Page 1

Industrial Insulation

Process Manual

Industrial & Mechanical Installation Guidelines

Page 2

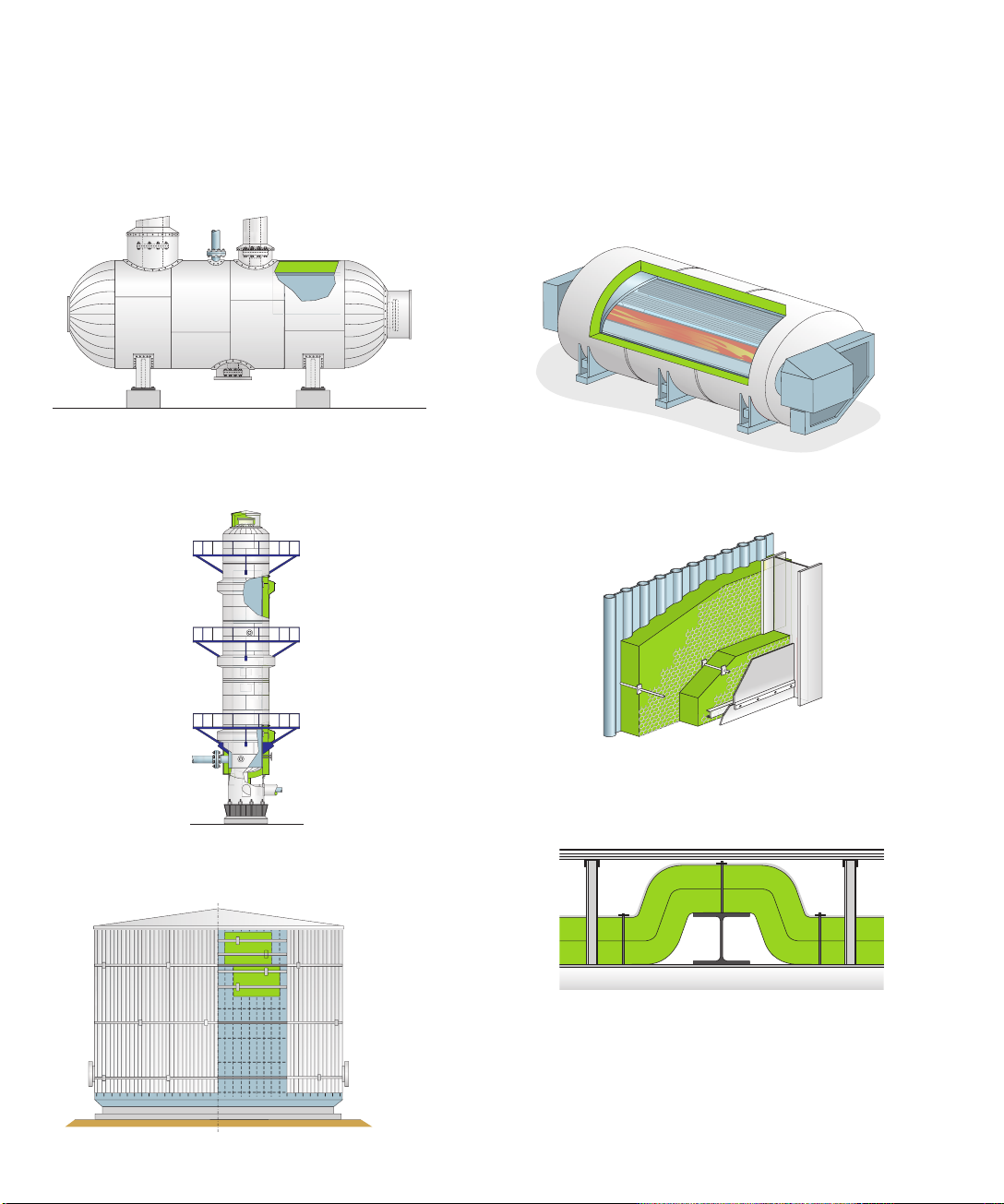

Overview: ROXUL® Industrial Insulation Solutions

1.2 Insulation of piping 23 1.6 Insulation of boilers 67

1.2.1 Insulation with pipe sections 29 1.6.1 Insulation of fire tube boilers 67

1.2.2 Insulation with pipe wraps (mats) 31

1.2.3 Insulation with wired mats 33

1.2.4 Insulation support 34

1.2.7 Insulation of valves and flanges 40

1.2.8 Insulation of pipe elbows and T pieces 42

1.2.9 Reducers 43

1.2.10 Expansion joints 44

1.2.5 Cladding 36

1.2.6 Pipe hangers and pipe support 39

1.2.11 Tracing 45

1.2.12 Foot traffic 46

Page 3

1.3 Insulation of vessels 47

1.4 Insulation of columns 53

1.6.2 Supercritical steam generators 69

1.5 Insulation of storage tanks 59

1.7 Insulation of flue gas ducts 75

1.8 Cold boxes 82

Page 4

Contents

1. System solutions 7

1.1 Planning and preparation 11

1.2 Insulation of piping 23

1.3 Insulation of vessels 47

1.4 Insulation of columns 53

1.5 Insulation of storage tanks 59

1.6 Insulation of boilers 67

1.7 Insulation of flue gas ducts 75

1.8 Cold boxes 82

2. Theory 85

2.1 Norms & Standards 88

2.2 Product properties & test methods 107

2.3 Bases for thermal calculations 120

3. Tables 127

3.1 Units, conversion factors and tables 130

3.2 Product properties insulation and cladding materials 146

3.3 Usage tables 149

4. Products 169

ProRox® PS 960NA 171

®

ProRox

ENERWRAP® MA 960

ProRox® SL 920

ProRox® SL 930

ProRox® SL 940

ProRox® SL 960

ProRox® SL 540

ProRox® SL 560

ProRox® SL 590

ProRox® SL 430

ProRox® SL 450

ProRox® SL 460

ProRox® SL 760

ProRox® FSL 920

ProRox® FSL 930

ProRox® FSL 940

ProRox® FSL 960

ProRox® MA 930

ProRox® MA 940

PS 980

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

ProRox® GR 903

®

ProRox

ProRox

LF 970

®

Rocktight

Page 5

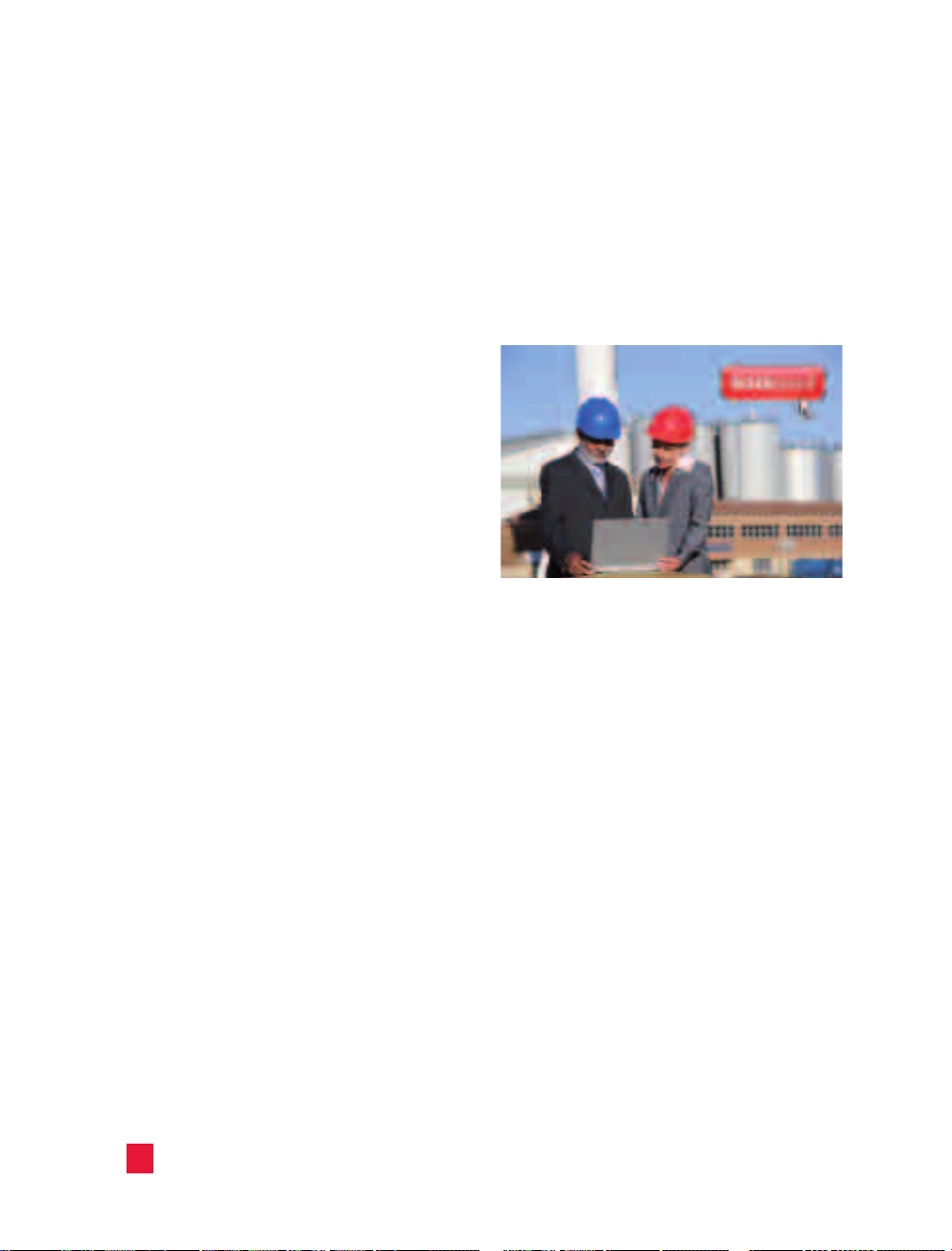

ROXUL® insulation provide superior thermal and

acoustical performance and are fire resistant, water

repellent, non-corrosive and resistant to mold.

Specialists often willingly turn to our products

and expertise in industrial and marine & offshore

insulation. We have now packaged that expertise into

a practical guide: the 'ProRox® insulation Process

Manual‘.

This manual offers a transparent overview of

our ProRox® product range, including thermal,

fire-resistant, compression, comfort/multi-purpose,

fabrication and acoustic insulation solutions for

technical installations in the process & power

generation industries.

The Process Manual is a convenient resource tool

with relevant information at your finger-tips. Fold-out

sections take you directly to the right page, whether

you are looking for straight forward piping insulation

or more complex applications for columns, tanks and

boilers. In addition to pictures and photographs, a

range of tables and diagrams are included.

The ROXUL Process Manual is a helpful tool for

the application of our ProRox® industrial insulation

solutions in a process environment. Should you need

any further information about a specific application,

procedure or practical problem, please consult

www.roxul.com or contact your local ROXUL

representative at 1 800 265 6878.

2

Page 6

ROXUL

®

Industrial Insulation

ROXUL an independent organization with the

ROCKWOOL Group - is a leading supplier of high

quality stone wool products in the industrial

insulation market. With the ProRox® & SeaRox®

lines for the industrial market and for the marine &

offshore industry, our experts provide a full range of

products and systems for the thermal, acoustic and

firesafe insulation of industrial installations. ROXUL

continuously monitors the market developments.

Our 75+ years of global experience is reflected

in a complete set of high-grade products and

expert advice. Today, we remain fully committed to

providing the very best service in the market and a

total range of cutting-edge insulation solutions.

3

Page 7

The ROXUL® Industrial

Insulation Process Manual

Know-how for designers, engineers, site supervisors and managers of

industrial plants

Energy keeps the world in motion. Without it,

everything would come to a standstill. The global

economy is dependent upon a secure & efficient

supply of energy. Over eighty percent of the energy

currently being consumed is obtained from nonrenewable resources. Those resources are becoming

increasingly scarce, while at the same time the

demand for energy is exploding. This means that

owners, designers and operators of large, industrial

plants are challenged with the task of reducing their

energy consumption as much as possible in order to

ensure the long term sustainability of their operations.

Solar energy is just one of the possible alternatives.

Through, for example, solar power plants we

already succeed in converting concentrated sunlight

very efficiently into electricity. And this is just one

of the solutions that can help us drive down fuel

consumption and carbon emissions.

On top of that, insulation significantly reduces the

energy needed to manufacture a product or provide

a service. Also, new technologies for emission

controls at existing fossil burning facilities is greatly

enhanced by insulation. Nowadays there are a variety

of efficient insulation systems that enable scarce

energy reserves to be put to the best possible use.

The ROXUL Industrial Insulation Process Manual

illustrates these systems both theoretically and

practically. This process manual targets designers,

engineers, installers and managers of industrial

plants and provides an overview of the modern

insulation techniques for, by way of example, chemical

or petrochemical installations and power generation

facilities. Based on current standards and regulations

the manual provides accessible, practical guidelines

for the implementation of numerous insulation

applications.

Restriction of thermal losses to an absolute minimum,

including during transfer or storage, can considerably

reduce the energy consumption of industrial plants.

This also results in a reduction in carbon dioxide

(CO²) emissions, which are created each time fossil

fuels such as coal or gas are burnt and which, as a

greenhouse gas, is responsible for the global increase

in temperature.

From an environmental perspective, adequate

insulation of industrial plants is a significant means of

reducing (CO²) emissions.

4

Page 8

In addition, the right insulation keeps temperatures,

for example in pipes and storage tanks, within

strict tolerances, thereby ensuring reliable process

efficiency. At the same time, adequate insulation

protects the plant itself. Modern insulating materials

can thoroughly protect plant components from

moisture and associated corrosion. Installation

and process maintenance costs can be reduced

considerably and the effective lifetime ofindustrial

plants can be successfully maximized.

Furthermore, industrial insulation also provides

a significant contribution to personnel protection.

Optimum insulation reduces process temperatures

and noise in the industrial environment to an

acceptable level, to the limits generally regarded

in the industry to be those required for a safe and

comfortable working environment.

With a complete range of techniques and insulation

systems, ROXUL® offers designers, engineers and

construction supervisors optimum tailored solutions

for the petrochemical, power generation, ship

building, offshore and processing industries.

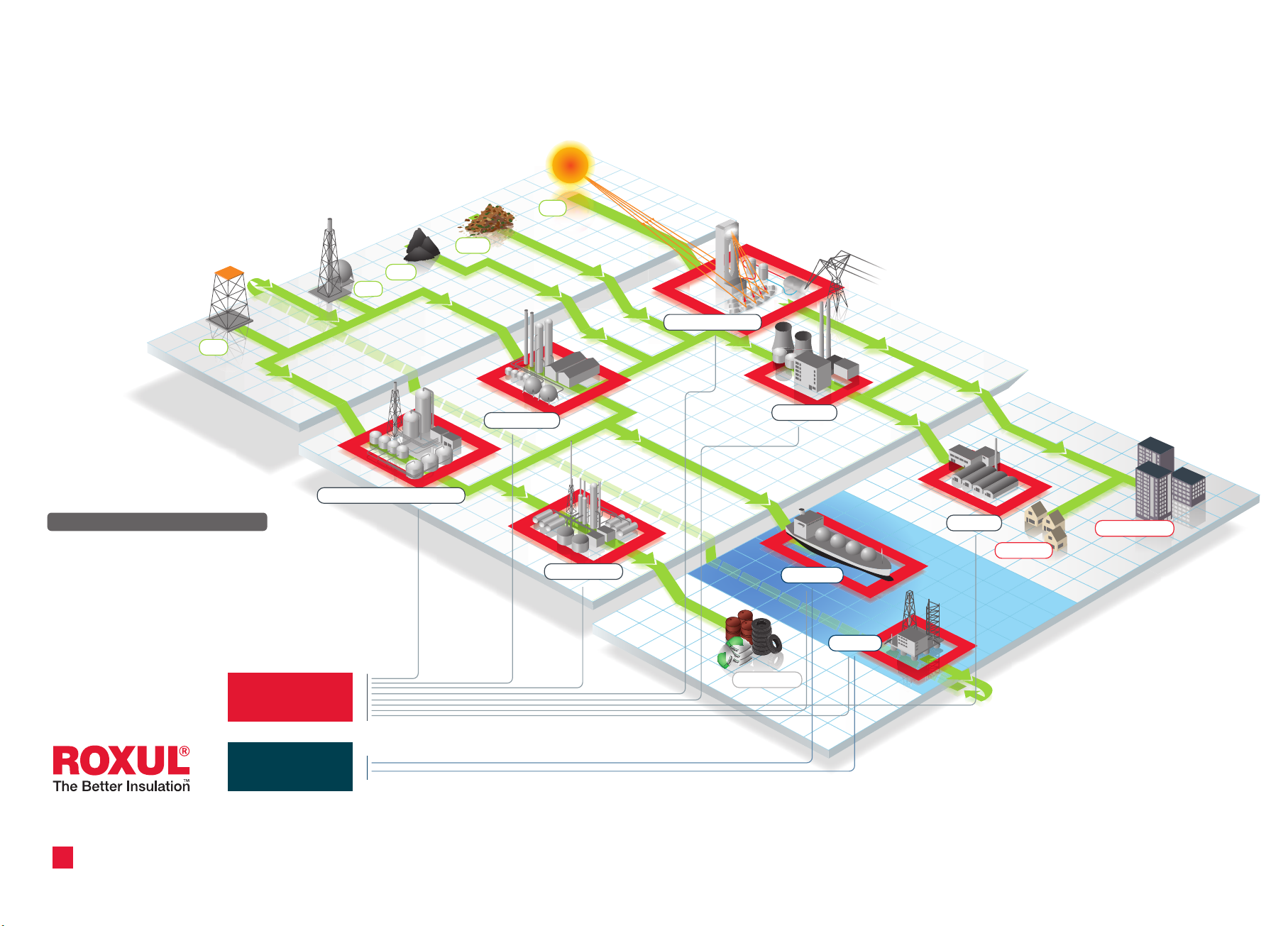

In the 'Flow of Energy' diagram on the following

page, you will find an overview of all of the sectors

in which ROXUL is active. All of our ProRox® (and

SeaRox®) products, such as pipe sections and boards

(slabs) are designed to meet the highest quality and

safety standards and comply with the strictest, and

therefore safest, fire safety classes. Stone wool is

non flammable, non combustible and can withstand

temperatures up to 2150 °F (1177 °C) and therefore

provides a crucial contribution towards passive fire

protection.

As a supplement to this process manual, ROXUL

also regularly provides infor mation about technical

innovations, product solutions and recent and

relevant documents available online at our website

www.roxul.com. NOTE: The process manual is a

guideline and can only provide general advice for

specific instances in the field of plant and processes.

For these instances, the ROXUL Technical Services

Team is available to provide advice during the design,

engineering and implementation phases. Please find

our contact details on the back cover of this manual.

5

Page 9

ROXUL® Industrial Insulation, Flow of Energy

Exploration, drilling and production

Sun

Waste

Coal

Gas

Oil

Flow of energy

Business Areas:

ProRox® insulation for industry:

Our ProRox® product line covers all our thermal, fire-resistant,

compression, comfort/multi-purpose, fabrication and acoustic

insulation solutions for industrial installations in the process

industry.

®

insulation for shipbuilding and offshore:

SeaRox

SeaRox® comprises the full marine and offshore product line.

This sharp focus enables us to combine our expertise and

extensive experience like never before to develop outstanding

insulation solutions for our customers.

ProRox

Petroleum Rening Processing

®

Gas Processing

Petrochemicals

Solar Power Plant

Power Plant

End Products

Marine

Oshore

Processing industry

Industrial

Residential

Consumption

Non-residential

SeaRox

®

6

Page 10

System solutions

Industrial insulation

System

solutions

1

Page 11

Page 12

1. System solutions

Table of contents

1.1 Planning and preparation 11

1.1.1 Decision criteria for the design of an insulation system 11

A. Functional requirements 12

B. Safety aspects 16

C. Economics 17

D. Environmental 18

E. Corrosion Prevention 18

1.1.2 Design & planning of the insulation work 19

1.1.3 Corrosion prevention 19

1.1.4 Storage of insulation materials 22

1.2 Insulation of piping 23

1.2.1 Insulation with pipe sections 29

1.2.2 Insulation with pipe wraps (mats) 31

1.2.3 Insulation with wired mats 33

1.2.4 Insulation support 34

1.2.5 Cladding 36

1.2.6 Pipe hangers and pipe supports 39

1.2.7 Insulation of valves and flanges 40

1.2.8 Insulation of pipe elbows and Tpieces 42

1.2.9 Reducers 43

1.2.10 Expansion joints 44

1.2.11 Tracing 45

1.2.12 Foot traffic 46

1.3 Insulation of vessels 47

1.4 Insulation of columns 53

1.5 Insulation of storage tanks 59

1.6 Insulation of boilers 67

1.6.1 Insulation of fire tube boilers 67

1.6.2 Supercritical steam generators 69

1.7 Insulation of flue gas ducts 75

1.7.1 Installation of the insulation systems for flue gas ducts 75

1.7.2 Cladding of flue gas ducts 78

1.7.3 Acoustic insulation of flue gas ducts 81

1.8 Cold boxes 82

9

Page 13

Notes

10

Page 14

1. System solutions

1.1 Planning and preparation

preparation

Planning and

The design of a suitable insulation system for

industrial installations is a major factor for its

economical operation, functionality, security,

durability and environmental impact. Additionally,

the installation-specific heat losses are specified

for the entire life cycleof the plant. Corrections at

a later stage, such as subsequently increasing the

thickness of the insulation, for example, may no

longer be possible due to lack of space. Corrections at a later stage may also entail a far greater

investment compared to the original planning.

Continually rising energy costs are also often

overlooked factors when dimensioning the

insulation. Insulation thicknesses that are

designed to last take energy price increases into

account. They form an important criterion for the

economical operation of the installation after just

a few years.

Properly dimensioned insulation systems

constitute an important contribution to

environmental protection, carbon dioxide (CO²)

reduction and to economic success. CO² reduction

is also an economical operation, as it lowers the

costs for CO² emission certificates.

Nowadays, conservational and economical

operations are no longer conflicting ideas, but are

two inseparable parameters.

1.1.1. Decision criteria for the design of

an insulation system

Selecting a suitable insulation system depends on

the following five parameters:

1. Functional requirements

a. Object dimensions

b. Operation of the installation

c. Operating temperatures

d. Permissible heat losses or temperature

changes ofthe medium

e. Frost protection

f. Ambient conditions

g. Maintenance and inspection

2. Safety aspects

a. Personal protection

b. Fire protection

c. Explosion prevention

d. Noise reduction within the plant

3. Economics

a. Economical insulation thickness

b. Pay-back time

4. Environment

5. Corrosion prevention

11

Page 15

1.1 Planning and preparation

A. Functional requirements

a) Object dimensions

The space requirements of the insulation must be

taken into account when the installation is being

designed and planned. Therefore, the insulation

thicknesses should be determined in the early

planning stages and the distances between the

individual objects should be taken into account in

the piping isometrics. To guarantee systematic

installation of the insulation materials and the

cladding without increased expense, observe the

minimum distances between the objects

asspecified in the following illustrations.

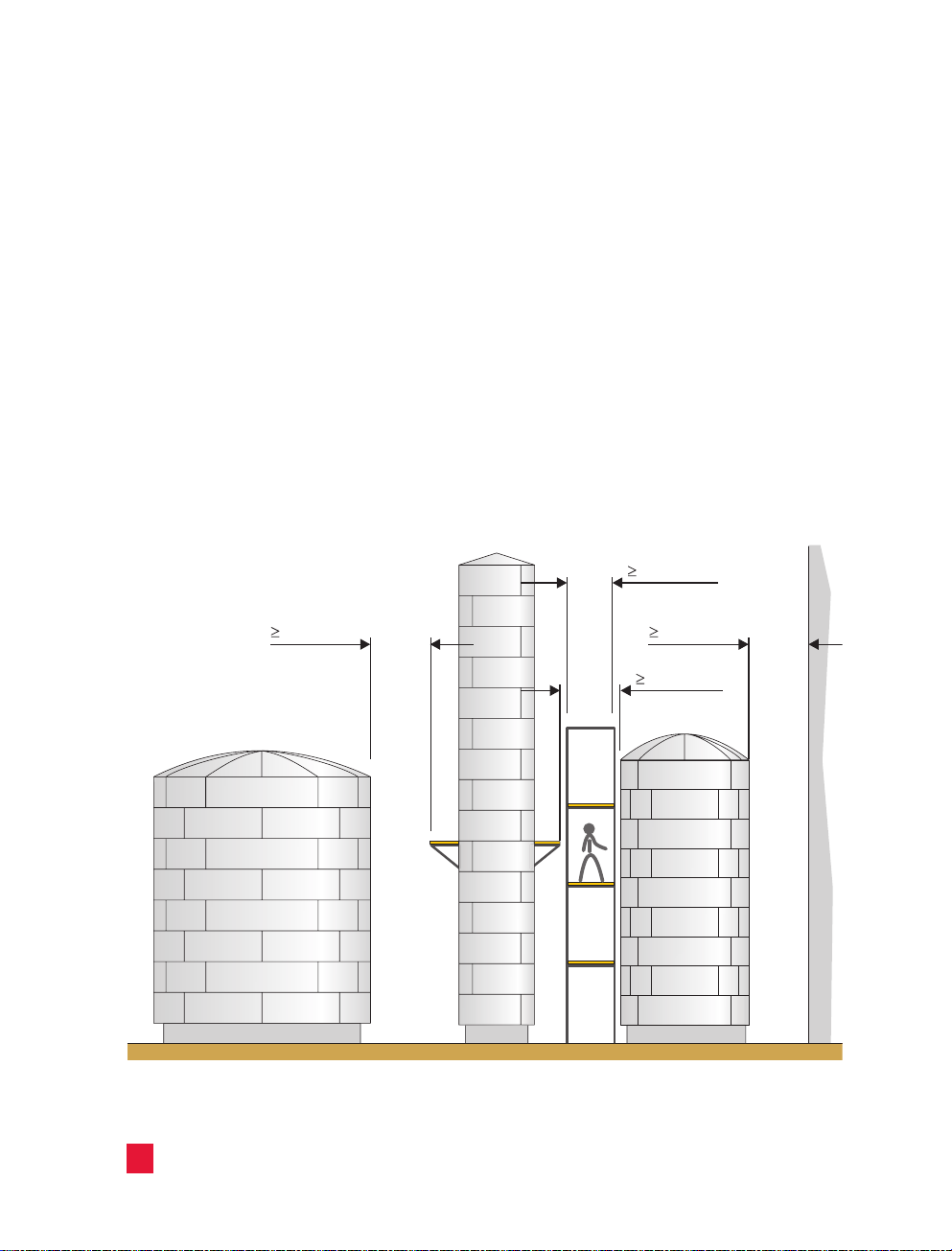

Minimum distances between vessels and columns; dimensions in inches (mm)

31.5” (800)

40” (1000)

40” (1000)

40” (1000)

12

Page 16

4” (100)

4” (100)

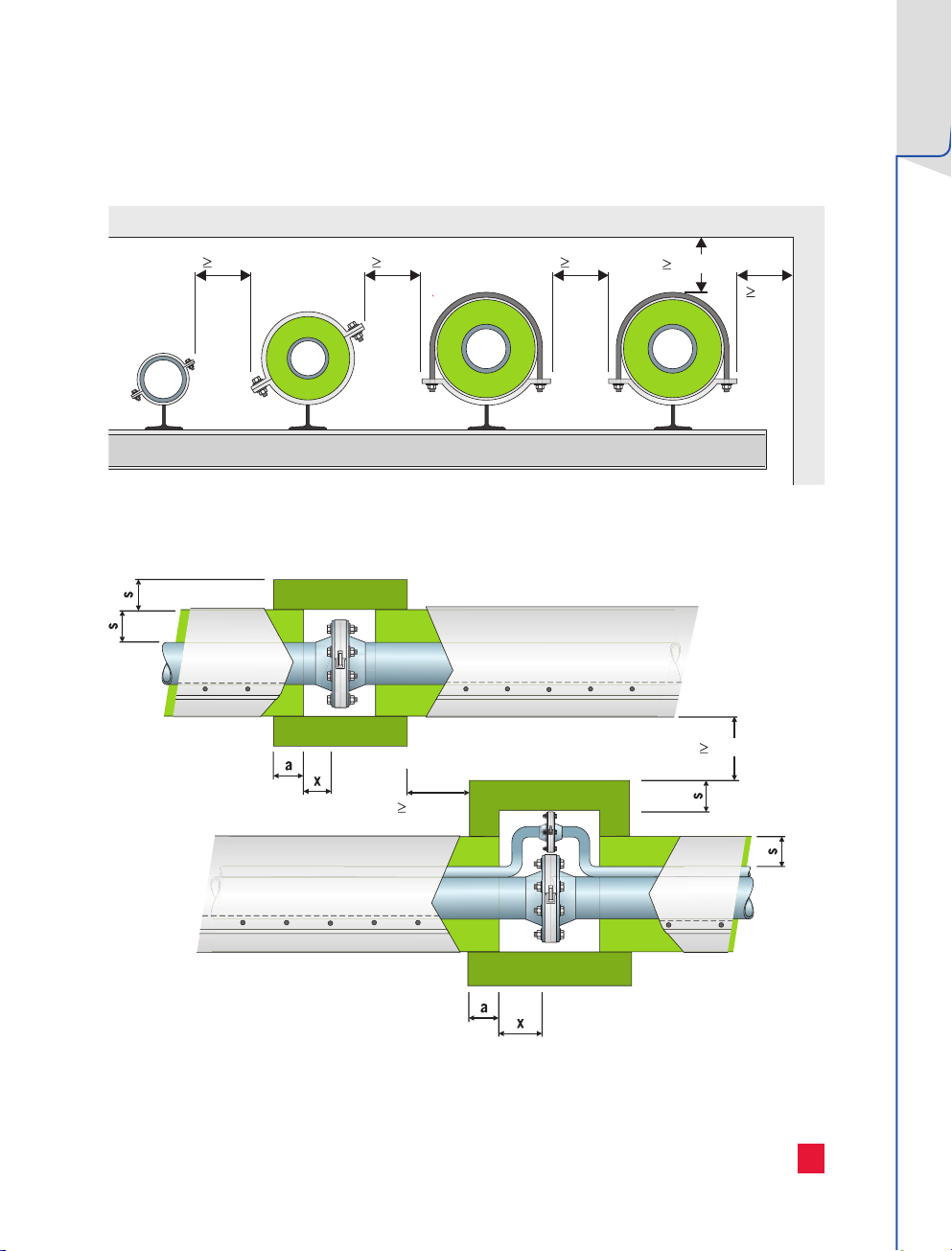

Minimum distances between insulated pipes; dimensions in inches (mm)

preparation

Planning and

4” (100) 4” (100) 4” (100)

Minimum distances within range of pipe flanges; dimensions in inches (mm)

4” (100)

4”

(100)

a = distance flange to normal insulation

a ≥ 2" (50 mm)

x = bolt length + 1.2" (30 mm)

s = insulation thickness

13

Page 17

1.1 Planning and preparation

A. Functional requirements

b) Operation of the installation

To select a suitable insulation system, the

operating method of the installation must be

considered. A basic distinction is made between

continuous and interrupted operation. With

continuous operation, the operating temperatures

are constantly above or constantly below the

ambient temperatures. The interrupted operating

method, also referred to as intermittent or batch

operation, is characterized by the fact that the

installation is switched off between each

operating phase and during that time can assume

ambient temperatures. For special applications,

e.g. dualtemperature systems, the operating

temperature alternates above or below the

ambient temperature.

c) Operating temperature

The appropriate insulation material should be

resistant to the intended operating/peak

temperatures. Thisproduct property is assessed

by the maximum service temperature (also see

Chapter 2.2 “Product properties & test methods”).

d) Permissible heat losses or temperature

changes ofthemedium

With many technical processes, it is essential that

media in vessels, columns or tanks do not fall

below a specific lower temperature limit,

otherwise chemical processes will not proceed as

intended or the media will set and can no longer

be pumped or extracted. Over-cooling can lead to

the precipitation of, for example, sulphuric acid in

exhaust and flue gas streams, which promotes

corrosion in the pipes or channels.

With flowing media, it is essential to ensure that

the temperature of the medium is still at the

desired level at the end of the pipe. The thermal

insulation is designed according to these

requirements. Under extreme conditions (e.g.

lengthy periods of storage, longtransport routes

or extreme temperatures), installing tracing may

be necessary, to ensure that the media is kept

within the required temperature limits.

Thermo-technical engineering calculation

programs like NAIMA's 3E Plus® or ROXUL's

"ROCKASSIST" (coming soon) can aid in ensuring

the optimum engineering and design of

these insulation systems. More information can be

found on our website www.roxul.com. For special

situations please contact the ROXUL® Technical

Services Team for further guidance.

Inside buildings, uninsulated or poorly insulated

parts of installations unnecessarily increase room

temperatures, which can have a negative effect on

the working environment - both for the people

who work long hours under these conditions and

for the electronic components. In addition to the

increased heat loss, the need for climate

controlled rooms requires further energy

consumption. The design of the insulation and the

related reductions in terms of heat loss from

parts of installations should be relevant to the

entire infrastructure and use of the building.

14

Page 18

e) Frost protection

Installations that are situated outside are at risk

from frost in the winter. In addition to the

malfunctioning of installations, installations also

risk damage caused by the expansion of frozen

water. Adequate measures against frost protection

are critical to protect the installation from

freezing. Insulation can reduce heat loss and aid

in frost protection. Insulation alone cannot

indefinitely prevent the installation from freezing.

Installing additional tracing may be necessary

between the object and the insulation. To prevent

freezing, the insulation must be designed so the

heat flow rate of the insulated object is less than

the heat provided by the tracing.

f) Ambient conditions

Select an insulation system that offers long-lasting

resistance to the surrounding environme nt.

Atmospheric influences: wind, rain

Mechanical loads such as vibrations or

foottraffic

Corrosive environment (proximity to sea,

chemicals,…)

an air space of at least 2/3” (15 mm) between the

insulation and the cladding, and create 0.4”

(10 mm) diameter ventilation and drain holes in

the covering at intervals at a maximum of 12"

(300 mm). If necessary, the insulation and

cladding must resist chemical influences that

develop within the environment.

Installations operating below ambient

temperatures have a high risk of moisture

condensing from the ambient air inside the

cladding. Use a continuous vapor retarder on

piping operating below ambient temperatures and

seal all joints, surfaces, seams and fittings to

prevent condensation (use of staples is not

recommended).

g) Maintenance and inspection

To avoid complicating routine maintenance and

inspection work unnecessarily, maintenanceintensive areas must be taken into account,

especially when designing the insulation work.

Removable insulation systems, such as removable

coverings and hoods, could be fitted in such areas,

for example. Easily removable covering systems

are also recommended for flanges and pipe

fittings. These coverings are generally fastened

with quick-release clamps, which can be opened

without special tools.

The insulation of fixtures such as flanges or pipe

fittings must be interrupted at a sufficient

distance to allow installation or dismounting to be

carried out. In this case, take the bolt length at

flange connections into consideration. Any fixtures

in the range of the insulation, including the

interruption in the installation, should be

insulated with removable coverings overlapping

the insulation and maintaining continuity across

the fixture.

preparation

Planning and

Moisture accumulation in insulation increases

thermal conductivity and the risk of corrosion of

the insulated installation components. Cladding

must be installed to prevent the ingress of

moisture into the system. If the ingress of

moisture into the insulation is unavoidable, retain

15

Page 19

1.1 Planning and preparation1.1 Planning and preparation

B. Safety aspects

a) Personal protection

Surface temperatures in excess of 140 °F (60°C)

can lead to skin burns, if the surface is touched.

Therefore, all accessible installation components

should be designed to protect personnel and

prevent injuries. The insulation applied to such

plant components must ensure that surface

temperatures in excess of 140 °F (60°C) do not

occur during operation. Consult our Technical

Services Team to determine the required

insulation thickness to aid in personnel

protection. All of the operational parameters must

be known to achieve a reliable design, including,

for example, the temperature of the object, the

ambient temperature, air movement, surface

materials, distance from other objects, etc.

NOTE

As the surface temperature depends on a set

of physical parameters, which cannot always

be calculated or estimated with any degree

of certainty, the surface temperature is not

a guaranteed measurement. If the required

protection (temperature) cannot be achieved

by insulation, apply additional protective

devices, such as safety guards or enclosement

of theobject.

companies and the operator.

As a basic principle, consider the fact that the fire

load in a building or industrial installation can be

considerably increased by flammable insulation

materials. On the other hand, non-flammable

insulation materials such as mineral wool (stone

wool), which has a melting point of >2150 °F

(>1,177 °C), not only have a positive impact on the

fire load, but in the event of a fire, also constitute

a certain fire protection for the installation

component.

b) Fire protection

The general fire protection requirements imposed

on structural installations are usually defined

within the local Building Codes or the

specifications of plant owner. Structural

installations must be designed, built, modified and

maintained to prevent the outbreak of a fire and

the spread of fire and smoke. In the event of a fire,

the rescuing of people and animals and effectively

extinguishing the fire must be made possible.

During the design of the installation, it is vital to

determine the nature and scope of the fire

prevention measures together with the building

supervisory board, the fire department, insurance

16

Installation components with tracing, in particular,

which use thermal oil as a heat transfer medium,

have an increased risk of catching fire in the event

of a leak. In this case, ensure that the thermal oil

cannot penetrate into the insulation material.

c) Explosion prevention

If there is a risk of fire and explosion, the surface

temperature of the object and the cladding must

be considerably lower than the ignition

temperature of the flammable substance and/or

gas mixtures. This requirement also applies to

thermal bridges, such as pipe mounting supports,

supporting structures and spacers etc.

With regard to insulation systems, explosion

Page 20

preparation

Costs

Planning and

protection can only be achieved with a doubleskin

covering. A doubleskin covering is a factory made

cladding that has been welded or soldered to

make it air proof and diffusion-resistant. In

addition special (local) explosion regulations must

be observed.

In explosive areas electrostatically charged

substances like unearthed cladding or nonconductive plastics must be grounded (earthed).

For further guidance please consult your local

safety guidelines relating to static electricity.

d) Noise protection

The guidelines for noise in the ordinance and

workplace are stated in the local regulations and

standards. Generally, the level of the guideline values

depends on the nature of the activity.

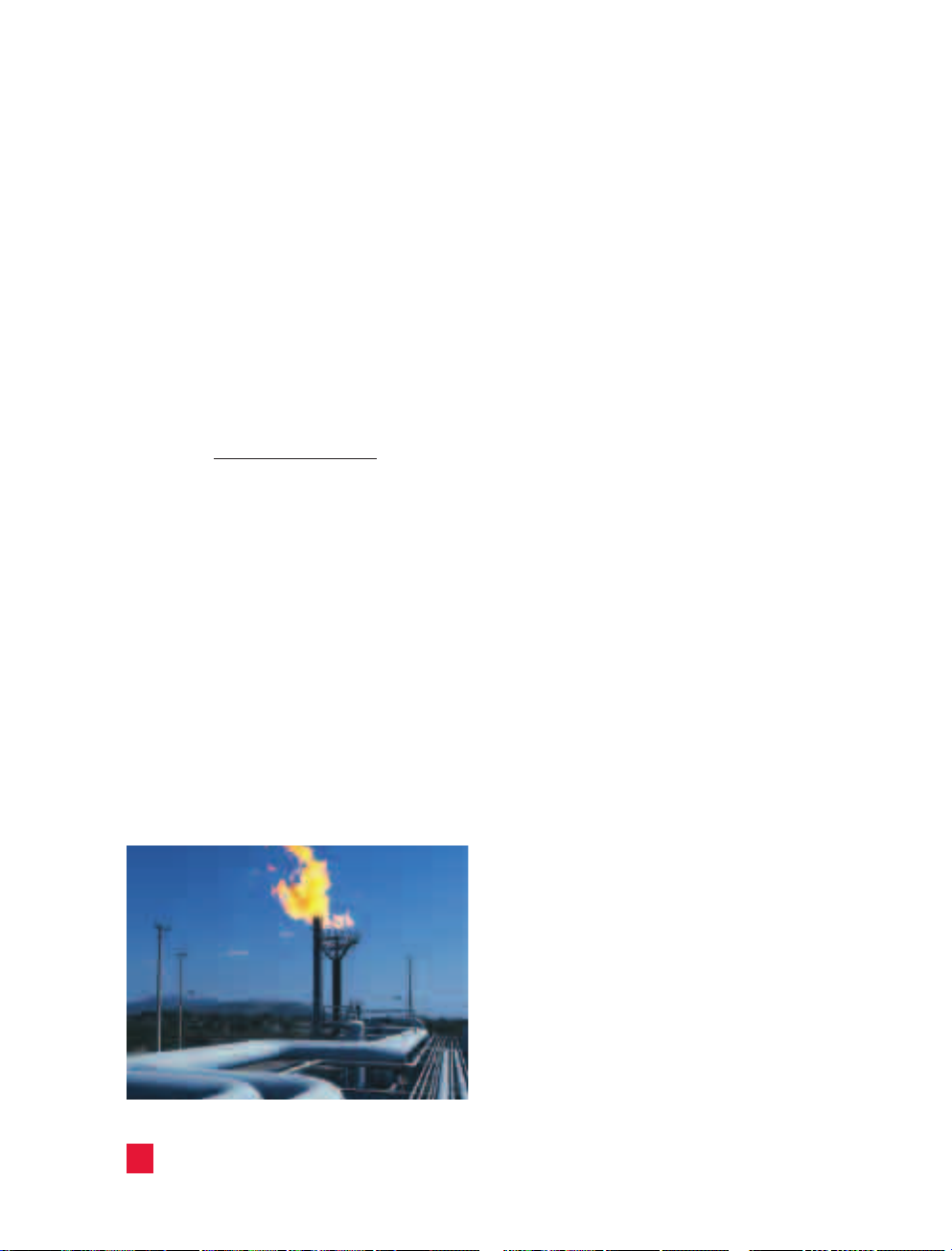

C. Economics

In the industry there are two grades of insulation.

The first grade focuses on reducing heat losses

and the prevention of injuries to people operating

or working nearby the installations. The second

grade of insulation, the so called “economical

insulation thickness” focuses on significant heat

loss reduction and as a result achieving a better

return on investment.

a) Economical insulation thickness

Insulation reduces the heat losses from the

object. Thethicker the insulation, the greater

theheat reduction and consequently, the more

energy is saved. However, the investment and

expenditure, e.g. for depreciation, interest rates

and higher maintenance costs also rise ifthe

insulation thickness is increased. At a certain

insulation thickness, the sum of the two cost flows

reaches a minimum. This value is known as the

economical insulation thickness. Aqualitative

curve of a similar costs function is shown below.

Economical

insulation

thickness

Total costs

The sound propagation of installation components

can be reduced using insulation systems. The

nature and effect of the sound insulation depend

onthe frequency and the sound pressure level.

Insulation costs

Heat loss costs

Insulation thickness

The energy costs cannot be based solely on the

current price. Developments over recent years

indicate energy costs will continue to rise.

17

Page 21

1.1 Planning and preparation1.1 Planning and preparation

C. Economics

Increasing energy prices are tending to bring

about a shift in economic insulation thicknesses

towards larger thicknesses.

b) Pay-back time

In addition to the economical insulation thickness,

another frequently used economical parameter is

the return on investment period (ROI), also

referred to as the payback period. This is defined

as the period within which the cost of the

insulation is recuperated through savings on heat

loss costs.

ROI period =

In the case of industrial insulation systems, the

return on investment period is generally very

short, often being much less than one year.

Considering only the return on investment period,

however, can be deceptive, as this approach

disregards the service life of the installation.

With long-life installations, it is advisable to select

higher insulation thicknesses, even if this means

accepting a longer return on investment period.

Throughout the entire service life of the

installation however, the increased insulation

thickness results in a significantly higher return

on the investment in insulation and achieves a

much more economic operation of the installation.

Costs of the insulation

annual saving

[a]

D. Environmental

The burning of fossil fuels, such as coal, oil or

gas, not only depletes the available primary

energy sources, but also, due to the emission of

carbon dioxide (CO²) into the atmosphere, places

aburden on the environment.

The increasing CO² concentration in the Earth’s

atmosphere plays a significant part in the global

increase in temperature, also referred to as the

“greenhouse effect”. CO² absorbs the thermal

radiation emanating from the earth’s surface

andin doing so reduces the dissipation of heat

into space. This is leading to a change in the

world’s climate with as yet inestimable

consequences. Reducing CO² emission can only

beachieved through more efficient management

of fossil fuels. Increasing the insulation

thicknesses is essential for the reduction of CO²

emissions.

Reducing CO² emissions also has a positive

financial benefit for businesses within the context

of an emissions trading scheme. The benefits of

increased insulation thicknesses in industrial

installations are twofold, as the costs for both

energy consumption and CO² emissions are

decreased.

E. Corrosion Prevention

See Chapter 1.1.3

18

Page 22

preparation

Planning and

1.1.2 Design & planning of the

insulation work

Requirements for insulation work must be

included in the design and construction phase of

industrial plants. It is advisable to involve all

project managers at an early stage to avoid

unnecessary issues or delays.

All preparatory works must be completed

according to the relevant insulation standards.

The following preconditions must be fulfilled:

If necessary, work has been carried out on the

object to protect against corrosion

Tracing and technical measurement equipment

have been installed

The minimum distance between the objects

hasbeen observed (see illustrations on pages

12and 13)

Surfaces have no coarse impurities

Mounting supports have been installed on the

object to accommodate the support structure

Collars and sealing discs have been fitted to

theobject

Taps on the object are long enough to ensure

that flanges lie outside the insulation and can

be screwed on without hindrance

Supports are designed so that insulation,

watervapor retarders and cladding can be

professionally installed

The insulation can be applied without any

obstacles (e.g. scaffolding)

Welding and bonding work has been carried out

on the object

The foundations have been completed

1.1.3 Corrosion prevention

Industrial facility disruptions are due to the lack

of, or inadequate forms of, protection against

corrosion. This considerably reduces the service

life of industrial plants, and more frequently,

essential shutdown or overhaul work impairs the

efficiency of the installation.

It is commonly, but wrongly, assumed that the

insulation system also protects an installation

against corrosion. For each installation it must be

determined whether protection against corrosion

is required and, if so, which are the appropriate

measures.

Generally, the design of the insulation system &

corrosion protection will depend on the following

parameters.

Operation of the installation

- Continuous operation

- Interrupted/intermittent operation

- Operation involving varying temperatures

- Type of plant (e.g. Petrochemical,

pharmaceutical, etc)

Operating and Ambient temperatures of the

installation

Metals and Materials Used

- Non-alloy or low-alloy steel

- Austenitic stainless steel

- Copper

External influences upon the installation

- Environment of the installation (chemically

aggressive?)

- Location

The best practices may vary per country and/or

standard. The design of corrosion protection is

often carried out on the basis of a small selection

of standards, such as ASTM C795, that do not

adequately take into account all the specific

features of protecting against corrosion in

insulation systems. For further details on

corrosion protection we recommend referring

NACE SP0198 and the ROXUL® Corrosion Under

Insulation (CUI) brochure.

19

Page 23

1.1 Planning and preparation1.1 Planning and preparation

1.1.3 Corrosion prevention

In the case of cold insulation, if the object is

made of non-alloy or low alloy steel, it must be

protected against corrosion.

In the case of objects made, for example, of

austenitic stainless steel or copper, the

installation must be tested in each individual

case by the planner to determine whether

protection against corrosion is necessary.

Objects made from austenitic stainless steel do

not require protection against corrosion if the

temperature never – even for a short period –

exceeds 120 °F (50 °C)

NOTE

Protection against corrosion should be applied

in the case of all installations made from

non-alloy or low-alloy steel where the

operating temperatures are below

250 °F (120 °C). Protection against corrosion

may be omitted in the case of:

Installations operating continuously under

extremely cold conditions [below -50 °F

(-50 °C)] such storage tanks.

Insulated surfaces of power plant

components, such as boiler pressure

components, flue gas and hot air ducts and

steam pipe systems with operating

temperatures that are constantly above

250 °F (120 °C).

If austenitic stainless steel is insulated with any

type of insulation - For temperatures of up to

930 °F (500 °C), aluminum foil of not less than

.06 mm thick to be applied to the steel surface,

arranged to shed water with overlaps of not less

than 2" (50 mm) at the joints.

CINI Manual “Insulation for industries”

CINI recommends applying corrosion protection

prior to the insulation work at any time.

In all phases, pay attention to CUI (corrosion

under insulation) prevention: design,

construction, paint & coating work, application

of the insulation system, inspection and

maintenance. Equipment and piping sections

like nozzles, supports etc. should be designed

and maintained to prevent ingress of water into

the insulation system.

The “paint” specifications are split up into:

-

Construction material

(carbon steel, stainless steel)

- Temperature ranges from -22 °F (-30 °C) to

1000 °F (540 °C) with special attention to the

temperature range between 0 °F (-20 °C) and

300 °F (150 °C).

The corrosion protection can be achieved using

aluminum foil wrapping, thermal sprayed

aluminum (TSA) or paint.

Protection against corrosion may be omitted in the

case of installations operating continuously under

extremely cold conditions [< -22 °F (-30 °C)]

Application

Before applying corrosion protection coating, the

surface must be free from grease, dust and acid

and, for better adhesion, the priming coat should

be roughened. Blasting is recommended as a

surface preparation method (with austenitic

stainless steel, use a ferrite free blasting

abrasive).

Observe the corresponding processing guidelines

of the coating manufacturer. If metals with

different electrochemical potentials, such as

aluminum and copper, come into contact with one

another, there is a risk of electrochemical

corrosion. If necessary, this can be avoided using

insulating, intermediate layers such as nonmetallic straps. The presence of moisture will

increase the development of electrochemical

corrosion.

20

Page 24

preparation

Planning and

The table further on this page, which has been

derived from the standard DIN 4140, indicates the

initial risks of electrochemical corrosion in cases

where various combinations of metals are used.

Electrochemical Corrosion Potential

Material Combination material

Metal

Zinc

Aluminum

Ferritic steel

Lead

Austenitic stainless

steel

Copper

Surface ratio in proportionto

combinationmaterial

Small - M M H H H

Large - L L L L L

Small L - L H H H

Large L - L M L H

Small L L - H H L

Large L L - L L L

Small L L L - H H

Large L L L - M M

Small L L L L - M

Large L L L L - L

Small L L L L L -

Large L L L L L -

Zinc Aluminum

NOTE

The table does not take into account forms

ofcorrosion with other root causes, such as

stress corrosion. For further information, see

Chapter 2.2 “Product properties & test

methods” – AS-Quality on page 115.

Ferritic

steel

Lead

Austenitic

stainless

steel

Copper

L - Light or little corrosion to material

M - Moderate corrosion to material, for example, in very humid atmospheres

H - Heavy electrochemical corrosion to material

Observation: The table shows the corrosion of the “material”, and not that of the “combination material”.

“Light” means: “small-scale in proportion to the combination material”, “heavy” means: “large-scale in

proportion to the combination material”.

Example 1: Material is a zinc galvanized screw in combination material, a cladding made from austenitic

stainless steel: Row “zinc small”: “H” – heavy corrosion of the screw.

Example 2: Material , a cladding made from austenitic stainless steel screwed on with a screw galvanized

with combination material zinc: Row “austenitic stainless steel large”. “L” – the corrosive attack upon the

austenitic steel is light.

21

Page 25

1.1 Planning and preparation

1.1.4 Storage of insulation materials

Incorrect storage of insulation materials outdoors

can cause insulation to deteriorate. Insulation

should be protected when stored, during

installation and when fitted to minimize moisture

exposure, physical damage and contamination. If

storage indoors is not possible, protect the

insulation material from weather influences by

covering it with waterproof material. Insulation

should also be stored a minimum of four inches

above ground and kept on a solid surface away

from ponding water and ground moisture.

Moisture causes many types of corrosion that

virtually never develop in a dry system. The major

types of corrosion in relation to insulation

technology are oxygen, electrochemical and stress

corrosion. Insulation materials that are

manufactured with properties (such as low

chloride content or added inhibitors) can

irrevocably lose these properties when exposed to

contamination or additives are leached out.

The thermal conductivity of water is approximately

25 times greater than that of air. An increase in

moisture therefore results in an increase in the

thermal conductivity of the insulation and,

correspondingly, a decrease in the insulation

efficiency. Higher moisture can also mean a

significantly higher weight, which, as a rule, is not

taken into account in the static design of an

insulation system. It is therefore important to

protect the insulation from moisture after

installation, as well as ensure insulation is

thoroughly dry when installed (especially in sealed

application at low temperatures or where the

temperature cycles).

22

Page 26

1. System solutions

1.2 Insulation of piping

Piping plays a central role in many industrial

processes in chemical or petrochemical

installations such as power plants, as it connects

core components such as appliances, columns,

vessels, boilers, turbines etc. withone another

and facilitates the flow of materials andenergy.

Toguarantee a correct process cycle, the

condition of the media within the pipes must

remain within the set limitations (e.g.

temperature, viscosity, pressure, etc.). In addition

to the correct isometric construction and

fastening of the piping, the piping insulation also

has an important function. It must ensure that

heat loss are effectively reduced and that the

installation continues to operate economically and

functionally on a permanent basis. This is the only

way to guarantee the maximum efficiency of the

process cycle throughout the design service life

without losses as a result of faults.

Requirements for industrial piping

The basic efficiency and productivity factors of

piping for the processing industry include: energy

efficiency, dependability and reliability under

different conditions, functionality of the process

control, appropriate support structure suitable for

the operating environment, as well as mechanical

durability. The thermal insulation of piping plays a

significant role in fulfilling these requirements.

Thermal insulation

The functions of proper thermal insulation for

piping include:

Reduction of heat losses (cost savings)

Reduction of CO² emissions

Frost protection

Process control: ensuring the stability of

theprocess temperature

Noise reduction

Condensation prevention

Personnel protection against high temperatures

ProRox® products for pipe insulation

ROXUL Inc offers a wide range of high-quality stone

wool insulation products for the insulation of

industrial plants. These products are part of our

extensive ProRox® range for industrial insulation.

With this specific field of application in mind we

developed our pre-formed pipe sections and pipe

wrap (mat) products for pipe insulation. All these

products are easy to install and contribute to a high

level of efficiency, functionality and reduced heat

losses. Continuous internal and external inspection

and high levels of quality assurance ensure the

consistently high quality ofall ROXUL® products.

The examples of use below cannot fully take into

account the particular circumstances of the

construction-related factors. Determine whether

the products are suitable for the corresponding

application in each individual case. If in doubt,

consult the ROXUL Technical Services Team.

The applicable standards and regulations must

also be observed. A few examples follow:

NACE SP0198 (Control of corrosion under

thermal insulation and fireproofing materials - a

systems approach)

MICA (National Commercial & Industrial

Insulation Standards)

DIN 4140 (Insulation works on technical

industrial plants and in technical facility

equipment)

AGI Q101 (Insulation works on power plant

components)

CINI-Manual “Insulation for industries”

BS 5970 (Code of practice for the thermal

insulation of pipework, ductwork, associated

equipment and other industrial

installations)

of piping

Insulation

23

Page 27

1.2 Insulation of piping

Hot insulation systems

Principally, a thermal insulation structure for

piping consists of an appropriate insulating

material, usually covered by sheet metal cladding.

This protects the object and the insulation from

external influences such as the weather and

mechanical loads. Spacers are also essential with

insulation such as wired mats, which do not offer

sufficient resistance to pressure to hold the

weight of thecladding and other external loads.

These spacers transfer the cladding loads directly

onto the object. In thecase of vertical piping,

support structures are fitted totake on the loads

of the insulation and the cladding. Ingeneral,

support structures and spacers form thermal

bridges.

Selecting a suitable insulation system depends on

numerous parameters. These are described in

greater detail in Chapter 1.1. Regarding the

different forms of pipe insulation, a fundamental

distinction can be drawn between the following

insulation systems.

Insulation with pipe sections

Generally, the best insulation is achieved using

ProRox® Pipe Sections and can be used up to

temperatures of 1400 °F (760 °C) when using

ProRox® PS 980NA Type V insulation. They are

supplied ready split and hinged for quick and easy

snap-on assembly and are suitable for thermal

and acoustical insulation of industrial pipe work.

Due to their excellent fit and high compression

resistance, pipe sections can often be applied in

asingle layer without any additional spacers.

If multiple layers are required, ROXUL® can also

supply double layered - ‘nested’ - pipe sections.

This reduces installation costs considerably. Also

the number of thermal bridges, which have a

negative influence on the insulation, is greatly

reduced, while a lower thickness may be applied

compared to wired mats.

Using pipe sections for the insulation of pipes

results in considerably reduced installation time

and costs. The lack of spacers and “unforeseen”

gaps minimizes heat losses and the risk of

personal injuries due to hot spots on the cladding.

At temperatures above 550 °F (300 °C), the

provisional application of spacers must be

determined in each individual case.

Pipe sections are always precisely tailored to the

corresponding pipe diameter to minimize the risk

of convection and processing defects. ROXUL pipe

sections are available in diameters of

NPS 1/2" (23 mm) to NPS 28" (713 mm).

Insulation with load-bearing pipe wraps

(mats)

Load-bearing pipe wraps (mats), such as

ENERWRAP® MA 960NA are the latest development

in the insulation sector. ENERWRAP® MA 960NA is

a stone wool (mineral wool) insulation wrap

available with a black mat or reinforced foil facing

and is designed for easy installation of large

diameter pipes. Typical applications include:

pipe diameters >NPS 12" (326 mm), or;

piping with a high number of shaped pieces

such as elbows or T-joints.

ENERWRAP® MA 960NA can be applied up to

temperatures of 1200 °F (650 °C). It is highly

compression resistant and can be applied without

any additional spacers.

24

Page 28

Consequently the number of thermal bridges,

which have a negative influence on the insulation,

is greatly reduced.

Pipe insulation with wired mats has been a

time-tested universal solution for many decades

now. Due to their flexibility and high temperature

resistance, wired mats can be easily cut and

mounted onto piping. Wired mats are ideal for

application in situations where the use of pipe

sections or load bearing wraps (mats) is difficult

or impossible. Historically this included large

diameter pipes and high temperatures (where the

wired mat provided structural integrity to the

insulation at high temperatures), but advanced

modern ProRox® pipe section and ProRox® pipe

wraps (mats) have provided a suitable alternative

to wired mats. Wired mat is still used today in

piping with a high number of shaped pieces such

as elbows or T-joints.

Wired mats have a relatively low resistance to

pressure and from a practical point of view should

only be mounted in combination with spacers or

support structures. Because of the resulting

thermal bridges, better insulation performances

are often achieved in thelower and middle

temperature range [up to 550 °F (300 °C)] with

pipe sections or load bearing wraps (mats).

of piping

Insulation

The result is considerably reduced installation

time and costs. The lack of spacers and

“unforeseen” gaps minimizes heat losses and the

risk of personal injuries due to hot spots on the

cladding.

corresponding length of the pipe circumference

on site and are fastened with clamps.

Pipe wraps (mats) are tailored to the

Insulation with wired mats

Wired mats, are lightly bonded stone wool wraps

(mats), usually stitched with galvanized wire onto

a galvanized wire mesh. For more details on

ProRox® wired mat insulation products, contact

your ROXUL® representative.

25

Page 29

1.2 Insulation of piping

Comparison of the different insulation

systems

The particular advantage of pipe sections and pipe

wraps (mats) lies in the fact that support

structures are not required and therefore thermal

bridges caused by the insulation are minimized or

removed. On the other hand, wired mat systems

have their advantages due to their ability to be

structurally sound when insulating around

irregularly shaped pipe sections.

The advantages of pipe sections and load-bearing

pipe wraps (mats) at a glance are:

It is not necessary to install spacers or support

structures.

Faster application without the interference of

spacers.

Both products offer an even, firm surface for

installing the sheet cladding.

Insulation system with a spacer ring

The lack of spacers gives rise to lower heat

losses.

It yields an even surface temperature across

the sheet cladding.

In comparison to wired mats, a more shallow

insulation thickness can be applied. Theoperating

costs of the installation decrease as a result of

lower heat loss.

Generally speaking, a spacer or support structure

functions as a thermal bridge, as a result of which

theheat loss in the total insulation is increased

considerably.

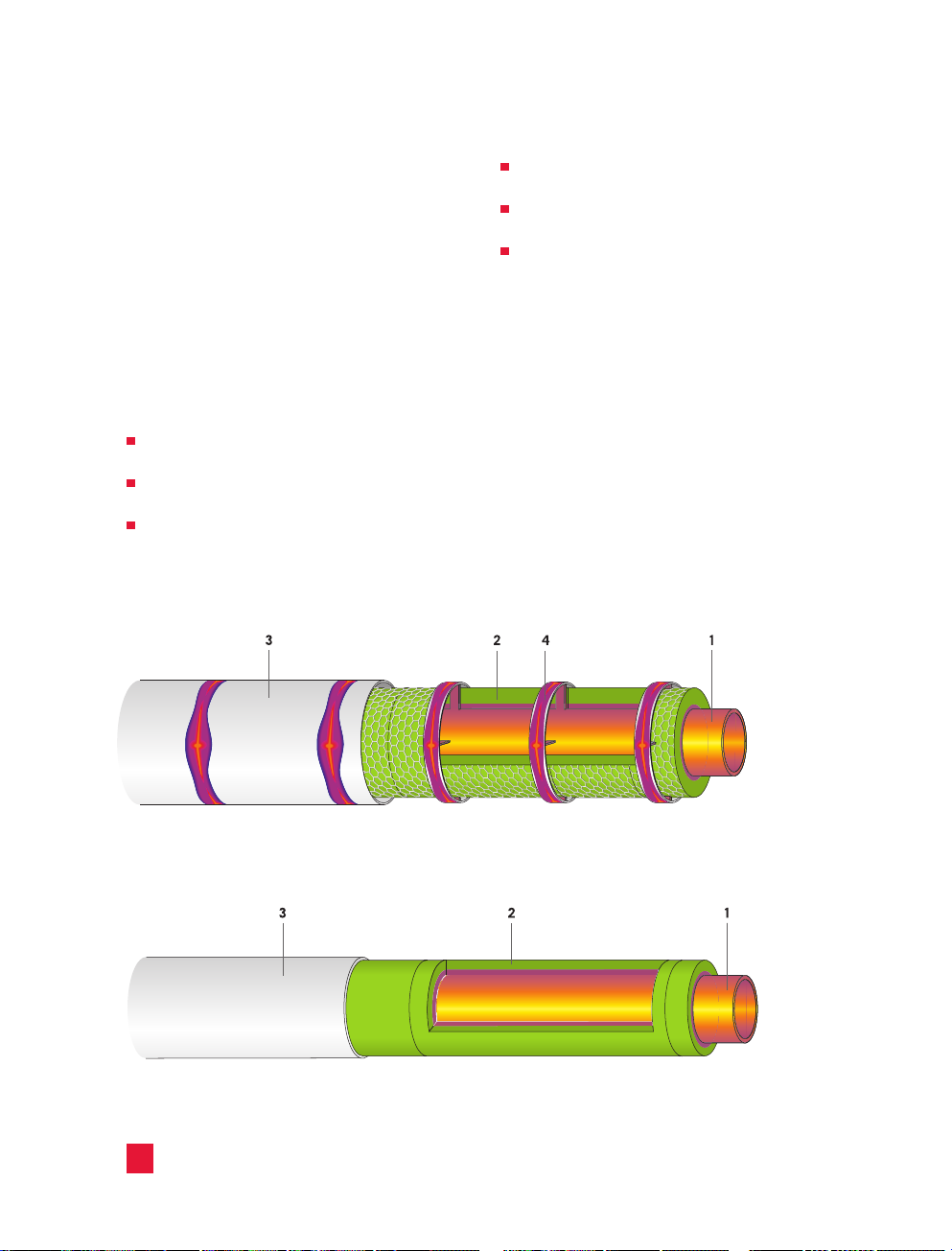

1. Pipe - 2. Insulation: ProRox® Wired Mats - 3. Cladding - 4.Spacer ring

Insulation system without a spacer ring

1. Pipe - 2. Insulation: ProRox® Pipe Sections or Pipe Wraps (Mats): ENERWRAP® MA 960NA - 3. Cladding

26

Page 30

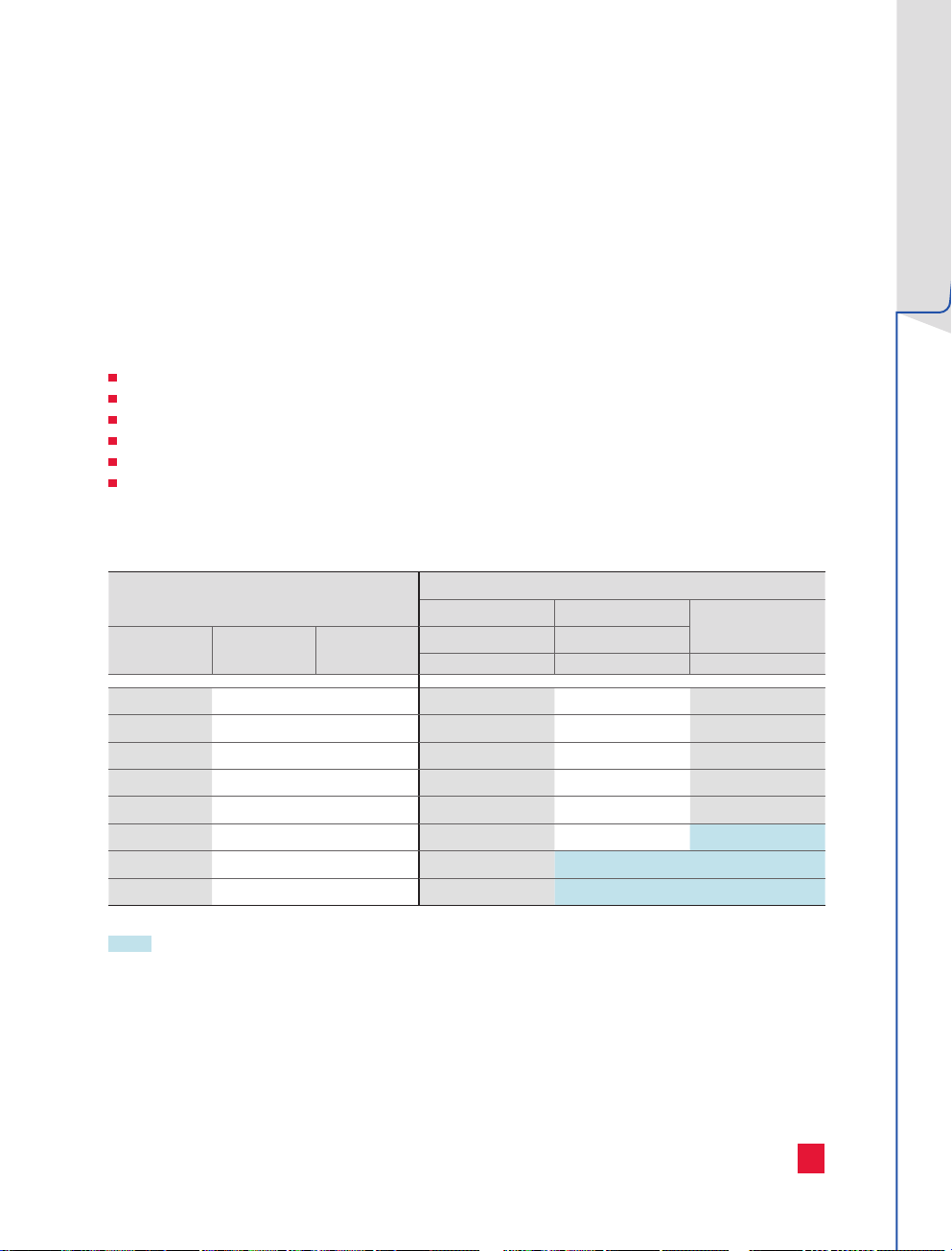

Required insulation thicknesses

If the three insulation systems are compared,

taking into consideration similar heat losses,

clear advantages are seen with regard to the

insulation thicknesses with systems using pipe

sections or pipe wraps (mats). These do not use

spacers, in contrast to insulation systems made

using wired mats. The table below shows the

required insulation thicknesses taking into

account the following boundary conditions:

Medium temperature: 480 °F (250 °C)

Ambient temperature: 50 °F (10 °C)

Wind speed: 1.1 mph (5 m/s)

Cladding: Aluminum

Heat loss: 150 BTU/ft.hr (150 W/m)

Application of spacers in the case of wired mats

of piping

Insulation

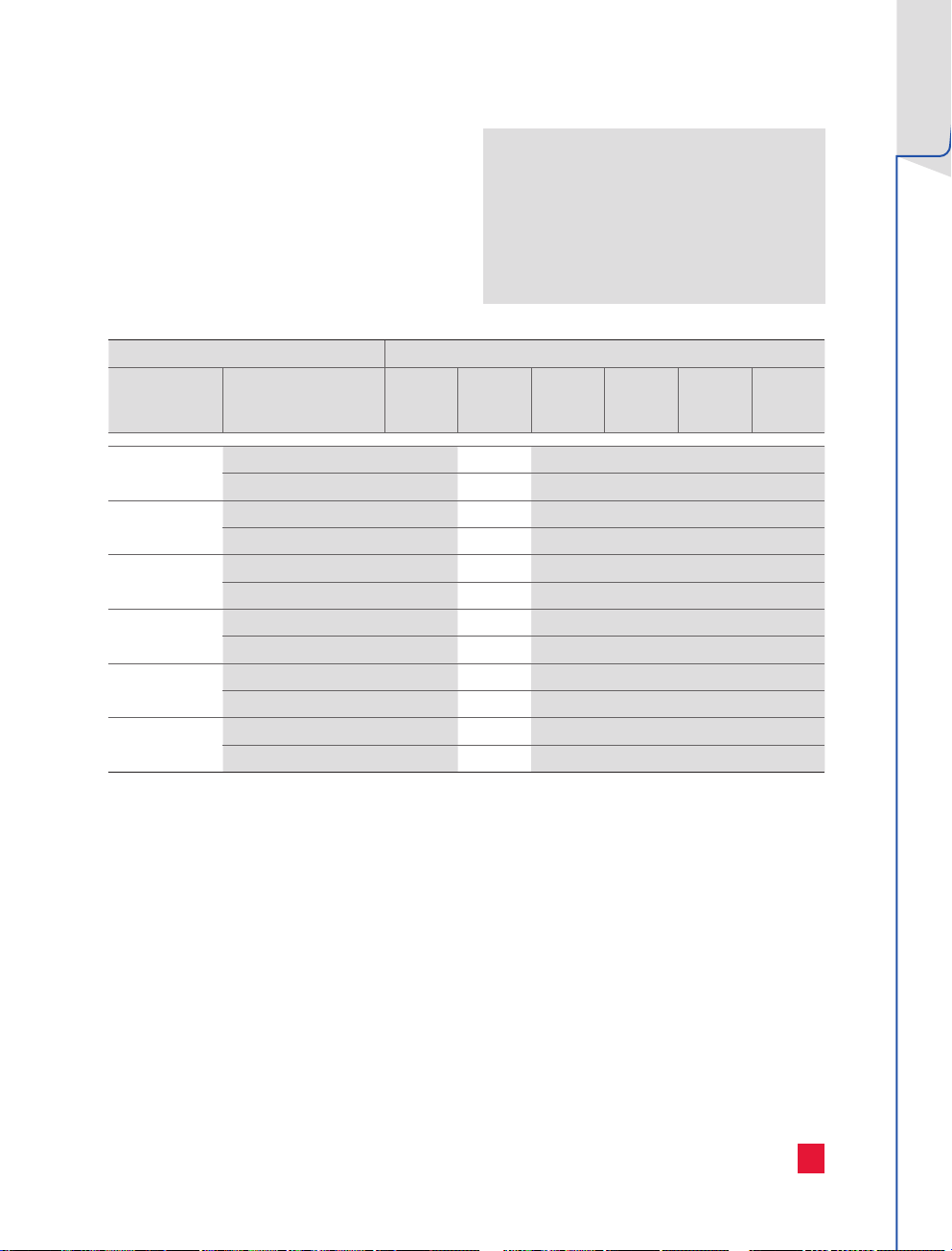

Minimum Insulation Thickness

NA

ENERWRAP® MA 960

NA

Wired mats

NPS

(inch)

Pipe Diameter

Nominal diameter

Ø DN

Pipe diameter

(mm)

Pipe sections Pipe wraps (mats)

®

PS 960

ProRox

inch inch inch

2 50 60 1" n.a. n.a.

3 80 89 1" n.a. n.a.

4 100 108 1.5" n.a. n.a.

6 150 159 2" n.a. n.a.

8 200 219 2.5" n.a. 5"

10 250 273 3" n.a. 6"

12 300 324 4" 4" 7.5"

14 350 356 4.5" 4.5" 8"

Multiple layer insulation n.a. = not applicable

27

Page 31

1.2 Insulation of piping

Selection of pipe insulation systems

Generally, the best insulation is achieved using

ProRox® Pipe Sections. The preformed sections

are quick and easy to install. Their excellent fit

and high compression resistance means pipe

sections can be applied in a single layer without

any additional spacers. They also have a lower

insulation thickness. Pipe wraps (mats), are

usually applied for the insulation of large pipe

diameters and can be applied to shaped pieces

like elbows and T-joints.

Comparison

®

ProRox

pipe sections and pipe wraps (mats)

offer theadvantage that spacers are generally

not required.

®

ProRox

pipe sections and pipe wraps

(mats) are applied more quickly without the

inter ference of spacers.

Both products offer an even, firm surface

for installing the cladding.

The lack of spacers creates lower heat loss.

It yields an even surface temperature

across the cladding.

In comparison to wired mats, a more

shallow insulation thickness can be used.

With a same insulation thickness, the

operational costs of the installation

decrease as a result of lower heat losses.

Generally speaking, a spacer or support structure

functions as a thermal bridge, as a result of which

the heat loss in the total insulation is increased

considerably.

The design of an insulation system depends upon

many factors such as the dimensions, mechanical

loads, safety aspects, economics, etc.

Consequently this also requires a considered

selection of the insulation material.

28

Page 32

1.2.1 Insulation with pipe sections

Generally, the best insulation is achieved using

ProRox® Pipe Sections. The sections can be used

up to temperatures of 1400 °F (760 °C) when

using ProRox® PS 980NA Type V insulation. They

are supplied ready split and hinged for quick

and easy snap-on assembly and are suitable for

thermal and acoustic insulation of industrial pipe

work. Their excellent fit and high compression

resistance means pipe sections can be applied

in a single layer without any additional spacers

or support structures. Consequently the number

of thermal bridges, which have a negative

influence on the insulation, is greatly reduced,

while a low thickness may be applied compared

to wired mats. The result is considerably reduced

installation time and costs. The lack of spacers

and “unforeseen” gaps minimizes heat loss and

the risk of personnel injuries due to hot spots on

the cladding.

At temperatures above 550 °F (300 °C), the

provisional application of spacers must be

determined in each individual case. ProRox®

Pipe Sections are available in a wide range of

diameters, ranging from NPS 1/2" (23 mm) to

36" (914 mm)

NOTE

D

ue to their low thermal conductivity, better

thermal insulation values can be achieved

with pipe sections than with wired mats.

With insulation on straight pipe sections, a

combination of both products in the same

insulation thickness is therefore not advisable.

If this combination is essential, for example,

in the case of bends or shaped pieces, it is

vital to select the correct insulation thickness.

This is the only way to guarantee that no

unexpected, potentially hazardous surface

temperatures occur.

Insulation thicknesses to guarantee

protection against contact

The table below is an initial guide to help select

suitable insulation thicknesses for the guards.

Itisbased on the following boundary conditions:

Ambient temperature: 75 °F (25 °C)

Wind speed: 1.1 mph (0.5 m/s)

Cladding: Aluminum

Maximum surface temperature: 140 °F (60 °C)

Insulation: ProRox® PS 960

NA

pipe sections

of piping

Insulation

Pipe Diameter Temperature

Nominal

NPS

(inch)

he thicknesses mentioned above should be seen as an indication. In the event of differing boundary conditions, please

T

contact the ROXUL

or NAIMA 3E Plus

diameter

Ø DN

1 25 33 0.5" 0.5" 0.5" 0.5" 1" 1" 1" 1"

2 50 60 0.5" 0.5" 0.5" 1" 1" 1" 1.5" 1.5"

3 80 89 0.5" 0.5" 1" 1" 1" 1.5" 1.5" 2"

4 100 114 0.5" 0.5" 1" 1" 1" 1.5" 1.5" 2"

6 150 168 0.5" 1" 1" 1" 1.5" 1.5" 2" 2"

8 200 219 0.5" 1" 1" 1.5" 1.5" 1.5" 2" 2.5"

10 250 273 0.5" 1" 1" 1.5" 1.5" 2" 2" 2.5"

12 300 324 0.5" 1" 1" 1.5" 1.5" 2" 2" 2.5"

Pipe

diameter

(mm)

®

Technical Services Team. The thermo-technical engineering program "ROCKASSIST" (coming soon)

®

can be used to design the insulation according to the specific requirements.

<250 °F

(<120 °C)

inch inch inch inch inch inch inch inch

300 °F

(150 °C)

350 °F

(175 °C)

400 °F

(200 °C)

450 °F

(230 °C)

500 °F

(260 °C)

550 °F

(290 °C)

(315 °C)

600 °F

29

Page 33

1.2 Insulation of piping

Installation

Before starting the insulation works, ensure

that all preparatory work on the object has been

completed. Refer to Chapter 1.1 for details.

The ProRox® PS 900 Series pipe sections are

mounted directly onto the pipe to form a close

fit. With horizontal pipes, the lengthwise joint of

the pipe section should be turned towards the

underside at the 6 o’clock position. With vertical

pipes, the lengthwise joints should be staggered

at an angle of 30 ° to one another. Secure the pipe

sections with galvanized binding wire or with steel

bands. With an insulation thickness exceeding

5 inches (120 mm) [or temperatures > 550 °F

(300 °C)], install the insulation in at least two

layers. If the insulation is assembled in multiple

layers, the joints of the individual insulation layers

must be staggered.

Support structures and spacers

Spacers are not generally essential in insulation

systems with pipe sections. With pipes that are

exposed to large mechanical loads (e.g. strong

vibrations) and/or temperatures above

550 °F (300 °C), determine whether a spacer ring

is required in each individual case.

With pipes that have been installed vertically,

with a height in excess of 13 feet (4 m), fit support

structures to transfer the dead load of the

insulation system onto the pipe. Attach the first

support ring to the lowest point of the vertical

pipe. The distance between the support rings

should not exceed approximately 13 feet (4 m).

1. Pipe - 2. Insulation: ProRox® Pipe Sections -

3. Clamp or binding wire - 4. Sheet cladding -

5. Sheet-metal screw or rivet

30

Page 34

1.2.2 Insulation with pipe wraps (mats)

Pipe wraps (mats), such as ENERWRAP® MA 960NA

are the latest development in the insulation

business. ENERWRAP® MA 960NA is a stone wool

insulation wrap available with black mat or

reinforced foil facing. The flexible application

makes the product easy to cut and install. Pipe

wraps (mats) are ideal for installations involving

large diameter pipes and a high number of shaped

pieces such as elbows or T-joints.

ENERWRAP® MA 960NA can be applied up to

temperatures of 1200 °F (650 °C). Due to the high

compression resistance, pipe wraps (mats) can be

applied without additional spacers in many cases.

Consequently, the number of thermal bridges

which have a negative influence on the insulation,

is greatly reduced.

Pipe Diameter Temperature

NPS

(inch)

Nominal

diameter

Ø DN

Pipe

diameter

(mm)

<250 °F

(<120 °C)

inch inch inch inch inch

The result is considerably reduced installation

time and costs. The lack of spacers minimizes

heat loss and the risk of personal injuries caused

by hot spots on the cladding. Pipe wraps (mats)

are precisely tailored to the corresponding length

of the pipe circumference on site and are fastened

with clamps.

Insulation thicknesses to guarantee

protection against contact

The table below is an initial guide to help select

suitable insulation thicknesses for the guards. It is

based on the following boundary conditions:

Ambient Temperature 75 °F (25 °C)

Wind speed: 1.1 mph (0.5 m/s)

Cladding: Aluminum

Maximum surface temperature: 140 °F (60 °C)

Insulation: ProRox® PS 960

300 °F

(150 °C)

400 °F

(200 °C)

NA

500 °F

(260 °C)

600 °F

(315 °C)

of piping

Insulation

12 300 324 0.5" 1" 1.5" 2" 2.5"

16 400 406 1" 1" 1.5" 2" 3"

20 500 508 1" 1" 1.5" 2.5" 3"

The thicknesses mentioned above should be seen as an indication.

In the event of differing boundary conditions, please contact the ROXUL

engineering program "ROCKASSIST" (coming soon) or NAIMA 3E Plus

the specific requirements.

®

Technical Services Team. The thermo technical

®

can be used to design the insulation according to

31

Page 35

1.2 Insulation of piping

Installation

Before starting the insulation works, ensure that

all preparatory work on the object has been

completed. Refer to Chapter 1.1 for details.

Cut the wraps (mats) to the required length, based

on the external insulation diameter (pipe diameter

+ two times the insulation thickness). Fasten the

wrap (mat) firmly to the pipe with steel bands.

Ensure that the wraps (mats) form a tight joint

and that no lengthwise joints or circular joints are

visible. The joints of the individual wraps (mats)

are securely taped with self-adhesive aluminum

tape. If the insulation is assembled in multiple

layers, the joints of the individual insulation layers

must be staggered.

Support structures and spacers

Spacers are not generally essential in insulation

systems with load bearing wraps (mats). With

pipes that are exposed to large mechanical loads

(e.g. strong vibrations), determine whether a

spacer ring is required in each individual case.

With pipes that have been installed vertically, with

a height in excess of 14 feet (4 m), fit support

structures to transfer the dead load of the

insulation system onto the pipe. Attach the first

support ring to the lowest point of the vertical

pipe. The distance between the support rings

should not exceed approximately 14 feet (4 m).

1. Pipe - 2. Insulation: ENERWRAP® MA 960NA - 3. Self-adhesive aluminum tape - 4. Steel bands - 5. Sheet cladding -

6.Sheet-metal screw or rivet

32

Page 36

1.2.3 Insulation with wired mats

Pipe insulation with wired mats has been a

time-tested universal solution for many decades

now. Due to their flexibility and high temperature

resistance, wired mats can be easily cut and

mounted onto the piping. These wired mats are

ideal for application on large pipe diameters and

shaped pieces as elbows or T-joints.

Wired mats have a relatively low resistance to

pressure and from a practical point of view should

only be mounted in combination with spacers.

Because of theresulting thermal bridges, better

insulation performances are often achieved in the

lower and middle temperature range [up to 550 °F

(300 °C)] with pipe sections or load bearing wraps

(mats) rather than with wiredmats.

Installation

Before starting the insulation works, ensure that

all preparatory work on the object has been

completed. Refer to Chapter 1.1 for details.

With an insulation thickness of more than 5 inches

(120 mm) [or temperatures > 550 °F (300 °C)],

apply multiple layer insulation. If the insulation is

assembled in multiple layers, the lengthwise and

crosswise joints of the individual insulation layers

must be staggered. If mechanical loads are

anticipated, use steel straps to secure the wired

mats.

of piping

Insulation

Cut the wrap (mat) to a length so that it can be

fitted to the pipe with slight pre stressing. Wire

the closing joints (lengthwise and circular) of the

wraps (mats) together using steel wire or secure

with wrap (mat) hooks. Stainless steel pipes and

pipes with an operating temperature > 750 °F

(400 °C) can only be insulated with wired mats

with stainless steel stitching wire and wire netting

to prevent galvanic corrosion cracking.

1. Pipe - 2. Insulation: ProRox® Wired Mats - 3. Stitching

of the joint edge with binding wire - 4. Sheet cladding -

5. Sheet-metal screw or riveted bolt - 6. Spacer ring

1. Pipe - 2. Insulation: ProRox® Wired Mat- 3. Joint

edge closed with mat hooks - 4. Sheet-metal cladding -

5.Sheet-metal screw or riveted bolt - 6. Spacer ring

Support structures and spacers

As wired mats do not offer sufficient resistance

topressure to bear the weight of the cladding,

spacer or support structures should be applied.

More information can be found in 1.2.4.

With pipes that have been installed vertically,

witha height in excess of 14 feet (4 m), fit support

structures to transfer the dead load of the

insulation system onto the pipe. Attach the first

support ring to the lowest point of the vertical

pipe. The distance between the support rings

should not exceed approximately 14 feet (4 m).

33

Page 37

1.2 Insulation of piping

m

a

x

.

2

7

"

(

7

0

0

m

m

)

1.2.4 Insulation support

A. Spacers

The purpose of spacers is to keep the cladding at

a predetermined distance from the pipe. Spacers

are essential when the insulation (e.g. wired mats)

cannot bear the mechanical load of the cladding.

The use of spacers is generally not necessary

ifpipe sections or pipe wraps (mats) are used.

Consideration should be given to support

structure or spacers on pipes where mechanical

loading (e.g. strong vibrations) of the insulation is

expected and/or the temperature is higher than

550 °F (300 °C).

Spacer rings usually consist of metal rings on

which the sheet cladding rests, and metal or

ceramic bars used as spacers, which rest on the

pipe. Elastic spacers such as Omega clamps are

frequently used to reduce the transference of

vibrations. With steel spacers, apply at least three

bars, whereby the maximum distance – measured

as circumference of the external ring – must be a

total of maximum 16 inch (400 mm). With ceramic

spacers, apply at least four bars at a maximum

permissible distance of 16 inch (400 mm).

Dimension spacers of support construction

The number of spacers depends on the insulation,

temperature and the mechanical load. Use the

following intermediate distances as a guide.

Horizontal

Insulation

system

Pipe sections none 10 to 13 ft none 16 to 20 ft

Load bearing wraps (mats) none 10 to 13 ft none 16 to 20 ft

Wired mats 3.3 ft 3.3 ft 3.3 ft 16 to 20 ft

piping

≤ 550 °F > 550 °F ≤ 550 °F > 550 °F

Vertical

piping

)

m

m

0

0

4

(

"

6

1

.

x

a

m

1. Pipe - 2. ProRox® insulation - 3. Spacer - 4. Thermal

dividing layer - 5. Cladding

The spacers on pipes are located under the

circular joint of the cladding. On shaped sections

such as pipe elbows, spacers are fitted at the start

1. Pipe - 2. ProRox® insulation - 3. Spacer - 4. Thermal

dividing layer - 5. Support ring

34

and at the end. If the external distance between

the two spacers exceeds 27 inch (700 mm), place

additional spacers between the two.

Page 38

B. Support construction

The purpose of support structures is to transfer

the mechanical load of the insulation system and

the forces affecting the insulation system onto the

object. Support structures are essential in the

case of vertical piping. In addition to the static and

dynamic forces, changes in piping length and

support structures due to temperature must also

be taken into account when dimensioning. Support

structures are fastened to mounting supports,

which are welded to the pipe beforehand, or are

mounted directly onto the pipe via a clamping

action with so-called double clamping rings. With

temperatures above 650 °F (350 °C), the support

structures must be made of high-temperature steels.

The table below is an initial dimensioning guide,

and shows the weight of the insulation system

against the nominal width of the pipe and the

insulation thickness. The table accounts for an

insulation with an apparent density of 6 lb/ft3

(100 kg/m³), including the spacer and a 0.20 inch

(1.0 mm) strong galvanized sheet.

Weight of the insulation (lb/ft pipe)

1. Support ring - 2. Bar - 3. Rivet or screw connection -

4. Thermal decoupling - 5. Clamping screw - 6. Screw

nut - 7. Internal clamping ring

of piping

Insulation

Pipe Diameter

Nominal

NPS

diameter

(inch)

0.5 15 21 lb / ft 0.3 0.5 0.8 1.1 1.5 2.5 3.7 5.2

1.0 25 34 lb / ft 0.5 0.7 1.0 1.4 1.8 2.8 4.1 5.7

2.0 50 60 lb / ft 0.8 1.1 1.5 1.9 2.4 3.6 5.0 6.7

2.5 65 76 lb / ft 1.0 1.3 1.7 2.2 2.7 4.0 5.5 7.2

3.0 80 89 lb / ft 1.2 1.5 2.0 2.5 3.0 4.3 5.9 7.7

4.0 100 114 lb / ft 1.5 2.0 2.5 3.0 3.6 5.1 6.8 8.7

8.0 200 219 lb / ft 2.9 3.6 4.4 5.2 6.1 8.1 10.3 12.8

12.0 300 324 lb / ft 4.4 5.3 6.3 7.4 8.5 11.0 13.8 16.8

20.0 500 508 lb / ft 7.2 8.6 10.2 11.8 13.5 17.0 20.8 24.8

28.0 700 711 lb / ft 10.0 12.0 14.0 16.2 18.4 22.9 27.8 32.9

planar surface lb / ft

Ø DN

Pipe

diameter

(mm)

Units of weight of

insulation system

2

1.00 1.50 2.00 2.50 3.00 4.00 5.00 6.00

1.3 1.6 1.8 2.1 2.3 2.8 3.3 3.8

Insulation Thickness (inch)

35

Page 39

1.2 Insulation of piping

1.2.5 Cladding

Suitable cladding should be applied to protect the

insulation from weather influences, mechanical loads

and (potentially corrosive) pollution. Selecting the

appropriate cladding depends on various factors, such

as working loads, foot traffic, wind and snow

accumulations, ambient temperatures and conditions.

NOTE

An insulation system resistant to foot traffic

must not become permanently damaged if a

person weighing 220 lbs (100 kg), (weight

including any tools being carried) walks

across it. It is not designed to bear additional

loads, such as the placing of heavy equipment.

For the purpose of the safety regulations, a

durable insulation is not considered to be a

walkable surface.

When selecting the appropriate cladding, take the

following points into account:

As a general rule, galvanized steel is used in

buildings due to its mechanical strength, fire

resistance and low surface temperature (in

comparison to an aluminum cladding).

Aluminum is used outdoors, because it is easy

to fit and more cost-effective than stainless

steel and does not tend to corrode under

common weather conditions.

In corrosive environments, aluminized steel,

stainless steel or glass reinforced polyester is

used as cladding. Stainless steel is

recommended for use in environments with a

fire risk.

The surface temperature of the cladding is

influenced by the material type. The following

applies as a general rule: the shinier the

surface, the higher the surface temperature.

To exclude the risk of galvanic corrosion, only

use combinations of metals that do not tend to

corrode due to their electrochemical potentials

(also see page 21 in Chapter 1.1).

For acoustic insulation, a noise absorbent

material (bitumen, mylar foil) is mounted on the

insulation or inside the cladding. To reduce the

risk of fire, limit the surface temperatures of

the cladding to the maximum operating

temperature of the noise absorbent material.

Max. surface temperature

Cladding material Areas at risk

Aluminum sheet - -

Aluminum/zinc coated steel sheet - -

Galvanized steel sheet -

Austenitic stainless steel sheet

Aluminized steel sheet

Plastic-coated steel or aluminum - -

Glass fiber-reinforced polyester

®

Rocktight)

(e.g. ProRox

Coatings/mastics - - 175 °F (80 °C)

Foils - -

The thickness of the metal sheet depends on the pipe dameter and the type of the metal.

With special acoustic requirements, a larger thickness [> 0.04" (1 mm)] is generally used.

36

of fire

-

Corrosive

environment

< 120 °F

(50 °C)

< 140 °F

(60 °C)

< 190 °F (90 °C)

> 140 °F

(60 °C)

Page 40

Recommended sheet thickness and overlaps regarding cladding made from flat sheets (CINI)

Surface (cladding) temperature °F

Aluminum

cladding

100

105

110

115

120

125

130

Galvanized

steel

Stainless

steel

Paint-coated

Plastic

cladding

Minimum thickness (inches) of metal cladding sheet (recomended by CINI)

External diameter of

the insulation (in)

< 5.5" 0.024 0.022 0.020 0.020 0.020

5" to 12" 0.031 0.031 0.031 0.031 0.031

> 12" 0.039 0.031 0.031 0.031 0.031

Aluminum

(CINI 3.1.01)

Aluminized

steelsheet

(CINI 3.1.02)

Alu-Zinc coated

steel sheet

(CINI 3.1.03)

Zinc coated

steelsheet

(CINI 3.1.04)

Austenitic stainless

steel sheet

(CINI 3.1.05)

of piping

Insulation

The recommended sheet thickness deviates to a

certain level per standard/country. The thickness

recommended by CINI is shown in the table above

(values converted to inches). See page 148 in

Chapter 3.2.2 for the thickness according to DIN

4140 and BS 5970.

To reduce the risk of galvanic corrosion, it is

important to use the correct screws, straps etc.

See the table on page 21 for more information.

The basic guidelines are:

Fasten sheet cladding on lengthwise joints with

at least six sheet metal screws or blind rivets

every meter.

Place the screws or blind rivets equidistant.

Ifscrews or rivets are fitted in two rows, do not

stagger the screws or rivets.

The cladding can also be held in place with

corrosion-resistant straps instead of screws

orrivets.

Do not use aluminum screws.

Influence of the cladding on the

surface temperature

In addition to the insulation thickness, the thermal

conductivity of the insulation and the ambient

conditions (for example temperature and wind),

the surface temperature of insulation is also

influenced by the emission ratio (emissivity) of the

cladding.

The following applies as a general rule for

thermal insulation: the shinier a surface is (lower

emissivity), the higher the surface temperature.

The following example shows the various surface

temperatures that depend on the cladding:

Diameter: 4 1/2" (114 mm)

Temperature of the medium: 930 °F (500 °C)

Place of installation: Interior [Wind speed 1.1

mph (0.5 m/s)]

Insulation: ENERWRAP® MA 960NA

pipe wrap (mat), thickness 4" (100 mm)

Various cladding materials