RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

RZ1500

RZ2000

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-ROTOZIP (1-877-768-6947) www.rotozip.com

For English Version Version française Versión en español

See page 2 Voir page 25 Ver la página 48

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 2

General Power Tool Safety Warnings

WARNING

!

Read all safety warnings and instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

us e a ny adapter pl ug s with earthe d

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating the power tool in damp locations

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduce the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e co mmon sense w hen opera ting a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in th e o ff-po sitio n b efore

connecting to power source and / or battery

pa ck, picki ng u p or carrying the t ool.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

co ntrol of the power to ol in unexpe ct ed

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not forc e the power to ol . Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

ca nn ot be co nt ro ll ed wi th th e swi tc h is

dangerous and must be repaired.

-2-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 3

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Ma ny acci de nt s a re caus ed by poorly

maintained power tools.

Spiral Saw Safety Rules

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live"

and shock the operator. If cutting into existing

walls or other blind areas where electrical

wiring may exist is unavoidable, disconnect

all fu ses or circui t br eakers fe eding this

worksite.

Always make sure the work surface is free

fr om nails and othe r foreig n object s.

Cutting into a nail can cause the bit and the

tool to jump and damage the bit.

Never hold the workpiece in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the material and guiding

the tool with both hands is safer.

Never lay wor kp ie ce on top of ha rd

surface s, li ke co ncret e, st on e, etc...

Protruding cutting bit may cause tool to jump.

Always wear saf ety goggl es and dus t

mask. Use only in well ventilated area.

Using personal safety devices and working in

safe environment reduces risk of injury.

After changing the bits or makin g any

adjustments, make sure the collet nut and

any other adjus tm en t d evice s ar e

se curel y tigh tened. Lo ose ad justm ent

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified

re pa ir person using o nl y id en ti ca l

replacement parts. This will ensure that the

safety of the power tool is maintained.

device can unexpectedly shift, causing loss

of control, loose rotating components will be

violently thrown.

Never start t he t oo l when th e bi t is

engaged in the material. The bit cutting

edge may grab the material causing loss of

control of the cutter.

Al wa ys ho ld the tool wi th tw o hands

during start-up. The reaction torque of the

motor can cause the tool to twist.

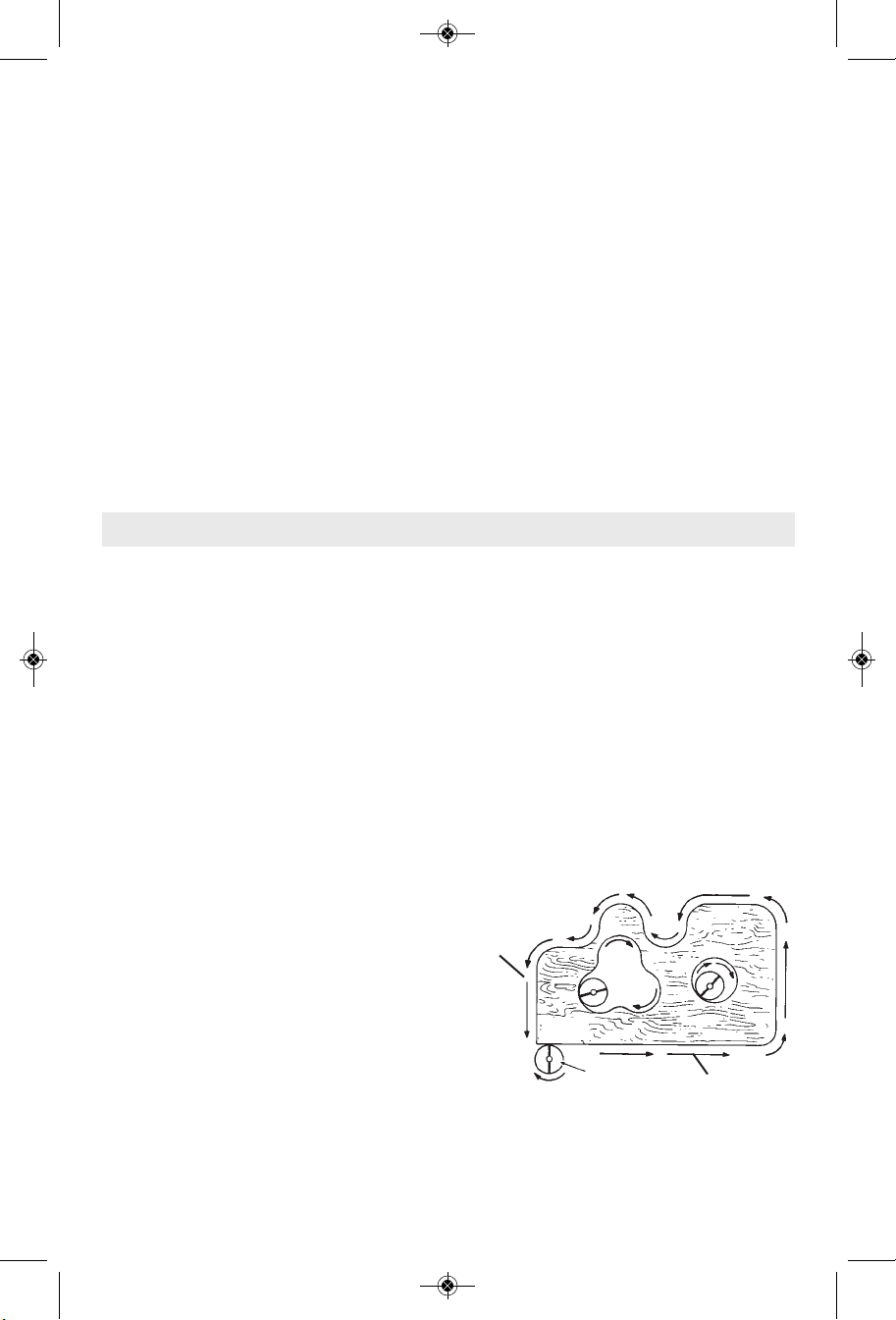

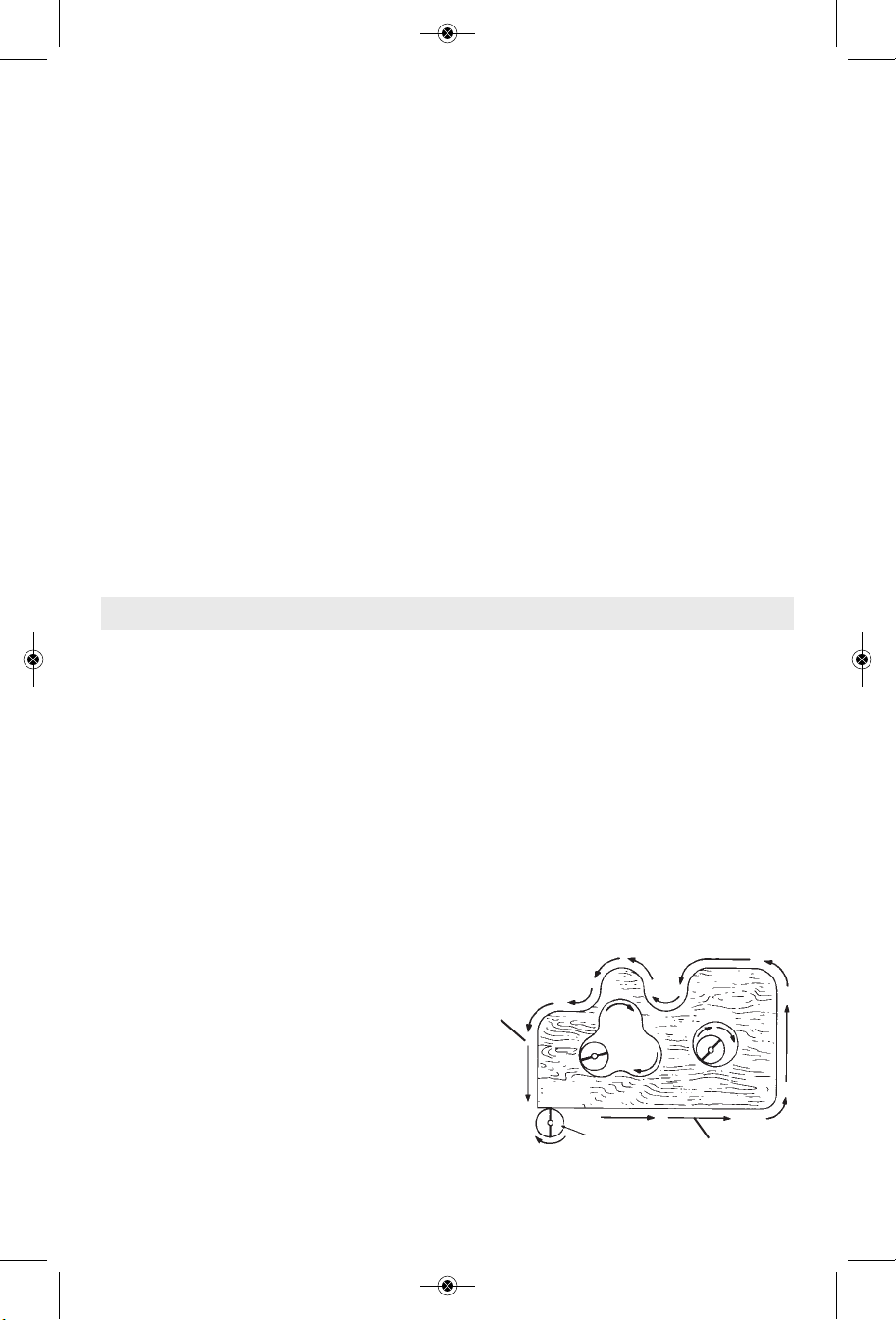

When routing or cutting, the direction of

feed with the bit’s cutting edge into the

material is very important. Always feed

the bit into the ma te ri al in th e same

direction as the cutting edge is exiting

from the material. When viewing the tool

START

HERE

WORK

BIT

from the top, the bit rotates clockwise. If the

tool is between the workpiece and your body,

DIRECTION OF

FEED

-3-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 4

then feed the to ol t o yo ur rig ht . If the

workpiece is between the tool and your body,

then feed the tool to your left. Feeding the

tool in the wrong direction causes the cutting

edge of the bit to climb out of the work and

pull the tool in the direction of this feed.

Never use dull or damaged bits. Sharp

bits must be handled with care. Damaged

bits can snap during use. Dull bits require

more force to push the tool, possibly causing

the bit to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to

be touched by bare hands.

Additional Safety Warnings

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

th e tool since inter nal wires may be

misplaced or pinched or safety guard return

sp rings ma y be impro perly mo unted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, a mmonia, etc. may

damage plastic parts.

Risk of injury to user. The power cord must only

be serviced by a Rotozip Factory Service

Center or Autho rized Rotozip Service Station.

Never lay the tool down until the motor

has come to a complete standstill. The

spinning bit can grab the surface and pull the

tool out of your control.

Never use bi ts t hat ha ve a cut ti ng

diameter greater than the opening in the

base.

Do not use the tool for drilling purposes.

This tool is not intended to be used with drill

bits.

Always use the tool with the depth guide

se curel y attached and pos ition ed flat

ag ainst ma te rial b ei ng cut. The gui de

securely positioned on the material improves

WARNING

!

drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chro mium from chemicallytreated lumber.

Yo ur ri sk from these ex po su res varies,

depending on how often you do this type of

work. To reduce your exposure to th ese

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Some dust created by power

sanding, sawing, grinding,

-4-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 5

Zipmate Abrasive Cut-Off Attachment Safety Rules

Always use wheel guard, and the Zipmate's

auxiliary handle with this abrasive cut off

tool. The guard must always be securely

attached to the tool and positioned for

maximum safety, so the least amount of

wheel is exposed on the operators side of

the tool. A guard protec ts operator f rom

broken wheel fragments. The support ribs and

auxiliary handle provide additional guarding,

stability and control in cut off applications. The

body of your Rotozip tool can also be used as

a handle.

Always be certain that the wheel guard,

an d Zipmat e' s auxili ary hand le a re

reassembled and securely fastened to the

tool when changing the point of operation

from fire forward to fire reverse or after

changing the whee ls. A tool missing an

essential safety component is dangerous to

operate.

We ar prope r appa re l whil e using an

abrasive cut off tool. Face shield or at least

safety goggles, dust mask, leather gloves and

shop apron capable of stopping small wheel or

workpiece fragments.

This attachment is not intended to be used

with Wet Diamond Wheels. Using water or

other liquid coolants with this tool may result in

electrocution or shock. Use of Dry Diamond

Wheels is acceptable.

Use only Type 1 abrasive cut off wheels

with the correct size arbor hole. Never use

damaged or incorrect wheel flanges or

round nut. Other types of wheels are not

intended to apply load on periphery and may

shatter. Wheels with arbor holes that do not

match the mounting hardware of the tool will

run eccentrically, vibrate excessively and will

cause loss of control.

Do not grind on the side of Type 1 abrasive

cut off wheels. Side forces applied to these

wheels may cause them to shatter.

Do n ot u se t his att ac hment wit h

“Woodcarving” blade or standard wood

cutting toothed blades. These blades are not

intended for this tool and can create loss of

control during use.

Abras ive Cut Off Whe els must ha ve a

maximum safe operating speed greater

than the “no load RPM” marked on the

attachment. Wheels running over the rated

speed can fly apart and cause injury.

Before each use inspect the cut off wheel

for chips and cracks. Do not use a wheel

that may be damaged. Install a new wheel if

tool was dropped. When installing a new

wheel carefully handle individual cut off

wheels to avoid chipping or cracking. Run

the tool at no load for one minute, holding

the tool in the direction away from people.

Wheels with flaws will normally break apart

during this time. Fragments from a wheel

that bursts during operation will fly away at

gr eat v elocity possib ly st riking you o r

bystanders.

Do not use a cut off wheel that is larger

than the maximum recommended size for

your tool, or worn down damaged wheels

from larger abrasive cut off tools. Wheels

intended for larger tools are not suitable for the

higher speed of a smaller tool, these wheels

may easily burst and the fragments strike you

or bystanders.

Position the cord clear of the spinning

wheel. Do not wrap the cord around your

arm or wrist. If you lose control and have the

cord wrapped around your arm or wrist, it may

entrap you and cause injury.

Keep your body positioned to either side of

the wheel, but not in line with the wheel. It

is important to support the tool properly and to

position your body such as to minimize body

exposure from the possible wheel binding and

the recoil of the tool.

Keep hands away from cutting area and

wheel. Keep your second hand on auxiliary

handle. Hold the tool firmly to prevent loss

of control. NEVER place your hand behind

the wheel since the tool may recoil over

your hand. Do not attempt to remove cut

material when whe el is m oving. If both

hands are holding the tool, they cannot be cut

by the wheel

Do not “jam” the abrasive wheel into the

work, apply excessive pressure or attempt

to use large depths of cut while using this

tool. Let the rota ting wheel do the work,

Abrasive Cut Off Tools are intended to “cut”

the material in a series of shallow depth of

cuts. See the instructions for depth of cut later

in this manual.

Avoid bouncing and snagging the wheel,

especially when working corners, sharp

edges etc. This can cause loss of control and

tool’s recoil.

-5-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 6

Do not run the tool while carrying it at your

side. Accidental contact with the spinning

wheel could result in serious personal injury.

Never lay the tool down until the motor has

come to a complete standstill. The spinning

wheel can grab the surface and pull the tool

out of your control.

Do not use the Zipmate near flammable

materials. Sparks from the wheel could ignite

these materials.

Never cut or attempt to cut magnesium

with this attachment. The dust generated

when cutting magnesium is highly flammable

and may be explosive under certain conditions.

Regularly clean the tool’s air vent s by

compressed air. Excessive accumulation of

powdered metal inside the motor housing may

cause electrical failures.

Causes and Operator

Prevention of Recoil:

Recoil is a sudden reaction to a pinched,

bound or misaligned rotating wheel. The wheel

may stall and cause an uncontrolled tool to

back out of the kerf toward the operator when

the tool is in the “fire forward” position, if the

tool is set in the “reverse fire” position the tool

may tend to walk away from the operator. The

rotation direction arrow located on the back

side of the guard can be used to identify the

“fire forward” and “reverse fire” positions. The

attachment is in the fire forward position when

th e directi on al ar row point s toward th e

operator, and it is in the reverse fire position

when the arrow is pointing away from the

operator.

If an ab ra sive wheel or di am ond wheel

becomes twisted or misaligned in the cut, the

side of the wheel that is entering into the

material can dig into the top surface of the

material causing the wheel to climb out or

recoil out of the kerf either toward or away

from the operator, depending on t he fire

forward or reverse fire orientation.

Abrasive wheels may also shatter under these

conditions causing pieces or fragments to

strike or impale the operator and bystanders.

Recoil or shattered wheels are the result of

to ol misuse an d/or incor re ct operati ng

procedures or conditions and can be avoided

by taking proper precautions as given below:

Maintain a firm grip with both hands on the

tool handles and position your body and

arm to allow you to resist recoil forces.

Re coil forces can be co nt rolled by the

operator, if proper precautions are taken.

Wh en w heel is binding , or w hen

interrupting a cut for any reason, slowly

ease the wheel out of the material while

maintaining a firm grip on the tool and

au xiliary handle with both h ands.

Investig ate and take cor rec tive actio n to

eliminate the cause of wheel binding.

When restarting a tool in a wo rkpiece,

center the wheel in the kerf and check that

the sides of the wheel are not engaged into

the material. If wheel is binding, it may walk

up or recoil from the workpiece as the tool is

restarted.

Support large panels to minimize the risk of

wheel pinching and recoil. Large panels tend

to sag under their own weight. Supports must

be placed under the panel on both sides, near

the line of cut and near the edge of the panel.

Use extra caution when making a “Pocket

Cut” into exist ing walls or o the r blind

areas. The protruding wheel may cut objects

that can cause recoil.

Jigsaw Handle Attachment Safety Rules

WARNING

!

than 1/4" with the Jigsaw Handle Attachment.

WARNING

!

Jigsaw Handle Attachment, the collet nut

must be tightened using the supplied wrench.

Finger tight is not sufficient for router bits.

Do not us e any r ou ter bi t

with a cutting diameter larger

When using a 1/4" shank bit

or any rout er bit wi th the

WARNING

!

from above, DOR is CW. When viewed from

the end of the bit, DOR is CCW.

WARNING

!

tighten the depth adjust screw tightly.

Indicate direction of rotation

of the bit. When vi ewing

Before doing any work with

the Jig S aw At tachm en t,

-6-

0

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 7

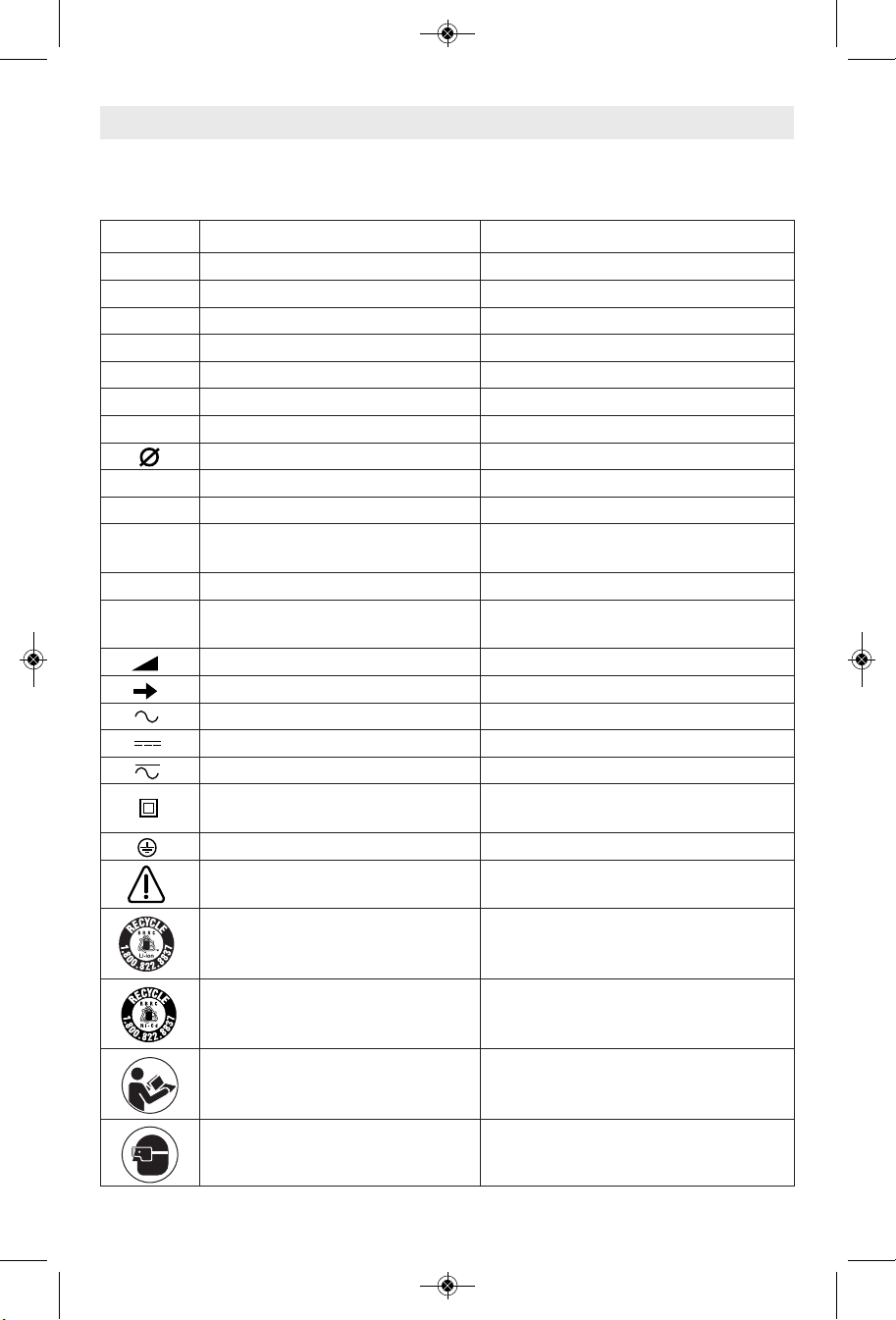

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

n Rated speed Manufacturers rated speed

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

No load speed Rotational speed, at no load

per minute orbits etc. per minute

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

-7-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 8

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

-8-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 9

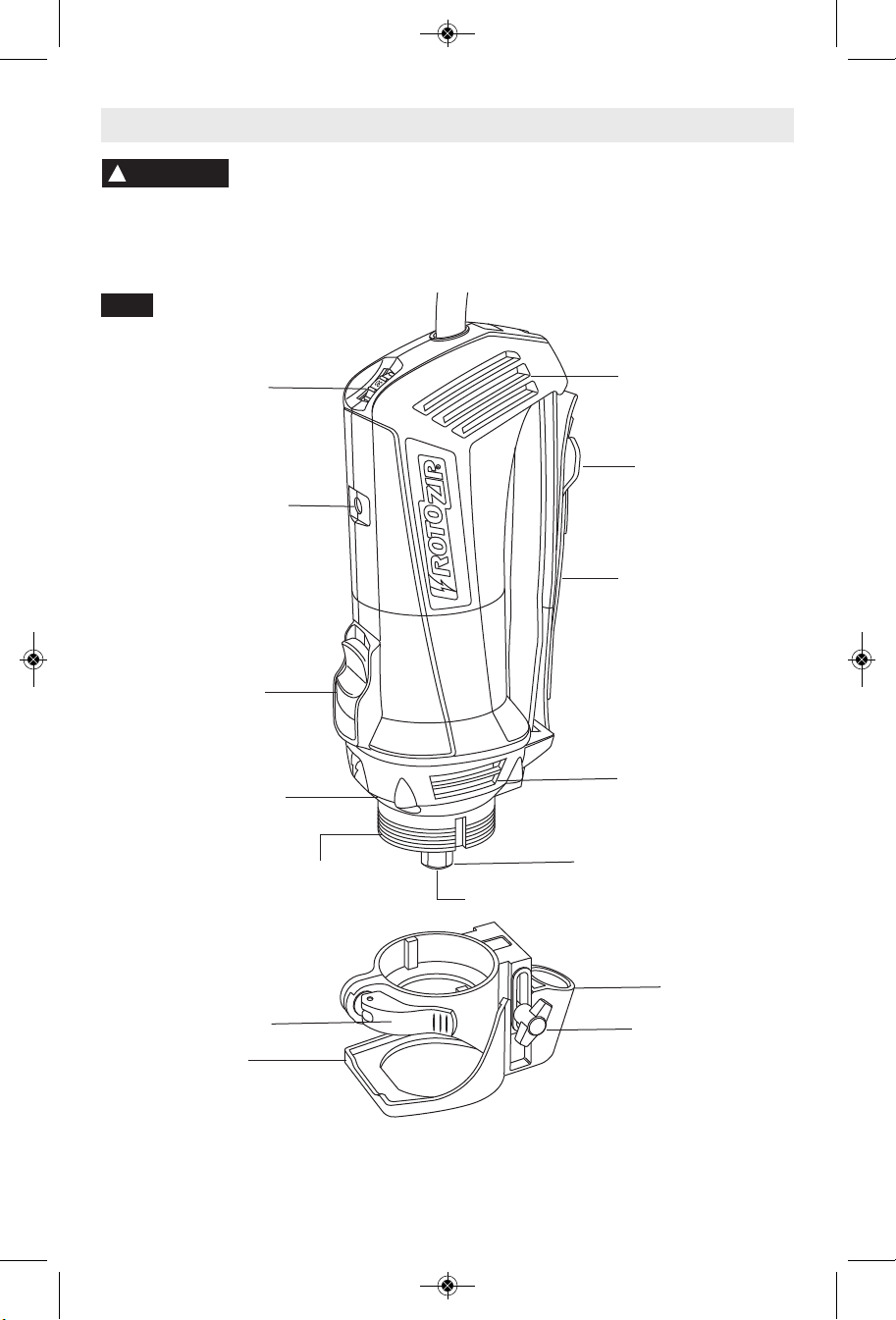

Functional Description and Specifications

WARNING

!

Di sc onnect the plug fro m the pow er source bef ore maki ng any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

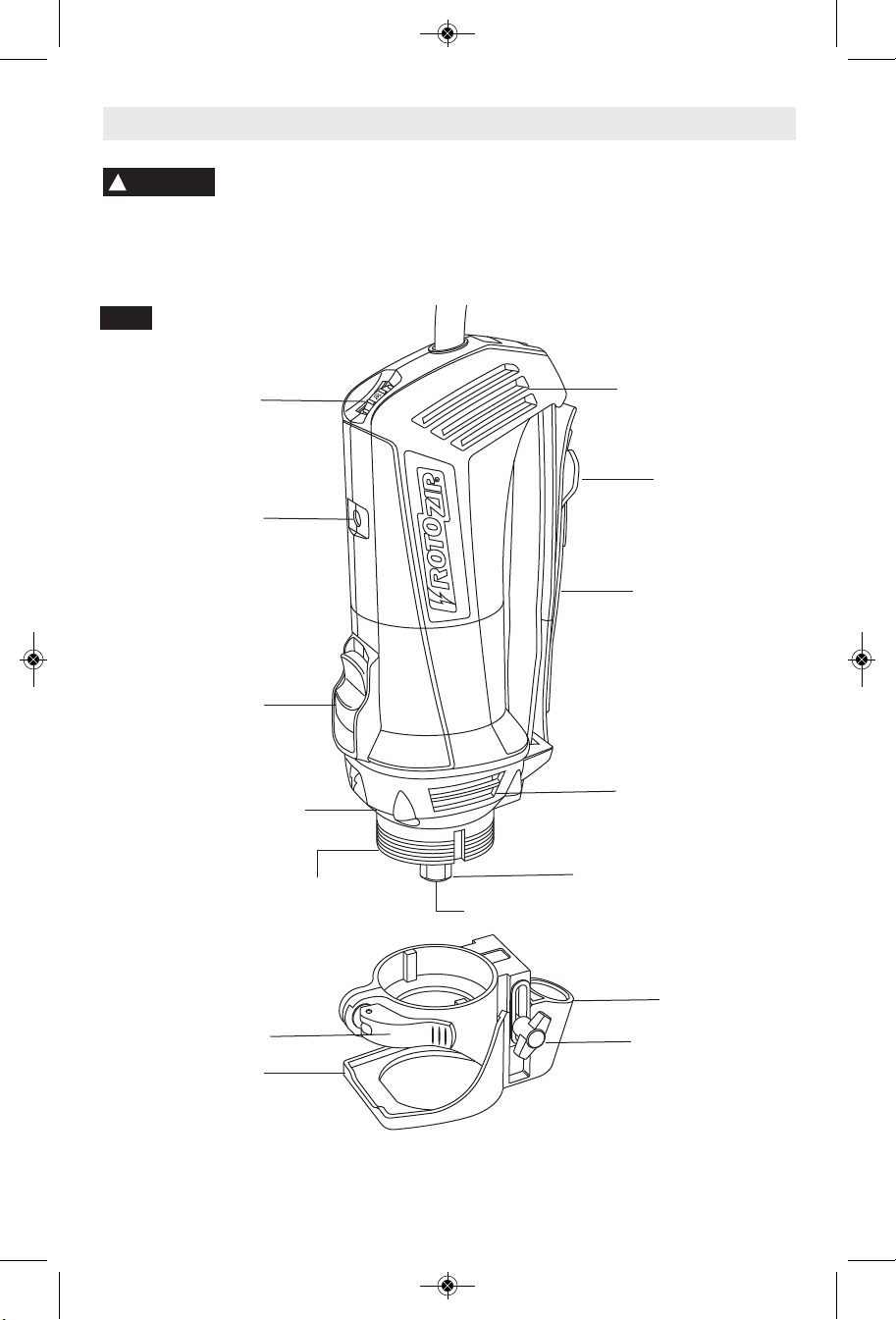

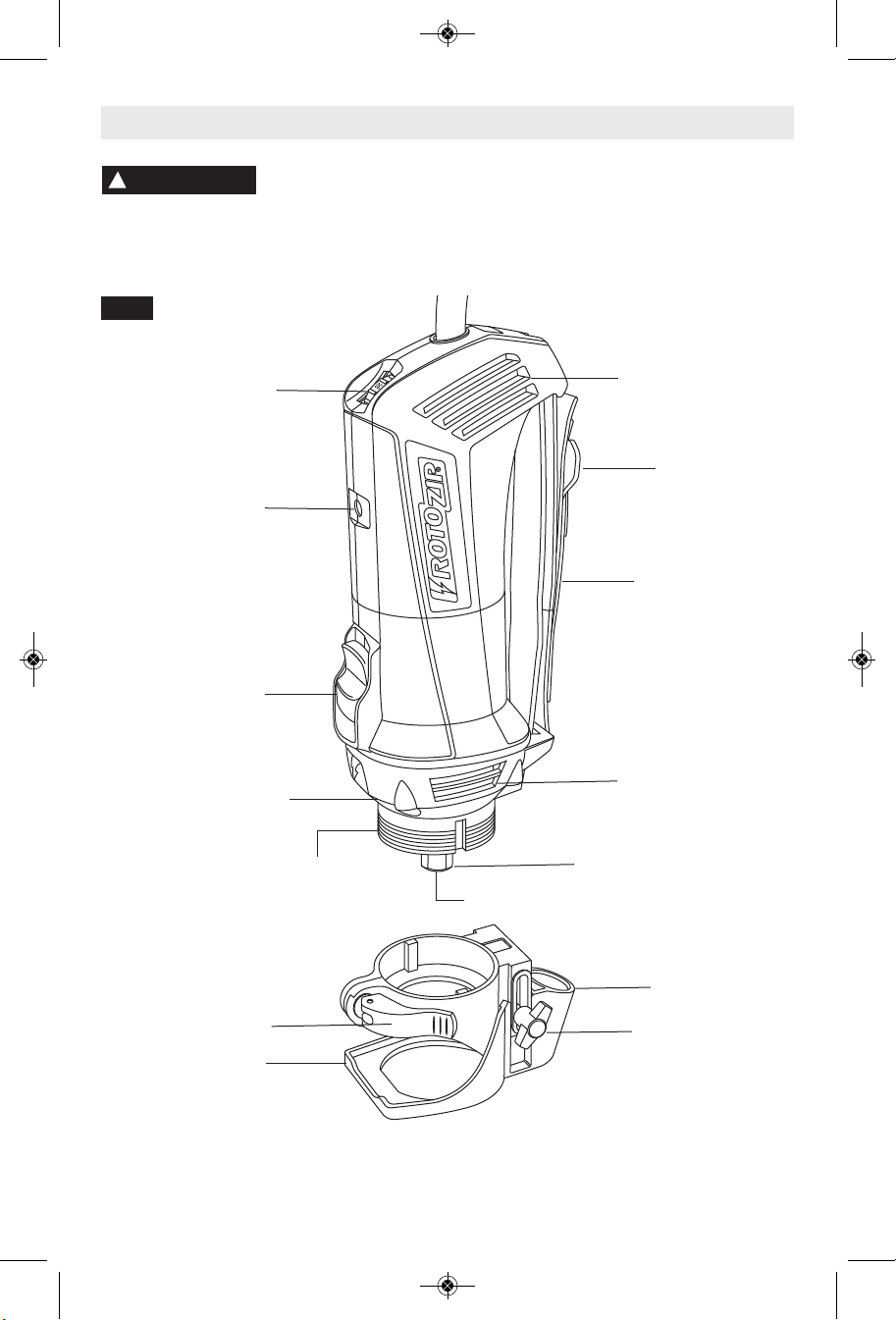

Spiral Saw™

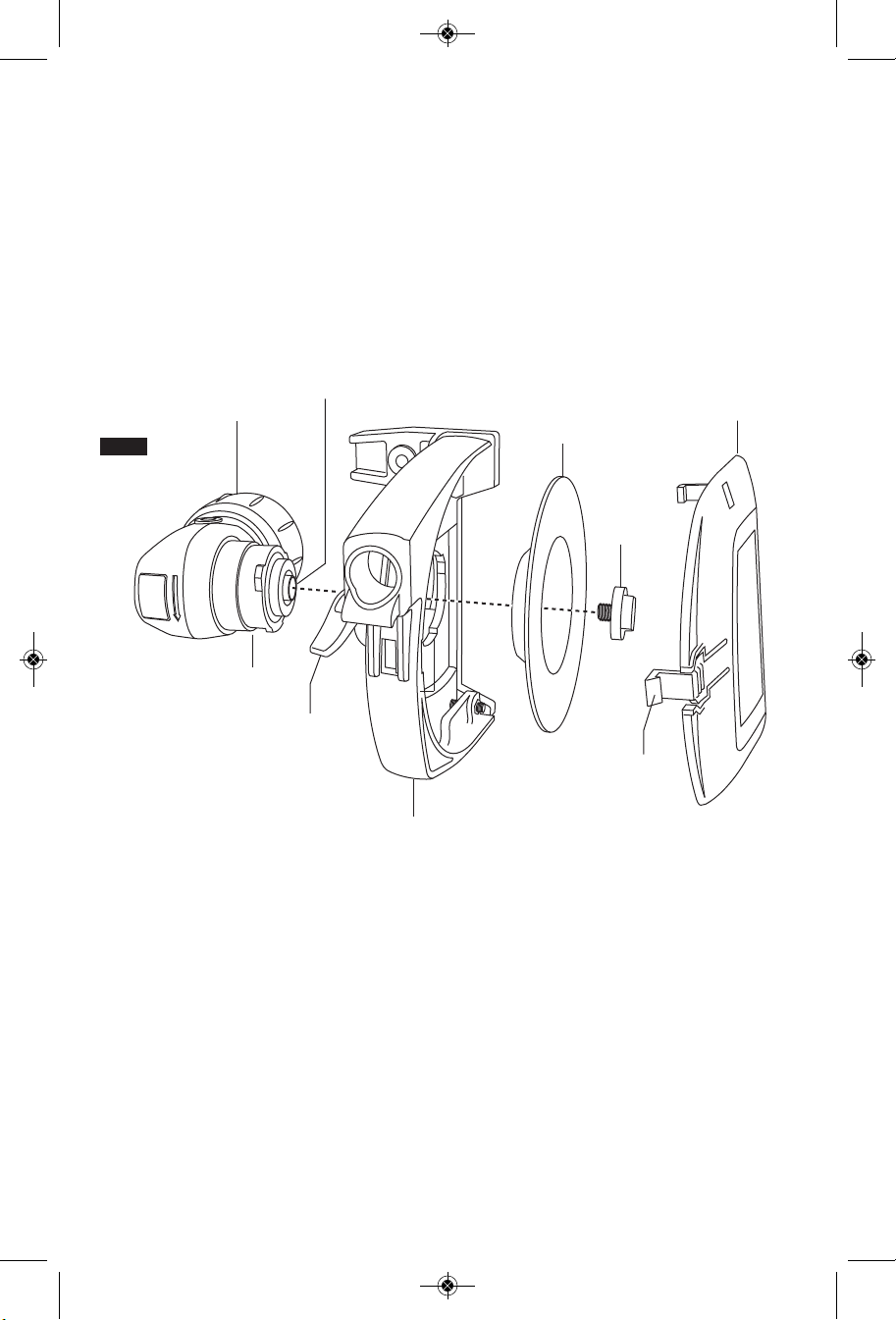

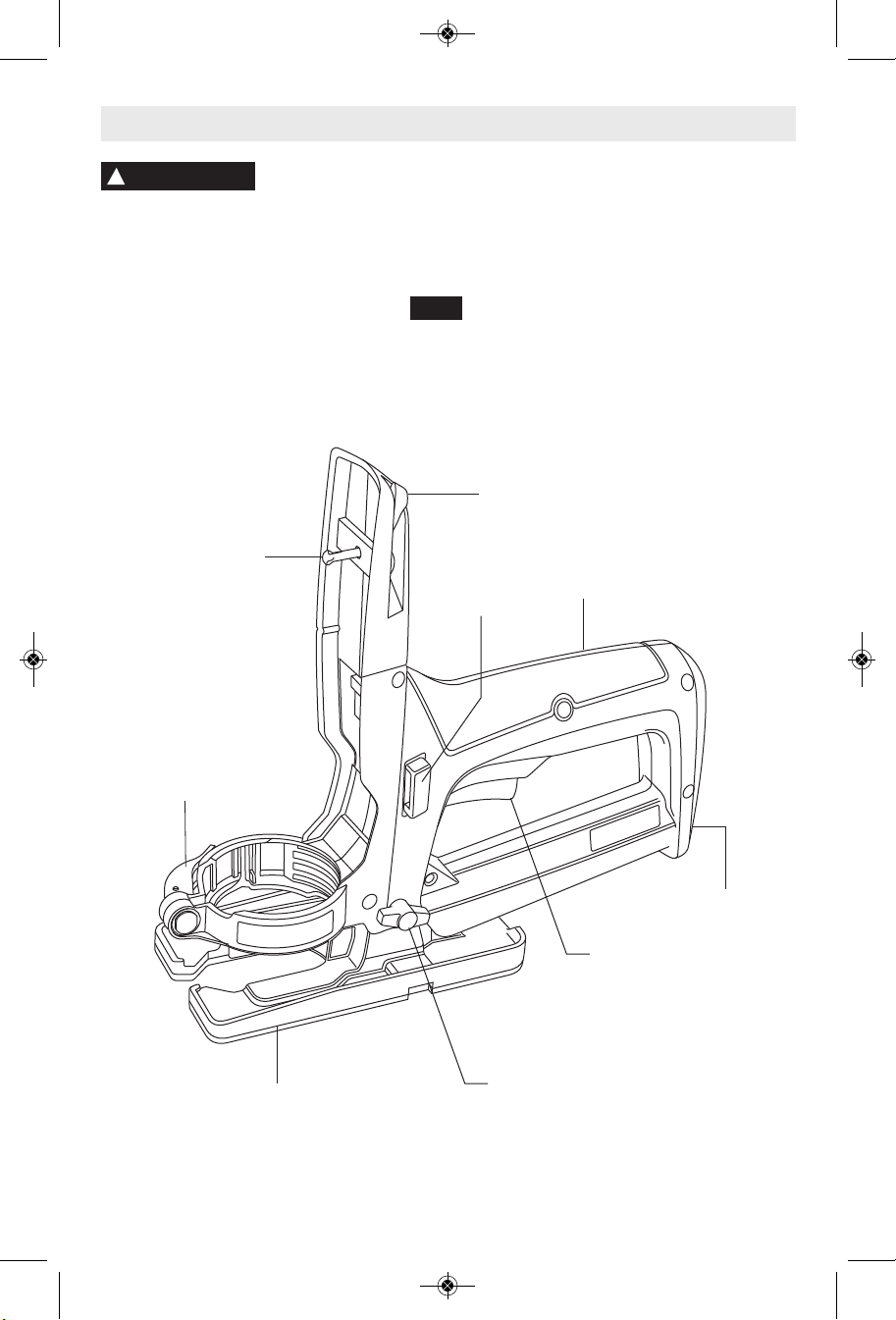

FIG. 1

SPEED

CONTROL DIAL

(Model RZ2000 only)

UPPER

ATTACHMENT

POINT

SLIDE ON-OFF

SWITCH WITH

LOCK

INTAKE

AIR VENTS

WRENCH STORAGE

COMPARTMENT

SUPPORT STRAP

WORKLIGHT

(Model RZ2000 only)

COLLAR

COLLET

LOCK LEVER

DEPTH GUIDE

NOTE: For tool specifications refer to nameplate on your tool.

-9-

EXHAUST

AIR VENTS

COLLET NUT

DUST PORT

THUMB SCREW

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 10

Assembly

WARNING

!

making any assembly, adjustments or

changi ng acces sories. Such preventive

safety measures reduce the risk of starting

the tool accidentally. Make certain that the

collet nut is securely tightened before turning

the tool on.

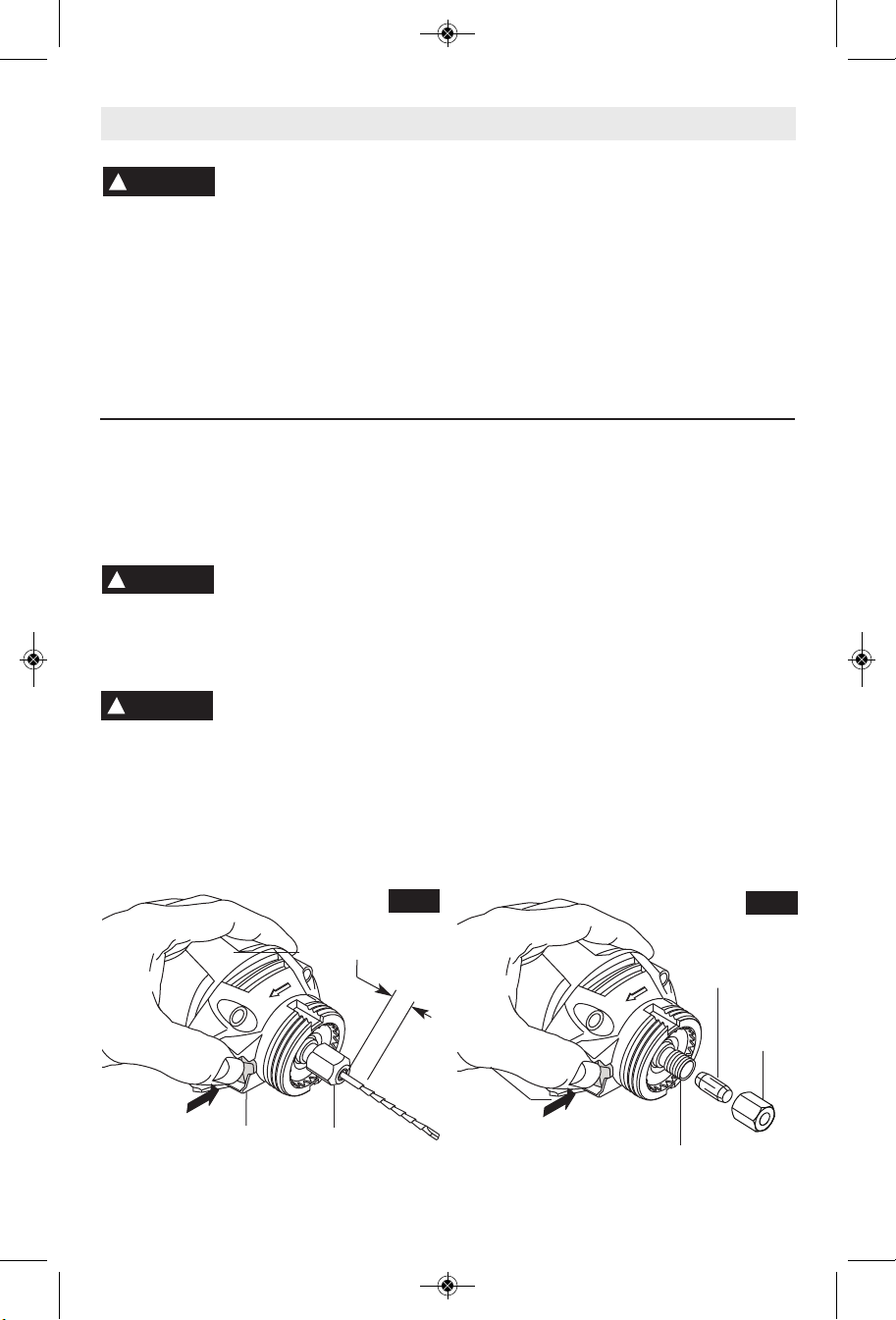

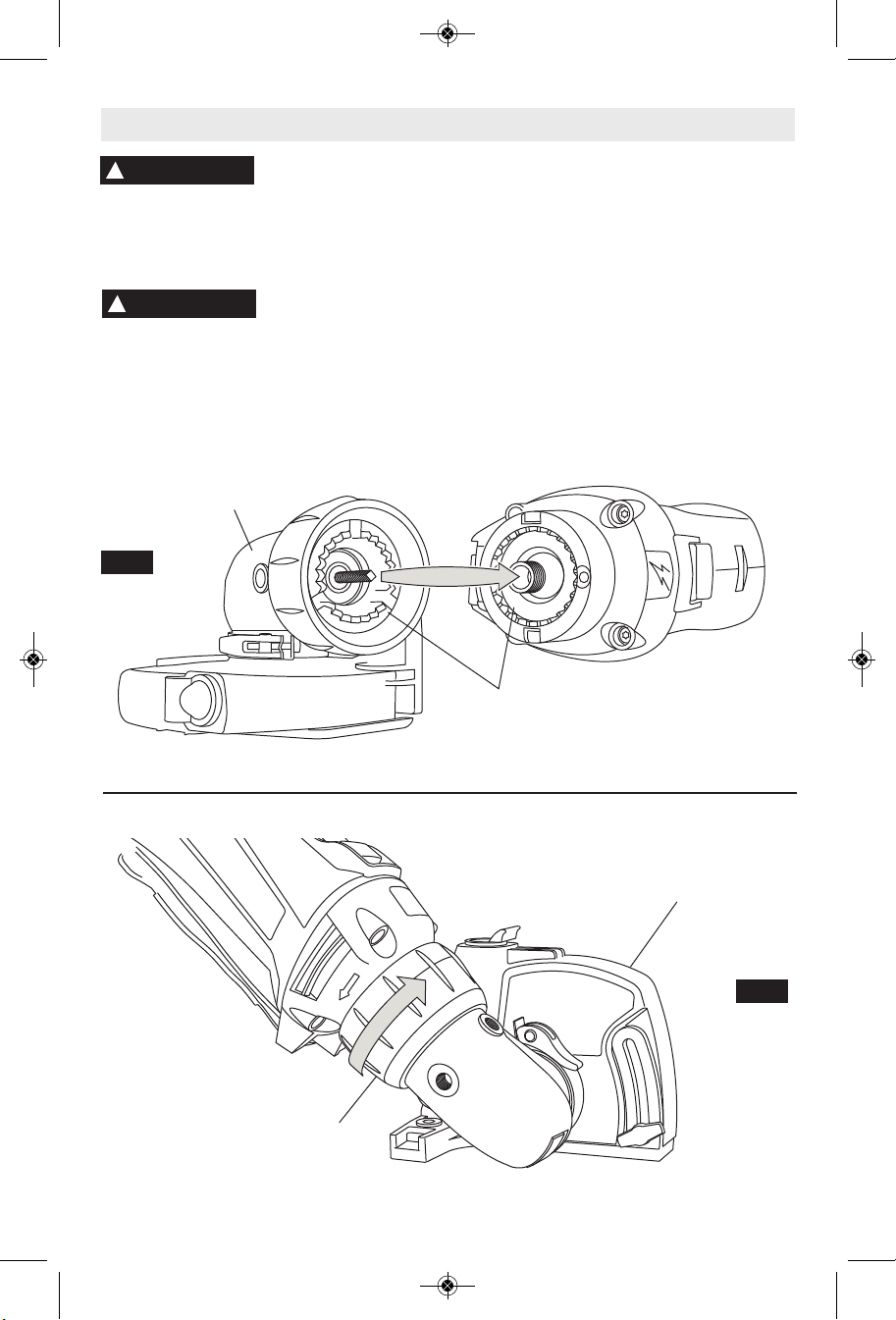

The bits are held by a collet system. Use either

the 1/8" (.125"), 1/4" (.250") or 5/32" (.156")

collet depending on the size of the bit shank.

WARNING

!

caution.

Depress and hold the shaft-lock in and rotate

the collet nut and shaft until the shaft-lock

engages and holds the shaft.

!

CAUTION

braking devise to stop the tool from rotating.

Us e the st an da rd equipment wrench to

lo osen nut (counte r-clock wise) (F ig. 2).

Remove the old bit (if there is one) insert the

new bit as far in as possible, but not so far

that the bit flutes engage the collet (leave

Disconnect the plug from

the power source before

INSTALLING BITS

The bit flutes are sharp and

sh ou ld b e h andled with

To prevent damage to tool.

Never use the shaft lock as a

REMOVING AND INSTALLING THE

DEPTH GUIDE ASSEMBLy

The depth guide assembly consists of the

depth guide, locking screw and bracket.

In order to remove the depth guide from the

tool, release the locking lever and pull the

entire assembly straight off of the tool. To

reattach the assembly, fully replace the guide

onto the tool collar and lock the clamp lever

(Fig. 1).

approxi ma te ly 1/8" of sh an k ex po sed)

Re-engage the shaft-lock and tighten the nut

(clockw is e) by han d and the n with th e

wrench until bit is held securely.

CHANGING THE COLLET

The 1/8" collet is used with 1/8" diameter

bits, the 1/4" collet is used with 1/4" diameter

bits and the 5/32" collet is used with 5/32"

diamete r b it s. To ch an ge co llets, fir st

re move the bit. Con tinue to loosen and

unscrew the collet nut until you can remove it

from the tool. Remove the collet and replace

it with the o ther (Fig. 3). (Each col let is

double-ended, and either end is acceptable

to use.) By hand, re-tighten the collet nut

around the collet in a clockwise direction.

You are now ready to insert a new bit as

instructed in Installing Bits (Fig. 2).

SHAFT

LOCK

1/8"

COLLET

NUT

FIG. 2

FIG. 3

COLLET

COLLET

NUT

OUTPUT SHAFT

-10-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 11

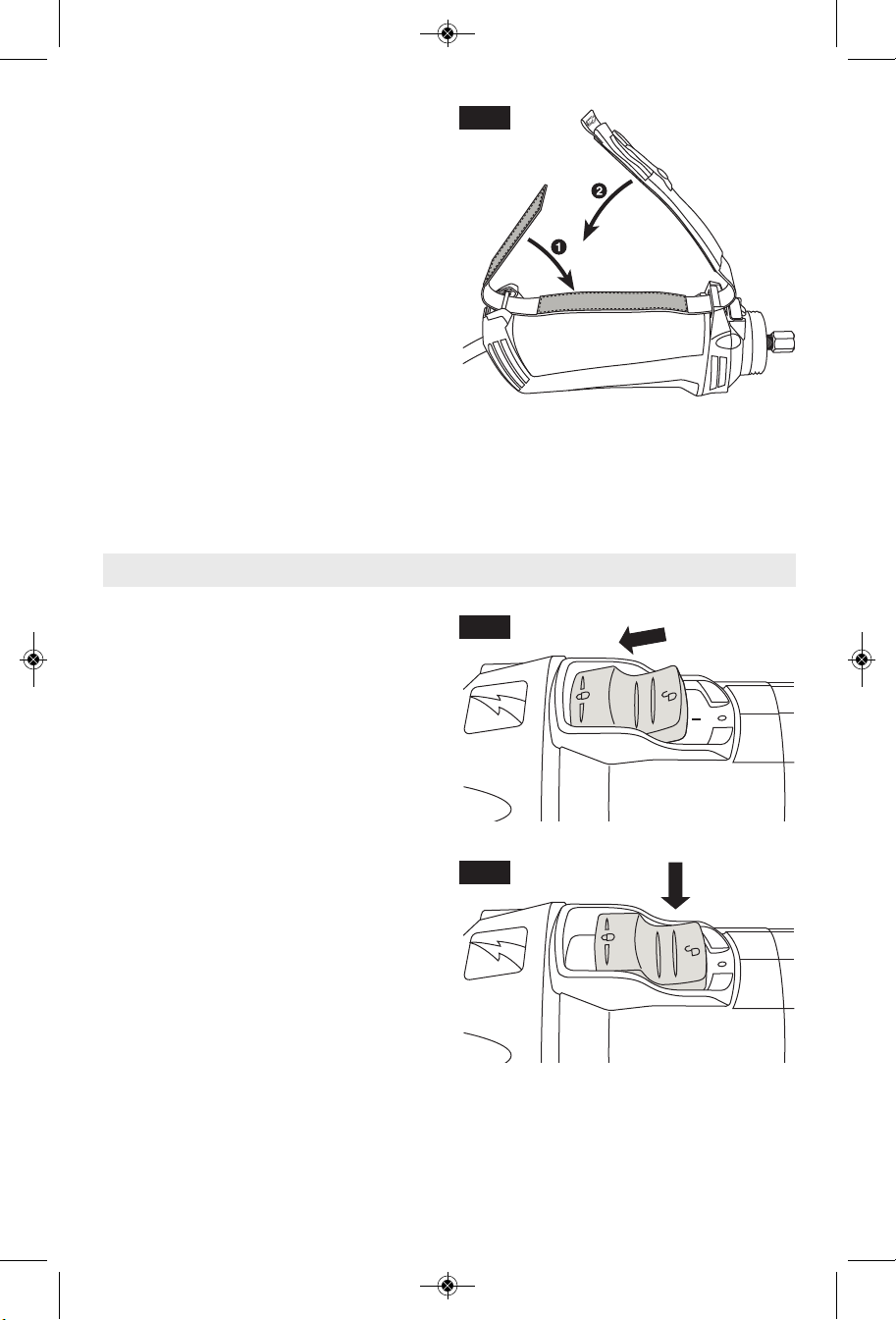

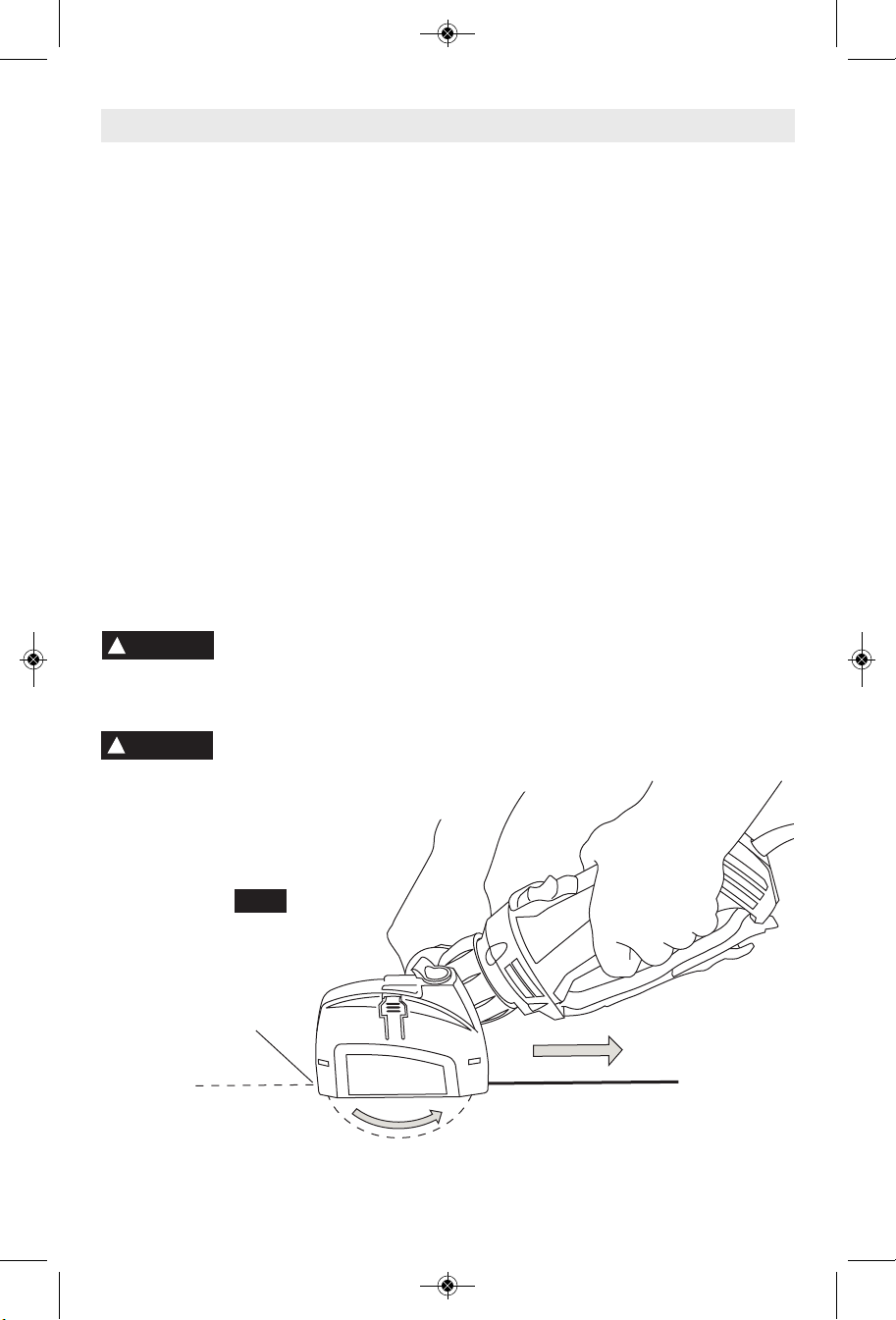

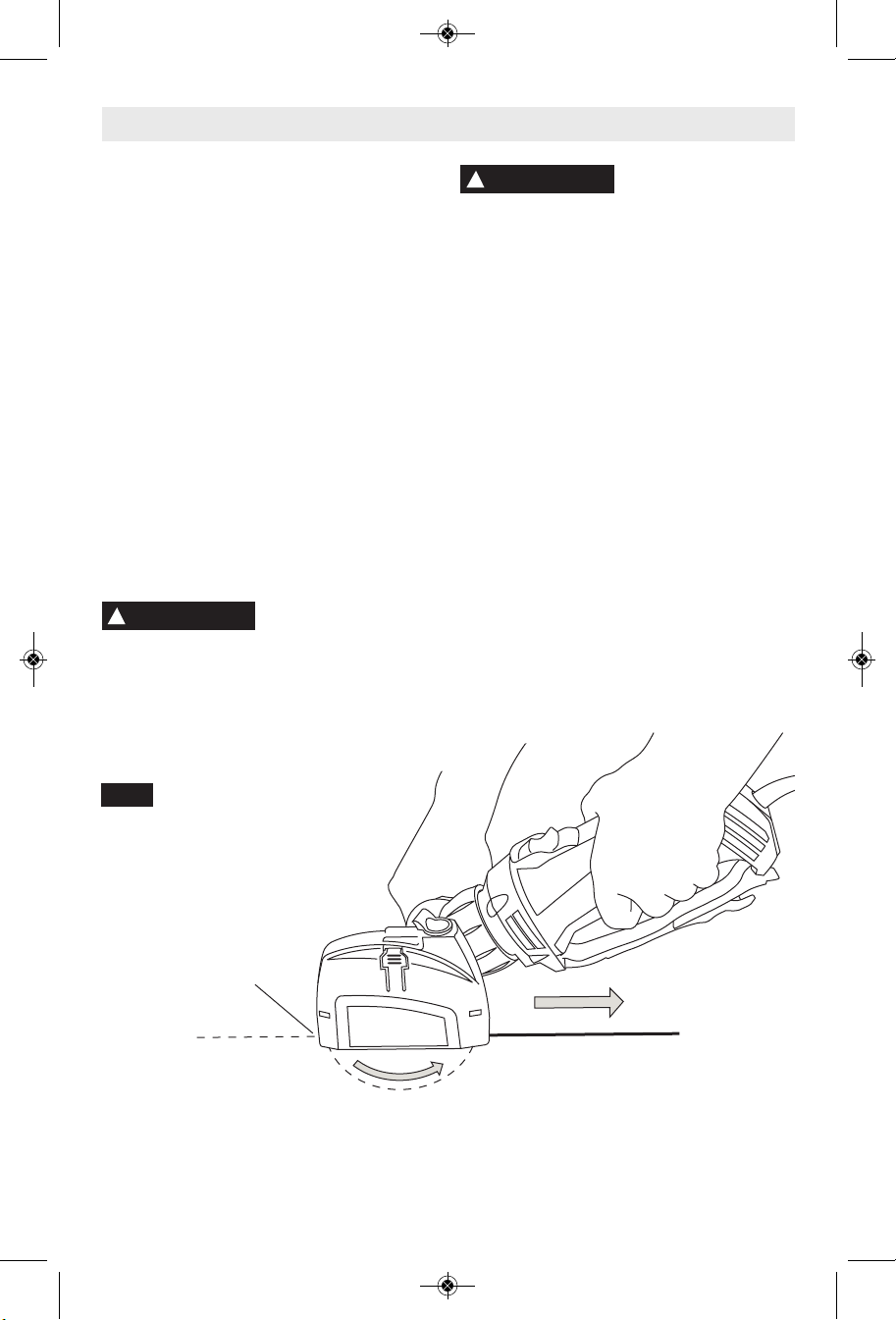

INSTALLING THE SUPPORT STRAP

With the wrench storage pocket facing down,

threa d the end of the st rap opp osi te the

Rotozip® logo through the post near the front

of the tool as shown. Continue to thread the

strap through the rear post near the cord. Fold

the back flap over first (1), then fold the end

with the Rotozip® logo (2) as shown in figure

4. Press firmly to ensure the strap is secured.

Operating Instructions

SLIDE ON-OFF SWITCH WITH LOCK

Th e to ol is switch ed “ON” by the switc h

bu tt on lo ca te d at the si de of th e motor

housing (Fig. 5). The switch can be locked in

the “ON” position, a convenience for long

cutting operations.

TO TURN THE TOOL “ON” without locking it,

slide the switch button forward by applying

pressure ONLY at the REAR portion of the

button. When pressure is released the switch

button will snap to “OFF” position.

TO LOCK THE SWITCH “ON”, slide the

switch button forw ard and p ress “IN” the

FRONT portion.

TO UNLOCK THE SWITCH, simply press

and release the REAR portion of the button.

Switch is spring loaded and will snap back

automatically.

FIG. 4

FIG. 5

FIG. 6

-11-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 12

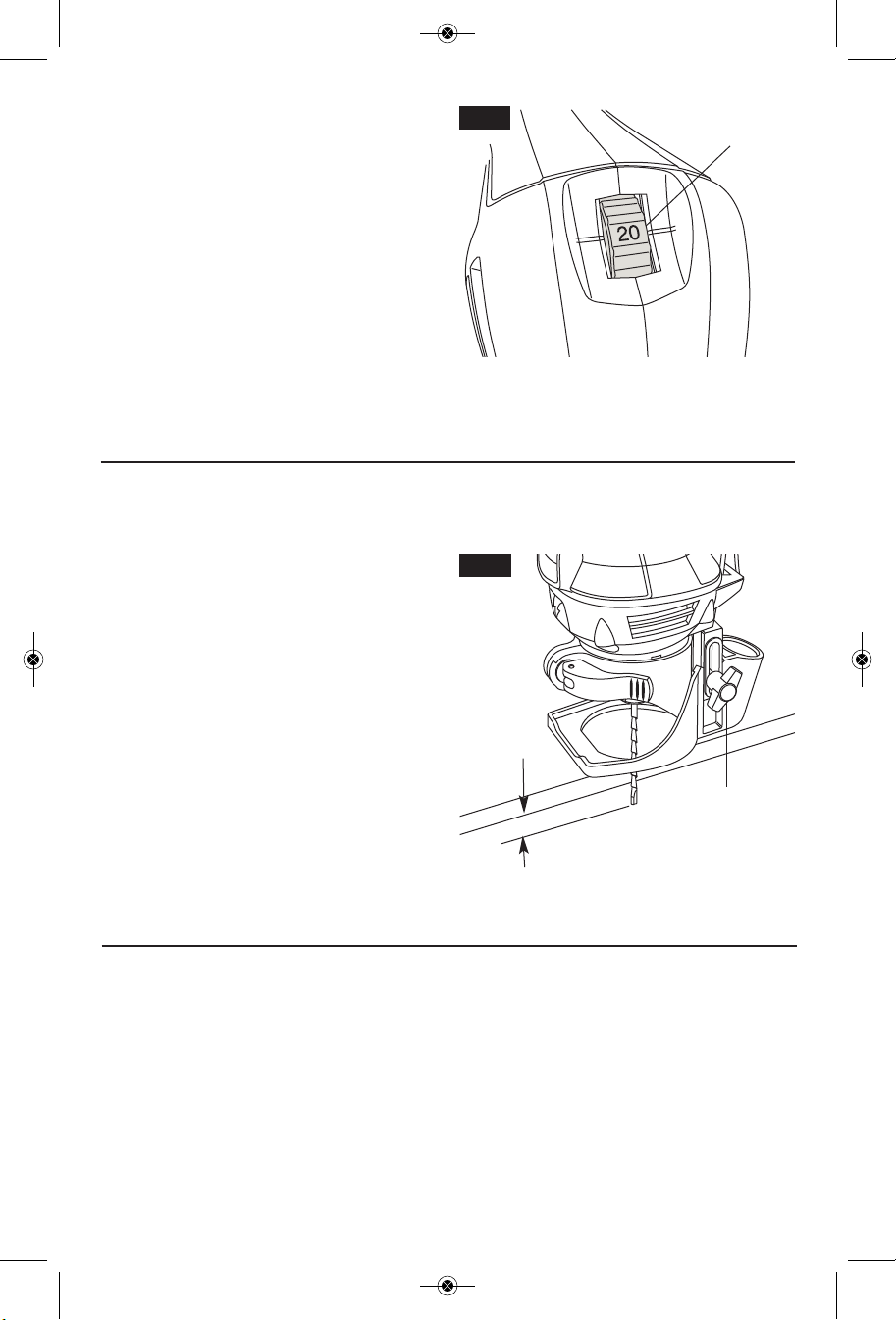

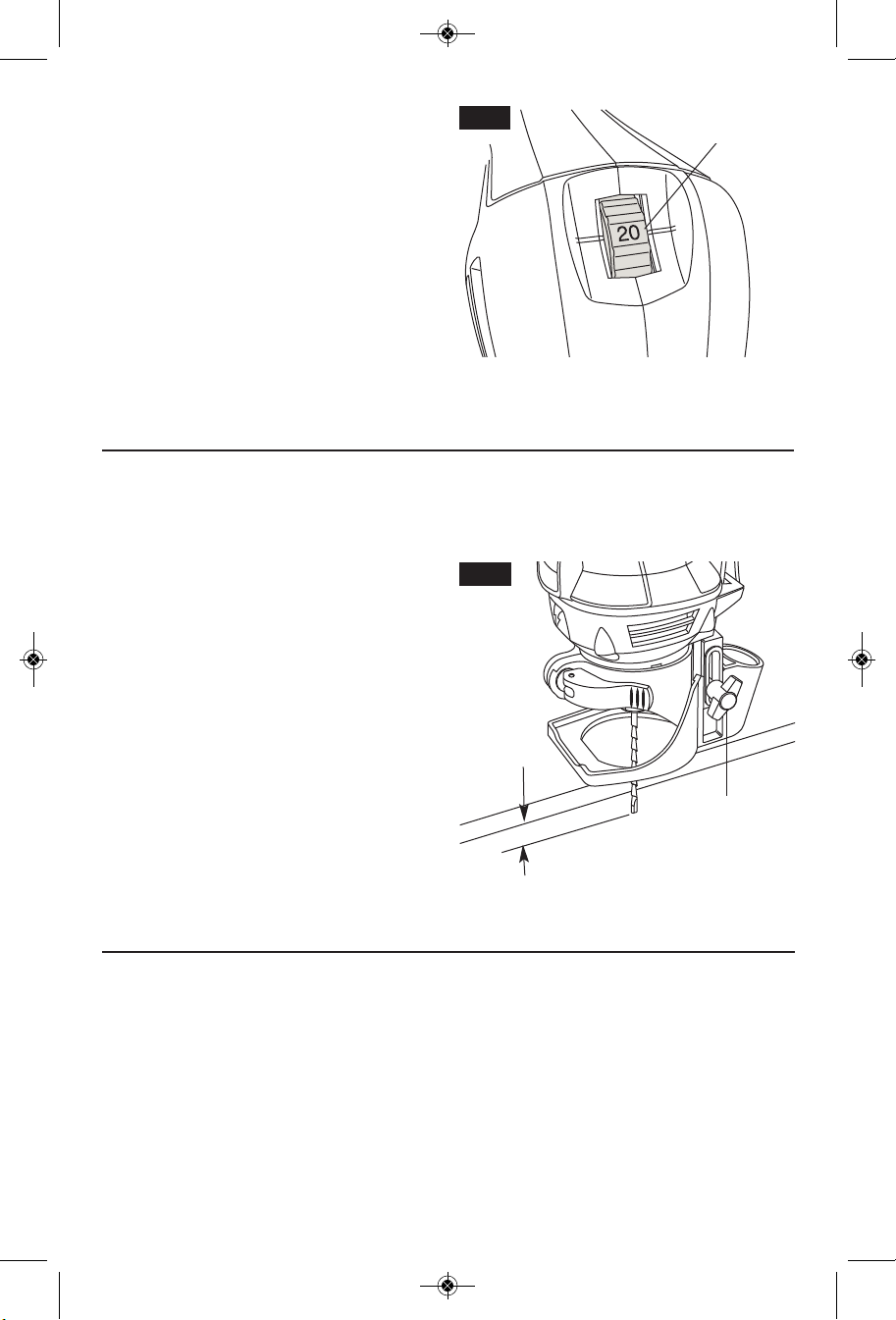

ELECTRONIC VARIABLE

SPEED CONTROL

(Model RZ2000 only)

The electronic speed control feature allows

motor speed to be matched to cutter size and

materia l ha rd ne ss f or impro ve d fi ni sh ,

extended bit life, and higher performance.

Speed c hanges are achieved by rota ting

Control Dial UP to increase speed, DOWN to

decrease as indicated on housing (Fig. 7).

Speed may be changed while tool is on. The

reference numbers on the dial facilitate resetting control to desired speed.

DEPTH GUIDE ADJUSTMENT

Use the depth guide to adjust the depth of

cut. Loosen the thumb screw by turning it

counter-clockwise until the depth guide can

slide freely to the desired depth of cut (about

1/8” greater than material thickness) and

retighten the thumb screw (clockwise) (Fig.

8). For bits with a guide point, make sure that

the entire guide point tip will extend 1/8”

beyond the material thickness (Fig. 2). For

standard point bits, make sure that the fluted

en d o f the bit extends 1/8” beyond the

material thickness.

FIG. 7

FIG. 8

SPEED

CONTROL DIAL

1/8"

THUMB

SCREW

WORKLIGHT

(Model RZ2000 only)

Your tool is also equipped with a light that

turns on automatically when the switch is

activated, for better visibility when cutting

(Fig. 1).

-12-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 13

MAKE A FEW PRACTICE CUTS

Af te r i nstalling th e bit in to the tool an d

adjusting your depth guide, you should make

a few pra ct ice cu ts with t he too l before

attempting an actual job. A few exercises will

give you the necessary practice to make

clean, professional cuts.

Step 1: Make certain that the collet nut is

securely tightened before turning the tool on.

Step 2: Hold the tool firmly and turn the tool

ON to your desired speed.

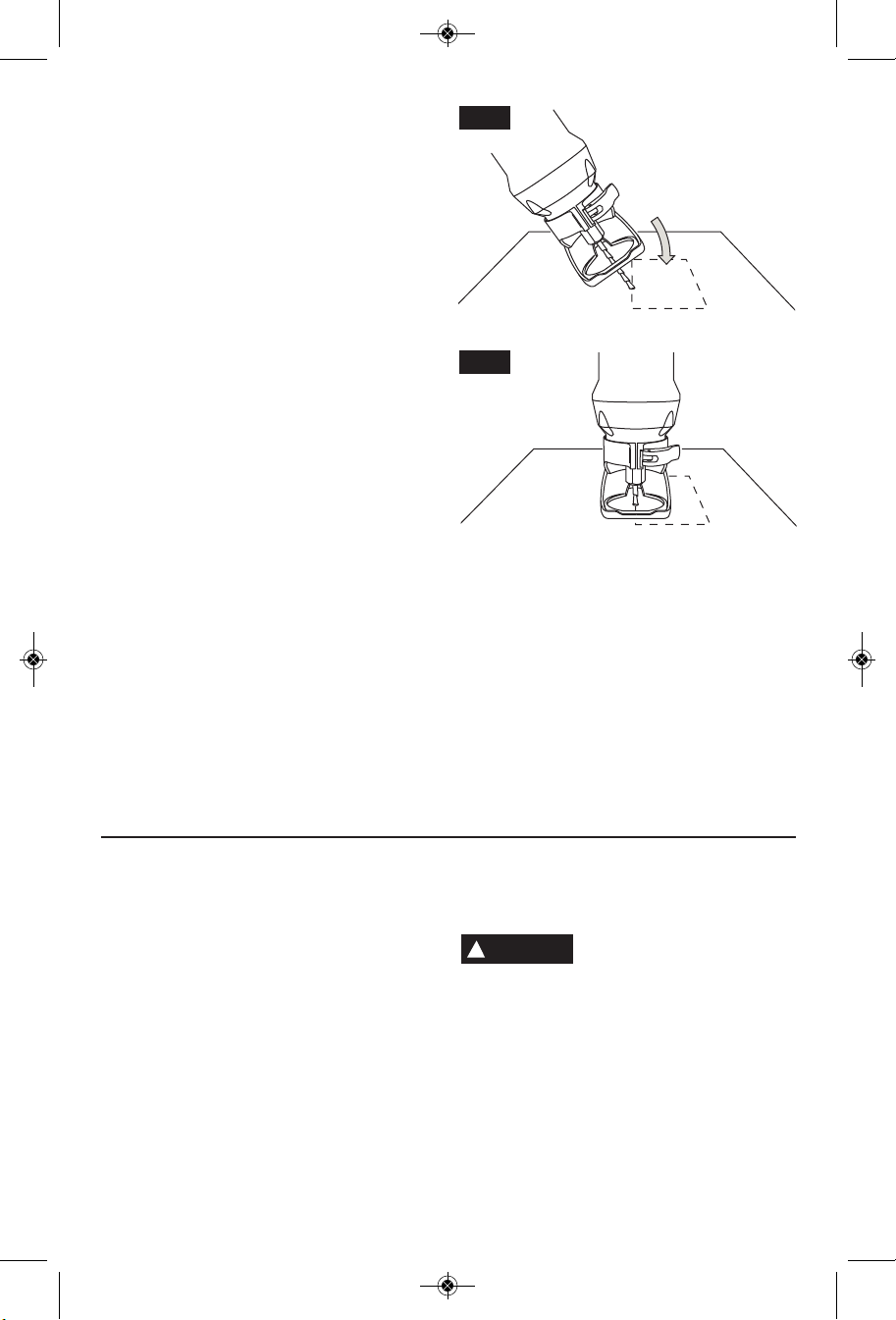

Step 3: While holding the tool firmly, insert the

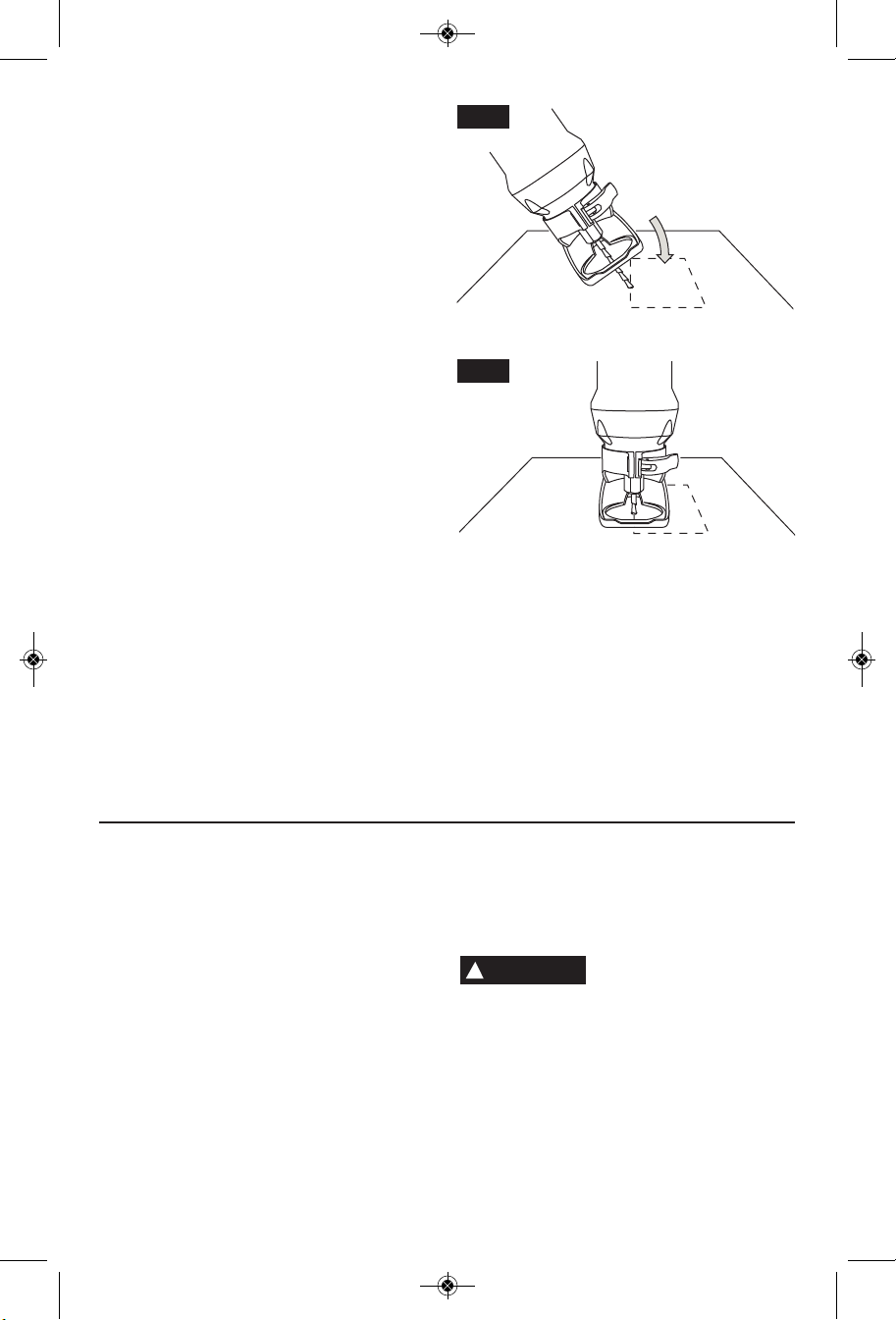

bit into the material at a 45° angle (Fig. 9).

Step 4: Slowly bring it to a 90° angle to begin

the cut (Fig. 10). The base guide should be

flush to the material surface. For all materials

(EXCE PT c utting around outle t boxes in

drywall), steer the tool in a clockwise direction

with slow, steady pressure to make the cut.

Step 5: After completing your cut, turn off the

tool and carefully remove it from the material.

Do not attempt to use this tool to make cutouts

around any fixture or opening which has live

electrical wires, or any wall which may have

live electrical wiring behind it, as the bit could

co nd uct cu rr en t to the tool , creati ng an

electrocution hazard for the operator. Shut off

breakers or remove fuses to disconnect the

ci rc ui t. A lw ay s h old the tool by its

thermoplastic housing, and always wear eye

protection when operating a Spiral Saw power

tool.

NOTE: Because of the rotating cutting action

of the bit, there will be a slight pull when

FIG. 9

FIG. 10

cutting. The slower you cut, the more control

you have. Excessive pressure or fast cutting

will cause excessive heat and may shorten

the life of the bit.

NOTE: When cutting on a vertical surface,

avoid ending your cut at the bottom of the

hole. If possible, start and end your cut at the

top so the scrap part will not drop onto the

rotating bit. Turn the tool off and remove it

from the material.

INSTRUCTIONS FOR CREATING CUT-OUTS IN DRyWALL

FOR OUTLETS, CAN LIGHTS, WINDOWS, AND DOORS

After assembling the bit into the tool as

described earlier, it will be necessary to review

the instructions provided below and make some

practice cut-outs with this tool before attempting

an actual job. The best method is to take some

scrap pieces and nail or screw them in place

over wall studs which have an electrical box or

other feature in place. A few such exercises will

give you the necessary practice to make clean,

professional cutouts around whatever is behind

the drywall you are installing.

!

WARNING

around any fixture or opening which has

live electrical wires, or on any wall which

may have live electrical wiring behind it, as

the bit could conduct current to the tool,

creating an electrocution hazard for the

operator. Shut off breakers or remove fuses to

disconnect the circuit. Always hold the tool by

its thermoplastic housing, and always wear

eye protection when operating this device.

Do not attempt to use this

to ol to ma ke cut-outs

-13-

3

4

5

6

7

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 14

Step 1: Be certain that the box or fixture is

firmly mount ed an d a ll wi re s o r oth er

obstructions around the opening are pushed

back out of the way. The bit uses the outer

edge of the box or fixture as a guide, so it is

important that there is nothing in the way

which can prevent it from guiding completely

around the opening. For the purposes of this

instruction manual, the procedure discussed

will be to make a cut-out around a standard 2

1/8" x 3 3/4" electrical box.

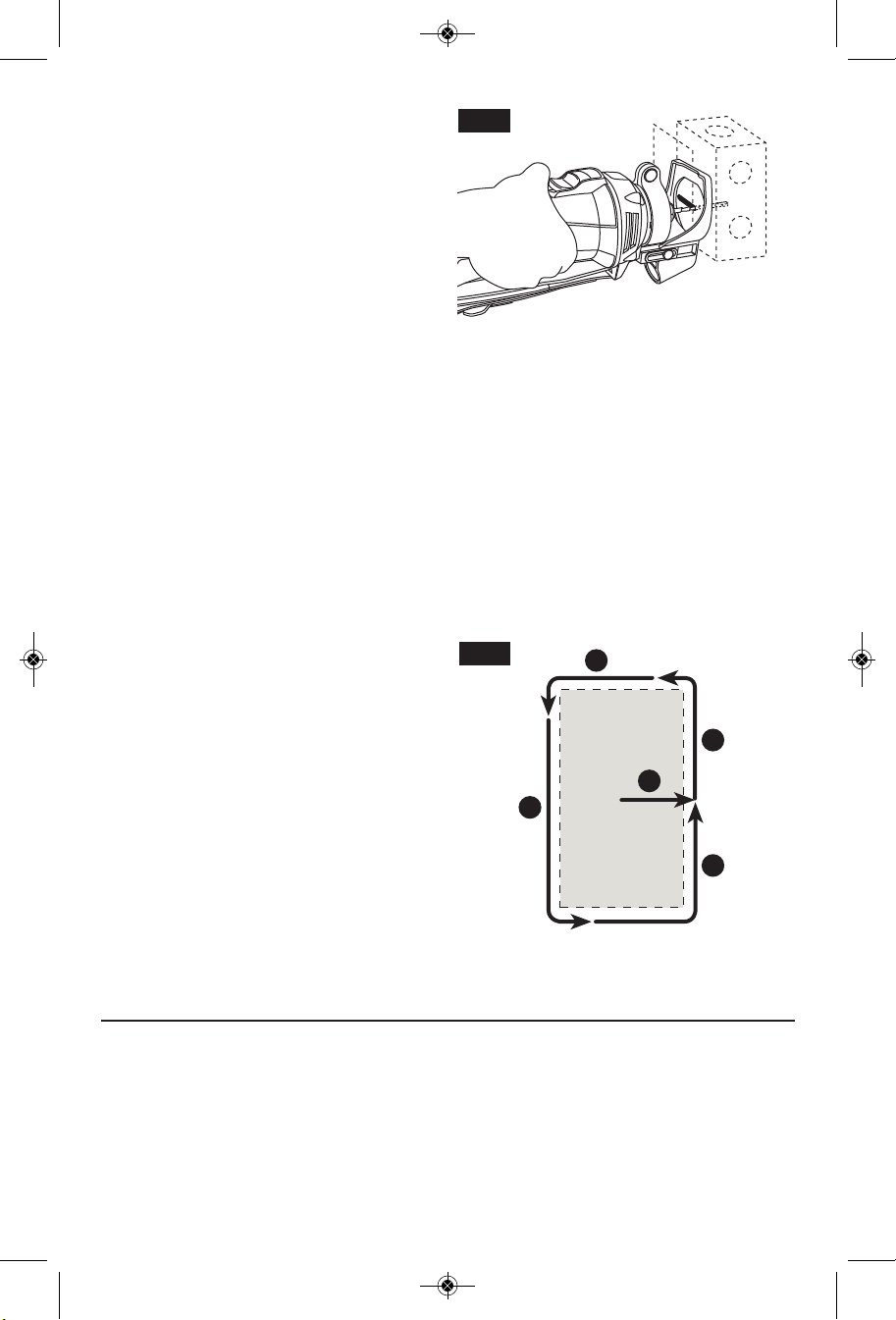

Step 2: Slide switch to turn the tool on. While

holding the Sp ria l Saw® firmly with b oth

hands, plunge the bit through the mark you

made. Then guide the bit to the right until you

feel and hear the bit touch the inside edge of

the box (Fig. 11).

Step 3: Pull the bit out far enough to slip it

over the edge of the box so it is now against

the outside of the box (Fig. 12).

Step 4: While keeping the bit in contact with

the outside of the box move the tool counter

clockwise while applying light inward and

upward pressure until you feel and hear it

come to the corner. As you round the corner

apply light pressure left and downward (Fig. 12).

Step 5: While moving slowly and continuously

along the top contour you will feel the bit come

to the next corner. Round the corner and

apply light down and inward pressure until the

bottom corner is reached (Fig. 12).

St ep 6: Mov e the bit ri gh t and upwar d

maintaining light continuous pressure toward

the box (Fig. 12).

Step 7: Round the right bottom corner and

begin moving the bit upward while applying

light pressure left toward the box until you

meet initial upward cut. Push Sprial Saw®

switch to off (Fig. 11).

Step 8: The completed box, executed quickly,

neatly, and in a fraction of the time taken by

other methods.

FIG. 11

NOTE: These step-by-step instructions are

generalized to acquaint you with the Sprial

Saw’s® operation. After some practice, you

may develop a technique with which you are

more comfortable. However, you must always

begin the cut somewhat centrally, and MOVE

TH E Spri al Saw® O NL Y COUN TE RCL OC KW IS E to take advantage of the

“hugging” action of the bit along the contours

of the template. Remember to use a smooth,

continuous motion. The exception to this rule

applies to cutting window and door openings.

Since you are tracing around the inside of the

framing members, move the bit clockwise to

take advantage of the bits “hugging” action.

FIG. 12

USING THE VACUUM PORT

Your Spiral Saw® is designed to work with

the Rotozip model DM5 Dust Management

Kit. Visit your local Rotozip retailer or call

1-877-ROTOZIP (1-877-768-6947) for more

information.

-14-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 15

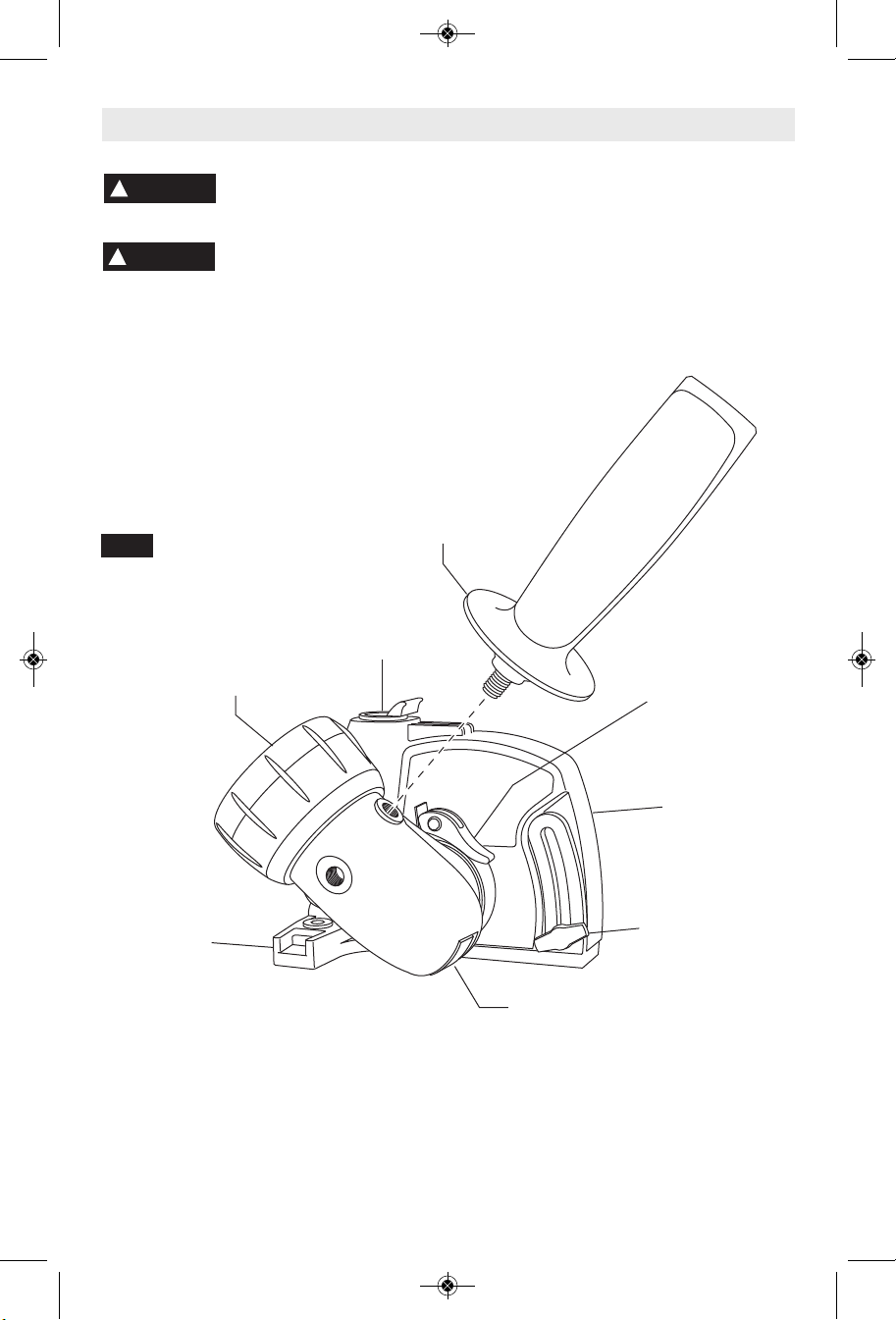

Functional Description and Specifications

WARNING

!

sufficient control of the cutting wheel in case of recoil.

WARNING

!

measures reduce the risk of starting the tool accidentally.

Zipmate attachment must be used only with an hard auxiliary control

side handle. Two handed control of solid gripping handles will provide

Di sc onnect t he plug fro m the pow er source bef or e making an y

assembly, adjustments or changing accessories. Such preventive safety

Zipmate®Abrasive Cut Off

Attachment

AUXILIARY CONTROL

FIG. 1

LOCKING

COLLAR

SIDE HANDLE

GUARD

PLUG

WHEEL GUARD

LOCK LEVER

FOOT

SHAFT-LOCK

NOT INCLUDED WITH ALL KITS

Note : The speed of your tool will be reduced 2.11 : 1 when using

your Abrasive Cut-Off attachment.

-15-

WHEEL

GUARD

DEPTH

ADJUSTMENT

THUMB

SCREW

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 16

Assembly

WARNING

!

making any assembly, adjustments or

changing accessories. Such preventive safety

measures reduce the risk of starting the tool

accidentally.

WARNING

!

hose is not connected. Wheel bursting may

eject wheel fragments towards user if guard

plug is not attached.

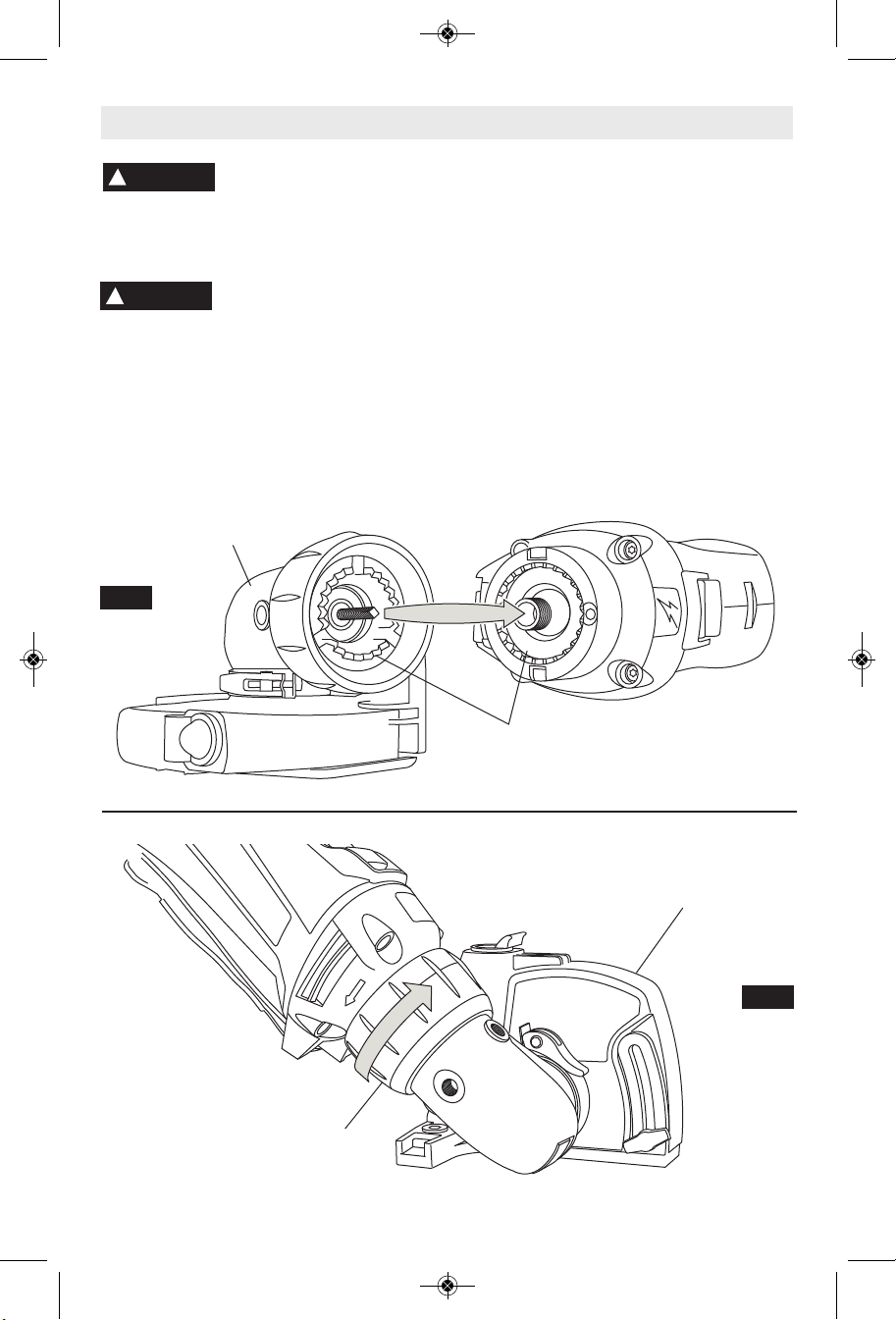

REMOVING AND INSTALLING

ABRASIVE CUT OFF ATTACHMENT

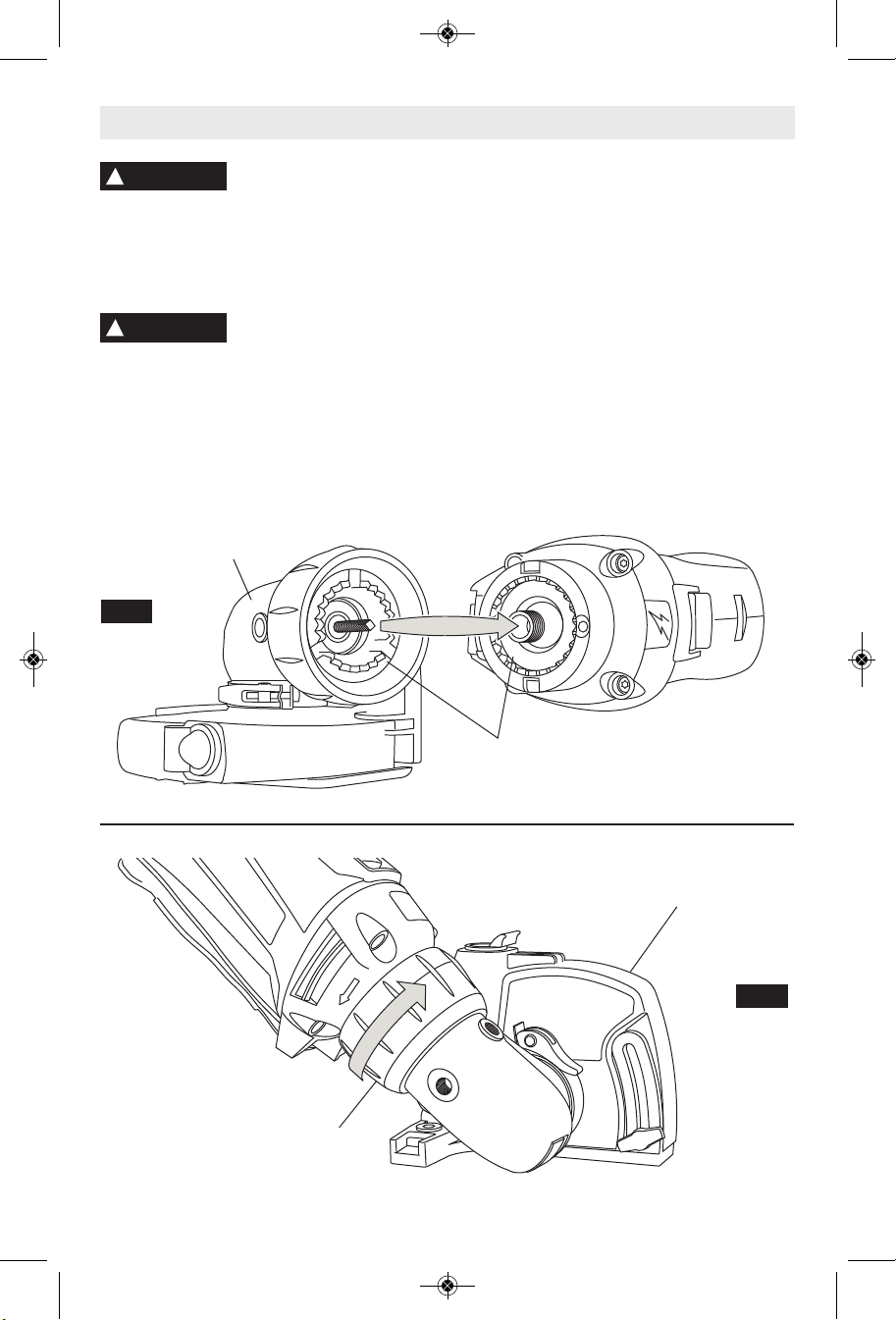

1. Depress and hold the shaft-lock in and

rotate the collet nut and shaft until the shaft

lock engages and holds the shaft.

Disconnect the plug from

the power source before

Guard plug should always

be attached when vacuum

ATTACHMENT

FIG. 2

2. Remove the collet nut by rotating it counter-

clockwise. Remove the collet from the tool

shaft.

3. Position the attachment onto the threaded

Rotozip Connect™ interface. Note: It may be

necessary to rotate attachment slightly to

engage square end of the right angle drive into

tool shaft (figure 2).

4. Position attachment in desired orientation

an d ro ta te th e lo ck ing c ol lar u nt il th e

attachment is secure. The locking collar has

been tightened sufficiently when the Zipmate

body can no longer move relative to the Spiral

Saw® (figure 3).

LOCKING

COLLAR

ROTOZIP

CONNECT™ INTERFACE

ATTACHMENT

FIG. 3

-16-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 17

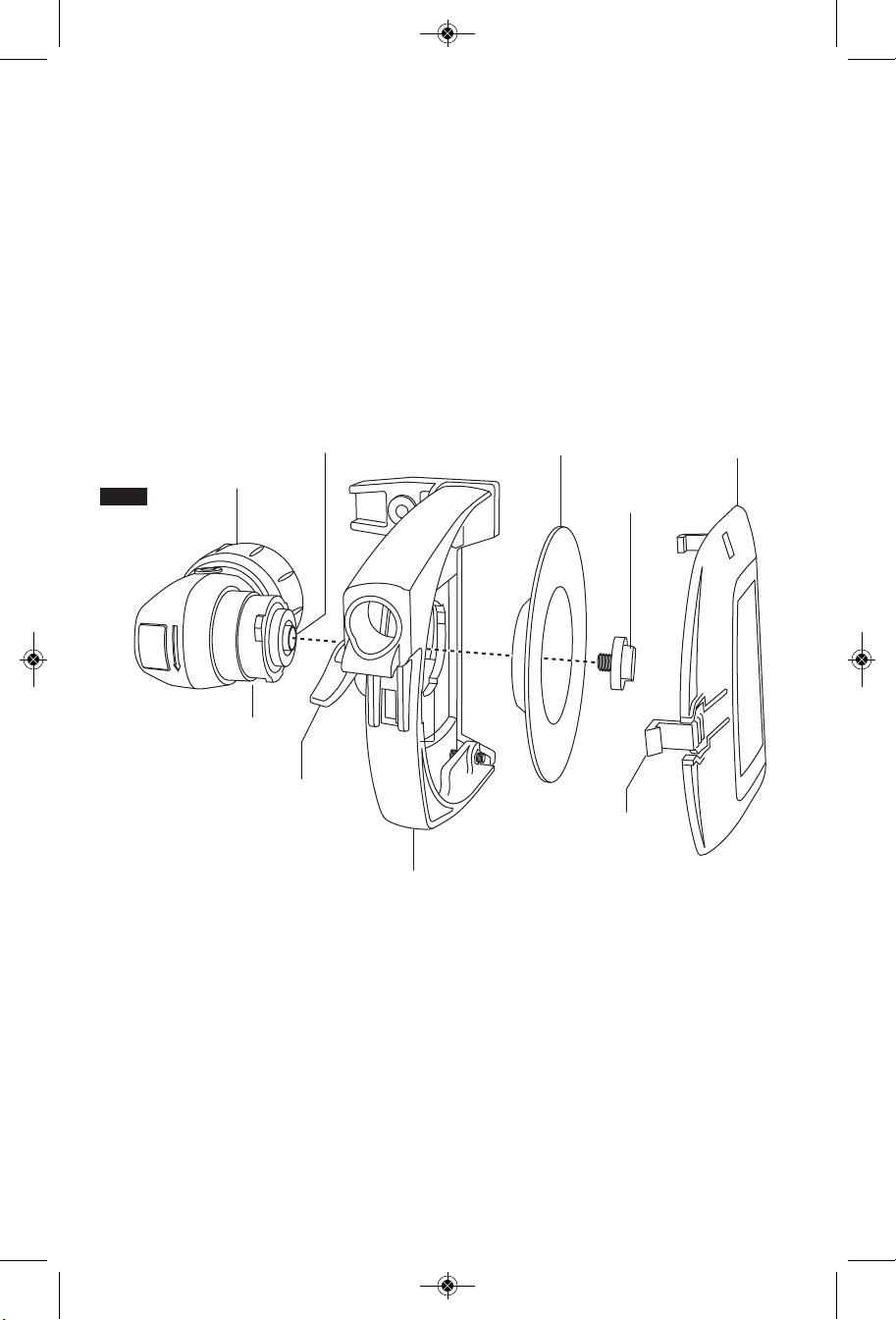

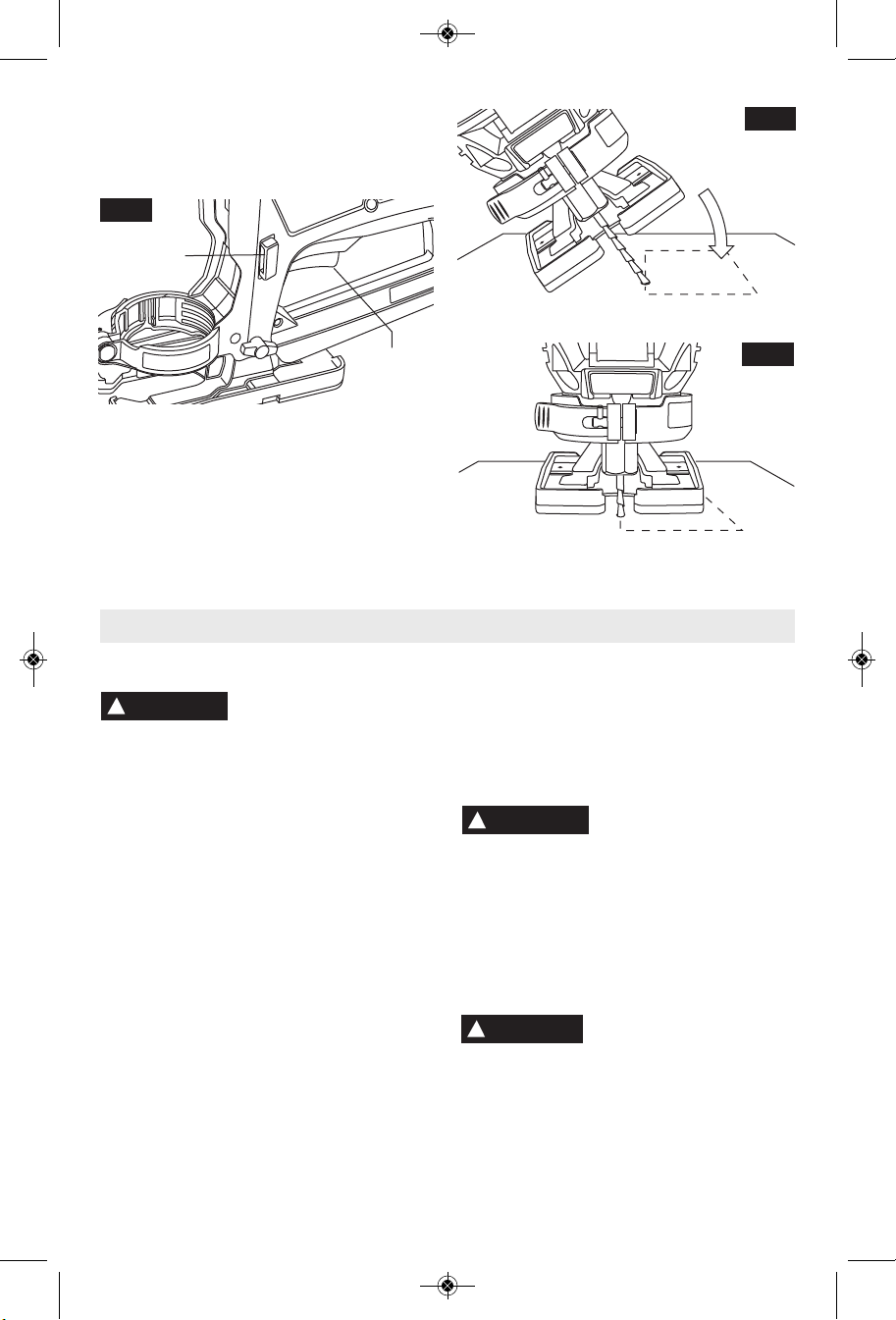

INSTALLING X-WHEEL and Zip®

ABRASIVE WHEELS

1. Dep ress the cover relea se b utton and

remove the X-SHIELD cover.

2. Install abrasive wheel onto output shaft.

3. Thread arbor nut provided onto output shaft

finger tight, depress shaft lock and tighten

wheel with the wrench provided (Fig. 2).

4. Attach X-SHIELD cover . Make su re XSHIELD cover is properly snapped onto the

X-SHIELD guard.

OUTPUT

ZIPMATE™

ATACHMENT

FIG. 4

COLLAR

SHAFT

5. Keep guard covering between wheel and

user.

6. Make sure the wheel guard lock lever is in

the closed position and the XSHIELD guard

is secure ly mo un ted t o the Zipm at e

attachment. Use the allen wrench to adjust

the wheel guard adjustment screw.

7. Adjust the foot of the X-SHIELD abrasive cut

off attachment to the desired depth of cut by

loosening and tightening the wing knob.

8. Maximum cutting depth is 3/4".

X-SHIELD

ABRASIVE

WHEEL

ARBOR

NUT

COVER

WHEEL

GUARD

LOCK

LEVER

COVER

RELEASE

BUTTON

X-SHIELD™

GUARD

-17-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 18

Operating Instructions

1. Make sure material being cut is secured in

a vise or fixture before attempting to cut.

2. Keep your body positioned to either side of

the wheel, but not in line with wheel. It is

important to support the tool properly and to

position your body such as to minimize body

exposure from possible wheel binding and

recoil.

3. Grip the tool with both hands when cutting

and always be ready and able to manage the

cut.

4. Avoid jamming, twisting or pinching the

wh ee l wi th the work pi ec e or otherwise

applying excessive side pressure to the wheel.

5. Keep guard covering between wheel and

user.

6. Make sure the guard lock lever is in the

closed position and the guard is securely

mounted to the attachment. Use the allen

wrench to adjust the guard adjustment screw.

7. Maximum cutting depth is 3/4”.

CAUTION

!

permanently damage the locking mechanism.

Test the tightness of the lever after each full

turn of the adjustment screw.

WARNING

!

ensure that the inner or outer flanges never

contacts the workpiece surface.

MAKING A CUT

Ov ertightening the g uard

adjustm en t screw ca n

To pr event re co il an d

damage to the tool, always

8. Generally, the harder the material being

worked on, the faster the wheel will wear.

9. When cutting thicker material, never make

the cut in one pass. Make successive passes

until you reach desired depth.

ATTENTION: If you run the tool continuously

for more than 5 minutes, it is normal for the

housing to feel warm.

It is important to read and understand the

section in this manual called “Causes and

Operator Prevention of Recoil”.

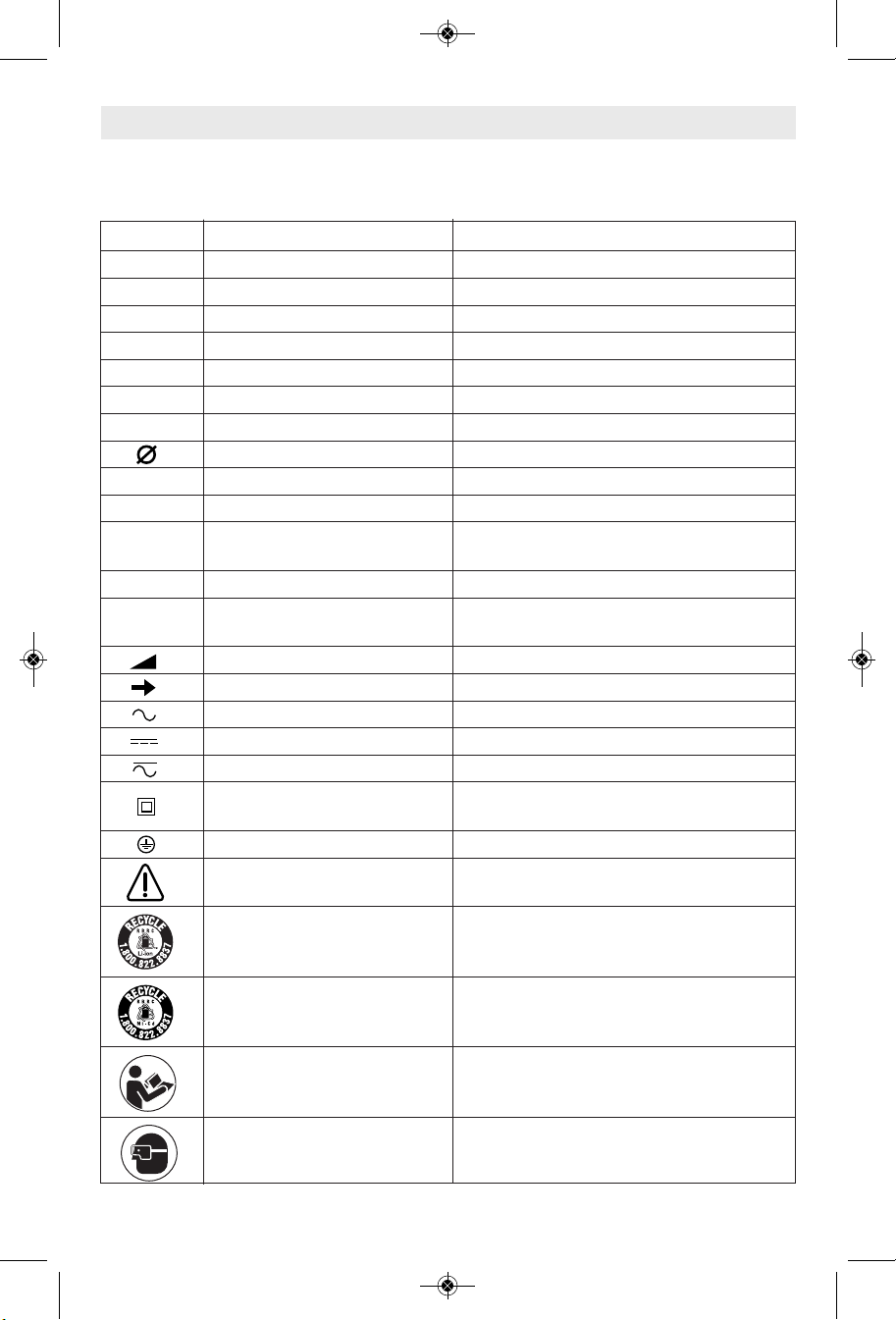

When making a cut in sheet metal, masonry,

etc.: You may start your cut at the end of the

piece or you can plunge cut somewhere in

the body of the material.

In order to try to avoid recoil (a situation where

the wheel wants to skip out of the material) it

is recommended to make cuts in the same

direction as the rotation of the wheel (Fig. 5).

USING THE VACUUM PORT

Your Zipmate® Abrasive Cut Off Attachment

is designed to work with the Rotozip model

DM5 Dust Management Kit. Visit your local

Ro to zip reta il er or cal l 1-877-RO TO ZIP

(1-877-768-6947) for more information.

FIG. 5

FOOT

DIRECTION OF

CUT

WHEEL DIRECTION

-18-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 19

Functional Description and Specifications

WARNING

!

measures reduce the risk of starting the tool accidentally.

Di sc onnect the plug fro m the pow er source bef ore maki ng any

assembly, adjustments or changing accessories. Such preventive safety

Jigsaw Handle

FIG. 1

NOT INCLUDED WITH ALL KITS

UPPER LOCK

LOCKING

PIN

LOCK OUT

LEVER

LEVER

HANDLE

LOWER LOCK

LEVER

VACUUM

PORT

TRIGGER

DEPTH ADJUSTMENT

THUMB SCREW

BASE PLATE

-19-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:16 AM Page 20

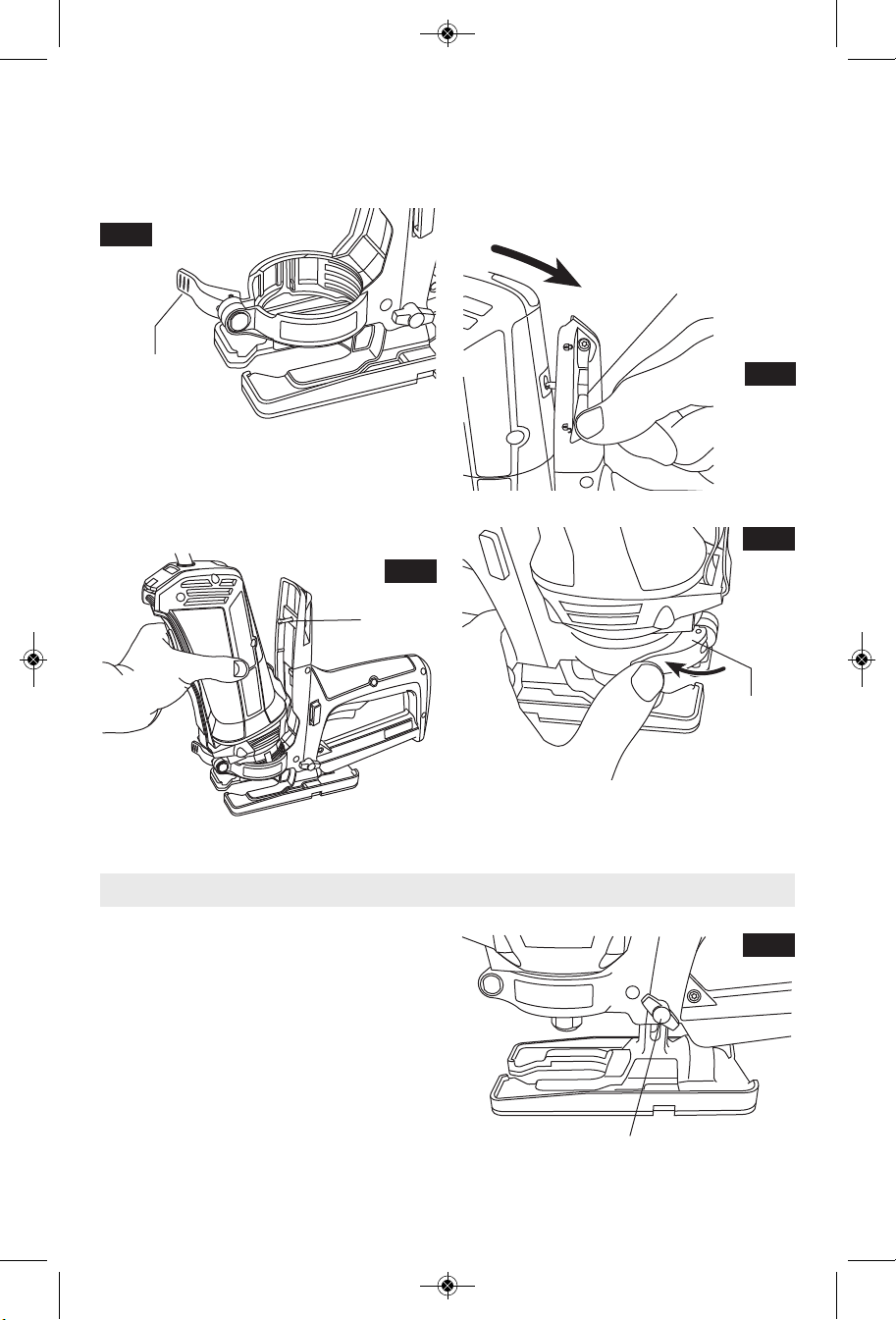

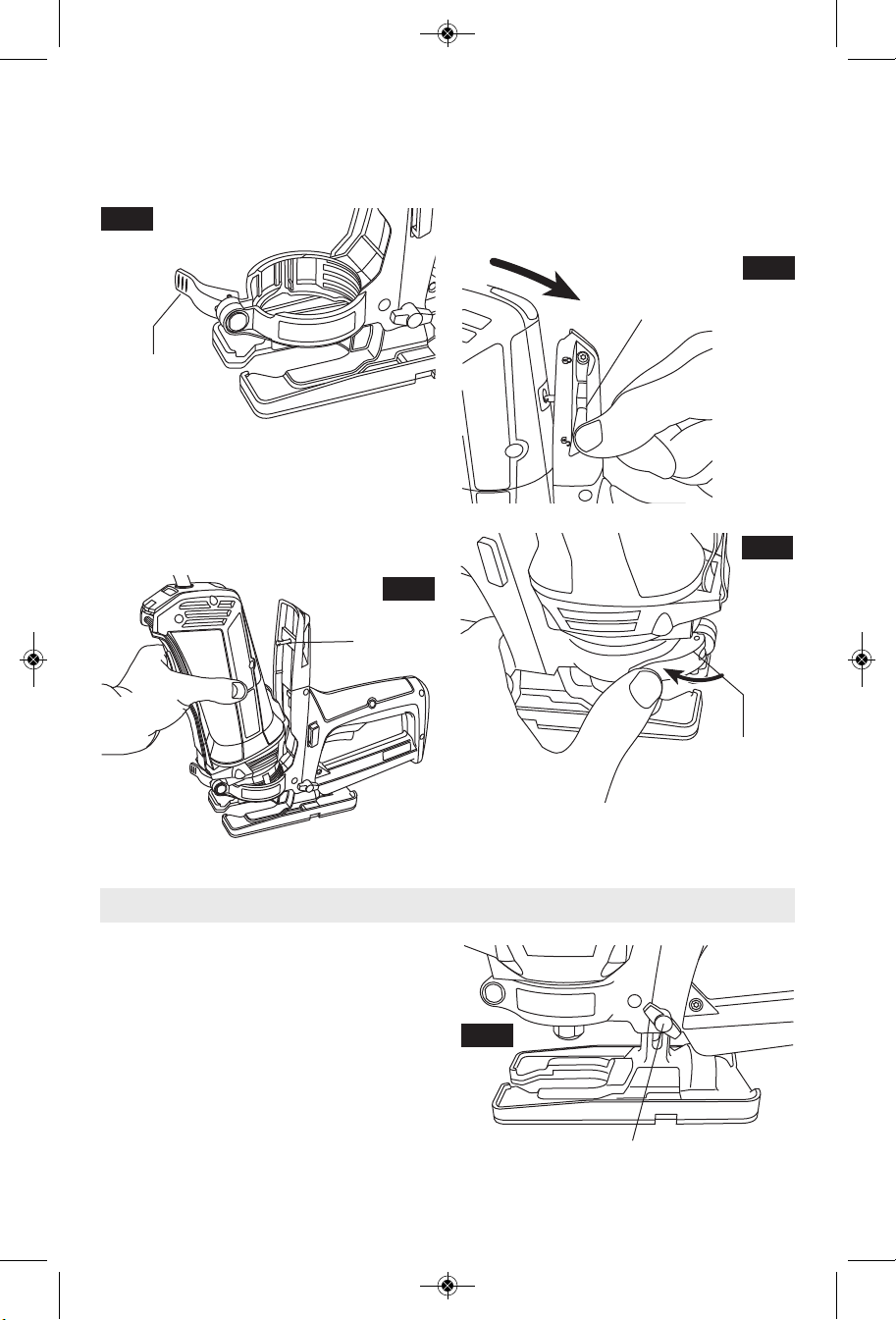

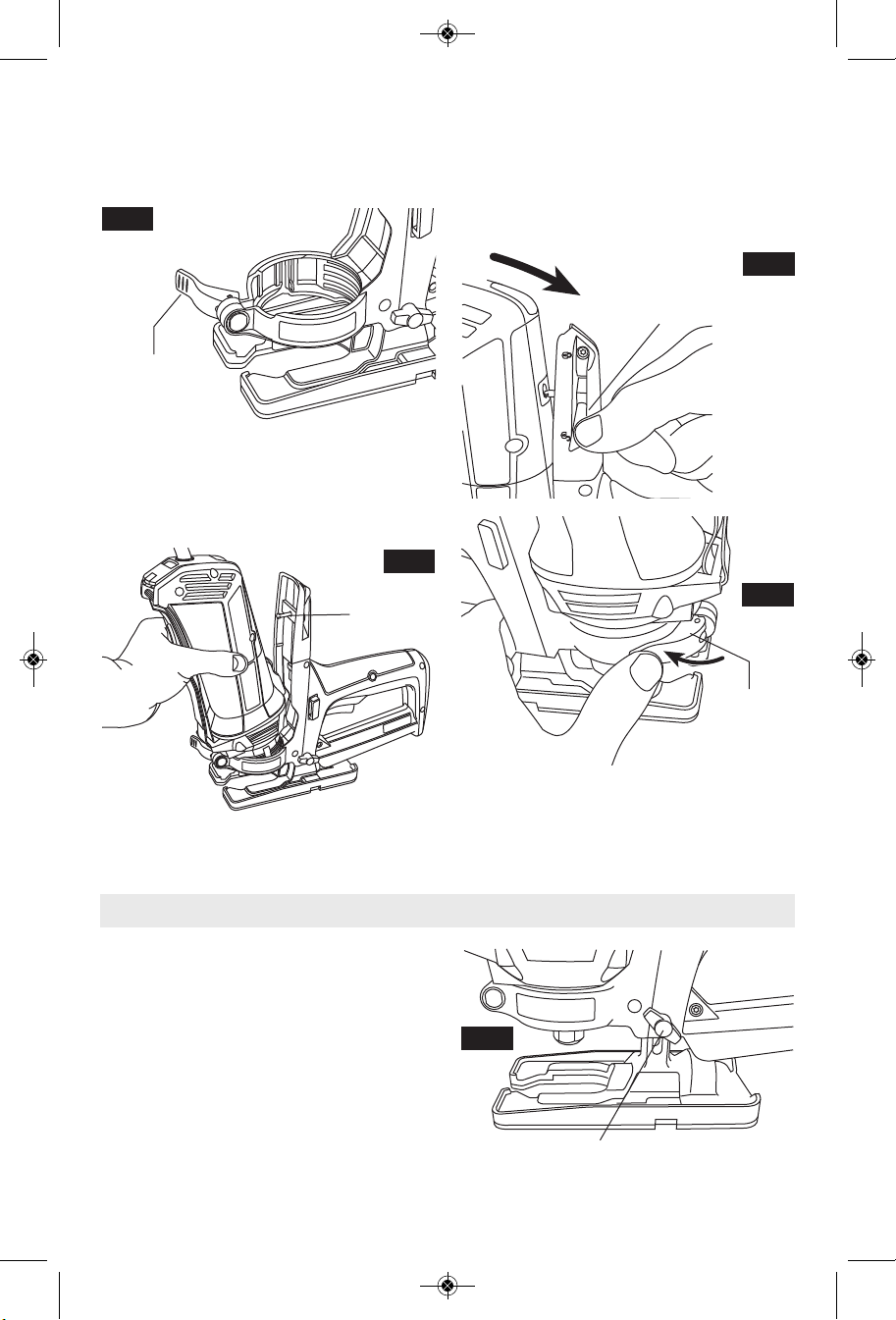

INSTALLING AND REMOVING THE

JIGSAW HANDLE ATTACHMENT

1. Remove depth guide from the tool.

2. Open the lock lever near the base of the

attachment (figure 2.)

FIG. 2

LOWER

LOCK LEVER

3. Insert your Spiral Saw® with the switch

toward the attachment as shown in (figure 3.)

Pr ess down firmly and squee ze the too l

toward the atta chment, m aking sur e th e

lo ck in g p in en ga ge s t he correspond in g

keyway on the Spiral Saw®.

FIG. 3

LOCKING

PIN

4. Rotate t he up pe r l oc k l ever to the

“UNLOCK” position and squeeze the tool

toward the attachment. With the Spiral Saw®

po sitio ned ti ght ag ainst the attachm ent,

release the upper lock lever. Make sure both

the lower and upper lock levers are in their

“LOCK” positions (figures 4 & 5.)

UPPER LOCK

LEVER

FIG. 4

FIG. 5

Operating Instructions

DEPTH ADJUSTMENT

Loosen the depth adjustment thumb screw

(counter-clockwise) to change the depth of

cut. Slide the base plate to the desired depth

of c ut and re-tigh te n th e th um b sc re w

(clockwise) (figure 6.)

LOWER

LOCK

LEVER

To remove the jigsaw handle attachment,

reverse steps 2, 3, and 4.

FIG. 6

DEPTH ADJUSTMENT

THUMB SCREW

-20-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 21

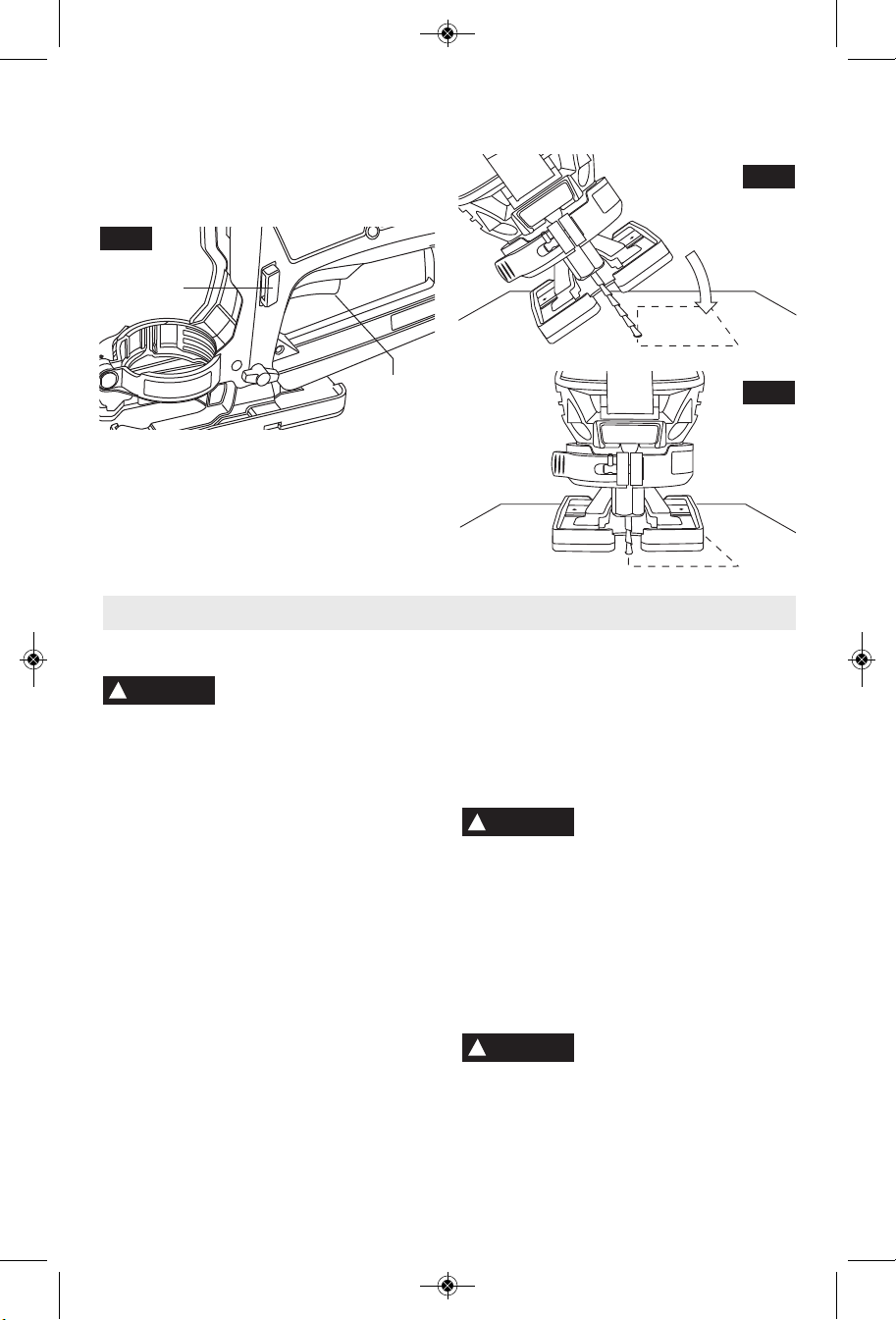

1. You r j igsaw h andle a ttachme nt is

equipped with a trigger switch. Slide the lockout lever (figure 7) to either side with your

thumb, then squeeze the trigger.

MAKING A CUT

FIG. 7

LOCK OUT

LEVER

TRIGGER

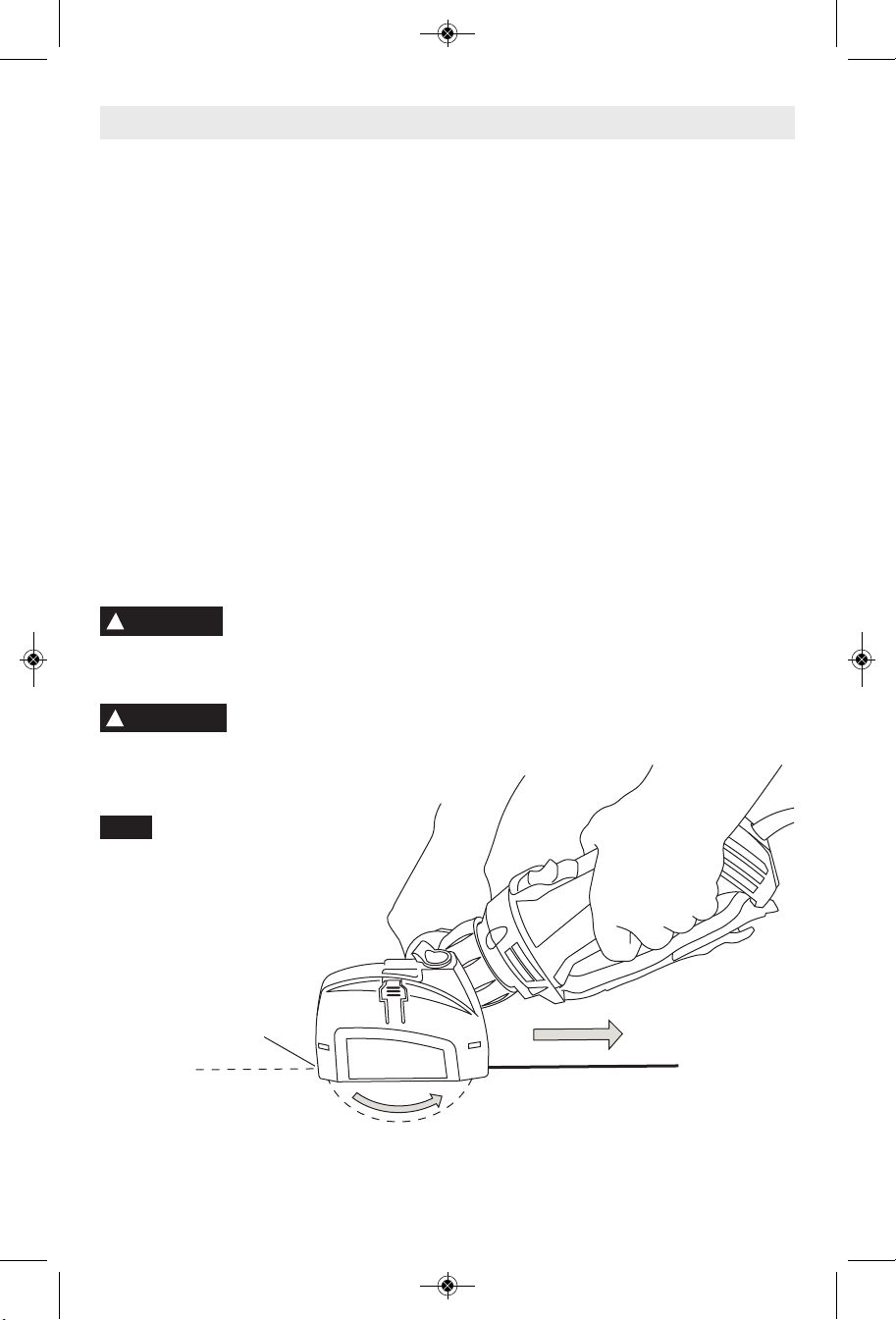

2. While holding the tool firmly, insert the bit

into the material at a 45° angle (figure 8).

3. Slowly bring it to a 90° angle to begin the

cut. The base plate should be flush to the

material surface (figure 9).

Maintenance

Service

!

WARNING

per so n nel may result in misplacing of

inter nal wires and c omponent s wh ich

co uld cau se serious hazard. We

recommend that all tool service be performed

by a Bosch or Rotozip Factory Service Center

or Authorized Bosch Service Station. Call 1877-ROTOZIP (1-877-768-6947) if your tool

needs service.

Your Rotozip tool has been properly lubricated

and is ready to use. The lubrication applied at

the factory lasts for the life of the tool.

The brushes and commutator in your tool have

be en engine er ed for ma ny hours of

de pendable s ervice. To maint ain peak

efficiency of the motor, we recommend every

two to six months the brush es be examined.

Only genuine Rotozip replace ment brushes

specially designed for your tool should be

used.

Your Rotozip tool and attachments contain

sealed bearings designed to last the life of the

Pr eventiv e main tenance

performed by unauthorized

TOOL LUBRICATION

CARBON BRUSHES

BEARINGS

4. Release the trigger to de-activate your tool

after the cut.

tool. Bearings which become noisy (due to

heavy load or very abrasive material cutting)

sh ould be in spected at once to a void

overheating or motor failure. Contact your local

Bosch or Rotozip Factory Service Center if

your bearings become noisy.

Cleaning

!

WARNING

th e power supp ly be fo re cl eaning or

performing any main tenance. The tool may

be cleaned most effectively with compressed

dry air. Always wear safety gog gles when

cleaning tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

at tempt to clean by inserting pointed objects

through openings.

!

CAUTION

plastic parts. Some of these are: gasoline,

carbon tetrachlo ride, chlo rinated cleaning

solvents, ammonia and house hold detergents

that contain ammonia.

-21-

To avoid accidents always

dis connect the tool from

Ce rtain clean ing agents

an d sol ve nts da mage

FIG. 8

FIG. 9

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 22

Extension Cords

!

WARNING

If an exten si on cord is

necessa ry , a cord wi th

adequate size conductors that is capable

of carrying the current necessary for your

tool mu st be us ed . Thi s wil l preve nt

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3wire extension cords that have 3-prong plugs

and receptacles.

NOTE: The smaller the gauge number, the

heav i er the cord.

Accessories & Attachments

WARNING

!

packaging or the attachment itself.

Your Rotozip Spiral Saw® is compatible with any Rotozip attachment bearing

the Rotozip Connect™ icon. This icon can be located on the attachment

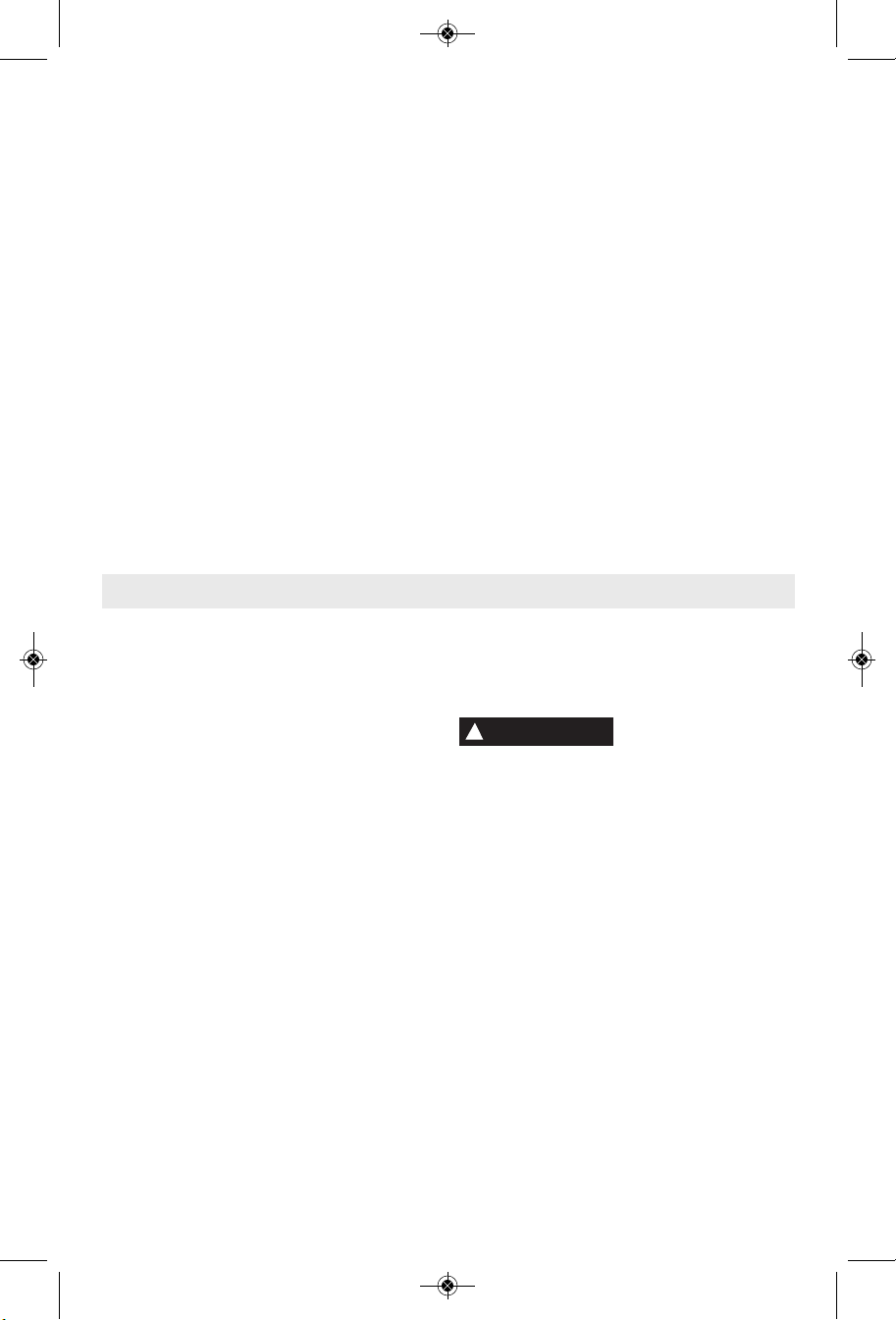

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

3-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G.

Cord Length in Feet Cord Length in Meters

25 50 100 150 15 30 60 120

18 16 16 14 0.75 0.75 1.5 2.5

18 16 14 12 0.75 1.0 2.5 4.0

18 16 14 12 0.75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 —— ————

Wire Sizes in mm

2

WARNING

!

Do not use metal cutting bits, router bits, or non-approved accessories

with this product unless a control handle, such as the Jigsaw Handle

Attachment, is attached.

ROTOZIP CONNECT™ Attachments include the following: (Items may be sold separately)

ZM5 ZIPMATE® Abrasive Cut Off Attachment

XSHIELD2™ Flush Cut Guard Attachment

JSH5 Jigsaw Handle Attachment

DM5 Dust Management Kit

CRCT4 Circle Cutting Attachment

-22-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 23

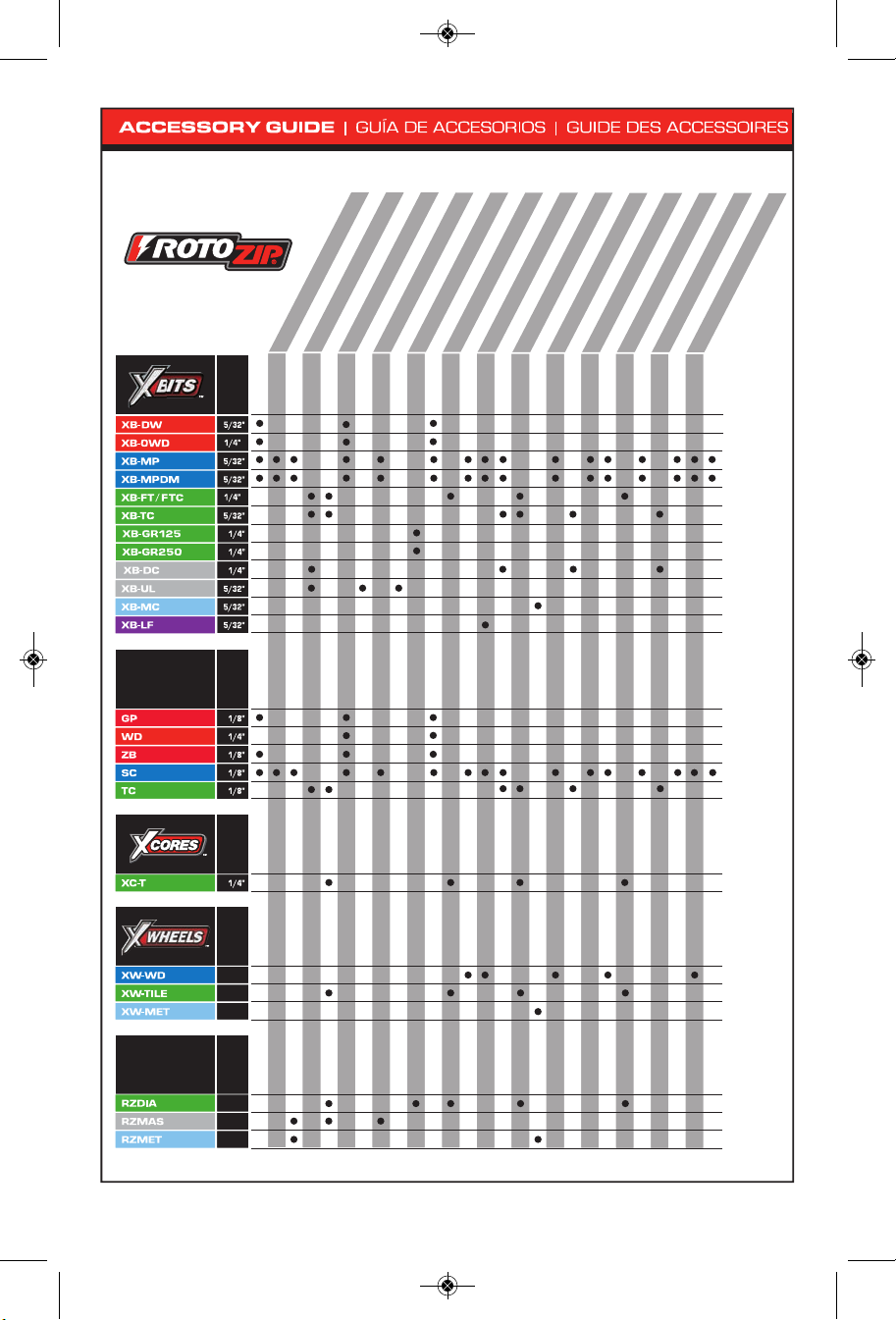

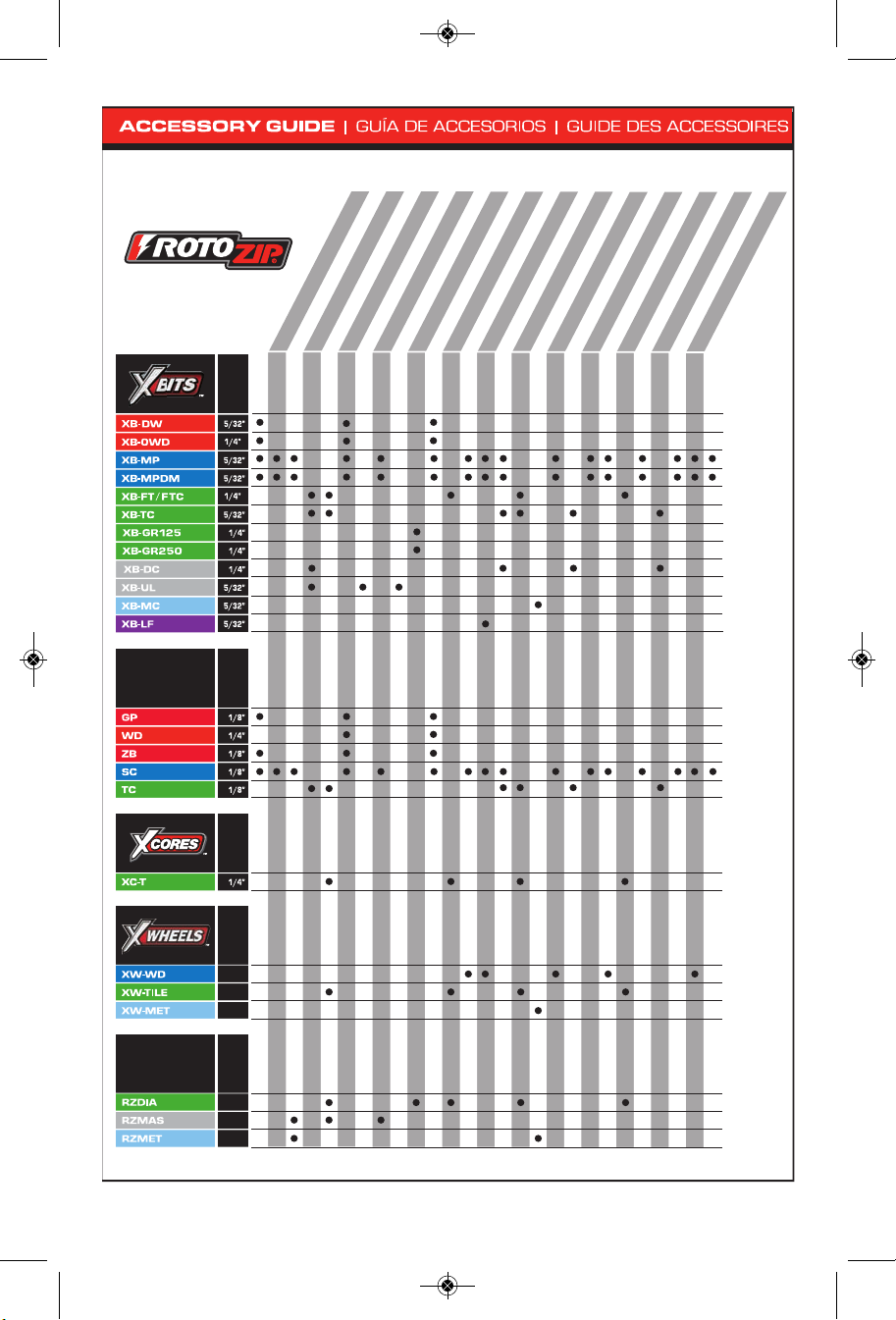

Your Spiral Saw® will work with all Rotozip

bits, including Zip® Bits and XBITS®, and

XCORES™. It is also compatible with all

Zip® Wheels and XWHEELS™.

Zip® Bits

Rotozip's patented line of versatile Zip® Bits

and a cc es sories provi de yo u wit h the

flexibility to quickly move from one material to

another and one job to another, without the

hassle of changing tools.

Sabrecut™ Multipurpose Zip® Bit (SC)

Standard Point Drywall Zip® Bit (ZB)

Guidepoint™ Drywall Zip® Bit (GP)

Window and Door Zip® Bit (WD)

Wall Tile Zip® Bit (TC)

XBITS®

X-BITS ar e d es igned for serious

professionals. They offer superior strength

and speed to cut through even the toughest

materials in seconds-flat.

Drywall XBITS® (XB-DW, XB-OWD)

Multipurpose XBITS® (XB-MP)

Multipurpose Dust Management XBITS®

(XB-MPDM)

Floor Tile XBITS® (XB-FT)

Floor Tile and Countertop XBITS® (XB-FTC)

Wall Tile XBITS® (XB-TC)

Grout Removal XBITS® (XB-GR)

Underlayment XBITS® (XB-UL)

Duracut™ Plaster XBITS® (XB-DC)

Laminate Flooring XBITS® (XB-LF)

Metal XBITS® (XB-MC)

The new line of RotoZip® tile hole saws, the

XCORES™

XC ORES™ , was des igned for im proved

performance and durability. The XCORES

operate at a higher speed, with a vacuumbrazed diamo nd core that can withstand

more heat, and are designed to work dry.

This yields a hole saw that works 10x faster

and lasts 4x longer than traditional tile hole

saws.

3/4" XCORES™ (XC-T750)

1" XCORES™ (XC-T1000)

1-3/8" XCORES™ (XC-T1375)

Zip® Wheels

Zip® Wheel s allow for easy cut-offs in a

variety of materials - up to 9/16” depth of cut.

Designe d sp ecifi ca ll y fo r use with th e

Zipmate® attachment, Zip® Wheels allow

you to make cuts in tight spaces.

Metal Zip® Wheel (RZMET)

Masonry Zip® Wheel (RZMAS)

Diamond Zip® Wheel (RZDIA)

XWHEELS™

The unique shape of these wheels allow for

flush, smooth cuts every time. XWHEELS™

provide controlled cuts when you need it and

in just about any material.

Metal XWHEELS™ (XW-MET)

Wood XWHEELS™ (XW-WD)

Tile XWHEELS™ (XW-TILE)

-23-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 24

-24-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 25

Avertissements généraux concernant la sécurité des outils électroportatifs

!

AVERTISSEMENT

choc électrique, d'incendie et/ou de blessures corporelles graves.

Veuillez lire tous les avertissements et toutes les consignes de sécurité. Si l'on

n'observe pas ces avertissements et ces consignes de sécurité, il existe un risque de

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES

DE SÉCURITÉ POUR RÉFÉRENCE FUTURE.

Dans les avertissements, le terme « outil électroportatif » se rapporte à votre outil branché sur le secteur (avec fil) ou

à votre outil alimenté par piles (sans fil).

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien éclairé.

Les risques d’accident sont plus élevés quand on

travaille dans un endroit encombré ou sombre.

N’utilisez pas d’outils électroportatifs dans des

atmosphères explosives, comme par exemple en

présence de gaz, de poussières ou de liquides

inflammables. Les outils électroportatifs produisent

des étincelles qui risquent d’enflammer les poussières

ou les vapeurs.

Éloignez les enfants et les visiteurs quand vous vous

servez d’un outil électroportatif. Vous risquez une

perte de contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs doivent

correspondre à la prise. Il ne faut absolument jamais

modifier la fiche. N’utilisez pas d’adaptateur de prise

avec des outils électroportatifs munis d’une fiche de

terre. Le risque de choc électrique est moindre si on

utilise une fiche non modifiée sur une prise qui lui

correspond.

Évitez tout contact du corps avec des surfaces reliées

à la terre tels que tuyaux, radiateurs, gazinières ou

réfrigérateurs. Le risque de choc électrique augmente

si votre corps est relié à la terre.

N’exposez pas les outils électroportatifs à la pluie ou

à l’humidité. Si de l’eau pénètre dans un outil

électroportatif, le risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en servez

jamais pour transporter l’outil électroportatif, pour le

tirer ou pour le débrancher. Éloignez le cordon de la

chaleur, des huiles, des arêtes coupantes ou des

pièces mobiles. Les cordons abîmés ou emmêlés

augmentent les risques de choc électrique.

Si vous utilisez un outil électroportatif à l’extérieur,

employez une rallonge conçue pour l’extérieur. Ces

rallonges sont faites pour l’extérieur et réduisent le

risque de choc électrique.

S'il est absolument nécessaire d'utiliser l'outil

électroportatif dans un endroit humide, utilisez une

alimentation protégée par un disjoncteur de fuite de

terre (GFCI). L'utilisation d'un disjoncteur GFCI réduit

les risques de choc électrique.

Restez concentré, faites attention à ce que vous

faites, et servez-vous de votre bon sens lorsque vous

utilisez un outil électroportatif. N'employez pas

d’outils électroportatifs quand vous êtes fatigué ou

sous l’emprise de drogues, d’alcool ou de

médicaments. Quand on utilise des outils

électroportatifs, il suffit d’un moment d’inattention pour

causer des blessures corporelles graves.

Utilisez des équipements de sécurité personnelle.

Portez toujours une protection oculaire. Le port

d'équipements de sécurité tels que des masques

antipoussières, des chaussures de sécurité

antidérapantes, des casques de chantier et des

protecteurs d'oreilles dans des conditions appropriées

réduira le risque de blessure corporelle.

Évitez les démarrages intempestifs. Assurez-vous que

l'interrupteur est dans la position arrêt (Off) avant de

brancher l'outil dans une prise de courant et/ou un

bloc-piles, de le ramasser ou de le transporter. Le

transport d'un outil électroportatif avec le doigt sur la

gâchette ou le branchement de cet outil quand

l'interrupteur est en position de marche (ON) est une

invite aux accidents.

Enlevez toutes les clés de réglage avant de mettre

l’outil électroportatif en marche. Si on laisse une clé

sur une pièce tournante de l’outil électroportatif, il y a

risque de blessure corporelle.

Ne vous penchez pas. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de

mieux maîtriser l’outil électroportatif dans des situations

inattendues.

Habillez-vous de manière appropriée. Ne portez pas

de vêtements amples ou de bijoux. Attachez les

cheveux longs. N’approchez pas les cheveux, les

vêtements ou les gants des pièces en mouvement.

Les vêtements amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en mouvement.

Si l’outil est muni de dispositifs permettant le

raccordement d’un système d’aspiration et de

collecte des poussières, assurez-vous que ces

dispositifs sont raccordés et utilisés correctement.

L'utilisation d'un dépoussiéreur peut réduire les

dangers associés à l'accumulation de poussière.

Sécurité personnelle

-25-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 26

Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez l’outil

électroportatif qui convient à la tâche à effectuer.

L’outil qui convient à la tâche fait un meilleur travail et

est plus sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si son

interrupteur ne parvient pas à le mettre en marche ou

à l’arrêter. Tout outil électroportatif qui ne peut pas

être commandé par son interrupteur est dangereux et

doit être réparé.

Débranchez la fiche de la prise ou enlevez le bloc-pile

de l’outil électroportatif avant tout réglage,

changement d’accessoires ou avant de ranger l’outil

électroportatif. De telles mesures de sécurité

préventive réduisent le risque de démarrage intempestif

de l’outil électroportatif.

Rangez les outils électroportatifs dont vous ne vous

servez pas hors de portée des enfants et ne permettez

pas à des personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces consignes de s’en

servir. Les outils électroportatifs sont dangereux dans

les mains d’utilisateurs inexpérimentés.

Consignes de sécurité pour Spiral Saw™

Tenez l'outil par les surfaces isolées de prise en

exécutant une opération lorsque l'outil de coupe peut

venir en contact avec des fils cachés ou son propre

cordon. Le contact avec un fil sous tension rendra les

parties métalliques exposées de l'outil sous tension et

causera des secousses électriques à l'opérateur. Pour

couper dans des murs existants ou autres endroits

aveugles pouvant dissimuler des fils électriques,

débranchez tous les fusibles ou les disjoncteurs

alimentant ce lieu de travail.

Assurez-vous toujours que la surface de travail est

exempte de clous et autres objets étrangers.La coupe

dans un clou peut faire sauter l’embout et l'outil, et ainsi

abîmer l’embout.

Ne tenez jamais le matériau d'une main et l'outil de

l'autre lorsque vous en faites usage. Ne placez jamais

les mains sous la surface de coupe ou à proximité de

celle-ci. Il est plus sûr de cramponner le matériau et de

guider l'outil des deux mains.

Ne posez jamais le matériau sur des surfaces dures

telles que le béton, la pierre, etc. L’embout de coupe

en saillie peut faire sauter l'outil.

Portez toujours des lunettes de sécurité et un masque

anti-poussières. N'utilisez l'outil qu'à un endroit bien

aéré. L'utilisation de dispositifs de sécurité personnelle

et le travail dans un environnement sûr réduisent les

risques de blessures.

Entretenez les outils électroportatifs. Vérifiez que les

pièces mobiles sont alignées correctement et ne

coincent pas. Vérifiez qu’il n’y a pas de pièces

cassées ou d’autre circonstance qui risquent

d’affecter le fonctionnement de l’outil électroportatif.

Si l’outil est abîmé, faites-le réparer avant de

l’utiliser. De nombreux accidents sont causés par des

outils électroportatifs mal entretenus.

Maintenez les outils coupants affûtés et propres. Les

outils coupants entretenus correctement et dotés de

bords tranchants affûtés sont moins susceptibles de

coincer et sont plus faciles à maîtriser.

Utilisez l'outil électroportatif, les accessoires et les

embouts d'outil, etc. conformément à ces instructions,

en tenant compte des conditions de travail et des

travaux à réaliser. L'emploi d’outils électroportatifs

pour des tâches différentes de celles pour lesquelles ils

ont été prévus peut résulter en une situation dangereuse.

Entretien

Faites réparer votre outil électroportatif par un agent

de service qualifié n’utilisant que des pièces de

rechange identiques. Ceci assure que la sécurité de

l’outil électroportatif est préservée.

Après avoir changé les embouts ou effectué quelque

réglage que ce soit, assurez-vous que l'écrou de la

douille et tout autre dispositif de réglage sont bien

serrés. Un dispositif de réglage lâche peut bouger

soudainement et causer ainsi une perte de contrôle avec

projection violente des composants en rotation.

Ne mettez jamais l'outil en marche alors que

l’embout est enfoncée dans le matériau.Le tranchant

de l’embout peut se coincer dans le matériau et vous

faire perdre le contrôle du couteau.

Tenez toujours l'outil des deux mains durant la mise

en marche. Le couple de réaction du moteur peut faire

tordre l'outil.

Lors du toupillage ou du découpage, le sens de

déplacement du tranchant de l’embout qui pénètre

COMMENCEZ

ICI

PIÈCE

EMBOUT

SENS DE

L’AVANCE

-26-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 27

dans le matériau est important. Il faut toujours

pousser l’embout dans le matériau dans le même

sens que celui du bord tranchant qui quitte le

matériau. Avec l’outil vu du dessus, l’embout tourne en

sens horaire. Si l’outil se trouve entre vous et la pièce,

poussez-le vers la droite. Si par contre la pièce se

trouve entre vous et l’outil, poussez alors ce dernier

vers la gauche. Si vous poussez l’outil dans le mauvais

sens, le bord tranchant de l’embout risque de grimper

hors de la pièce et de tirer l’outil dans la direction de

l’avance.

N'utilisez jamais d’embouts émoussés ou abîmés.

Les embouts affilés doivent être maniés

soigneusement. Les embouts abîmés peuvent se

rompre brusquement durant l'usage. Les embouts

émoussés nécessitent plus de force pour pousser

l'outil, causant éventuellement un bris de l’embout.

Avertissements supplémentaires concernant la sécurité

L’emploi d’un GFCI et de dispositifs de protection

personnelle tels que gants et chaussures d’électricien en

caoutchouc améliorent votre sécurité personnelle.

N’utilisez pas un outil conçu uniquement pour le C.A.

sur une alimentation en C.C. Même si l’outil semble

fonctionner, les composants électriques d’un outil prévu

pour le C.A. tomberont probablement en panne et

risquent de créer un danger pour l’utilisateur.

Maintenez les poignées sèches et exemptes d’huile et

de graisse. On ne pas maîtriser un outil électroportatif

en toute sécurité quand on a les mains glissantes.

Utilisez des brides ou d’autres moyens pratiques de

brider ou de supporter la pièce sur une plate-forme

stable. Tenir la pièce à la main ou contre le corps est

instable et risque de résulter en une perte de contrôle.

Créez un agenda d’entretien périodique pour votre

outil. Quand vous nettoyez un outil, faites attention de

n’en démonter aucune pièce car il est toujours

possible de mal remonter ou de pincer les fils

internes ou de remonter incorrectement les ressorts

de rappel des capots de protection. Certains agents de

nettoyage tels que l’essence, le tétrachlorure de

carbone, l’ammoniaque, etc. risquent d’abîmer les

plastiques.

Ne touchez jamais l’embout durant ou

immédiatement après l'usage. Après usage, l’embout

est trop chaud pour être touché à main nue.

Ne posez jamais l'outil avant que le moteur ne se soit

arrêté complètement. L’embout en rotation peut saisir

la surface et vous faire perdre le contrôle de l'outil.

N’utilisez jamais des embouts dont le diamètre de

coupe est supérieur à celui de l’ouverture pratiquée

dans la base.

N'utilisez pas l'outil pour percer. Cet outil n'est pas

destiné à être utilisé avec des mèches de perceuse.

Utilisez toujours l'outil avec le guide de profondeur

fixé solidement et placé à plat contre le matériau à

couper. Le guide positionné solidement sur le matériau

améliore la stabilité et le contrôle de votre outil.

Risque de blessure pour l'utilisateur. Le cordon

d'alimentation électrique ne doit être réparé que par un

Centre de service usine de Rotozip ou par une Station

service agréée de Rotozip .

!

AVERTISSEMENT

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière

conçus spécialement pour filtrer les particules

microscopiques.

Les travaux à la machine

tel que ponçage, sciage,

-27-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 28

Consignes de sécurité pour l’accessoire de

tronçonnage à meule Zipmate

Utilisez toujours le capot de meule ainsi que la

poignée auxiliaire de Zipmate’s avec cet outil à

tronçonner à meule. Le protecteur doit toujours être

fixé solidement à l'outil et positionné en vue d'une

sécurité maximale de manière à exposer le moins

possible de meule sur le côté opérateur de l'outil. Un

protecteur protège l'opérateur contre les fragments brisé

de meule. Les nervures de support et la poignée

auxiliaire améliorent la protection, la stabilité et la

maîtrise de l’outil lors des travaux de tronçonnage. Le

corps de votre outil Rotozip peut aussi servir de poignée.

Assurez-vous toujours que le capot de meule et la

poignée auxiliaire ont été remontés et fermement

fixés sur Zipmate’s quand vous changez de sens de

rotation pour passer de l’éjection avant à l’éjection

arrière ou après que vous ayez changé la meule. Un

outil qui manque un composant de sécurité essentiel est

dangereux à utiliser.

Portez des vêtements appropriés lors de l'utilisation

d'un outil à tronçonner à meule. Un écran facial ou, à

tout le moins, des lunettes de sécurité, un masque

antipoussières, des gants en cuir et un tablier d'atelier

pouvant arrêter les petits fragments de meule ou

d'ouvrage.

Cet accessoire n’est pas prévu pour être utilisé avec

des meules diamants à eau. L'utilisation d'eau ou

d'autres agents liquides de refroidissement avec cet outil

peut provoquer une électrocution ou des chocs.

L'utilisation de meules à diamant par voie sèche est

acceptable.

Utilisez uniquement des meules de tronçonnage de

type 1 avec le trou d'arbre de la dimension correcte.

N'utilisez jamais des brides de meule abîmées ou

incorrectes ou un écrou rond.Les autres types de meule

ne sont pas destinés à appliquer la charge sur la

périphérie et peuvent voler en éclats. Les meules avec

trous d'arbre qui ne correspondent pas aux ferrures de

montage de l'outil fonctionneront de manière

excentrique, vibreront excessivement et causeront une

perte de contrôle.

Ne rectifiez pas sur le côté des meules de tronçonnage

de type 1.Les forces latérales appliquées sur ces meules

peuvent les faire voler en éclats.

N'utilisez pas cet accessoire avec une lame à sculpter

le bois ou avec des lames à dents standard prévues

pour scier du bois. Ces lames ne sont pas destinées à

cet outil et peuvent provoquer une perte de contrôle en

cours d'utilisation.

La vitesse maximale de fonctionnement sûr des

meules de tronçonnage doit être supérieure à la

vitesse à vide marquée sur la plaque signalétique de

l'outil. Les meules qui fonctionnent à une vitesse

supérieure à la vitesse prévue peuvent voler en éclats et

causer des blessures.

Avant chaque usage, inspectez la meule de

tronçonnage pour y relever tout éclat et fissure.

N'utilisez pas une meule qui peut être abîmée. Posez

une nouvelle meule si l'outil est tombé. Lors de la

pose de la nouvelle meule, maniez soigneusement les

meules de tronçonnage individuelles en vue d'éviter

les éclats ou les fissures. Faites fonctionner l'outil à

vide pendant une minute, en tenant l'outil en sens

opposé aux personnes présentes. Les meules

présentant des défaillances voleront normalement en

éclats durant cette période. Les fragments d'une meule

qui éclate durant le fonctionnement seront projetés à

grande vitesse et pourraient vous frapper ou frapper des

personnes présentes.

N'utilisez pas une meule de tronçonnage de

dimensions supérieures aux dimensions maximales

recommandées pour votre outil, ni des meules

abîmées et usées provenant d’outils à tronçonner à

meule de dimensions supérieures. Les meules

destinées aux outils plus gros ne conviennent pas à la

vitesse supérieure d'un outil plus petit ; ces meules

peuvent facilement éclater et les fragments peuvent vous

frapper ou frapper les personnes présentes.

Placez le cordon à l'écart de la meule en rotation.

N'enroulez pas le cordon autour de votre bras ou de

votre poignet. Si vous perdez le contrôle et que le

cordon est enroulé autour de votre bras ou poignet, il

peut vous emprisonner et vous blesser.

Gardez votre corps placé d'un côté ou de l'autre de la

meule, mais non dans le prolongement de celle-ci.Il

est important de supporter l'outil adéquatement et de

positionner votre corps de manière à minimiser

l'exposition de votre corps à un éventuel grippage de la

meule et au rebond de l'outil.

Tenez les mains à l'écart de l'aire de coupe et de la

meule. Conservez votre seconde main sur la poignée

auxiliaire. Tenez l’outil fermement afin de prévenir

une perte de contrôle. Ne placez JAMAIS votre main

derrière la meule étant donné que l’outil peut rebondir

par-dessus votre main. Ne tentez pas de retirer le

matériau coupé lorsque la meule se déplace. Si les

deux mains tiennent l’outil, elles ne peuvent être coupées

par la meule.

Ne coincez pas la meule dans l'ouvrage, n'exercez pas

une pression excessive et ne tentez pas une coupe très

profonde en utilisant cet outil. Laissez la meule en

rotation faire l'ouvrage. Les outils à tronçonner à meule

sont destinés à « couper » le matériau en une série de

coupes peu profondes. Reportez-vous aux instructions

concernant la profondeur de coupe plus loin dans ce

manuel.

-28-

RZ 2610011540 04-10:RZ 2610011540 04-10 4/7/10 8:17 AM Page 29

Évitez de faire rebondir et d'accrocher la meule,

surtout lorsque vous travaillez des coins, des arêtes

vives, etc. Ceci peut causer une perte de contrôle et un

rebond de l’outil

Ne faites pas fonctionner l’outil tout en le portant à

votre côté. Un contact accidentel avec la meule en

rotation peut causer des lésions graves.

Ne posez jamais l'outil avant que le moteur ne se soit

arrêté complètement.La meule en rotation peut saisir la

surface et vous faire perdre le contrôle de l'outil.

N'utilisez pas le Zipmate à proximité de matières

inflammables. Les étincelles provenant de la meule

pourrait allumer ces matériaux.

Il ne faut jamais couper ou tenter de couper du

magnésium avec cet accessoire.La poussière produite

durant la coupe de magnésium est très inflammable et

peut être explosive dans certaines conditions.

Nettoyez régulièrement les prises d'air de l'outil à

l'aide d'air comprimé. L'accumulation excessive de

métal en poudre à l'intérieur du carter du moteur peut

causer des défaillances électriques.

Causes du rebond et façons dont

l'opérateur peut le prévenir :

Le rebond est une réaction soudaine à une meule en

rotation pincée, grippée ou mal alignée. La meule peut se

bloquer et faire sortir un outil non contrôlé hors du trait

de scie en direction de l'opérateur lorsque l’outil est en

position de « marche avant » ; si l’outil est mis en

position de « marche arrière », l’outil peut avoir tendance

à s'éloigner de l'opérateur. On peut se servir de la flèche

du sens de marche située au dos du capot pour identifier

les postions d’éjection des fragments vers l’avant ou

vers l’arrière. L’accessoire est dans la position d’éjection

vers l’avant quand la flèche du sens de marche est

dirigée vers l’utilisateur et dans la position d’éjection vers

l’arrière quand la flèche est dirigée à l’opposé de

l’utilisateur.

Si une meule abrasive ou une meule à diamant devient

tordue ou mal alignée dans la coupe, le côté de la meule

qui entre dans le matériau peut creuser dans la surface

supérieure du matériau, ce qui fait remonter ou rebondir

la meule hors du trait de scie soit en direction de

l'opérateur ou en sens opposé à celui-ci, suivant

l'orientation de marche avant ou de marche arrière.

Les meules abrasives peuvent également éclater dans

ces conditions, l'opérateur et les personnes présentes

pouvant être frappés ou empalés par les morceaux ou les

fragments. Le rebond ou les meules éclatées résultent

d'une mauvaise utilisation de l'outil et/ou de conditions

ou de modes de fonctionnement incorrects et peuvent

être évités en prenant les précautions appropriées

comme indiqué ci-après :

Maintenez une prise ferme des deux mains sur les

poignées de l’outil et positionnez votre corps et votre

bras de manière à vous permettre de résister aux

forces de rebond. Les forces de rebond peuvent être

contrôlées par l'opérateur, si des précautions

appropriées sont prises.

Si la meule se coince ou si vous interrompez une

coupe, quelle qu’en soit la raison, enlevez doucement

la meule de la pièce tout en tenant l’outil et la poignée

auxiliaire fermement à deux mains. Faites enquête et

prenez des mesures correctives pour éliminer la cause

du grippage de la meule.

Lorsqu'un outil est remis en marche dans un ouvrage,

centrez la meule dans le trait de scie et assurez-vous

que les côtés de la meule ne sont pas engagés dans

l'ouvrage. Si la meule grippe, elle peut remonter ou

rebondir hors de l'ouvrage lorsque l’outil est remis en

marche.

Supportez les grands panneaux afin de minimiser le

risque de pincement de meule et de rebond. Les

grands panneaux ont tendance à s'affaisser sous leur

propre poids. Des supports doivent être placés sous le

panneau des deux côtés, près de la ligne de coupe et

près du bord du panneau.

Redoublez de prudence en effectuant une « coupe en

poche » dans des murs existants ou autres endroits

aveugles. La meule en saillie peut couper les objets qui

peuvent causer un rebond.

Consignes de sécurité pour l’accessoire de poignée de scie à chantourner

!

AVERTISSEMENT

coupe supérieur à 1/4 po quand vous utilisez

l’accessoire de poignée de scie à chantourner

!

AVERTISSEMENT

toupiller quelconque avec l’accessoire de poignée de

scie à chantourner, vous devez serrer l’écrou de douille

à l’aide de la clé fournie. Le serrage à la main n’est pas

suffisant pour les fers à toupiller.

N’employez pas de fer à

toupiller d’un diamètre de

Si vous utilisez un embout à

queue de 1/4 po ou un fer à

!