Page 1

Mini Contact Toaster

Model VCT-2

Mfg. Numbers:

9210904

www.ajantunes.com

P/N 1011271 Rev. A 06/14

Page 2

CONTENTS

General ...................................................... 2

Warranty

Information ............................................... 2

Service/Technical

Assistance ..................................................2

Important Safety

Information ............................................... 3

Warnings ...................................................3

Specications ............................................ 4

Installation ................................................ 5

Installing the Release Sheet ...........................6

Bun Thickness Compression

Knob Settings ......................................................6

Operating

Instructions ............................................... 7

Toasting Product ................................................7

Adjusting Toast Quality .................................... 8

Shutting down the Toaster .............................8

Reset to Default Settings .................................8

Hi Limit Reset Button ........................................8

Errors .......................................................................8

Maintenance .............................................9

Daily Maintenance .............................................9

Troubleshooting .....................................10

Replacement Parts..................................11

Wiring Diagram .......................................16

Notes ........................................................17

Limited Warranty ....................................20

IMPORTANT

A.J. Antunes & Co. reserves the right to

change specications and product de-

sign without notice. Such revisions do not

entitle the buyer to corresponding changes,

improvements, additions or replacements

for previously purchased equipment.

IMPORTANT

Keep these instructions for future refer-

ence. If the unit changes ownership, be sure

this manual accompanies the equipment.

GENERAL

This manual provides the safety, installation, and operating procedures for

your toaster. Please read all of the information contained in this manual prior

to installing and operating the toaster.

Your toaster is manufactured from

the nest materials available and is

assembled to Roundup’s strict quality

standards. This toaster was tested at the

factory to ensure dependable troublefree operation.

WARRANTY

INFORMATION

Please read the full text of the Limited

Warranty in this manual.

If the unit arrives damaged, contact the

carrier immediately and le a damage claim with them. Save all packing

materials when ling a claim. Freight

damage claims are the responsibility

of the purchaser and are not covered

under warranty.

The warranty does not extend to:

y Damages caused in shipment or

damage as result of improper use.

y Installation of electrical service.

y Normal maintenance as

outlined in this manual.

y Malfunction resulting from

improper maintenance.

y Damage caused by abuse

or careless handling.

y Damage from moisture into

electrical components.

Damage from tampering with, removal

of, or changing any preset control or

safety device.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with

the installation or operation of your

system, contact A.J. Antunes & Co.

at 1-630-784-1000, or toll free in the

United States at 1-800-253-2991.

Fill in the information in the next

column and have it handy when calling

for assistance. The serial number is on

the specication plate located on the

system.

Purchased From

Date of Purchase

Model Number

Serial Number

Mfg. Number

Use only genuine Roundup replacement parts in this unit. Use of replacement parts other than those supplied

by the manufacturer will void the warranty. Your Authorized Service Agency

has been factory trained and has a complete supply of parts for this unit.

Visit www. ajantunes.com or contact the factory at 1-630-784-1000 to

locate your nearest Authorized Service

Agency. Refer to the service agency

directory packaged with your manual

and ll in the information below.

Authorized Service Agency

Name

Phone Number

Address

2

P/N 1011271 Rev. A 06/14

Page 3

IMPORTANT SAFETY

INFORMATION

Use the following guidelines for safe

operation of the unit.

y Read all instructions be-

fore using equipment.

y For your safety, the equip-

ment is furnished with a properly grounded cord connector. Do not attempt to defeat

the grounded connector.

y Install or locate the equip-

ment only for its intended use

as described in this manual.

Do not use corrosive chemicals in this equipment.

y Do not operate this equipment if

it has a damaged cord or plug, if

it is not working properly, or if it

has been damaged or dropped.

y This equipment should be

serviced by qualied personnel only. Contact your nearest

Authorized Service Agency

for adjustment or repair.

y Do not block or cover any

openings on the unit.

y Do not immerse cord

or plug in water.

y Keep cord away from

heated surfaces.

y Do not allow cord to hang over

edge of table or counter.

y Turn the power o, unplug the

power cord, and allow unit to cool

down before performing any service or maintenance on the unit.

y The equipment should be

grounded according to local

electrical codes to prevent the

possibility of electrical shock. It

requires a grounded receptacle

with separate electrical lines,

protected by fuses or circuit

breaker of the proper rating.

y All electrical connections must

be in accordance with local electrical codes and any

other applicable codes.

y Do not clean this appli-

ance with a water jet.

WARNINGS

Be advised of the following warnings

when operating and performing maintenance on this unit.

y If the supply cord is damaged, it

must be replaced by the manufacturer or its service agent or

a similarly qualied person

in order to avoid a hazard.

y Do not modify the power sup-

ply cord plug. if it does not t

the outlet, have a proper outlet

installed by a qualied electrician.

y Do not use an extension

cord with this appliance.

y Electrical ground is re-

quired on this appliance.

y Check with a qualied electrician

if you are unsure if the appliance is properly grounded.

y If a chemical cleaner is used, be

sure it is safe to use on cast aluminum. Observe all precautions

and warnings on product label.

y Inspection, testing, and re-

pair of electrical equipment

should only be performed by

qualied service personnel.

y This equipment is to be installed

to comply with the basic plumbing code of the Building Ocials

and Code Administrators, Inc.

(BOCA) and the Food Service

Sanitation Manual of the Food

and Drug Administration (FDA).

y Do not use abrasive materials.

The use of these may cause damage to the stainless steel nish.

y Chlorides or phosphates in clean-

ing agents (e.g. bleach, sanitizers,

degreasers or detergents) could

cause permanent damage to

stainless steel equipment. The

damage is usually in the form of

discoloration, dulling of metal

surface nish, pits, voids, holes, or

cracks. This damage is permanent

and not covered by warranty.

y The following tips are recom-

mended for maintenance of

your stainless steel equipment:

y Always use soft, damp cloth

for cleaning, rinse with clear

water and wipe dry. When

required, always rub in direction of metal polish lines.

y Routine cleaning should be

done daily with soap, ammonia detergent, and water.

y Stains and spots should be

sponged using a vinegar solution.

y Finger marks and smears

should be rubbed o using soap and water.

y Hard water spots should be

removed using a vinegar solution.

P/N 1011271 Rev. A 06/14

3

Page 4

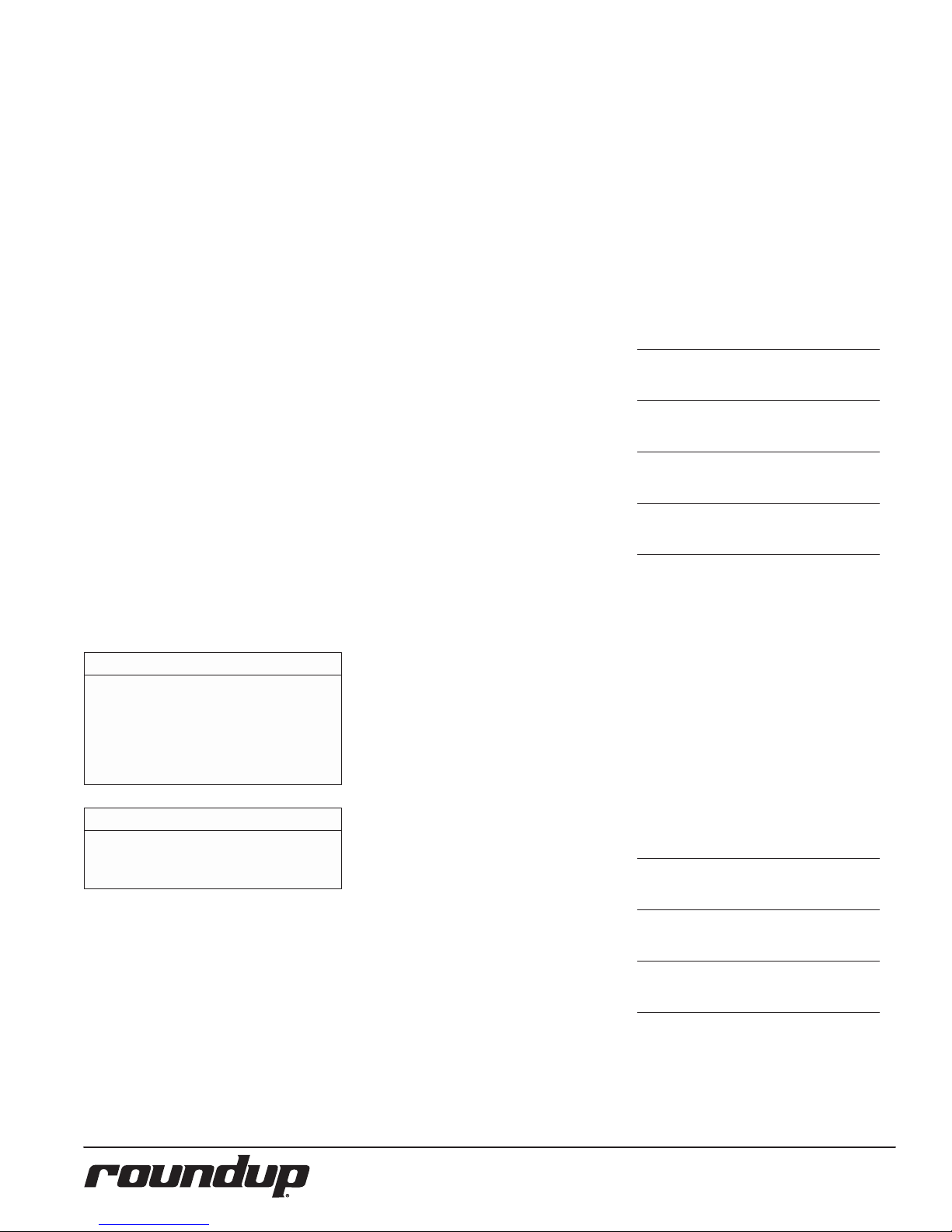

25”

(635 mm)

10.17”

(258.3 mm)

12.97”

(329.5 mm)

SPECIFICATIONS

Model &

Mfg. No.

9210904

VCT-2

Volts Watts Amps Hertz

120 1800 15 50/60

Plug

Description

5-15P 15 Amps., 120 V.,

Non-Locking

(assembly only)

4

P/N 1011271 Rev. A 06/14

Page 5

INSTALLATION

NOTE: When placing the toaster

into service, make sure to

provide at least 3 inches of

space on all sides of the unit.

1. Remove unit and all packing materials from shipping

carton. The toaster is shipped

with the items listed below:

• Owner’s Manual

• Authorized Service Agency

Directory

NOTE: If any parts are missing or dam-

aged, contact Antunes Technical

Service IMMEDIATELY at 1-877392-7854 or 1-630-784-1000.

2. Remove all packing materials and protective coverings from the unit.

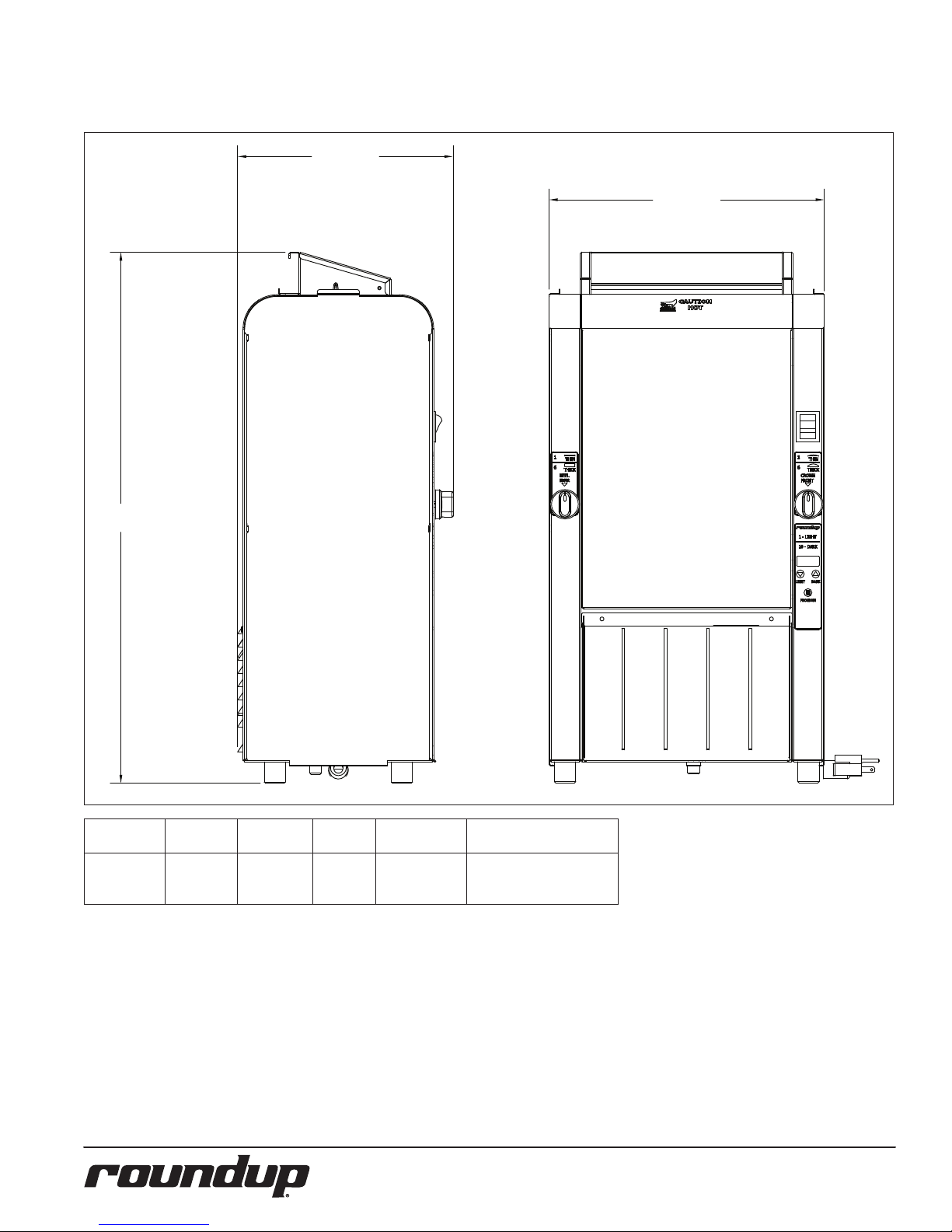

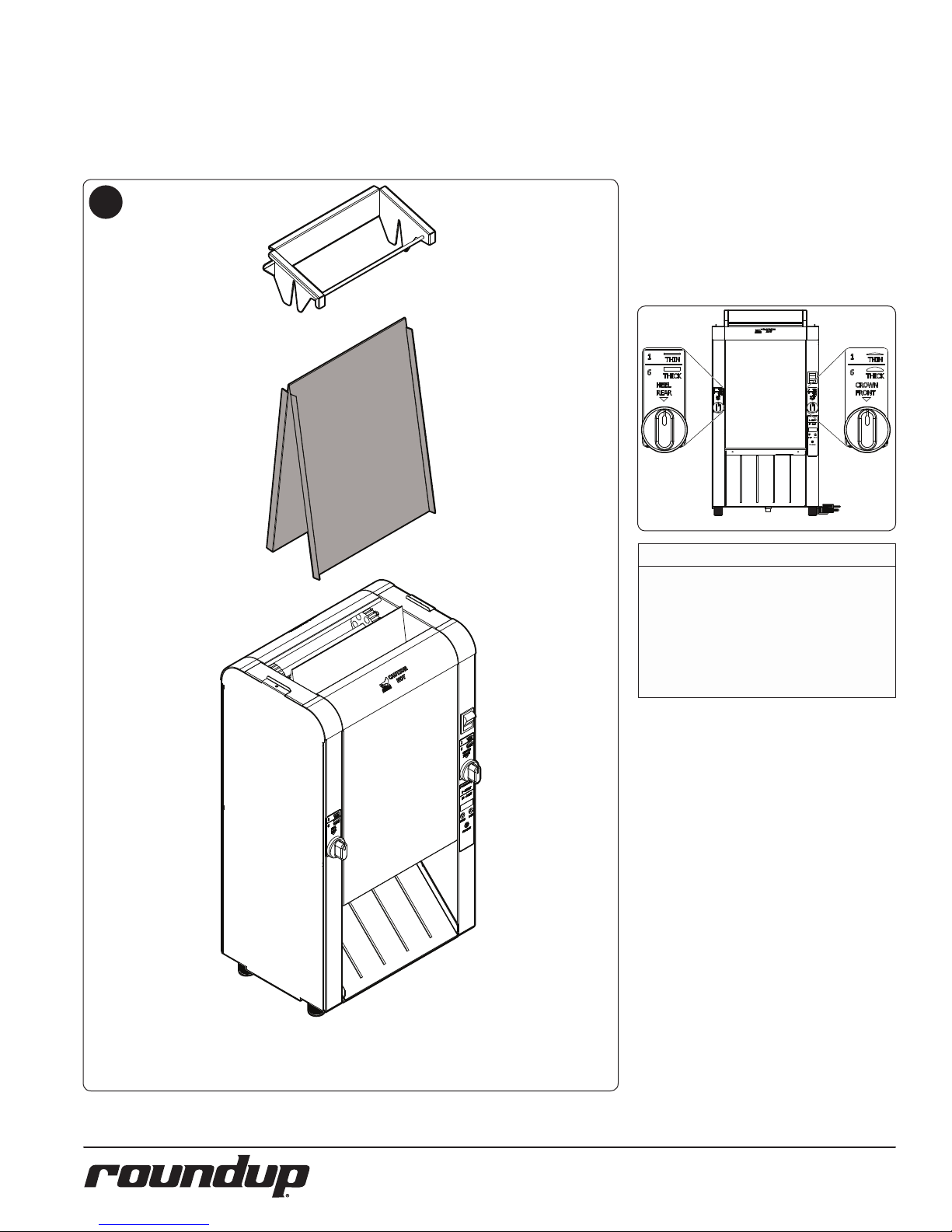

3. Refer to Figure 1. Remove the

Bun Feeder and Bun Chute. Wash

these items at the 3 compartment sink and set aside to air dry.

4. Refer to Figure 2. Remove

the Release Sheet.

NOTE: Do not wash the Release

Sheet or Release Sheet Retainers in the sink. These

must be washed by hand.

5. Wipe all surfaces of the unit

with a hot damp cloth.

6. Wipe both sides of the Release

Sheet with a hot damp cloth.

NOTE: Do NOT use a dripping wet

cloth. Wring out before use.

7. Re-install the Bun Feeder and

Bun Chute onto the unit.

8. Refer to the section titled

Installing the Release Sheet

on the next page. Install

the Release Sheet according to those instructions.

When placing the unit into service, pay

attention to the following guidelines.

y Make sure to provide at

least 3 inches of space on

all aides of the unit.

y Make sure the power switch

is o and the unit is at room

temperature before plugging in the power cord.

y Do not block or cover any

openings on the unit.

y Do not immerse the power

cord or plug in water.

y Keep the power cord away

from heated surfaces.

y Do not allow the power

cord to hang over edge

of table or counter.

Figure 1 Figure 2

Bun Feeder

Release Sheet

NOTE: The main Control Panel is

Bun Chute

located on the front of the unit.

P/N 1011271 Rev. A 06/14

5

Page 6

INSTALLING THE RELEASE SHEET

The Release Sheet allows buns to pass through the

toaster without sticking. The toaster should never be

operated without a clean Release Sheet installed.

BUN THICKNESS COMPRESSION

KNOB SETTINGS

The toaster uses two Bun Thickness

Compression Knobs for proper toasting

of buns (heels and crowns).

1

For best results, set both Bun Thickness

Compression Knobs to 4.

The compression settings range from

1 to 6. Setting 1 is the thinnest setting

and Setting 6 is the widest setting.

WARNING

Do NOT operate the toaster without the

release sheet installed. Do not use any

abrasive cleansers or tools such as scrub-

bers or scrapers on the Platen. Damage to

the Platen from operation without a Release

Sheet or damage caused from abrasive

cleansers or tools voids the warranty.

Remove the Bun Feeder. Install the Release Sheet evenly over the platen.

Reinstall the Bun Feeder.

6

P/N 1011271 Rev. A 06/14

Page 7

OPERATING

CROWNS

(Cut sides

facing IN)

HEELS

(Cut sides

facing IN)

INSTRUCTIONS

NOTE: If the toasting quality needs

adjustment, refer to Adjusting

Toasting Quality in the Operation section of this manual.

1

Power

Switch.

2

8888

The unit displays the software version,

the current platen setpoint tempera-

ture and starts to warm up .

3

TOASTING PRODUCT

Facing the front of the unit, insert product as described:

y Insert Crowns into the front lane

with the cut side facing in.

y Insert Heels into the rear lane

with the cut side facing in.

Refer to the image below.

Turn the Power switch to the on position. The unit makes a clicking sound.

This is normal.

4 D

After the system check, the unit begins

to warm up and Lo-P appears

on the display.

4

USE

The unit displays the USE

message when it reaches proper

operating temperature.

Buns Exit

Toaster Here

P/N 1011271 Rev. A 06/14

7

Page 8

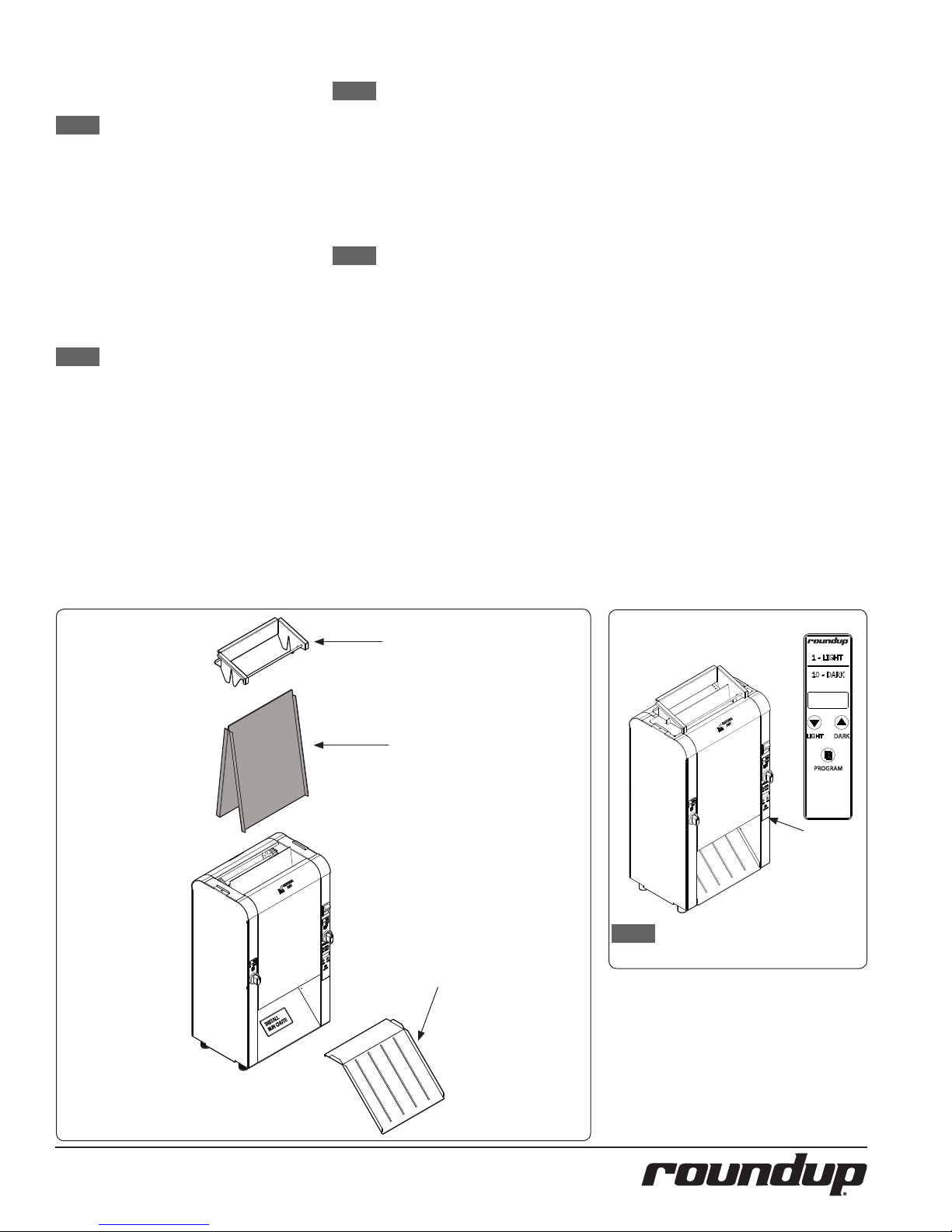

ADJUSTING TOAST QUALITY

The unit can be adjusted to provide a

lighter or more darkly toasted product.

The lightest setting is 1 and the darkest

setting is 10.

Follow these steps to adjust toasting

quality.

1

D 4

1

USE

When the toaster reaches the newly

set Light/Dark temperature, the USE

message stops ashing and remains

on. The toaster is ready for use.

NOTE: The Light/Dark value is

maintained when the

unit is powered o.

HI LIMIT RESET BUTTON

A hi-limit control turns o power to

the unit if it overheats. To reset this HiLimit control, allow sucient time (1015 minutes) for the unit to cool down,

then remove the Hi-Limit control cap

and press the reset button located

on the bottom of the unit. If the unit

requires continuous resetting, call for

service.

To view the current Light/Dark setting,

briey press Light or Dark button. The

current Light/Dark setting

appears in the display.

2

USE

To change the Light/Dark setting,

press and hold the Light or Dark but-

ton until the unit beeps.

SHUTTING DOWN THE TOASTER

To turn the toaster o, turn the Power

switch to the o position.

RESET TO DEFAULT SETTINGS

Follow these steps to reset the toaster

to the factory settings

Follow these steps to reset to default

settings:

1. Turn the toaster o.

2. Pres and hold both the

Light and Dark buttons

and turn the toaster on.

3. Continue holding the Light and

Dark buttons until “fr” (factory

reset) appears in the display. The

toaster beeps when resetting is

done and starts up normally.

HILIMIT RESET

BUTTON

ERRORS

The toaster displays any kind of error

message, contact the factory immediately at 1-630-784-1000

Press the Light or Dark button set the

Light/Dark value as desired. Release

the Button. The USE message ashes

in the display as the unit adjusts the

platen temperature accordingly.

8

P/N 1011271 Rev. A 06/14

Page 9

MAINTENANCE

WARNING

The unit will remain hot while it is cooling

down. Personal injury and burns may result

from touching the unit before it is nished

cooling down. Wear Heat Resistant Gloves.

DAILY MAINTENANCE

The daily maintenance steps involve:

y Cleaning the Acces-

sories and Toaster

y Cleaning the Release Sheet

Cleaning the Accessories and Toaster

1. Turn the toaster o and allow

it to cool before proceeding.

2. Refer to Figure 3. Remove the

Bun Feeder, Release Sheet,

and Bun Chute and set aside.

NOTE: Do not wash the Release

Sheet in the sink. It must

be washed by hand.

3. Wash the Bun Feeder and

Bun Chute in soap and water. Rinse with clean water and allow to air dry.

4. Wipe all surfaces of the unit

with a hot damp cloth.

NOTE: Do not use a dripping wet

cloth. Wring out before use.

Figure 3

Cleaning the Release Sheet

1. Inspect the Release Sheet.

Replace the Release Sheet if

it is worn, creased, or torn.

2. Spray an approved cleanser

on a clean, dry towel.

3. Wipe the Release Sheet

rmly from top to bottom.

4. Repeat this procedure

with a clean, dry towel

dampened with water.

5. Next, wipe the release sheet

with a clean towel dampened with an approved

sanitizer. Allow to air dry.

6. Repeat Steps 1 through

6 on the inside portion

of the Release Sheet.

7. Refer to the section titled

Installing the Release Sheet.

Install the Release Sheet according to those instructions.

Cleaning the Belt Wraps

1. Open the front and rear Con-

veyor Covers (Figure 4)

2. Inspect the front and rear Belt

Wraps. Replace the Belt Wraps

if there are any signs of tearing, folding, or other damage.

3. Turn on the unit.

NOTE: This step requires that the

toaster be turned on with the

Conveyor Covers open. Use

caution during these steps.

4. Spray a clean, sanitized towel

with an approved cleanser and

wipe the front and rear Belt

Wraps for one full rotation.

5. Repeat Step 3 with an approved sanitizer.

NOTE: Repeat these steps as needed

until the Belt Wraps are clean.

Figure 4

P/N 1011271 Rev. A 06/14

9

Page 10

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Power cord not plugged in Plug power cord into the proper electrical outlet

Hi-Limit has tripped

No Control Display

Conveyor does not turn on

Conveyor(s) hesitate

Buns not toasting adequately

Crowns and/or Heels must be

forced into the toaster. Buns

sticking and burning.

Toaster making unusal sounds

Buns/muns/bagels getting

caught in bun chute area

Circuit breakers turned o or tripped. Damaged electrical outlet, plug, or cord. Power switch damaged

Faulty or mis aligned communication cable Replace or align communication cable

Faulty Transformer Replace transformer.

Conveyor Belt/Chain has stretched. Chain skipping on

sprockets.

Loose sprocket Verify setscrew is tight on at part of shaft.

Motor Drive Chain came o sprocket(s) Reinstall drive chain

Inernal part /object interfering within conveyor system Check for interference & clear up as necessary.

Dive chains need lubrication. Lubricate chain

Loose or misaligned sprocket Align and tighten set screw on sprocket

Motor drive chain loose or stretched Replace or tighten up slack on drive chain.

Drive motor(s) have failed Contact your Maintenance person or Authorized Service agancy for service

Compression settings are incorrect. Use the recommended settings.

Release sheet is worn or needs cleaning (replace every

3-5 weeks)

Silicone belts are worn or need cleaning (replace every

2-4 months).

Silicone belts are not tacky.

Silicone belts not being cleaned properly. Clean silicone belts as described in the Maintenance section of this manual.

Silicone belts are not tacky.

Silicone belts are dirty, worn, or damaged (replace every

2-4 months)

Release sheet is not being cleaned properly.

Release sheet is not being reversed as required.

Conveyor Belt/Chains are skipping on sprockets.

Drive motor stalls intermittently. Contact your Maintenance person or Authorized Service agancy for service

Compression settings are incorrect. Use the recommended settings (4).

Buns are not inserted into the toaster properly.

Compression settings are too tight. Set bun thickness compression knobs to the correct setting.

Conveyor belt chains have stretched or adjusted incorrectly.

Motor Drive chain needs lubrication. Lubricate chain

Conveyor shaft bearing is binding. Contact your Maintenance person or Authorized Service agency for service

Bun chute installed incorrectly Reinstall Bun chute with lip end facing down towards exit

Allow unit to cool and reset the Hi-Limit Control. If it trips again, contact your

Maintenance person or Authorized Service Agency.

Reset circuit breakers. If they trip again, check the power cord,plug, and outlet for

damage. Contact your Maintenance person, Authorized Service Agency.

Measure and adjust the conveyor belt chains as described in the Maintenance

section of this manual.

Inspect release sheet for cleanliness, worn spots, wrinkles , or tears. Clean or

replace release sheet as described in the Maintenance section of this manual.

Replace or clean Silicone belts as desribed in thw Maintenance section of this

manual.

Replace or clean Silicone belts as desribed in thw Maintenance section of this

manual.

Replace or clean Silicone belts as desribed in thw Maintenance section of this

manual.

Replace or clean Silicone belts as desribed in thw Maintenance section of this

manual.

Clean both sides of release sheet as described in the Maintenance section of this

manual.

Reverse the release sheet or replace release sheet as described in the Maintenance section of this manual.

Adjust the conveyor belt chains as described in the Maintenance section of t his

manual.

Muns & Bagels should be inserted in the top feeder (#1) with cut side up.

Crowns should be inserted in the middle feeder(#2) with the cut side down. Heels

should be inserted in the lowere feeder only(#3) with the cut side up.

Adjust the conveyor belt chains as described in the Maintenance section of t his

manual.

10

P/N 1011271 Rev. A 06/14

Page 11

REPLACEMENT PARTS

Item Part No. Description Qty. Item Part No. Description Qty.

1 0012472 Inner Spring Tensioner Assy. 4

2 0012982 Conveyor Belt Assembly 37/2 2

3 0012988 Tensioner Assembly 4

4 0012989 Bun Feeder Assembly 1

5 0012990 Conveyor Cover Assembly 2

6 0021900 Idle Bearing Retainer Weldment 1

7 0021959 Cam Weldment 2

8 0021960 Base Weldment 1

9 0021962 Control Panel Weldment 2

10 0021964 End Housing Weldment 1

11 0021965 Control Housing Weldment 1

12 0100287 Platen, Grill 120V/1800W 1

13 0400147 Bushing, Shorty 7/8” 1

14 0400265 Bushing, Shorty 3/8” 4

15 0400437 Strain Relief, Rt Angle 1

16 0500464 Bearing Retainer 1

17 0503495 Bracket, Retainer Right 2

18 0503496 Bracket, Tensioner-Right 2

19 0503497 Bracket, Tensioner-Left 2

20 0503507 Bracket, Retainer Left 2

21 0506754 Panel, Electrical 1

22 0506755 Retainer, Bearing 6

23 0506756 Plate, Motor 1

24 0506763 Bracket, Trx-Conn 1

25 0506764 Chute, Bun 1

26 0700463 Power Cord,14/3 5-15P 1

27 0800455 Rod, Knob (Heel) 1

28 0800457 Rod, Knob (Crown) 1

29 0800458 Rod, Support 4

30 0800460 Shaft, Drive 2

31 0800461 Shaft, Idler 2

32 1000900 Label - Warning 1

33 1001181 Label, Crown 2

34 1001527 Label, Roundup Service 1

35 1001550 Label, Control 1

36 1001551 Label, Install 1

37 1001552 Label, Cam (Heel) 1

38 1001553 Label, Cam (Crown) 1

39 1001556 Label, Wiring Diagram 1

40 1031188 Spec Label 1

41 2100230 Bumper, Recess W/Washer 4

42 2100348 Knob, 1/4” Shaft, Push-On 2

43 2110127 Ring, Retaining 8

44 2120107 Spacer, Aluminum 2

45 2150158 Bearing, 1/2”Id X 1 1/8”Od 2

46 2150173 Sprocket, 25B12 5/16” Bore 1

47 2150179 Sprocket, 25B14 1/2” Bore 3

48 2150186 Bearing High Temp 1/2” Bore 6

49 2150190 Sprocket, 25B28 1/2”Bore Stepped Tooth 8

50 2150258 Bearing, Idler 1

51 2150260 Spacer, Bearing 6

52 2150368 Miter Gear, 20° Pressure Angle 4

53 2150370 Chain, Drive 1

54 2180145 Cover, Bumper 4

55 3000124 Ring, Penaining 3/8” 1

56 304P105* Nut, Hex ‘Keps’ #4-40 1

57 306P121* Screw, Mach #6-32 X 3/4” 1

58 306P123* Screw, Mach #6-32 X 7/8” Slrndhd 1

59 306P130* Nut, Hex Keps #6-32 (Small Pattern) 1

60 306P156* Screw, Mach. #6-32 X 1/2” 1

61 308P115* Screw, Mach. #8-32 X 3/8” 1

62 308P143* Nut, Hex ‘Keps’ #8-32 1

63 308P144* Screw, #8-32 X 1/4” (#6 Head) 1

64 308P157* Screw, Tap 8-32 X 3/8”Lg 1

65 308P203* Screw, Tap 8-32 X 3/8” W/

Int. Tooth Washer 1

66 310P103* Screw, Mach. #10-32 X 1/4” 1

67 310P136* Screw, Mach. #10-32 X 1/4” 1

68 310P146* Nut, Hex ‘Keps’ #10-32 1

69 310P213* Screw, Phpnhd #10-16 X 3/4” Thrd Form 1

70 325P163* Set Screw, 1/4-28 X 5/16” 1

71 325P203* Washer, Spring Steel Single-Wave 1

72 338P116* Screw, Shoulder 3/8-16 X 3/8 W/

1/2 Shoulder 1

73 4000173 Gearmotor, 9 Rpm, 115V 1

74 4000210 Fan, Axial 115V 1

75 4010199 Transformer, 120 Vac/12Vac 1

76 4010245 Switch, Rocker 1

77 4030332 Thermostat, Hi-Limit 1

78 4050214 Thermocouple Type “K” (Open End) 1

79 4051010 Relay, Random Phase, Solid State-50A 1

80 4060195 Terminal Block 2

81 4060355 Terminal Block, 3-Pole 1

82 4070202 Assy-Pcb, Cfa Contact Toaster 1

83 4070213 Varistor Board 1

84 7000985 Black Wavy Silicone Belt 1

85 0021961 Conveyor Cover Weldment 2

86 0011311 Roller Tensioner Assy. 2

87 0502199 Spacer 4

88 308P145 Nut, Hex Acorn #08-32 Low Crown 1

89 7000989 Platen Sheet (Pkg. of 2) 1

*Available in Packages of 10

P/N 1011271 Rev. A 06/14

11

Page 12

4

89

64

64

14

52

71

52

37

42

76

38

42

25 82

28

35

43

80

56

15

26

12

78

13

79

81

83

80

59

59

60

72

51

48

22

68

57

9

P/N 1011271 Rev. A 06/14

Page 13

64

51

48

22

68

72

52

52

71

43

45

16

68

47

47

47

46

53

9

68

55

50

65

72

45

6

27

42

73

23

66

P/N 1011271 Rev. A 06/14

13

Page 14

SEE EXPLOSION BELOW

ON THIS PAGE

5

5

5

5

2

84

2

12

63

20

61

63

17

70

49

70

70

70

49

31

49

31

44

49

44

49

7

49

30

70

70

18

61

7

19

61

18

61

61

61

19

20

63

63

17

3

5 55

1

5

14

P/N 1011271 Rev. A 06/14

Page 15

65

69

21

74

75

64

24

77

41

67

54

P/N 1011271 Rev. A 06/14

15

Page 16

WIRING DIAGRAM

BRD

MOV

WHT/BLU

POWER

CORD

BLK/BRN

GRN-YEL

TERMINAL

BLOCK #1

*GRN

POWER

SWITCH

*WHT

WIRING DIAGRAM

* 14 GA. AWM 105° C

∆ 14 GA. TFE 200Ā C

# 18 GA. AWM 105° C

22 GA. XLP 125Ā C

GND

*WHT

#WHT

8

7

#WHT

15

5

17

TERMINAL

BLOCK #3

*BLK

#BLK

TERMINAL

BLOCK #2

11

16

14

4

6

*WHT

#WHT

J1

1

2

J2

TERMINAL

#WHT

#WHT

#YEL

1

2

J3

MAIN

DISPLAY

BOARD

M

F

TRANSFORMER

#YEL

J5

1

2

3

4

MOTOR

#BLK

FAN

#BLK

#BLK

#BLK

RED

BLK

*BLK

+

3

S.S.

RELAY

2

1

-

4

HI-LIMIT

∆ WHT

TC

1800W PLATEN

16

∆ BLK

P/N 1011271 Rev. A 06/14

Page 17

NOTES

P/N 1011271 Rev. A 06/14

17

Page 18

18

P/N 1011271 Rev. A 06/14

Page 19

P/N 1011271 Rev. A 06/14

19

Page 20

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of the nest materials available and manufactured to high quality standards. These units are warranted to be free from electrical and mechanical defects for a period of one (1) year from date of purchase under normal use and service, and when installed in accordance

with manufacturer’s recommendations. To insure continued operation of the units, follow the maintenance procedures outlined in the Owner’s Manual. During the rst 12 months, electro-mechanical parts, non-overtime labor, and travel expenses up

to 2 hours (100 miles/160 km), round trip from the nearest Authorized Service Center are covered.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the

Equipment. This warranty does not cover overtime charges or work done by unauthorized service agencies or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments as specied in operating

and maintenance instructions of this manual, and/or labor involved in moving adjacent objects to gain access to the

equipment. This warranty does not cover consumable/wear items such as Release Sheets, Conveyor Belt Chain Assemblies, Belt Wraps, and Dampers. This warranty does not cover damage to the Platen due to operating the toaster

without a Release Sheet or cleaning with abrasive cleansers or tools, misuse or dropping of unit. This warranty does

not cover problems or failures resulting from improper/incorrect voltage supply. This warranty does not cover Travel

Time & Mileage in excess of 2 hours (100 miles/160 km) round trip from the nearest authorized service agency.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right is always reserved to modify equipment because of factors beyond our control and government regulations. Changes to update equipment do not constitute a warranty charge.

3. If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt. Damage should be reported to the carrier. This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or

use taxes. All such freight and taxes are the responsibility of the purchaser.

5. This warranty is exclusive and is in lieu of all other warranties, expressed or implied, including any implied warranty or merchantability or tness for a particular purpose, each of which is hereby expressly

disclaimed. the remedies described above are exclusive and in no event shall roundup be liable for special consequential or incidental damages for the breach or delay in performance of this warranty.

Loading...

Loading...