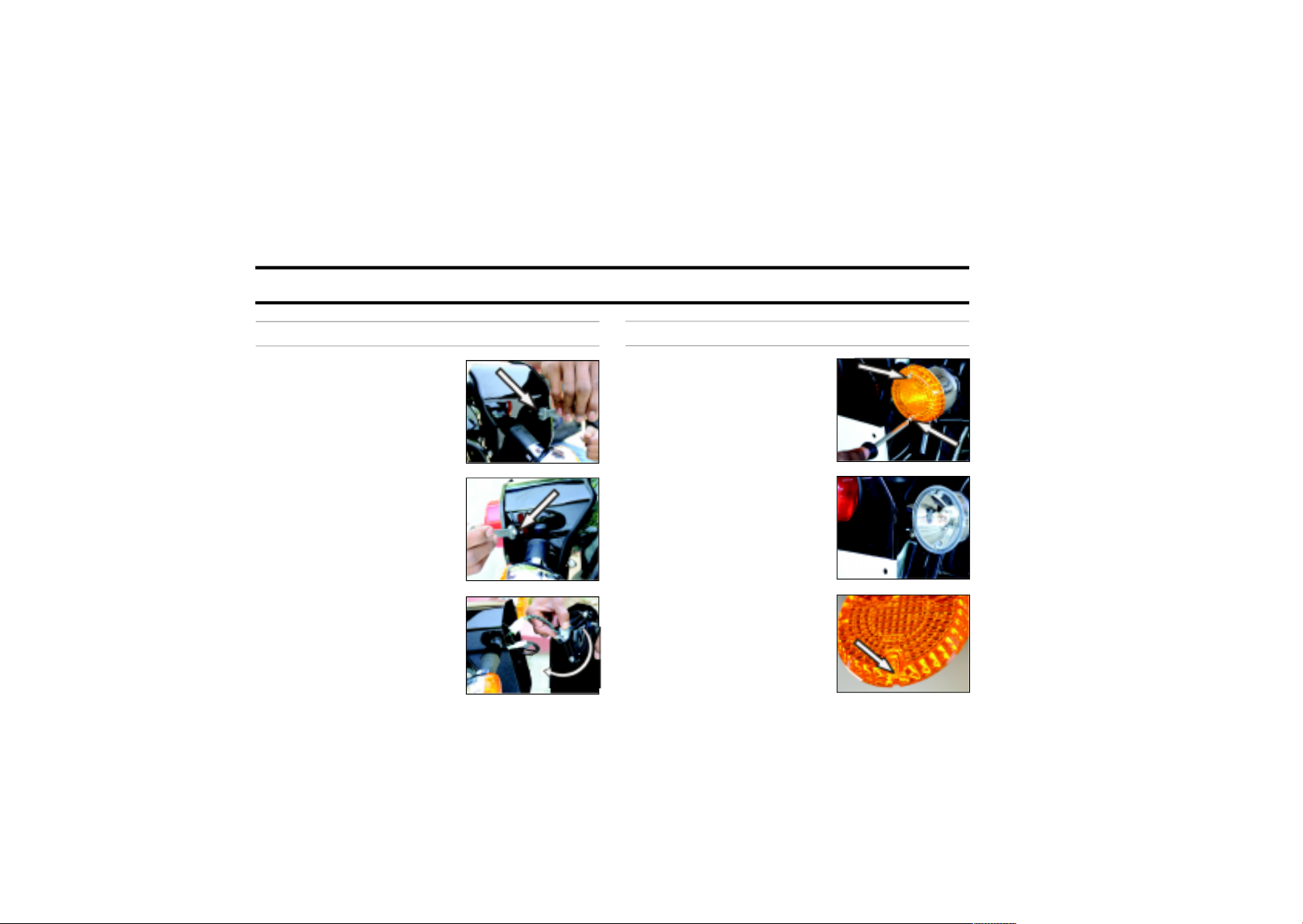

TRAFFICATOR BULB REPLACEMENT

n Re m ove th e 2 scr e ws &

take out trafficator glass

cover.

n Press bulb gently & Turn

anticlockwise to take out

the bulb.

n Po s i t ion t h e new b u l b

insi d e th e ho l der,

ensuring t hat the pins in

the bulb, match with the

slots in the holder.

n Pre ss the bulb and tu rn

clockwise to lock the bulb

in the holder.

n Refit the trafficator cover

cut s l o t m a r k f acin g

downwards and tight en

the 2 screws.

Cut Mark

60

MIN OR MAINTENANCE TIPS

1

2

3

4

FUSE

n Open the LH tool box.

n Take out tool kit.

n Remove fuse holder

ru b b e r & l i f t fus e

carrier top cover.

l Rep la ce the required fuse with the spar e fus e

available in the fuse carrier.

NO TE

Please e nsure to replace a spare fuse in the holder

at the earliest opportunity.

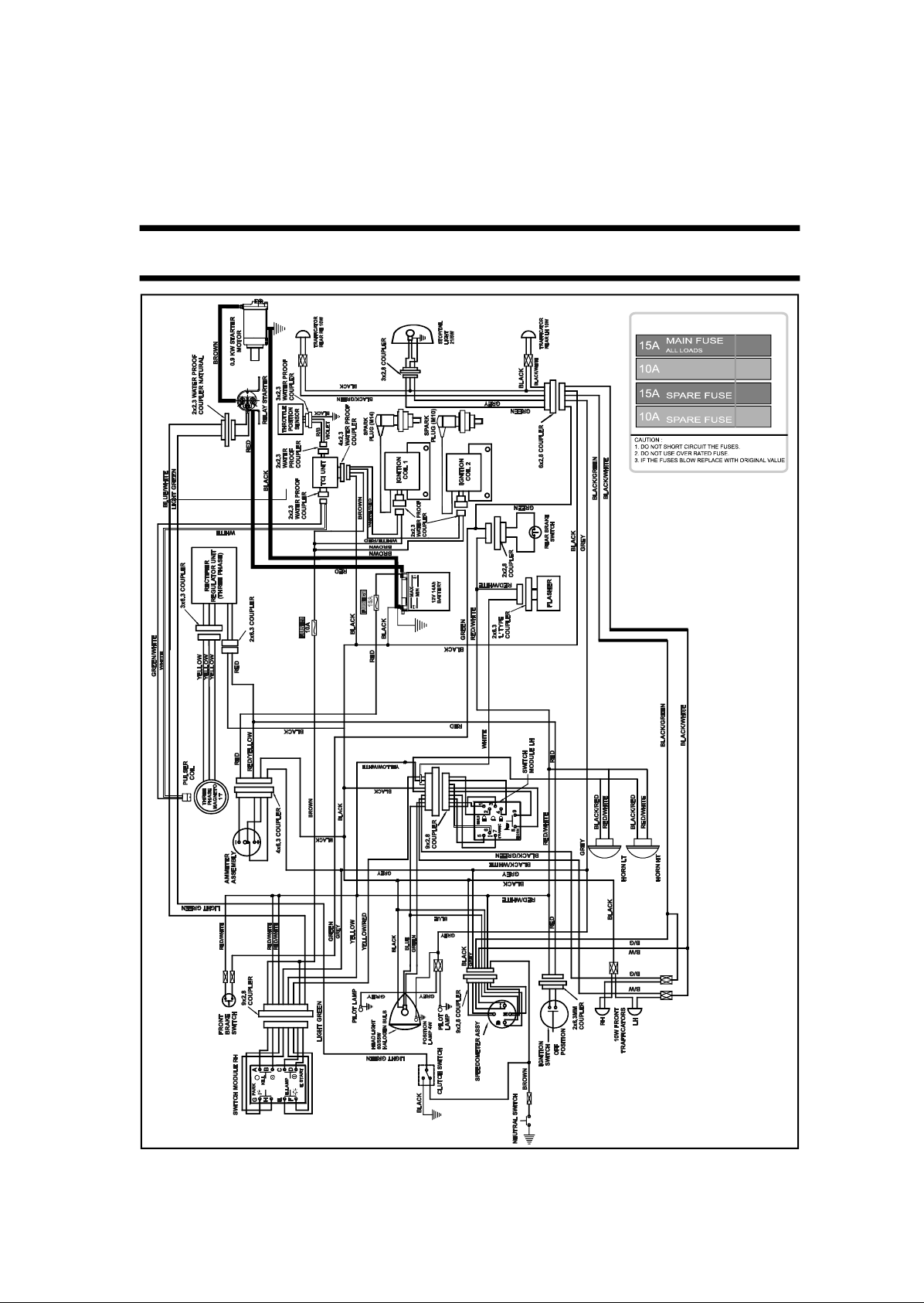

BLADE FUSE USAGE LIST

Fuse No.

1 Blue Main Fuse (15A)

2 Red Ignition Fuse (10A)

3 Red Spare Fuse (10A)

4 Blue Spare Fuse (15A)

Color

Remarks

61

MIN OR MAINTENANCE TIPS

AIR FILTER ELEMENT CLEANING / REPLACEMENT

n Insert the key, turn

anti c l o k w i se to

remove RH side air

filter box lid.

n Lo o sen th e fi l ter

ho l d i n g n u t by

10mm spanner as

shown in pic.

n Re m o v e t h e nut,

washer and cover

air filter to take out

air filter element.

n Tap the filter element

to re m o v e d u s t a s

sh o w n a n d c lea n

tho r o u g h ly b e f o r e

assembly.

Clean both intake

adaptors and duct as

shown in pic.

n As sem ble the fil ter

element and cover in

the reverse order of

dismantling process.

n Please ensure proper

sealing of cover plate

agai nst air fil ter

element.

62

WASHING PROCEDURE

PRECAUTIONS

n Wash vehicle when the engine is cold.

n Cover the silencer tail end and control switches with

suitable plastic bags and tie it firmly to prevent

water entry into them.

n Remove igni ti on key and seal key hole us ing

adhesive tape.

n Use a suitable engine degreaser, available with

your local parts store, to remove dirt or grease from

the engine external parts if required. Follow the

directions in the label carefully before using the

degreaser.

n Use low pressure jet of water to clean the entire vehicle.

n Never spray water with great force on head lamp,

speedometer, trafficator lights, front and rear wheel

hubs, electrical connections and wires, control

cables, sparkplug, battery, etc.

n Use luke warm water and mild detergent on the

painted components to remove dirt, etc.

n Rinse vehicle thoroughly with plain water to remove

the detergent and wipe vehicle dry.

n If possible, use compressed air and blow off water

particles from the obscure areas of the vehicle,

electrical connections etc.

AFTER WASHING

n Ensure, the vehicle is thoroughly dry by wiping with

a clean soft absorbent cloth or chamois leather.

n Remove all plastic bags and adhesive tapes.

n Lubricate control cables, pivot and rear chain with

lube oil

n Polish the painted and plate d surfaces using

polishing wax.

n Start the bike allow engine to idle and warm up.

n Drive the motorcycle slowly, applying both brakes

intermittently to dry up the brake shoes.

n Test brakes for full efficiency.

WARN ING

Observe warnings and cautions given on labels

of cleaning compounds.

When washing your motorcycle, be careful not to get

the brakes, engine, mufflers or air cleaner etc., too

wet.

63

STORAGE PRECAUTIONS

Incase you r Motorcycle is not going to be used for a

month or mor e, we advise the following precautions

to the taken.

n Carryout required repair / adjus tments on the

motorcycle.

n Wash the motorcycle thoroughly and lubricate as

per the maintenance chart.

n Start the engine, warm up for a few minutes and

switch off.

n Drain out the fuel comple tely from the fuel tank

and fuel lines.

n Remove spark plug. Pour in about 25ml of clean

engine oil through spark plug hole. Close the hole

and cra n k en g i n e s e v e r a l ti me s and re f i t

sparkplug.

n Clean rear chain thoroughly and apply a thin

film of lu be oil.

n Re m o v e b a t ter y f r o m t h e bi k e . C l e an the

terminals fre e of corrosion.

n Maintain electrolyte level between max or min

mark, by adding distilled water and wipe the

batter y dry.

n Sto r e t h e ba tte r y i n a c o ol, dr y a n d w e ll

ventilated place.

n Do not place the battery in direct sun light, near

open flame or where temperature is above 40oC

or below 0oC

n Cover the silencer with plastic bags to prevent

moisture entr y. Set the motorcyc le on its center

stand.

n Apply anti rust solutio n on al l chrome plated

part s. Take care not to apply this solution on

rubber or painte d parts.

n Store motorcycle in a clean covered area free -

of moisture and keep it covered to prevent dust

settling on it.

64

STORAGE PRECAUTIONS

PREPARING THE MOTORCYCLE FOR RE USE

n Remove anti rust solution from al l chrome plated

parts and clean the motorcycle.

n Inflate the tyres to the correc t tyre pressure.

n En s u re bat t e r y is fully cha rged an d pr oper

electrolyte level is maintained.

n Connect the battery.

n Lubricate all c ontrol cables and pivots.

n Check proper level of oil in engine.

n Fill fuel tank with fresh petrol.

n Check fuel line / hose for any cracks or cuts.

n Clean the air filter.

n Remove plastic covering from the silencer.

n Remove spar k plug on cylinder head and pour

in a few drops of engine oil. Cr ank engine a few

ti mes to lubr ica te cyli nde r walls and pis ton .

Clean spark plug and refit.

n Switch “ON” ignition switch.

n St ar t vehic le and war m up eng ine for a fe w

minu tes before riding the vehicle.

NO TE

Do not raise the engine rpm the moment it is started,

but allow the engine to ru n at idling speed.

CAUTIO N

Proper long-term storage is important for the safe ,

tro u b l e -f r e e o p er at i o n o f y ou r R o y a l E n fie l d

motorcycle.

65

LONG TRIP PRECAUTIONS

CHECKS PRIOR TO THE COMMENCEMENT OF

LONG JOURNEY

n Se r v ice the mot o r c ycle thor o u ghly at Ro y al

Enfield Authorised Dealer / Service Point as per

periodical maintenance chart. (Ref. Page No. 40,

41 & 42)

n Sufficient quantity of petrol in the fuel tank for

the journey planned.

n Check and correct tyre pressure if necessar y.

CHECKS AFTER EVERY 1500 KMS OF RUN

n Tightness of all fasteners.

n Tyre tread condition and wear of tyres.

n Battery condition and elect rolyte level.

n Correct oil level in engine.

n Working of all lights and horn.

n Proper drive chain tension.

ITEMS TO BE CARRIED

n Tool kit.

n First aid kit.

n Bulbs for Headlight, Trafficator light , Rear Tail

Lamp and Fuse (10 & 15 Amps).

n Accele rator, Clutch and Speedo Cable.

n Rear chain master link lock assembly.

n Spare tube, puncture repair kit - cold vulc anising

type.

n Foot operat ed Air Pump.

n Insulation tape.

n Spark plugs (M14 & M10), Fuel hose.

66

CARING FOR MILEAGE

STOP THE DROP THAT LEAKS

n Petrol leak at a rate of one dro p per min ute

accumulates to 5,25,600 drops a YEAR! That is, 35