Roto Zip SLS-01, SLS-02 User guide

Roto Zip Tool Corporation

1861 Ludden Drive, Cross Plains, Wisconsin 53528 • Phone 608-798-3737

TOLL-FREE 1-877-768-6947 U.S. & CANADA

FAX: 608-798-3739 WEB SITE: www.rotozip.com

Customer Service Hours: 8:00am - 4:30pm (CST) Monday-Friday

IMPORTANT: Read Before Using

IMPORTANT : Lire avant usage

IMPORTANTE: Leer antes de usar

Solaris Owner’s Manual

Le Manuel du Propriétaire de Solaris

El Manual del Dueño de Solaris

Parlez-vous français? Voir page 10

¿Habla español? Ver página 18

© 2001 Roto Zip Tool Corporation. All Rights Reserved. May be protected by pending patent applications and U.S. Patents:

5323823, 5143490, 5902080, 5813805, 6048260.

© 2001 Roto Zip Tool Corporation. Tous droits réservés. Peut être protégé par des brevets en instance et les brevets suivants

des États-Unis : 5323823, 5143490, 5902080, 5813805, 6048260.

© 2001 Roto Zip Tool Corporation. Todos los derechos reservados. Es producto puede estar protegido por solicitudes de

patente pendientes y las siguientes patentes de Estados Unidos : 5323823, 5143490, 5902080, 5813805, 6048260.

* The ZM101 Zip Mate Attachment is not recommended for use with the Solaris Spiral Saw power tool

* Le compagnon Zip Mate ZM101 n’est pas recommandé pour usage avec la Solaris Scie mécanique à spirale

* No se recomienda usar el accesorio Zip Mate ZM101 con la herramienta Solaris Herramienta Spiral Saw

Model: SLS-01 Model: SLS-02

Spiral Saw™ Power Tool Safety Rules

Store idle tools out of reach of children and

other untrained persons. Tools are dangerous

in the hands of untrained users.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools

with sharp cutting edges are less likely to bind

and are easier to control. Any alteration or

modification is a misuse and may result in a

dangerous condition.

Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tools operation. If damaged,

have the tool serviced before using. Many accidents

are caused by poorly maintained tools. Develop

a periodic maintenance schedule for your tool.

Use only accessories that are recommended

by the manufacturer for your model.

Accessories that may be suitable for one tool, may

become hazardous when used on another tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or maintenance

performed by unqualified personnel could result

in a risk of injury. For example: internal wires

may be misplaced or pinched, safety guard

return springs may be improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual. Use

of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning agents

such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

-3-

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or its

own cord. Contact with a "live" wire will make

exposed metal parts of the tool "live" and shock

the operator. If cutting into existing walls or

other blind areas where electrical wiring may

exist is unavoidable, disconnect all fuses or

circuit breakers feeding this worksite.

Always make sure the work surface is free

from nails and other foreign objects. Cutting

into a nail can cause the bit and the tool to jump

and damage the bit.

Never hold the workpiece in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the material and guiding the

tool with both hands is safer.

Never lay workpiece on top of hard surfaces,

like concrete, stone, etc... Protruding cutting

bit may cause tool to jump.

Always wear safety goggles and dust mask.

Use only in well ventilated area. Using

personal safety devices and working in safe

environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely

tightened. Loose adjustment device can

unexpectedly shift, causing loss of control, loose

rotating components will be violently thrown.

Never start the tool when the bit is engaged

in the material. The bit cutting edge may grab

the material causing loss of control of the cutter.

Always hold the tool with two hands during

start-up. The reaction torque of the motor can

cause the tool to twist.

The direction of feeding the bit into the

material is very important and it relates to

the direction of bit rotation. When viewing

the tool from the top, the bit rotates

clockwise. Feed direction of cutting must be

counter-clockwise. NOTE: inside and outside

cuts will require different feed direction, refer to

section on feeding the router. Feeding the tool

in the wrong direction, causes the cutting edge

of the bit to climb out of the work and pull the

tool in the direction of this feed.

Always use the tool with the depth guide

securely attached and positioned flat against

material being cut. The guide securely

positioned on the material improves the stability

and control of your tool.

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits can

snap during use. Dull bits require more force to

push the tool, possibly causing the bit to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to be

touched by bare hands.

Never lay the tool down until the motor has come

to a complete standstill. The spinning bit can grab

the surface and pull the tool out of your control.

Do not use the tool for drilling purposes.

This tool is not intended to be used with drill bits.

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

Read and understand all instructions. Failure to follow all instructions listed

below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

-2-

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or

fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with a

polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to

install a polarized outlet. Do not change the

plug in any way. Double Insulation

eliminates the need for the three wire grounded

power cord and grounded power supply system.

Before plugging in the tool, be certain the outlet

voltage supplied is within 10% of the voltage

marked on the nameplate. Do not use “AC only”

rated tools with a DC power supply.

Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool.

Electrician’s rubber gloves and footwear will

further enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

When operating a power tool outside, use an

outdoor extension cord marked "W-A" or

"W." These cords are rated for outdoor use

and reduce the risk of electric shock. Refer to

“Recommended Sizes of Extension Cords” in

the Accessory section of this manual.

Personal Safety

Stay alert, watch what you are doing and use

common sense when operating a power

tool. Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long hair can

be caught in moving parts. Keep handles dry,

clean and free from oil and grease.

Avoid accidental starting. Be sure switch is

“OFF” before plugging in. Carrying tools with

your finger on the switch or plugging in tools

that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches before

turning the tool “ON”. A wrench or a key that

is left attached to a rotating part of the tool may

result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

Tool Use and Care

Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

!

WARNING

Power Tool Safety Rules

-5-

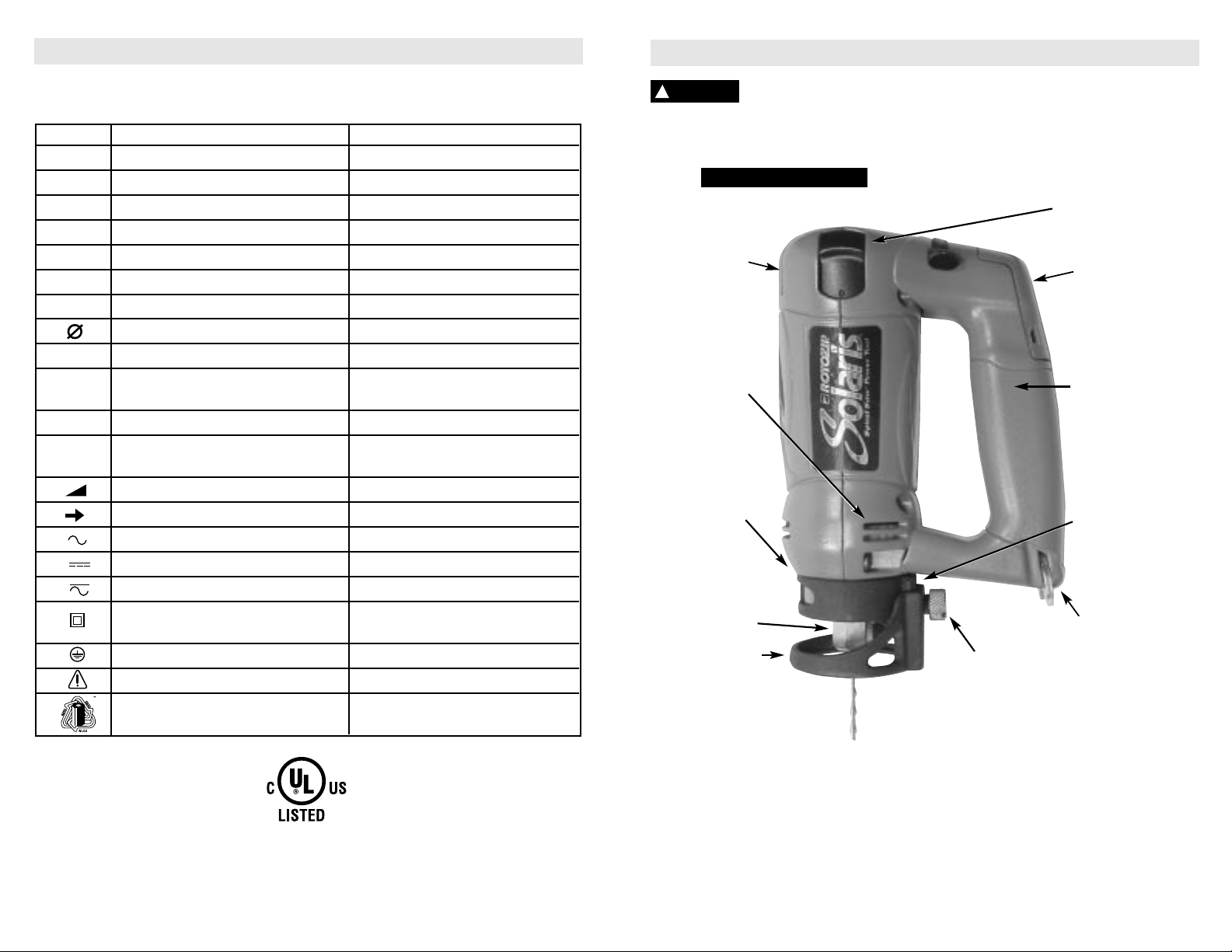

Functional Description and Specifications

SHAFT LOCK

BUTTON

QUICK

RELEASE

HANDLE

WRENCH

STORAGE

AREA

INTAKE

AIR VENTS

BASE PLATE/

DEPTH GUIDE

EXHAUST

AIR VENTS

DEPTH GUIDE

BRACKET

COLLET NUT

Disconnect the plug from the power source before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

!

WARNING

ON/OFF

SLIDE

SWITCH

DEPTH GUIDE

LOCKING KNOB

COLLET & ZIP

BIT STORAGE

AREA

-4-

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC™ seal Designates Ni-Cad battery recycling

program

Symbols

0

This product is listed by Underwriters Laboratories Inc.

Representatives samples of this product have been evaluated by

UL and meet the applicable U.S. and Canadian safety standards

SLS-01 model shown

-7-

DURING STORAGE of your

tool when there is no Zip Bit

in the collet, DO NOT tighten the collet nut

down onto an empty collet. Doing so will make

the collet hole smaller, preventing you from

inserting Zip Bits into it in the future.

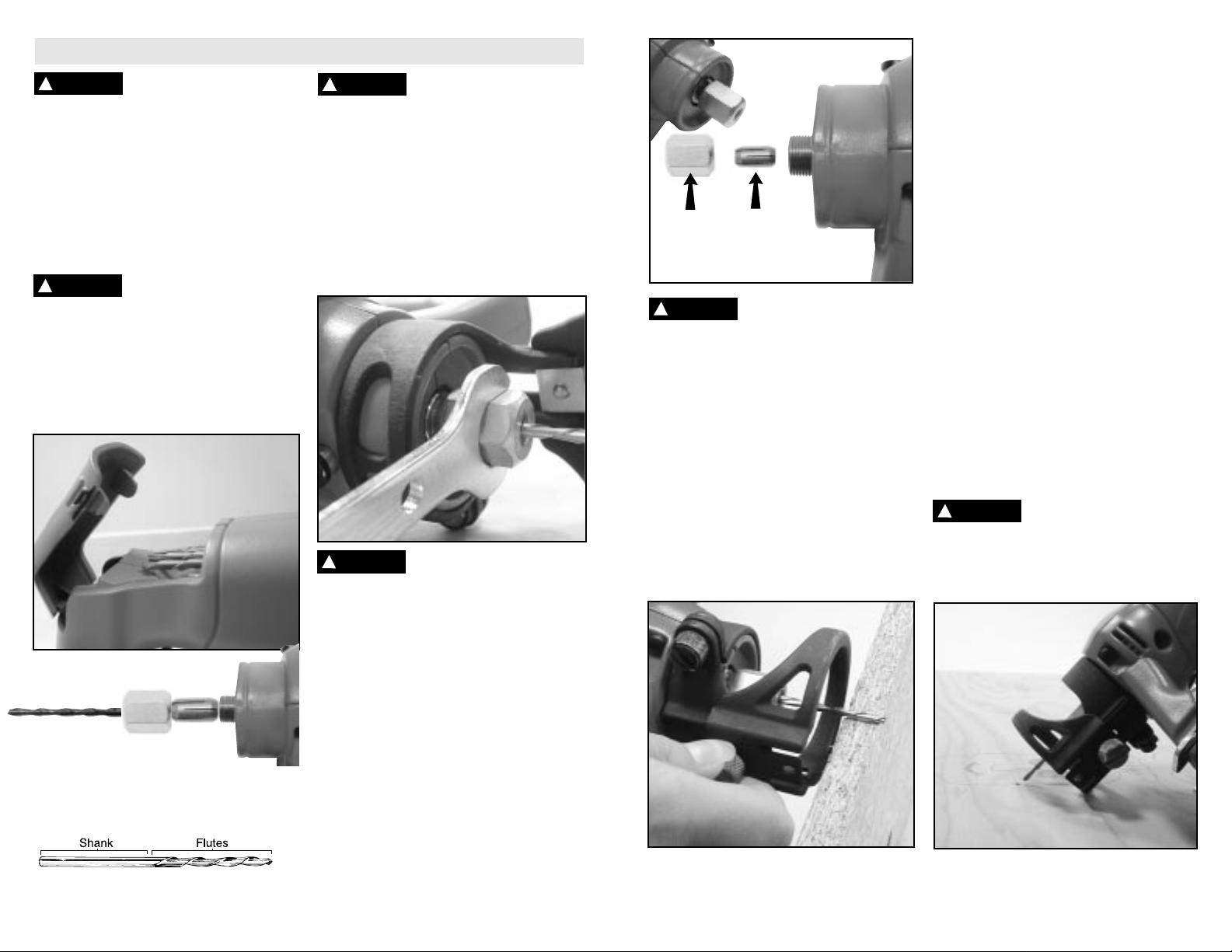

Adjusting, removing and installing the depth

guide assembly.

Step 2:

The depth guide is used to adjust the depth of

the cut. The depth guide assembly consists of

the depth guide, locking knob, base screw, and

bracket in addition to the wrench. Loosen the

locking knob by turning it counter clockwise with

the flat end of the wrench and slide the depth

guide up or down to the desired depth of your

cut. Retighten the locking knob with the wrench

in a clockwise direction. For best results, set

the guide at about 1/8" greater than the material

thickness. For example, to cut 1/2" plywood,

set the Zip Bit end so it protrudes 5/8" below the

base guide.

Note: Zip Bits can cut materials up to 1" thick.

To remove the depth guide, loosen the base

screw located on the collar of the depth guide

with the wrench. Twist the depth guide counter

clockwise and pull the assembly straight off the

tool. To re-attach the assembly, push down and

twist the depth guide clockwise until it is flush

with the tool. Tighten the guide screw with the

wrench.

Make A Few Practice Cuts

After assembling the Zip Bit into the tool and

adjusting your depth guide, as described above,

you should make a few practice cuts with the

tool before attempting an actual job.

A few exercises will give you the necessary

practice to make clean, professional cuts.

Step 3:

Make certain that the collet nut is securely

tightened before turning the tool on.

Step 4:

Hold the Spiral Saw power tool firmly and turn

the tool ON.

Hold the tool with both hands

while starting, since torque

from the motor can cause the tool to twist.

Step 5:

While holding the tool firmly, insert the Zip Bit

into the material at a 45° angle.

!

CAUTION

!

WARNING

SYSTEM COMPLETE

COLLET

NUT

COLLET

SYSTEM SEPERATED

-6-

Operating Instructions

Disconnect the plug from the

power source before making

any assembly, adjustments or changing

accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Slide "ON/OFF" Switch

This tool is switched "ON" by the slide switch

located on the front of the motor housing.

TO TURN THE TOOL "ON" slide the switch

button up.

TO TURN THE TOOL "OFF" slide the switch

button down or "0" position.

Hold the tool with both hands

while starting, since torque of

the motor can cause the tool to twist.

Installing Zip®Bits

The Zip Bits are held by a collet system. At the

time your tool was assembled, the 1/8" collet

(used for 1/8" Zip Bits) was installed for your

convenience. A 1/4" collet is required for 1/4"

inch diameter Zip Bits, sold separately.

Do not use .118" shank bits in the 1/8" collet, use

only Roto Zip Tool Corporation 1/8" Zip Bits.

Identify the different parts of your Zip Bits.

The Zip Bit flutes are sharp

and should be handled with

caution.

Step 1:

To insert a Zip Bit into the tool, first remove the

standard equipment wrench and locate the shaft

lock button. Depress and hold down the shaft

lock button with one hand and at the same time

loosen the collet nut with the other hand by

turning it counter clockwise with the wrench for

a couple rotations.

Remove the old Zip Bit (if there is one), insert

shank of Zip Bit into the collet so that 1/16" to

1/8" of smooth shank remains visible above the

collet.

Do not allow the flutes/cutting

edges of the Zip Bit to fall into

the collet, and do not tighten the collet around

the flutes; doing so will result in broken Zip Bits.

After properly placing the Zip Bit into the collet,

depress the shaft lock button and simultaneously

tighten the collet nut in a clockwise directionfirst by hand and then with the wrench until Zip

Bit is held securely.

Changing the collet

As stated above, the 1/8" collet is used with 1/8"

diameter Zip Bits and the 1/4" collet is used with

1/4" diameter Zip Bits, sold separately. To

interchange collets, first remove the Zip Bit.

Continue to loosen and unscrew the collet nut

until you can remove it from the tool. Remove

the collet and replace it with another. (Each

collet is double-ended, and either end is

acceptable to use.) By hand, re-tighten the

collet nut around the collet in a clockwise

direction. You are now ready to insert a new

Zip Bit as instructed in step 1 above.

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

ZIP BIT STORAGE

Sabrecut™ Zip Bit

-9-

Maintenance

Service

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of

internal wires and components which could

cause serious hazard. Roto Zip Tool

Corporation is the only authorized repair center

for their tools. Contact the Customer Service

department, toll free in the U.S. and Canada, at

1-877-768-6947, Monday through Friday

between 8am-4:30pm CST, for further

instructions.

Cleaning

To avoid accidents always

disconnect the tool from the

power supply before cleaning or performing

any maintenance.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

Certain cleaning agents and

solvents damage plastic

parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents,

ammonia and household detergents that

contain ammonia.

!

WARNING

!

WARNING

!

CAUTION

Accessories

Use only Roto Zip Tool

Corporation’s recommended

accessories with this tool. Accessories that

may be suitable for one tool, may become

hazardous when used on another tool.

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

tool must be used. This will prevent

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles

.

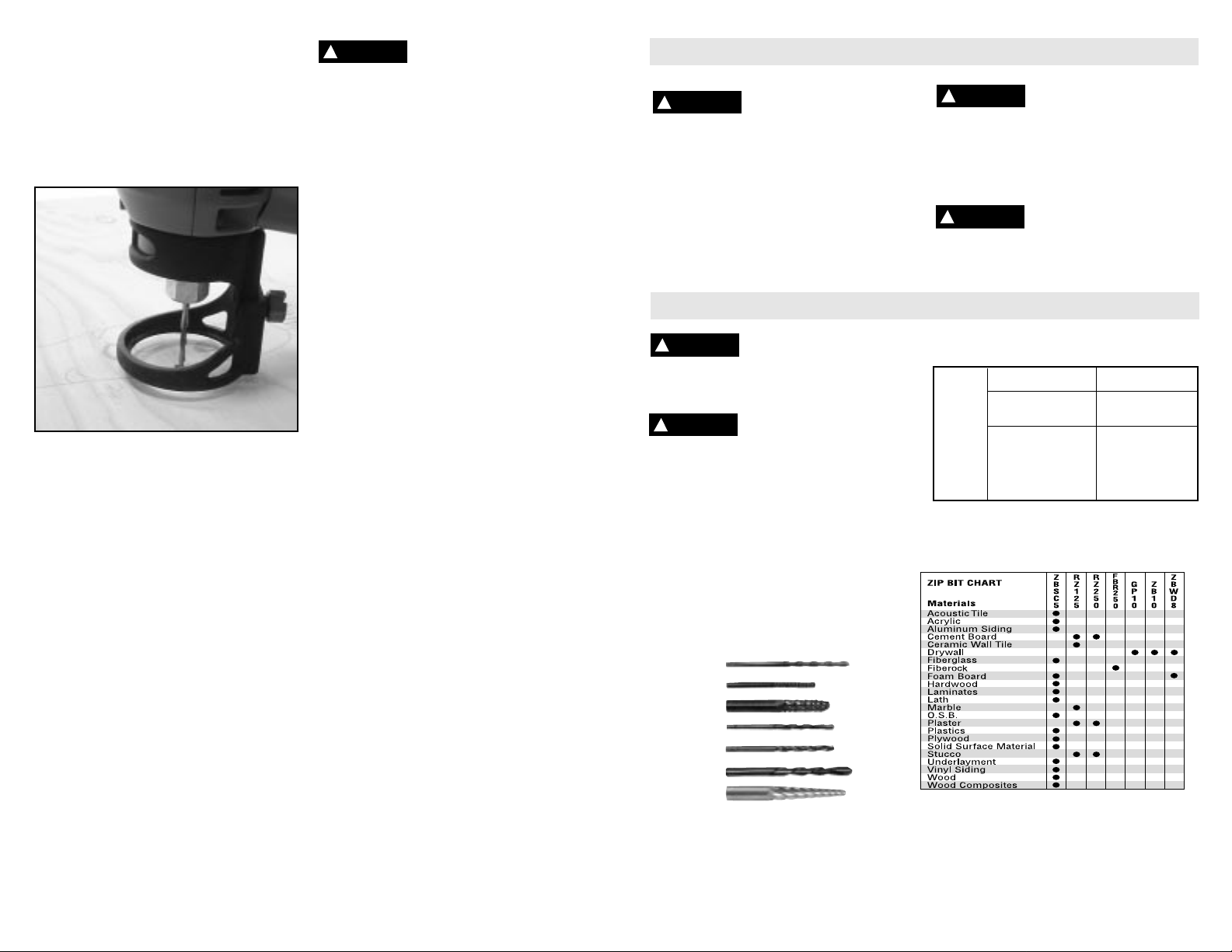

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

NOTE: The smaller the gauge number, the heavier

the cord.

!

WARNING

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Cord Length in Feet Cord Length in Meters

!

WARNING

Zip®Bits

Roto Zip Tool Corporation's patented line of

versatile Zip Bits and accessories provide you

with the flexibility to quickly move from one

material to another and one job to another,

without the hassle of changing tools.

Where Can You Buy Accessories?

The location where you purchased your tool should also carry Roto Zip Tool Corporation’s full line of

accessories. Our products are available at most home improvement centers and hardware stores. If

you are looking for a source, please call our Customer Service representatives Monday through

Friday between 8am - 4:30pm (CST) at 1-877-768-6947 (toll free in the U.S. and Canada).

-8-

Step 6:

Slowly bring it to a 90° angle to begin the cut.

The base guide should be flush to the material

surface. For all materials (EXCEPT cutting

around outlet boxes in drywall*), steer the tool in

a clockwise direction with slow, steady pressure

to make the cut.

Step 7:

After completing your cut, turn off the tool and

carefully remove it from the material.

Do not attempt to use this tool

to make cut-outs around any

fixture or opening which has live electrical wires,

or any wall which may have live electrical wiring

behind it, as the Zip Bit could conduct current to

the tool, creating an electrocution hazard for the

operator. Shut off breakers or remove fuses to

disconnect the circuit. Always hold the tool by

its thermoplastic housing, and always wear eye

protection when operating a Spiral Saw™

power tool.

NOTE: Because of the rotating cutting action of

the Zip Bit, there will be a slight pull when

cutting. The slower you cut, the more control

you have. Excessive pressure or fast cutting

will cause excessive heat and may shorten the

life of the Zip Bit.

NOTE: When cutting on a vertical surface,

avoid ending your cut at the bottom of the hole.

If possible, start and end your cut at the top so

the scrap part will not drop onto the rotating Zip

Bit. Turn the tool off and remove it from the

material.

!

WARNING

ZBSC5

RZ125

RZ250

GP10

ZB10

ZBWD8

FBR250

Loading...

Loading...