REV01

Owner’s Manual

Guide de l’utilisateur

Manual del ususario

Roto Zip Tool Corporation

1861 Ludden Drive, Cross Plains, Wisconsin 53528 • Phone 608-798-3737

TOLL-FREE 1-877- Rotozip (1-877-768-6947) U.S. & CANADA

FAX: 608-798-3739 WEB SITE: www.rotozip.com

Customer Service Hours: 8:00am - 4:30pm (CST)

IMPORTANT: Read Before Using

IMPORTANT : À lire avant d’utiliser

IMPORTANTE: Lea este manual antes de usar su herramienta

Parlez-vous francais? Voir page 17 ¿Habla español? Ver página 32

-3-

Read and understand all instructions. Failure to follow all instructions listed

below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

-2-

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or

fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with a

polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to

install a polarized outlet. Do not change the

plug in any way. Double Insulation

eliminates the need for the three wire

grounded power cord and grounded power

supply system. Before plugging in the tool, be

certain the outlet voltage supplied is within 10%

of the voltage marked on the nameplate. Do

not use “AC only” rated tools with a DC power

supply.

Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool.

Electrician’s rubber gloves and footwear will

further enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

When operating a power tool outside, use an

outdoor extension cord marked "W-A" or

"W." These cords are rated for outdoor use

and reduce the risk of electric shock. Refer to

Recommended sizes of Extension Cords

section of this manual.

Personal Safety

Stay alert, watch what you are doing and use

common sense when operating a power

tool. Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long hair can

be caught in moving parts. Keep handles dry,

clean and free from oil and grease.

Avoid accidental starting. Be sure switch is

“OFF” before plugging in. Carrying tools with

your finger on the switch or plugging in tools

that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches before

turning the tool “ON”. A wrench or a key that

is left attached to a rotating part of the tool may

result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

Tool Use and Care

Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

!

WARNING

General Tool Safety Rules

Store idle tools out of reach of children and

other untrained persons. Tools are dangerous

in the hands of untrained users.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools

with sharp cutting edges are less likely to bind

and are easier to control.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop a

periodic maintenance schedule for your tool.

Use only accessories that are recommended

by the manufacturer for your model.

Accessories that may be suitable for one tool,

may become hazardous when used on another

tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual. Use

of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning agents

such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

Spiral SawTMPower Tool Safety Rules

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or its

own cord. Contact with a "live" wire will make

exposed metal parts of the tool "live" and shock

the operator. If cutting into existing walls or

other blind areas where electrical wiring may

exist is unavoidable, disconnect all fuses or

circuit breakers feeding this worksite.

Always make sure the work surface is free

from nails and other foreign objects. Cutting

into a nail can cause the bit and the tool to jump

and damage the bit.

Never hold the workpiece in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the material and guiding the

tool with both hands is safer.

Never lay workpiece on top of hard surfaces,

like concrete, stone, etc... Protruding cutting

bit may cause tool to jump.

Always wear safety goggles and dust mask.

Use only in well ventilated area. Using

personal safety devices and working in safe

environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely

tightened. Loose adjustment device can

unexpectedly shift, causing loss of control, loose

rotating components will be violently thrown.

Never start the tool when the bit is engaged

in the material. The bit cutting edge may grab

the material causing loss of control of the cutter.

Always hold the tool with two hands during

start-up. The reaction torque of the motor can

cause the tool to twist.

The direction of feeding the bit into the

material is very important and it relates to

the direction of bit rotation. When viewing

the tool from the top, the bit rotates

clockwise. Feed direction of cutting must be

counter-clockwise. NOTE: inside and outside

cuts will require different feed direction, refer to

section on feeding the router. Feeding the tool

in the wrong direction, causes the cutting edge

of the bit to climb out of the work and pull the

tool in the direction of this feed.

Always use the tool with the depth guide

securely attached and positioned flat against

material being cut. The guide securely

positioned on the material improves the stability

and control of your tool.

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits

can snap during use. Dull bits require more

force to push the tool, possibly causing the bit to

break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to be

touched by bare hands.

Never lay the tool down until the motor has

come to a complete standstill. The spinning

bit can grab the surface and pull the tool out of

your control.

Do not use the tool for drilling purposes. This

tool is not intended to be used with drill bits.

Some dust created by power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement

and other masonry products.

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

-5--4-

Functional Description and Specifications

NOTE: For tool specifications refer to nameplate on your tool.

REV01

RECESSED HIGH

INTENSITY LED LIGHTS

VARIABLE SPEED

CONTROL PANEL

(with LED speed indicator)

DEPTH GUIDE

BRACKET

INTAKE

AIR VENTS

BASE PLATE

LOCKING SCREW

3 POSITION ON/OFF

BUMP-OFF SLIDE SWITCH

SHAFT LOCK

BUTTON

COLLET NUT

ADJUSTABLE

BASE PLATE

COLLET AND ZIP BIT

STORAGE AREA

WRENCH AND

STORAGE AREA

REMOVABLE

TRIGGER HANDLE

ADJUSTABLE AIR

DIVERTER SWITCH

CAM LOCK LEVER TO

REMOVE HANDLE

Disconnect the plug from the power source before making any assembly, adjustments or

changing accessories. Such preventive safety measures reduce the risk of starting the tool

accidentally.

Reverse Angle

CAM LOCK

LEVER

TRIGGER SWITCH

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Symbols

0

This symbol designates that

this tool is listed to U.S. and

Canadian standards by

Underwriters Laboratories.

Disconnect the plug from the

power source before making

any assembly, adjustments or changing

accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

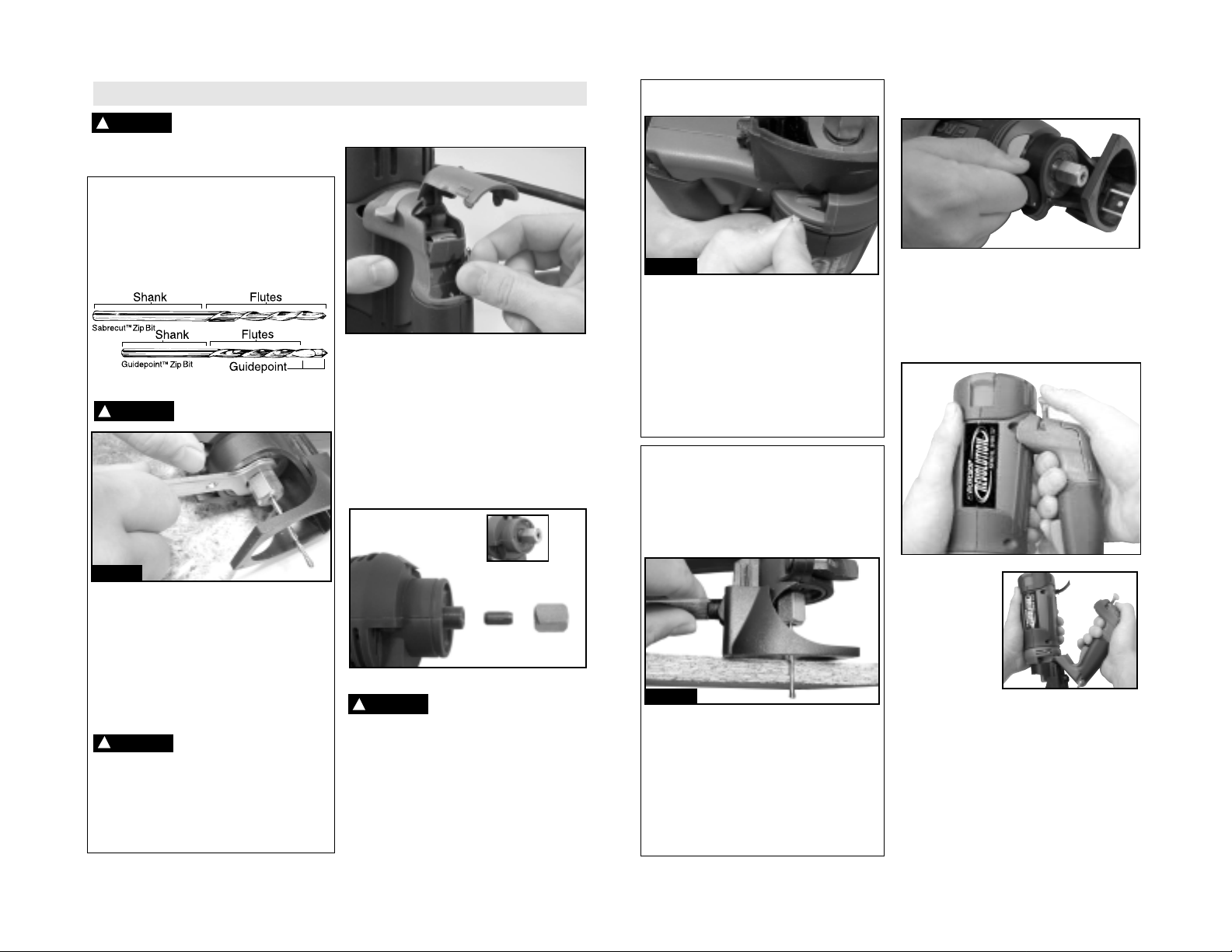

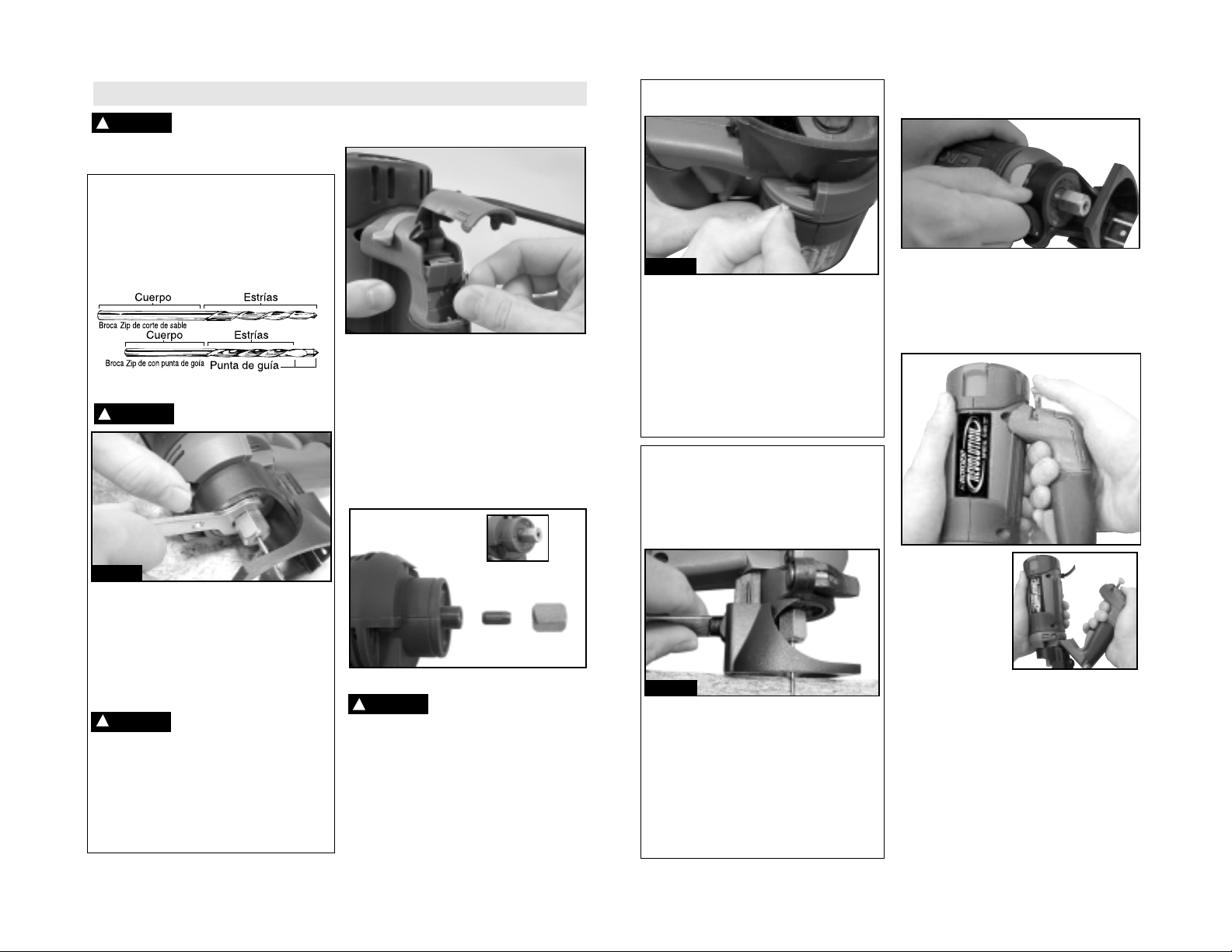

STEP 1: INSTALLING ZIP® BITS

The Zip Bits are held by a collet system. At the

time your tool was assembled, the 1/8" collet (used

for 1/8" Zip Bits) was installed for your convenience.

The 1/4" collet (used for 1/4" Zip Bits) is located in

the Zip Bit package with your tool.

Only use Roto Zip Tool Corporation Zip Bits

with your Spiral Saw power tool.

Identify the different parts of your Zip Bits.

The Zip Bit flutes are sharp and

should be handled with caution.

To insert a Zip Bit into the tool, first remove the

standard equipment wrench and locate the

shaft lock button. Depress and hold down the

shaft lock button with one hand and at the same

time loosen the collet nut with the other hand by

turning it counter clockwise with the wrench for

a couple rotations. Remove the old Zip Bit (if

there is one), insert shank of Zip Bit into the

collet so that 1/16" to 1/8" of smooth shank

remains visible above the collet.

Do not allow the flutes/cutting

edges of the Zip Bit to fall into

the collet, and do not tighten the collet around the

flutes; doing so will result in decreased Zip Bit life.

After properly placing the Zip Bit into the collet,

depress the shaft lock button and simultaneously

tighten the collet nut in a clockwise direction, first

by hand, and then with the wrench until Zip Bit is

held securely.

Collet and Zip Bit storage compartment

area located in the handle

Changing the Collet

As stated above, the 1/8" collet is used with 1/8"

diameter Zip Bits and the 1/4" collet is used with

1/4" diameter Zip Bits. To interchange collets,

first remove the Zip Bit. Continue to loosen and

unscrew the collet nut until you can remove it

from the tool. Remove the collet and replace it

with another. (Each collet is double-ended, and

either end is acceptable to use.) By hand,

re-tighten the collet nut around the collet in a

clockwise direction. You are now ready to insert a

new Zip Bit as instructed in step 1 above.

DURING STORAGE of your

tool when there is no Zip Bit

in the collet, DO NOT tighten the collet nut

down onto an empty collet. Doing so will make

the collet hole smaller, preventing you from

inserting Zip Bits into it in the future.

-7-

-6-

Operating Instructions

!

WARNING

SYSTEM COMPLETE

SYSTEM SEPERATED

COLLET

NUT

COLLET

!

CAUTION

!

CAUTION

!

WARNING

STEP 2: ADJUSTING THE AIR

DIVERTER

Always make sure tool is OFF ("0" position)

before making any adjustments to the air

diverter vents.

The exhaust air diverter vent redirects cooling

air toward the base plate to help remove debris

that may gather in the base plate while cutting.

To open the diverter vent so air pushes towards

the cutting surface, slide the air diverter lever

toward the handle. To close the vent, slide the

lever away from the handle.

STEP 3: ADJUSTING THE DEPTH

GUIDE BEFORE MAKING A CUT

The Revolution is designed to cut materials up

to 1” thick. Use the depth guide to adjust the

depth of the cut. The depth guide assembly

consists of the depth guide & locking lever, and

the adjustable base plate & locking screw.

Locate the base plate and its locking screw.

Using the end of the standard wrench, loosen

(counter clockwise) the screw enough to enable

the base plate to slide up or down to the desired

depth of cut. For best performance, set the base

plate so the Zip Bit protrudes approximately 1/8"

beyond the material being cut. For example, to

cut a piece of 1/2" thick plywood, set the base

plate so the Zip Bit protrudes 5/8" below the

base plate, as shown here. Re-tighten the screw

in a clockwise direction.

Removing Depth Guide Assembly From Tool

and Reinstalling

In order to remove the depth guide from the

tool, release the locking lever and pull the entire

assembly straight off of the tool. To reattach

the assembly, fully replace the guide onto the

tool collar and lock the clamp lever.

Removing and Replacing the Handle

Turn the tool OFF

and unplug it.

Firmly grasp the

tool. Slide open

the cam lock lever

to the unlock

position. Gently

lift-up the rear end

of the handle and

the cam lock pin will

disengage from the

tool. Continue to gently lift-up the handle and

the 2 latches at the front of the handle will also

disengaged. Remove handle from tool.You can

only operate the tool in the "2" ON position

while the handle is disengaged from the tool.

To replace the handle, reverse the steps above.

Gently engage the 2 front latches into the tool,

slide the cam lock pin into the open hole. Gently

pull handle to check that both ends are secured

before using.

Step 2

Step 3

Step 1

-8-

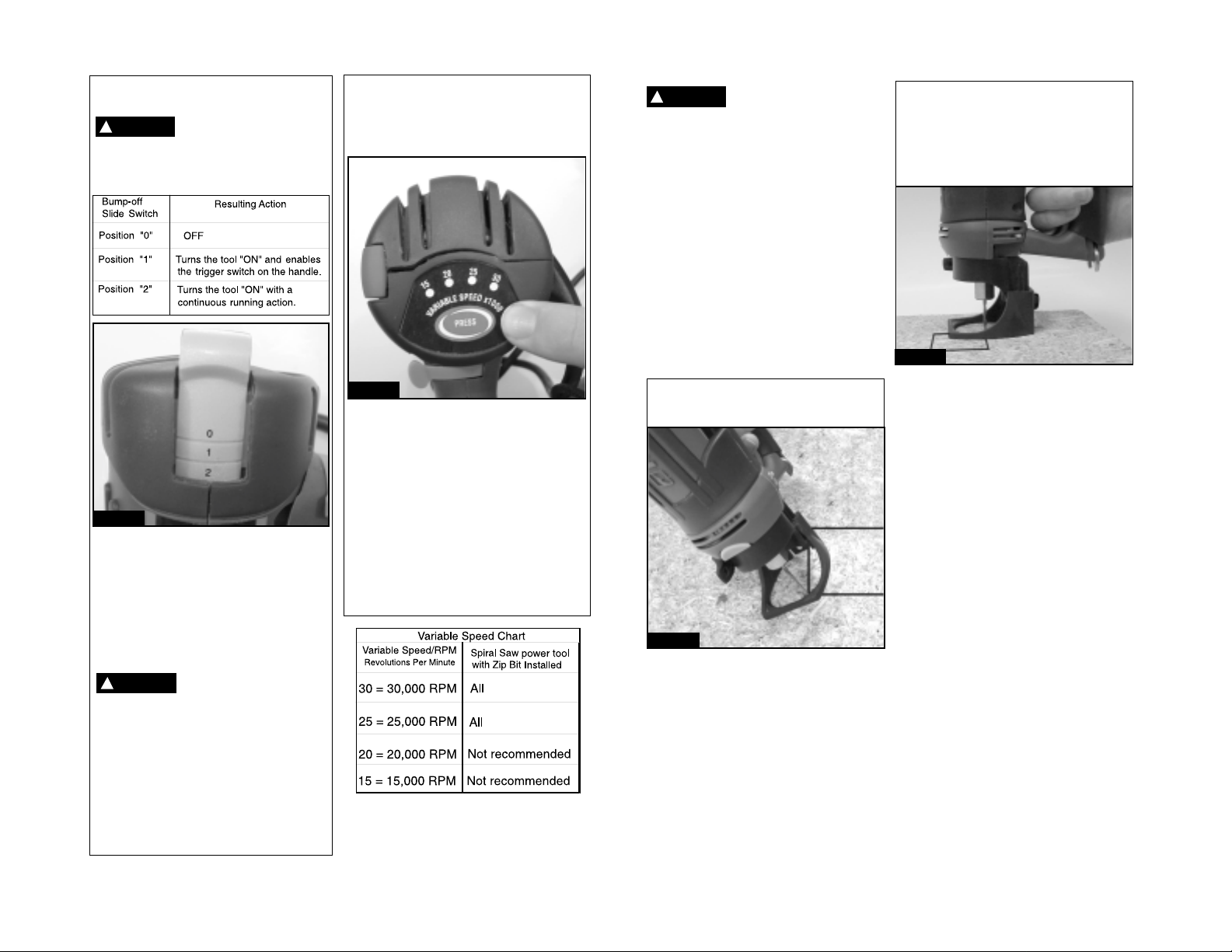

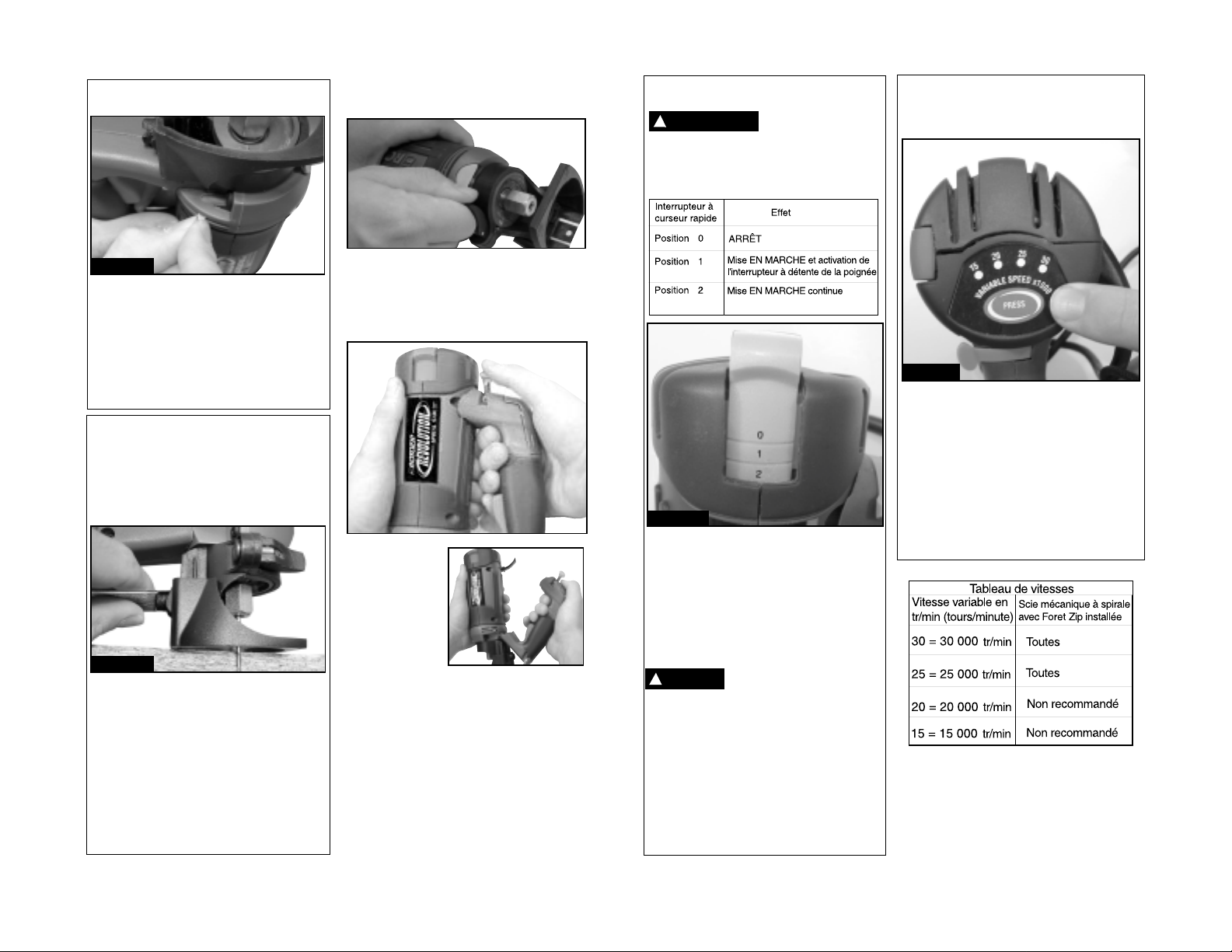

STEP 4: LOCATE THE

BUMP-OFF SLIDE SWITCH

Never leave tool unattended in

either the "1" or "2" ON positions.

The tool is powered by a three position

bump-off slide switch located on the rear, side

of the tool.

Position "0" is the OFF position

Position "1" turns the tool ON and activates

the trigger switch on the handle.

When the power switch is slid upward to the

first - or "1" - position, the tool is "live" and is

activated by depressing the trigger switch on

the removable handle. To turn the tool OFF

release the trigger switch and push the slide

switch to the "0" position.

Never leave the tool

unattended in the "1" ON

position. It is considered a live tool and is

activated by the trigger switch.

Position "2" turns the tool ON with a

continuous running action.

When the power switch is slid upward to the

second - or "2" - position, the tool runs

continuously. To turn the tool OFF, push the

slide switch down to the "0" position.

Note: When the auxiliary handle is removed, the

tool can only be turned ON in the "2" position.

STEP 5. LOCATE THE VARIABLE

SPEED INDICATOR

The Revolution Spiral Saw power tool features

a variable speed range of 15, 20, 25 and

30,000 RPMs.

* The default rating is 30,000 RPMs. Meaning, if

you turn the tool OFF and then back ON again,

the tool automatically starts at 30,000 RPMs.

* While the tool is ON (either in the "1" or "2"

position) you can move between speeds by

pressing the VARIABLE SPEED button.

* An illuminated red LED light on the touch pad

indicates the variable speed chosen.

* For the best results, when using the Spiral

Saw power tool and Zip® Bits, we recommend

only using the 30,000 and 25,000 RPM. You

will not obtain a quality cut if you lower the

RPM to 20,000 or 15,000.

!

WARNING

-9-

Step 4

Step 5

Hold the tool with both hands

while starting, since torque of

the motor can cause the tool to twist.

Make A Few Practice Cuts

After assembling the Zip Bit into the tool and

adjusting your depth guide, as described

above, you should make a few practice cuts

with the tool before attempting an actual job.

A few exercises will give you the necessary

practice to make clean, professional cuts.

STEP 6:

Make certain that the collet nut is securely

tightened before turning the tool on.

STEP 7:

Hold the Spiral Saw power tool firmly and turn

the tool ON.

Hold the tool with both hands while starting,

since torque from the motor can cause the tool

to twist.

STEP 8:

While holding the tool firmly, insert the Zip Bit

into the material at a 45° angle.

STEP 9:

Slowly bring it to a 90° angle to begin the cut.

The base guide should be flush to the material

surface. For all materials (EXCEPT cutting

around outlet boxes in drywall), steer the tool

in a clockwise direction with slow, steady

pressure to make the cut.

STEP 10:

After completing your cut, turn off the tool and

carefully remove it from the material.

Do not attempt to use this tool to make cut-outs

around any fixture or opening which has live

electrical wires, or any wall which may have

live electrical wiring behind it, as the Zip Bit

could conduct current to the tool, creating an

electrocution hazard for the operator. Shut off

breakers or remove fuses to disconnect the

circuit. Always hold the tool by its thermoplastic

housing, and always wear eye protection when

operating a Spiral Saw power tool.

NOTE: Because of the rotating cutting action

of the Zip Bit, there will be a slight pull when

cutting. The slower you cut, the more control

you have. Excessive pressure or fast cutting

will cause excessive heat and may shorten the

life of the Zip Bit.

NOTE: When cutting on a vertical surface,

avoid ending your cut at the bottom of the

hole. If possible, start and end your cut at the

top so the scrap part will not drop onto the

rotating Zip Bit. Turn the tool off and remove it

from the material.

Step 9

!

CAUTION

Step 8

!

CAUTION

-11-

Step 5

Pull the Zip Bit out far enough to slip it over the

edge of the box so it is now against the outside

of the box.

Step 6

While keeping the Zip Bit in contact with the

outside of the box move the tool counter clockwise

while applying light inward and upward pressure

until you feel and hear it come to the corner. As

you round the corner apply light pressure left and

downward.

Step 7

While moving slowly and continuously along

the top contour you will feel the Zip Bit come to

the next corner. Round the corner and apply

light down and inward pressure until the bottom

corner is reached.

Step 8

Move the Zip Bit right and upward maintaining

light continuous pressure toward the box.

-10-

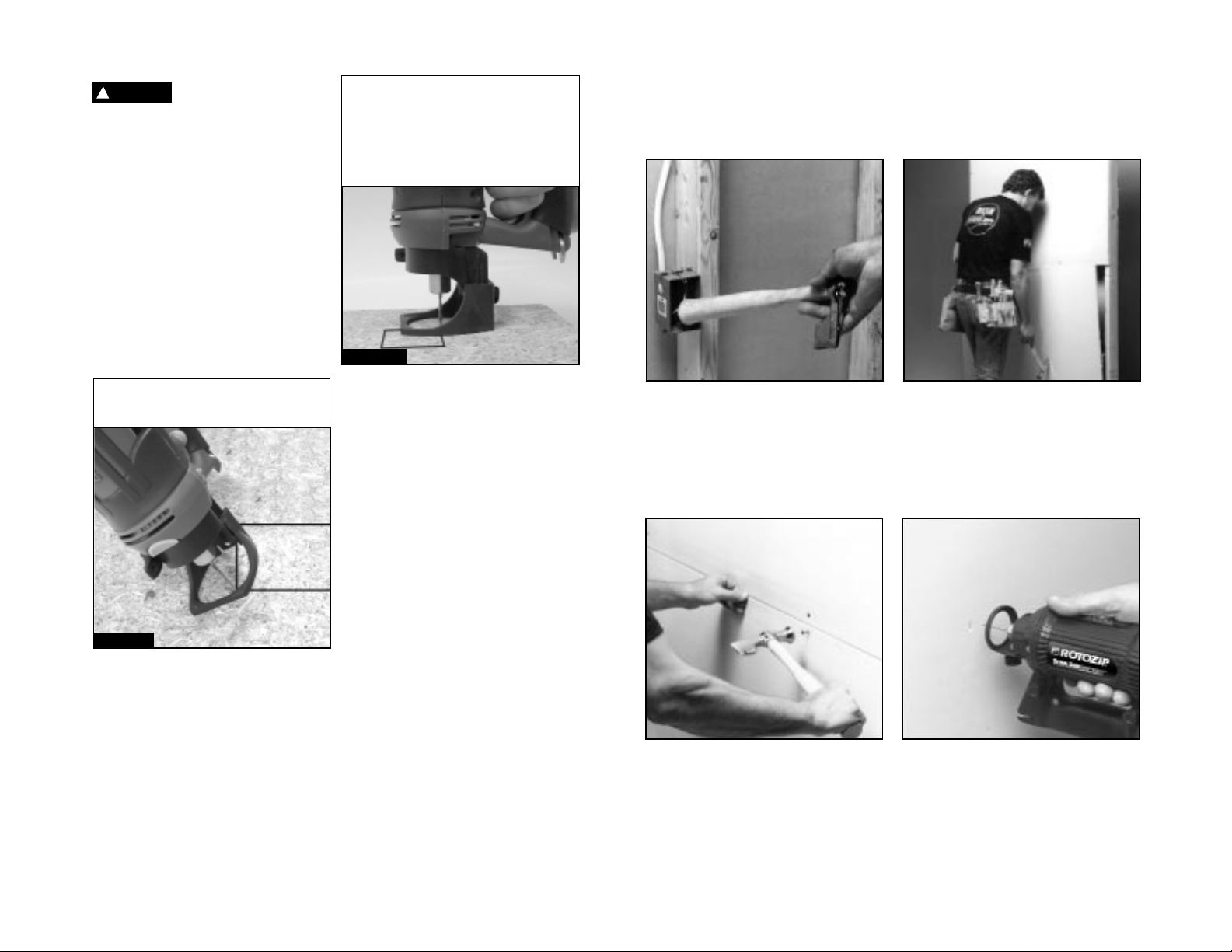

Step 1

Make certain that the electrical wires are pushed

back or to the far side of the box so that the Zip Bit

does not cut the wires when inserted through the

drywall. Your hammer handle is an excellent tool

for this.

Step 2

Before fastening the sheet you must make a mark

somewhat near the center of the opening in the

box on the side of the drywall facing you. A

drywall hammer (hatchet end) works well for this.

Step 3

Do not nail or fasten screws closer then 12"

from the box, or the drywall may bulge or blister

from the excess pressure.

Step 4

Slide switch to turn the tool on. While holding

the Spiral Saw™ power tool firmly with both

hands plunge the Zip Bit through the mark you

made. Then guide the Zip Bit to the right until

you feel and hear the Zip Bit touch the inside

edge of the box.

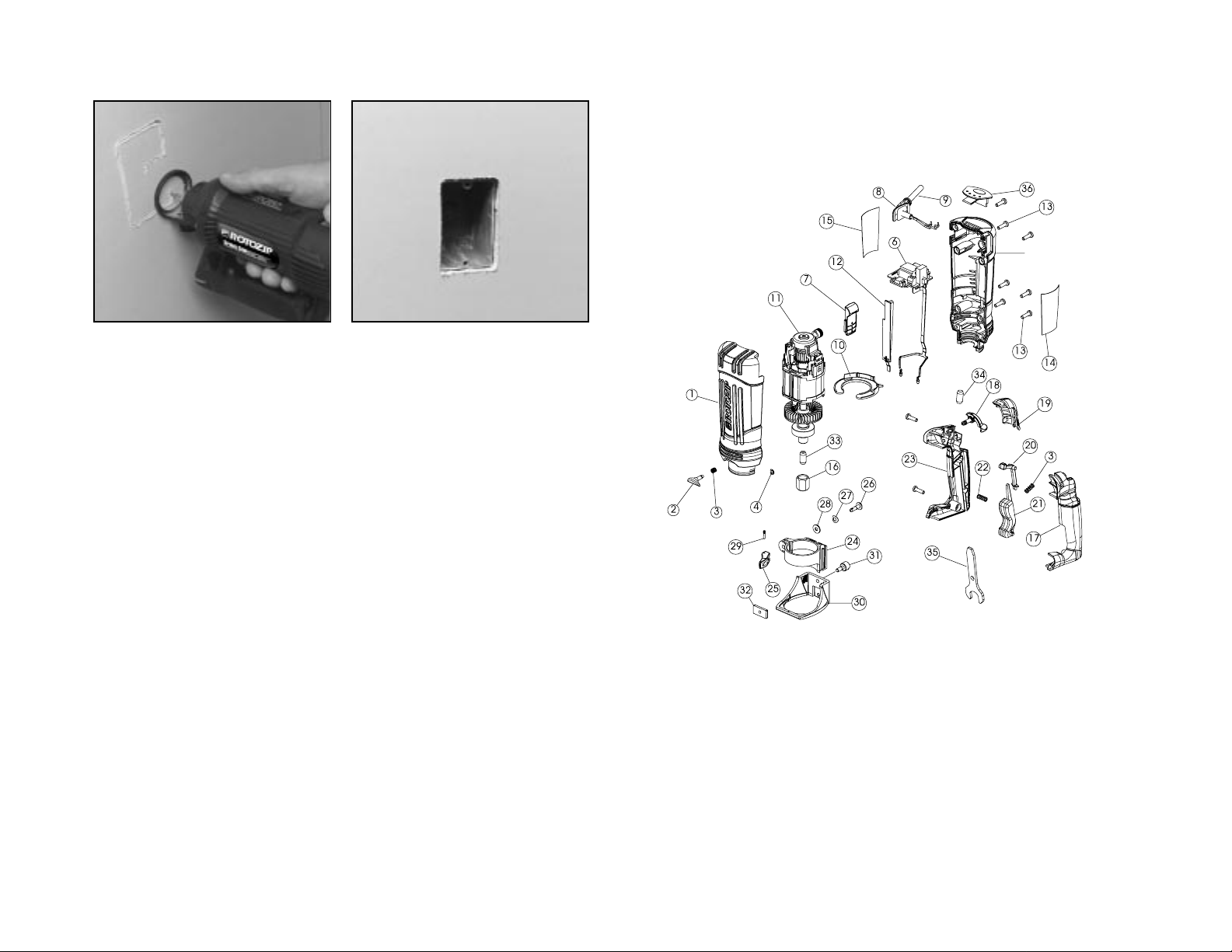

ILLUSTRATED INSTRUCTIONS FOR PERFECT OUTLET

OPENINGS IN DRYWALL (SCS01 model shown)

The following procedure will illustrate cutting out a standard 2 1/8" X 3 3/4" electrical box.

SCHEMATIC FOR REV01 MODEL

-13-

-12-

Step 9

Round the right bottom corner and begin moving

the Zip Bit upward while applying light pressure

left toward the box until you meet initial upward

cut. Push tool switch to off.

Step 10

The completed box, executed quickly, neatly and

in a fraction of the time taken by other methods.

These step-by-step instructions are generalized

to acquaint you with the Spiral Saw™ power

tool operation. After some practice, you may

develop a motion technique with which you are

more comfortable. However, you must always

begin the cut somewhat centrally, and MOVE

THE SPIRAL SAW POWER TOOL ONLY

COUNTERCLOCKWISE to take advantage of

the “hugging” action of the rotating Zip Bit along

the contours of the template. Remember to use

a smooth continuous motion.

-15-

1 100326 HOUSING - FRONT SUBASSEMBLY

2 100352 SHAFT LOCK SUBASSEMBLY

3 100342 SPRING, SHAFT LOCK

4 100308 RETAINING RING, SHAFT LOCK

5 100310 HOUSING - BACK SUBASSEMBLY

6 100314 PCB SUBASSEMBLY - HIGH END

7 100315 SWITCH CAP

8a 100316 STRAIN RELIEF (Type 1 & 2)

8b 100350 STRAIN RELIEF (Type 3)

9 100317 POWER CORD

10 100318 DIVERTOR RING

11 100380 MOTOR SUBASSEMBLY

12 100327 COVER, WIRE

13 RTM710 SCREWS

14 100328 DECAL, INFO

15 100329 DECAL, PRODUCT NAME

16 SC701 NUT, COLLET

17 100333 HANDLE - LEFT - HIGH END

18 100334 CAM LOCK SUBASSEMBLY

19 100337 STORAGE COVER

20 100338 LINKAGE SUBASSEMBLY

21 100341 TRIGGER

22 100345 SPRING, WRENCH

23 100344 HANDLE - RIGHT - HIGH END

24 100353 CLAMP

25 100354 LEVER

26 100355 LINK, CLAMP

27 100356 WASHER, SPRING

28 100307 WASHER, SLIDE

29 100357 PIN, PIVOT

30 100359 BASE

31 100362 SCREW, THUMB

32 100363 NUT, PLATE

33 RTM125 COLLET, 1/8"

34 RTM250 COLLET, 1/4"

35 100346 WRENCH

36 100313 MEMBRANE PANEL

Ref. Part No. Description

No.

-14-

Maintenance

Service

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of

internal wires and components which could

cause serious hazard. Roto Zip Tool

Corporation is the only authorized repair center

for their tools. Contact the Customer Service

department, toll free in the U.S. and Canada, at

1-877-768-6947, or 1-608-798-0139 Ext. 520,

Monday through Friday between 8am-4:30pm

CST, for further instructions.

Cleaning

To avoid accidents always

disconnect the tool from

the power supply before cleaning or

performing any maintenance.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

Certain cleaning agents and

solvents damage plastic

parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents,

ammonia and household detergents that

contain ammonia.

!

WARNING

!

WARNING

!

CAUTION

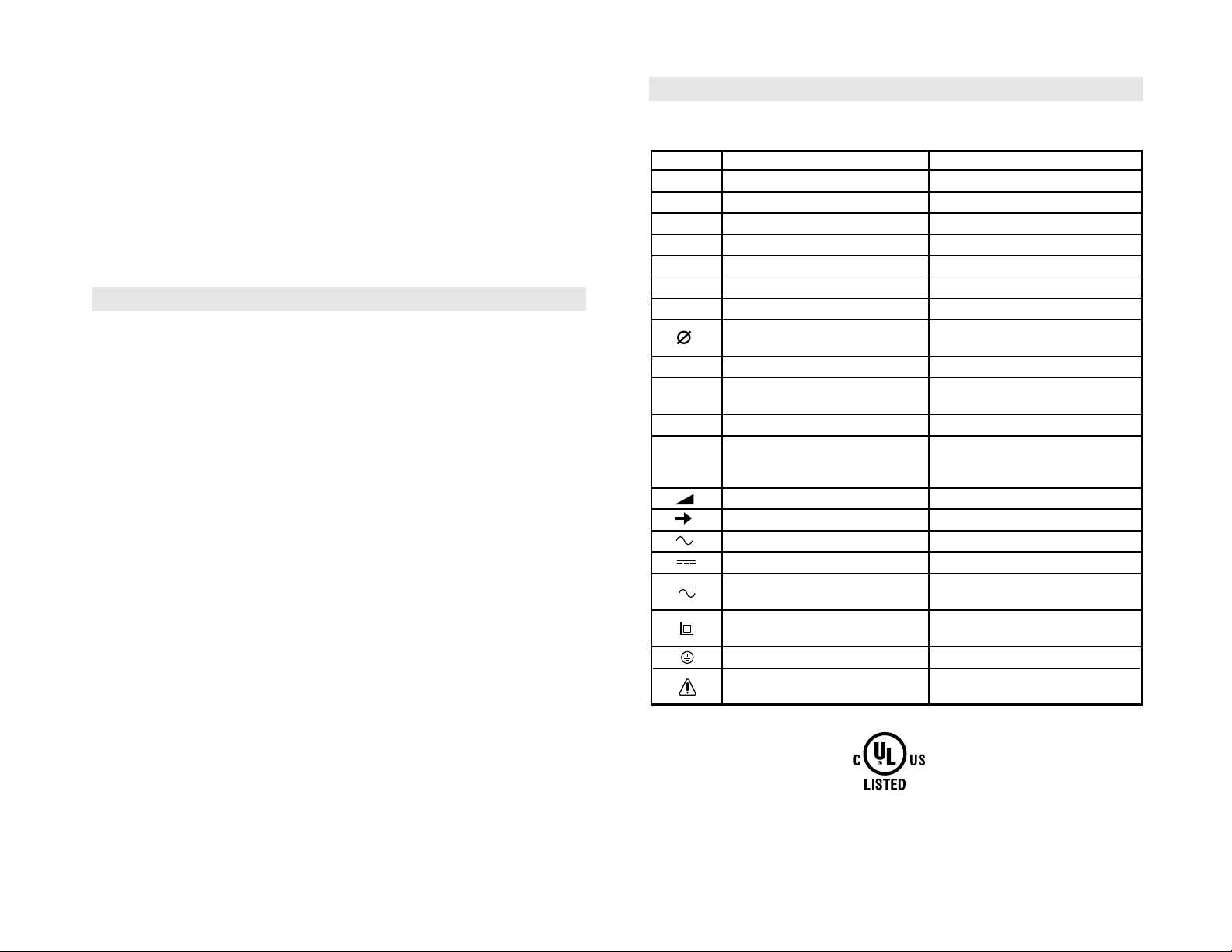

Recommended Sizes of Extension Cords

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

tool must be used. This will prevent

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles

.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

NOTE: The smaller the gauge number, the heavier

the cord.

!

WARNING

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Cord Length in Feet

Cord Length in Meters

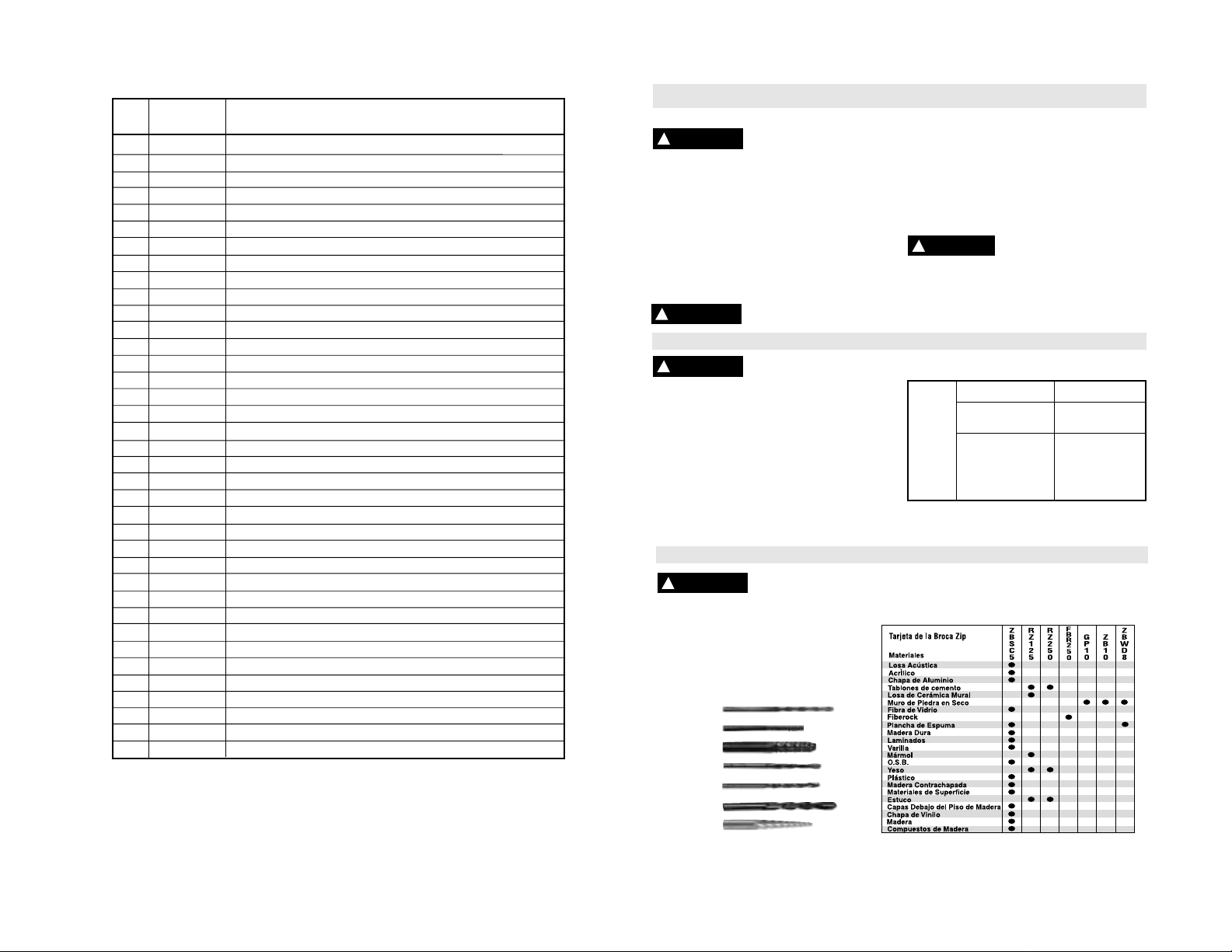

Accessories

Use only Roto Zip Tool Corporation’s recommended accessories with this tool.

Accessories that may be suitable for one tool, may become hazardous when

used on another tool.

!

WARNING

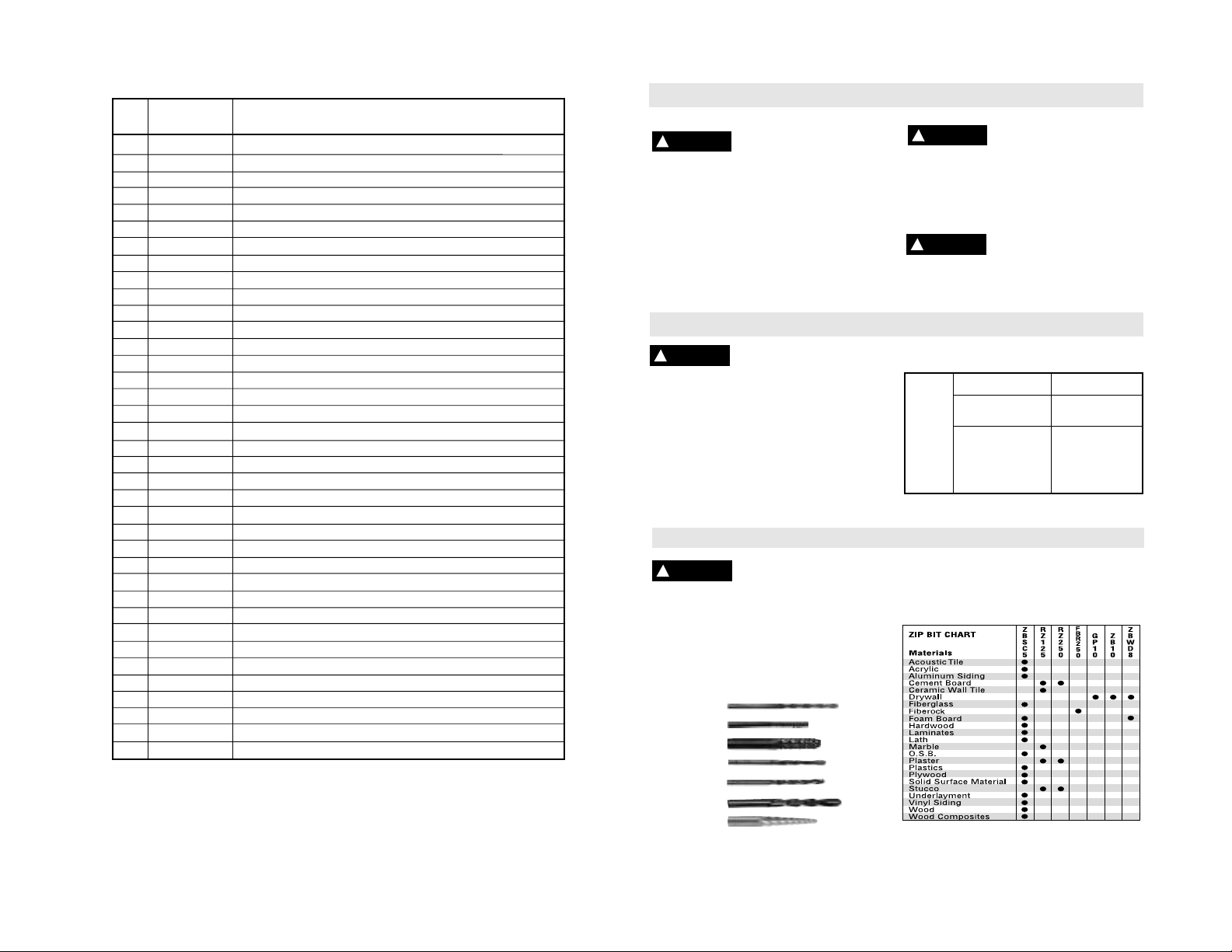

ZBSC5

RZ125

RZ250

GP10

ZB10

ZBWD8

FBR250

Zip®Bits

Roto Zip Tool Corporation's patented line of versatile

Zip Bits and accessories provide you with the

flexibility to quickly move from one material to

another and one job to another, without the hassle of

changing tools.

Prière de lire et de comprendre toutes les directives, à défaut de quoi vous

risquez de causer un incendie ou de subir un choc électrique ou des blessures.

CONSERVER LES DIRECTIVES

-17-

Aire de travail

Tenir l’aire de travail propre et bien éclairée. Les

aires de travail sombres et les établis encombrés

peuvent entraîner des accidents.

Ne pas utiliser un outil mécanique en présence de

liquides, de poussières ou de gaz inflammables. Le

moteur dégage des étincelles qui pourraient

enflammer la poussière ou le gaz.

Tenir les observateurs, les enfants et les visiteurs

à l’écart de tout outil mécanique en usage. Les

distractions risquent de vous en faire perdre la

maîtrise.

Emploi sécuritaire de l’électricité

Les outils à double isolation sont dotés d’une fiche

polarisée (dont une broche est plus large que

l’autre). Cette fiche ne se branche sur une prise de

courant que dans un sens. Si la fiche ne rentre pas

complètement dans la prise, la retourner et

ressayer. Si elle ne rentre toujours pas, demander

à un électricien qualifié d’installer une prise de

courant polarisée. Ne modifier la fiche sous aucun

prétexte. La double isolation élimine la nécessité

d’utiliser un cordon d’alimentation à trois broches et un

réseau d’alimentation avec mise à la terre. Avant de

brancher l’outil, s’assurer que la tension aux bornes de

la prise ne présente pas une différence de plus de

10 % par rapport à la tension indiquée sur la plaquette

signalétique. Ne pas utiliser des outils cotés “C.A.

seulement” avec une source d’alimentation C.C.

Éviter qu’une partie du corps ne touche à une

surface mise à la terre, comme un tuyau, un

radiateur, une cuisinière ou un réfrigérateur. Le

risque de subir un choc électrique s’accroît lorsque le

corps est mis à la terre. Si l’utilisation de l’appareil

dans un lieu humide est inévitable, il est obligatoire de

faire appel à un interrupteur différentiel pour

l’alimenter. Le port de gants et de souliers isolants en

caoutchouc augmentera le degré de protection de

l’utilisateur.

Ne pas exposer l’appareil électrique à la pluie ou à

un milieu où il y a beaucoup d’eau. Les risques de

subir un choc électrique s’accroissent si de l’eau

pénètre dans un appareil électrique.

Ménager le cordon. Ne jamais transporter l’appareil

en le tenant par le cordon. Ne jamais tirer sur le cordon

pour débrancher la fiche. Tenir le cordon à l’écart de la

chaleur, de l’huile, des coins coupants et des pièces

mobiles. Un cordon endommagé accroît le risque de

subir un choc électrique.

Pour utiliser un outil mécanique à l’extérieur,

employer un cordon de rallonge d’extérieur

identifié “W-A” ou “W”. Ces cordons sont cotés pour

utilisation à l’extérieur et ils diminuent les risques de

subir un choc électrique. Se reporter à la section

Calibre recommandé des rallonges.

Sécurité des personnes

Rester alerte, garder les yeux sur le travail et faire

preuve de bon sens en utilisant l’appareil. Ne pas

l’utiliser lorsque l’on est fatigué ou lorsque l’on a

les facultés affaiblies par des drogues, de l’alcool

ou des médicaments. Un moment d’inattention en

utilisant l’appareil peut entraîner des blessures graves.

S’habiller convenablement. Ne pas porter de bijoux

ou de vêtements amples. Attacher les cheveux

longs. Tenir les cheveux, les vêtements et les

gants à l’écart des pièces mobiles. Les vêtements

amples, les bijoux et les cheveux longs risquent d’être

happés par les pièces mobiles. Tenir les poignées et

les manches secs, propres et exempts d’huiles ou de

graisses.

Prévenir tout démarrage imprévu. S’assurer que

l’interrupteur est à la position d’arrêt avant de

brancher l’appareil. Transporter l’appareil avec le

doigt sur l’interrupteur ou le brancher alors que

l’interrupteur est en position de marche entraîne des

accidents.

Retirer les clés de réglage avant de mettre

l’appareil en marche. Une clé qui a été laissée sur

une pièce tournante risque de causer des blessures.

Ne pas s’étirer au-delà de sa portée. Toujours se

tenir d’aplomb avec les pieds bien plantés au sol.

Cela permet une meilleure commande de l’appareil en

cas d’imprévu.

Porter un équipement de protection. Toujours

porter des lunettes de sécurité. Porter au besoin un

masque antipoussière, des souliers antidérapants, un

casque protecteur et un casque antibruit.

Emploi et entretien de l’appareil

Employer des serre-joints ou toute autre méthode

pratique pour fixer la pièce à travailler à une

surface stable et pour la supporter. Une pièce tenue

dans ses mains ou contre son corps sera instable et

pourra entraîner une perte de maîtrise.

Ne pas forcer l’appareil. Utiliser l’appareil qui

convient au travail à exécuter. L’appareil qui

convient exécutera le travail correctement et en toute

sécurité à la cadence pour laquelle il a été conçu.

Ne pas utiliser l’appareil s’il est impossible de

l’allumer ou de l’éteindre à l’aide de l’interrupteur.

Tout appareil qui ne peut pas être commandé à l’aide

de son interrupteur est dangereux et doit être réparé.

Débrancher l’appareil avant d’en changer un

accessoire, de l’ajuster ou de le ranger. L’appareil

risque de démarrer de manière imprévue s’il reste

branché.

Ranger l’appareil inutilisé hors de la portée des

enfants et de toute autre personne n’ayant pas

reçu une formation convenable. Entre les mains

d’une personne qui n’a pas été formée à sa bonne

utilisation, l’appareil peut être dangereux.

!

MISE EN GARDE

Les Règles de la Sécurité Générales

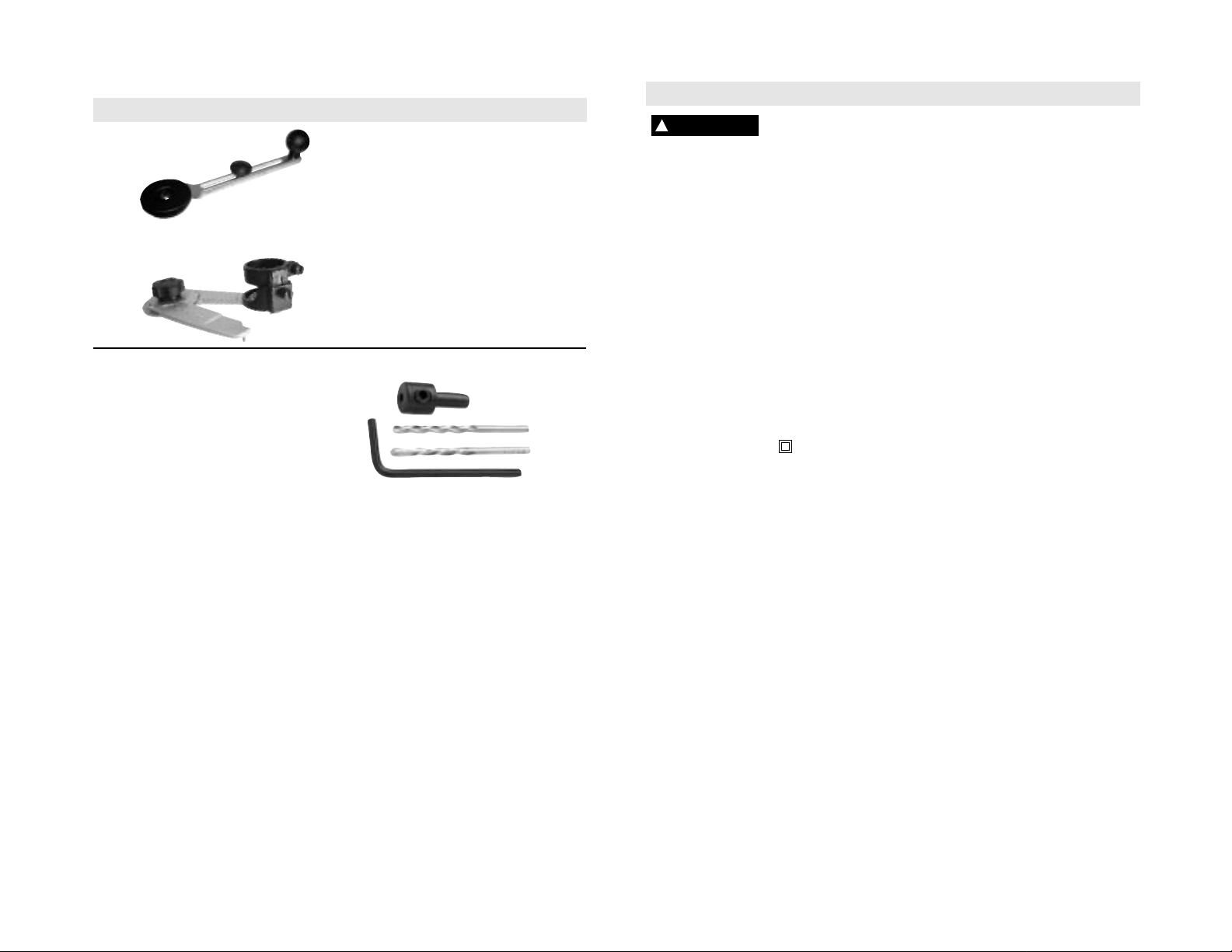

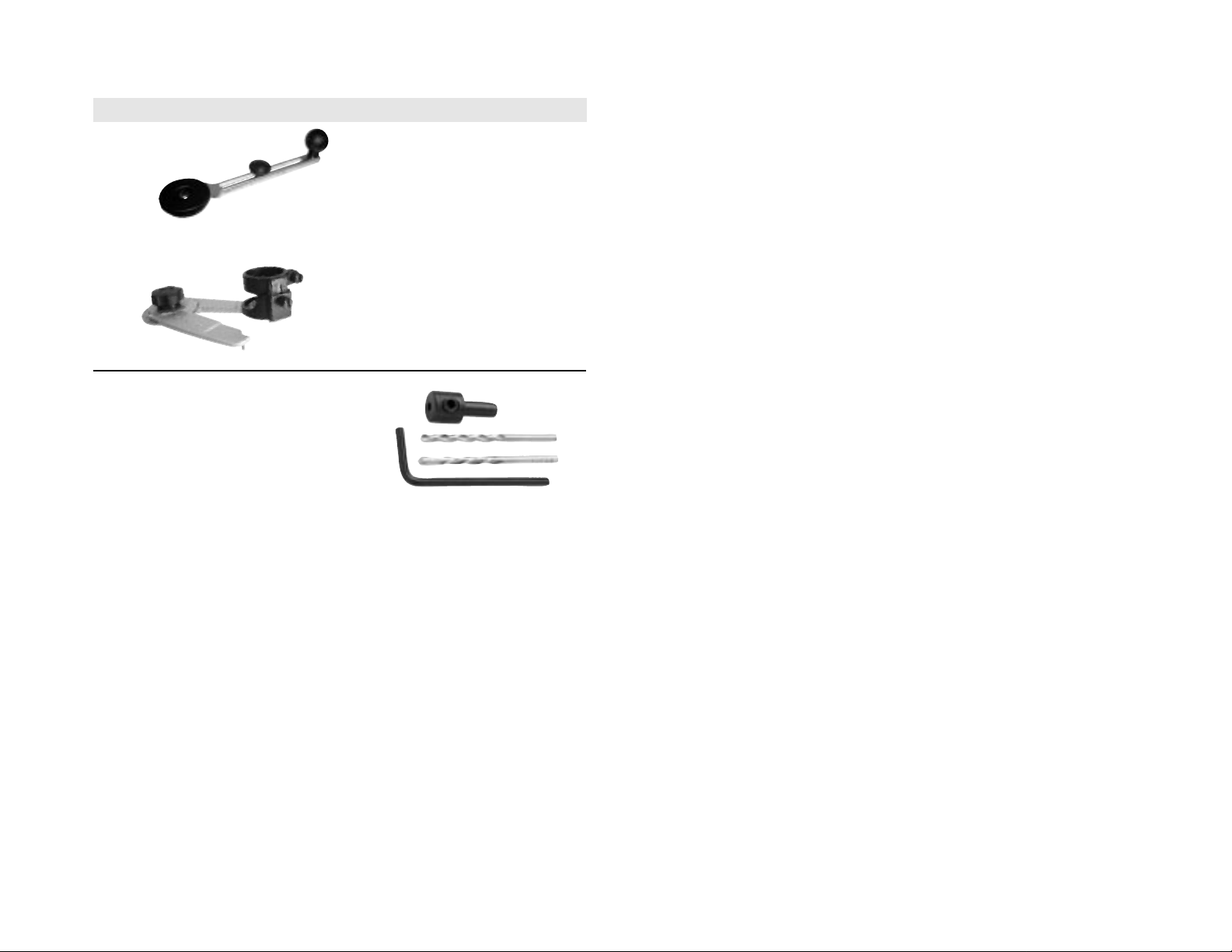

Circle Cutter – CRCT1

This attachment allows you to cut perfect circles

from 4.5 to 12” in diameter using your Spiral Saw power tool.

Accessories

Chuck Adapter Kit – CH01

This adapter kit allows the use of 1/8” Zip Bits in

tools that normally accept 1/4” Zip Bit such as

routers and laminate trimmers. Using Zip Bits in

this manner will decrease Zip Bit life.

-16-

Where Can You Buy Accessories?

The location where you purchased your tool should also carry Roto Zip Tool Corporation’s full line of

accessories. Our products are available at most home improvement centers and hardware stores. If

you are looking for a source, please call our Customer Service representatives Monday through

Friday between 8am - 4:30pm (CST) at 1-877-768-6947 (toll free in the U.S. and Canada) or at 608798-0139 ext. 520.

Circle Cutter – CRCT2

Easily makes circles from 1” to 20” in diameter in

most commonly used building materials. Works

with most Spiral Saw power tools. Required for the

Solaris model.

-19-

-18-

Règles de sécurité de la scie mécanique à spirale

MC

BIen entretenir l’appareil. Tenir les Forets Zip

propres et bien affûtées. Un appareil bien entretenu

doté d’une Foret Zip bien affûtée est plus facile à

maîtriser et risque moins de se coincer.

S’assurer qu’aucune pièce mobile n’est coincée ou

mal alignée, qu’aucune pièce n’est brisée et

qu’aucune condition n’existe qui pourrait nuire au

bon fonctionnement de l’appareil. Si l’appareil est

endommagé, le faire réparer avant de l’utiliser. Bien

des accidents sont causés par des appareils mal

entretenus. Établir et suivre un horaire régulier

d’entretien de l’appareil.

Utiliser exclusivement des accessoires recommandés par le fabricant pour votre modèle d’appareil.

Des accessoires qui conviennent à un appareil

peuvent représenter un risque de blessures s’ils sont

utilisés avec un autre.

Révisions

Toute révision de l’appareil doit être effectuée par

du personnel qualifié. La révision ou l’entretien

effectué par une personne non qualifiée risque

d’entraîner des blessures.

Lors de la révision d’un appareil, utiliser exclusivement des pièces de rechange identiques. Suivre

les directives de la section intitulée Entretien du

présent manuel. Toute utilisation de pièces non

autorisées et tout défaut de suivre les directives

d’entretien peut entraîner un risque de choc électrique

ou de blessures. Certains agents de nettoyage,

comme l’essence, le tétrachlorure de carbone,

l’ammoniaque, etc., peuvent endommager les pièces

de plastique.

Pour exécuter une opération lors de laquelle l’outil

coupant risque d’entrer en contact avec des fils

dissimulés ou avec son propre cordon, tenir l’outil

par les surfaces de prise isolées. Tout contact avec

un fil sous tension mettrait sous tension les parties

métalliques exposées de l’outil, donnant un choc à

l’utilisateur. Si l’on n’a pas le choix d’entamer une

cloison ou tout autre élément susceptible de dissimuler

des fils électriques, alors prendre soin de couper le

courant alimentant le lieu à l’aide des disjoncteurs ou

des fusibles.

Toujours s’assurer que la surface de travail ne

comporte pas de clous ou d’autres corps étrangers.

Le contact avec un clou risque de faire sautiller la Foret

Zip et l’outil et d’ainsi endommager la Foret Zip .

Ne jamais utiliser l’appareil d’une main en tenant la

pièce de l’autre. Ne jamais se placer les mains

sous la surface de coupe. Il est plus sécuritaire de

fixer la pièce à l’aide de serre-joints et de guider

l’appareil avec les deux mains.

Ne jamais poser la pièce à travailler sur une

surface très dure, comme le béton, la pierre, etc. La

Foret Zip, en dépassant de la pièce à travailler,

pourrait faire sautiller l’appareil.

Toujours porter des lunettes de sécurité et un

masque antipoussière. Toujours utiliser l’appareil

dans un endroit bien aéré. L’emploi de dispositifs de

protection personnelle et le travail dans un milieu

sécuritaire réduit le risque de blessures.

Après avoir changé la Foret Zip ou effectué un

réglage, s’assurer que l’écrou de mors et tout autre

dispositif de réglage est bien serré. Un dispositif de

réglage lâche risque de bouger de façon imprévue,

entraînant une perte de maîtrise et la possibilité que

les composants non fixés soient projeté violemment.

Ne jamais démarrer l’appareil avec la Foret Zip

engagée dans le matériau. Le tranchant de la Foret

Zip pourrait se coincer dans le matériau, entraînant

une perte de maîtrise.

Toujours tenir l’appareil avec les deux mains lors

de son démarrage. Le couple de réaction du moteur

pourrait vous arracher l’appareil des mains.

Le sens dans lequel la Foret Zip est avancée dans

le matériau doit être adapté au sens de sa rotation.

Ainsi, on doit tailler la plupart des matériaux en suivant

le sens de rotation des aiguilles d’une horloge. Il existe

des exceptions : par exemple, pour tailler dans une

plaque de plâtre autour d’une boîte de raccordement,

on suivra le sens inverse des aiguilles d’une horloge.

Si l’appareil est avancé dans le mauvais sens, le

tranchant de la Foret Zip risque de grimper hors de la

pièce et de tirer l’outil dans le sens de l’avance.

Toujours utiliser l’appareil avec le guide de coupe

fixé solidement et à plat contre la pièce à tailler.

Lorsqu’il est positionné solidement sur la pièce, le

guide augmente la stabilité de l’appareil ainsi que la

maîtrise que vous en aurez.

Ne jamais employer de Forets Zip émoussées ou

endommagées. Manipuler avec soin les Forets Zip

affûtées. Une Foret Zip endommagée peut casser à

l’usage. Une Foret Zip émoussée nécessite une plus

grande pression sur l’appareil pour tailler, ce qui peut

entraîner son bris.

Ne jamais toucher la Foret Zip pendant son usage

ou immédiatement après. Immédiatement après

usage, la Foret Zip est trop chaude pour être touchée à

mains nues.

Ne jamais déposer l’appareil avant que son moteur

ait complètement cessé de tourner. La Foret Zip en

rotation risque de happer la surface et de vous faire

perdre prise de l’appareil.

Ne pas employer cet appareil pour forer. Il n’est pas

conçu pour s’utiliser avec des Forets Zip.

Les travaux à la machine tel que ponçage, sciage,

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par exemple:

• Le plomb provenant des peintures à base de

plomb,

• Les cristaux de silices provenant des briques et

du ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut

travailler dans un lieu bien ventilé et porter un

équipement de sécurité approprié tel que certains

masques à poussière conçus spécialement pour

filtrer les particules microscopiques.

Symboles

Important : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules,

etc.

n

0

Vitesse à vide Vitesse de rotation, à vide

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

minute etc., par minute,

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de

l, ll, lll, ... position. Un nombre plus élevé signifie

une vitesse plus grande.

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif Type ou caractéristique du courant

ou continu

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

0

Ce symbole indique que cet outil

est approuvé conformément aux

Etats-Unis et normes canadiennes

par Underwriters Laboratories.

Débrancher la fiche de la

prise de courant avant

d’exécuter un assemblage, d’effectuer un réglage ou

de changer un accessoire. Cette mesure de

précaution réduira le risque que l’appareil se mette en

marche de manière imprévue.

1. ÉTAPE : INSTALLATION DES

FORETS ZIP

Les Forets Zip sont tenues en place par un collet.

Lors de la fabrication de l’outil, le mors de 3,2 mm

(utilisé avec les Forets Zip de 3,2 mm) a été installé.

Le mors de 6,4 mm (utilisé avec les Forets Zip de

6,4 mm)se trouve dans le paquet de Forets Zip

fourni avec l’appareil. Utiliser exclusivement des

Forets Zip de Roto Zip Tool Corporation avec la

scie mécanique à spirale.

Identifier les parties des Forets Zip

Les arêtes des Forets Zip

sont tranchantes et

doivent être manipulées avec soin

.

Pour introduire une Foret Zip dans l’outil, retirer

d’abord la clé fournie et identifier le bouton de

blocage de l’arbre. Tenir ce bouton enfoncé avec une

main et, en même temps, desserrer l’écrou de mors

avec l’autre main en le tournant quelques tours à

gauche à l’aide de la clé. Retirer la Foret Zip (s’il y en

a une), puis introduire dans le mors la queue de la

nouvelle Foret Zip de manière à ce que 1,6 à 3,2mm

de tige lisse soit visible au-delà du mors.

Ne pas permettre aux arêtes

tranchantes de la Foret Zip de

pénétrer dans le mors et ne pas serrer le mors sur les

arêtes. Cela réduirait la longévité des Forets Zip .

Une fois la Foret Zip bien installée dans le mors,

enfoncer le bouton de blocage d’arbre et serrer en

même temps l’écrou de mors en le tournant à droite,

d’abord avec les doigts, puis avec la clé jusqu’à ce

que la Foret Zip soit retenue solidement.

Compartiment de rangement de mors et de

Forets Zip situé dans la poignée

Changement du mors

Comme on l’a mentionné plus haut, le mors de

3,2 mm s’utilise avec les Forets Zip de 3,2mm et le

mors de 6,4 mm s’utilise avec les Forets Zip de

6,4 mm. Pour changer le mors, commencer par

retirer la Foret Zip. Continuer ensuite de dévisser

l’écrou de mors jusqu’à ce qu’il se détache de

l’appareil. Retirer le mors et le remplacer par l’autre.

(Les deux mors sont réversibles et s’utilisent

indifféremment dans un sens comme dans l’autre.)

Serrer à nouveau l’écrou sur le mors en le tournant à

droite avec ses doigts. On peut maintenant y

introduire une Foret Zip de la manière indiquée à la

1 étape (ci-dessus).

EN RANGEANT l’appareil sans

Foret Zip dans le mors, NE PAS

serrer complètement l’écrou sur le mors vide. Cela

rétrécirait l’ouverture du mors et ferait en sorte à

l’avenir qu’il soit impossible d’y introduire des

Foret Zip.

-21-

Mode d’emploi

!

MISE EN GARDE

COLLET COMPLET

COLLET EN PIÈCES

DÉTACHÉES

ÉCROU

DE MORS

MORS

!

ATTENTION

!

ATTENTION

!

MISE EN GARDE

1. étape

-20-

Caractéristiques et fonctions

REMARQUE : Pour connaître les caractéristiques techniques de l’appareil, se reporter à sa plaquette signalétique.

LAMPES DÉL À

HAUTE INTENSITÉ EN

RETRAIT

PANNEAU DE COMMANDE

DE VITESSE

(avec indicateur à DÉL)

SUPPORT DU

GUIDE DE

COUPE

PRISES

D’AIR

VIS DE BLOCAGE

DE LA BASE

CURSEUR À 3 POSITIONS AVEC

INTERRUPTEUR RAPIDE

BOUTON DE

BLOCAGE

D’ARBRE

ÉCROU DE

MORS

BASE

RÉGLABLE

RANGEMENT DE

MORS ET DE

FORETS ZIP

CLÉ ET

RANGEMENT

POIGNÉE

AMOVIBLE

RÉGLAGE DE LA

DÉRIVATION D’AIR

MANETTE À CAME

POUR DÉTACHER LA

POIGNÉE

Débrancher la fiche de la prise de courant avant d’exécuter un assemblage, d’effectuer un réglage ou de

changer un accessoire. Cette mesure de précaution réduira le risque que l’appareil se mette en marche de

manière imprévue.

Angle inversé

MANETTE DE

BLOCAGE À

CAME

INTERRUPTEUR À

DÉTENTE

REV01

-23-

4. ÉTAPE : IDENTIFICATION DU

INTERRUPTEUR À CURSEUR RAPIDE

Ne jamais laisser l’outil

sans surveillance avec le

sélecteur en position de MARCHE1 ou 2.

L’appareil est actionné par un curseur à trois

positions avec arrêt rapide qui est situé à l’arrière de

l’appareil.

La position 0 est la position d’ARRÊT.

La position 1 met l’outil en marche et active

l’interrupteur à détente qui se trouve sur la poignée.

Lorsque le sélecteur est glissé à la première position,

la position 1, l’appareil se met en marche; il est alors

en attente et pourra être activé à l’aide de

l’interrupteur à détente se trouvant sur la poignée

détachable. Pour ÉTEINDREl’outil, relâcher

l’interrupteur à détente et ramener le sélecteur à la

position 0.

Ne jamais laisser l’appareil sans

surveillance avec le sélecteur à la

position de MARCHE 1, car il est alors en attente et

on peut en faire tourner la Foret Zip par seule

pression de l’interrupteur.

La position 2 met l’appareil en marche continue.

Lorsque le sélecteur est glissé à la seconde position,

la position 2, alors l’appareil fonctionne sans

interruption. Pour l’ÉTEINDRE, ramener le sélecteur

à la position 0.

Remarque : Lorsque la poignée auxiliaire est

détachée, l’appareil ne s’utilise qu’à la position de

MARCHE 2.

5. ÉTAPE : IDENTIFICATION DE

L’INDICATEUR DE VITESSE

La scie mécanique à spirale Revolution s’utilise à des

vitesses de 15, 20, 25 et 30 000 tr/min.

* La vitesse par défaut est 30 000 tr/min. Cela signifie

que si vous ÉTEIGNEZ l’appareil et le RALLUMEZ, il

se réglera automatiquement sur 30 000 tr/min.

* Lorsque l’outil est EN MARCHE (en position 1 ou 2),

l’utilisateur peut changer la vitesse en appuyant sur la

touche de VITESSE VARIABLE.

* Une lampe rouge à DÉL indique la vitesse

sélectionnée..

* Pour obtenir les meilleurs résultats de la scie

mécanique utilisée avec les Foret Zip, il est

recommandé de la faire tourner à 25000 ou à

30 000 tr/min. L’appareil ne réalisera pas une coupe de

bonne qualité au régime de 15000 ou 20 000 tr/min.

!

MISE EN GARDE

4. étape

5. étape

!

ATTENTION

-22-

2. ÉTAPE : RÉGLAGE DE LA

DÉRIVATION D’AIR

Toujours s’assurer que l’outil est ÉTEINT(position 0)

avant de régler les volets de dérivation d’air.

Le volet de dérivation d’air oriente l’air servant au

refroidissement de l’appareil vers la base afin de

chasser les copeaux qui s’y sont accumulés pendant

la coupe.

Pour ouvrir le volet afin que l’air soit dirigé vers la

surface de coupe, glisser la manette vers la

poignée. Pour fermer le volet, glisser la manette

dans l’autre sens.

3. ÉTAPE : RÉGLAGE DU GUIDE DE

COUPE AVANT DE TAILLER

La scie Revolution est conçue pour tailler des

matériaux d’une épaisseur allant jusqu’à 25mm. Se

servir du guide de coupe pour ajuster la profondeur

de la surface à tailler. Ce guide fait partie d’un

ensemble qui inclut le guide et sa manette de

blocage ainsi que la base et sa vis de blocage.

.

Identifier la base et sa vis de blocage. En se servant

de l’extrémité de la clé, desserrer (tourner à gauche)

la vis juste assez pour permettre à la base de glisser

jusqu’à la profondeur de coupe désirée. Pour assurer

les meilleures performances, régler la base pour que

la Foret Zip dépasse d’environ 3 mm la surface à

tailler. par exemple, pour tailler une planche de

contreplaqué de 13 mm, régler la base pour que la

Foret Zip dépasse de 16 mm sous la base, comme le

montre l’illustration. Serrer à nouveau la vis en la

tournant à droite.

Démontage du guide de coupe

et réinstallation

Pour détacher le guide de coupe de l’appareil,

dégager d’abord la manette de blocage, puis enlever

l’ensemble complet en tirant. Pour réinstaller

l’ensemble, le replacer sur le collet de l’appareil et

engager la manette de blocage.

Démontage et remontage de la poignée

Éteindre l’appareil et

le débrancher. Le

tenir solidement.

Glisser la manette à

came en position de

déblocage. Soulever

doucement l’arrière

de la poignée de

manière à dégager la

tige de blocage de

l’appareil. Continuer

de soulever doucement la poignée de manière à

déloger les deux pattes à l’avant de la poignée.

Détacher la poignée de l’appareil. Sans la poignée,

l’appareil ne s’utilise qu’à la position de MARCHE2.

Pour réinstaller la poignée, refaire l’opération en sens

inverse. Engager soigneusement les deux pattes

avant dans l’appareil, puis glisser la tige de blocage

dans son logement. Avant d’utiliser l’appareil, vérifier

en tirant dessus doucement que la poignée est bien

engagée des deux côtés.

2. étape

3. étape

-25-

1. étape

S’assurer que les fils électriques ont été repoussés

au fond de la boîte afin d’éviter qu’ils ne soient

coupés par la Foret Zip lorsqu’elle sera enfoncée

dans la cloison. Le manche d’un marteau se porte

très bien à ce travail.

2. étape

Avant de fixer la planche, faire une marque quelque

part au centre de l’ouverture de la boîte, sur la face

orientée vers soi. Un marteau à cloison sèche fera

très bien l’affaire.

3. étape

Ne pas poser de clous ou de vis à moins de 30 cm

de la boîte, sans quoi la plaque de plâtre risque de

gondoler en raison d’une pression excessive.

4. étape

Glisser le sélecteur pour allumer l’appareil. Tenir

solidement la scie mécanique à spirale

MC

avec ses

deux mains et enfoncer la Foret Zip dans la marque

faite plus tôt. Guider ensuite la Foret Zip vers la droite

jusqu’à ce qu’elle touche le bord de la boîte.

INSTRUCTIONS ILLUSTRÉES POUR L’EXÉCUTION D’OUVERTURES

PARFAITES POUR LES PRISES DANS LA PLAQUE DE PLÂTRE

(modèle SCS01 illustré)

La procédure qui suit illustre comment tailler une ouverture pour une boîte de raccordement

standard de 54 x 95 mm.

Toujours tenir l’appareil avec les

deux mains pour le démarrer,

car le couple du moteur pourrait vous l’arracher

des mains.

Exécuter des coupes d’essai

Après avoir installé la Foret Zip dans l’appareil et

ajusté le guide de profondeur de la manière décrite

plus haut, exécuter quelques coupes d’essai avant

d’amorcer de vrais travaux.

Ces quelques exercices vous donneront

l’expérience requise pour réaliser des coupes nettes

d’aspect professionnel.

6. ÉTAPE :

Avant d’allumer l’appareil, s’assurer que l’écrou de

mors est serré solidement.

7. ÉTAPE :

Tenir solidement la scie mécanique à spirale et la

mettre EN MARCHE.

Toujours tenir l’appareil avec les deux mains pour le

démarrer, car le couple du moteur pourrait vous

l’arracher des mains.

8. ÉTAPE:

Tenir solidement l’appareil et entamer la matériau

avec la Foret Zip à un angle de 45°.

9. ÉTAPE :

Redresser doucement l’outil pour amorcer la coupe.

Le guide de coupe doit se trouver à ras avec la

surface du matériau. Pour tous les matériaux (SAUF

pour tailler dans de la plaque de plâtre autour d’une

boîte de raccordement), diriger l’outil dans le sens

des aiguilles d’une horloge en exerçant une

pression lente et uniforme.

10. ÉTAPE :

Après avoir exécuté la coupe, éteindre l’appareil et

le dégager doucement du matériau.

Ne pas employer cet appareil pour réaliser des

découpages autour d’appareils ou d’ouvertures

comportant des fils électriques sous tension ou dans

des parois derrière lesquelles de tels fils pourraient

se trouver, car la Foret Zip assurerait la conduction

du courant vers l’appareil et mettrait l’utilisateur à

risque de subir un choc électrique. Couper le

courant alimentant ces fils à l’aide des fusibles ou

des disjoncteurs. Toujours tenir l’appareil par son

boîtier thermoplastique et toujours porter une

protection des yeux pour employer une scie

mécanique à spirale.

REMARQUE : En raison de la rotation de la Foret

Zip, l’utilisateur ressentira une légère traction en

taillant. Plus l’utilisateur exécute la coupe lentement,

plus il pourra exercer de maîtrise. Une pression trop

grande ou une exécution trop rapide causera un

excès de chaleur qui pourrait réduire la longévité de

la Foret Zip.

REMARQUE : Lors de l’exécution de coupes dans

une surface verticale, éviter de terminer l’opération

au bas de l’ouverture. Dans la mesure du possible,

débuter et terminer la coupe en haut afin d’éviter

que la retaille ne chute sur la Foret Zip en rotation.

Éteindre ensuite l’appareil et le dégager du

matériau.

-24-

9. étape

!

ATTENTION

8. étape

-27-

9. étape

Tourner le coin inférieur droit, puis déplacer la Foret

Zip vers le haut en exerçant une légère pression à

gauche contre la boîte jusqu’à ce que le début de la

coupe soit atteint. Éteindre l’appareil.

10. étape

Voici la boîte, exécutée rapidement et nettement en

une fraction du temps requis par les autres

méthodes.

Ces instructions par étape sont généralisées afin de

vous familiariser avec l’utilisation de la scie méca-

nique à spirale

MC

. Avec un peu de pratique, vous

développerez une technique avec laquelle vous

serez confortable. Néanmoins, vous devez toujours

débuter la coupe quelque part au centre et

DÉPLACER LA SCIE MÉCANIQUE À SPIRALE

SEULEMENT DANS LE SENS INVERSE DES

AIGUILLES D’UNE HORLOGE afin de profiter de

l’effet de rotation de la Foret Zip qui la fait coller

contre les contours du modèle à découper. Toujours

tailler avec un mouvement uniforme et continu.

-26-

5. étape

Retirer la Foret Zip juste assez pour qu’elle passe

par-dessus le bord de la boîte et qu’elle se retrouve

tout contre sa paroi extérieure.

6. étape

Tout en gardant la Foret Zip en contact avec la paroi

extérieure de la boîte de raccordement, déplacer

l’appareil dans le sens inverse des aiguilles d’une

horloge tout en y exerçant une légère pression vers

l’intérieur et vers le haut jusqu’à ce que le coin soit

atteint. Une fois le coin atteint, exercer une légère

pression vers la gauche et le bas.

7. étape

Déplacer l’appareil doucement et uniformément le

long du haut de la boîte jusqu’au coin suivant.

Tourner le coin, puis exercer une légère pression

vers le bas et l’intérieur jusqu’au coin suivant.

8. étape

Déplacer ensuite la Foret Zip vers la droite et le haut

en exerçant toujours une légère pression vers la

boîte.

1 100326 Carter, section avant, partie supérieure

2 100352 Ensemble de blocage d’arbre

3 100342 Ressort de blocage d’arbre

4 100308 Anneau de retenue, blocage d’arbre

5 100310 Carter, section arrière, partie supérieure

6 100314 Sous-ens. du bloc d’alimentation, partie supérieure

7 100315 Capuchon de commutateur

8a 100316 Manchon protecteur

8b 100350 Manchon protecteur

9 100317 Cordon d’alimentation

10 100318 Anneau de dérivation

11 100380 Sous-ensemble moteur

12 100327 Couvercle des fils

13 RTM710 Vis

14 100328 Autocollant de renseignements

15 100329 Autocollant de nom du produit

16 SC701 Écrou de mors

17 100333 Poignée de gauche, partie supérieure

18 100334 Ensemble de came de blocage

19 100337 Volet de rangement

20 100338 Sous-ensemble d’assemblage

21 100341 Détente

22 100345 Ressort de clé

23 100344 Poignée de droite, partie supérieure

24 100353 Pince

25 100354 Manette

26 100355 Lien de pince

27 100356 Rondelle à ressort

28 100307 Rondelle coulissante

29 100357 Pivot

30 100359 Base

31 100362 Vis à ailettes

32 100363 Écrou plat

33 RTM125 Mors de 3,2 mm

34 RTM250 Mors de 6,4 mm

35 100346 Clé

36 100313 Panneau de membrane

Rep. Node Description

pièce

-29-

SCHÉMA POUR LE MODÈLE REV01

-28-

Coupe-cercle CRCT1

Cet accessoire permet de tailler des cercles

parfaits de 114.3 mm à 305 mm de diamètre à l’aide

de la scie mécanique à spirale.

Accessoires

Porte-mandrin CH01

Cet ensemble permet d’utiliser les Forets Zip de

3,2 mm dans les outils qui acceptent normalement

les fraises de 25 mm, comme les toupies et les

dresseuses. L’emploi des fraises de cette façon en

réduira la durée.

-31--30-

Entretien

L’entretien préventif

effectué par des employés

non autorisés peut entraîner un positionnement

erroné des composants et des fils internes, et ainsi

causer des dangers sévères. Roto Zip Tool Corporation

est le seul centre de réparation autorisé des outils

Roto Zip Tool Corporation. Contactez le service

clientèle en composant le numéro sans frais aux

États-Unis et au Canada 1-877-768-6947, ou 1-608798-1039 Ext. 520, du lundi au vendredi entre 8 et

16h30, heure normale du centre, pour de plus amples

instructions.

Nettoyage

Pour éviter le risque

d’accidents, débranchez

toujours l’outil de la prise de courant avant de

procéder au nettoyage ou à l’entretien. Vous pouvez

très bien le nettoyer à l’air comprimé. Dans ce cas,

portez toujours des lunettes de sécurité.

Gardez les prises d’air et les interrupteurs propres et

libres de débris. N’essayez pas de les nettoyer en

introduisant des objets pointus dans leurs ouvertures.

Certains produits de

nettoyage et dissolvants

dont la gazoline, le tétrachlorure de carbone, les

nettoyeurs chlorés, l’ammoniaque et les détergents

ménagers contenant de l’ammoniaque peuvent

abîmer les pièces en plastique.

Maintenance

Dimensions Recommandées de Prolongateurs

AVERTISSEMENT

!

MISE EN GARDE

!

AVERTISSEMENT

!

Si un cordon de rallonge

s'avère nécessaire, vous

devez utiliser un cordon avec conducteurs de

dimension adéquate pouvant porter le courant

nécessaire à votre outil. Ceci préviendra une chute

excessive de tension, une perte de courant ou une

surchauffe. Les outils mis à la terre doivent utiliser des

cordons de rallonge trifilaires pourvus de fiches à trois

broches ainsi que des prises à trois broches.

DIMENSIONS DE RALLONGES RECOMMANDÉES

OUTILS 120 VOLTS COURANT ALTERNATIF

REMARQUE : Plus le calibre est petit, plus le fil est gros.

Intensité

nominale

de l’outil

Longueur en pieds

Longueur en mètres

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 —— ————

25 50 100 150 15 30 60 120

Calibre A.W.G.

Calibre en mm

2

AVERTISSEMENT

!

Forets Zip

®

La gamme d’accessoires et de Forets Zip

polyvalentes brevetées par RotoZip Tool

Corporation vous donne la flexibilité requise

pour passer d’un matériau à un autre et d’un

projet à un autre sans avoir à changer d’outil.

Accessoires

Utilisez uniquement les accessoires recommandés par Roto Zip Tool

Corporationavec cet outil. Les accessoires qui peuvent convenir à un outil peuvent

devenir dangereux lorsqu'ils sont utilisés sur un autre outil.

AVERTISSEMENT

!

Où pouvez-vous acheter des accessoires ?

L'endroit où vous avez acheté votre outil offre fort probablement la gamme complète d'accessoires Roto Zip. Si

vous cherchez une source, veuillez appeler nos représentants du service clientèle du lundi au vendredi entre 8 et

16h30 (heure normale du centre) au 1-877-768-6947 (sans frais aux États-Unis ou au Canada) ou au 608-7980139 Ext. 520..

ZBSC5

RZ125

RZ250

GP10

ZB10

ZBWD8

FBR250

Circle Cutter – CRCT2

Réalise facilement des cercles de 25 mm à 50 cm

de diamètre dans la plupart des matériaux de

construction les plus courants. Fonctionne avec la

plupart des scies mécaniques à spirale. Obligatoire

avec le modèle Solaris.

Reglas de seguridad para manejar la herramienta Spiral Saw™

Cuando no use la herramienta, guárdela lejos del

alcance de los niños y de cualquier otra persona que

no esté capacitada para manejarla. Las herramientas

son peligrosas en manos de personas inexpertas.

Dé mantenimiento adecuadoa la herramienta.

Mantenga afiladas y limpias las herramientas

de corte, así habrá menos probabilidades de

que sus bordes afilados se traben y podrá

controlarlas con mayor facilidad.

Revise si las partes móviles están desajustadas o

trabadas, si no hay piezas rotas o si existe alguna

otra condición que pueda afectar la operación de

la herramienta. Si ésta se encuentra dañada, déle

servicio antes de utilizarla. Muchos accidentes se

deben a la falta de mantenimiento adecuado de las

herramientas. Establezca un programa de

mantenimiento periódico para su herramienta.

Utilice únicamente los accesorios que el fabricante

recomiende para el modelo de su herramienta. Los

accesorios que pueden ser convenientes para una

herramienta pueden no serlo para otra.

Servicio

El servicio a las herramientas sólo debe

llevarlo a cabo personal de reparaciones

calificado. Si el servicio o mantenimiento se deja

en manos de personas no calificadas, se corre el

riesgo de provocar lesiones.

Cuando le dé servicio a una herramienta, utilice

únicamente piezas de repuesto originales. Siga

las instrucciones en la sección de Mantenimiento

de este Manual. Si utiliza piezas de repuesto no

autorizadas o no sigue las instrucciones de

mantenimiento puede provocar una electrocución

o lesiones. Algunos productos de limpieza como la

gasolina, el tetracloruro de carbono, el amoníaco,

etc. pueden dañar las piezas de plástico.

Cuando realice una operación en la que la

herramienta cortante puede tener contacto con

cables ocultos o con su propio cable, tómela de

las superficies de sujeción aisladas. Un contacto

con un cable “vivo” ocasionará que la corriente se

transmita a las partes metálicas expuestas de la

herramienta y el operador se electrocute. Si tiene

que hacer algún corte en paredes u otras áreas

ciegas donde puede haber cableado eléctrico,

desconecte todos los fusibles y los interruptores de

circuito que alimenten su área de trabajo.

Siempre asegúrese de que la superficie de

trabajo esté libre de clavos y otros objetos

extraños. Si corta un clavo, puede provocar que la

Broca Zip y la herramienta salten y se dañe la broca.

Nunca sostenga la pieza de trabajo con una mano

y la herramienta con la otra. Nunca ponga las

manos cerca o debajo de la superficie de corte.

Es más seguro sujetar el material con una

abrazadera y guiar la herramienta con ambas manos.

Nunca coloque la pieza de trabajo sobre

superficies duras (concreto, piedra, etc.). El

contacto de la Broca Zip cortante con la superficie

puede ocasionar que la herramienta salte.

Siempre utilice anteojos de seguridad y máscara

contra el polvo y asegúrese de que el área esté

bien ventilada. Hacer uso de dispositivos de

seguridad personal y trabajar en ambientes seguros

reducen el riesgo de sufrir lesiones.

Después de cambiar las Brocas Zip o hacer

algunos ajustes, cerciórese de que la tuerca de la

boquilla y demás dispositivos de ajuste estén

bien apretados. Un dispositivo de ajuste suelto

puede moverse inesperadamente y hacerle perder el

control de la herramienta. Los componentes

giratorios sueltos pueden salir disparados.

Nunca encienda la herramienta después de

introducir la Broca Zip en el material. El borde

cortante de la Broca Zip puede atrapar el material y

hacerle perder el control de la máquina. Para poner

en marcha la herramienta, sujétela con las dos

manos. La fuerza de reacción del motor puede

hacer que la herramienta serpentee.

La dirección de avance de la Broca Zip en el

material es muy importante y se relaciona con la

dirección de rotación de la broca. La mayoría de

los materiales deben cortarse hacia la derecha.

Pero si corta alrededor de una caja de salida en un

muro de piedra, debe hacerlo hacia la izquierda. Si

guía la herramienta en la dirección incorrecta,

ocasionará que el borde cortante de la Broca Zip se

salga de la pieza de trabajo y que la herramienta

siga la dirección del avance.

Siempre utilice la herramienta con la guía de

profundidad sujeta firmemente y bien asentada

en el material que está cortando. Con esto

mejorará la estabilidad y el control de su

herramienta.

Nunca utilice Brocas Zip sin filo o dañadas.

Maneje con cuidado las Brocas Zip demasiado

afiladas. Las Brocas Zip dañadas pueden romperse

mientras las está utilizando; y las Brocas Zip sin filo

le exigirán empujar la herramienta con más fuerza,

y puede provocar que la Broca Zip se rompa..

Nunca toque la Broca Zip mientras la está

usando ni inmediatamente después, ya que

estará demasiado caliente para tocarla con las

manos descubiertas.

Nunca ponga la herramienta en el piso antes de

que el motor haya parado por completo. Si la

Broca Zip está girando puede “morder” la superficie y

hacer que pierda el control de la herramienta.

No utilice la herramienta para perforar, pues no

está diseñada para usarse con Brocas Zip de

perforación.

Cierto polvo generado por el lijado, aserrado,

amolado y taladrado mecánicos, y por otras

actividades de construcción, contiene agentes

químicos que se sabe que causan cáncer, defectos

de nacimiento u otros daños sobre la reproducción.

Algunos ejemplos de estos agentes químicos son:

• Plomo de pinturas a base de plomo,

• Sílice cristalina de ladrillos y cemento y otros

productos de mampostería, y

• Arsénico y cromo de madera tratada

químicamente.

Su riesgo por causa de estas exposiciones varía,

dependiendo de con cuánta frecuencia realice este

tipo de trabajo. Para reducir su exposición a

estos agentes químicos: trabaje en un área bien

ventilada y trabaje con equipo de seguridad

aprobado, como por ejemplo máscaras

antipolvo que estén diseñadas especialmente

para impedir mediante filtración el paso de

partículas microscópicas.

Lea con cuidado todas estas instrucciones. Su inobservancia puede

provocar electrocución, incendio y/o lesiones personales.

GUARDE ESTAS INSTRUCCIONES

-32-

Área de trabajo

Mantenga su área de trabajo limpia y bien

iluminada. Tener mesas de trabajo llenas de objetos y

áreas mal iluminadas puede ocasionar accidentes.

No maneje herramientas mecánicas en atmósferas

explosivas, por ejemplo en presencia de líquidos

inflamables, gases o polvo debido a que producen

chispas que pueden inflamar el polvo o los gases.

Cuando opere una herramienta mecánica, evite que

se acerquen transeúntes, niños y visitantes.

Cualquier distracción puede causar la pérdida de

control.

Seguridad eléctrica

Las herramientas con doble aislamiento están

equipadas con un enchufe polarizado (una pata

más ancha que otra). Sólo hay una manera de

introducir este enchufe a un contacto polarizado. Si

el enchufe no entra totalmente en el contacto, dele

media vuelta; si aún así no entra, pida a un

electricista calificado que instale un contacto

polarizado. No cambie el enchufe por ningún

motivo. El doble aislamiento elimina la necesidad

de utilizar un cable de alimentación trifilar con tierra y un

sistema de alimentación con conexión tierra. Antes de

conectar la herramienta, asegúrese de que el voltaje de

salida no difiera más del 10% del voltaje especificado en

la placa del fabricante. No utilice corriente continua con

herramientas con la leyenda “Únicamente corriente

alterna”.

Evite el contacto de su cuerpo con superficies

puestas a tierra como tubos, radiadores, escalas y

refrigeradores. El riesgo de electrocución aumenta al

hacer tierra con su cuerpo. Si tiene que utilizar una

herramienta en un lugar húmedo, la alimentación de

energía debe hacerse con un interruptor de circuito de

pérdidas a tierra. Para aumentar su seguridad personal,

use guantes y zapatos de caucho de electricista.

No exponga las herramientas a la lluvia ni a la

humedad. El riesgo de electrocución aumenta cuando

se filtra agua en una herramienta mecánica.

No haga mal uso del cable. Nunca lo emplee para

cargar la herramienta ni lo jale para desconectarla.

Manténgalo alejado del calor, de aceites, de bordes

con filo o partes móviles. Reemplace

inmediatamente los cables dañados, ya que

aumentan el riesgo de electrocución.

Cuando opere su herramienta al aire libre, utilice

una extensión para exteriores con la especificación

"W-A" o "W". Estas extensiones están diseñadas

para utilizarse a la intemperie y reducen el riesgo de

electrocución. Lea Medidas recomendadas para

extensiones.

Seguridad personal

Al operar una herramienta mecánica, manténgase

alerta, fíjese en lo que está haciendo y aplique el

sentido común. No maneje este tipo de

herramientas si está cansado o bajo el influjo de

drogas, alcohol o medicamentos. Cualquier

distracción puede ocasionarle una lesión grave.

Vístase adecuadamente. No use ropa suelta ni

joyería. Si tiene el cabello largo, sujételo. Mantenga

su cabello, ropa y guantes lejos de las piezas

móviles. La ropa suelta, las joyas y el cabello largo

pueden atorarse en estas piezas. Mantenga los

mangos de las herramientas secos, limpios y sin aceites

o grasas.

Evite accidentes en el arranque. Antes de

conectarla asegúrese de que el interruptor esté en

“OFF” [APAGADO]. Transportar herramientas con un

dedo en el interruptor, o conectarla con el interruptor en

“ON” [ENCENDIDO], puede provocar accidentes.

Antes de encender la herramienta, retire las cuñas

o llaves de tuercas, si deja alguna de éstas en una

parte giratoria de la herramienta, puede sufrir lesiones

corporales.

No se estire demasiado. Mantenga el cuerpo

equilibrado adecuadamente en todo momento.

Esto le ayudará a controlar mejor la herramienta en

situaciones inesperadas.

Utilice equipo de seguridad. Protéjase los ojos. Para

trabajar en condiciones adecuadas lleve una máscara

contra el polvo, zapatos de seguridad antiderrapantes,

casco o protectores para los oídos.

Uso y cuidado de las herramientas

Use abrazaderas o cualquier otro dispositivo

práctico para asegurar y apoyar la pieza de

trabajo a una plataforma estable. Si sujeta la

pieza con la mano o contra su cuerpo puede

perder el control de la misma

No fuerce las herramientas. Utilice la herramienta

adecuada para cada aplicación. La herramienta

correcta le permitirá realizar su trabajo mejor, con mayor

seguridad y a la velocidad para la que está diseñada.

No utilice la herramienta si el interruptor de

encendido y apagado no funciona. Toda

herramienta que no puede controlarse con el interruptor

es peligrosa y debe repararse inmediatamente.

Desconecte la herramienta antes de hacer