Field Service Manual and Parts Catalog

Part No. 25553601 Second Edition

Century Series C-2, C-4, C-6 Bill Changer

Field Service Manual and Parts Catalog

Rowe International, Inc. 1500 Union Ave., SE • GRAND RAPIDS, MI 49507-1884 • (616) 243-3633 Printed in USA

Preface

The Century Series is an all new model bill changer. This manual has been designed and organized to provide you with an easy-to-use source of service information.

This service manual is divided into eight sections:

- Section 1: SYSTEM DESCRIPTION Introduces you to the C-2, C-4, C-6, their features, and their major components. A Sequence of Operation Flowchart details Bill Changer operation.

- Section 2: INSTALLATION Provides you with the information that you need to install your Bill Changer safely and securely.

- Section 3: LOADING & AUDITING Outlines instructions for loading and unloading the Bill Changer coin hopper, as well as a basic auditing procedure to guard against loss of money from theft or malfunction.

- Section 4: PROGRAMMING Gives instructions for changing Bill Changer default (factory) programming.

- Section 5: MAINTENANCE & ADJUSTMENTS Provides instructions for removing Bill Changer components for service, and details mechanical maintenance procedures.

- Section 6: TROUBLESHOOTING & SELF-DIAGNOSTICS Describes the meaning of Bill Changer fault codes, as well as remedies for each. This section also describes miscellaneous problems that can occur but may not cause a fault code to be displayed, as well as checking procedures used to verify that the Bill Changer is functioning properly.

- Section 7: TECHNICAL INFORMATION Contains the Bill Changer System Schematic Diagram, as well as the board layout and components list for the Control Computer.

- Section 8: PARTS CATALOG Lists and illustrates all replaceable modules in the Bill Changer.

This manual is intended for owners, route operators, and technicians. This manual provides all field and shop related service and maintenance material. Accessories and their installation and service are discussed in the corresponding accessory instructions (or manuals).

Specific Bill Acceptor information is discussed in the Bill Acceptor Field Service Manual and Parts Catalog included with your Bill Changer.

Contents

| PREFACE | ••••• |

|

ii |

|---|---|---|---|

| CENTURY SERIES BUL | CHANGER MAI | ····· |

SECTION 1: SYSTEM DESCRIPTION

| INTRODUCTION 1 | |-1 |

| FEATURES 1 | -1 |

| GENERAL OPERATION | -2 |

| SYSTEM COMPONENTS | 2 |

| BILL ACCEPTOR 1 | 2 |

| -2 | |

| -3 | |

| -4 | |

| HOPPER1 | -4 |

| CHANGER CONTROL COMPUTER (CCC) 1 | -5 |

| Status Display 1 | -6 |

| Service and Control Switches1 | -6 |

| PROGRAM/NORMAL Slide Switch1 | -6 |

| MODE Button1 | -6 |

| UP Button1 | -6 |

| DOWN Button | -6 |

| TEMPORARILY OUT OF SERVICE LAMP | -7 |

| ELECTRICAL BOX | -7 |

| -/ |

SECTION 2: INSTALLATION

| INTRODUCTION | 2-1 |

|---|---|

| BILL CHANGER MOUNTING & SPECIFICATIONS | 2-1 |

| C-2/4 MOUNTING DIAGRAM | 2-2 |

| C-6 MOUNTING DIAGRAM | 2-4 |

| POWER CONNECTION | 2-6 |

| LINE CORD | 2-6 |

| CONDUIT | 2-6 |

| - |

SECTION 3: LOADING & AUDITING

SECTION 4: PROGRAMMING

| PROGRAMMING THE CENTURY 2 AND CENTURY 4 BILL CHANC | JES 4-1 |

| PROGRAMMING | 4-2 |

| Coin Acceptor Settings | 4-2 |

| Bill Acceptor Settings | 4-3 |

| Money Meter Settings | 4-4 |

| Coin Level Settings | 4-4 |

| Recommended Settings | 4-5 |

| BILL PAYOUT SETTINGS | 4-6 |

| PROGRAMMING EXAMPLES |

SECTION 5: MAINTENANCE AND ADJUSTMENTS

| NTRODUCTION | 1 |

|---|---|

| BILLACCEPTOR | 1 |

| REMOVING A IAMMED BILL |

ר

ז |

|

ן.

כ |

|

| INSTALLING THE BILL ACCEPTOR |

ピ

つ |

| HOPPER | 2 |

| 2 | |

| 2 | |

| HOPPER CHAIN ADJUSTMENT | 5 |

| DISPENSER |

כי

ג |

|

ں

م |

|

| INSTALLING THE DISPENSER ASSEMBLY |

с

А |

SECTION 6: TROUBLESHOOTING & SELF-DIAGNOSTICS

SECTION 7: TECHNICAL INFORMATION

| INTRODUCTION | |

|---|---|

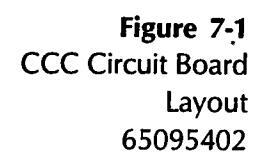

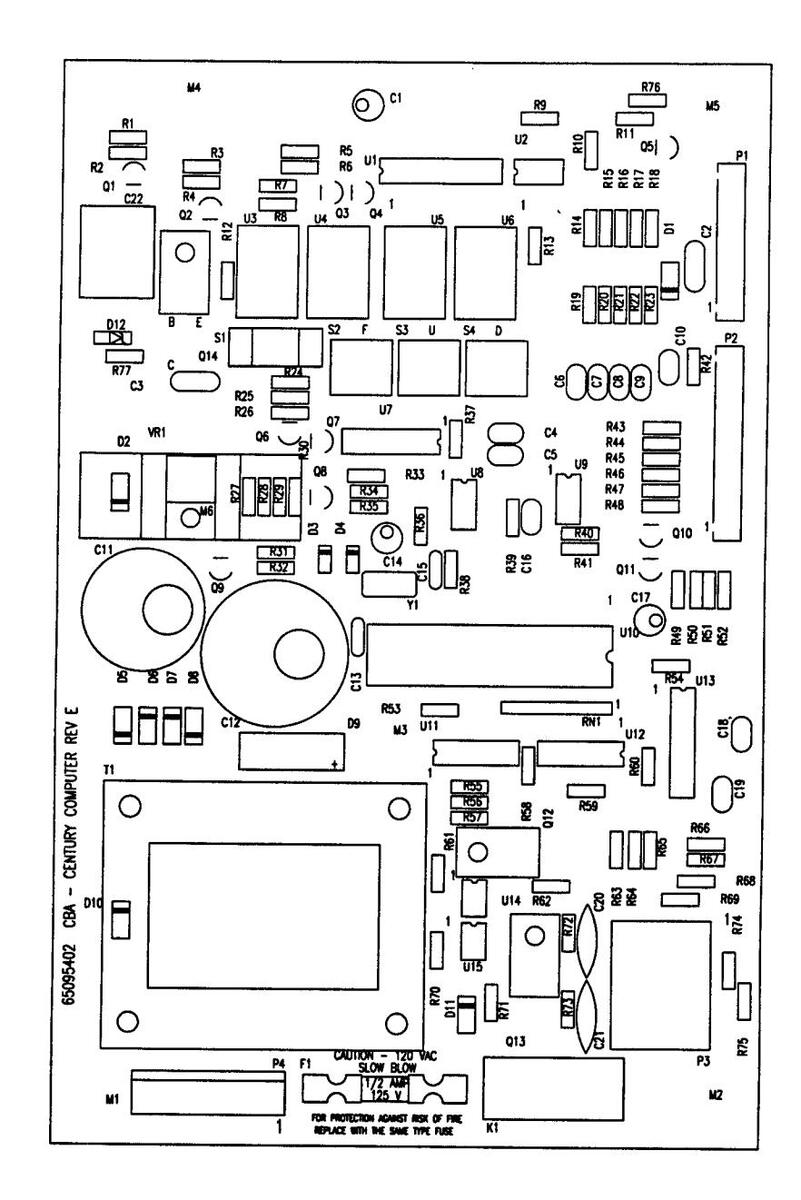

| CCC Circuit Board Layout | |

| CCC CIRCUIT BOARD COMPONENTS LIST | |

| BILL CHANGER SYSTEM SCHEMATIC | |

| (Eng. Draw., 25553301 Q2) |

SECTION 8: PARTS CATALOG

| INTRODUCTION | |

|---|---|

| Catalog Description | |

| Parts List Description | |

| Ordering Replacement Parts | |

| PARTS CATALOG | 8-4 |

| ACCESSORY KITS |

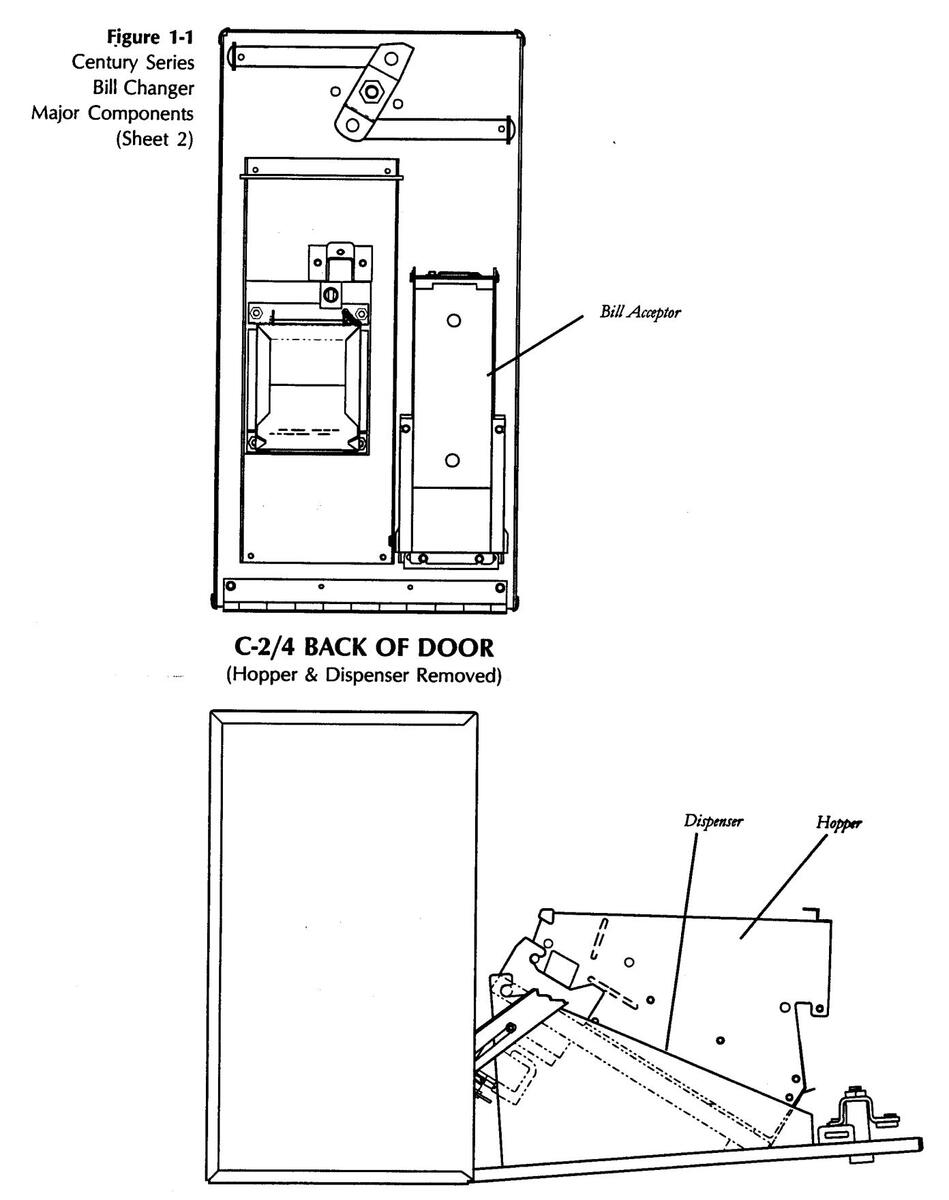

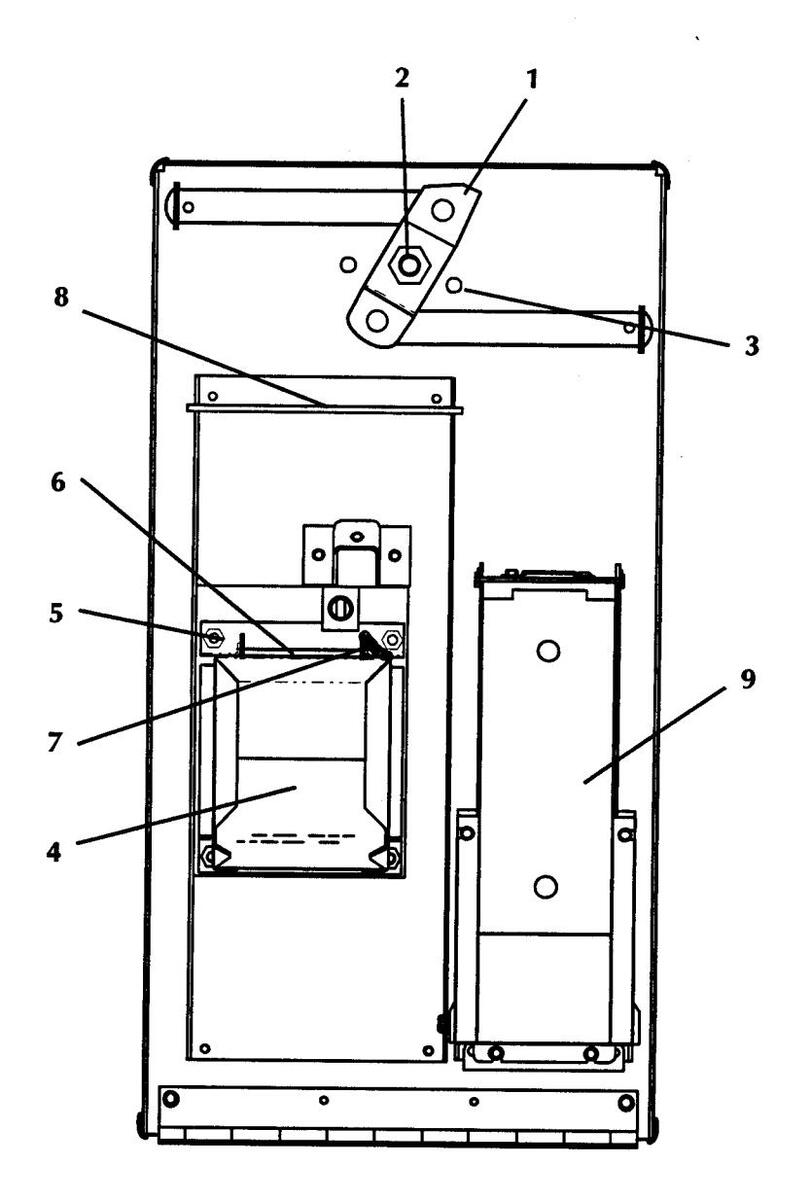

C-2/4 SIDE VIEW, DOOR OPEN

ix

This page intentionally left blank

.

SECTION 1: SYSTEM DESCRIPTION

INTRODUCTION

NOTE:

Throughout this manual, the word "coin" is used to refer to either coins or tokens, interchangeably.

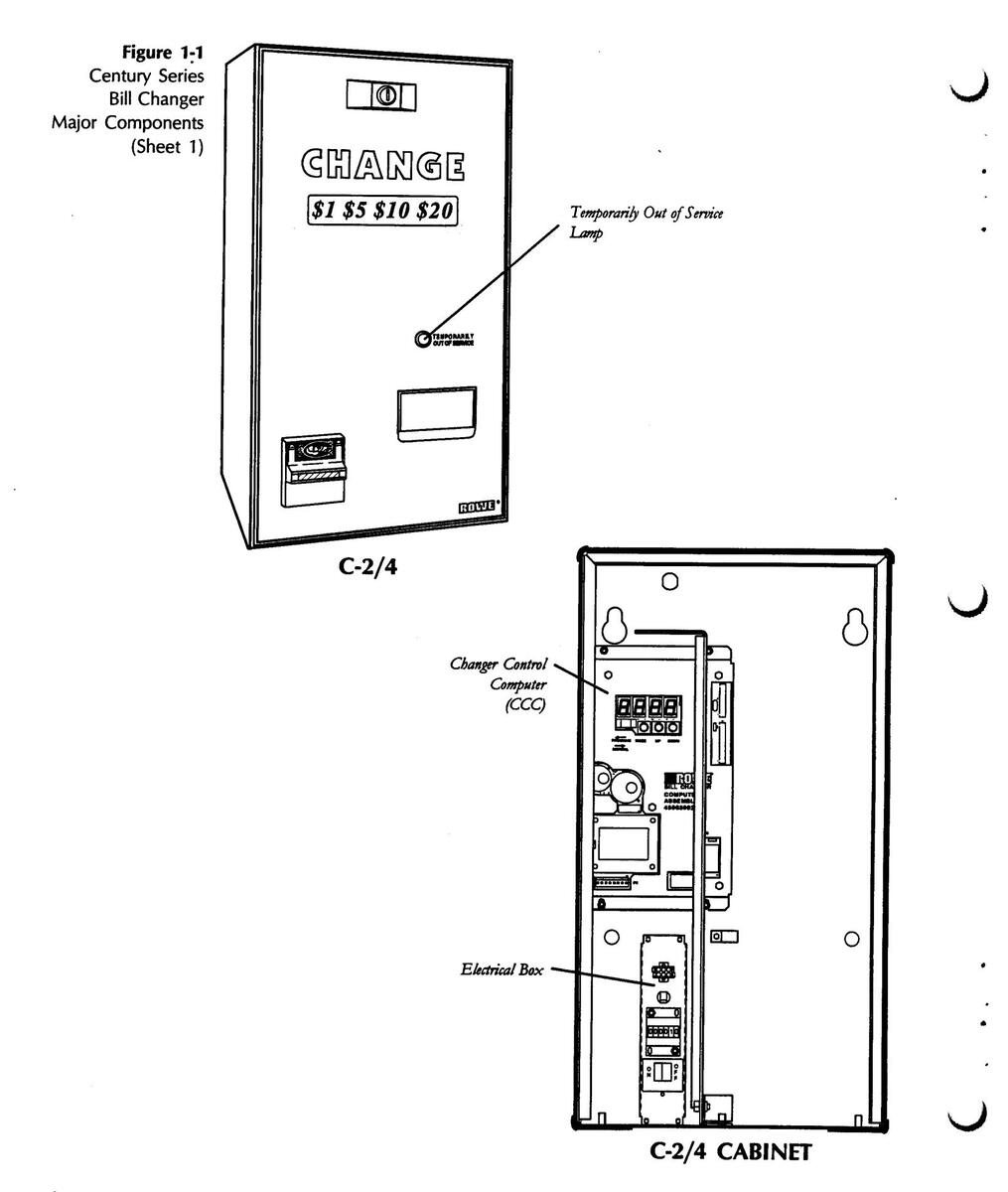

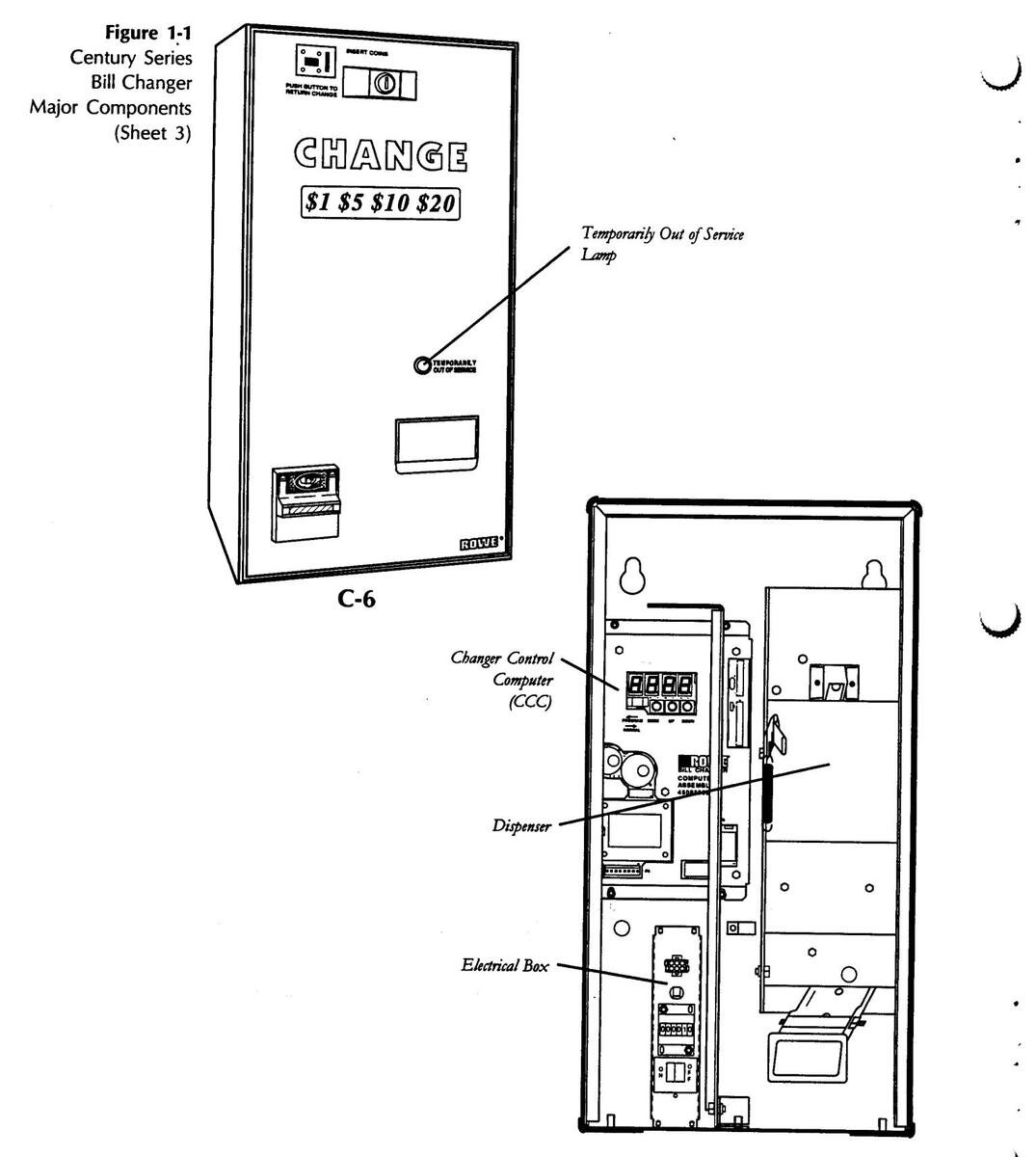

The Rowe® Century Series C-2 Bill Changer will accept 1 dollar ($1) and 5 dollar ($5) bills and the C-4 and C-6 Bill Changers can accept $1 thru $100 bills of United States currency. Using the appropriate bill acceptor, up to 7 denominations of any non-U.S. currency can be accepted. The unit can be programed by the operator to accept any or all of the bills. Figure 1-1 illustrates the major components of the Bill.

The Bill Changer can dispense one type of coin or token at a time. The number of coins dispensed for each bill denomination accepted is programmable.

FEATURES

- . A microcomputer inside the Bill Changer monitors system status, accepts credit inputs from the bill acceptor or coin acceptor (when used), and controls the change dispensing functions.

- . Modular assemblies are featured for fast field substitution.

- . Setup and programming options are easily changed using the MODE, UP and DOWN pushbutton switches.

- . The removable coin hopper permits rapid bulk loading of coins.

GENERAL OPERATION

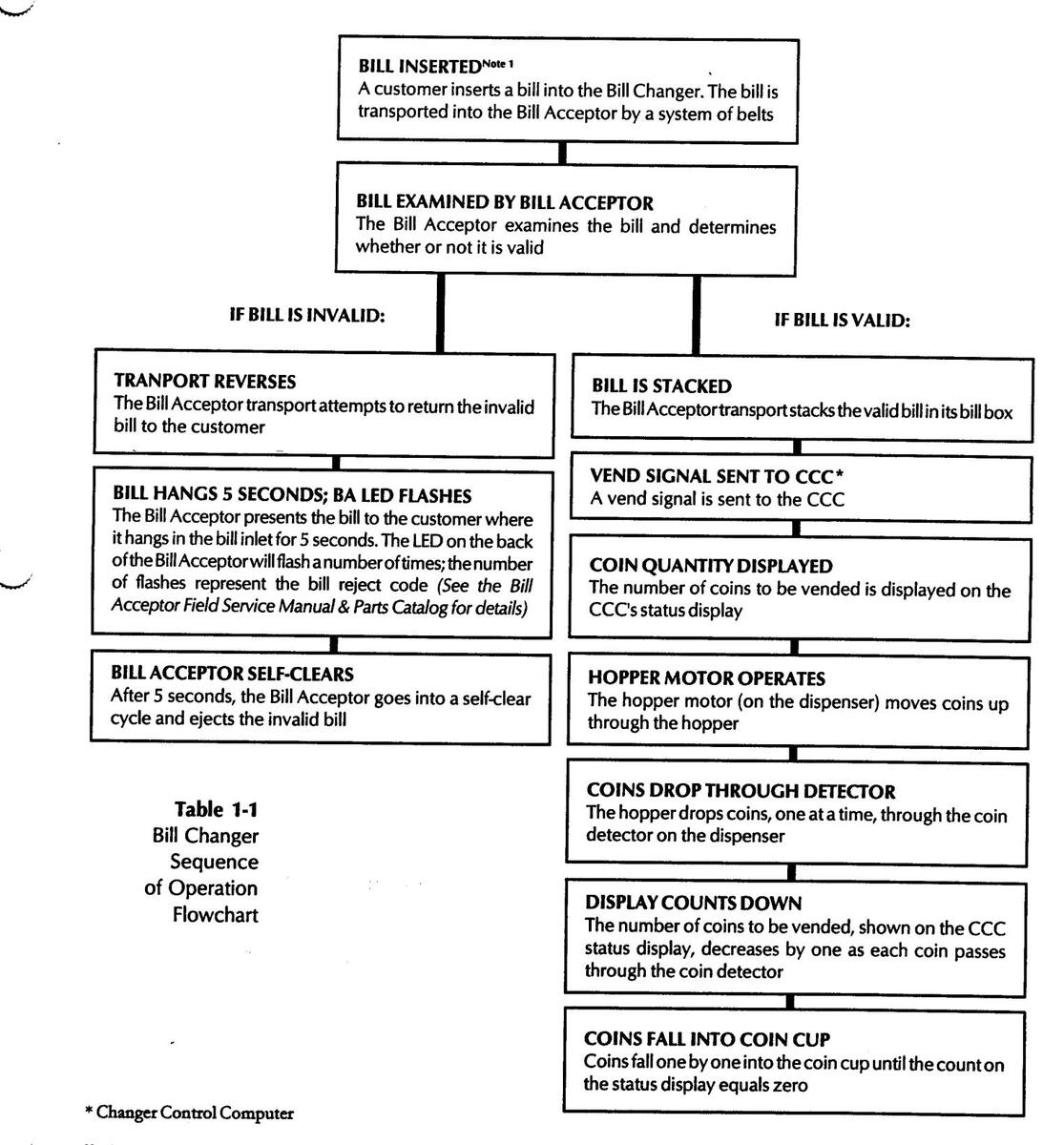

The Bill Changer Sequence of Operation Flowchart (Table 1-1, opposite) gives an overview of the Bill Changer sequence of operation, from the time that a bill is inserted into the changer until coins fall into the Coin Cup. For detailed information regarding the location and function of individual Bill Changer components, refer to System Components, which follows.

SYSTEM COMPONENTS

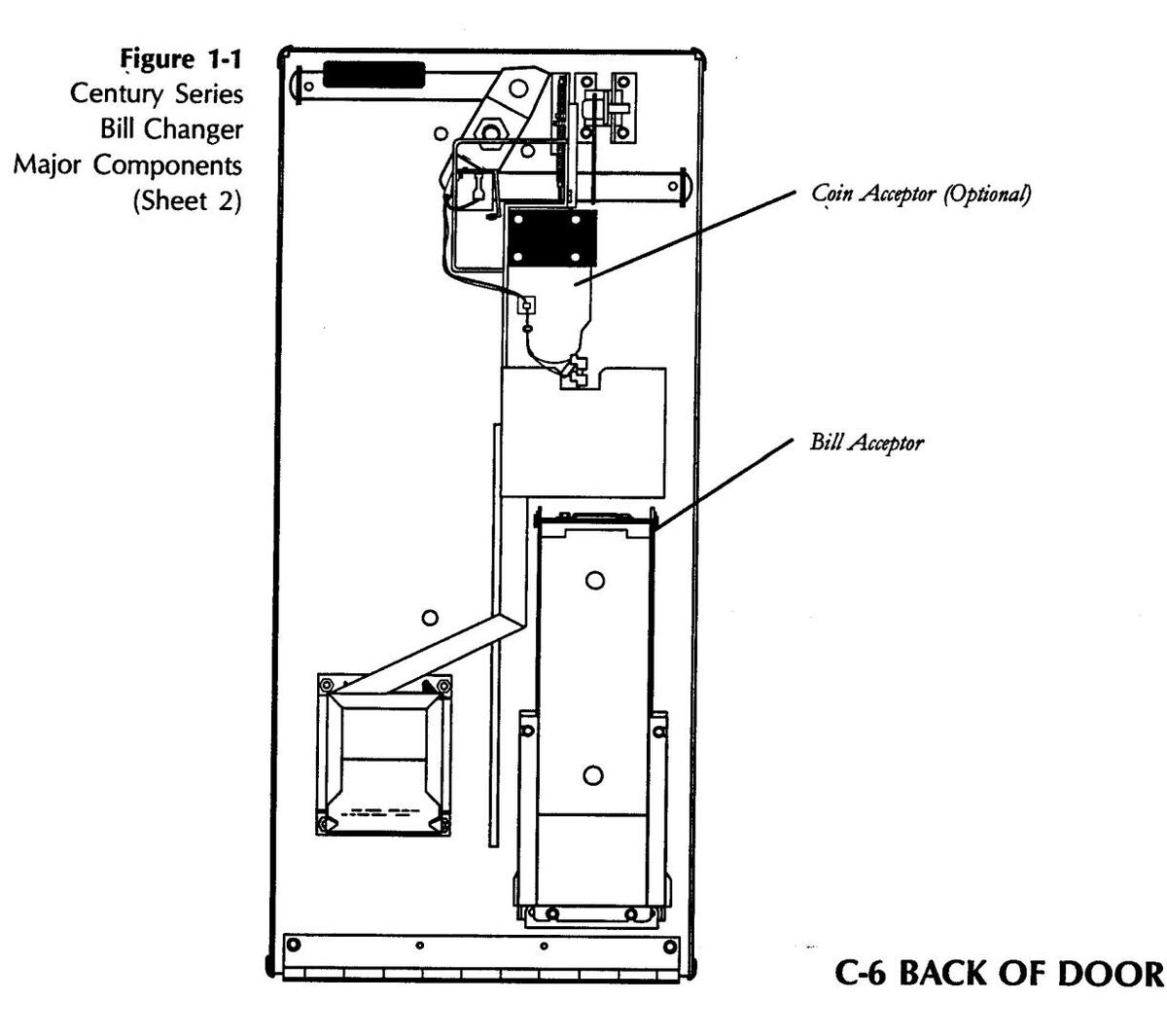

Refer to Figure 1-1 for placement of each of the following Bill Changer components:

Figure 1-2 Bill Acceptor

BILL ACCEPTOR*

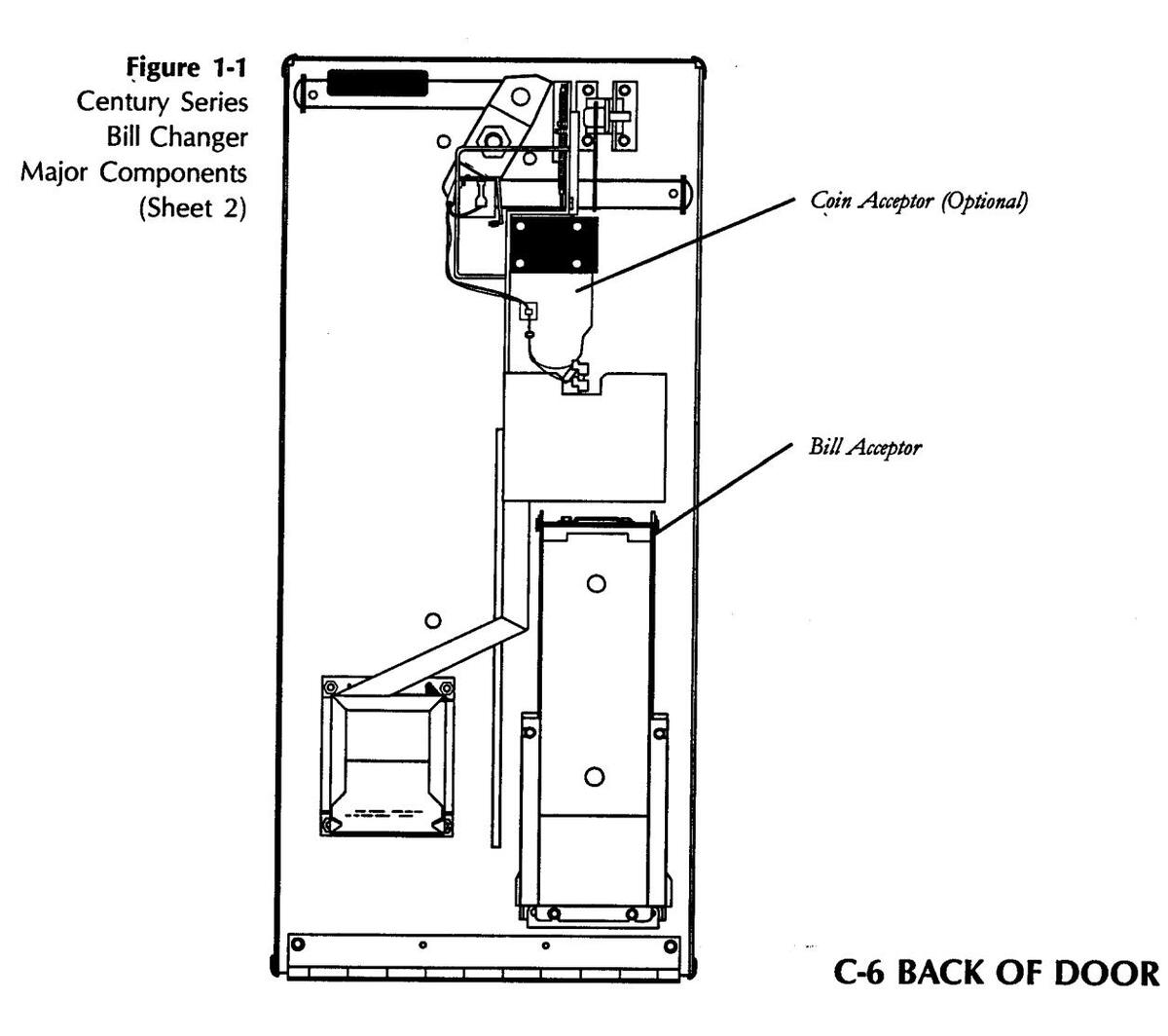

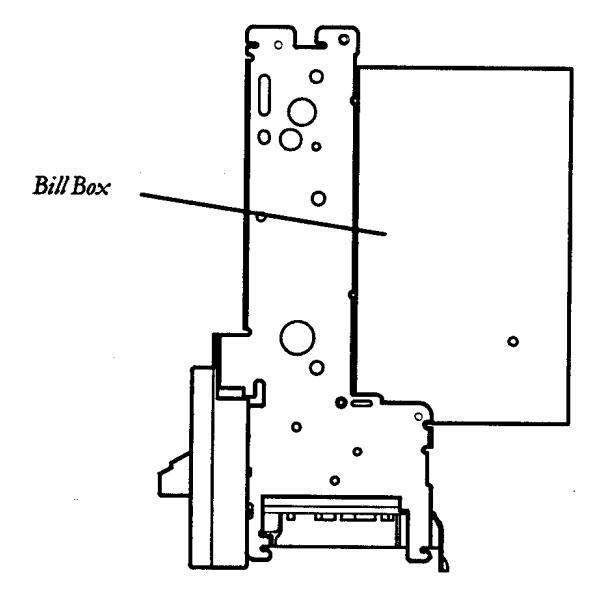

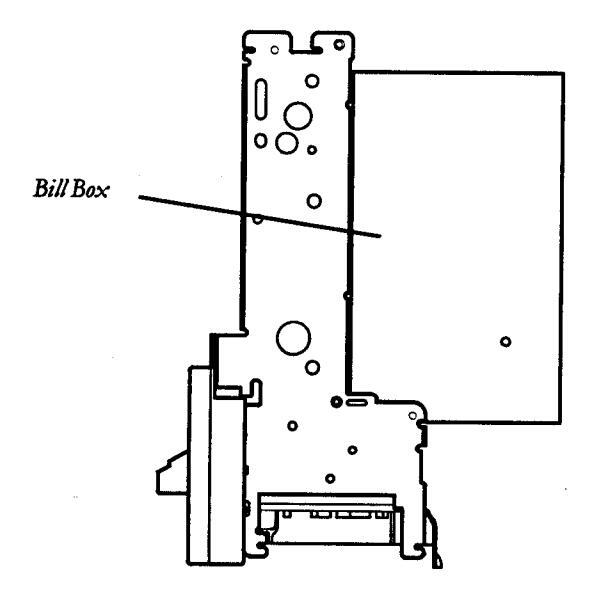

The bill acceptor accepts and validates $1 and $5 or $1 thru $100 bills depending on the bill acceptor. It stacks valid bills in a bill box that opens for easy bill removal. The bill acceptor mounts on the back of the Bill Changer door.

For specific bill acceptor information refer to the bill acceptor field service manual and parts catalog included with the Bill Changer.

* Rowe® Bill Acceptor pictured. Your changer may be equipped with an Acceptor from another manufacturer.

Bill Changer Sequence of Operation Flowchart

Nom 1 The Bill Acceptor Operation described here is applicable when a Rowe® Bill Acceptor is used. Bill Acceptors from other manufacturers may operate differently.

DISPENSER

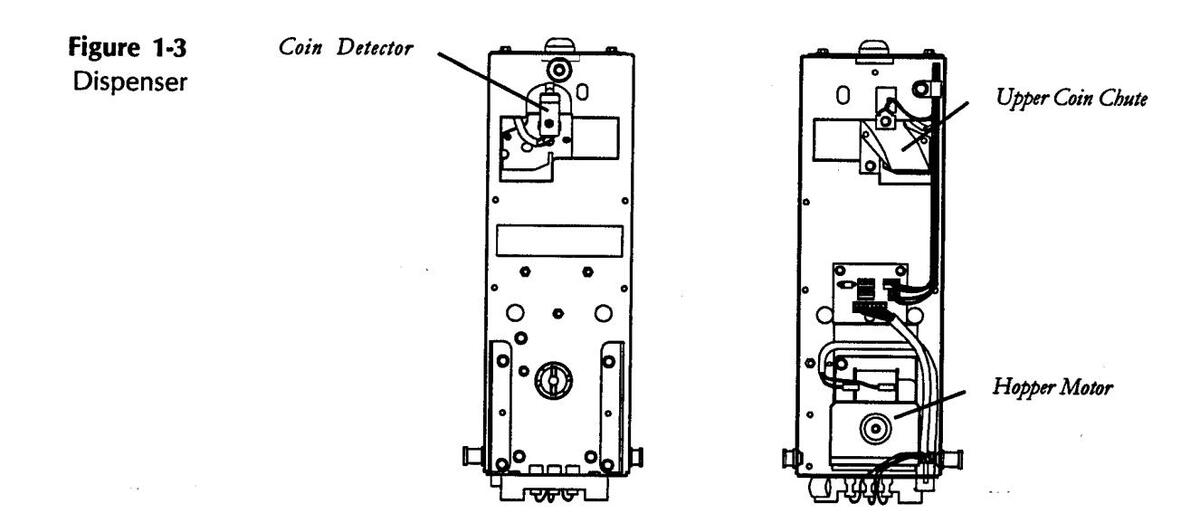

The Bill Changer coin dispenser (Figure 1-3) contains the coin detector system and the hopper motor. On the C-2/4 the dispenser mounts on a bracket on the back of the Bill Changer door. On the C-6 the dispenser mounts on a bracket in the cabinet.

The coin detector system consists of an LED and a photo-transistor, which "count" the coins as they exit the hopper and fall through the upper coin chute into the coin cup.

The hopper motor engages a sprocket that drives the hopper. This 110 VAC motor is controlled by the CCC.

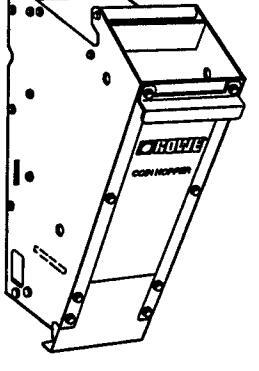

Figure 1-4 Hopper

HOPPER

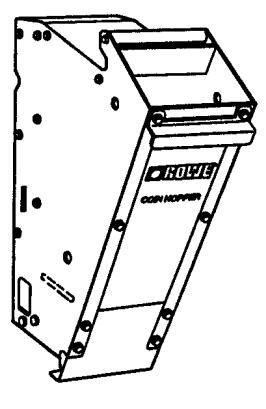

The Bill Changer contains one hopper (Figure 1-4), which mounts on the front surface of the dispenser assembly and pivots out for easy removal.

The hopper transports coins to the coin detector and upper coin chute by means of a chain conveyor driven from below by a sprocket. The chain picks up coins from the bottom of the hopper and carries them up to the top, where they fall through the upper chain guide ring and through the coin detector system.

The hopper chain follows a serpentine path that causes excess coins to fall back into the hopper. This ensures that only one coin per pin enters the coin counting area.

An agitator, which is mounted on the drive shaft inside the hopper, agitates the coin load to minimize coin jams in the hopper and to ensure efficient coin pick up. The hopper also contains the low coin sensor antenna and circuit board.

NOTE:

The low coin sensor alerts the computer when the number of coins in the hopper falls below a certain level.

The Bill Changer uses the low coin sensing system which simplifies the day to day operation. With this system, the operator does not have to program the computer with the number of coins that have been added to the hopper. When the hopper is loaded, the sensing circuit will automatically signal the computer that coins are present. As the hopper is emptied via the normal changemaking process, eventually the level of coins will fall below the threshold required by the low coin sensing circuit. This circuit will then signal the computer that the low level has been reached.

The sensing circuit is mounted on the front surface of the coin hopper with electrical connections made through high pressure contact springs on the dispenser assembly. Because there are no elements inside the hopper to contact the coins, there is absolutely no impact on hopper operation and no degradation of the sensor due to contamination deposited by the coins themselves.

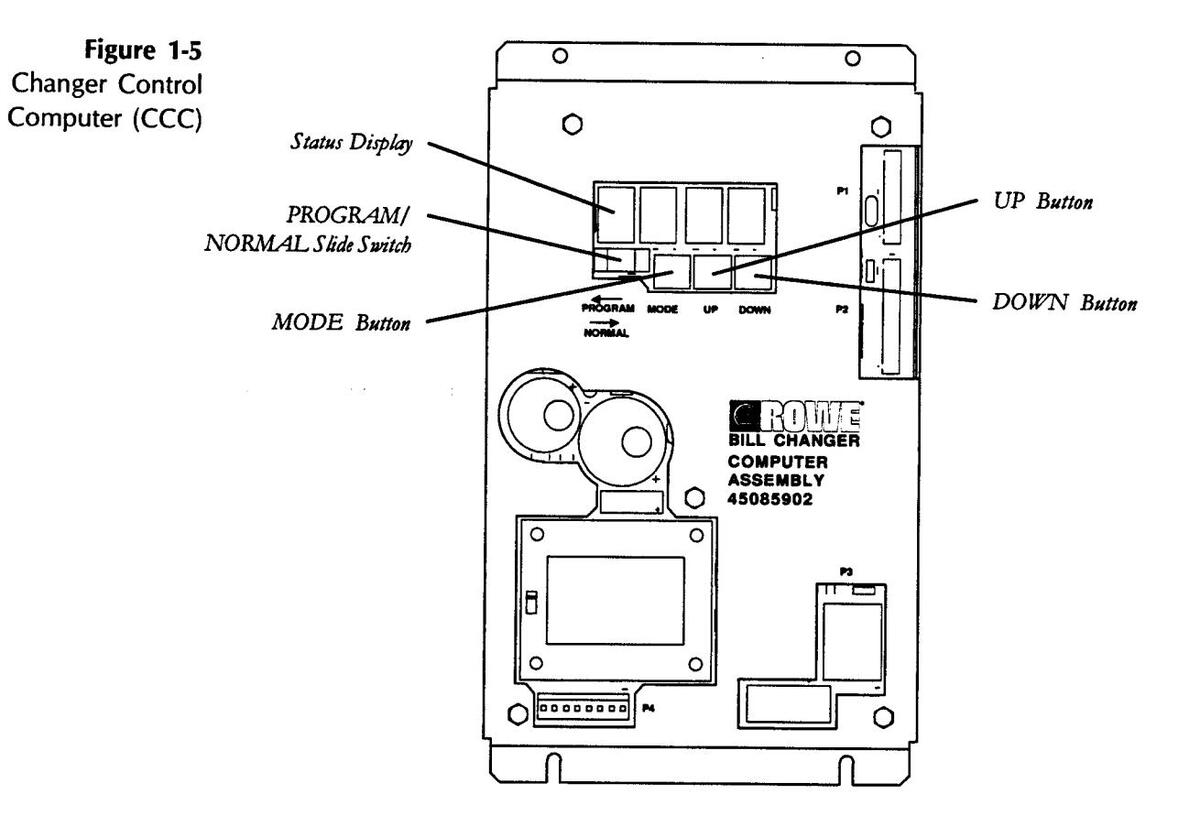

CHANGER CONTROL COMPUTER (CCC)

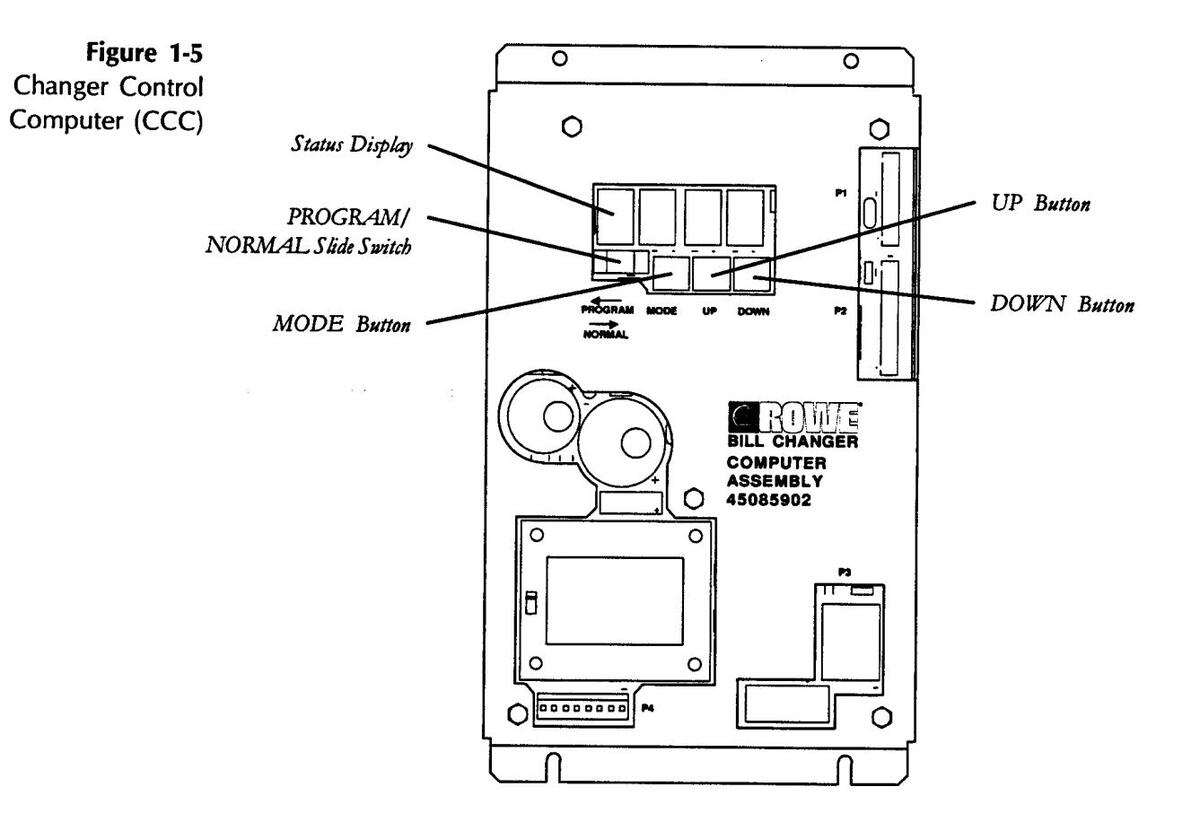

The Changer Control Computer (CCC, Figure 1-5) mounts on the back wall inside the changer cabinet. The CCC contains a microcomputer that controls and/or monitors all of the major functions of the Bill Changer, including communication with the Bill Acceptor and change dispensing functions. It also contains the following controls and displays:

NOTE: ·

Status Display

When the CCC is initially switched from the NORMAL to PROGRAM position, the status display will show Pcp 9.

The four character LED status display window displays the many Bill Changer programming and self-diagnostic features described in this manual. See Section 4 for detailed programming information; see Section 6 for error code meanings.

Service and Control Switches

The Bill Changer's service features and programming options are controlled by three push button switches and one slide switch. The descriptions that follow are introductory. Refer to the detailed procedures and instructions in Section 4 for specific programming information.

PROGRAM/NORMAL Slide Switch

Selects either the NORMAL operating position or the PROGRAM position:

PROGRAM Position - Allows you to inspect and/or change Bill Changer setup information. This information is displayed on the status display and is selected and changed by using the MODE, UP and DOWN buttons.

NORMAL Position - Places the changer in a standby condition waiting to give change for a valid bill while the CCC monitors all systems. While in standby, a dash moves from left to right across the 4-character status display.

MODE BUTTON

The MODE button is used to step through the setup options.

UP BUTTON

Increases the displayed value.

DOWN BUTTON

Decreases the displayed value.

TEMPORARILY OUT OF SERVICE LAMP

The temporarily out of service lamp (Figure 1-1) is located on the Bill Changer door above the coin cup. It lights when the hopper is low or out of change, or the changer has shutdown due to malfunction.

Reset the Bill Changer by pushing the UP and DOWN buttons simultaneously on the CCC while the PROGRAM/NORMAL switch is in the NORMAL position. If the error has been corrected, the out of service lamp will go out and a dash will move from left to right accross the 4-character status display. See Section 6 for detailed troubleshooting information

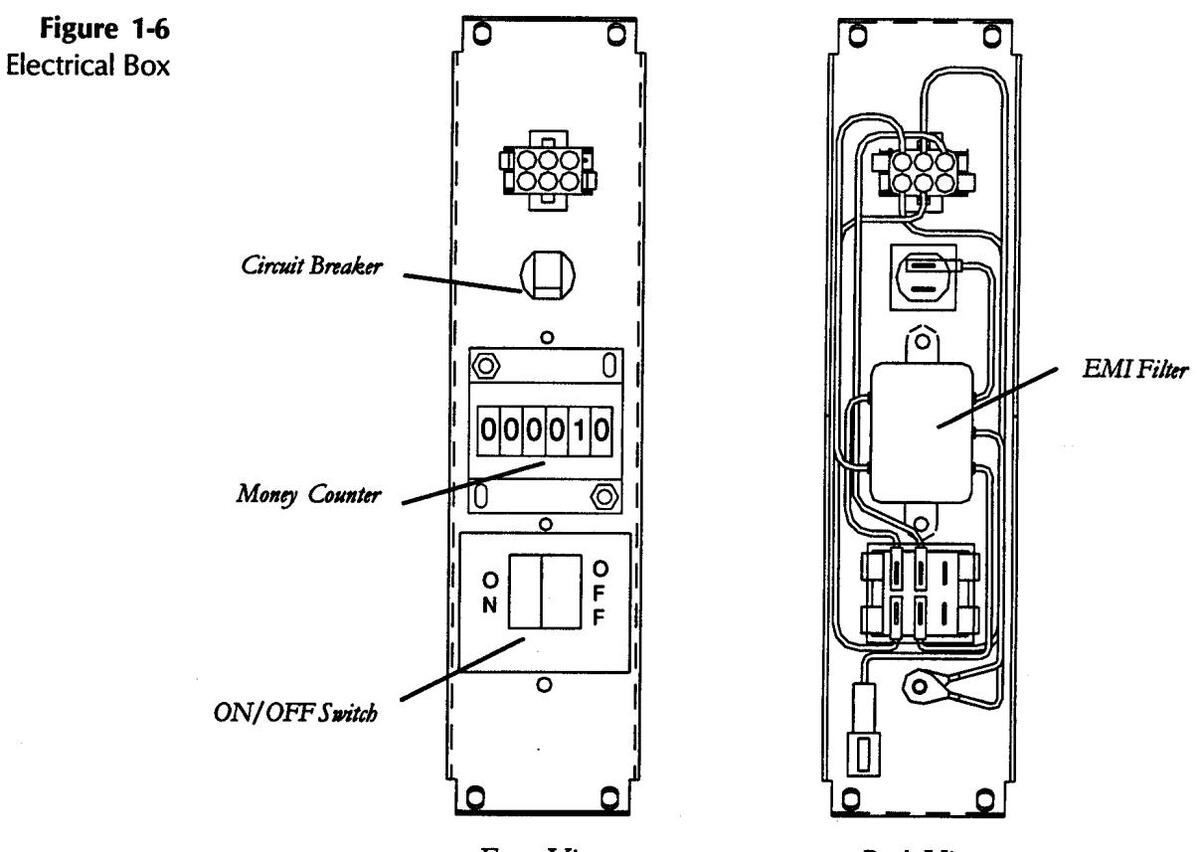

ELECTRICAL BOX

The Electrical Box (Figure 1-6), located inside the Bill Changer cabinet, houses the following electrical components:

The ON/OFF switch controls all power to the machine.

A 5 amp circuit breaker protects the power line to the bill changer.

An EMI filter (ElectroMagnetic Interference filter) removes undesirable electrical noise from the incoming power line.

The Money Counter is non-resettable, and indicates the amount of money handled by the changer.

Front View

Back View

This page intentionally left blank.

SECTION 2: INSTALLATION

INTRODUCTION

NOTE:

For both safety and security reasons, Rowe® strongly recommends that the Bill Changer be securely anchored to a wall or sturdy countertop. Please follow the mounting instructions provided in this manual.

This section provides instructions for installing the Century Series Bill Changers. To prevent theft, or the possibility of damage or injury should the Bill Changer fall, Rowe® strongly recommends that the Bill Changer be securely anchored to a wall or a sturdy countertop1. The instructions that follow provide directions for a secure installation.

Before you begin any installation, be sure that a power source is available and that the changer can be mounted level. Choose a location that is easily accessible to customers, with enough room to open the Bill Changer door for convenient service.

Be sure that you read and understand the warnings and instructions in Power Connection, page 2-6, before making any electrical connections to the Bill Changer.

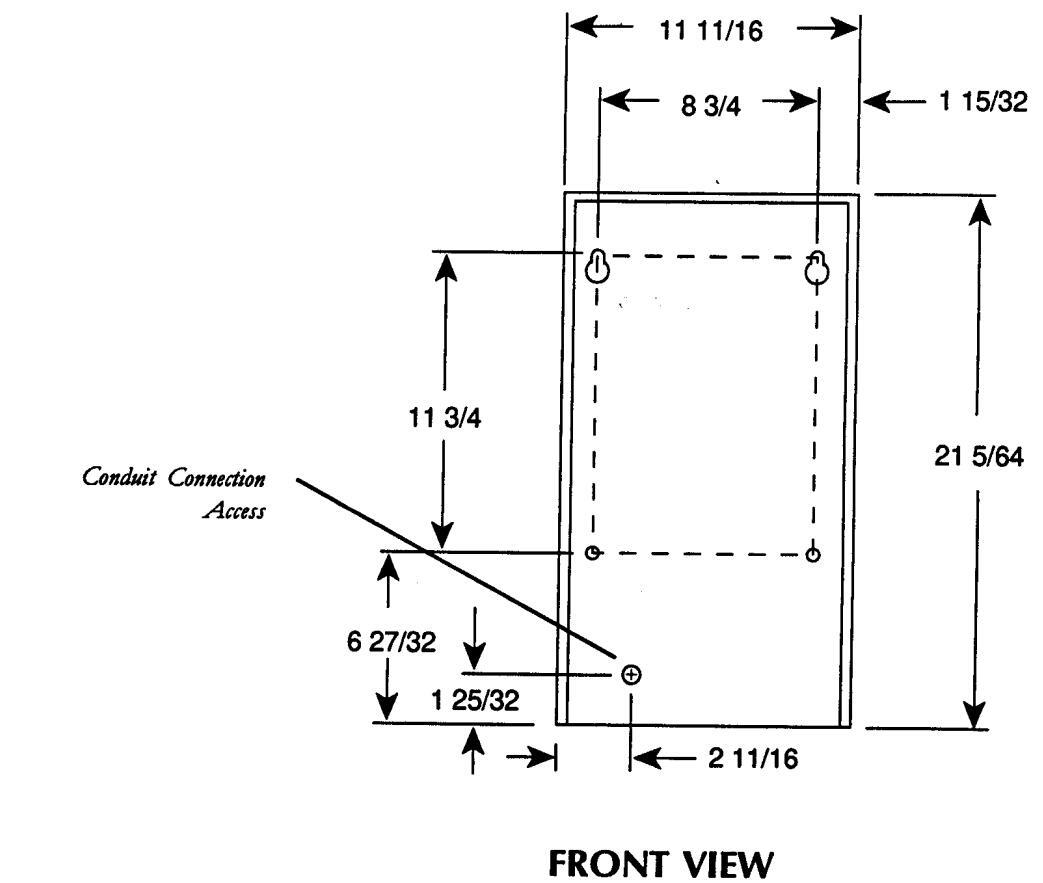

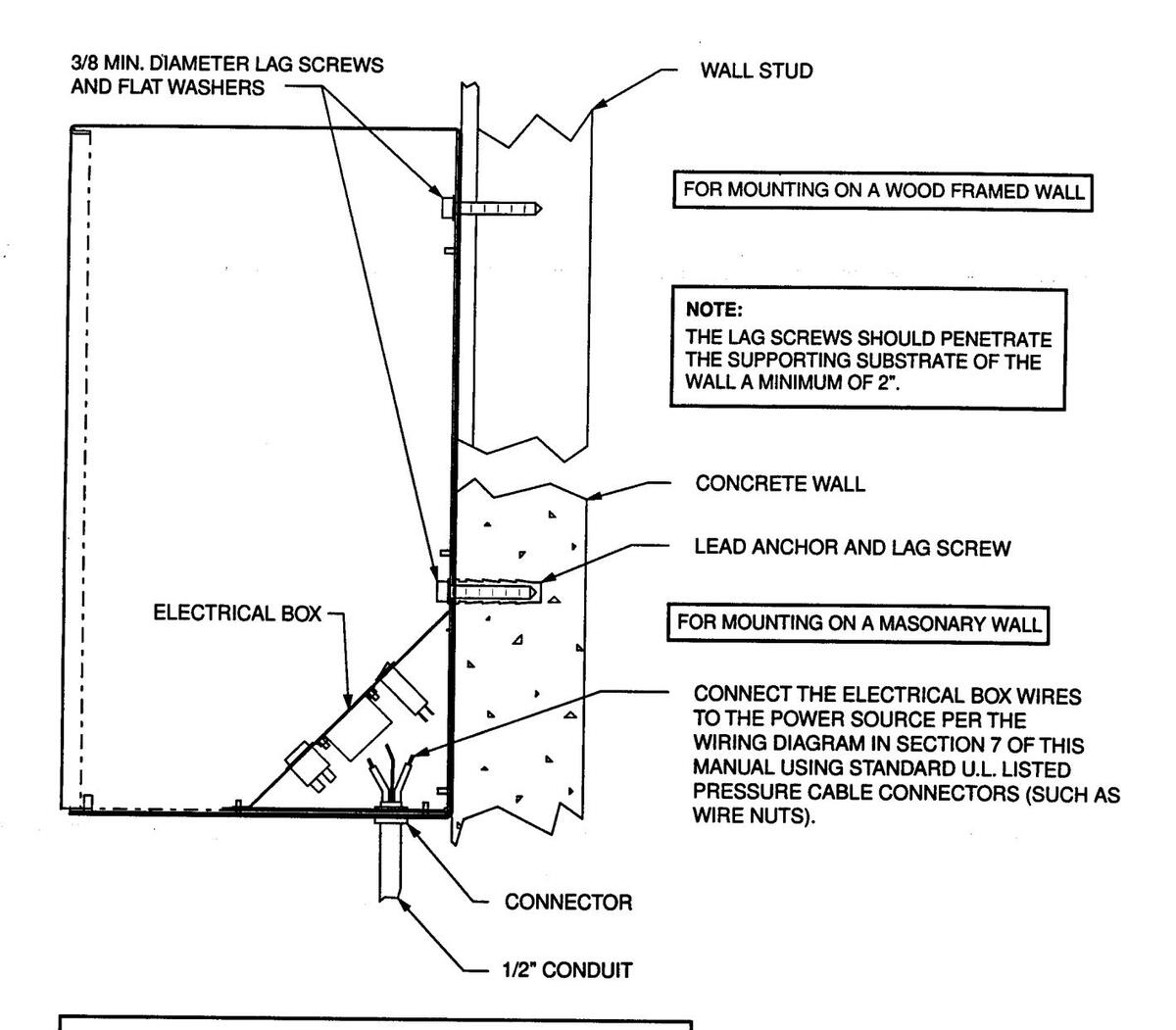

BILL CHANGER MOUNTING & SPECIFICATIONS

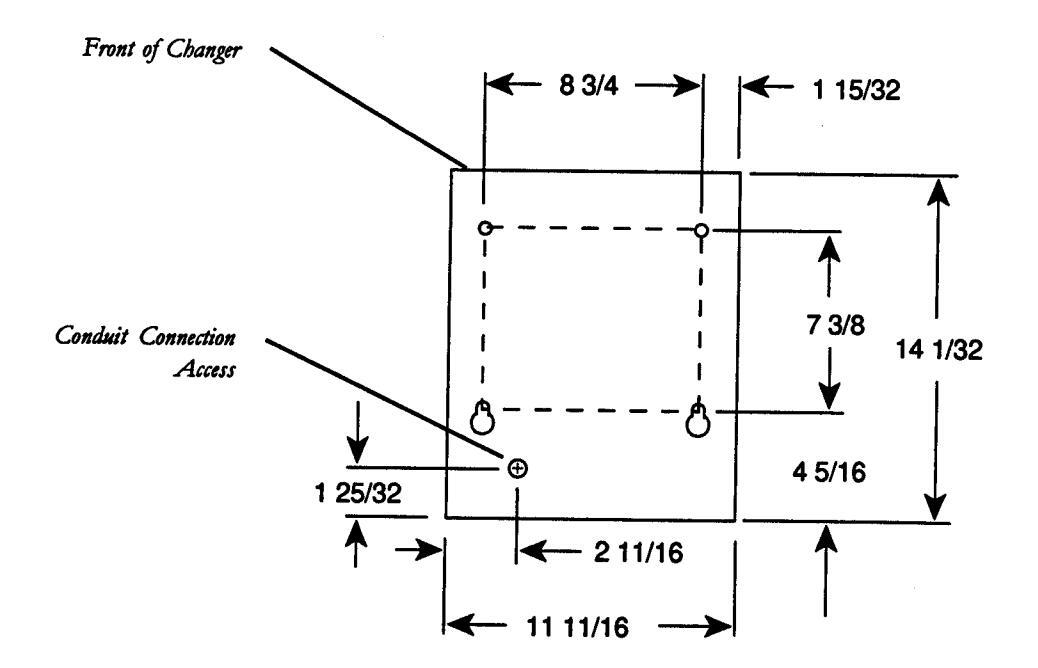

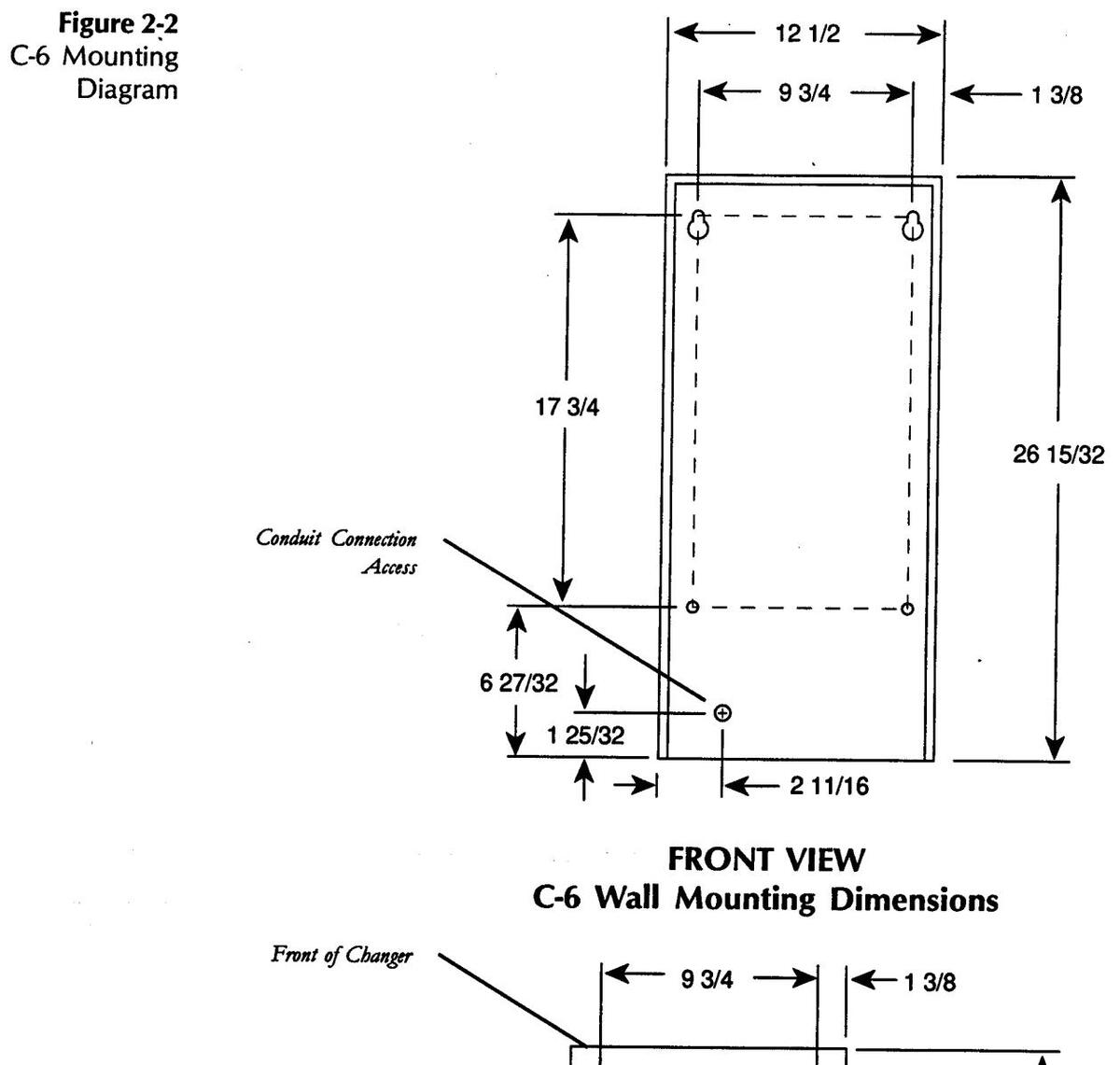

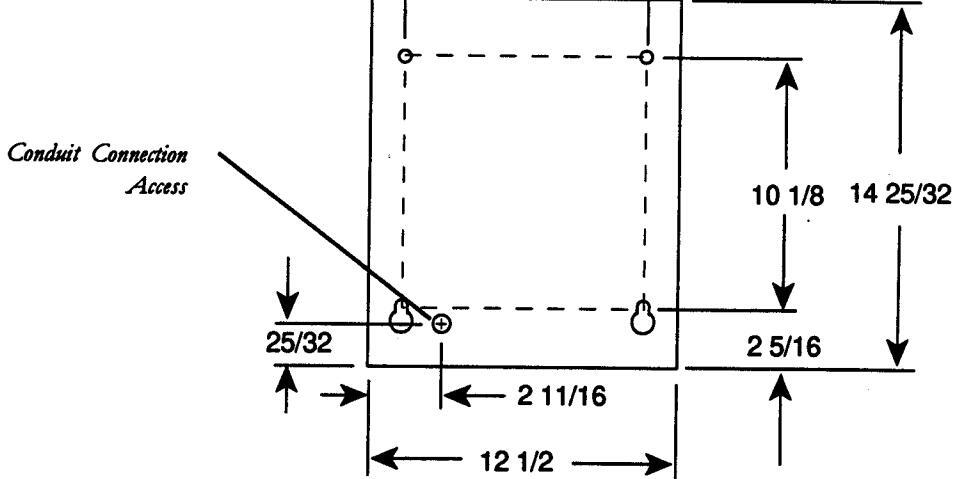

Figures 2-1 thru 2-2 illustrate the Bill Changer mounting requirements and specifications, and provides dimensions for drilling.

To mount the Bill Changer, use four 3/8" minimum diameter lag screws (with flat washers) that are long enough to penetrate the counter or supporting surface of the wall at least 2 inches. For wood frame mounting, screw directly into the wall studs. For mounting to concrete or masonry walls, use lag screws with lead anchors.

If the mounting surface is not even, you may need to add spacer washers between the mounting surface and the Bill Changer until the Bill Changer is level.

1 Rowe® also offers two different mounting bases as options. See the Accessory Kits section for details.

Figure 2-1

Diagram

C-2/4 Mounting

BOTTOM VIEW C-2/4 Table or Countertop Mounting Dimensions

WARNING:

BE SURE THAT YOU READ AND UNDERSTAND THE WARNINGS AND INSTRUCTIONS IN THIS SECTION OF THE MANUAL BEFORE MAKING ANY ELECTRICAL CONNECTIONS.

THE CONDUIT CAN BE INSTALLED THROUGH THE BOTTOM OR THROUGH THE BACK BY REVERSING THE ELECTRICAL PLATES. THE POSITION OF THE POWER CORD CAN BE CHANGED IN THE SAME MANNER.

C-2/4 POWER REQUIREMENTS: 120 VAC (MIN. 105 VAC), 60 Hz SHIPPING WEIGHT: 78 lbs. (220 or 240 VAC, 50 HZ optional)

BOTTOM VIEW C-6 Table or Countertop Mounting Dimensions

WARNING:

BE SURE THAT YOU READ AND UNDERSTAND THE WARNINGS AND INSTRUCTIONS IN THIS SECTION OF THE MANUAL BEFORE MAKING ANY ELECTRICAL CONNECTIONS.

THE CONDUIT CAN BE INSTALLED THROUGH THE BOTTOM OR THROUGH THE BACK BY REVERSING THE ELECTRICAL PLATES. THE POSITION OF THE POWER CORD CAN BE CHANGED IN THE SAME MANNER.

C-6 POWER REQUIREMENTS: 120 VAC (MIN. 105 VAC), 60 Hz SHIPPING WEIGHT: 99 lbs. (220 or 240 VAC, 50 HZ optional)

POWER CONNECTION

Always obey local codes and ordinances when making Power connection.

LINE CORD

On 120 VAC models, the Bill Changer power cord can be plugged into any standard three-hole 120 VAC outlet. Do not connect your Bill Changer using a two-pronged grounding adaptor. For 220V/240 VAC operation, install an appropriate connecting plug for your location, follow local safety codes and regulations, and make an earth connection to the case if allowed. To avoid possible voltage spikes that might effect the Bill Changer, do not operate any other high-wattage equipment on the same circuit with the Bill Changer.

The line cord comes factory installed through the back of the changer. Some installations require that the position of the cord be changed to run through the bottom of the changer. This can be done by removing the screws that hold the electrical box in place and reversing the electrical plates underneath ( Figure 2-1, 2-2 ).

CAUTION:

To avoid the hazard of serious electrical shock and/or damage to the Bill Changer, direct wiring to the Bill Changer should only be attempted by a person familiar with proper electrical wiring procedures.

CONDUIT

If the changer is rigidly mounted to a wall, U.L. requirements specify that a direct power connection be made to the changer through a rigid, 1/2 inch conduit.

If a conduit is required for your installation, remove the nuts that hold the electrical box in place, and disconnect the standard line cord and strain relief. The conduit connector will run through the 7/8" diameter round hole in the electrical plate. Position the electrical plates so that the conduit will run either out the bottom or the back of the changer — whichever suits your installation — while blocking off the unused hole.

To install the conduit, cut the connectors of the line cord leaving three inches of wire on each connector. Connect these electrical box wires to the power source per the wiring diagram in Section 7 of this manual using standard U.L. listed pressure cable connectors (such as wire nuts).

CAUTION:

To avoid serious electrical shock, disconnect power at the source before making any electrical connections.

Field Service Manual and Parts Catalog

Part No. 25553601 Second Edition

Century Series C-2, C-4, C-6 Bill Changer

Field Service Manual and Parts Catalog

Rowe International, Inc. 1500 Union Ave., SE • GRAND RAPIDS, MI 49507-1884 • (616) 243-3633 Printed in USA

Preface

The Century Series is an all new model bill changer. This manual has been designed and organized to provide you with an easy-to-use source of service information.

This service manual is divided into eight sections:

- Section 1: SYSTEM DESCRIPTION Introduces you to the C-2, C-4, C-6, their features, and their major components. A Sequence of Operation Flowchart details Bill Changer operation.

- Section 2: INSTALLATION Provides you with the information that you need to install your Bill Changer safely and securely.

- Section 3: LOADING & AUDITING Outlines instructions for loading and unloading the Bill Changer coin hopper, as well as a basic auditing procedure to guard against loss of money from theft or malfunction.

- Section 4: PROGRAMMING Gives instructions for changing Bill Changer default (factory) programming.

- Section 5: MAINTENANCE & ADJUSTMENTS Provides instructions for removing Bill Changer components for service, and details mechanical maintenance procedures.

- Section 6: TROUBLESHOOTING & SELF-DIAGNOSTICS Describes the meaning of Bill Changer fault codes, as well as remedies for each. This section also describes miscellaneous problems that can occur but may not cause a fault code to be displayed, as well as checking procedures used to verify that the Bill Changer is functioning properly.

- Section 7: TECHNICAL INFORMATION Contains the Bill Changer System Schematic Diagram, as well as the board layout and components list for the Control Computer.

- Section 8: PARTS CATALOG Lists and illustrates all replaceable modules in the Bill Changer.

This manual is intended for owners, route operators, and technicians. This manual provides all field and shop related service and maintenance material. Accessories and their installation and service are discussed in the corresponding accessory instructions (or manuals).

Specific Bill Acceptor information is discussed in the Bill Acceptor Field Service Manual and Parts Catalog included with your Bill Changer.

Contents

| PREFACE | ••••••• | ii | |

|---|---|---|---|

| CENTURY SERIES BILL CHANGER | MAIOR | COMPONENTS | vi |

SECTION 1: SYSTEM DESCRIPTION

| INTRODUCTION | 1-1 |

| FEATURES | 1-1 |

| GENERAL OPERATION | 1-2 |

| SYSTEM COMPONENTS | 1_2 |

| BILL ACCEPTOR | 1_2 |

| SEQUENCE OF OPERATION FLOWCHART | 1.2 |

| DISPENSER | 1-5 |

| 1-4 | |

| 1-4 | |

| Status Dianlau | 1-5 |

| Status Display | 1-6 |

| Service and Control Switches | 1-6 |

| PROGRAM/NORMAL Slide Switch | 1-6 |

| MODE Button | 1-6 |

| UP Button | 1-6 |

| DOWN Button | 1-6 |

| TEMPORARILY OUT OF SERVICE LAMP | 1.7 |

| FIFCTRICAL BOX | 17 |

| 1-/ |

SECTION 2: INSTALLATION

| INTRODUCTION | |

|---|---|

| BILL CHANGER MOUNTING & SPECIFICATIONS | |

| C-2/4 MOUNTING DIAGRAM | |

| C-6 MOUNTING DIAGRAM | |

| POWER CONNECTION | |

| LINE CORD | |

| CONDUIT | |

SECTION 3: LOADING & AUDITING

| LOADING THE BILL CHANGER | |

| LOADING THE HOPPER | |

| UNLOADING THE HOPPER C-2/4 | |

| UNLOADING THE HOPPER C-6 | |

| AUDITING | |

SECTION 4: PROGRAMMING

| PROGRAMMING THE CENTURY 2 AND CENTURY 4 BILL CHA | NGES 4-1 |

|---|---|

| PROGRAMMING | |

| Coin Acceptor Settings | 4-2 |

| Bill Acceptor Settings | 4-3 |

| Money Meter Settings | 4-4 |

| Coin Level Settings | 4-4 |

| Recommended Settings | 4-5 |

| BILL PAYOUT SETTINGS | 4-6 |

| PROGRAMMING EXAMPLES | 4_7 |

SECTION 5: MAINTENANCE AND ADJUSTMENTS

| INTRODUCTION | 5_1 |

|---|---|

| BILLACCEPTOR | |

| REMOVING A JAMMED BILL | 5-1 |

| REMOVING THE BILL ACCEPTOR | 5-2 |

| INSTALLING THE BILL ACCEPTOR | 5-2 |

| HOPPER | 5-3 |

| REMOVING THE HOPPER | 5-3 |

| CLEANING THE HOPPER COIN PATH | 5-3 |

| HOPPER CHAIN ADJUSTMENT | 5-5 |

| DISPENSER | 5-6 |

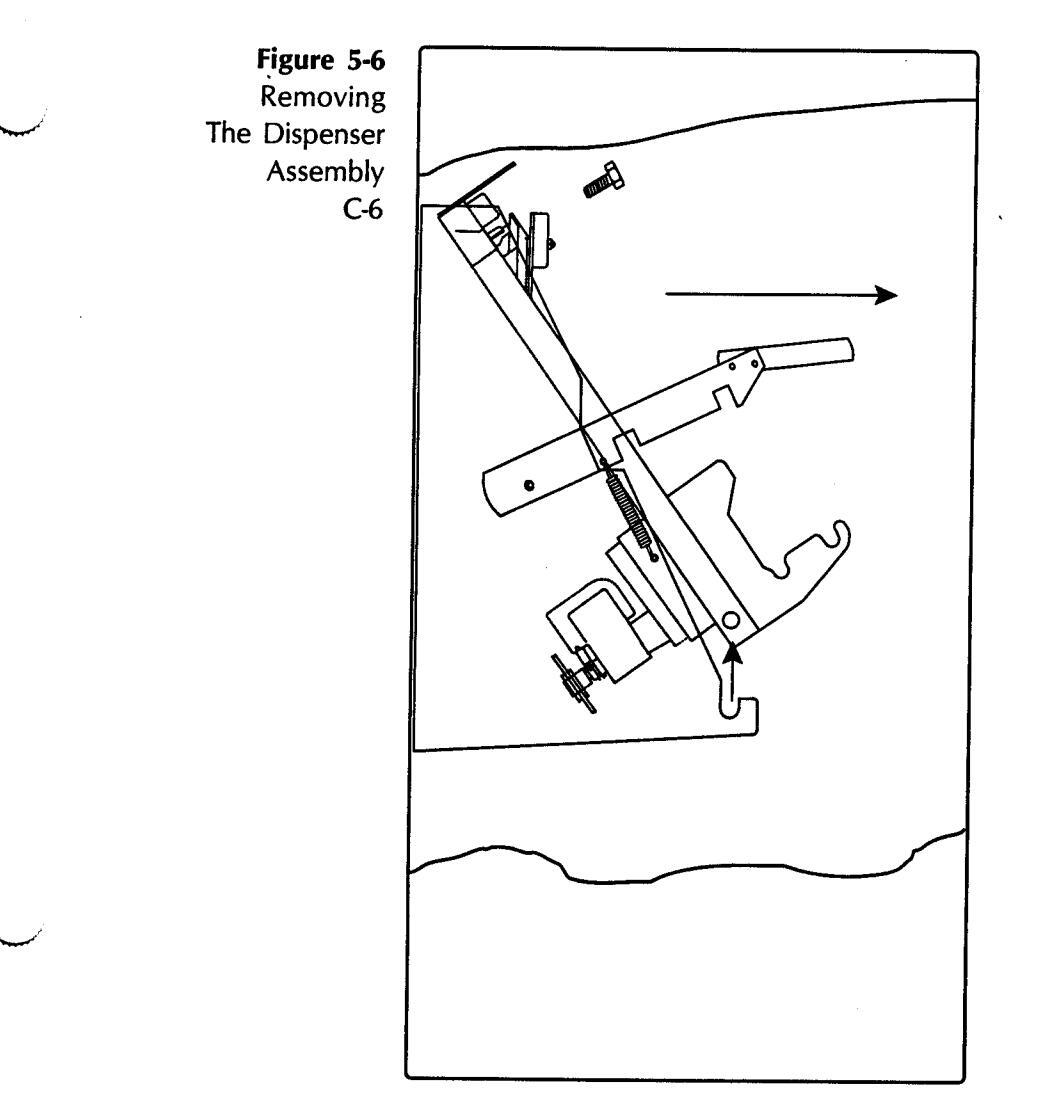

| REMOVING THE DISPENSER ASSEMBLY | 5-6 |

| INSTALLING THE DISPENSER ASSEMBLY | 5-6 |

SECTION 6: TROUBLESHOOTING & SELF-DIAGNOSTICS

| INTRODUCTION | 6-1 |

|---|---|

| TROUBLESHOOTING | |

| CLEARING BILL CHANGER ERROR CODES | |

| ERROR CODES | |

| Er 1 | |

| Er 2 | 6-3 |

| Er 3 | |

| Ег Ч | |

| Er 5 | |

| Ег Б | |

| Er 7 | 0-5 |

| Er R | ····· 0-0 |

| Er 9 | ·····0-0 |

| Erl D | |

| Erl P | |

| E-1 3 | |

| E-14 | |

| E-1 5 | 6-8 |

| E-15 | 6-8 |

| 6-9 | |

| 6-9 | |

| 6-10 | |

| MISCELLANEOUS PROBLEMS | 6-11 |

| ERRATIC PAYOUT | 6-11 |

| LARGE NUMBER OF VALID BILLS REJECTED | 6-11 |

| BILLS JAM FREQUENTLY | 6-11 |

| COIN COUNTING PHOTOTRANSISTOR (SENSOR) CHECK . | 6-12 |

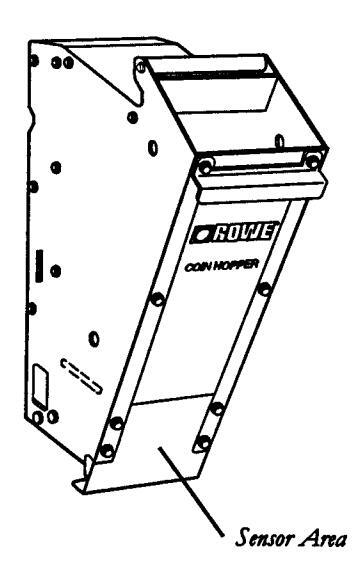

| LOW COIN SENSOR ELECTRICAL CHECK |

SECTION 7: TECHNICAL INFORMATION

| INTRODUCTION | |

|---|---|

| CCC Circuit Board Layout | |

| CCC CIRCUIT BOARD COMPONENTS LIST | 7-3 |

| BILL CHANGER SYSTEM SCHEMATIC | |

| (Eng. Draw., 25553301 Q2) |

SECTION 8: PARTS CATALOG

| INTRODUCTION | |

|---|---|

| Catalog Description | |

| Parts List Description | |

| Ordering Replacement Parts | |

| PARTS CATALOG | |

| ACCESSORY KITS |

C-2/4 SIDE VIEW, DOOR OPEN

C-6 CABINET (Hopper Removed)

This page intentionally left blank

SECTION 1: SYSTEM DESCRIPTION

INTRODUCTION

NOTE:

Throughout this manual, the word "coin" is used to refer to either coins or tokens, interchangeably.

The Rowe® Century Series C-2 Bill Changer will accept 1 dollar ($1) and 5 dollar ($5) bills and the C-4 and C-6 Bill Changers can accept $1 thru $100 bills of United States currency. Using the appropriate bill acceptor, up to 7 denominations of any non-U.S. currency can be accepted. The unit can be programed by the operator to accept any or all of the bills. Figure 1-1 illustrates the major components of the Bill.

The Bill Changer can dispense one type of coin or token at a time. The number of coins dispensed for each bill denomination accepted is programmable.

FEATURES

- . A microcomputer inside the Bill Changer monitors system status, accepts credit inputs from the bill acceptor or coin acceptor (when used), and controls the change dispensing functions.

- . Modular assemblies are featured for fast field substitution.

- . Setup and programming options are easily changed using the MODE, UP and DOWN pushbutton switches.

- . The removable coin hopper permits rapid bulk loading of coins.

GENERAL OPERATION

The Bill Changer Sequence of Operation Flowchart (Table 1-1, opposite) gives an overview of the Bill Changer sequence of operation, from the time that a bill is inserted into the changer until coins fall into the Coin Cup. For detailed information regarding the location and function of individual Bill Changer components, refer to System Components, which follows.

SYSTEM COMPONENTS

Refer to Figure 1-1 for placement of each of the following Bill Changer components:

BILL ACCEPTOR*

The bill acceptor accepts and validates $1 and $5 or $1 thru $100 bills depending on the bill acceptor. It stacks valid bills in a bill box that opens for easy bill removal. The bill acceptor mounts on the back of the Bill Changer door.

For specific bill acceptor information refer to the bill acceptor field service manual and parts catalog included with the Bill Changer.

* Rowe® Bill Acceptor pictured. Your changer may be equipped with an Acceptor from another manufacturer.

Bill Changer Sequence of Operation Flowchart

Note 1 The Bill Acceptor Operation described here is applicable when a Rowe® Bill Acceptor is used. Bill Acceptors from other manufacturers may operate differently.

DISPENSER

The Bill Changer coin dispenser (Figure 1-3) contains the coin detector system and the hopper motor. On the C-2/4 the dispenser mounts on a bracket on the back of the Bill Changer door. On the C-6 the dispenser mounts on a bracket in the cabinet.

The coin detector system consists of an LED and a photo-transistor, which "count" the coins as they exit the hopper and fall through the upper coin chute into the coin cup.

The hopper motor engages a sprocket that drives the hopper. This 110 VAC motor is controlled by the CCC.

Figure 1-4

Hopper

HOPPER

The Bill Changer contains one hopper (Figure 1-4), which mounts on the front surface of the dispenser assembly and pivots out for easy removal.

The hopper transports coins to the coin detector and upper coin chute by means of a chain conveyor driven from below by a sprocket. The chain picks up coins from the bottom of the hopper and carries them up to the top, where they fall through the upper chain guide ring and through the coin detector system.

The hopper chain follows a serpentine path that causes excess coins to fall back into the hopper. This ensures that only one coin per pin enters the coin counting area.

An agitator, which is mounted on the drive shaft inside the hopper, agitates the coin load to minimize coin jams in the hopper and to ensure efficient coin pick up. The hopper also contains the low coin sensor antenna and circuit board.

NOTE:

The low coin sensor alerts the computer when the number of coins in the hopper falls below a certain level.

The Bill Changer uses the low coin sensing system which simplifies the day to day operation. With this system, the operator does not have to program the computer with the number of coins that have been added to the hopper. When the hopper is loaded, the sensing circuit will automatically signal the computer that coins are present. As the hopper is emptied via the normal changemaking process, eventually the level of coins will fall below the threshold required by the low coin sensing circuit. This circuit will then signal the computer that the low level has been reached.

The sensing circuit is mounted on the front surface of the coin hopper with electrical connections made through high pressure contact springs on the dispenser assembly. Because there are no elements inside the hopper to contact the coins, there is absolutely no impact on hopper operation and no degradation of the sensor due to contamination deposited by the coins themselves.

CHANGER CONTROL COMPUTER (CCC)

The Changer Control Computer (CCC, Figure 1-5 ) mounts on the back wall inside the changer cabinet. The CCC contains a microcomputer that controls and/or monitors all of the major functions of the Bill Changer, including communication with the Bill Acceptor and change dispensing functions. It also contains the following controls and displays:

NOTE:

Status Display

When the CCC is initially switched from the NORMAL to PROGRAM position, the status display will show ProS.

The four character LED status display window displays the many Bill Changer programming and self-diagnostic features described in this manual. See Section 4 for detailed programming information; see Section 6 for error code meanings.

Service and Control Switches

The Bill Changer's service features and programming options are controlled by three push button switches and one slide switch. The descriptions that follow are introductory. Refer to the detailed procedures and instructions in Section 4 for specific programming information.

PROGRAM/NORMAL Slide Switch

Selects either the NORMAL operating position or the PROGRAM position:

PROGRAM Position - Allows you to inspect and/or change Bill Changer setup information. This information is displayed on the status display and is selected and changed by using the MODE, UP and DOWN buttons.

NORMAL Position - Places the changer in a standby condition waiting to give change for a valid bill while the CCC monitors all systems. While in standby, a dash moves from left to right across the 4-character status display.

MODE BUTTON

The MODE button is used to step through the setup options.

UP BUTTON

Increases the displayed value.

DOWN BUTTON

Decreases the displayed value.

TEMPORARILY OUT OF SERVICE LAMP

The temporarily out of service lamp (Figure 1-1) is located on the Bill Changer door above the coin cup. It lights when the hopper is low or out of change, or the changer has shutdown due to malfunction.

Reset the Bill Changer by pushing the UP and DOWN buttons simultaneously on the CCC while the PROGRAM/NORMAL switch is in the NORMAL position. If the error has been corrected, the out of service lamp will go out and a dash will move from left to right accross the 4-character status display. See Section 6 for detailed troubleshooting information .

ELECTRICAL BOX

The Electrical Box (Figure 1-6), located inside the Bill Changer cabinet, houses the following electrical components:

The ON/OFF switch controls all power to the machine.

A 5 amp circuit breaker protects the power line to the bill changer.

An EMI filter (ElectroMagnetic Interference filter) removes undesirable electrical noise from the incoming power line.

The Money Counter is non-resettable, and indicates the amount of money handled by the changer.

This page intentionally left blank.

SECTION 2: INSTALLATION

INTRODUCTION

NOTE:

For both safety and security reasons, Rowe® strongly recommends that the Bill Changer be securely anchored to a wall or sturdy countertop. Please follow the mounting instructions provided in this manual.

This section provides instructions for installing the Century Series Bill Changers. To prevent theft, or the possibility of damage or injury should the Bill Changer fall, Rowe® strongly recommends that the Bill Changer be securely anchored to a wall or a sturdy countertop1. The instructions that follow provide directions for a secure installation.

Before you begin any installation, be sure that a power source is available and that the changer can be mounted level. Choose a location that is easily accessible to customers, with enough room to open the Bill Changer door for convenient service.

Be sure that you read and understand the warnings and instructions in Power Connection, page 2-6, before making any electrical connections to the Bill Changer.

BILL CHANGER MOUNTING & SPECIFICATIONS

Figures 2-1 thru 2-2 illustrate the Bill Changer mounting requirements and specifications, and provides dimensions for drilling.

To mount the Bill Changer, use four 3/8" minimum diameter lag screws (with flat washers) that are long enough to penetrate the counter or supporting surface of the wall at least 2 inches. For wood frame mounting, screw directly into the wall studs. For mounting to concrete or masonry walls, use lag screws with lead anchors.

If the mounting surface is not even, you may need to add spacer washers between the mounting surface and the Bill Changer until the Bill Changer is level.

1 Rowe® also offers two different mounting bases as options. See the Accessory Kits section for details.

FRONT VIEW C-2/4 Wall Mounting Dimensions

BOTTOM VIEW C-2/4 Table or Countertop Mounting Dimensions

WARNING:

BE SURE THAT YOU READ AND UNDERSTAND THE WARNINGS AND INSTRUCTIONS IN THIS SECTION OF THE MANUAL BEFORE MAKING ANY ELECTRICAL CONNECTIONS.

THE CONDUIT CAN BE INSTALLED THROUGH THE BOTTOM OR THROUGH THE BACK BY REVERSING THE ELECTRICAL PLATES. THE POSITION OF THE POWER CORD CAN BE CHANGED IN THE SAME MANNER.

C-2/4 POWER REQUIREMENTS: 120 VAC (MIN. 105 VAC), 60 Hz SHIPPING WEIGHT: 78 lbs. (220 or 240 VAC, 50 HZ optional)

BOTTOM VIEW C-6 Table or Countertop Mounting Dimensions

WARNING:

BE SURE THAT YOU READ AND UNDERSTAND THE WARNINGS AND INSTRUCTIONS IN THIS SECTION OF THE MANUAL BEFORE MAKING ANY ELECTRICAL CONNECTIONS.

THE CONDUIT CAN BE INSTALLED THROUGH THE BOTTOM OR THROUGH THE BACK BY REVERSING THE ELECTRICAL PLATES. THE POSITION OF THE POWER CORD CAN BE CHANGED IN THE SAME MANNER.

C-6 POWER REQUIREMENTS: 120 VAC (MIN. 105 VAC), 60 Hz SHIPPING WEIGHT: 99 lbs. (220 or 240 VAC, 50 HZ optional)

POWER CONNECTION

Always obey local codes and ordinances when making Power connection.

LINE CORD

On 120 VAC models, the Bill Changer power cord can be plugged into any standard three-hole 120 VAC outlet. Do not connect your Bill Changer using a two-pronged grounding adaptor. For 220V/240 VAC operation, install an appropriate connecting plug for your location, follow local safety codes and regulations, and make an earth connection to the case if allowed. To avoid possible voltage spikes that might effect the Bill Changer, do not operate any other high-wattage equipment on the same circuit with the Bill Changer.

The line cord comes factory installed through the back of the changer. Some installations require that the position of the cord be changed to run through the bottom of the changer. This can be done by removing the screws that hold the electrical box in place and reversing the electrical plates underneath ( Figure 2-1, 2-2 ).

CONDUIT

If the changer is rigidly mounted to a wall, U.L. requirements specify that a direct power connection be made to the changer through a rigid, 1/2 inch conduit.

If a conduit is required for your installation, remove the nuts that hold the electrical box in place, and disconnect the standard line cord and strain relief. The conduit connector will run through the 7/8" diameter round hole in the electrical plate. Position the electrical plates so that the conduit will run either out the bottom or the back of the changer — whichever suits your installation — while blocking off the unused hole.

To install the conduit, cut the connectors of the line cord leaving three inches of wire on each connector. Connect these electrical box wires to the power source per the wiring diagram in Section 7 of this manual using standard U.L. listed pressure cable connectors (such as wire nuts).

CAUTION:

To avoid serious electrical shock, disconnect power at the source before making any electrical connections.

CAUTION:

To avoid the hazard of serious electrical shock and/or damage to the Bill Changer, direct wiring to the Bill Changer should only be attempted by a person familiar with proper electrical wiring procedures.

SECTION 3: LOADING & AUDITING

INTRODUCTION

This section provides instructions for loading and unloading the Century Series coin hopper.

LOADING THE BILL CHANGER

NOTE:

The hopper may be loaded with either quarters, dimes, nickels, OR tokens – but different coin types may not be mixed in the hopper.

Refer to Section 4: PROGRAMMING to change the default coin payout.

Loading the hopper is easiest when the coins are delivered via a coin bag. Hopper capacities vary depending on the machine model, hopper type, and coin/token size. Tables 3-1 and 3-2 give approximate capacities.

C2/C4 Hopper Capacities

| Hopper Type |

Dimes

17.9mm |

Nickels

21.21mm |

Quarters

24.25mm |

.984"

Tokens 25mm |

SBA $1/

Canadian $1 26.5mm |

Canadian $2

(1.10") 27.95mm |

1.125*

Tokens 28 57mm |

|---|---|---|---|---|---|---|---|

| 65094904 (Small Coin) | 5000 | 2400 | 2100 | N/A | N/A | N/A | N/A |

| 65094905 (Large Coin) | N/A | N/A | 1850 | 1600 | 1400 | 1200 | 1000 |

Table 3-1

| C6 | Hopper | Сара | cities |

|---|

| Hopper Type |

Dimes

17.9mm |

Nickels

21.21mm |

Quarters

24.25mm |

.984"

Tokens 25.0mm |

SBA $1/

Canadian $1 26.5mm |

Canadian $2

(1.10") 27.95mm |

1.125"

Tokens 28.57mm |

|---|---|---|---|---|---|---|---|

| 65092901 (Small Coin) | 8000 | 4000 | 3400 | N/A | N/A | N/A | N/A |

| 65092902 (Large Coin) | N/A | N/A | 3200 | 3000 | 2200 | 2100 | 1800 |

Table 3-2

LOADING THE HOPPER

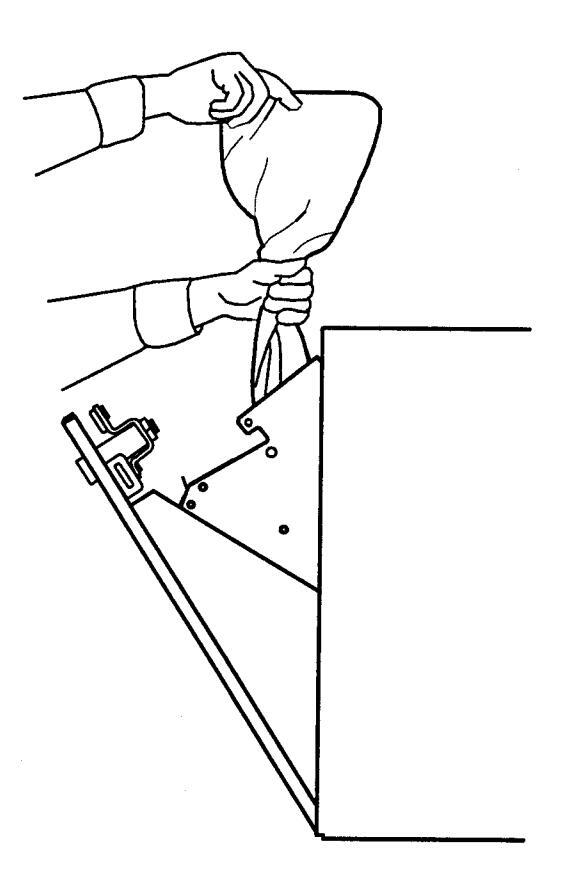

Refer to Figure 3-1 and load the hopper as follows:

- 1. Open front door as far as it will go without releasing the door latch. On the C-6 ONLY, lift up the hopper catch and pull the hopper out to the second catch position.

- 2. Twist the top of a full coin bag one full turn. Grasp the twisted top with one hand and hold the bottom of the bag with the other. Invert the bag and insert the top into the mouth of the hopper.

- 3. Slowly release the twist as the bag empties. Avoid spilling coins into the changer. When the bag is almost empty, grasp it at the bottom and shake it to dislodge coins tucked in the folds of the bag.

NOTE:

UNLOADING THE HOPPER C-2/4

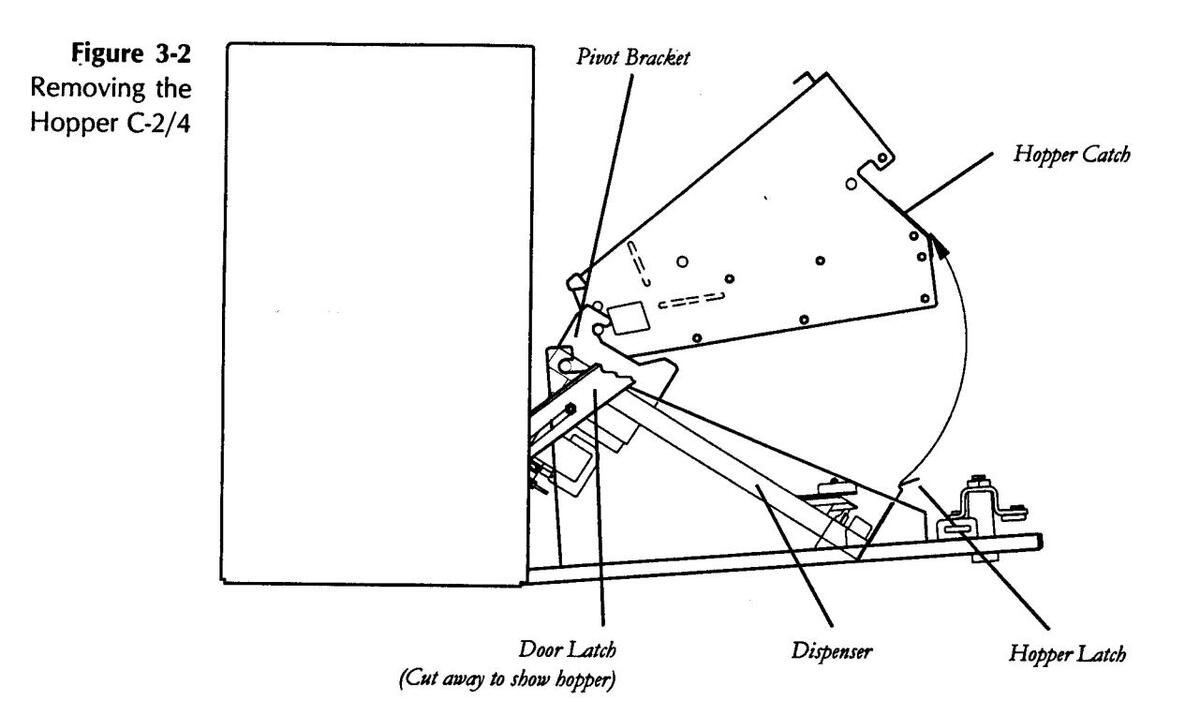

Refer to Figure 3-2 as you remove the hopper as follows:

- 1. Open the door as far as it will go without releasing the door latch.

- 2. While supporting the door with one hand, lift the latch handle to release the door latch and lower the door all the way down (See Figure 3-2).

- 3. Release the hopper catch and lift the hopper out.

- 4. Place the top of the bag over the hopper opening. Invert the hopper over the bag to empty it ( Figure 3-3 ).

- 5. Replace the hopper. Be sure it is sitting securely in the pivot brackets, snug against the dispenser plate, and the catch is engaged (Figure 3-2).

If the hopper is full, place your hand or an empty bag over the hopper opening to keep coins from spilling out of the top of the hopper.

UNLOADING THE HOPPER C-6

Refer to Figure 3-4 as you remove the hopper as follows:

- 1. Open the door as far as it will go without releasing the door latch.

- 2. While supporting the door with one hand, lift the latch handle to release the door latch and lower the door all the way down (See Figure 3-4) .

- 3. Lift up the hopper catch and pull the hopper out past the second catch position. Lift the hopper out.

- 4. Place the top of the bag over the hopper opening. Invert the hopper over the bag to empty it (Figure 3-3).

Figure 3-4 Removing the Hopper C-6

Hopper shown in second catch - loading position. Lift handle and pull hopper forward to remove.

Auditing

There are three pieces of information needed in order to thoroughly audit your bill changer. The amount of cash removed from the bill box (and coin box if you have a coin acceptor-equipped C-6) should match the difference in money counter readings. Also, the difference between the number of coins (or tokens) initially loaded in the hopper and the remaining number should match the total cash removed multiplied by the number of coins or token paid per unit or cash input. Some examples follow:

| C2 | C6 | |

|---|---|---|

| Initially | Initially | |

| Accepts: $1 and $5 | Accepts: $1, $5, $10 and 25¢ | |

| Payout: 25¢ (4 for $1, 20 for $5) | Payout: Tokens (.984") | |

| Initial Hopper Load: 2,000 coins | (1 for25¢, 4 for $1, 24 for $5, 50 for $10) | |

| Initial Counter Reading: 047233 | Initial Hopper Load: 3,000 coins | |

| At Service Interval | Initial Counter Reading: 047233 | |

| Intake Check: | At Service Interval | |

| Removed: 276 x $1 = $276 | Intake Check: | |

| 26 x $5 = $130 | Removed: 40 x .25 = $ 10 | |

| Total Intake = $406 | 154 x $1 = $154 | |

| Counter Reading: 047639 | 26 x $5 = $130 | |

| Counter Difference 47639 - 47233 = 406 | 23 x $10 = $260 | |

| Total Intake = $524 | ||

| Counter Reading: 047757 | ||

| Counter Difference 47757 - 47233 = 524 ✓ | ||

| Coin Count Check: | Coin Count Check: | |

| Hopper Contents: 376 Coins | Hopper Contents: 570 Tokens | |

| Should have dispensed: 276 x 4 = 1104 | Should have dispensed: 40 x 1 = 40 | |

| 26 x 20 = 520 | 154 x 4 = 616 | |

| Total = 1624 | 26 x 24 = 624 | |

| Actual dispensed: 2000 (initial) | 23 x 50 = 1150 | |

| - 376 (remaining) | Total = 2430 | |

| 1624 🗸 | Actual dispensed: 3000 (initial) | |

| - 570 (remaining) | ||

| 2430 🗸 | ||

This page intentionally left blank.

SECTION 4: PROGRAMMING

PROGRAMMING THE CENTURY 2 AND CENTURY 4 BILL CHANGERS

There are three pushbuttons and one slide switch on the controller board. These are used to perform all programming activities.

The Program switch is positioned to the left for normal operations. In this position, if everything is normal, a dash will walk across the four displays, from left to right. If an error has occurred, an error code will be displayed, indicating what has caused the error. See Section 6 for Troubleshooting information.

Sliding the Program switch to the right will place the controller in the programming mode. In this mode the type of coin acceptor, bill validator, mode of operation, and payouts for each bill may be set or adjusted.

The pushbutton switch on the left is the mode switch and is used to step through the options. The middle and right hand switches are used for adjusting the options choices or payout amounts. The middle switch steps up and the right switch steps down.

The middle and right switches are also used to reset the error codes. See Section 6 for details.

PROGRAMMING

NOTE:

Use Pulse setting for Rowe UBA or CBA2 in a Century 2. Use Serial setting for Mars VN2501. Coinco BA30SA, or CashCode, etc. Use the Serial setting for all applications in the Century 4 and Century 6. All bill validators must be 120 VAC or 12VDC. Anadditional transformer (not supplied by Rowe) is required for 24VAC operation.

NOTE:

If the Coin Acceptor type was set to 0 no acceptor installed these options will not be displayed. If the Coin Acceptor type was set to type 1, only [] through [] 4 will be displayed.

Slide the normal / program switch to the right. The display will show P – 9.

Press the mode button once for each option to be programmed. The options appear on the display in order as shown below. When a setting has been changed, always press the mode button at least once to "save" the setting.

Coin Acceptor Settings

This option selects the type of Coin Acceptor installed in the machine. Using the up and down pushbuttons choose the appropriate type.

C2 and C4

C6

LR D This setting must be set to 0 as no coin acceptors can be installed in these models.

LR D No Coin Acceptor is installed

- [R | A Standard Coin Acceptor is installed. (4 coin types max.)

- CR 2 A Special Electronic Coin Acceptor is installed. (8 coin types max.)

- Coin type 1. This option selects the coins to be accepted. Use the up and down pushbuttons to enable or disable the displayed coin type. If the value is set to 0, the changer will not recognize that coin. If the value is set to 1, that coin will be recognized, and the change will be paid. Be sure to set the coin acceptor to accept only those coins you want accepted as the changer controller cannot control which coins the coin acceptor will accept and send to the cashbox.

- [2] [] Coin type 2. Program as in [] [] above.

- [3] Coin type 3. Program as in [1] above.

- [4] Coin type 4. Program as in [1] above.

- [5] [] Coin type 5. Program as in [1] [] above.

- [5] Coin type 6. Program as in [1] above.

- [7] Coin type 7. Program as in [1] D above.

- [B] [] Coin type 8. Program as in [] [] above.

Bill Acceptor Settings

BR I This option selects the type of Bill Acceptor installed in the machine.

Using the up or down pushbuttons select the appropriate type.

Pulse type Bill Acceptor is installed. (2 bill types max.)

2 Serial type Bill Acceptor is installed. (7 bill types max.)

- 1 1 1 1 This option selects the bills to be accepted. Use the up and down pushbuttons to enable or disable the displayed bill type. If the value is set to 0, the changer will not recognize that bill. If the value is set to 1, that bill will be recognized, and change will be paid. Be sure to set the bill acceptor to accept only those bills you want accepted as the changer controller cannot select which bills the bill acceptor will accept and store in the stacker. There is a maximum of 2 bills for the pulse type of Bill Acceptors. There is a maximum of 7 bills for the serial type Bill Acceptors.

- 62 D Bill type 2. Program as in 61 D above.

- b∃ □ Bill type 3. Program as in b1 □ above.

by D Bill type 4. Program as in b / D above.

- 65 [] Bill type 5. Program as in 61 [] above.

- 65 (D) Bill type 6. Program as in (b) (D) above.

- Ь7 □ Bill type 7. Program as in Ь/ □ above.

Coin Ratio Settings

[ - ] Set to type ] for the Century 2, 4 and 6.

Money Meter Settings

NOTE:

Setting the value of this option to 00 will disable the money counter.

This setting is not required on US or Canadian Models and will not appear in the setup sequence. On these models, the counter will increment once for every dollar inserted.

PcDDThis option is used by the computer to calculate the number of times to<br/>increment the money counter when any particular denomination of coin or bill<br/>has been accepted. Bill Acceptors for different countries provide identical<br/>signals to indicate vastly different bills. For example, a single pulse from an<br/>English version of a popular brand means that a £5 bill was accepted; a single<br/>pulse from the same company's Mexican model means that a 10 Peso bill was<br/>accepted. Therefore, the input signal cannot be used to control the money<br/>counter increments as it does not indicate the same denomination from country<br/>to country.

To overcome this limitation, the computer of the Century changer provides this programmed variable to allow the user to define the money counter activity based on the number of coins or tokens output when a vend takes place.

This option selects the correct number of pulses to send to the money counter. The Pulse Count should be set to the number of coins from the hopper required to advance the Money Counter 1 count. Use the up and down pushbuttons to select the appropriate setting. Any value between 00 and 99 may be set.

Examples:

You want the Counter to count Pesos, and are dispensing ½ Peso coins from the hopper. Since there are 2 coins per Peso, choose P ⊂ D 2. For every 2 coins delivered, the counter will increment - if a 10 Peso bill is accepted and there are 20 coins paid for this value, the counter will increment 20 /2 = 10 counts.

You want to count Pesos and are dispensing 10 Centavo coins. Since there are 10 coins per Peso, choose Pc / D . For every 10 coins delivered, the counter will increment - if a 10 Peso bill is accepted and there are 100 coins paid for this value, the counter will increment 100 /10 = 10 counts.

Coin Level Settings

LI D.D This option informs the controller of the minimum number of coins remaining in the hopper when it's low-level sensor signals that a low level has been reached. Use the up and down pushbuttons to set this option to an appropriate value. Any value between 60 and 990 may be set in 10 coin increments.

These settings are used so that the changer can dispense the maximum number of coins or tokens, without the possibility of shortchanging a customer, before going out of service for lack of coins. The number you program here lets the computer know how many coins remain in the hopper when the coin level sensing system signals a low level.

88.88 The decimal point at the center of the display digits indicates the state of the low-level sensor. The decimal point indicates that a low-level condition exists in the hopper when it is lit.

The setting depends on the type of hopper being used and the type of coin or token loaded. To choose the correct setting, use one of the tables below based on the hopper and coins being used:

| SMALL COINS HOPPER (65094904) | |||||

|---|---|---|---|---|---|

|

US 5¢

(21.21mm) |

US 10¢

(17.9mm) |

US 25¢

(24.25mm) |

.880" Token

(22.35mm) |

||

| 160 | 350 | 140 | 150 | ||

Recommended Low Coin Settings for Century 2 and 4

| LA | ARGE COINS TOKI | EN HOPPER (650949 | 905) |

|---|---|---|---|

|

US 25¢

(24.25mm) |

US SBA Dollar

(26.5mm) |

.984" Token

(25mm) |

Can. $2

(28mm) |

| 130 | 70 | 90 | 55 |

Recommended Low Coin Settings for Century 6

| SMALL COINS H | OPPER (65092901) | ||

|---|---|---|---|

|

US 5¢

(21.21mm) |

US 10¢

(17.9mm) |

US 25¢

(24.25mm) |

.880" Token

(22.35mm) |

| 220 | 500 | 200 | 210 |

| LA | RGE COINS TOKE | N HOPPER (650929 | 02) |

|---|---|---|---|

|

US 25¢

(24.25mm) |

US SBA Dollar

(26.5mm) |

.984" Token

(25mm) |

Can. $2

(28mm) |

| 150 | 110 | 140 | 80 |

There is a second limitation on the number you set into the computer—it must be at least 30 higher than the highest number of coins or tokens to be paid to the customer.

You must choose the hoppers, coins or tokens used, and/or the operating mode as appropriate in order to maintain this 30 coin margin.

Payout Settings

Coin Payout Setting - Century 6 Only

These options will set the number of coins dispensed from the hopper for the coin types set earlier. If a Coin type is disabled, its payout amount setting will not be displayed.

- I ⊂ □□. Payout for Coin type 1. This option sets the number of coins dispensed from the hopper. Use the up and down pushbuttons to set this option to an appropriate value. Any value between 00 and 99 may be set.

- 2c00. Payout for Coin type 2. Program as in / c00. above.

- . Payout for Coin type 3. Program as in . above.

- Ч ⊂□□. Payout for Coin type 4. Program as in l ⊂ □□. above.

- 5 c 00. Payout for Coin type 5. Program as in / c 00. above.

- . Payout for Coin type 6. Program as in l . above.

- ¬ ⊂ □□ . Payout for Coin type 7. Program as in ! ⊂ □□ . above.

- B⊂□□. Payout for Coin type 8. Program as in / ⊂□□. above.

Bill Payout Settings

These options will set the payout of coins for each type of bill accepted. If a bill type is disabled, its payout setting will not be displayed.

- 1 b D D. This option sets the number of coins dispensed from the hopper for the bill types set earlier. Use the up and down pushbuttons to set the payout to the desired value. Any value between 00 and 99 may be set.

- 2600. Payout for Bill type 2. Program as in / 600. above.

- 3600. Payout for Bill type 3. Program as in 1 600. above.

- 4600. Payout for Bill type 4. Program as in 1 600. above.

- 5600. Payout for Bill type 5. Program as in / 600. above.

- 5500. Payout for Bill type 6. Program as in 1 500. above.

- 7600. Payout for Bill type 7. Program as in / 600. above.

- 8600. Payout for Bill type 8. Program as in / 600. above.

Programming Examples

Example 1:

Typical for US/Candian C2 Model

Coin accepted:NoneBills accepted:$1 (US), $5Hopper:Small Coin (65094904)Payout25¢

Machine settings:

L R D No coin acceptor installed.

- LR I Pulse type Validator installed.

- b1IBill value 1 accepted ($1 US)

- b2 / Bill value 2 accepted ($5)

- [ ] Always set to 0 for the C2

- LI 40. 140 coins See Chart

- / ЬПЧ. 4 x .25 = 1.00

- 2620. 20 x .25 = 5.00

- end of programming

Example 2:

Typical for US/Canadian C4 Model or C6 without Coin Acceptor

Coin accepted: None Bills accepted: $1, $5, $10, $20 Hopper: Small Coin (65094904 - C4) or (65092901 - C6) Payout 25¢

Machine settings:

- CA D No coin acceptor installed. BR 2 Serial type Validator installed.

- b/ / Bill value 1 accepted ($1 US)

- b2 D Bill value 2 not accepted ($2)

- Bill value 3 accepted ($5)

- b Ч I Bill value 4 accepted ($10)

- b5 / Bill value 5 accepted ($20)

- BE D Bill value 6 not accepted ($50)

- b 7 D Bill value 7 not accepted ($100)

- [- ] Always set to 0 for the C4 and C6

- C4-

- LI 40. 140 coins See Chart

- C6-

- L200. 200 coins See Chart

- / 」 」 日 日 : 4 x .25 = 1.00 (US only)

- 3620 . 20 x .25 = 5.00

- ЧЬЧ[]. 40 x .25 = 10.00

- 5680. 80 x .25 = 20.00

end of programming

Programming Examples

Example 3:

Typical for C2 Model

| Coin accepted: | None |

|---|---|

| Bills accepted: | £5 and £10 (England) |

| Hopper: | Small Coin (65094904) |

| Payout | £1 (22.5mm Dia.) |

Machine settings:

- CR D No coin acceptor installed.

- BR 1 Pulse type Validator installed.

- b! ! Bill value 1 accepted (£5)

- b2 / Bill value 2 accepted (£10)

- [- ] Always set to 0 for the C2

- Pc Dl 1 Coin per £

- LI 50. 150 coins See Chart

- 1 605. 5 x £1 = £5

- 2Ы D . 10 х £1 = £10

- end of programming

Example 4:

Typical for C4 Model or C6 without Coin Acceptor

Coin accepted: None Bills accepted: 10, 20 and 50 Peso Hopper: Small Coin (65094904 - C4) or (65092901 - C6) Payout 1 Peso (24mm Dia.)

Machine settings:

LA D No coin acceptor installed. BR P Serial type Validator installed. bl / Bill value 1 accepted (10 Peso) B 2 | Bill value 2 accepted (20 Peso) b 3 / Bill value 3 accepted (50 Peso) B G Bill value 4 not accepted b5 D Bill value 5 not accepted b5 0 Bill value 6 not accepted B 7 D Bill value 7 not accepted [- ] Always set to 0 for the C4 and C6 Pc [] 1 Coin per Peso C4_ LI 40. 140 coins – See Chart C6-1 200 coins - See Chart 1 b1 Π. 10 x 1 = 10 Peso 2620, 20 x 1 = 20 Peso Peso

end of programming

Programming Examples

Example 5:

Typical for C6 Model with Coin Acceptor

Coin accepted: $1 Bills accepted: $1, $5, $10, $20 Hopper: Small Coin (65092901) Payout 25¢

Machine settings:

- LH l Std. Coin acceptor installed.

- BR 2 Serial type Validator installed.

- [ | | Coin 1 accepted ($1)

- b1 1 Bill value 1 accepted ($1)

- b 2 D Bill value 2 not accepted ($2)

- b∃ / Bill value 3 accepted ($5)

- 占 Ч / Bill value 4 accepted ($10)

- 65 / Bill value 5 accepted ($20)

- [- ] Always set to 0 for the C6

- L200. 200 coins See Chart

- I СОЧ. 4 х .25 = $1

- 1 БОЧ. 4 х .25 = $1

- 3620. 20 x .25 = $5

- ЧЬЧ(). 40 x .25 = $10

- 5680. 80 x .25 = $20

end of programming

Example 6:

Typical for Canadian C6 with Mars ME330 Coin Acceptor Coin accepted: $2 Bills accepted: $5, $10, $20

Hopper: Large Coin (65092902) Payout $1

Machine settings:

- CR 2 Electronic coin acceptor installed.

- 6R 2 Serial type Validator installed.

- [1] [] Coin value 1 not accepted (5¢)

- Coin value 2 not accepted (10¢)

- Coin value 3 not accepted (25¢)

- [] 4 [] Coin value 4 not accepted (Can. $1)

- [5 ] Coin value 5 not accepted (US 25¢)

- [5] Coin value 6 not accepted (US $1)

- [7] / Coin value 7 accepted (Can. $2)

- [B] [] Coin value 8 not accepted

- 61 Bill value 1 not accepted ($1)

- 62 1 Bill value 2 not accepted ($2)

- b 3 l Bill value 3 accepted ($5)

- b4 / Bill value 4 accepted ($10)

- b5 / Bill value 5 accepted ($20)

- bbb b b

- B Bill value 7 not accepted

- [- ] Always set to 0 for the C6

- LII []. 110 coins See Chart

- 7 CO2 . 2 x $1 = $2

- 3 605. 5 x $1 = $5

- ЧЫ . 10 х $1 = $10

- 5620. 20 x $1 = $20

end of programming

SECTION 5: MAINTENANCE & ADJUSTMENTS

INTRODUCTION

The modular design of the Century Series allows for fast field substitution and easy maintenance of changer components. This section provides instructions for removing Bill Changer components for service, and details mechanical maintenance procedures.

BILL ACCEPTOR

For specific Bill Acceptor information not included in this manual, refer to the Bill Acceptor Field Service Manual and Parts Catalog included with the Bill Changer.

REMOVING A JAMMED BILL – Rowe® Bill Acceptor Only

To remove a jammed bill from the Bill Acceptor, first try to determine where the bill is jammed in the transport.

Open the bill box and determine if the bill can be reached. If necessary, the gear on the side of the transport can be turned by hand, forward or reverse, to remove the bill.

If the bill is jammed near the bill inlet, first try removing it by turning the transport gear by hand. If this does not free the bill, you will need to remove the inlet. Follow the instructions in this section to remove the transport from the Bill Changer, then refer to Section 3 of your Bill Acceptor manual for instructions to remove the bill inlet.

If bills jam frequently, refer to the Bill Jamming Checklist in Section 3 of your Bill Acceptor manual.

If your Bill Changer is equipped with a non-Rowe Bill Acceptor, please refer to its manual for instructions.

CAUTION:

Always turn the Bill Changer power to off before turning the Bill Acceptor gears by hand. Be careful not to pinch your fingers between the gears.

Figure 5-1 Removing the Bill Acceptor (C-2/4 Shown)

NOTE:

You may want to open the bill box in order to reach the screw between the Bill Acceptor body and the dispenser mounting frame.

NOTE:

If the hopper is full, place your hand or an empty bag over the hopper opening to keep coins from spilling out of the top of the hopper.

REMOVING THE BILL ACCEPTOR

Refer to Figure 5-1 as you remove the Bill Acceptor as follows:

- 1. Open the door as far as it will go without releasing the door latch.

- 2. While supporting the door with one hand, lift the latch handle to release the door latch and let the door all the way down.

- 3. On the C-2/4 only, remove the hopper following the instructions in Section 3, Unloading the Hopper.

- 4. Unplug the harness(es) from the Bill Acceptor.

- 5. Loosen the nut between the Bill Acceptor body and the dispenser mounting frame. Remove the other 3 nuts holding the Bill Acceptor in place. Remove the Bill Acceptor.

INSTALLING THE BILL ACCEPTOR

Refer to Figure 5-1 as you install the Bill Acceptor as follows:

- 1. Plug the connector(s) into the Bill Acceptor.

- 2. Install the Bill Acceptor to its mounting bracket by sliding it under the loosened nut, then replacing the other three #8-32 nuts. Tighten all nuts.

HOPPER

REMOVING THE HOPPER

If you are unfamiliar with the procedure to remove and replace the hopper, refer to Unloading the Hopper in Section 3 of this manual.

CLEANING THE HOPPER COIN PATH

NOTE:

Chain lubrication is not normally required.

The coin tracks inside the hopper are Teflon coated to minimize dirt build-up. It may still be necessary to clean them at regular intervals, as dictated by the number of vends and the environment, to prevent dirt accumulation in the coin path.

Failure to keep the coin path clean may result in coins sliding out of the track, causing the E r B message to occur even though the hopper contains a sufficient amount of coins.

Clean the hopper as follows:

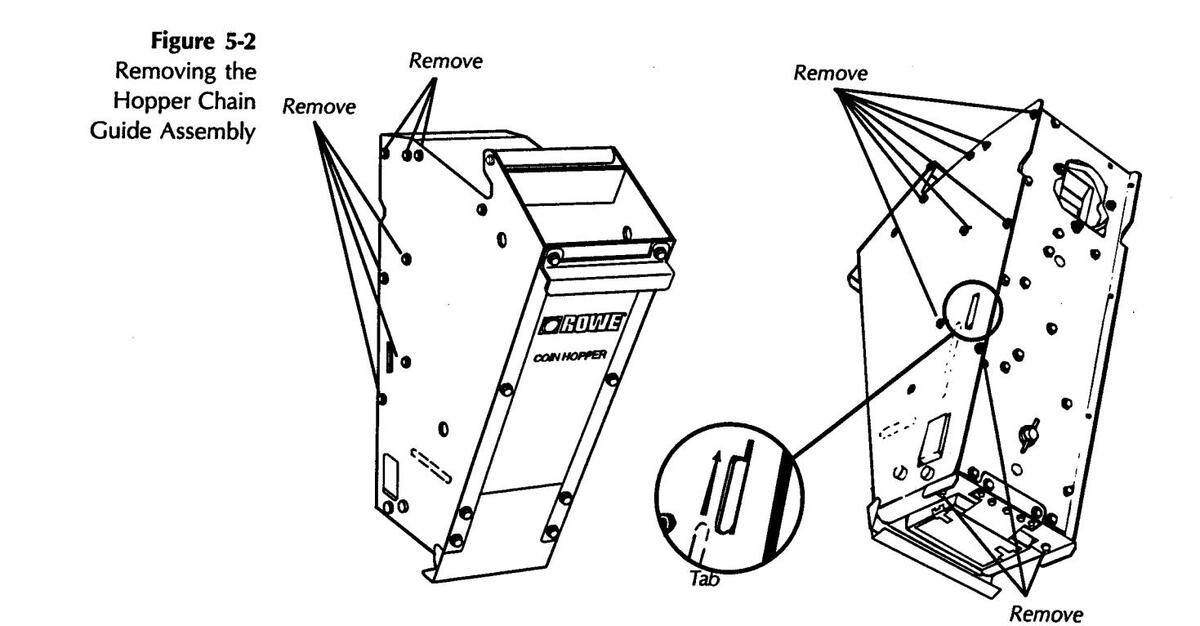

- 1. Remove the hopper from the bill changer and place it on a working surface.

- 2. Remove the black screws on each side of the hopper (Figure 5-2, 17 total), and lift the chain guide assembly up so that the tab (Figure 5-2, enlarged) can be pulled through the slot in the right hand side plate of the hopper assembly. When the tab is free, pull the chain guide assembly straight back out of the hopper.

NOTE:

Do not use detergents to clean the hopper. Detergent cleaners destroy the hopper's factory lubrication.

- 3. Using the Nylon hopper cleaning brush supplied with each machine, remove all dirt from the angular sides and flat surfaces of the serpentine coin path (Figure 5-3).

- 4. To reassemble the hopper, replace the chain guide assembly, securing the tab in its slot, and then start each of the screws removed in step 2. When all of the screws have been started, tighten all screws.

- 5. Replace the hopper in the bill changer. Be sure it is sitting securely in the pivot brackets, snug against the dispenser plate, and the catch is engaged.

- 6. Make a test vend to check for proper hopper operation.

Figure 5-3 Cleaning the Hopper Coin Path

Clean top and angular coin path surfaces, especially at guide edges, as shown

HOPPER CHAIN ADJUSTMENT

If the hopper coin path has been cleaned and the hopper still fails to operate correctly (jams or fails to pick up coins), you may need to adjust the hopper chain.

- 1. Remove the hopper from the bill changer and empty it of all coins (Section 3, Unloading the Hopper).

- 2. Loosen the three screws at the top back of the hopper (Figure 5-4, Ref. A and B) which allow the black plastic upper chain guide ring to move diagonally upward.

- 3. Pull the chain guide ring up with your index finger as shown in Figure 5-4. At the same time, rotate the hopper drive pin clockwise with your other hand until all slack is removed from the chain, but no binding is evident.

- 4. Tighten the two top screws (A), and then the bottom screw (B), that you loosened in step 2. If a torque wrench is available, adjust the chain so that the torque input at the drive shaft is one to four inch pounds.

Figure 5-4 Hopper Chain Adjustment

NOTE:

Make sure that all coins have been removed from the hopper before you adjust the chain tension.

DISPENSER

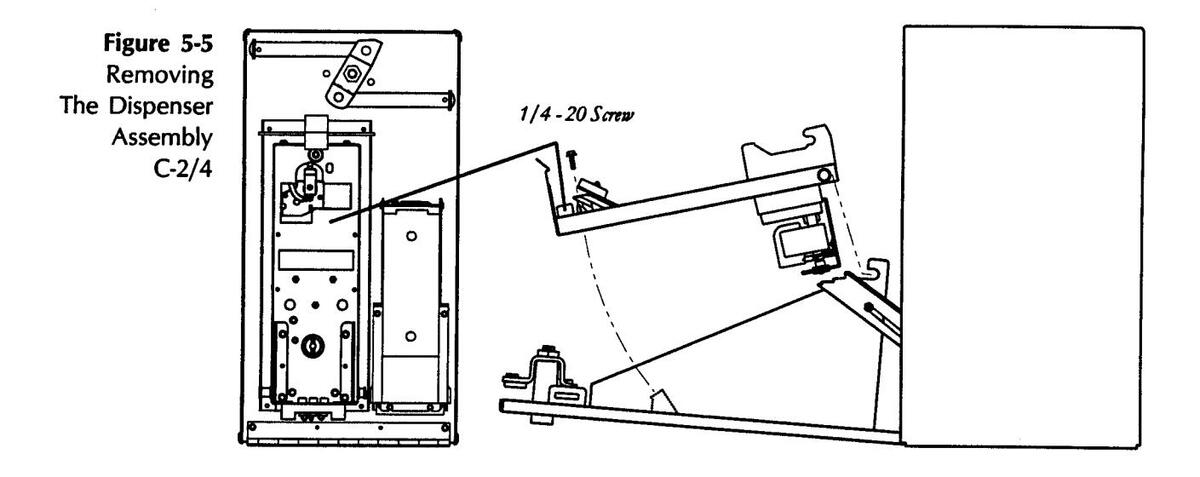

REMOVING THE DISPENSER ASSEMBLY

- 1. Remove the hopper from the dispenser assembly (Section 3, Unloading the Hopper).

- 2. Unplug the main harness from the dispenser.

- 3. Remove the 1/4 20 screw on the dispenser plate near the upper coin chute assembly (See Figure 5-5 for C-2/4 and Figure 5-6 for C-6).

- 4. Pivot and slide the dispenser assembly towards you and lift it off of its mounting bracket.

INSTALLING THE DISPENSER ASSEMBLY

- 1. Seat the dispenser assembly in its bracket with the motor toward the bracket.

- 2. Insert the 1/4 20 screw through the hole in the dispenser plate and thread it into the mounting bracket.

- 3. Plug the dispenser harness to the main harness.

- 4. Replace the hopper. Be sure it is sitting securely in the pivot brackets, snug against the dispenser plate, and the catch is engaged.

C-2/4 Door (Hopper Removed)

Side View

This page intentionally left blank.

SECTION 6: TROUBLESHOOTING & SELF-DIAGNOSTICS

INTRODUCTION

The Century Series Bill Changers offer a number of self-diagnostic features that aid in troubleshooting. The microcomputer in the Changer Control Computer (CCC) monitors the changer functions, and displays an error code if it detects a malfunction. The meaning of each of the two-character error codes, and instructions for correcting each error, are discussed in this section.

This section also describes miscellaneous problems that can occur but may not cause an error code to be displayed, as well as checking procedures used to verify that the Bill Changer is functioning properly.

TROUBLESHOOTING

Logical troubleshooting minimizes the effort and expense of removing and replacing the wrong part. The Corrective Actions in this section are written in order from the most common to least probable solution, to help you put your Bill Changer back in service quickly, and with as little effort as possible.

Many failures are caused by minor problems such as loose connections or dirty contacts. Before replacing any parts, check to make sure that all plugs are firmly seated and that connector pins are not bent, broken, or pushed through the back of the connector when mated.

WARNING:

The Bill Changer operates on 120 or 220/240 VAC line voltage. If any possibility exists that the wall outlet may be wired backwards, or if the changer is connected to a wall outlet via a two-pronged grounding adapter, pull the plug from the outlet before attempting troubleshooting procedures. Failure to do so could result in serious electrical shock.

CLEARING BILL CHANGER ERROR CODES

After performing one of the Corrective Actions , reset the Bill Changer by pushing the UP and DOWN buttons simultaneously on the CCC while the NORMAL/PROGRAM switch is in the NORMAL position. If the error has been corrected, a dash will move from left to right across the 4-character status display.

If necessary, perform a test vend (or a number of them) with a valid bill to make sure that the error does not reappear.

ERROR CODES

The self diagnostic features of the Century Series Bill Changers are centered around the four-character status display on the CCC. The message displayed will tell you the type of fault encountered.

A description of each of the possible Bill Changer error codes follows. The Bill Acceptor may experience an error condition that is not communicated to the Changer Control. This is particularly true when pulse-type Bill Acceptors are used. There may be no indication that the Changer is disabled, but there will be no activity with the Bill Acceptor due to such an internal malfunction. In these cases, refer to the status indicator on the Bill Acceptor itself-and the Bill Acceptor Manual provided - in order to isolate and solve the problem.

ERROR CODES:

Er 1

Problem:

No coins or bills are accepted.

Symptom:

The changer is in shutdown due to an EEPROM error.

Corrective Action:

- 1. Enter the programming mode and check each program option.

- 2. Reprogram the machine if necessary.

- 3. Exit the programming mode. If the error returns, replace the CCC.

Er 2

Problem:

The changer did not payout coins for a bill accepted. A bill may have been stacked but no payout made.

Symptom:

The changer is in shutdown because the bill acceptor sent the credit signal for a bill that was not programmed.

Corrective Action:

1. Verify that if a bill type is enabled at the bill acceptor, it is also enabled and the payout for that bill is programmed into the CCC. Verify proper setup of the bill acceptors' switch or jumper settings. See setup instructions provided by the bill acceptor manufacturer for further instructions.

Problem:

The changer did not payout coins for a bill accepted. A bill may have been stacked but no payout made.

Symptom:

The changer is in shutdown because the bill acceptors' output pulse was too long.

Corrective Action:

- 1. Check wiring harness from CCC to bill acceptor for a short to ground.

- 2. Replace bill acceptor.

Er 4

Problem:

No coins or bills are accepted.

Symptom:

The changer is in shutdown because of a fault with the bill acceptor.

Corrective Action:

- 1. Check for a full bill acceptor stacker.

- 2. Check for any debris in the bill acceptor.

- 3. Replace the bill acceptor.

Er S

This error should never occur in a Century 2, 4, or 6 Changer. If it does, replace the CCC.

Problem:

The changer did not payout the correct number of coins.

Symptom:

Note:

If the motor feels veryhot to the touch, wait until it cools down, then reset the CCC. Insert a bill to test for proper operation. If the motor operates after cooling off, check hopper for coin jams or binds.

The changer is in shutdown because no coins were paid out of the hopper for 60 seconds after the dispenser was enabled or for 60 seconds after the previous coin during a dispense cycle.

Corrective Action:

- 1. Make sure the hopper is lifting the coins into the coin chute. Check for dirt build-up on the coin path (See Section 5). Check for coin jam or binding parts in the hopper.

- 2. Check the hopper motor. Remove the hopper and clear the error code. Perform a test vend on the changer using a valid bill or coin. If the motor runs, check carefully for excessive bind in the hopper ( See Section 5 ). If the motor does not run, check for 120 VAC at the hopper motor. If voltage is present, the motor is defective. If there is no voltage present, proceed to Step 3.

- 3. Check for voltage at the CCC connection to the dispenser harness. If 120 VAC is present between P3 Pin 6 and P3 Pin 9, then the harness is at fault. Disconnect the 120 VAC, either at the wall plug or by disconnecting the harness at P4 on the CCC and then check for continuity between pin 6 and the hopper motor and pin 9 and the hopper motor. If continuity test fails, repair or replace the harness.

Problem:

The changer may have paid an extra coin from the hopper.

Symptom:

The changer is in shutdown because two extra coins have been paid out, since the last time the changer was reset.

Corrective Action:

- 1. Check for mechanical problems with the dispenser assembly. Most likely the cause is mechanical, rather than electrical. Check the hopper motor brake's stop-pawl for wear or breakage. Check magnetic brake actuator for binds or sticking. Repair or replace hopper motor.

- 2. Check the wiring to the photo-detector cell and LED on the dispenser assembly for loose connections or pinched wiring. Repair wiring or replace photo-detector cell or LED.

Er B

This error should never occur in a Century 2, 4, or 6 Changer. If it does, replace the CCC.

Problem:

The changer may have paid an incorrect number of coins.

Symptom:

The changer is in shutdown because the coin-detector is (or was) blocked.

Corrective Action:

- 1. Check for debris such as paper or a foreign object stuck between the photodetector and the LED on the dispenser assembly.

- 2. Verify that the LED is lit. Check the wiring to the photo-detector cell and LED on the dispenser assembly for loose connections or pinched wiring. Repair wiring or replace photo-detector cell or LED.

Erl D

Problem:

Programming Error.

Symptom:

The computer will not exit the programming mode because there is an error in the present setup.

Corrective Action:

1. A programmable setting is not correct for the conditions under which it was set. An example of this would be an additional bill type was enabled, but the payout settings for that bill type were not set. Verify all programming options and make any necessary changes. If the settings are correct, and the error persists, replace the CCC.

Erl 2

Problem:

The changer is out of service.

Symptom:

The last customer was most likely short-changed due to loss of power during the payout cycle.

Corrective Action:

- 1. Make certain that there is a continuous power source connected to the Changer. Check to be certain that the supply is again restored properly. Check the fuse or circuit breaker is OK.

- 2. Check the internal circuit breaker (5A) and the ON-OFF switch for intermittent contact.

- 3. If the problem recurs, and power failure can be completely ruled out, replace the CCC.

Er 13

This error should never occur in a Century 2, 4, or 6 Changer. If it does, replace the CCC.

Er 14

This error should never occur in a Century 2, 4, or 6 Changer. If it does, replace the CCC.

Er 15

This error should never occur in a Century 2, 4, or 6 Changer. If it does, replace the CCC.

Erl 6

Problem:

The changer does not contain enough coins to continue in service.

Symptom:

The changer is in shutdown because the low coin level sensor in the hopper has signalled a low level and the CCC has counted down to within 25 coins of the maximum payout.

Corrective Action:

- 1. Refill the hopper with the appropriate coins or tokens.

- 2. If the hopper contains sufficient coins, check the low level sensing circuit. The decimal point on the second-from-left 7-segment display is used as a low coin condition indicator for the hopper when lit.

If a low-level indicator is lit, but the hopper contains sufficient coins, the low coin level sensing circuit should be checked for proper operation.

3. Remove the hopper. The low-level indicator LED should not be lit. If it is lit, check the wiring between the low-level sensor contacts on the dispenser assembly and the CCC for pinched or shorted wiring. The voltage across pins 2 & 5 of P3 on the CCC should be 4.5 - 5.0 VDC. If this is the case, replace the hopper, or repair the low-level sensing circuits in the hopper.

Er21 or Er22 or Er23

Problem:

The changer goes out of service when trying to exit the programming mode.

Symptom:

The computer experienced a problem while saving information in its onboard memory chip.

Corrective Action:

1. The most likely cause for this would be a power loss during the programming process. Another possible cause could be a recurring low line voltage condition—See E r l 2.

- -

This error should never occur in a Century 2 or Century 4 Changer. If it does, replace the CCC.

Problem (Century 6 only):

The Changer will not accept coins.

Symptom:

The coin equipment is disabled because of a coin related error.

Corrective Action:

- 1. If a mechanical coin acceptor is installed, check the coin switch and switch actuator wire for proper operation. Check for a stuck coin or other object holding the switch closed. Clear the obstruction, and reset the error.

- 2. If an electronic coin acceptor is installed, check for a stuck coin or other object in the flight deck. Check the programming. Verify that if a coin type is enabled at the coin acceptor, it is enabled and the payout for that programmed into the CCC. If an electronic coin acceptor accepts a coin that was not programmed into the CCC, this error code will appear.

- 3. Check the wiring between the coin acceptor and the CCC for pinched or shorted wiring. If in doubt, disconnect the coin acceptor harness at the CCC. Reset the error. If the error does not return, replace the coin acceptor or the coin acceptor harness. If the error does return, replace the CCC.

MISCELLANEOUS PROBLEMS

The following problems may occur in the Bill Changer without causing a fault code.

ERRATIC PAYOUT

Problem:

The changer is not consistently dispensing the correct number of coins.

Symptom:

One vend is short a coin. The next vend contains an extra coin.

Corrective Action:

1. Check the coin chute on the back of the dispenser. Most likely, a coin is getting hung up in the dispenser coin chute, after it has been "counted" by the detector, then being shaken loose by a later vend. Check the coin chute for any dirt or obstruction that might cause a coin to hang up.

LARGE NUMBER OF VALID BILLS REJECTED

Problem:

The bill acceptor rejects a large number of valid bills.

Corrective Action:

Refer to the Troubleshooting Chart in the Bill Acceptor Field Service Manual and Parts Catalog included with your Bill Changer .

BILLS JAM FREQUENTLY

Problem:

Bills repeatedly become jammed in the Bill Acceptor transport.

Corrective Action:

Refer to the Bill Jamming Checklist in the Bill Acceptor Field Service Manual and Parts Catalog included with your Bill Changer .

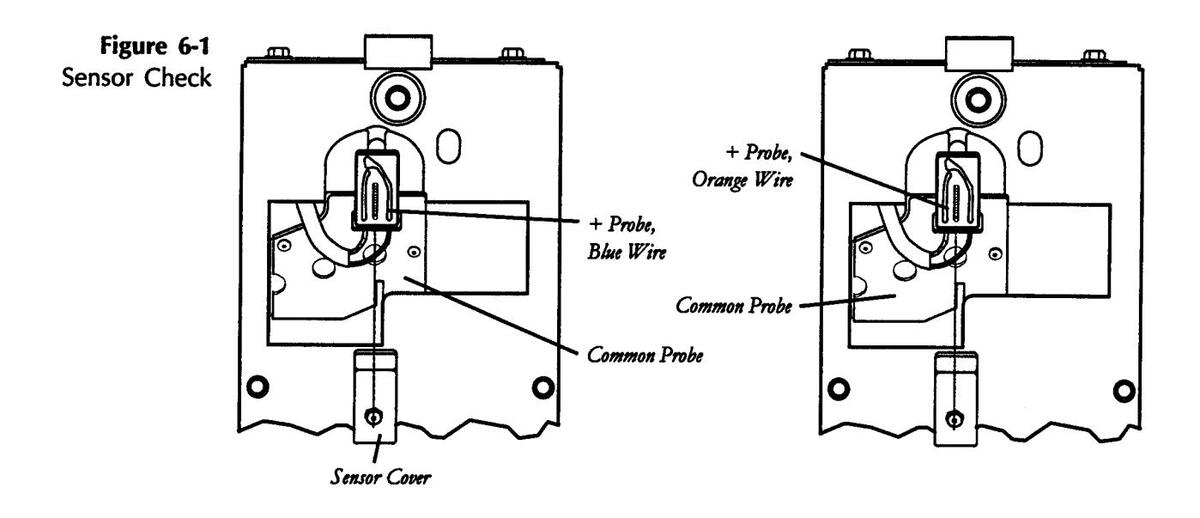

COIN COUNTING PHOTOTRANSISTOR (SENSOR) CHECK

Use the following procedure to check the phototransistor (sensor) in the dispenser coin detector system:

- 1. Switch the Bill Changer power OFF at the electrical box.

- 2. Remove the black plastic cover from the phototransistor and connect a common meter lead to the metal dispenser backing plate as shown in Figure 6-1.

- 3. Connect the positive (+) meter lead to the blue wire (Figure 6-1, Sensor Check-Blue Wire).

- 4. Turn the power switch ON and check to see that the LED is lit. The meter should indicate between 4.7 and 5.2 VDC.

If the meter indication is not correct (between 4.7 and 5.2 VDC), the voltage regulator on the CCC board may need replacement (see Section 7) . Repair the malfunction before continuing this procedure.

If the meter reading is correct:

5. Move the + meter lead to the orange wire on the phototransistor as shown in Figure 6-1, Sensor Check - Orange Wire. The meter should indicate between 3.5 and 5.0 VDC.

If the voltage is less than 3.5 volts, replace the phototransistor board with the correct part number listed in Section 8: PARTS CATALOG .