Safety, Operation and Maintenance Instructions

For Electric Upholstery Staple Gun (NS12)

I-50AA

Product Specications:

• Operating at 110 volts, 60 Hz, 12.5A.

• Staple type: 22 gauge ne wire, 71 series staples.

• Staple crown width: 9.1 mm.

• Staple leg length range: 1/4" to 5/8".

• Use our fasteners. Stock #: NS32/E, NS33/E,

NS34/E, NS35/E .

Applications:

• Upholstery applications: covering cornice boards,

head boards, sofas, chairs, ottomans, upholstered

walls etc.

• Window treatment applications: covering dust boards,

mounting soft treatments to dust boards, etc.

Important:

This manual contains safety warnings, tool operation,

maintenance, cleaning procedures, parts list and

diagram. Keep the manual in a safe place for future

reference.

Limited Warranty

• The warranty covers material and workmanship

defects of the Electric Staple Gun ( NS12 ).

• The warranty period is 90 days from the date of

purchase.

• During the warranty period, replacements or

repairs (at Rowley Co.’s discretion) of the tool will

be made free of charge.

• The warranty does not cover damages by accident,

misuse or due to using staples not recommended

by Rowley Co. Unauthorized repair or modication

of the tool will void the warranty.

• After warranty period expires, customers can still

receive repair services from Rowley Co. The

customer will be charged the labor and parts cost.

• To receive the repairs or replacements under

warranty or to obtain repair services after warranty

period expires, the tool must be returned to Rowley

Co. at the customer’s expense.

• The user of the tool must read and understand the

safety warnings, tool operation procedures and

tool maintenance information contained in this

instruction manual. Rowley Co. is not liable for any

personal injuries or material damages associated

directly or indirectly with using this tool.

Safety Instructions:

Read and understand all safety, tool operation and

maintenance instructions BEFORE using the tool.

A) Work Area Safety

1. Keep work area clean and well lit. Cluttered

benches and dark areas invite accidents. Always

keep the work area free of obstructions, grease,

oil, trash and other debris.

2. Do not operate the Staple Gun near ammable

fumes or liquids. Sparks created by the Staple

Gun may ignite fumes or liquids.

3. Keep bystanders, especially children away while

operating the Staple Gun.

B) Electrical Safety

4. The Staple Gun must be plugged into an outlet

properly installed and grounded in accordance

with all codes and ordinances. This Staple Gun is

equipped with a polarized plug and will t in a

polarized outlet only one way. If plug does not

plug fully into the outlet, turn the plug around. Do

not use any adapter plugs. Check with a qualied

electrician if you are in doubt as whether an outlet

is properly installed.

5. Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is

grounded.

6. Do not expose the Staple Gun to rain or any damp

or wet conditions.

7. Do not abuse the Power Cord. Never use the

Power Cord to carry the Staple Gun or yank it to

unplug the tool. Keep the Power Cord away from

heat, oil, sharp edges, or moving parts. Replace

damaged Power Cords immediately. Damaged

Power Cords increase the risk of electric shock.

8. If an extension cord must be used, make sure the

extension cord exceeds the recommended

minimum wire gauge (See Table below).

Cord Length (ft.) 0-25 26-50 >50

Minimum Wire Gauge 14 1 0 Not

Rec ommended

9. Make sure your extension cord is properly wired

and in good condition. Always replace a damaged

extension cord.

10. Keep your extension cords from sharp objects,

excessive heat, and wet areas.

11. When operating the Staple Gun outdoors, use an

outdoor rated extension cord.

Updated August, 2007

© Rowley Co. 2007

1

C) Personal Safety

12. Avoid accidental firing. Unplug Staple Gun and

avoid placing fingers on the Trigger when carrying

the tool, loading or unloading staples.

13. Always wear safety glasses and ear plugs when

using the Staple Gun.

14. Maintain proper footing, balance and proper

control of the Staple Gun at all time.

15. Stay alert. Always use common sense and watch

what you are doing. Do not operate the tool when

you are tired.

D) Operation Safety

16. Stapling will be more successful if you have a firm,

stationary and non cushioned surface underneath

the workpiece.

17. Use clamps to secure and support the workpiece

to a stable platform. Holding the workpiece by

hand or against your body can be unstable and

may lead to loss of control.

18. Do not use the Staple Gun if Safety or Trigger

does not operate properly.

19. Always keep hands away from the workpiece,

Staple Gun Nose when firing staples. The Staple

Gun has enough power to force staples through

skin and causing serious injury.

20. Fire staples into an appropriate surface only. Do

not attempt to fire staples into surfaces too hard

to penetrate. Do not fire a staple on top of another

staple, or at too steep of an angle. Fasteners can

ricochet causing personal injury.

21. Do not fire staples too close to the edge of a

workpiece. Staples may split the workpiece and

fly free, causing personal injury.

22. Never point the Staple Gun at yourself or at

anyone else. Always assume that Staple Gun is

loaded with staples and powered. Never engage

in horseplay.

23. If the Staple Gun overheats, unplug it from the

power source and let it cool down.

24. Always keep tool clean, properly maintained. Do

not use a damaged tool. Tag damaged tools "Do

not use" until repaired.

25. Never leave the Staple Gun unattended when it is

plugged into an electrical outlet.

26. Disconnect the Staple Gun from power source,

empty out staples before clearing a staple jam,

servicing, cleaning, repairing or storing.

27. Store the Staple Gun at a safe place and keep it

out of reach of children.

28. When servicing a tool, use only authorized

replacement parts. Follow instructions in the

"Inspect, Maintain and Clean the Tool" section of

this manual. Using unauthorized parts or failure to

follow maintenance instructions may create a risk

of electric shock or injury.

Operation Instructions:

Warning: This Staple Gun is not suited for nailing or

stapling into concrete, masonry, bricks, or metal.

Warning: Do not fire if there is a staple jam. Unplug the

unit and follow the "Remove Jammed Staples"

section of this instruction manual.

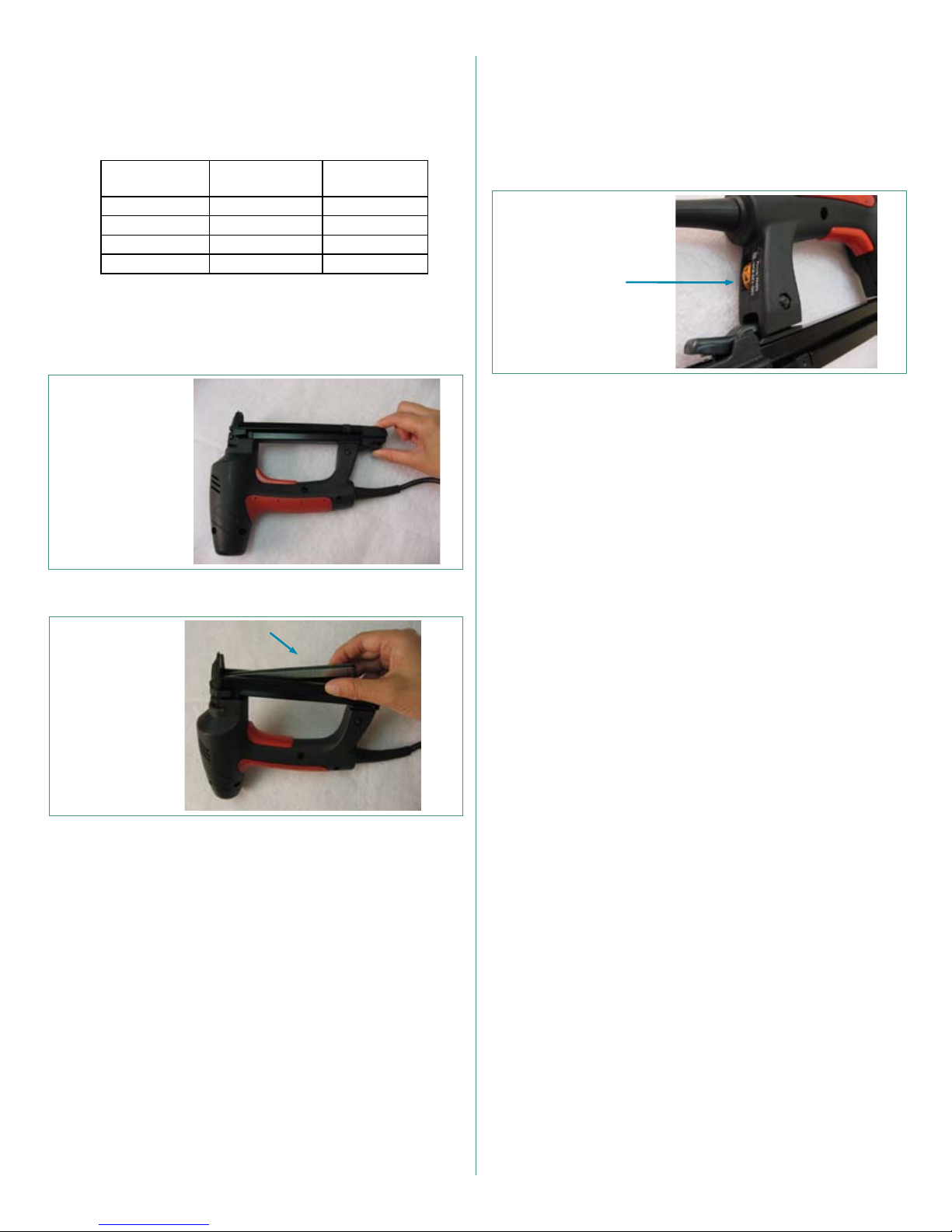

Warning: This Staple Gun has a safety mechanism. With

the safety depressed against the stapling surface, the

staple gun will fire only once when the trigger is

pressed. Do not attempt to disable the safety. Test the

safety mechanism and make sure it is always in proper

working order.

Apply Pressure Here

When Fire Staples

Trigger

Safety

Nose

A) Test the Safety Mechanism

1. The Staple Gun should not fire if the Safety is not

depressed against the stapling surface.

2. Make sure the Staple Gun is unplugged from the

power supply. Empty staples out of the Magazine.

Check the Trigger and the Safety, make sure both

move freely, without sticking.

3. Plug the Staple Gun into the power outlet. Test the

staple gun by depressing the Safety against the

stapling surface without pressing the Trigger. The

Staple Gun must not fire. If it fires, stop

immediately and contact us for repair.

4. Remove the Staple Gun from the stapling surface.

The Safety should return to its original position.

Squeeze the Trigger. The Staple Gun must not fire.

If it fires, stop immediately and contact us for

repair.

5. Depress the Safety against the stapling surface

and squeeze the Trigger. The tool should fire only

once. If it does not fire or fires more than once,

contact us for repair.

Fastener View

Window

Magazine

Fig. 1

Power Cord

Magazine

Lever

2

B) Load Staples

Warning: Unplug the Staple Gun before loading staples.

1. We strongly suggest using following staples from

Rowley Co. See size chart below.

Approx.

Stock # Leg Length Leg Length

NS32/E 6mm 1/4"

NS33/E 10mm 3/8"

NS34/E 13mm 1/2"

NS35/E 16mm 5/8"

2. Make sure the Staple Gun is unplugged from the

power outlet.

3. Turn the Staple Gun upside down. Depress the

Magazine Lever as shown in Fig. 2, and Magazine

cover will slide open.

Fig. 2

Depress Lever to

open Magazine

4. Drop in a strip of staples with staple legs pointing

up as shown in Fig. 3.

Fig. 3

Drop in Staples with

legs up

4. If you need to adjust stapling depth, turn the

Depth Adjuster as shown in Fig. 4. Turn to a

higher number for deeper penetration. Apply more

pressure on the Staple Gun head (See Fig. 1)

when even deeper staple penetration is desired or

when driving a staple into hard wood. Try depth

adjustment on a scrap piece first.

Fig. 4

Depth

Adjuster

5. Do not hold Staple Gun at an extreme angle when

firing staples.

6. Avoid firing Staple Gun when empty of staples.

7. If the Staple Gun overheats during stapling, stop

stapling and let it cool down before resuming

operation.

D) Remove Jammed Staples

1. Stop firing. Unplug the Staple Gun. Release the

Magazine Lever and remove the remaining clip of

staples. If a staple is jammed in the discharge

area, remove it with a pair of pliers.

2. If a staple is jammed in the front of the Magazine,

use a flat screwdriver and/or needle nose pliers to

remove the Staple. Be careful not to damage the

Staple Gun with the pliers or screwdriver.

5. Slide the Magazine forward until Magazine Lever

clicks into place. Do not force.

C) Operate Staple Gun:

Caution: Always wear safety glasses and ear plugs before

operating Staple Gun!

1. Plug the Stapler Gun Power Plug into a power

outlet.

2. Firmly grasp Staple Gun by handle, and with the

other hand applying pressure at the head of the

Staple Gun (See Fig. 1), so that the Nose is flat

against the stapling surface, and the Safety is

depressed.

3. Gently squeeze the Trigger to fire a staple. Test

stapling action by firing a few staples into a scrap

piece.

Note: Each time you fire the Staple Gun, the

Safety must be depressed firmly against the

stapling surface.

E) Inspect, Maintain and Clean the Tool

Warning: Make sure that the Staple Gun is unplugged

and staples are unloaded before performing any

inspection, maintenance, or cleaning procedures.

1. Before each use, inspect the general condition of

the Staple Gun. Check for loose screws,

misalignment or binding of moving parts, cracked

or broken parts, damaged electrical wiring, and

any other condition that may affect its safe

operation. If abnormal noise or vibration occurs,

have the problem corrected before use. Do not

use a damaged Staple Gun.

2. Wipe Staple Gun clean with a lint free cloth.

3. Keep the Nose and Safety free of dirt or debris at

all times. Debris jammed in the Safety can prevent

the Safety mechanism from working properly.

3

Parts List:

Part No. Description

1 Stop

2 Striking Pad

3 Blade

4 Coil Spring

5 Coil

6 Bumper

7 Power Cord

8 Wire Cover

9 Rod

10 Control Unit

11 Trigger Switch

12 Trigger Spring

13 Trigger

14 Body A

15 Body B.

16 Safety Switch

17 Hex Bolt

18 Nose Cover

19 Nose Plate

20 Spacer

21 Safety

22 Magazine

23 Feeder Shoe

24 Inner Magazine

25 Label

26 Brace

27 Magazine Back

28 Lever Spring

29 Lever

30 Feeder Spring

31 Support

32 Depth Adjuster

1

8

2

10

3

11

12

4

13

5

6

16

14

9

7

32

15

17

18

19

20

21

31

29

22

30

24

23

4

25

28

27

26

Loading...

Loading...