Page 1

ISSUED: 04-15-14 SUPERSEDES 04-11-14

WWW.ROXUL.COM

ROXUL REPORT:

Fastener Guidelines

TECHNICAL COMMUNICATION

WWW.ROXUL.COM

Fastener

Guidelines

©ROXUL INC 2014

1 OF 8

Page 2

ISSUED: 04-15-14 SUPERSEDES 04-11-14

WWW.ROXUL.COM

TECHNICAL COMMUNICATION

DESIGN BASIS

1. MECHANICAL ATTACHMENT

For permanent attachment, ROXUL stone

wool (mineral wool) insulation should be

mechanically attached or pressure held by

supporting members.

2. ADHESIVES

Adhesives and adhesive applied stick-pins

should NOT be used for permanent

attachment of ROXUL stone wool insulation.

Adhesives, and adhesive based systems

can used for temporary attachment, but

mechanical attachment (or supporting

members) must be used for permanent

attachment.

3. EXPOSED INSULATION

ROXUL stone wool insulation is not

intended to be left exposed to the elements.

Cladding should be installed after insulation

attachment. If the insulation is to be left

exposed, or installation takes place in bad

weather, the insulation should be

permanently mechanically attached and

covered with a breathable protective layer

(such as tarp). Designers can increase

number of fasteners to meet specific

conditions and design requirements

(including wind-driven rain-loads).

4. DESIGN LOADS

Fastening connections should be designed

to withstand all the combined applied loads,

including (but not limited to) Dead-Load and

Wind-Loads. Where applicable,

consideration should also be given to

Seismic- Load, Live-Load and Wind-Driven

Rain-Load (Not covered in this guide).

5. DEAD LOAD

Fastening connections should be designed

to withstand all the combined applied dead

loads, including (but not limited to) the

insulation, fasteners and any other

supported members or cladding.

6. WIND LOAD (LIVE LOAD)

Fastening connections should be designed

to withstand horizontal loads imposed by

wind pressures. Wind loads often govern

lateral load scenarios

7. FASTENER SELECTION

Fasteners should be: a) appropriate type for

the substrate; b) capable of withstanding

applied pull-out and shear-loads ; c)

numerous enough and of large enough

cross-section to prevent tear-through of the

insulation under expected conditions; d)

suitable for use outside if being used in

exterior applications.

8. ENGINEERED DESIGN

The design of fastened connections is a task

normally completed, or reviewed, by a

structural engineer. The primary purpose of

this fastener guide is to provide suggestions

for attachment design of ROXUL stone wool

insulation attachment to various structures

and buildings.

9. LIMITATION

ROXUL stone wool insulation boards are

suitable for mechanical attachment using a

number of fasteners and fastening systems.

Mechanically attached fastening systems

are subject to various loads including dead

load, wind load and seismic load; all of

which vary with location and over time.

WARNING: Failure to include safety factors

or adequately design for applied loads can

result in failure of mechanical attachment.

The determination of the specific design

requirements and safety factors regarding a

fastener system is the sole responsibility of

the installer and/or end user. ROXUL Inc

assumes no responsibility whatsoever for

any failure of insulation attachment or

related fastening systems.

WWW.ROXUL.COM

©ROXUL INC 2013

2 OF 8

Page 3

ISSUED: 04-15-14 SUPERSEDES 04-11-14

WWW.ROXUL.COM

Plain Insulation

1. APPLICATIONS

Exposed Exterior Insulation

Basements (Inside / Outside)

Parking Garages

Acoustic Panels

2. EXPOSED INSULATION

ROXUL stone wool insulation is not

intended to be left exposed to the elements.

Cladding should ideally be installed

immediately after insulation attachment. If

the insulation is to be left exposed, or

installation takes place in bad weather,

ROXUL recommends a minimum of 5

mechanically attached insulation fasteners

per board.

3. TYPE OF FASTENERS

Screw & Washer

Insulation Fastener

Plastic Cap Nails

Impaling Pins

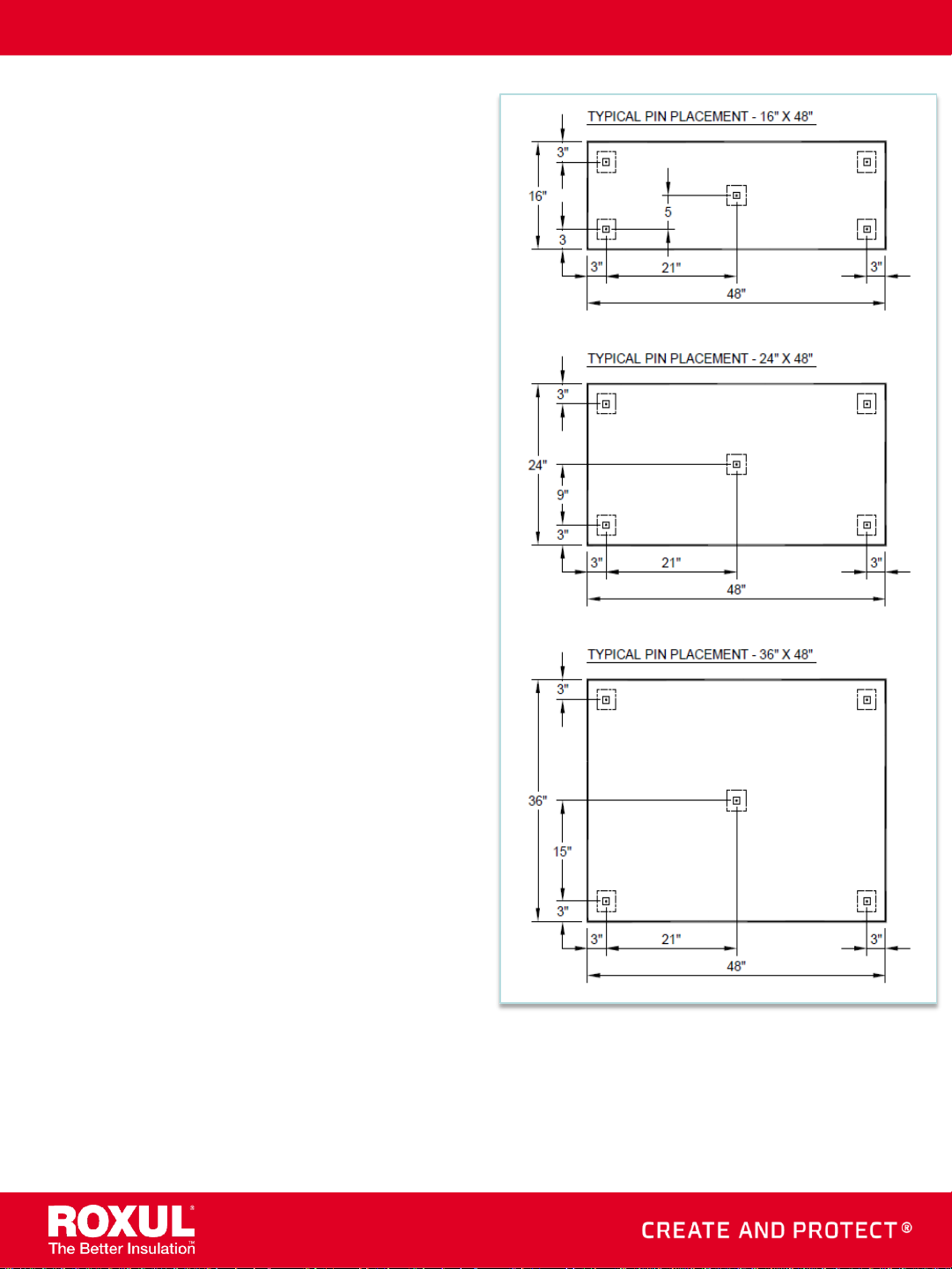

4. NUMBER OF FASTENERS

ROXUL recommends a minimum of 5

mechanically attached insulation fasteners

per board. Designers can increase number

of fasteners to meet specific conditions and

design requirements (including wind-driven

rain-loads).

5. EMBEDDED DEPTH OF FASTENER

Embedded depth required to resist fastener

pull-out will vary with both substrate

material and the fastener type. ROXUL

recommends a minimum 1” embedded

depth, designers may vary this amount.

6. PROPRIETARY FASTENERS

Some proprietary Insulation Fasteners can

provide adequate support with fewer than 5

fasteners per board and less than 1”

embedded depth. Individual fastener

manufacturers should be consulted for

details.

WWW.ROXUL.COM

TECHNICAL COMMUNICATION

5. THERMAL CONTROL LAYER

ROXUL® COMFORTBOARD ™ IS

continuous insulation is the primary thermal

control layer.

The amount of insulation recommended

varies by climate region (see Table 2)

6. VAPOR CONTROL LAYER

The assembly as illustrated is a “vapor

open” assembly, meaning that there is a

single line of vapor control and that drying

can occur towards the interior or towards

the exterior from this line. Selection of

vapor-open interior finishes should be

considered. If vapor impermeable finishes

are used, analysis should be conducted to

assess drying potential.

7. EXTERIOR CLADDING

A drained and back-ventilated wood or fiber

cement siding is illustrated.

Material options for the exterior cladding

include:

• Vinyl siding (see manufacturer’s notes

for installation on furring)

• Wood siding

• Fiber cement siding or panels

8. QUALITY CONTROL

CONSIDERATIONS

Inspect the lapping of drainage plane pieces

to ensure that pieces are installed in

“shingle” fashion.

Ensure a tight fit where the exterior

insulation boards are fit together. At

mechanical and structural penetrations, an

opening in the ROXUL COMFORTBOARD

IS layer may be cut slightly undersized to

ensure a tight fit.

©ROXUL INC 2013

3 OF 8

Page 4

ISSUED: 04-15-14 SUPERSEDES 04-11-14

WWW.ROXUL.COM

Strapping

1. GENERAL

Strapping, attached to the building structure,

will act like giant clamps to hold insulation in

place. ROXUL insulation boards will be

permanently mechanically supported by the

strapping attachment if the attachment is

designed to withstand live loads and total

applied dead loads. Insulation boards can

be temporarily held in place prior to

strapping unless the insulation is to be left

exposed without strapping or installation

takes place in bad weather; in which case

guidelines for Plain Insulation attachment in

the previous section should be followed

2. DESIGN

ROXUL recommends installing strapping

vertically to provide a drained cavity;

drained metal hat-channels can be

installed horizontally.

Strapping attachment should be

designed to withstand wind loads and

total applied dead loads (Insulation +

Fasteners + Strapping + Cladding)

ROXUL recommends a maximum

system dead load area weight of 12 psf

for wood frame construction and 5 psf for

metal frame construction.

TECHNICAL COMMUNICATION

3. FASTENERS

Fasteners should be: a) appropriate type

for the substrate; b) capable of

withstanding applied pull-out and shearloads.

Required length, number, spacing and

embedded depth of fasteners will depend

on the type of fastener, the applied loads,

the substrate and the thickness of the

insulation, strapping and any sheathing.

Anti-unwinding fasteners (or alternative

precautions) should be used for metal

frame construction.

Fasteners should be embedded 1.5” in

wood studs and concrete, and extend at

least 3 full threads past the inside face of

steel studs.

Designers can vary the type, number and

embedded depth of fasteners to meet

specific requirements.

4. STRAPPING TYPE

Metal or treated wood strapping can be

used. ROXUL recommends using 2x3 or

2x4 dimensional lumber (laid on the flat), or

metal hat-channels.

5. INSTALLATION TIPS

Use Experienced Installers or a lazer-

level with inexperienced installers

Use 2x3 or 2x4 lumber instead of thinner

strapping

Use double-thread screws for wood

strapping

Recommended for maximum insulation

thickness ≤ 3”

6. REFERENCES

NTA Engineering Evaluation Report

TRU110910-21 can be used to design

strapping attachment for wood-frame

and concrete with TRUFAST SIP and

TRUFAST Tru-Grip fasteners.

ROXUL Continuous Exterior Insulation –

Deflection Report

IMETCO IntelliScreen system is

recommended for cladding installation

using horizontally installed drained

metal hat channels

WWW.ROXUL.COM

©ROXUL INC 2013

4 OF 8

Page 5

ISSUED: 04-15-14 SUPERSEDES 04-11-14

WWW.ROXUL.COM

Masonry Ties

1. GENERAL

Wedges / clips installed over masonry ties

can be used to attach ROXUL insulation

boards. Non-proprietary or proprietary

masonry ties can be used.

2. DESIGN

Spacing and design of the masonry tie

pattern should follow accepted practice and

be adequate to support wind and dead

loads.

Where permissible by codes and design, the

spacing of ties should be made to be 16” or

24” in at least one orientation (vertical or

horizontal) to allow easy installation of

ROXUL insulation boards with little or no

cutting of the insulation.

3. INSULATION ATTACHMENT

Wedges or clips over masonry ties can be

used to hold the insulation in place at board

edges. Additional fasteners can be used in

the middle of boards if needed.

The average number of masonry tie wedges

and / or fasteners holding a single piece of

insulation should be a minimum of 5.

Designers can increase the number of

fasteners or wedges to meet specific

conditions and design requirements.

4. FASTENERS

ROXUL recommends wedges or clips

designed for the particular type of masonry

tie being used.

If additional fasteners are required in the

middle of boards these can be:

Plastic cap nails

Screws & washers

Insulation Fasteners

Impaling Pins

TECHNICAL COMMUNICATION

5. STPE – ADHESIVE WRB

Some STPE based WRB (Weather

Resistive Barrier) compounds have

adhesive properties prior to curing and can

be used to attach ROXUL stone wool

insulation to the wall when used in

combination with brick ties and wedges

around board edges.

Follow manufacturers direction when using

an STPE based WRB as an adhesive for

ROXUL insulation.

WWW.ROXUL.COM

©ROXUL INC 2013

5 OF 8

Page 6

ISSUED: 04-15-14 SUPERSEDES 04-11-14

WWW.ROXUL.COM

Clips & Girts

1. GENERAL

Proprietary clips / brackets or nonproprietary stand-offs designed to support

vertically installed z-girts or L-channels can

be used. Insulation is not required to provide

any structural support with this type of

system.

2. THERMAL BRIDGING & Z-GIRTS

ROXUL does NOT recommend using z-girts

through the full thickness of insulation.

Clips, brackets or stand-offs should be used

to minimize thermal bridging.

3. DESIGN

Z-girts and fastening system should be

designed to support wind loads and total

applied dead loads independently of the

insulation.

If clips & girts do NOT provide structural

support to the insulation it should be

fastened per directions for Plain Insulation.

If clips & girts provide structural support to

the insulation then designers can reduce the

required number of fasteners appropriately.

4. CASCADIA CLIPS & OTHER

PROPRIETARY SYSTEMS

Follow manufacturers recommendations

TECHNICAL COMMUNICATION

5. FASTENERS

Fasteners should be appropriate type for

the substrate

Use the manufacturers recommended

fasteners when using proprietary clips &

brackets

Anti-unwinding fasteners (or alternative

precautions) should be used for metal

frame construction and metal-to-metal

fastening of clips & girts.

Fasteners for attaching insulation

Impaling Pins

Screws & Washers

Plastic Cap Nails

Insulation Fasteners

WWW.ROXUL.COM

©ROXUL INC 2013

6 OF 8

Page 7

ISSUED: 04-15-14 SUPERSEDES 04-11-14

WWW.ROXUL.COM

Fastener -

Examples

TECHNICAL COMMUNICATION

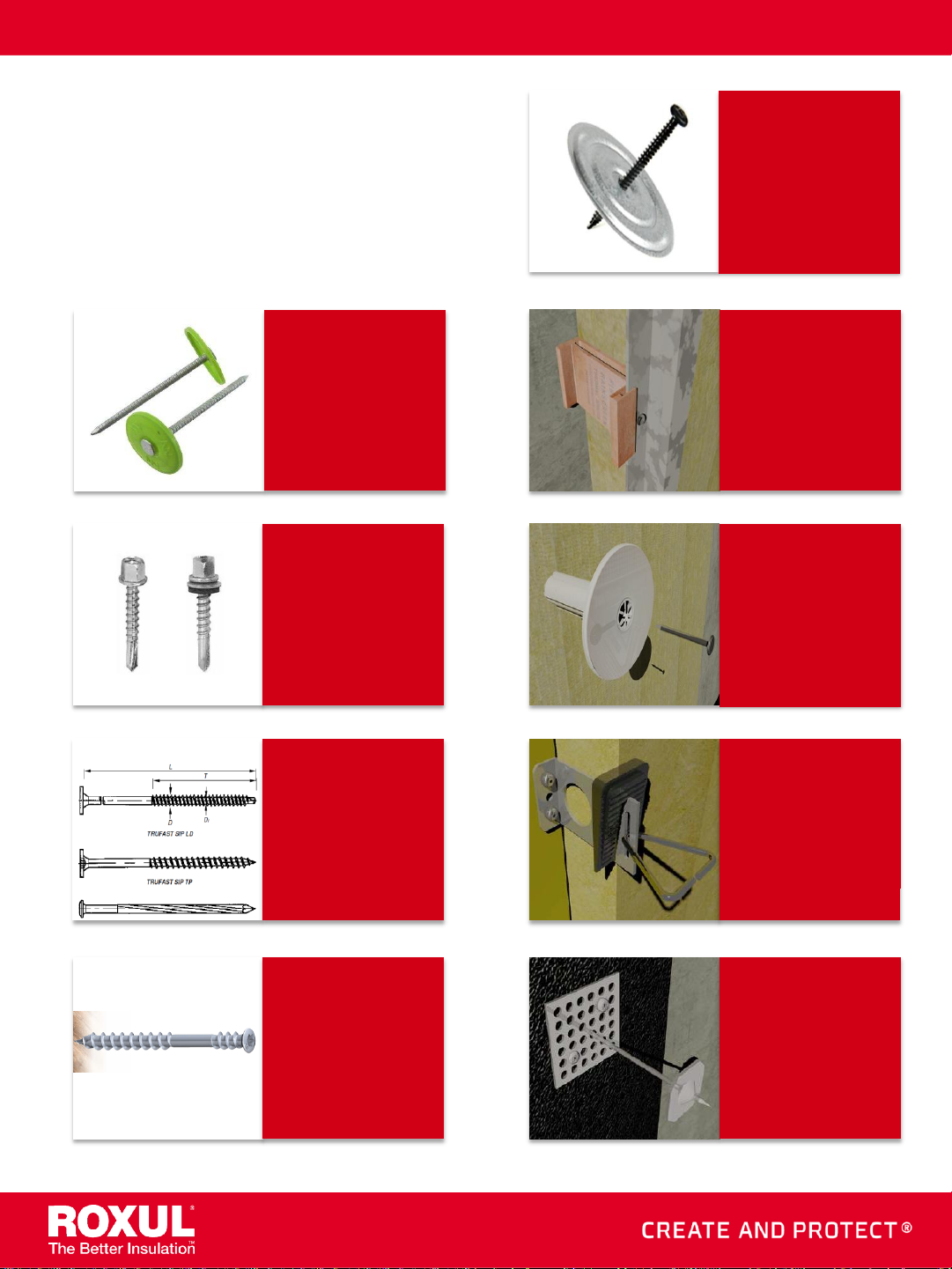

Fastener &

Washer

Recommended for use

will all types of ROXUL

stone wool insulation

boards

Fastener should be

appropriate type for the

substrate

Plastic Cap

Nails

Recommended for

temporarily holding

insulation and fastening

insulation to wood and

wood based substrates

Metal Fasteners

Recommended for use

with metal frame

construction.

Anti-unwinding fasteners

(or other precautions)

should be used with

metal frame construction

Regular

Wood Screws

Concrete Screws

Concrete Nails

Must be right type for

the substrate and

suitable for outside use

if not being used inside.

Clip & Z-Girt

e.g. CASCADIA CLIPS

Recommended for thick

exterior insulation (over

3”)

Follow manufacturers

recommendations for

use

Insulation

Fasteners

e.g. RAMSET

INSULFAST

Recommended for

fastening insulation to

concrete, masonry block

and exterior gypsum

sheathing

Brick-Tie &

Wedge

Wedges or clips used

with masonry ties can be

used to attach ROXUL

CAVITYROCK DD and

MD insulation

WWW.ROXUL.COM

Dual-Thread

Fasteners

e.g. Heco-Topix

Recommended for use

with wood strapping to

reduce risk of

compression deflection

Impaling Pin

Mechanically attached

or bonded to structure.

Recommended for use

with all types of ROXUL

stone wool insulation

boards.

Adhesive “stick” pins

should be avoided

©ROXUL INC 2013

7 OF 8

Page 8

ISSUED: 04-15-14 SUPERSEDES 04-11-14

WWW.ROXUL.COM

TECHNICAL COMMUNICATION

DISCLAIMER AND LIMITATION OF

LIABILITY:

The statements and data contained in

this brochure are for general information

purposes ONLY. They are NOT specific

technical recommendations as to any

particular design or application and the

ultimate determination as to product

suitability is the sole responsibility of the

installer or end user. Although the

information contained herein, including

ROXUL product descriptions, is

believed to be correct at the time of

publication, accuracy cannot be

guaranteed and results may vary

depending on the particular design

and/or application.

WWW.ROXUL.COM

ROXUL fully reserves the right to make

product specification changes, without

notice or obligation, and to modify or

discontinue any of its products at any

time. In no event

shall ROXUL be liable for any direct,

indirect, or consequential damages of

any kind arising from information

contained in this bulletin, including, but

not limited to, claims for loss of profits,

business interruption, or damages to

business reputation. This limitation of

liability shall apply to all claims whether

those claims are based in contract, tort,

or any legal cause of action.

©ROXUL INC 2013

8 OF 8

Loading...

Loading...