Page 1

ROXUL® Insulation Products For Residential Thermal Applications

Better | Best

ROXUL® Solutions For Residential

Thermal Applications.

Page 2

Better | Best

Better. Best.

When deciding on the quality of insulation to include

in a residential construction or renovation project,

builders, contractors and homeowners need input

in determining effectiveness of the insulation and

whether to just meet minimum code requirements

or exceed them, creating a comfortable environment

through all seasons.

From meeting the specified minimum, to achieving

R-values that will exceed building codes well into

the future, it’s great to know you have options.

This thermal guide to ROXUL

solutions can address various common residential

applications using ROXUL insulation, including:

n

exterior walls

n

attics

n

cathedral ceilings

n

crawl spaces and

n

exposed floors

The Better: Although building codes for insulation

requirements vary between states, most building

codes are designed to meet minimum standards.

Using ROXUL to meet these minimum codes is Better

than using other types of insulation because of the

exclusive features and benefits of ROXUL insulation.

In our Better solutions we will show you how to use

ROXUL to achieve or exceed building code standards.

The Best: The R-value of insulation is worth

considering to achieve optimum energy efficiency and

improve the overall comfort of your home. When you

choose the BEST solution, you are creating a warm

and comfortable home to enjoy immediately, as well as

making a long-term commitment to the environment

and energy savings well into the future.

®

Insulation’s Better I Best

Compared to other insulation like foam plastics and fiberglass,

ROXUL

ROXUL’s Better. Best. Thermal Insulation Guide

Features and Benefits .............................................. pg 3

Attic applications ...................................................... pg 8

Cathedral ceilings applications ..............................pg 10

Residential exterior wall applications ...................pg 12

2

®

stone wool ranks superior.

Interior basement foundation wall .........................pg 16

Exterior exposed floors ...........................................pg 18

Non-vented crawl spaces ...................................... pg 21

Vented crawl spaces............................................... pg 22

Page 3

ROXUL® Insulation Products For Residential Thermal Applications

What sets ROXUL® insulation apart

from other insulation.

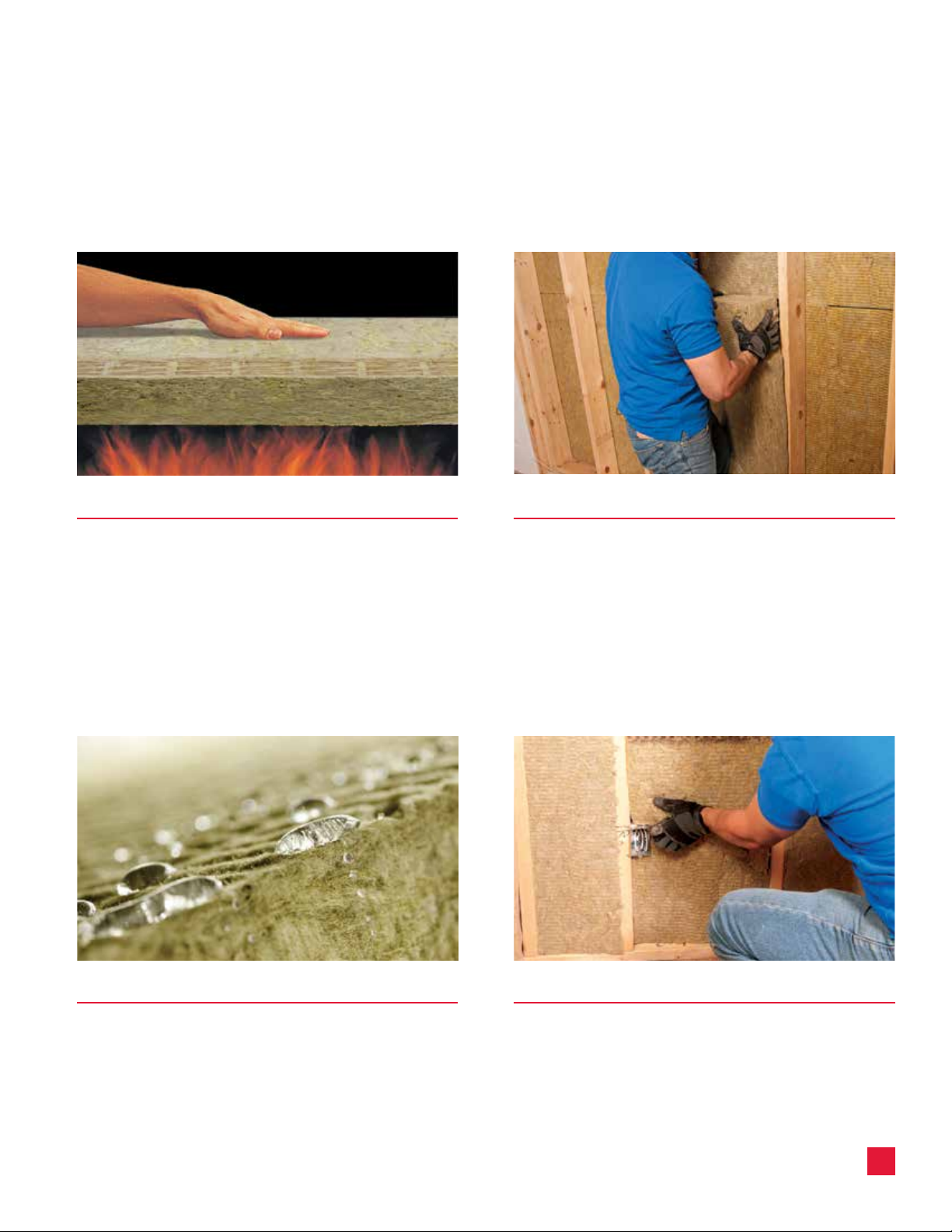

Fire resistant

The combination of stone wool and recycled content

makes ROXUL® insulation fire resistant. This noncombustible product does not develop smoke or

promote flame spread when exposed to fire, making

ROXUL insulation a critical line of defense in fire

protection. In fact, studies have shown that stone

or mineral wool insulations provide a 54% increase*

in overall fire resistance rating compared to

non-insulated walls.

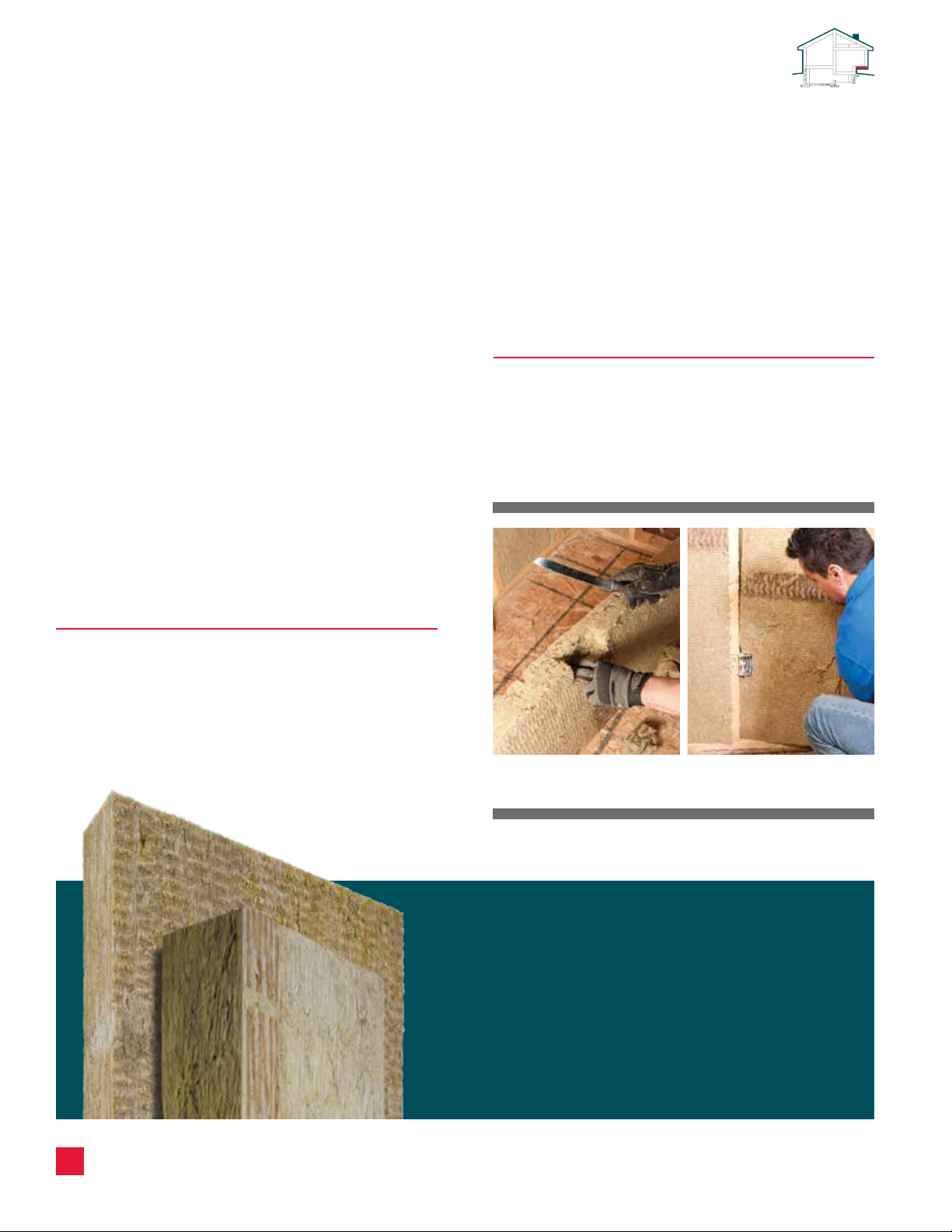

Sag free, tight fit

The higher density of ROXUL insulation provides

superior sag resistance and fit. Once installed,

ROXUL insulation holds its shape without sagging

or slumping in the wall cavity to provide continuous

fire protection and thermal performance over time.

Water repellent

ROXUL insulation does not absorb or hold water and

will not promote mold or fungi growth. It has superior

drying potential, effectively managing moisture in the

event that it does get into the wall or floor, allowing it

to dry out and maintain its thermal properties.

* Su ltan , M.A . (1996), A Model for Predic ting the Heat Transfer Through Non-in sulated Unloaded Steel-Stud G ypsum Board Wall Assemblies Exposed to Fire,

Institute for Research in Cons truction, National Re sear ch Council Canada , Ottawa, Ontario, C anada.

Fast, easy installation

Working with ROXUL insulation is a breeze. Simply cut

with a serrated knife for quick and easy installation

between studs, around electrical boxes, pipes,

wiring, ductwork and between studs and joists

with non-standard widths.

3

Page 4

Better | Best

Fire Stopping Board Insulation

Thermal Insulated Sheathing

ROXUL® thermal insulation for residential applications.

Top Up Attic Insulation

ROXUL COMFORTBOARD™ IS

Rigid stone wool insulation board fastens to

outside studs and is fabricated to improve thermal

performance to the building envelope.

Thermal Insulated Sheathing

ROXUL COMFORTBATT

®

Thermal insulation for use in exterior walls, attics and

crawlspaces. It provides indoor comfort and energy

savings all year ‘round.

4

Page 5

ROXUL® Insulation Products For Residential Thermal Applications

ROXUL ROCKFILL

™

Loose fill thermal insulation that is easy to apply

over existing attic insulation. Pour, fluff to aerate and

spread. No need to rent an expensive blowing machine

required with other types of insulation.

ROXUL DRAINBOARD

®

Rigid stone wool insulation board for fibrous

foundation drainage. Its non-directional fiber

structure means the boards can be installed

either horizontally or vertically without any

loss of drainage ability.

5

Page 6

Better | Best

What is R-value?

R-value is a unit of measure describing the resistance of heat flow through a material (e.g. insulation, stud, wallboard)

or a wall assembly. Generally, the higher the R-value, the better the material/assembly is at reducing heat loss

(or heat gain). Many factors play a role in this transfer of heat, including the structural components that bypass

the insulation, as well as humidity and variance of fluctuating daily temperatures.

Effective R-values versus Nominal R-values

People are often surprised at the difference

between the commonly stated (nominal) R-value

of insulation and the effective R-value of the

insulation within the wall assembly. This reflects

the difference between controlled lab tests

versus the real-world performance.

Although the insulation package may state a nominal

R-13, the effective R-value of the assembly may be

smaller. This reduction is dependent on the thermal

bridging of the structural elements that bypass the

insulation. Thermal bridging is where heat escapes

through a conductive material that creates a bridge

between the outside and inside causing heat loss.

For example, wood studs conduct heat relatively

well as compared to insulation. Steel studs conduct

thermal energy extremely efficiently, thereby reducing

the effectiveness of the wall assembly to resist the

loss of heat. High-density stone wool insulation

resists heat loss better and achieves better energy

performance than fiberglass insulation, which is

less dense and less stable.

Today’s building codes are moving to mandate

effective R-values over nominal R-values – and

ROXUL® stone wool, because of its higher density

and dimensional stability, leads the way as the

interior and exterior insulation of choice for

residential applications.

Decreased thermal bridging equals

a better performing wall

ROXUL insulation helps reduce thermal bridging

through wood studs, leading to a better performing

thermal wall. In a typical single-family building,

wood studs make up 25% of the wall surface, so it’s

important to ensure the use of exterior insulation

to complete the building envelope.

Factors that contribute to

superior thermal performance

With informed consumers and the building industry

pushing for innovative solutions that are truly

energy efficient, ROXUL raises the bar in developing

wall systems with excellent long-term thermal

performance. This is the result of two inherent

properties in its insulating systems – lack of thermal

loss due to dimensional changes, and the insulation’s

ability to repel water, which aids in the control of

heat loss and gain.

The use of ROXUL stone wool as a continuous insulation

(c.i.) also contributes to a building envelope's efficiency,

giving it higher effective thermal resistance values

than foam plastics.

Made from stone wool, an inorganic combination

of basalt and recycled slag, ROXUL insulation is

thermally stable, maintaining its R-value over time.

The insulation will not expand or contract due to

humidity or temperature variance.

6

Page 7

4

6

7

6

4

5

5

3

2

2

2

1

3

ROXUL® Insulation Products For Residential Thermal Applications

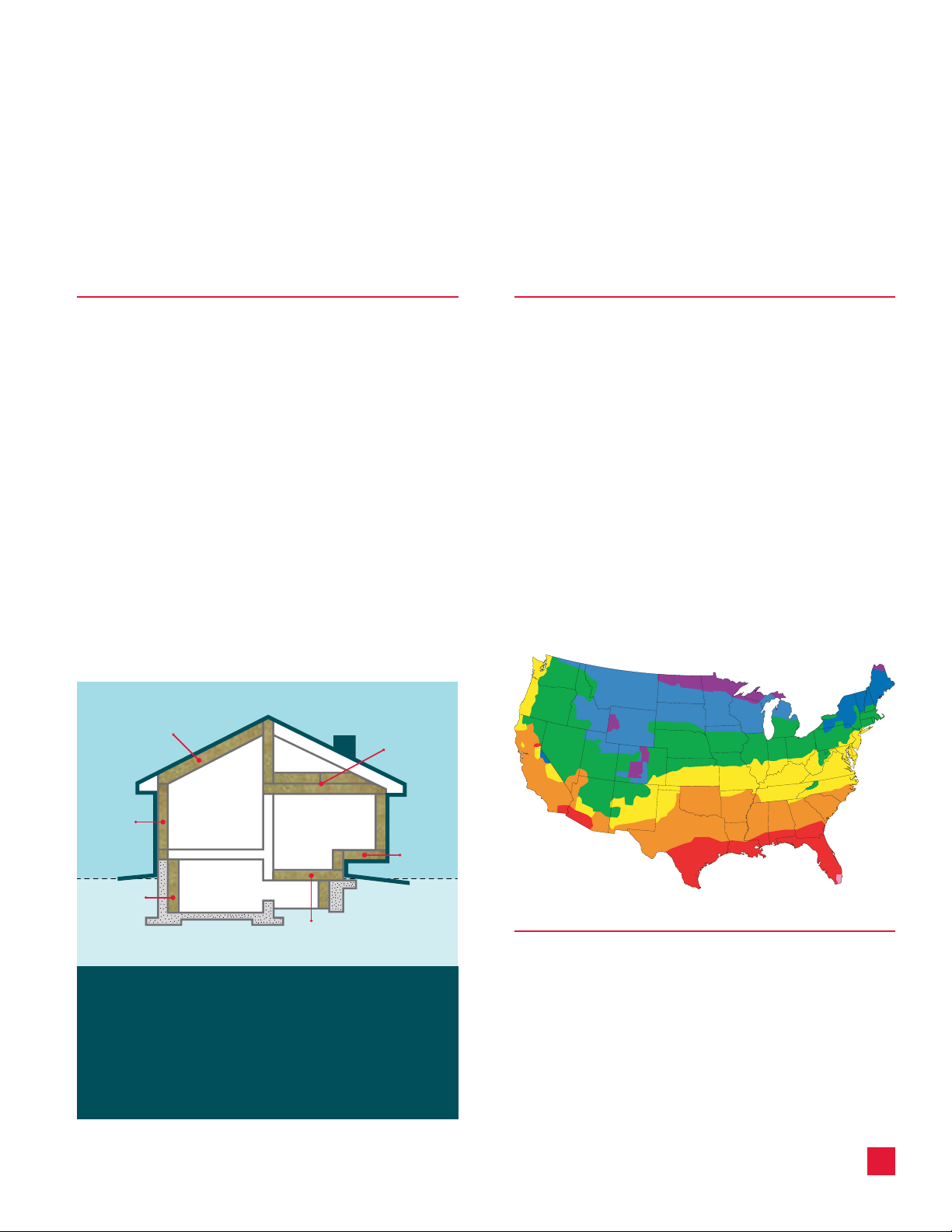

Meeting the challenges of today’s

climate zones.

Building codes vary by state/municipal codes

and climate zone

ASHRAE – History of R-Value Requirements

Building codes often differ by state/municipal codes

and climate zone. The insulation solutions shown

on the following pages represent applications based

on specific locations and on current building

code regulations.

While R-value applications will differ depending

on location, thermal preferences and financial

considerations, one factor should remain invariable:

the quality features of your insulation. When compared

to other insulation like foam plastics and fibreglass,

ROXUL® stone wool ranks superior for soundproofing

and fireproofing, as well as for ease of installation and

long-term performance in wall systems, floors and attics.

The following solutions are only suggested approaches

to consider. Check with your local building code for

specific details.

Catherdal

Ceilings

Attics

The American Society of Heating, Refrigerating and

Air Conditioning Engineers (ASHRAE), is an

international society of technical individuals who

provide knowledge to the building industry on

heating, ventilation, air conditioning, and refrigeration

(HVAC&R). The Society developed ASHRAE 90.1,

an energy conservation standard that provides the

minimum requirements for energy efficient buildings.

This standard, and others are applied today in many

states for commercial, government and high-rise

and residential building applications.

Look to the National Building Code and refer to section

A-5.3.1.2 for information on condensation and energy

conservation standards.

Exterior

Walls

Exposed

Floors

Basement

Walls

Heated

Crawl Space

ASHRAE Map of Climate Zones

Every rating agency has its own maps that divide

regions into thermal or climate zones to tailor codes

and standards to what is appropriate for that

ROXUL COMFORTBATT® thermal home

insulation keeps your home warm in the

particular region.

winter and cool in the summer for more

comfortable living all year round.

7

Page 8

Better | Best

Thermal insulation systems for

residential attic applications.

To increase home comfort and save energy year

round, start by reducing the heat loss through

the attic, probably the most cost-effective area

to add insulation.

*

:

R-49

The New Minimum R-Value Requirement for Attics

Using ROXUL® thermal insulation, this can easily

be done as a weekend project to insulate the attic

portion of a new extension, or to increase the R-value

and top up the current attic insulation, especially in

an older home.

Gaps and voids in the attic can account

for up to 30% of the heat loss. Areas

around pipes, wiring and attic vents are

often neglected and can account for

the majority of those gaps and voids.

™

ROXUL ROCKFILL

loose fill, top up attic

insulation makes it easy because unlike

other attic insulation, there is no blowing

machine required, and installation can

be done by hand.

Venting Your Attic

Before adding insulation, ensure proper venting in the attic,

which is usually supplied by vents in the soffit. Inadvertently

blocking the vents with insulation allows moist air to collect in

the attic, which can cause wood rot and mildew. To avoid this,

install baffles over the soffit vent and staple the baffles in place.

8

*Som e state/mun icipaliti es may d iffer. Check your loc al bulding co des.

Page 9

ROXUL® Insulation Products For Residential Thermal Applications

Better: R-53

CB R-30 + CB R-23 + ROCKFILL™

(as much as desired)

1

2” x 8” Joists

2

ROXUL COMFORTBATT® (R23)

3

ROXUL COMFORTBATT® (R30)

4

ROXUL ROCKFILL

5

Vapor Control Layer

™

*

4

1

3

2

5

Best: R-61

CB R-23 + CB R-23 + CB R-15 +

ROCKFILL™ (as much as desired)

1

2” x 8” Joists

2

ROXUL COMFORTBATT® (R23)

3

ROXUL COMFORTBATT® (R23)

4

ROXUL COMFORTBATT® (R15)

5

ROXUL ROCKFILL

6

Vapor Control Layer

™

*

5

4

1

3

2

6

*Meet s code in most locations.

9

Page 10

Better | Best

Thermal insulation systems for

cathedral ceiling applications.

When building a cathedral ceiling as a room

renovation project or as the ceiling for an entire

new home or cottage, it makes sense to start with

the best solution possible if starting from scratch.

This makes sense in colder climate zones since

a cathedral ceiling, by its very design, lacks the

optimum thermal performance when compared

to a vented attic.

Regardless, in warmer climate zones, and from an

aesthetic design perspective, many architects and

homeowners opt for modern cathedral ceilings,

and ROXUL COMFORTBATT® insulation can play

an effective role in the Better I Best solution.

To increase the R-value of the cathedral ceiling, either

start with 2 x 12 ceiling joists, or add a 2" furring strip

to existing 2 x 10 joists, which gives a deeper

joist cavity to add the COMFORTBATT® insulation.

Ceiling air space

When building a cathedral ceiling, the most

important reminder is to properly maintain an air

space of 25 mm (1") between the insulation and

the sheeting. Check your local building code for

specific recommendations.

Zero Net Energy (ZNE) Residential Buildings

The critical steps to reduce a building’s energy consumption usually

occur during the design process. The development towards modern zero

net energy (ZNE) buildings that take as little off the grid as possible, has

become possible through sustainable products like ROXUL® stone wool

insulation. All ROXUL products produced in the Milton facility contain

a minimum of 40% recycled content.

10

Page 11

ROXUL® Insulation Products For Residential Thermal Applications

Better: R-30

CB R-30 + VB + Air Space

(51 mm / 2")

1

Shingles

2

Roofing Felt (Tar Paper)

3

Sheathing

4

2” x 10” Roof Joists

5

ROXUL COMFORTBATT® (R30)

6

Vapor Control Layer

*

1

2

3

5

4

6

Best: R-36

CB R-30 + CB IS R-6 + VB + Air Space

(51 mm / 2")

1

Shingles

2

Roofing Felt (Tar Paper)

3

Sheathing

4

2” x 10” Roof Joists

5

ROXUL COMFORTBATT® (R30)

6

ROXUL COMFORTBOARD™ IS (R6)

7

Vapor Control Layer

*

1

2

3

5

4

6

7

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information.

11

Page 12

Better | Best

Thermal insulation systems for

residential exterior wall applications.

As society demands more energy-efficient houses,

building codes and builders (and DIY homeowners)

are responding by increasing the R-value of the

building enclosure, in particular, the above-grade

exterior wall. Given that the cavity of the standard

2 x 6 wood frame wall used in residential housing

(new construction) is already filled with insulation,

the clear path forward to higher R-values is to

add layers of exterior insulation.

ROXUL COMFORTBOARD™ IS is a rigid stone wool

insulation board fastened to the outside face of the

exterior studs used in residential construction and

designed to provide increased thermal performance

to the building envelope.

As building codes adjust to increased effective R-value

requirements, the need for insulated sheathing will

increase accordingly, and COMFORTBOARD™ IS leads

the way as the exterior insulation of choice for

residential applications.

What makes ROXUL COMFORTBOARD IS

a superior exterior insulation sheathing

More “Breathability” than Foam Plastics

COMFORTBOARD™ IS is a moisture resistant, yet vapor

permeable insulation (30-40 perms) and will allow

transient vapors to pass through with little restriction.

This unique vapor permeable quality of ROXUL®’s

cavity wall insulation allows for an increased potential

for drying “breathability” without trapping moisture

in the wall assembly.

Lower permeable insulations such as foam plastics can

act as vapor retarders and negatively affect the drying

potential of many typical residential wall assemblies.

Fast Outward Drying

Highly permeable insulation like COMFORTBOARD IS

has the added benefit of allowing fast outward drying

during cold weather. This dries the wood-frame cavity

very quickly, even if the framing is wet from construction

or becomes wet because of incidental water leaks.

How to insulate a typical above-grade

exterior wall

Exterior walls should be insulated to their maximum

R-value, in part, determined by the thickness of the

stud wall. If your walls are constructed with 2 x 6

studs, then COMFORTBATT® R-24 batts should be

used. R-24 batts are 5 ½ inch thick and snugly fit

intoa 2 x 6 cavity wall.

When installing COMFORTBATT between the wall

studs, eliminate any gaps and ensure the ends butt

snugly together. Ensure the surface of each batt is

flush with the interior surface of the studs.

Determining your climate zone and

building code requirements

In the northern states chances are that building

codes mandate a vapor control layer be installed on

the warm side of the insulation. A vapor control layer

in northern climates helps to reduce the moisture

diffusion through the wall assembly and through to

the drywall. Vapor control layers and barriers have

different permeance levels measured in perms,

and depending on your building code, you may

need to install a vapor control layer with a specific

perm rating. In some northern US states, a 6 mil

polyethylene sheet is commonly used, but always

check with your local building code for guidance.

Installing vapor barriers

Typically, a vapor barrier/retarder (e.g. poly sheeting)

is installed on the warm side of the wall, over the

insulation and studs. If a single membrane is used as

a combined air/vapor barrier, seal all vapor barrier

seams with suitable tape to completely seal the wall

and eliminate any chance of warm air getting into the

wall cavity, where it can contribute to condensation and

cause mold problems.

*

12

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information.

Page 13

ROXUL® Insulation Products For Residential Thermal Applications

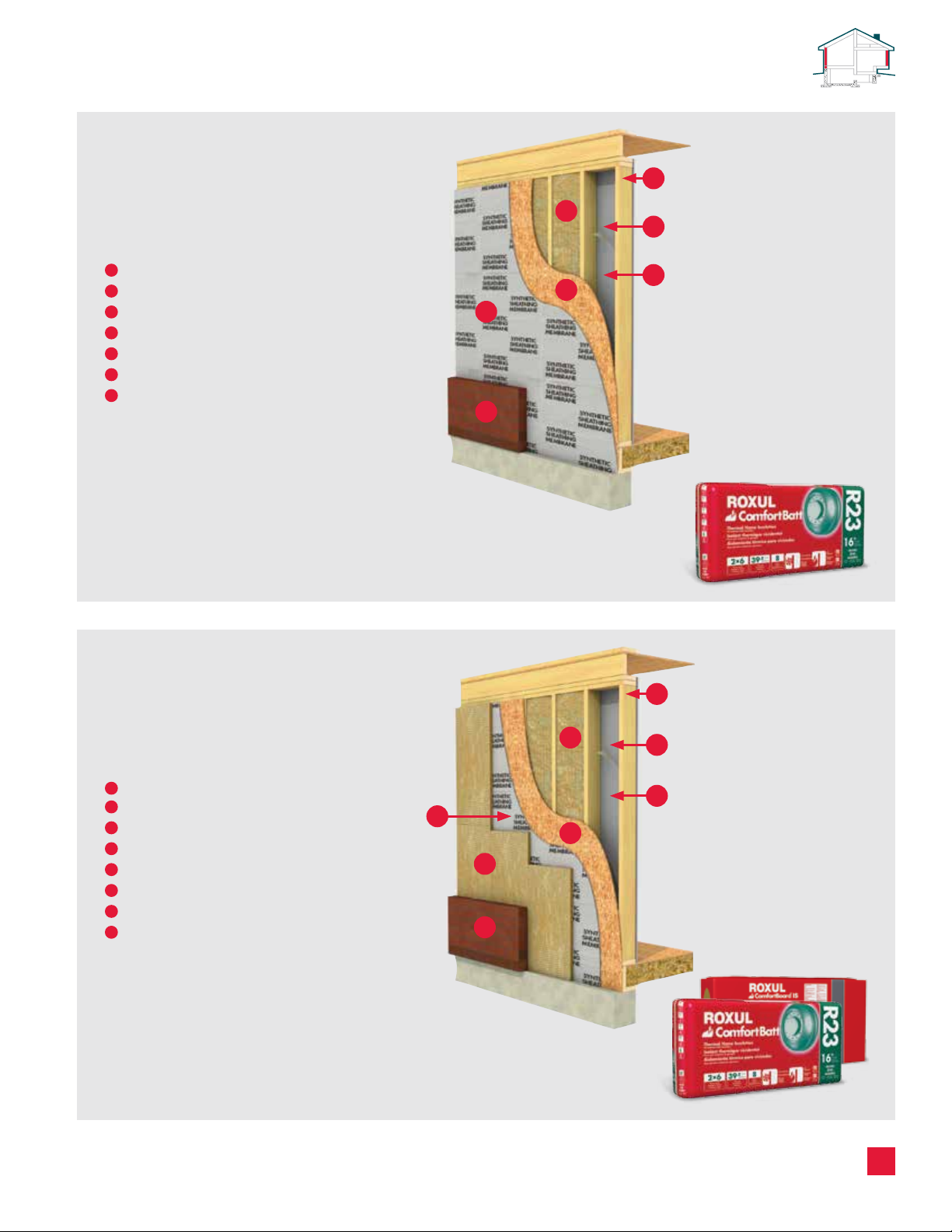

Better: R-23

2 x 6 Stud Cavity + CB R-23 +

Vapor Barrier

1

Cladding

2

Air Barrier

3

Sheathing

4

2 x 6 Wood Studs

5

ROXUL COMFORTBATT® (R23)

6

Vapor Control Layer

7

Gypsum Wall Board

*

*

4

5

7

6

3

2

1

Best: R-29

2 x 8 Stud Cavity + CB R-23 +

CB IS R-6 + Vapor Barrier

1

Cladding

2

Air Barrier

3

ROXUL COMFORTBOARD™ IS (R6)

4

Sheathing

5

2 x 8 Wood Studs

6

ROXUL COMFORTBATT® (R23)

7

Vapor Control Layer

8

Gypsum Wall Board

*

*

5

6

8

7

2

4

3

1

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information.

13

Page 14

Better | Best

Typical exterior wall claddings using ROXUL COMFORTBATT

2

3

1

7

10

4

5

8

6

9

Vinyl wall components

(shown from outside to inside)

1

Vinyl siding

2

Fasteners

3

1 x 3 furring strips

4

1.25" (R5) to 3" (R12) of insulating

ROXUL COMFORTBOARD™ IS sheathing

5

Exterior air/weather resistive barrier membrane

6

Sheathing

7

(2 x 6) stud wall @ 16" o.c or best practice of 24" o.c.

8

ROXUL COMFORTBATT® cavity insulation

9

Vapor control layer*

10

Gypsum wall board

2

1

7

10

4

5

8

3

6

9

Wood wall components

(shown from outside to inside)

1

Wood siding

2

Fasteners

3

1 x 3 furring strips,

4

1.25" (R5) to 3" (R12) of Insulating

ROXUL COMFORTBOARD™ IS Sheathing

5

Exterior air/moisture barrier membrane

6

Sheathing

7

(2 x 6) stud wall @ 16" o.c or best practice of 24" o.c.

8

ROXUL COMFORTBATT® cavity insulation

9

Vapor control layer*

10

Gypsum wall board

Vinyl and wood siding

n

Minimum 1" x 3" furring strip to be placed vertically

with screw attachment of 16" OC for 16" on wood

studs and 12" OC for 24" on-center wood studs.

n

#8 or #10 screws recommended.

n

Each screw must have a minimum embedment of

1" into the wood stud or substrate.

14

Brick

n

Metal ties or anchors required for nailing into the

framing through the insulation boards

(to building code requirements).

n

1" (25 mm) space between the masonry and

insulation required.

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information.

Page 15

ROXUL® Insulation Products For Residential Thermal Applications

®

and ROXUL COMFORTBOARD™ IS.

2

7

3

4

5

1

6

10

8

9

Brick wall Components

(shown from outside to inside)

1

Brick

2

Air space

3

Brick ties

4

1.25" (R5) to 3" (R12) of Insulating

ROXUL COMFORTBOARD™ IS sheathing

5

Exterior air/weather resistive barrier membrane

6

Sheathing

7

(2 x 6) stud wall @ 16" o.c or best practice of 24" o.c.

8

ROXUL COMFORTBATT® cavity insulation

9

Vapor control layer*

10

Gypsum wall board

2

3

1

7

10

4

5

8

6

9

Cement board wall components

(shown from outside to inside)

1

Cement board

2

Fasteners

3

1 x 3 furring strips

4

1.25" (R5) to 3" (R12) of insulating

ROXUL COMFORTBOARD™ IS sheathing

5

Exterior air/weather resistive barrier membrane

6

Sheathing

7

(2 x 6) stud wall @ 16" o.c or best practice of 24" o.c.

8

ROXUL COMFORTBATT® cavity insulation

9

Vapor control layer*

10

Gypsum wall board

Air barrier

n

Air barrier is required as per building code and

necessary for effective air tightness.

n

Can be applied on the inner side or outer side of

the insulation board and should be continuous.

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information.

15

Page 16

Better | Best

Thermal insulation systems for

interior basement wall foundations.

Building codes are changing: R-values

are increasing

Insulating a new or unfinished basement is an

excellent way to make your home comfortable,

more energy efficient and reduce your overall

heating and cooling costs.

In addition to comfort and efficiency reasons for

insulating the basement, new building codes are

mandating that the foundation wall assembly have

increased R-values, depending on the climate

zone. Generally speaking, the colder the climate,

the higher the R-value requirements.

ROXUL® has two thermal insulation products

for interior basement wall assemblies:

ROXUL COMFORTBOARD™ IS (Insulation Sheathing)

and ROXUL COMFORTBATT®. When used in tandem

within the 2 x 4 stud wall cavity, these two products

help create a drier, more comfortable basement.

Note: To help ensure soil moisture doesn’t have a

chance to seep through the concrete foundation, you

may wish to attach a layer of ROXUL DRAINBOARD®

to the exposed exterior foundation before the soil

is filled in.

ROXUL DRAINBOARD is a rigid stone wool insulation

board specifically designed for foundation drainage.

Its non-directional fiber structure means the boards

can be installed either horizontally or vertically

without any loss of drainage performance.

Won’t trap moisture & won’t grow mold

or mildew

Basements are notorious for dampness, which

is why COMFORTBOARD™ IS sheathing is so

highly recommended. Like all ROXUL insulations,

COMFORTBOARD IS is moisture-resistant and

yet vapor permeable: moisture can pass through

without being trapped.

COMFORTBOARD IS won’t absorb water and is not

susceptible to mold or mildew growth due to its

inorganic composition of basalt and recycled slag.

In the event of a basement leak where the insulation

becomes wet, COMFORTBOARD IS quickly dries out

and maintains its R-value.

COMFORTBOARD IS and the effects of

thermal bridging

Before recommending the Better I Best R-values for

the basement wall assembly, we need to understand

thermal bridging, the process that describes a material’s

capacity to conduct heat from one material to another.

In a typical basement, thermal energy transfers

from the interior of the concrete foundation through

the wood studs and eventually into soil to the exterior

of the foundation. The studs perform as the conduit

or “thermal bridge”, lowering the effective R-value

of the wall assembly. Insulated sheathing like

COMFORTBOARD IS reduces this thermal bridging

by acting as a thermal buffer between the concrete

and the studs.

Vapor Barrier or Not?

In many regions, particularly in colder climates, local building codes may require a vapor barrier within

the wall assembly. If so, remember to staple and overlap the vapor barrier to reduce reduce the rates of

vapor diffusion before adding the drywall. Note: The average below-grade temperature of soil is between

39.2-42.8 degrees Fahrenheit. Below 39 inches, the temperature remains constant all year round.

16

Page 17

ROXUL® Insulation Products For Residential Thermal Applications

Better: R-15

2 x 4 Studs + CB R-15

1

Foundation Wall

2

2 x 4 Studs

3

ROXUL COMFORTBATT® (R15)

4

Vapor Control Layer*

5

Gypsum Wall Board

2

3

4

1

5

Best: R-21

2 x 4 Studs + CB R-15 + CB IS R-6

1

Foundation Wall

2

ROXUL COMFORTBOARD™ IS (R6)

3

2 x 4 Studs

4

ROXUL COMFORTBATT® (R15)

5

Vapor Control Layer*

6

Gypsum Wall Board

3

4

2

5

1

6

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information. ROX UL suggest t he use of 'smar t' vapor control l ayers.

17

Page 18

Better | Best

Thermal insulation systems for

exterior exposed floors.

Many home and cottage owners experience a

multitude of long-term benefits by insulating their

exposed floors. This can apply to an overhang that

extends beyond the house, an unheated porch you

wish to turn into living space, or a cottage with

floors too cold for bare feet.

Sometimes the most difficult aspect of insulating an

exposed floor is having enough working room to apply

the insulation. If the underfloor area is easy to get at,

the application is simple.

Insulating the exposed floor with ROXUL® insulation

can make the home or cottage more comfortable,

reduce the incidence of frozen pipes, and help

eliminate mold growth problems and, ultimately,

help save on overall energy costs.

ROXUL COMFORTBOARD™ IS

installation recommendations

ROXUL COMFORTBOARD IS high-performance

insulation boards should be attached to wood studs

using roofing nails or wood screws with heads/

washers with a minimum diameter of 1" (25 mm)

at spacing no more than 12" on-center along the

perimeter of the board and along the studs.

When properly installed, the product's rigid yet

flexible edges allow for a tightly butted edge where

the boards meet, further increasing the floor’s

thermal performance.

How to hold insulation in place over time

While the insulation batts should stay in place, you can

apply an extra layer of material to secure the batts over

time. This includes plastic strapping, a crisscross of

string, or holding in place with a layer of chicken wire.

Simply unroll the wire and staple it to the joists.

ROXUL COMFORTBATT

precise cutting to ensure a fit without gaps and voids.

®

higher density batts make it simple for

18

The combination of ROXUL COMFORTBOARD IS

and ROXUL COMFORTBATT ensures optimum

long-term thermal performance from your

exposed floor and crawl space assembly.

Page 19

ROXUL® Insulation Products For Residential Thermal Applications

Better: R-30

2 x10 Joists + CB R-30

(or attach 1 x 2 furring/strapping strip to

2 x 8 joist to build up the joist cavity depth)

1

Flooring

2

Sub-Floor

3

Vapor Control Layer

4

2 x10 Joists

5

ROXUL COMFORTBATT® (R30)

*

1

2

5

4

3

Best: R-36

2 x10 Joists + CB R-30 + CB IS R6

(or attach 1 x 2 furring/strapping strip

to build up the joist cavity depth)

1

Flooring

2

Sub-Floor

3

Vapor Control Layer

4

2 x10 Joists

5

ROXUL COMFORTBATT® (R30)

6

ROXUL COMFORTBOARD™ IS (R6)

*

1

2

5

4

6

3

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information.

19

Page 20

Better | Best

Thermal insulation systems

for crawl spaces.

Many home and cottage owners can enjoy additional

benefits by insulating their crawl spaces. In some

cases, the most difficult aspect of insulating a crawl

space is having enough room to work around to

properly install the insulation. If the crawl space area

is easy to get at, the installation of ROXUL® insulation is

quite simple.

Non-Vented Crawl Spaces (page 21)

A non-vented crawl space is defined as having a

heating or cooling source, or some other source that

conditions the air within the crawl space. Conditioning

the room helps to manage the relative humidity

in the space, and helps to avoid the growth of mold.

We would treat insulating a non-vented crawl space

in the same manner we do a conditioned basement.

The exterior foundation would be framed in with

studs and then insulation would be installed

between the studs.

Typically, there are two types of crawl spaces – they

are defined by either being vented or non-vented.

The difference in how the two crawl space types are

insulated is defined by either applying insulation to

the exterior wall, or to the ceiling/floor between the

heated living space and the crawl space.

Vented crawl spaces (page 22)

Vented simply refers to the space having air vents,

typically more than one, and are generally located

across from one another at the upper part of the

foundation wall. The vents allow for air movement,

helping to eliminate dry rot, moisture build up, and

other conditions that can develop in these enclosed

spaces. This type of venting would be very common

in a lot of older homes.

With a vented crawl space, it would be treated in the

same manner as a cantilever, or insulating a room

of your house where the underside is exposed to the

elements. The underside of the floor would then be

insulated by adding batt insulation between the

floor joists.

ROXUL Insulation: a two-tiered solution

to insulating crawl spaces

ROXUL has two thermal insulation products

for interior crawl space wall assemblies:

ROXUL COMFORTBOARD™ IS (Insulation Sheathing)

and ROXUL COMFORTBATT®. When used in tandem

within the 2 x 4 stud wall cavity, these two products

help create a more comfortable space.

A vented crawl space can be notorious for dampness,

but ROXUL insulation is water repellent, moisture

resistant yet vapor permeable. The permeance of

ROXUL products allows moisture vapor to pass

through the insulation without being trapped. In the

unfortunate event of a flooded basement where the

insulation becomes wet, ROXUL insulation quickly

dries out and maintains its R-value. Unlike other

insulations, ROXUL won’t absorb water and is not

susceptible to mold growth.

20

COMFORTBOARD™ IS and the effects of

thermal bridging

Before recommending the Better I Be st R-values for

the crawl space wall assembly, we need to understand

thermal bridging – the process that describes a

material’s capacity to conduct heat or cold from

one material to another.

In a typical crawl space, thermal energy transfers

from the wood studs and interior of the concrete

foundation into the exterior foundation and

surrounding soil. The studs perform as the conduit

or “thermal bridge”, lowering the effective R-value

of the wall assembly. Insulated sheathing like

COMFORTBOARD IS reduces this thermal bridging

by acting as a thermal buffer between the concrete

and the studs.

Page 21

ROXUL® Insulation Products For Residential Thermal Applications

Non-vented crawl spaces.

Better: R-15

2 x 4 Studs + CB R-15

1

Foundation Wall

2

2 x 4 Studs

3

ROXUL COMFORTBATT® (R15)

4

Vapor Control Layer*

1

Best: R-21

2 x 4 Studs + CB R-15 + CB IS R-6

1

Foundation Wall

2

ROXUL COMFORTBOARD™ IS (R6)

3

2 x 4 Studs

4

ROXUL COMFORTBATT® (R15)

5

Vapor Control Layer*

2

3

4

1

3

2

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information.

4

5

21

Page 22

Better | Best

Vented crawl spaces.

Better: R-30

2 x 10 Joists + CB R-30

(or attach 1 x 2 furring/strapping strip to

2 x 8 joist to build up the joist cavity depth)

1

Vapor Control Layer

2

2 x 10 Joists

3

ROXUL COMFORTBATT® (R30)

4

Foundation Wall

*

2

1

3

Best: R-36

2 x 10 Joists + CB R-30 + CB IS R-6

(or attach 1 x 2 furring/strapping strip

to build up the joist cavity depth)

1

Vapor Control Layer

2

2 x 10 Joists

3

ROXUL COMFORTBATT® (R30)

4

ROXUL COMFORTBOARD™ IS (R6)

5

Foundation Wall

*

4

2

1

3

4

5

22

*Check with your state/munic ipal building code for app rove d vapor barrier/retarder information.

Page 23

ROXUL® Insulation Products For Residential Thermal Applications

Creating a more

comfortable home

for today, tomorrow

and beyond.

In our ever changing world, we

are always looking for new ways

to live more comfortably, be

more environmentally conscious,

and save money along the way.

ROXUL®’s Better I Be st solutions to

thermal insulation applications give

contractors, builders, and home

owners the information needed to

make educated decisions about

the options available.

Using the ROXUL “Better” solution

means you are meeting the current

building code. With the ROXUL

"Best" solution, you are not only

exceeding current and future

building codes, but you are taking

one additional step toward reducing

your environmental footprint.

So, whether you are building a

new home, putting on an addition,

or renovating an existing room in

your home, it is always good to

think about your home comfort,

the environment, and the money

you could save – both today,

and down the road.

23

Page 24

Better | Best

A global leader

R O X U L ® Inc. is part of ROCKWOOL International, the

largest producer of stone wool insulation, which is

made from natural basalt rock and recycled material.

ROCKWOOL International was founded in 1909 and

today operates worldwide withmore than 9,700

employees, with 26 factories across three continents.

ROCKWOOL has more than 40 years experience in

developing and manufacturing advanced wall system

products. For more than 25 years, ROXUL has been

serving the North American market.

In addition to residential insulation, ROXUL also

manufactures a range of other premium insulation

products for commercial and industrial applications.

ROXUL is The Better Insulation™

ROXUL is an innovative insulation offering a world

of green features. When ROXUL is the specified

insulation, green building developers can earn a variety

of LEED® (Leadership in Energy and Environmental

Design) points across four key categories toward

sustainable development.

Environmentally sustainable

Our stone wool production process utilizes some of

the most advanced technology available. The ROXUL

facility is designed to capture and recycle rainwater,

reduce energy consumption, and create zero waste

to landfill by recycling raw materials back into the

production process.

ROXUL insulations are created using naturally

occurring, inorganic raw materials and materials

with a high-recycled content. Stone wool insulation

is non-combustible and achieves its thermal

performance without the use of blowing agents.

The products do not off-gas and are fully recyclable,

therefore contributing to a sustainable environment.

ROXUL is pleased to have third-party certification

of our products’ recycled content for our Milton

facility, completed by ICC-ES SAVE™. All ROXUL

products produced at the Milton facility contain a

minimum of 40% recycled content. For further details,

contact your ROXUL Sales Representative. Please visit

www.roxul.com for the latest information.

TM

2012-2013

COMFORTBATT® and DR AINBOARD

COMFORTBOARD™ IS and ROCKFILL™ are tr ademarks of ROXUL Inc.

LEED® is a register ed tradema rk of Un ited St ates Green Building Council.

GREENGUARD® is a register ed tradema rk of Gr eenguard Envir onmental Institute.

Suite 105, Milton, Ontario L9T 0H9

420 Bronte Street South

®

are registe red tr ademark of ROXUL Inc.

ROXUL INC.

Tel: 1-800-265-6878

www.roxul.com

ROX-2589_1213

Loading...

Loading...