Rowe BC-3500 Service Manual

BC-3500

BC-3500

Bill & Coin Changer

Bill & Coin Changer

with Fast Pay System

with Fast Pay System

Field Service Manual

and

Parts Catalog

PART NO. 25238801

REV. N

BC-3500

Bill and Coin Changer

Field Service Manual

and

Parts Catalog

Rowe by American Changer

1400 N.W. 65th P

Fort Lauderdale, Florida 33309

techsupport@rowebillchangers.com

Printed in USA

lace

Machine Safety

This is a safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either “DANGER”,

“WARNING”, or “CAUTION”.

These words mean:

You can be killed or seriously injured if you don’t immediately

follow instructions

You can be killed or seriously injured if you don’t follow

instructions

You can be injured if you don’t follow instructions

Distributors, retailers, operators, and/or service people are to insure the following warning label is

properly affixed on the ACC products to which you/they are using and/or servicing in order to help

meet the applicable Proposition 65 requirements. For more information go to

www.P65Warnings.ca.gov

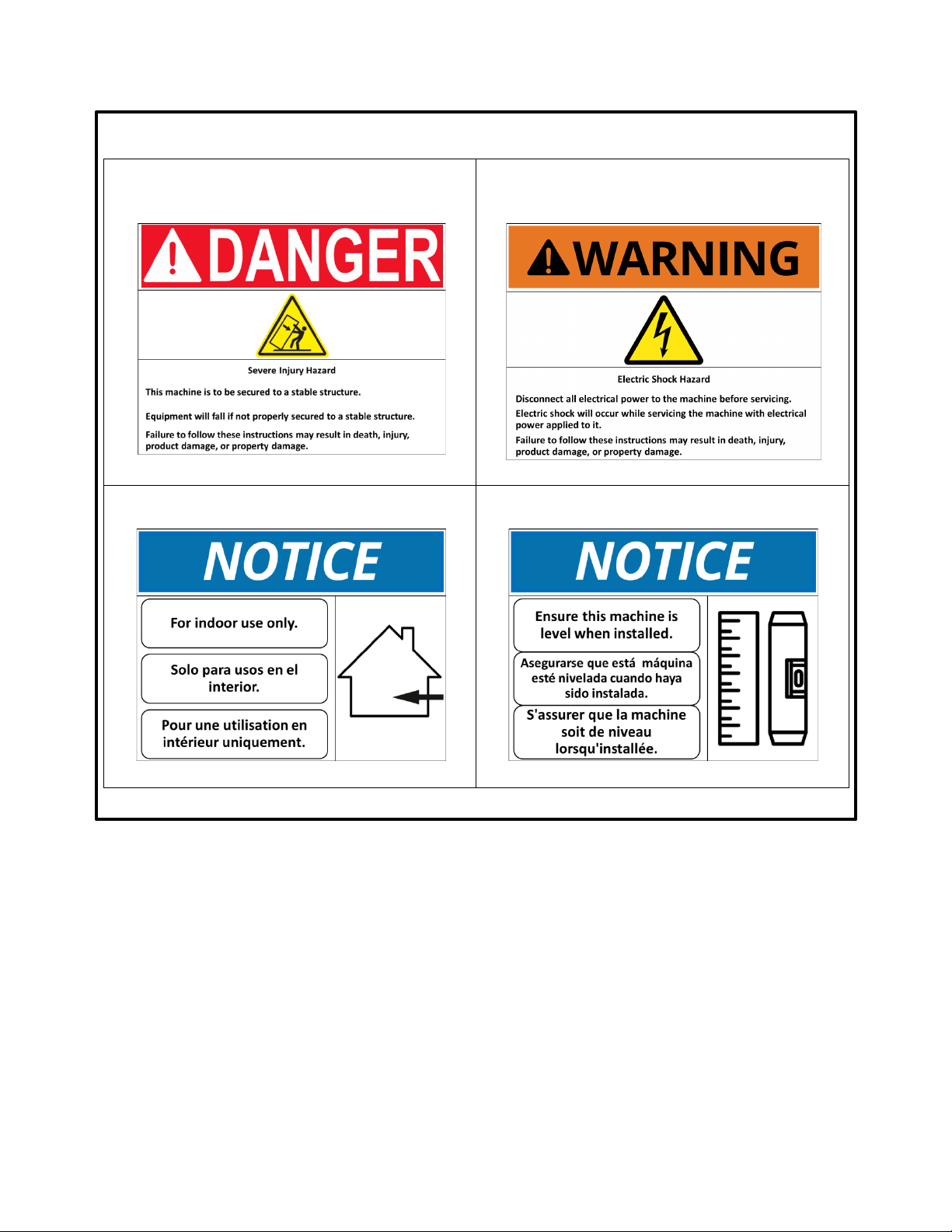

Your safety and the safety of others are very important to

American Changer.

We have provided important safety messages in this manual and on your machine. Always read and

obey all safety messages.

All safety messages will tell you what the potential hazard is, tell you how reduce the risk of injury, and

tell you what can happen if the instructions are not followed.

Important Safety Instructions

DANGER: To reduce the risks of severe injury

secure the machine to a stable structure.

WARNING: To reduce the risk of electrical shock,

disconnect all electrical power to the machine

before servicing.

NOTICE: For indoor use only.

NOTICE: Ensure this machine is level when

installed

American Changer does not guarantee machines (products) or services to be 100% secure against criminal

attempts. All machines (products) and services are to be used in accordance with business best practices and the

owner’s or operator’s best judgement.

Installation, use, service and maintenance must be performed in accordance with applicable machine (product)

manuals provided by American Changer and comply with any and all pertinent laws or regulations.

Inspect your machine (product), at a minimum annually, by a qualified service technician.

Dimensions and weights are reasonably close estimates. Specifications in this manual can vary without notice.

SAVE THESE INSTRUCTIONS

Section 2 – Setup & Installation

2.2 – Mounting Instructions

This machine must be installed in accordance with local codes. If you are unsure in any way what your

local codes are or unsure of anything in the following steps, please hire a licensed professional to

mount your machine.

1. Disconnect any and all AC power going to the machine. (Unplug AC line cord from the rear of the

machine.)

2. Note: You will need to verify with the building code enforcement to see if it is allowable to plug the

changer into a grounded outlet. If it is not, there must be 120VAC run through conduit or other

means to meet local codes to the changer. If it is not required, proceed to step #6.

3. Have a licensed electrician run the conduit, install the new breaker, wire and help decide how the

wiring will enter the changer (from the back or the bottom).

4. After the conduit has been installed, proceed with securing the machine to a stable structure.

5. Find an appropriate stable structure which to secure the machine to.

6. NOTICE: BEFORE SECURING ENSURE THE MACHINE IS LEVEL.

7. : PROPERLY SECURE MACHINE (PRODUCT) TO THE FLOOR SO THE MACHINE

(PRODUCT) CANNOT BE MOVED OR TIPPED. USE STRUCTURAL SOUND FASTENERS THAT CAN BE

PROPERLY TIGHTENED AND SECURE THE MACHINE (PRODUCT) THROUGH EACH OF THE HOLES IN

THE BASE OF THE MACHINE (PRODUCT) TO THE APPLICABLE SURFACE TO WHICH IT IS BEING

SECURED.

8. Use the four holes located in the back, bottom, or sides of the cabinet to secure the machine to a

stable structure.

9. Verify that the machine is properly secured to the stable structure.

10. Connect your AC line to the outlet. If conduit was run wire it to the power supply located in the

machine.

a. Do not use an extension cord unless allowed by the building electrical code.

b. Installation is completed. Proceed to the “Programming the Changer” section.

The proper performance of your American Changer machine is directly related to the quality of the power it is

supplied. AC power fluctuations, including blackouts, brownouts, over voltages, sags, surges, and spikes may cause

the machine to miss pay. To ensure the most trouble-free operation, we strongly recommend plugging all of our

machines into a DEDICATED AC outlet (this means there are no other machines on location plugged into the same

AC line). A simple way to check if this is true is to turn off the breaker associated with our machine at the breaker

box. No other equipment on location should lose power.

Additionally, if your unit is located in an area prone to lightning storms or other sources of frequent power

disturbances, we also strongly recommend using an Uninterruptible Power Supply (UPS). If power is lost during a

payout to a customer, a UPS will allow your machines to complete the transaction that would otherwise not be

completed. In some cases, a UPS may also correct long-term under and/or over voltages on the AC line by

converting to the proper line voltage before the power reaches the machine.

Every American Changer machine has a surge suppressor built into the main logic board. This helps eliminate

power related noise problems, but it will not protect from substantial voltage spikes or nearby lightning strikes. If

this is a concern for your area, we recommend purchasing a commercial grade UPS with integrated surge

protection. NOTE: A POWER STRIP IS NOT A SURGE PROTECTOR.

WARNING:

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used in accordance

with the instructions manual, may cause interference to radio communications. It has been tested and found to

comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which are

designed to provide reasonable protection against such interference when operated in a commercial environment.

Operations of this equipment in a residential area is likely to cause interference. In which case, the user, at his own

expense, will be required to take whatever measures may be required to correct the interference.

ii 25238801

Preface

This service manual is divided into six sections:

Section 1 System Description — Introduces you to the BC-3500, its features, and its major components,

principles of operation, and capacities.

Section 2 Installation and Programming — Guides you through step-by-step installation instructions and

detailed setup (programming) procedures.

Section 3 Routine Service — Provides routine service instructions for general maintenance and preventive

maintenance. This section provides information for routine service and identified problems. Refer to

Section 4: Troubleshooting for procedures and techniques to identify a malfunction or reject problem.

Section 4 Troubleshooting — Provides troubleshooting charts, detailed error message descriptions, trouble-

shooting procedures, a block diagram, schematics, circuit board layouts, and components lists. This

section also contains a detailed sequence of operation.

Section 5 Miscellaneous — Contains a harness color code list and other miscellaneous information.

Section 6 The Parts Catalog — Lists and illustrates all replaceable modules in the BC-3500.

This manual is intended for owners, route operators, and technicians. It provides all field and shop related service

and maintenance material. Accessories and their installation and service are discussed in the corresponding

accessory instructions (or manuals).

25238801 iii

Table of Contents

SECTION 1 — SYSTEM DESCRIPTION

Introduction ......................................................................................................................................................... 1-1

General Operation .............................................................................................................................................. 1-1

Changing a Bill ................................................................................................................................................... 1-1

Changing Coins ................................................................................................................................................. 1-2

Functional Description ....................................................................................................................................... 1-2

Bill Transport ....................................................................................................................................................... 1-2

Dual Bill Stacker ................................................................................................................................................. 1-3

Coin Acceptor ..................................................................................................................................................... 1-4

Solid-State Coin Switches ................................................................................................................................... 1-5

Coin Dispenser .................................................................................................................................................. 1-5

Coin or Bill Return Button .................................................................................................................................... 1-6

Hoppers ............................................................................................................................................................. 1-6

Hopper Capacities ............................................................................................................................................. 1-7

Machine Capacities (Bill Stacker, Coin Box) ........................................................................................................ 1-7

Temporarily Out of Service Lamp ........................................................................................................................ 1-8

Power Control Center .......................................................................................................................................... 1-8

Dollars Accepted Counter ................................................................................................................................ 1-8

EMI Filter ......................................................................................................................................................... 1-9

Power Supply ................................................................................................................................................. 1-9

Test Switches ................................................................................................................................................. 1-9

Power Control Relay ....................................................................................................................................... 1-9

Computer Control Center ..................................................................................................................................... 1-9

Status Display .............................................................................................................................................. 1-10

Service and Control Switches ........................................................................................................................ 1-10

Denominations Accepted ................................................................................................................................. 1-11

SECTION 2 — INSTALLATION AND PROGRAMMING

Installation .......................................................................................................................................................... 2-1

Wall Mounting .................................................................................................................................................... 2-1

Change Payout Programming ........................................................................................................................... 2-3

Loading the Hoppers .......................................................................................................................................... 2-5

Unloading the Hoppers ...................................................................................................................................... 2-5

Operational Information .................................................................................................................................... 2-6

Setting Up the BC-3500....................................................................................................................................... 2-7

Quick Setup for a BC-3500 Dispensing Quarters Only ........................................................................................ 2-7

Normal Setup ..................................................................................................................................................... 2-8

Key Information ................................................................................................................................................... 2-8

Turning the Power On ......................................................................................................................................... 2-8

Switching to the PROGRAMMING Mode ........................................................................................................... 2-9

If No Access Code Has Been Established ...................................................................................................... 2-9

If an Access Code Has Been Established ..................................................................................................... 2-10

To Program a Different Access Code ............................................................................................................. 2-10

Self-Diagnostics ................................................................................................................................................ 2-15

Diagnostic Check ............................................................................................................................................. 2-15

Fault Message Check ...................................................................................................................................... 2-15

Status Messages ............................................................................................................................................. 2-15

Non-Shutdown Faults .................................................................................................................................... 2-15

Bill Acceptance Messages ............................................................................................................................ 2-15

iv 25238801

Table of Contents

SECTION 2 — INSTALLATION & PROGRAMMING (Continued)

Transport Self-Clear Check .............................................................................................................................. 2-15

Acceptance Check ............................................................................................................................................ 2-16

Dispensing Tokens ............................................................................................................................................ 2-17

Token Control ................................................................................................................................................... 2-18

Fast-Feed Shutdown ........................................................................................................................................ 2-18

Accessing the Fast-Feed Menu ......................................................................................................................... 2-19

Navigating the Fast-Feed Menu ........................................................................................................................ 2-19

Anti-Pullback System ....................................................................................................................................... 2-20

Accessing the Anti-Pullback Menu .................................................................................................................. 2-21

Navigating the Anti-Pullback Menu ................................................................................................................. 2-21

Miscellaneous ................................................................................................................................................... 2-21

SECTION 3 — ROUTINE SERVICE

Introduction ......................................................................................................................................................... 3-1

Removing a Jammed Bill from the Bill Acceptor ............................................................................................ 3-1

Bill Jamming Check List .................................................................................................................................... 3-1

Filling and Emptying the BC-3500 ..................................................................................................................... 3-2

Filling the Changer ............................................................................................................................................ 3-2

Emptying the Changer ....................................................................................................................................... 3-3

Coin Inlet Cleaning Procedure .......................................................................................................................... 3-3

Cleaning the Hopper Coin Path ........................................................................................................................ 3-4

Change Bucket Lubrication ............................................................................................................................... 3-6

Test Procedures .................................................................................................................................................. 3-6

Checking a Bucket Solenoid ................................................................................................................................ 3-6

Transport Motor Speed Check ............................................................................................................................ 3-6

Testing BC-3500 Transport Photocells ................................................................................................................. 3-7

VI - Transport Inlet ........................................................................................................................................... 3-7

VF - Flipper Cell ............................................................................................................................................... 3-7

VT - Transmissive Cell ..................................................................................................................................... 3-7

VR - Reflective Cell ......................................................................................................................................... 3-7

Coin Counting Phototransistor (Detector) Check ................................................................................................... 3-8

Adjustments ......................................................................................................................................................... 3-9

Bill and Coin Return Switch Assembly ................................................................................................................ 3-9

Coin Inlet to Top Door Clearance ..................................................................................................................... 3-9

Bill Return Switch Adjustment ......................................................................................................................... 3-10

Hopper Chain Adjustment ................................................................................................................................. 3-10

Adjsuting the Bill Acceptor Rails ......................................................................................................................... 3-12

Adjusting the Bill Transport to Stacker Alignment ................................................................................................. 3-13

Bill Stacker ........................................................................................................................................................ 3-13

Home Switch Adjustment ............................................................................................................................... 3-13

Adjusting the Pusher Plate ................................................................................................................................ 3-14

Adjusting the Upper Bill Box .............................................................................................................................. 3-15

Bill Stop Flipper Check ...................................................................................................................................... 3-16

Adjusting the Bill Stop Flipper ............................................................................................................................ 3-17

Installing a New or Replacement Bill Stacker ..................................................................................................... 3-17

Timing Belt Tension ........................................................................................................................................... 3-20

25238801 v

Table of Contents

SECTION 4 — TROUBLESHOOTING

Introduction ......................................................................................................................................................... 4-1

Power Up Diagnostics ........................................................................................................................................ 4-1

Sequence Descriptions ....................................................................................................................................... 4-2

Machine Status .................................................................................................................................................. 4-2

Standby Mode ................................................................................................................................................... 4-2

Accept, Payout, and Replenish Modes ............................................................................................................... 4-3

Reject Mode ....................................................................................................................................................... 4-3

Out of Service Mode ........................................................................................................................................... 4-3

Index to Error Messages and Troubleshooting Charts .................................................................................... 4-4

Validation Rejects .............................................................................................................................................. 4-6

Cell Sequence Rejects ........................................................................................................................................ 4-6

Bill Parameter Rejects ..................................................................................................................................... 4-16

Transport Errors ................................................................................................................................................ 4-20

Clearing Errors .................................................................................................................................................. 4-20

Machine Errors ................................................................................................................................................. 4-22

Clearing Machine Errors .................................................................................................................................... 4-22

Changer Errors (Non-Shutdown) ....................................................................................................................... 4-22

Coin Switch Errors ......................................................................................................................................... 4-26

Bill Changer Errors (Shutdown) ....................................................................................................................... 4-29

Coin Detector Errors While in the Standby Mode ............................................................................................... 4-29

MC Dispense Mode ........................................................................................................................................... 4-47

Detailed Control Computer Board Operation ................................................................................................. 4-64

Control Computer .............................................................................................................................................. 4-64

Reset Circuit .................................................................................................................................................. 4-64

I/O Ports ....................................................................................................................................................... 4-65

Digital Display Driver ........................................................................................................................................ 4-65

Output Circuits .................................................................................................................................................. 4-66

Transport Motor Control .................................................................................................................................. 4-66

Hopper Motor Control ..................................................................................................................................... 4-66

LED Drive ..................................................................................................................................................... 4-66

Out of Service Lamp ..................................................................................................................................... 4-67

Stacker Drive ................................................................................................................................................. 4-67

Dollar Counter ............................................................................................................................................... 4-67

Bucket Drive .................................................................................................................................................. 4-67

Stacker Solenoid ............................................................................................................................................ 4-67

Coin Lockout ................................................................................................................................................. 4-67

Input Circuits ..................................................................................................................................................... 4-67

Power Supply Circuit Board .............................................................................................................................. 4-75

Computer Control Board ................................................................................................................................... 4-94

Bill Stacker Driver Circuit Board ......................................................................................................................... 4-103

Coin Switch Circuit Board ................................................................................................................................. 4-105

SECTION 5 — ADDITIONAL INFORMATION

Harness Color Coding ........................................................................................................................................ 5-1

vi 25238801

Table of Contents

SECTION 6 — PARTS CATALOG

BC-3500 Code Sheet ........................................................................................................................................... 6-2

Introduction ......................................................................................................................................................... 6-3

Catalog Description ............................................................................................................................................ 6-3

Parts List Description .......................................................................................................................................... 6-3

Ordering Replacement Parts ............................................................................................................................... 6-3

Parts Catalog ...................................................................................................................................................... 6-5

FREQUENTLY USED FIGURES AND TABLES

Coin

Acceptor Options (Table 1-1) .............................................................................................................................. 1-4

Dispenser (Figure 1-5) ........................................................................................................................................ 1-5

Computer Control Center (CCC) (Figure 1-9) .......................................................................................................... 1-9

Diagrams

Block Schematic Diagram (Figure 4-1) ............................................................................................................... 4-69

Coin Switch

Schematic (Figure 4-7) .................................................................................................................................4-104

Circuit Board Layout (Figure 4-8) .................................................................................................................. 4-105

Computer Control Board (CCC) (Figure 4-5) ..................................................................................................... 4-87

Driver Circuit Board Schematic (Figure 4-6) . ...................................................................................................... 4-102

Power Supply (Figure 4-2) ............................................................................................................................... 4-71

Escrow Bucket Capacities (Table 2-1) ................................................................................................................... 2-3

Hopper

Chain Adjustment (Figure 3-9) .......................................................................................................................... 3-11

Value Codes (Table 2-3) .................................................................................................................................. 2-12

Machine Capabilities (Table 1-2) ........................................................................................................................... 1-7

Money

Accepted (Table 2-4) ........................................................................................................................................ 2-12

Combinations Which Are Not Allowed (Table 2-2) ............................................................................................... 2-4

Power Control Center (Figure 1-8) .......................................................................................................................... 1-8

Transport

Check Points (Figure 3-1) ................................................................................................................................... 3-2

To Stacker Alignment (Figure 3-10B) ................................................................................................................. 3-13

View

Bottom (Figure 1-3) .......................................................................................................................................... 1-3

Top (Figure 1-2) .............................................................................................................................................. 1-2

25238801 vii

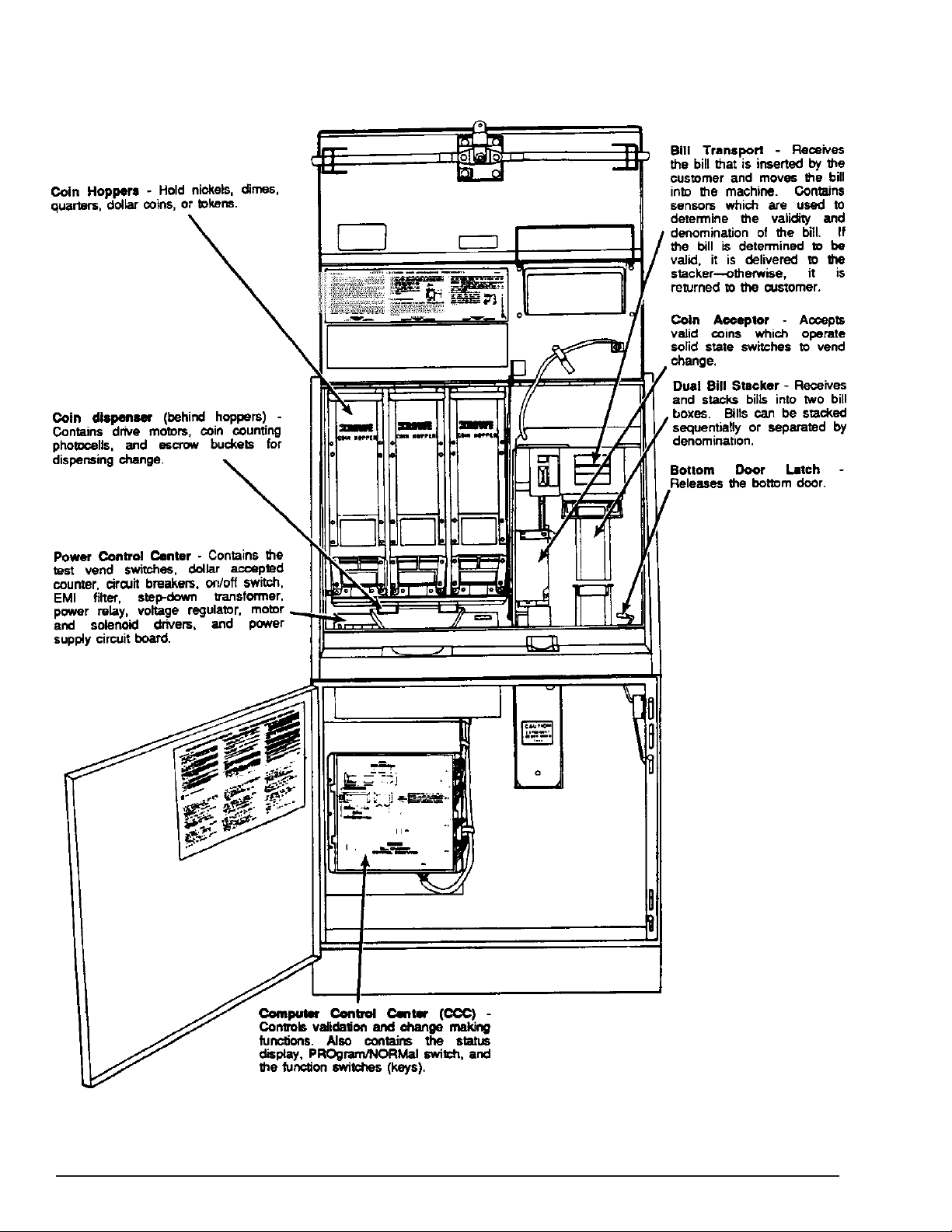

Figure 1-1. BC-3500 Major Components

viii 25238801

Section 1: System Description

INTRODUCTION

The Rowe BC-3500 Bill and Coin Changer is our top-of-the-line money changer that uses computer and money

changer technology which combines Rowe quality and reliability with maximum flexibility and ease of installation and

service.

The BC-3500 accepts and dispenses change for combinations of quarters, half-dollars, and dollar coins as well as

1, 2, 5, 10, and 20 dollar bills of United States currency. Denominations can be programmed to be accepted in many

combinations, as can the choice of coins paid out.

• A high security cabinet provides theft protection.

• A microcomputer in the Computer Control Center (CCC) selectively discriminates between denominations,

provides protection against bogus bills, and controls the change dispensing functions.

• Plug-in circuits and assemblies are featured for fast field substitution.

• Coin combinations and acceptable denomination programming is easily changed using the FUNCTION, UP,

DOWN, VALUE, and HOPPER buttons on the computer control center.

• Removable coin hoppers permit rapid bulk loading of coins.

• During setup, a special payout check feature ensures that the payout amount selected matches the

denomination accepted, unless tokens are being dispensed.

Refer to Figure 1-1 for the locations of the major BC-3500 components.

GENERAL OPERATION

The entire validation and payout sequence is controlled by a microcomputer to ensure the maximum security against

bogus currency and jackpotting. Refer to the Detailed Computer Board Operation in Section 4 for a complete

explanation of how the machine works.

Changing a Bill

Inserting a dollar bill in the transport starts a motor which movies the bill along the acceptor track. While in motion,

the bill is examined to determine whether or not it is valid. (During this time, the message “VALIDATING” will appear

on the computer’s display.)

If the bill is valid, a vend signal is transmitted to the dispenser and the bill drops into the bill stacker where it is stacked

flat against other valid bills. At this time, the message “PAY $1” (for example) for a $1 bill will appear on the display.

The one dollar change bucket opens, and the dollar’s worth of change drops into the coin cup.

25238801 1-1

BC-3500 Bill and Coin Changer

The coin hopper motors then operate, loading the correct number of coins from the left, center, and right coin hoppers

into the change bucket for the next payout.

If the bill is not valid, the bill transport motor reverses, returning the bill to the customer.

Changing Coins

Quarters, half-dollars, and dollar coins pass through the coin acceptor if the changer is so equipped. Solid-state coin

sensors start the payout cycle for these coins.

FUNCTIONAL DESCRIPTION

This functional description can be used to gain an overall understanding of the BC-3500 and its operation.

Bill Transport

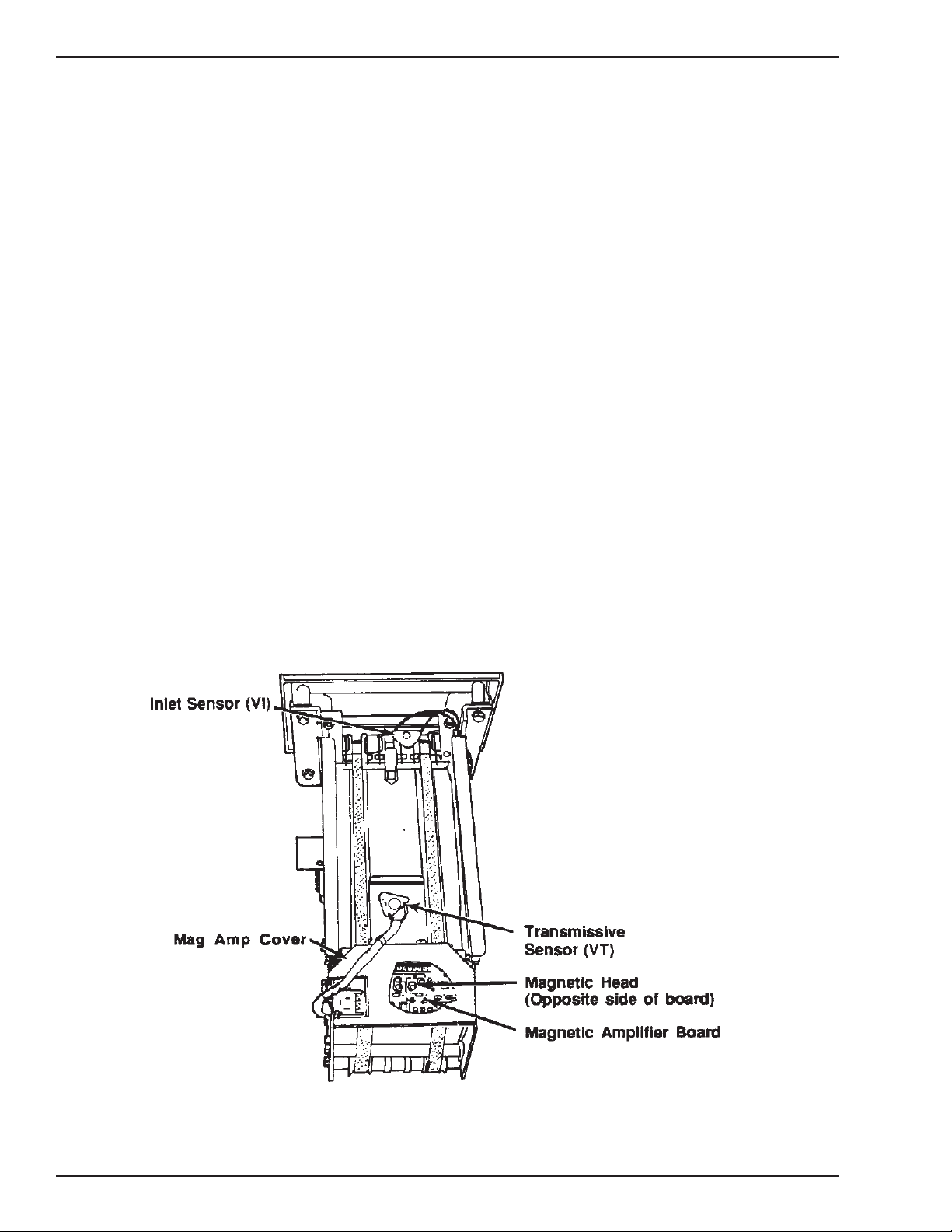

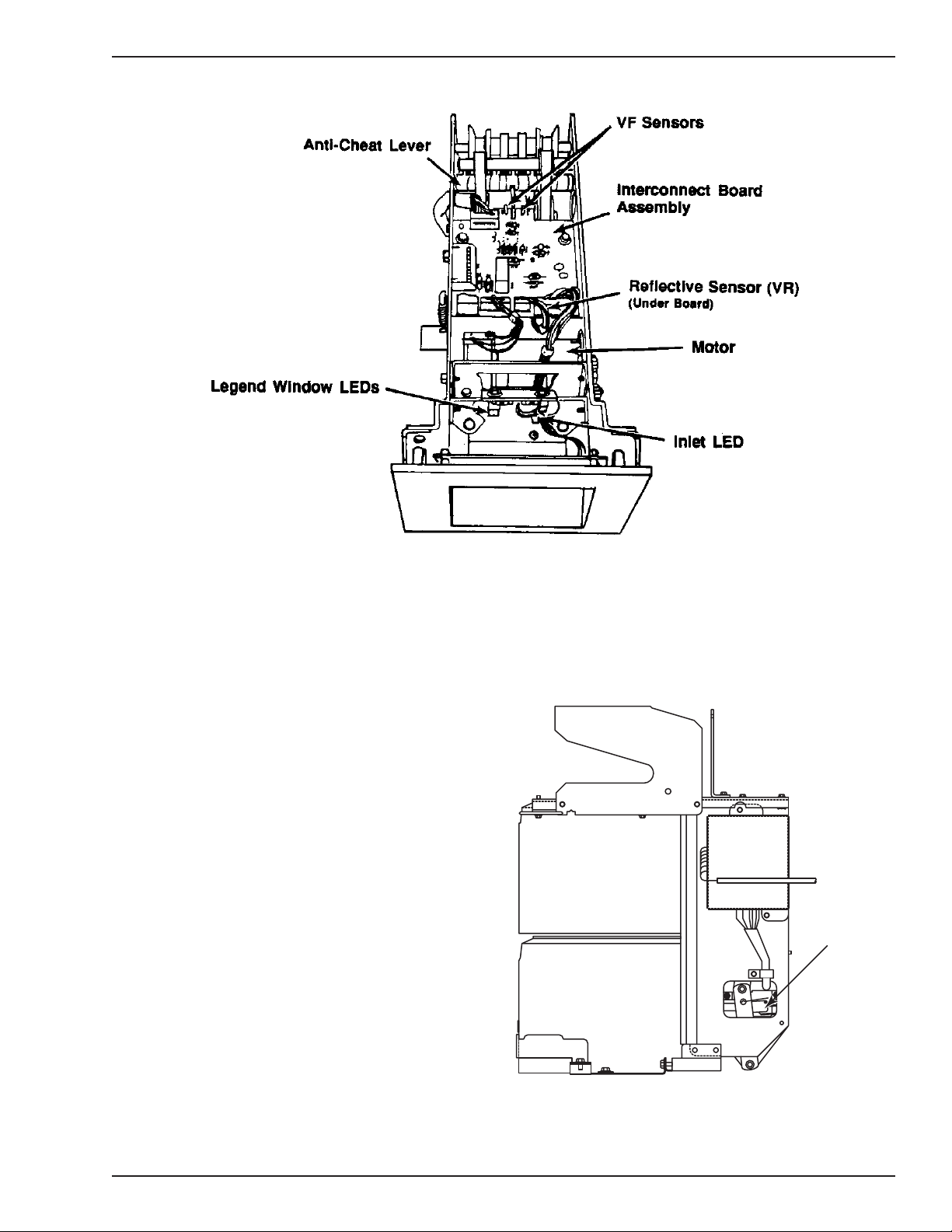

The bill transport (see Figures 1-2 and 1-3) receives a bill as it is inserted by the customer. The bill is transported

through the transporter on a belt system, carefully examined and , if the bill is determined to be valid, is delivered to

the bill stacker.

If the bill fails any of the validation tests, the transport reverses and returns the bill to the customer. The bill will hang

in the transport inlet for a period of three seconds during which time the control computer will display a message

explaining the cause for the rejection. If the bill is not removed during this these three seconds, the computer will

display “PURGING ACCEPTOR” and a self-purging routine will begin. If the bill is removed in the three-second

period, the cause of the rejection will remain on the display for 30 seconds.

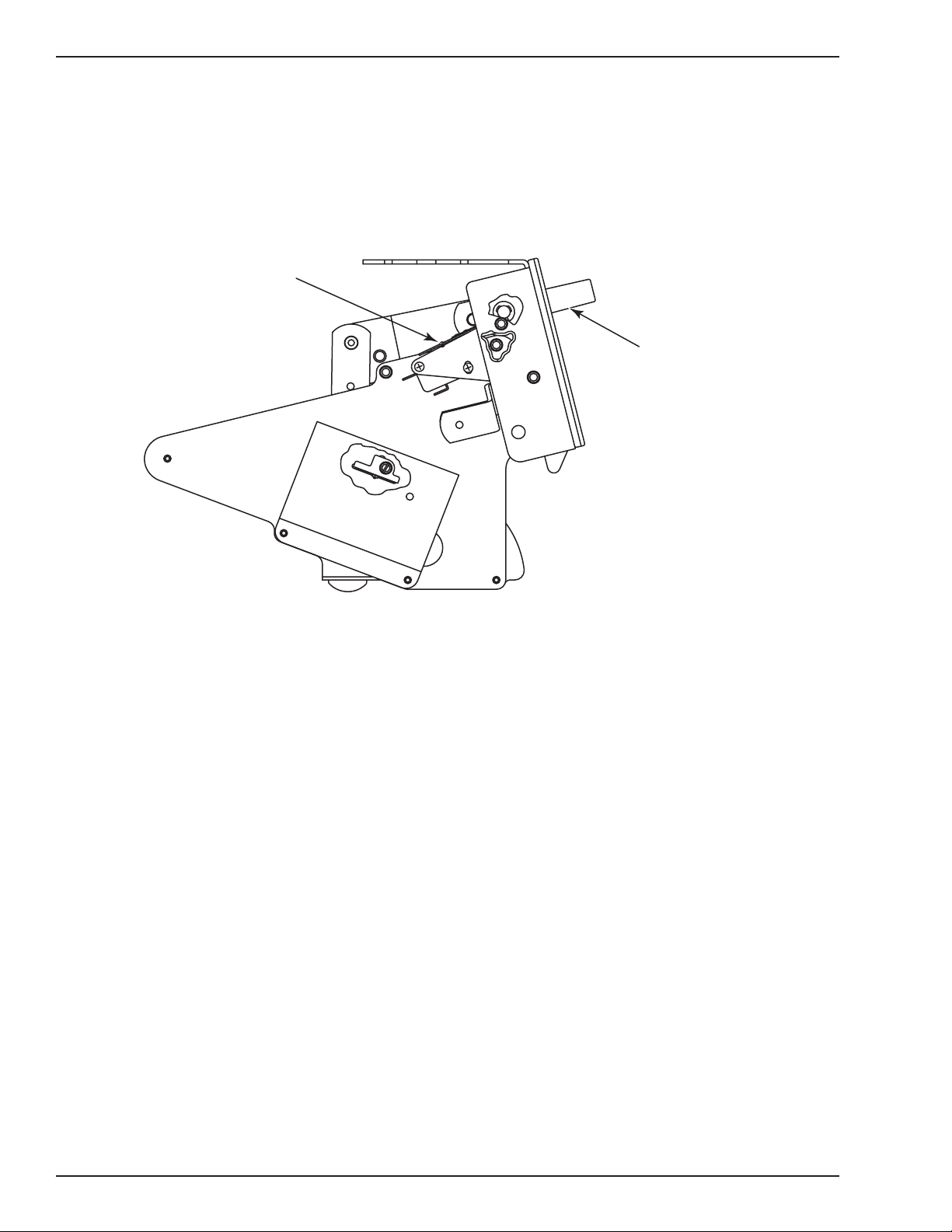

Figure 1-2. Bill Transport (Top View)

1-2 25238801

Section 1: System Description

h

Figure 1-3. Bill Transport (Bottom View)

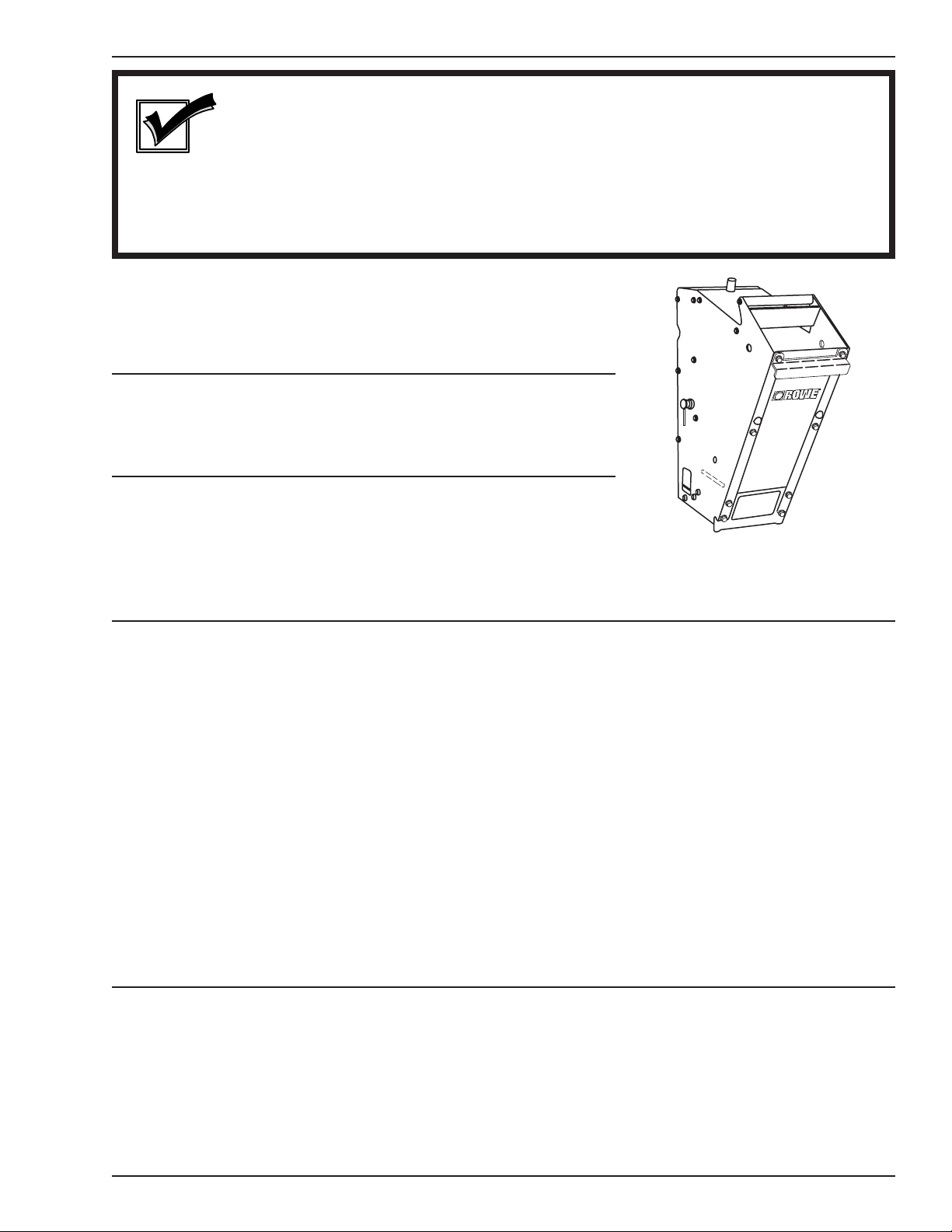

Dual Bill Stacker

The dual bill stacker in Figure 1-4 has the capability

of stacking bills in two separate bill boxes. This feature

allows the bill changer to alternate between the two bill

boxes or to separate bills by denomination. This

function is controlled by the CCC, which activates a

solenoid-driven lever in the stacker. When this lever

is in its rest position, it acts as a stop to position the

falling bill in line with the upper bill box. When

energized, this lever drops out of the way and allows

the bill to fall to the lower bill box position. Once the

bill is positioned properly, a signal from the CCC

activates a triac drive circuit in the stacker. As the

stacker leaves home position, a single cam switch

closes and performs two functions:

Cam

Switc

25238801 1-3

Figure 1-4. Dual Bill Stacker

BC-3500 Bill and Coin Changer

• It holds the triac drive circuit ON and also activates the stacker monitor line to the CCC.

• When the stacker completes its cycle, the cam switch opens, stopping the stacker motor and deactivating the

monitor line to signal the CCC that it is ready for the next cycle.

Coin Acceptor

The coin acceptor checks the coins for which it was designed to determine their validity. Each coin is checked for

thickness, diameter, weight, and metallic content. If the coin is deformed or invalid, it is directed through the coin

acceptor to the coin return cup. Genuine coins are directed through the coin acceptor and actuate either of the two

solid-state coin switches located on the rear bottom of the slug rejector frame.

Jammed coins or slugs are cleared from the coin acceptor by a wiper arm on the coin acceptor, which is actuated

by the

COIN or BILL RETURN button. The coin inlet and chute deters cheating and jamming. The coin inlet and chute

can be opened for easy clean out by removing the lower thumbscrew and rotating the coin track up. Various coin

acceptors are available as order options. Use Table 1-1 that follows as a guide:

Table 1-1. Coin Acceptor Options

Coin

Accepted

None

25¢

Imonex

$1

Imonex

25¢/$1

Imonex

25¢/$1

25¢/$1

Coin

Acceptor

-------

Mechanical

40861402

Mechanical

40861404

Mechanical

40861405

Electronic NRI

27064002

Electronic Mars

27063802

Bracket &

Harness

-------

35026111

35026111

35026111

35028211,

30984404, and

27065301

35028216 and

30984404

Instruction

Panel

25081202

25081201

25061603

25061602

25061602 and

25061603

25061602 and

25061603

Coin Block

27027204

27027201

(Down position)

27027201

(Up position)

27027201

(Up position)

27027201

(Up position)

27027201

(Down position)

NOTE:

Accepting any combination of coins may reduce the number of bill combinations that can

be accepted. (See Section 2 for details.)

1-4 25238801

Section 1: System Description

Solid-State Coin Switches

As a coin passes through a slot in the coin switch assembly with any mechanical coin acceptor, it momentarily

interrupts an infrared light beam, causing a solid-state optical detector to send an electric pulse to the CCC. The

duration of this pulse is then checked by the computer to determine its validity. Valid coins will initiate the dispense

cycle. A separate infrared LED and optical sensor and photo-transistor pair is provided for each of the two possible

coin denominations accepted.

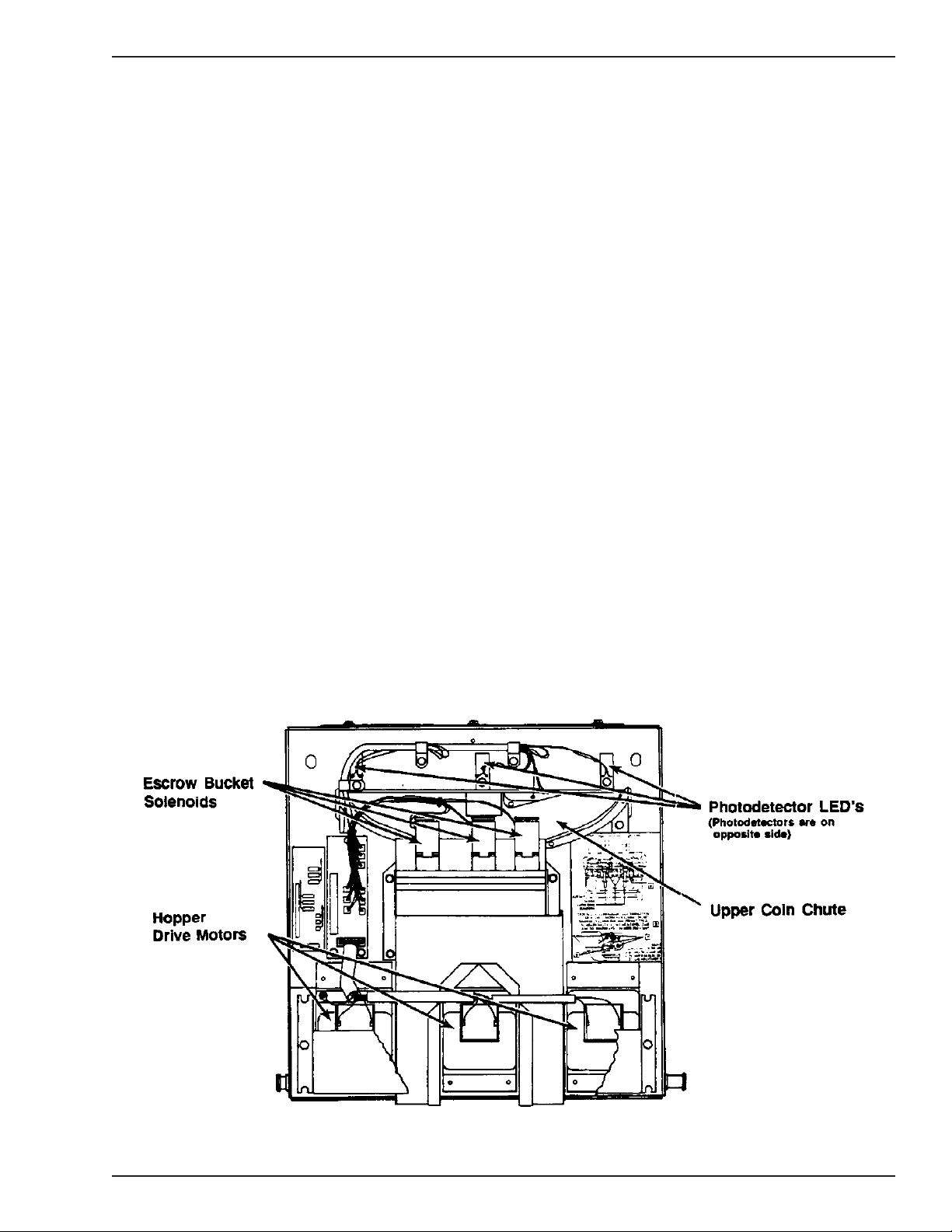

Coin Dispenser

The coin dispenser (see Figure 1-5) contains the necessary components to handle the coins. The escrow buckets,

the solenoid assemblies, the chute from the bucket to the channel mounted on the power control center, and the upper

coin chute from the coin detectors to the buckets are located on this assembly.

The three coin detectors, each consisting of an LED and a photo-transistor, detect the coins as they exit from their

respective hoppers and fall into the upper coin chute.

The upper coin chute directs the change to the escrow buckets.

The drive for the hoppers consists of three AC motors, which are also on the dispenser. These motors, as well as

the solenoids which open the bottom door of the escrow buckets, are controlled by signals from the CCC.

You can access the rear of the dispenser assembly by removing the two screws in the upper corners, grasping the

dispenser at the arrow, and tilting the entire assembly forward on its lower pivots.

When you replace the dispenser, be sure that you tighten down the two top screws securely. If these screws are

not tightened down, the entire dispenser assembly may tilt forward when the hoppers are unloaded or removed.

Figure 1-5. Coin Dispenser (Rear View)

25238801 1-5

BC-3500 Bill and Coin Changer

n

Coin or Bill Return Button

When the COIN or BILL RETURN button (see Figure 1-6) is depressed, a switch closes and sends a signal to the

CCC. The coin lockout coil in the coin acceptor is released and the transport motor rotates in the reverse direction.

If the bill reject button is pressed (

excess wear and overheating and the message “CK BILL RETRN SW” will be displayed and the switch will be ignored

until the FUNCTION button is pressed.

Bill Return

ON) for more than 10 seconds, the transport will turn OFF automatically to prevent

Switch

Coin or Bill

Return Butto

Figure 1-6. Bill Return Switch

Hoppers

The bill changer contains three coin hoppers (see Figure 1-7) which mount on the front surface of the dispenser

assembly and pivot forward from the bottom for loading, unloading, and removal (see Table 1-2 for required

hopper types and capacities).

The hopper transports coins to the detectors and coin chutes by means of a chain conveyor, which is driven from

below by a sprocket. The chain follows a serpentine path, so that excess coins fall back into the hopper ensuring

only one coin per pin enters the coin counting area.

The chain picks up coins from the bottom of the hopper and carries them up to the top, where they fall through the

upper chain guide ring and interrupt a light beam to a photodetector, which is mounted on the dispenser. The required

number of coins for a desired change combination are counted in this manner as the coins then fall through a closed

chute to the escrow bucket.

An agitator, which is mounted on the drive shaft of each hopper, agitates the coin load to minimize coin jams in the

hopper and ensure efficient coin pick up.

To reduce jams and minimize the need for cleaning, the hoppers in the BC-3500 also have Teflon-coated coin tracks.

1-6 25238801

NOTE:

The hoppers do not have an “Empty Sensor”. Empty hoppers are indicated by a failure

to count the required number of coins in a specified period of time (approximately three

minutes), however, if the changer shuts down frequently with an error relating to empty

hoppers when they are not, then the “serpentine coin path” should be cleaned as shown

in Section 3.

HOPPER CAPACITIES

Hopper Popular Coin Capacities

65027608 (High-Capacity) Dimes - 8,000

Small Coin Nickels - 4,000

.705 to .955 inch diameter Quarters - 3,400

Section 1: System Description

R

HI-CAPACITY

COIN HOPPER

65027609 (High-Capacity) Quarters - 3,200

Large Coin/Token Dollars - 2,200

.937 to 1.125 inch diameter .984 inch Tokens - 3,000

Figure 1-7. High-Capacity Coin

Hopper

MACHINE CAPACITIES

Bill Stacker Separate Mode - 1000 bills in the upper bill box plus 1000 bills in the

lower bill box - however, since it is unlikely that the machine will

take in the same number of bills in both bill boxes, the capacity

may be limited to something less (the stacker is filled when either

bill box reaches 1000 bills).

Alternate Mode - 1000 bills in the upper bill box plus 1000 bills in the

lower. Bills are not separated, in order to fill both boxes to

maximum capacity.

Coin Box 3500 Quarters

NOTE: For escrow bucket capacities, see Table 2-1.

25238801 1-7

BC-3500 Bill and Coin Changer

er

D

Temporarily Out of Service Lamp

This lamp is located on the top door above the bill and coin inlet area. It lights whenever the machine is empty of

change or shutdown due to some malfunction. In addition, the 40 VDC LED will normally go out if the out of service

lamp is lit. Press the

reloaded or if the malfunction has been repaired.

FUNCTION button on the CCC to turn the OUT OF SERVICE light off after the machine has been

The temporarily

errors. The

OUT OF SERVICE lamp also lights during all transport errors. These errors include recoverable

OUT OF SERVICE lamp will turn OFF if a recoverable error condition clears by itself.

The changer will shut down for reasons other than being empty; specifically if a fault or malfunction of the machine

occurs. When the changer shuts down, a message will appear on the display located on the computer board. This

message will greatly aid the service person in quickly determining the malfunction or faulty part

Troubleshooting)

.

(see Section 4:

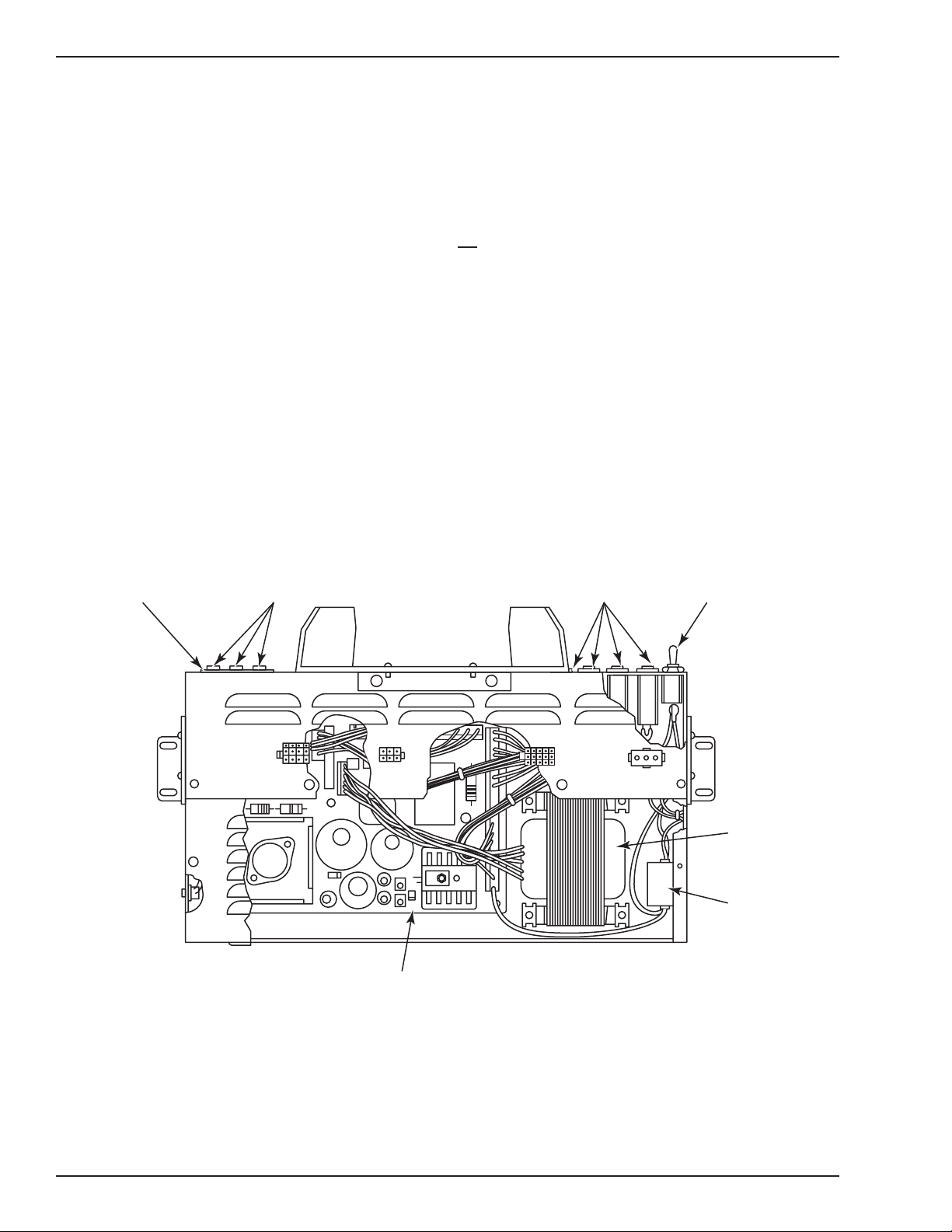

Power Control Center

All power supply components and associated circuitry are located in this single subassembly for easy diagnosis and

repair. The power control center (see Figure 1-8) is located below the dispenser assembly and contains the dollars

accepted counter, TEST VEND switches, EMI filter, power transformer, power supply circuit board, circuit

breakers, and ON/OFF switch.

ollars Accepted

Counter

Test Vend

Switches

Circuit

Breakers

On/Off

Switch

Power

Transform

EMI Filter

Power Supply

Circuit Board

Figure 1-8. Power Control Center

DOLLARS ACCEPTED COUNTER

The dollars accepted counter registers the number of dollars accepted by the machine. The counter increments once

for each dollar. (For example: A $5 bill will make the counter increment five times.) This counter is not resettable.

1-8 25238801

Section 1: System Description

EMI FILTER

The ElectroMagnetic Interface (EMI) filter removes undesirable electrical noise from the incoming power line. The

power transformer supplies 36 VAC and 22 VAC from which the rest of the system voltages are derived.

POWER SUPPLY

The ON/OFF switch controls power to the machine.

A 7-amp circuit breaker is in the power line to the bill changer. The power transformer is protected by a 2-amp circuit

breaker in the primary winding. A 7-amp and a 5-amp circuit breaker protect the secondary windings.

The power supply circuit board rectifies and filters the 36 VAC and 22 VAC to provide 40 VDC, 30 VDC (current

limited), 12 VDC, 8 VDC, and 5 VDC to the rest of the system. It contains indicator LED’s for the 40 VDC, 30

VDC, 12 VDC, and 5 VDC supplies. Note that the 12 VDC actually runs at about 14.6 V – this is normal.

TEST SWITCHES

The three TEST switches are used to manually initiate a change dispense cycle for each of the machine’s escrow

buckets. The computer will not recognize a TEST switch closure if the machine is in the process of validating a bill,

dispensing change, or in SHUTDOWN. Pushing a TEST switch will also cause the stacker to cycle.

POWER CONTROL RELAY

The power control relay switches the 40 VDC, 30 VDC, and 120 VAC supplies to the machine and 5 VDC to the

OUT OF SERVICE lamp. This relay is controlled by the CCC and is energized under normal operating conditions.

Under OUT OF SERVICE conditions, the CCC de-energizes the relay to disconnect the previously mentioned

voltages from the rest of the system and shut down the machine. In this condition, the +40 VDC LED on the power

supply board will be OFF, while the other three remain ON.

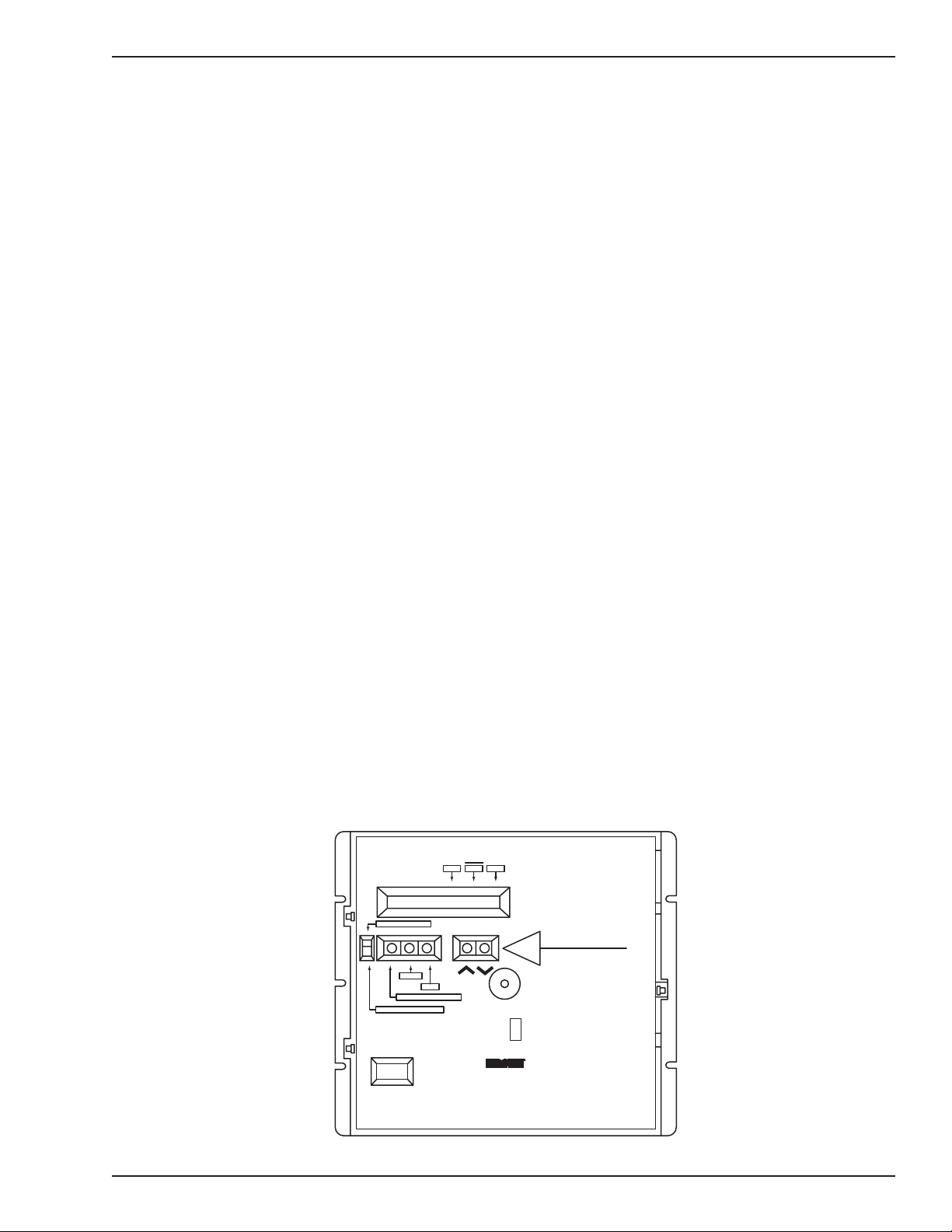

Computer Control Center

The computer control center (referred to as the “CCC” and shown in Figure 1-9) directs all of the operations of

the bill changer including both validation and change dispensing functions. It contains a microcomputer which controls

all of the major functions of the bill changer. It also contains the following controls and displays:

12

P1

1

14

P2

1

8

P3

1

15

P4

1

PROGRAMMING MODE

HOPPER

VALUE

FUNCTION - ERROR RESET

NORMAL OPERATING MODE

NOTE:

PRESS FUNCTION - ERROR RESET

BUTTON TO CLEAR DISPLAYED ERROR

HOPPER

CNTRLEFT RIGHT

EITHER BUTTON ACTS AS YES/NO,

ON/OFF, ALT/SEP, OR UPPER/LOWER

COUNT

SWITCHES

PRESS BOTH BUTTONS TO CLEAR

DISPLAYED TEMPORARY COUNTER

4

P6

1

BILL CHANGER

CONTROL COMPUTER

65069059

P5

91

Figure 1-9. Computer Control Center

25238801 1-9

BC-3500 Bill and Coin Changer

STATUS DISPLAY

The CCC contains many programming and self-diagnostic features which are described in the paragraphs that follow.

All messages are shown on a 16-character vacuum fluorescent display. In some cases, the message is short enough

so that the word(s) can be spelled out: in other cases the word(s) are abbreviated. The abbreviations are clear and

logical and each message is described in

Section 4

of this manual.

SERVICE AND CONTROL SWITCHES

The BC-3500 Bill Changer’s service features and programming options are controlled by six switches. The

descriptions that follow are introductory; follow the detailed procedures and instructions in Section 2 for specific

operating and programming information.

Programming/Normal

Select either the NORMAL operating mode or the PROGRAMMING mode.

NORMAL POSITION

In the NORMAL mode position, the changer operates in a normal manner. The CCC monitors all systems for faults

or customer input.

The VALUE and HOPPER buttons provide unique features while the machine is in the NORMAL mode.

Value Button

Pressing the VALUE button will cause the display to show the total dollar amount accepted since the temporary audit

value was cleared. Thus, if you clear this audit counter (see Section 2) each time you load the hoppers, you can

quickly see how much change has been paid out and thus determine whether or not the bill changer needs to be loaded

again.

Hopper Button

Pressing the HOPPER button will cause the display to show the last three denominations accepted. The most recent

denomination is displayed on the left side, the bill before that is displayed on the right side. If a test vend in included

in this list, the display will show: “TVL”, “TVC”, or “TVR” (depending on which TEST VEND switch was pressed)

in its proper position on the display. If a coin was accepted, the display will show “25”, “50”, or “$1C” on the display

in its proper sequential position (left, center, or right position).

When the PROGRAMMING/NORMAL switch is moved from PROGRAMMING to the NORMAL position, the

message “STORING NEW DATA” will be displayed.

PROGRAMMING POSITION

Setting the PROGRAMMING/NORMAL switch to the PROGRAMMING position allows you to inspect and/or change

the audit and setup information. This information is displayed on the status display and is selected and changed by

using the five pushbuttons that are described in the following paragraphs

Programming Also)

1-10 25238801

:

(see Section 2: Changing Payout

Section 1: System Description

Function Button

Advances from the current set of options to the next set. The following list shows the sequence of options that will

be displayed as the

FUNCTION button is pressed repeatedly:

1. TEMP COUNTERS 6. ACCEPT

2. PERM COUNTERS 7. PAYOUT

3. PROGRAMMING 8. STACKER MODE ALT/SEP

4. MC PAYOUT 9. BILL B CHECK

5. HOP VAL 10. BILL TEST

If the FUNCTION button is pressed while BILL TEST is showing, the “TEMP COUNTERS” display will reappear.

Hopper Button

In the PROGRAMMING mode, this button advances the display to the next hopper if the display includes hopper

information.

Value Button

During the PROGRAMMING mode, this button is used to move between various values: i.e., the value of coins in

the hoppers, denominations to be accepted, etc.

Up

and ^ Down Buttons

Increment or decrement the displayed option value. Options that have only two possibilities, such as ON and OFF,

are toggled between the two options using either of these buttons.

DENOMINATIONS ACCEPTED

The BC-3500 can accept quarters, half-dollars, and dollar coins as well as 1, 2, 5, 10, and 20 dollar bills of United

States currency. All of these denominations can be selected in combination with other denominations. However,

due to mechanical limitations and other considerations, some combinations cannot be used. (See the Accept

Function in Section 2 for further detail.)

25238801 1-11

BC-3500 Bill and Coin Changer

This page intentionally left blank.

1-12 25238801

Section 2: Installation & Programming

INSTALLATION

Installing the BC-3500 Bill and Coin Changer requires some instruction. For all types of installation, be sure that

a power source is convenient and that the changer is mounted level. Always use a grounded (3-prong) outlet.

NOTE:

For both security and safety reasons, Rowe strongly recommends that this bill changer be

securely anchored to the floor and/or wall. Please check the instructions that follow:

WALL MOUNTING

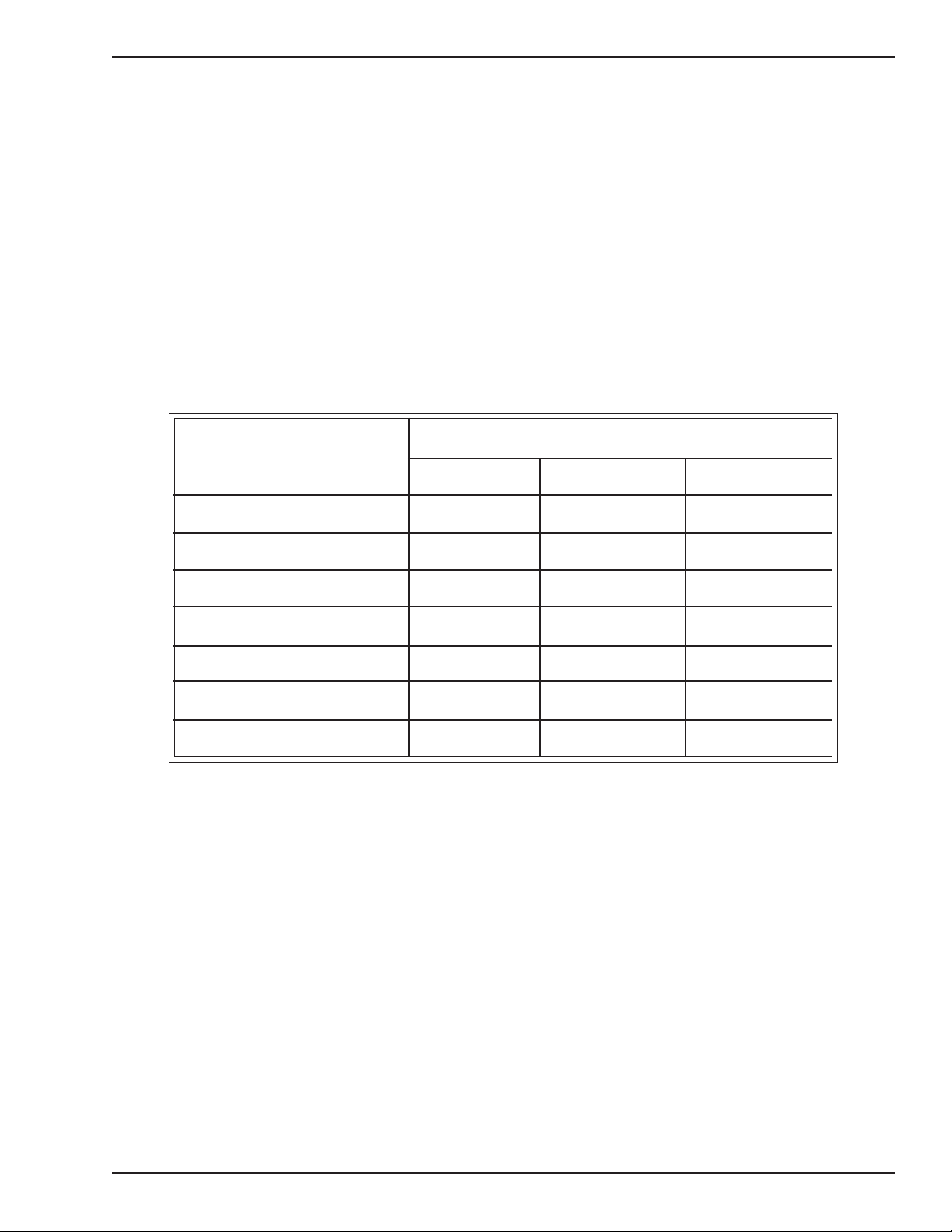

The following illustrations and procedures should be used for wall mounting. For concrete or masonry wall mounting,

use lag screws and lead anchors. For wood frame wall mounting, use lag screws attached directly into the wall studs.

If the wall is not flat, you may need to add spacer washers between the wall and the mounting plate.

If the changer is rigidly mounted to the wall, make the power input connection through rigid conduit into the changer

to meet U.L. requirements (see Figure 2-1).

For convenience, the back of the upper cabinet is dimpled in four places. You may choose to use these for the

placement of mounting bolts; if so, drill a 7/16- to 1/2-inch hole in each of these locations to accommodate a 3/8inch bolt (see Figure 2-2). Be careful not to drill into any internal BC-3500 components.

NOTE:

Be sure to remove all metal filings before putting the changer into service.

25238801 2-1

BC-3500 Bill and Coin Changer

E

,

A

C

L

ONNECT THE POWER SUPPLY WIRES TO

THE INTERNAL MACHINE WIRES PER

OF THIS MANUAL USING STANDARD U.L.

LISTED PRESSURE CABLE CONNECTORS

THE WIRING DIAGRAM IN SECTION 4

(SUCH AS WIRE NUTS).

JUNCTION BOX

EARTH GROUND

(GREEN/YELLOW OR GREEN WIRE)

AFTER REMOVING THE LIN

CORD AND STRAIN RELIEF

ENLARGE THE HOLE WITH

7/8" DIA. CHASSIS PUNCH

CONDUIT

CONNECTOR

CABINET RACK

Figure 2-1. Installing a 1/2-Inch Conduit

LEAD ANCHORS

NOTE:

BE SURE THAT THE LAG SCREWS USED

FOR ATTACHMENT ARE AT LEAST 3/8"

LAG

SCREW

Mounting Detail - Wood Frame Wall

CHANGER

STUD

LAG

SCREW

& WASHER

DIA., AND, FOR WOOD RAME WALLS,

ARE ATTACHED DIRECTLY TO THE WAL

STUDS.

Mounting Detail - Masonry Wall

CONCRETE

WALL

LEAD

ANCHOR

& LAG

SCREW

Figure 2-2. Attaching the BC-3500 to a Wall

2-2 25238801

Section 2: Installation & Programming

CHANGE PAYOUT PROGRAMMING

Many different change combinations can be dispensed for the various denominations of money accepted. Change

payout programming is accomplished using the five buttons on the CCC. As mentioned earlier, there are mechanical

limitations which must be considered. The BC-3500 has three escrow buckets which will be preloaded with three

different payout values.

The CCC will automatically assign the highest payout to the right escrow bucket, the next highest denomination to

the left escrow bucket, and the smallest denomination to the center bucket. Even though the computer reassigns the

escrow bucket values automatically, you must be aware of and obey the capacity limitations of each of the escrow

buckets in order to maintain reliable operation. Table 2-1 shows the capacities of the three escrow buckets. You

must limit your payout combinations such that the total volume of coins in any escrow bucket does not exceed the

guidelines shown in the following table:

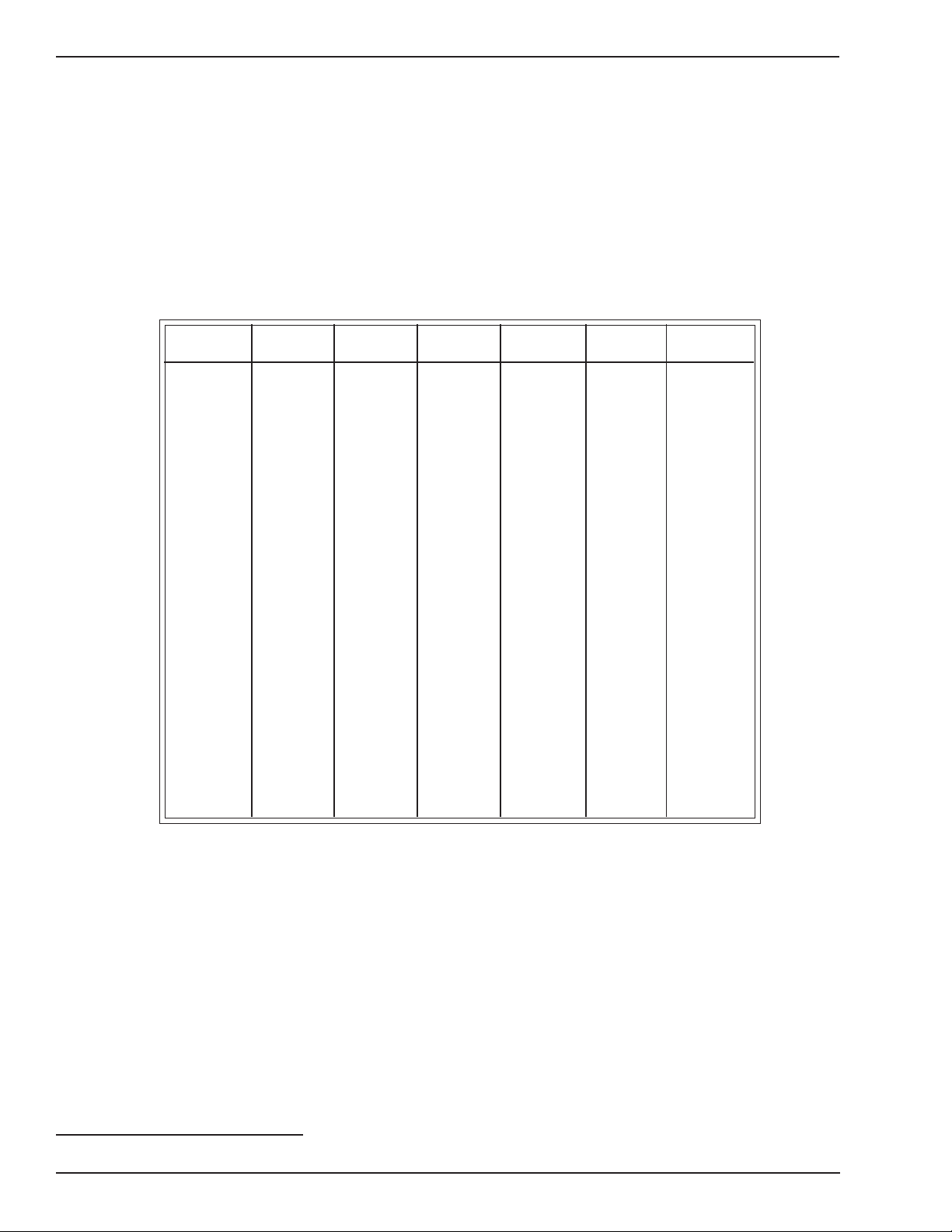

Table 2-1. Maximum Escrow Bucket Capabilities

Coins Escrow Bucket

or

Tokens Left Center Right

Dimes (.705” Dia.) 55 40 85

Nickels (.835” Dia.) 40 22 65

Quarters (.955: Dia.) 32 20 65

Tokens (.984” Dia.) 25 15 60

Dollar Coins (1.04” Dia.) 16 12 45

Tokens (1-1/8” Dia.) 8 6 25

In order to pay out for more than three denominations, the computer will, under certain circumstances, vend an

escrow bucket and hold that bucket door open while the remainder of the required payout is issued directly from

the hoppers to the coin cup. (Of course, after the entire amount has been paid, the escrow bucket door will be closed

and replenished under the computer’s direction.) One further rule is that the right bucket shall never exceed the

escrow value of the $10 bills.

As an example of how this works, consider the case where the denominations accepted are $1, $2, $5, $10, and

$20. The computer will assign the right bucket the escrow of the $10 bill; a $20 bill will then be an immediate $10

issue followed by $10 of direct payout. The $5 payout will be assigned in the left escrow bucket and the $1 will be

assigned to the center – with a $2 payout being an immediate $1 issue followed by $1 of direct payout. If you now

enable 25¢ coin acceptance, the escrow amounts would be reassigned: the 25¢ would be assigned to the center

bucket, the $1 to the left bucket, and the $5 to the right bucket. A $10 would be paid as an immediate $5 issue

followed by $5 of direct payout; the $20 would be an immediate $5 followed by $15 of direct payout. This new

feature is available with CCC P/N 65069059.

25238801 2-3

BC-3500 Bill and Coin Changer

There are very few payout combinations which cannot be allowed. If you review them briefly, you will easily

understand why they cannot be used. Table 2-2 lists those combinations:

Table 2-2. Acceptance Combinations Which Are Not Allowed

$20 $10 $5 $2 $1

1

50¢

2

25¢

OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF ON

OFF OFF OFF OFF OFF ON OFF

OFF OFF OFF OFF OFF ON ON

ON OFF ON OFF ON OFF ON

ON OFF ON OFF ON ON OFF

ON OFF ON OFF ON ON ON

ON OFF ON ON OFF OFF ON

ON OFF ON ON OFF ON OFF

ON OFF ON ON OFF ON ON

ON OFF ON ON ON OFF ON

ON OFF ON ON ON ON OFF

ON OFF ON ON ON ON ON

ON ON ON OFF ON ON OFF

ON ON ON OFF ON ON ON

ON ON ON ON OFF OFF ON

ON ON ON ON OFF ON OFF

ON ON ON ON OFF ON ON

ON ON ON ON ON ON OFF

Using the rules of operations shown previously, it will be very simple for you to determine the escrow bucket values

for any allowable combination. This understanding is only important when using the

TEST VEND switches as they

only vend and replenish each of the buckets once. As an example, there is no $20 test vend.

1

$1 bills and coins are treated as the same for these purposes.

2

Quarters accumulated (25A) are treated exactly as 50¢ pieces for these purposes.

2-4 25238801

LOADING THE HOPPERS

Review Figure 2-4 before you begin.

1. Pull the hopper forward to its stop point.

2. Twist the top of a full coin bag one full turn. Grasp

the twisted top with one hand and hold the bottom

of the bag with the other. Invert the bag and insert

the top into the mouth of the hopper.

3. Slowly release the twist as the bag empties. Avoid

spilling coins into the changer. Empty the bag by

grasping it at the bottom and shaking it to dislodge

coins in folds of the bag. Push the hopper back into

place.

4. Load the change escrow buckets with change by

pressing each of the three TEST VEND switches one

at a time. Repeat this process for each test switch

and verify that the change that was dispensed is

correct.

Section 2: Installation & Programming

5. Coin I.D. stickers are supplied with the machine to

identify the coin denominations in each hopper.

Attach one of these stickers on each hopper so that

the coin denomination can easily be identified.

NOTE:

Hoppers may be loaded with either dollar coins, quarters, dimes, nickels, or tokens

unmixed depending on the type of hopper used. Make sure that the value of coins loaded

into the hopper agrees with the values programmed into the computer during the

HOPPER VALUE (HOP VAL) step of the setup.

UNLOADING THE HOPPERS

Refer to Figure 2-5 and unload the hoppers as follows:

1. Pull the hopper forward to its stop point.

Figure 2-3. Loading the Hoppers

2. Place the opening of the coin bag over the mouth of the hopper, wrapping the lip of the bag around the handle.

Grasp the bag and handle with one hand, tilt the hopper back, release the latch, and slowly tip the hopper

forward while holding the bag against the front of the hopper.

3. Hold the bag securely while you tip the hopper forward. Tap the hopper against the front shelf and return it

to the upright position. Repeat two or three more times to ensure that the hopper is completely empty.

25238801 2-5

Loading...

Loading...