Page 1

USER'S MANUAL

On-Grid PV Inverter

Series: RITxK(x=5,6,8,10,15,20,30,40,50,60)

USERS MANUAL

1

Page 2

INSTALLATION,OPERATION AND REPAIR MANUAL

About Rotosol

Rotosol solar (Division of Rotomag Motors and Controls Pvt. Ltd., located Near Anand,Gujarat,India .,

which is specialized in manufacturing of solar PV inverters.

Rotosol is dedicated to providing perfect power conversion and control solutions for solar power generation

installations , manufacturing and marketing of solar PV inverters. Rotosol possesses the first-class

production equipment . Rotosol provide all kinds of high-quality and reliable grid-connected solar inverters

and energy system solutions to satisfy the consistently increasing demands for global energy.

The newly designed PV Inverter features itself with full load high efficiency, high reliability and user-friendly

interface. The maximum conversion efficiency of our inverter is up to 98%. A user-friendly installation &

interface, professional industrial design, and design for reliability mechanism, give the Inverter Family a

competitive edge for customers from all regions.

As a customer-oriented company, Rotosol is always trying to improve product and enhance customer

satisfaction. High quality with customer satisfaction is the Goal of Rotosol , not just in product quality control,

but also in quality of service and support. Rotosol is able to help customers reduce energy consumption and

carbon dioxide emissions by leading green solutions.

2

Page 3

CONTENTS

1. About This manual

1.1Scope of Validity.................................................................................................................................. 4

1.2TargetGroup........................................................................................................................................... 4

1.3Additional Information........................................................................................................................4

2Safety Instructions

2.1 Safety Precautions..............................................................................................................................5

2.2 Explanations of Symbols................................................................................................................... 6

3 Unpacking

...............................................................................................................................................................

3.1 Assembly Parts...................................................................................................................................7

3.2 Identifying the Inverter...................................................................................................................... 8

4 Mounting

..................................................................................................................................................................

4.1 Safety................................................................................................................................................. 9

4.2 Selecting the Appropriate Mounting Location...................................................................................9

4.3 Mounting the Inverter with Wall Mounting Bracket........................................................................11

5 Electrical Connection

Notes:

...........................................................................................................................................................................

5.1 Overview of the Connection Area................................................................................................... 13

The following figures show the assignment of the individual connection areas on the bottom of

theInverter..............................................................................................................................................13

5.2 Connection to the Public Grid (AC)................................................................................................ 13

5.3 Connection to the PV Generator (DC).............................................................................................16

6 System Diagram

7 Operation

..............................................................................................................................................................

7.1 Overview of Control and Displays........................................................................................................ 23

7.2 Commissioning.................................................................................................................................... 24

7.3LED Display........................................................................................................................................ 24

7.4LCDDisplay........................................................................................................................................25

8 Trouble Shooting

9 Inverter Inspection and Repair

9.1LCDcannotDisplay..............................................................................................................................34

9.2LCDdisplay FaultCodes....................................................................................................................... 34

9.3RepeatCountdown, cannot generation......................................................................................................35

9.4ACcircuit breakertrip............................................................................................................................ 35

9.5MonitoringFault...................................................................................................................................35

9.6Problem During Inverter Generation.........................................................................................................35

9.7 PowerComponents Inspection(without DC power supply)......................................................................36

9.8 MOSFET Driver Inspection(for 5th generation models).......................................................................... 41

9.9 Inverter FrequentlyTrippingDue to Grid Fluctuation..............................................................................41

10 Contact

Annex Warranty Terms (Overseas)

...............................................................................................................................................................

............................................................................................................................................

..................................................................................................................................................

....................................................................................................................................

...............................................................................................................................................

.................................................................................................................................................

.................................................................................................................

............................................................................................................

4

5

7

9

12

12

21

23

30

34

43

43

3

Page 4

1. About This manual

1.1 Scope of Validity

This manual describes the installation, commissioning, operation and maintenance of the following on-grid

PV inverters produced by Rotosol:

Commercial Systems & Power Plants 5-60KW

RIT5K , RIT6K, RIT8K, RIT10K, RIT15K, RIT20K, RIT30K, RIT40K, RIT50K, RIT60K

Please keep this manual all time available in case of emergency.

1.2 Target Group

This manual is for qualified personnel. The tasks described in this manual must only be performed by

qualified personnel.

1.3 Additional Information

For more information please go through the website www.rotosol.solar

4

Page 5

2 Safety Instructions

2.1 Safety Precautions

1. All work on the inverter must be carried out by qualified electricians and ensure that children can

not access to the equipment.

2. The device may only be operated with PV generators. Do not connect any other sources of energy

to the device.

3. This PV generator and inverter must be connected to the ground in order to reach maximum

protection for property and persons.

4. Do not touch cover until 3 minutes after disconnecting all sources of supply. This is because the

charge stored in capacitors may result a risk of electric shock.

5. The enclosure of Inverter can become hot during operation. To reduce the risk of injury, do not

touch the cover, heat sink at the back of the PV-lnverter or nearby surfaces while Inverter is

operating.

6. Do not use the equipment for purposes other than those described in this manual.

7. Both the inverter and associated transport packaging are mainly made of recyclable raw materials.

Please ensure that the used device and any relevant accessories are disposed of in accordance

with applicable regulations.

8. Packed with damping EPE and carton, Rotosol inverter should be placed upwards and handled with

care in delivery. Pay attention to waterproof.

9. Alternative uses, modifications to the inverter not recommended by Rotosol or the installation of

components not sold by Rotosol void the warranty claims.

5

Page 6

2.2 Explanations of Symbols

6

Page 7

3 Unpacking

Object

Quantity

Description

Object

Quantity

Description

A1Solar inverter

B1Wall mounting bracket

C1User manual

D1Certificate of inspection

E1Installation diagram

F

1

Notice for installation

G

1

Warranty card

H

1

RV5.5-6 terminal

I

3

Plastic Expansion Tube

J

3

Tapping screw

K

1

Security screw

L

1

Screwdriver for security screw

M

2sets

DC plug connector

N4Screw

O

1

Waterproof Junction Box

P

4

Terminal

3.1 Assembly Parts

Please check the delivery for completeness and any visible external damage. Contact your dealer at once

if anything is damaged or missing.

Assembly parts are as listed below:

7

Page 8

3.2 Identifying the Inverter

You can identify the inverter by the type label. Information such as serial number (Serial No.) and

model name of the inverter, as well as the device's technical parameters are specified on the type label.

The type label is on the right side of the enclosure.

8

Page 9

4 Mounting

4.1 Safety

DANGER!

Danger to life due to potential fire or electric shock.

Do not install the inverter near any inflammable or explosive items. The inverter will be directly connected

with high voltage power generation device. The installation must be performed by qualified personnel only

in compliance with national or local standards and regulations.

CAUTION!

Danger of burn injuries due to hot enclosure parts.

•Install the inverter so that it cannot be touched inadvertently.

Risk of injury due to the heavy weight of the inverter.

• Take the inverter's weight into account for mounting. (Weight of inverter refers to chapter 8.)

4.2 Selecting the Appropriate Mounting Location

Consider the following points when selecting where to install:

The mounting method and location must be suitable for the inverter's weight and dimensions.

The inverter must be installed in the solid walls ,such as brick walls or concrete walls in case of

vibration noise or inverter falling off.

The installation site should be clearly visible and can be safely into without aids such as scaffold.

For the convenience of checking the LCD display and possible maintenance activities, please

install the inverter at eye level.

The altitude of installation site should be below 2000m,more than 2000m above the sea level will

cause derating.

The ambient temperature of installation site should be between -20 °C and +55 °C (between -4 °F

and 131 °F).

Install the inverter directly exposing to strong sunshine is not recommended, the excess heating

9

Page 10

might lead to power reduction.

Leave enough effective space around the inverter for better ventilation.

• Vertical installation, wiring area must be downside, lateral installation is not allowed; in backward

tilted installation, tilt angle should not exceed 30 degrees; Forward tilted, horizontal or inverted

installation is not allowed.

10

Page 11

4.3 Mounting the Inverter with Wall Mounting Bracket

1. Use the wall mounting bracket mark the drilling position and drill the holes for the screws.

2.Fix the wall mounting bracket with the equipped self-tapping screw.

3. Hang the inverter to the mounting bracket and ensure the slot is fitted on the bracket.

4. Check to ensure the inverter is correctly seated. Make sure to lock it with the security

screws. (See the figure below.)

11

Page 12

5 Electrical Connection

Notes:

1. Electrical installation & maintenance shall be conducted by licensed electrician and shall comply

with local Wiring Rules.

2. After the inverter has been installed in its fixed position, the electrical connection to the unit can be

established.

3. Make sure Max. Open Voltage and short-circuit current of the each PV strings accord with the Spec.

4. Choose the appropriate cable width for AC/DC wire. The cross sectional area of DC input conductor

lead should be 4mm2PV wire, that of AC output conductor should also be 4mm2cooper wire, and

that of external ground conductor should be 4mm2cooper wire.

5. On both sides of inverter to the grid and PV array, there must be between circuit breaker and surge

protector, and during inverter electrical connections, circuit breakers on both sides should be

disconnected to prevent electric shock.

6. To connect the inverter,the AC and DC sides must be disconneted from all power sources and

secured against being inadvertently swithced back on.

7. Before connecting the inverter to PV arrays and public grid, make sure the polarity is correct.

12

Page 13

5.1 Overview of the Connection Area

Object

Description

a

DC connectors ( + ) for connecting the PV strings

b

DC connectors ( − ) for connecting the PV strings

c

WiFi/RS485 Communication Waterproof Connector

d

Waterproof Junction Box, AC connection

e

DC Switch

The following figures show the assignment of the individual connection areas on the bottom of theInverter.

5.2 Connection to the Public Grid (AC)

5.2.1 Conditions for Connection

CAUTION!

Unit Disconnection From Load

Disconnect the circuit breakers and switches of inverters AC and DC sides.

5.2.2 Connection to Public Grid (AC)

13

Page 14

Measure the grid voltage to make sure within the permissible range. Disconnect the circuit

1. Disconnect the DC and AC breaker, DC switch in the"OFF"state..

2.Disconnect the DC and AC breaker, DC switch in the"OFF"state.

3. Assembly yellow-green Ground wire RV5.5-6 terminal, and connect to one ground terminal.

breaker between the inverter and the grid.

14

Page 15

4.Prepare AC cable(Φ4mm2 or bigger), stripping length is 14±0.5mm. Connect the cable with

terminals.

5. Run the cable harness with the pressed terminals through the junction box and insert the black

cable harness, L1, L2 and L3 into the caps of N, W, V and U as shown in the system connection

diagram. Tighten the screws.

15

Page 16

6. Close junction box and tight the screws

5.3 Connection to the PV Generator (DC)

CAUTION!

Unit Disconnection From Load

Disconnectcircuit breakers and switches on bothAC and DCsides

5.3.1 Conditions for the DC Connection

The connected PV modules must meet following requirements

-Sametype

-Samemodel

-Identical alignment

- Identical tilt

The following limit values at the DC input of the inverter must not be exceeded (connecting to a higher

16

Page 17

voltage will destroy the device):

Type

Maximum input voltage [Vd.c]

Maximum input current [Ad.c]

RIT5K

1000

11x2

RIT6K

1000

11x2

RIT8K

1000

11x2

RIT10K

1000

11x2

RIT15K

1000

22+11

RIT20K

1000

22x2

RIT30K

1000

33x2

RIT40K

1000

40x2

RIT50K

1000

36x3

RIT60K

1000

40x3

5.3.2 Assembling the DC Plug Connector

In order to connect to the inverter, all connection cables of the PV modules must be equipped with the DC

plug connectors provided. You will find the necessary DC plug connector for DC connection in the package.

To assemble the DC plug connectors, proceed as detailed below. Ensure the plug connectors have the

correct polarity.

The plug connector in DC side includes male and female as blow.

Please note that the sizes of metal connecting tubes are different. The bigger one is for female connector

and the smaller one is for male connector.

17

Page 18

Assembly Instructions:

♦ Prepare the DC wire to connect the positive and negative DC arrays. Stripping length is 12~15mm,

sectional area is 4 mm2as below.

♦ Insert the DC wire to metal connecting tube. Make sure all line heads are in the connecting tube as

picture blow.

♦ Use crimping pliers to fasten the metal connecting tube and copper wire. Make sure the harness will not

18

Page 19

fall off, see picture below.

♦ Insert the assembled cable into male/female connector. A "chick" sound can be heard when

connecting correctly. Then tighten the cap. Refer to the picture below.

5.3.3 Connecting the PV Generator (DC)

DANGER!

Danger to life due to high voltage in the inverter.

• Before connecting the PV generator, ensure that the AC&DC circuit breaker is switched off.

Notes:

1. Make sure that you have disconnected circuit breakers and switches on both DC and AC sides.

2. Check the connection cables of the PV modules for correct polarity and that the maximum input

voltage of the inverter is not exceeded.

3. Check the DC plug connector for correct polarity and well connected.

19

Page 20

Plug the DC plug connectors into DC terminals on Inverter.

The inverter DC input is equipped with two groups(DC-A and DC-B) of connecting sockets for DC input ,

and each group contains two pairs of connecting sockets (DC+ and DC-). Make sure at least one pair of

DC terminal in each group is connected with PV array in installation,and group A and B must be

connected with two arrays separately but not with one array,see picture below.

20

Page 21

6 System Diagram

Type

Max AC Current [A]

Rate current of AC breaker[A]

RIT5K

8.5

16

RIT6K

10.5

16

RIT8K

13.5

20

The typical connection diagram for the entire PV system is shown in the following figure.

1. PV Panel: Provide DC power to inverter

2. Inverters: Converts DC (Direct Current) power from PV panel(s) to AC (Alternating Current) power.

Because Inverter is grid-connected, it controls the current amplitude according to the PV Panel

power supply. Inverter always tries to convert the maximum power from the PV array.

3. QF1/QF2 Breaker: The current per DC string does not exceed 25A.

4. QF3 Breaker: Refer to the following table to choose the AC breaker.

Refer to the following table to choose the AC breaker.

21

Page 22

RIT10K

17

25

RIT15K

27

32

RIT20K

32

40

RIT30K

45

63

RIT40K

60

100

RIT50K

75

100

RIT60K

90

125

5. LPS: Lightning protection system, refer to the fol owing options:

AC side, nominal discharge current 20KA, second grade lightning protection, protection voltage 2.5KV

DC side, nominal discharge current 20KA, second grade lightning protection, protection voltage 3.2KV

6. The wiring distance between the inverter and the distribution box should be at least 5 meters.

7.Utility: Referred to as "grid" in this manual, i.e. the media your electric power company provides power to

your place. Please note that Inverter can only be connected to low-voltage systems (namely, 220/230Vac,

50/60Hz).

22

Page 23

7 Operation

Product Overview

7.1 Overview of Control and Displays

There are four function keys on the front panel: UP, DOWN, ESC, ENT. The keypad is used for:

Up and Down keys: Scrolling the displayed parameter, or modify the adjustable parameters; Esc and Ent keys:

Cancel orEnter.

23

Page 24

7.2 Commissioning

Sign

Color

Instructions

POWER

Green

On: Power On

COM

Green

On: Normal Operations and Feed the utility grid.

FAULT

Red

Flash: Check wiring

After completing of the mechanical and electrical installation, the inverter could be put into operation.

1. Switch off DC and AC side circuit breakers and switches.

2. Wait until the screen is on and set up grid connection standard. (Please refer to 7.4.1 for specific

operations)

3. The inverter starts up and feed into the utility grid automatically when all the necessary conditions

of normal operation for the inverter is fulfilled.

4. Check whether the display and LEDs are indicating a normal operating state.

7.3 LED Display

Three LED lights are assembled on the inverter, COM,POWER, FAULT. When DC andAC power are normaland

the inverters startsup,the POWER LED turns on. Whentheinverter is operating andfeedelectricityinto the utility grid

normally,theCOM LED turnson. When thereis faulty in the PVSystem orinverter,theFAULT LED flashes,andthe faulty

code willbe shown on LCD Screen.

POWER LED (Green)

POWER LED turns on when DC voltage reaches the start-up voltage and turns off when it falls below a

certain value. POWER LED is on represents inverter is active and so is the inverter control system. If POWER

LED is off, inverter cannot be normally started up.

Under normal operation conditions, when light is sufficient, inverter connects to the grid and generates in

the morning and stops after dark. This procedure may repeat several times in one day, especially in

morning and at night. It is a normal working phenomenon but not a wrong signal.

COMLED(Green)

TheCOMLEDturnsonwhentheinverterstart feedelectricity intogrid.Andthe COMLEDisoffwhentheinverter is standby.

FAULTLED(Red)

Red FAULT LED turns on means the on-grid generation is stopped due to some faults. Please wait 10

24

Page 25

minutes to be sure whether the fault is temporary. If yes, inverter will automatically restart again. If not,

contact after-sales personnel.

7.4 LCD Display

Inverter will start up automatically with enough DC voltage provided by PV array. When starting up (POWER

LED is on), it shows "Rotosol" on LCD in front of the inverter.

The inverter will delay 1 second and automatically jump to the System Checking Interface.

7.4.1 First Boot Setting

First turned on power, the inverter will delay 1 second and automatically jump to the reminder interface to

set country.

Press Ent to country and standard setting interface. Press UP and DOWN to show countries. Choose

corresponding country and standard and press Ent.For example installed in India, please choose

Country setting completed, system will automatically jump to the reminder interface to set time.

25

Page 26

Press Ent to time setting interface. Press UP and DOWN to adjust number and press Ent. Set year, month,

Display

Description

Power

Current Output Power

IPV1/IPV2

DC Input Current in MPPT One/Two

VPV1 /VPV2

DC Input Voltage in MPPT One/Two

BUS+/BUS-

Voltage of BUS+/BUS-

Ia/Ib/Ic

AC output Current per phase

Ua/Ub/Uc

AC output Voltage per phase

FAC

AC Output Frequency

day, hour, minute and second one by one according to local time.

7.4.2 Main Interface

When time setting is completed, press Ent to exit and system will enter into the main interface as below.

The LCD will automatically enter into the main interface after system checking when the inverter starts up

next time. Operation status and generation information of inverter will be show on the main interface

(Display Info),the current time will be shown in the last line.

Generation information interface scrolls every 3 seconds. Up and Down also can be used to select.

Items of generation information are as follows:

26

Page 27

Etoday

Total Generation Capacity today

Etotal

Total Generation Capacity

ETPV1/ETPV2

Total Generation Capacity today in MPPT One/Two

RunTim

Total Running Time Today

SumTim

Total Running Time

7.4.3 Query Interface

Dispay

Description

Standard

Country and standard setting

Case_Temp

Chasis temperature

ModleTemp

Power module temperature

Screenwriter

LCD temperature

Rated Power

Inverter rated output power

PG1Imp

The insulation resistance of positive pole in PV1

NG1Imp

The insulation resistance of negative pole in PV1

PG2Imp

The insulation resistance of Positive pole in PV2

Press Ent on main interface to view related information in query interface. Eight choosing items on the

query interface: System Info,Error Record,SET,Clear Record,Data & Time SER,RS485 Address,SN

Number,GridpowerCtrl. Press UP and DOWN to select the query item,press Ent to get in and Esc back to

main interface.

System Info

System Informationshows country standard and operation parameters.

UPand DOWN could beused to show the itemsof Systeminfo as follows:

27

Page 28

NG2Imp

The insulation resistance of negative pole in PV2

Error Record

Display

Description

Nub/Total

Fault sequence/Total faults number

E

Fault Code

ST

Fault starting time

ET

Fault Ending Time

In Error Record, it shows fault series number, the time fault happens, faulty code and error display. When fault

happens, FAULT LED turns on. "Trouble Shooting" in Chapter 9 is for users to refer to investigate and solve

the faults. Please contact after-sales if the problem stillexists.

Error Record Shows:

SET

Reset the inverter parameters by selecting SET. Passwords are needed for the setting. Which only can be

operated by after sales personnel to make sure the safety and normal operations of the inverter.

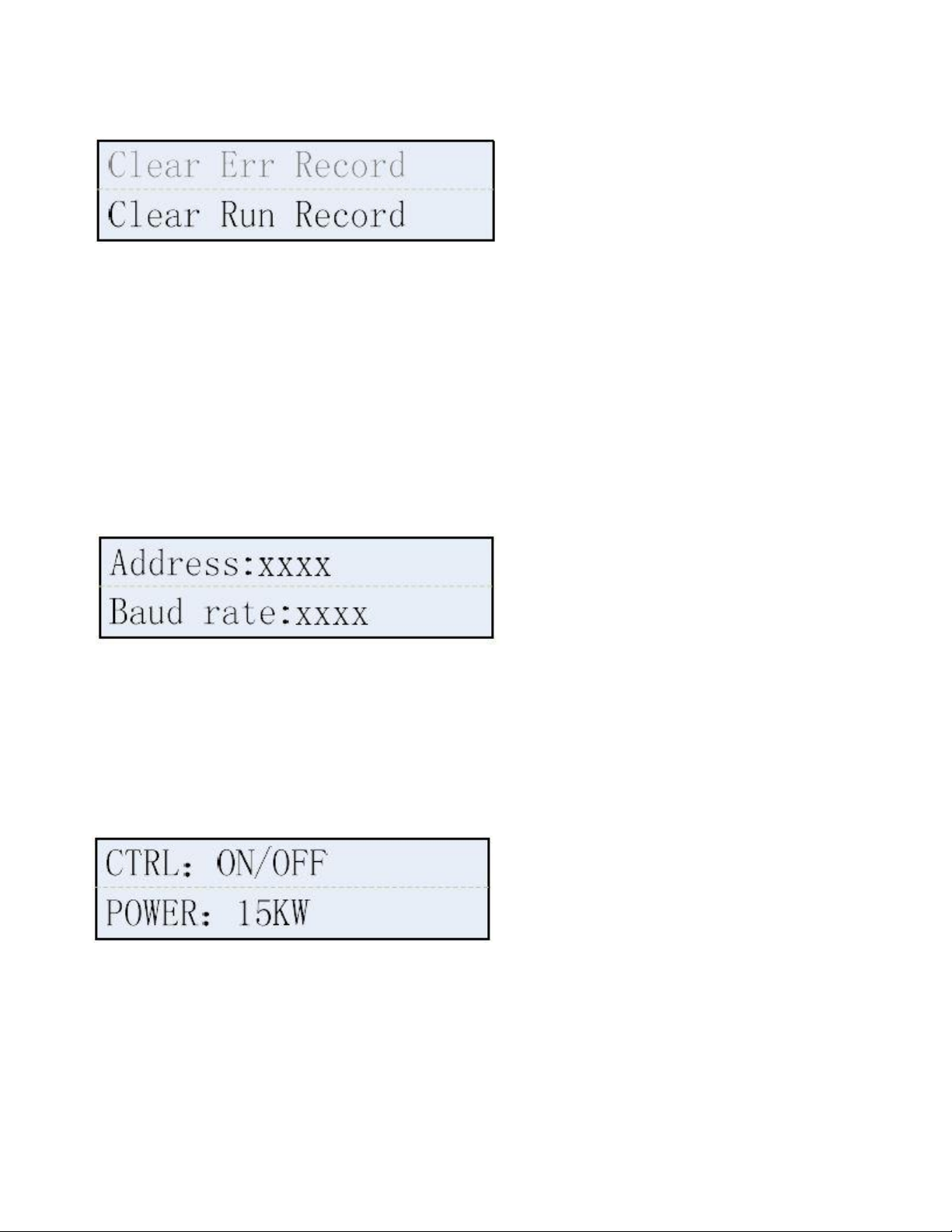

Clear Record

Clear inverter's Error Record and Run records. Passwords are needed for the setting,which only can be

28

Page 29

operated by after sales personnel to make sure the safety and normal operation of the inverter.

Date & Time SET

Press Ent to Date and Time setting interface.Press UP and DOWN to adjust number and press ESC go to next step.

Set year,month,day,hour and minute one by one according to local time. Press ENT save and back to main interface.

RS485Setting

485 address shows communication address and baud rate. Press ENT to enter communication address setting

interface;press UPand DOWN to change values;Press ENTto confirm.

SN It shows inverter's serial Number

SetPowerCtrl

This item is for setting grid-connecting power limitation. Press ENT to enter control selection interface. Press UP and

DOWN to choose start-up or use forbidden,then press ENT to confirm;Press ENT to enter power limitation setting

interface. Press UPand DOWN to set limitationvalue,then press ENT to confirm.

7.4.4 LCD Back light Control

The back light of LCD will automatically turn off after 5 minutes,and LCD will automatically turn off after 10 minutes to

saving-electricity mode. Press any key to turn on the LCD.

29

Page 30

8 Trouble Shooting

Error display

Possble causes

Corresponding measures

EepromErr

1.Unstable PV Input voltage

2. Machine Failure

1.After PV input voltage is stabilized, the machine will

automatically restart.

2. Please contact with local dealer if error remains the

same after several reset.

GFCI.Err

1.PV(+) or PV(-) earthing

2.Machine Failure

1.Check PV(+) and PV(-)ground impedance, make sure

impedance is more than 2M Q.

2.Please contact with local dealer if error remains the

same after several reset.

GridF.OutLim

Electricity grid fluctuations

1. After electricity grid returns to

normal,the machine will automatically restart.

Electricity grid Frequency out

of range

2.Please contact with local dealer if error remains the

same after several reset.

Machine failure

GridV.OutLim

1. Off Phase

1.Disconnect the input/output switch, check the ACside wiring and reset the plug to rule out bad

2.Electricity grid Phase/line

voltage overload

2.After electricity grid returns to normal,

the machine will automatically restart.

3.electricity grid Voltage

unbalance

3.Please contact with local dealer if error remains the

same after several reset.

IntFaultA

Machine failure

Please contact with local dealer if error remains the

same after several reset.

IntFaultB

1.PV input voltage is too high

1..Adjust the panel configuration to lower the input

voltage.

2.Electricity grid abnormal

2.After electricity grid returns to normal,

the machine will automatically restart.

3.Bus hardware overvoltage

fault

3.Please contact with local dealer if error remains the

same after several reset.

IntFaultC

Electricity grid abnormal

1.After electricity grid returns to normal, the

machine will

In most situations, the inverter requires very little service. However, if inverter is not able to work perfectly,

we recommend the following solutions for quick troubleshooting.

30

Page 31

Unbalanced current fault

automatically restart.

2.Please contact with local dealer if error remains the

same after several reset.

IntFaultD

1.Electricity grid abnormal

1.After electricity grid returns to normal, the

machine will automatically restart.

2.Software over current fault

2.Please contact with local dealer if error remains the

same after several reset.

IntFaultE

1.Electricity grid abnormal

1.After electricity grid returns to normal,

the machine will automatically restart.

2.Hardware over current fault

2.Please contact with local dealer if error remains the

same after several reset.

IntFaultG

1.Electricity grid abnormal

1.After electricity grid returns to normal,

the machine will automatically restart.

2.DCI too high

2.Please contact with local dealer if error remains the

same after several reset.

IntFaultJ

Relay failure

Please contact with local dealer if error remains the

same after several reset.

IntFaultK

1.Electricity grid abnormal

1.After electricity grid returns to normal,

the machine will automatically restart.

2.Bus differential fault

2.Please contact with local dealer if error remains the

same after several reset.

IntFaultL

1.Electricity grid abnormal

1.After electricity grid returns to normal,

the machine will automatically restart.

2.Low Bus voltage fault

2.Please contact with local dealer if error remains the

same after several reset.

IntFaultM

1.Electricity grid abnormal

1.After electricity grid returns to normal,

the machine will automatically restart.

2.High Bus voltage fault

2.Please contact with local dealer if error remains the

same after several res

IntFaultN

Internal hardware fault

Please contact with local dealer if error remains the

same after several reset.

IntProtectA

Offset current protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectB

Relay protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectC

Over current protection

Please contact with local dealer if error remains the

same after several reset.

31

Page 32

IntProtectD

l.PVside high current

1.Adjust the panel configuration to lower the input

current.

2.Boost over current protection

2.Please contact with local dealer if error remains the

same after several reset.

IntProtectE

1.Electricity grid abnormal

1.After electricity grid returns to normal,

the machine will automatically restart.

2.Soft start overtime protection

2.Please contact with local dealer if error remains the

same after several reset.

IntProtectF

When direct current is at

low

Please contact with local dealer if error remains the

same after several reset.

voltage, Soft start

overtime protection.

IntProtectG

Bus voltage differential

protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectH

Low Bus voltage protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectl

High Bus voltage protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectl

Inverter bridge protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectK

Bus hardware overvoltage

Please contact with local dealer if error remains the

same after several reset.

protection

IntProtectL

Power module protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectM

1.electricity grid unbalance

1.After electricity grid returns to normal,

the machine will automatically restart.

2.Unbalanced current protection

2.Please contact with local dealer if error remains the

same after several reset.

IntProtectN

1.Electricity grid abnormal

1.After electricity grid returns to normal,

the machine will automatically restart.

2.Hardware

32

Page 33

overcurrentprotection

2.Please contact with local dealer if error remains the

same after several reset.

IntProtectO

MCU protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectP

Frequency fault protection

Reset grid frequency in accordance to local grid

standard

IntProtectQ

DCI too high protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectR

DCI offset protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectS

Voltage offset protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectT

PV over current protection

Please contact with local dealer if error remains the

same after several reset.

IntProtectU

Internal hardware

abnormal

protection

Please contact with local dealer if error remains the

same after several reset.

IsolationErr

1.PV(+) or PV(-) earthing

2.Lightening

3.Machine failure

1.Check PV(+) and PV(-) ground

impedance, make sure impedance is more

than 2MQ.

2.Please contact with after-sales if error remains the

same after several reset.

PV. Reverse

1.PV polarity reverse protection

1.Turn off input/output switch,check if pv polarity is

correct or

2.Machine failure

not, for troubleshooting.

2.Please contact with after-sales if error remains the

same after

PVVoltOver

PV The input voltage is too high

1. Adjust the panel configuration to lower the input

voltage.

2.Please contact with local dealer if error remains the

same after several reset.

SPICommErr

SPI communication error

Please contact with local dealer if error remains the

same after several reset.

TempOver

1.The machine is exposed to

sun.

1. Lower machine surrounding temperature or move it

to a lower

2.the ambient temperature is too

temperature place.

33

Page 34

high

2. Remove foreign matter.

3. The heat sink or fan blocked

by foreign matter

3.Please contact with local dealer if error remains the

same after several reset.

4.Machinefailure

TempSensorErr

Abnormal temperature sensor

Please contact with local dealer if error remains the

same after several reset.

ExtFanErr

1.Fan blocked by foreign matter

1.Remove foreign matter.

2.Machine failure

2.Please contact with local dealer if error remains the

same after several reset.

IntFanErr

Internal fan fault

Please contact with after-sales if error remains the

same after several reset.

Restart: Disconnect input and output switches in order, reconnect them after LCD and indicating

lights go off.

If there is no display on the LCD, please check both AC and DC wiring.

If the input DC voltage is higher than start up voltage, the inverter still doesn't work, please call local

service.

If it is intended to replace the cable or open the enclosure lid, please call our service.

Under the low light conditions, the inverter may continuously start up and shut down. It is due to

insufficient power generated to operate the control circuits.

9 Inverter Inspection and Repair

9.1 LCD cannot Display

a. check DC wiring is ok.

b. PV array’s ‘+’ and ‘-’ is right connect with inverter’s DC input connector;

c. check DC switch is at ‘ON’ position;

d. check PV array’s voltage within right range by use multi meter.

9.2 LCD display Fault Codes

9.2.1 Grid Fault

a. check safety code or country code is correct (all of the models provide to Rotomag is India);

b. check grid’s voltage and frequency is within setting range (for the place where the real range is out of

setting, please contact us for detailed setting);

34

Page 35

c. check all of AC wiring connection point is well connected.

9.2.2 Isolation Fault

Check PV array have leak current.

9.2.3 Input DC bus voltage High

9.2.3.1 check DC input voltage is within inverter’s input range;

9.2.3.2 check all of AC wiring connection point is well connected.

9.3 Repeat Countdown, cannot generation

9.3.1 check the resistance between PV(+) and ground, PV(-) and ground bigger than 2MΩ;

9.3.2 check PV array’s output voltage is correct.

9.4 AC circuit breaker trip

9.4.1 check circuit breaker’s capacity is suitable with inverter’s maximum output power;

9.4.2 for the system installed with leak current sensor circuit breaker,

a. trip during cloudy /rainy day, change with higher capacity of current senor breaker;

b. check if the PV panel’s frame is too close with ground or roof , exit the leakage current;

c. check if the PV DC wiring have the leakage current.

9.5 Monitoring Fault

9.5.1 cannot search wifi single of inverter,

before open the cover of monitoring card, please make sure the inverter is generation;

a. check the cable wiring is well connected;

b. the LED on the monitoring card is flash;

c. Measure the voltage of signal cable is correct(DC 5V)

9.5.2 WIFI cannot upload data

connect inverter’s WIFI with smart-phone, and go to 10.10.100.254 website via smart-phone’s explorer.

a. check if the inverter’s WIFI card have been assigned IP address;

b. check the inverter’s power generation date or serial information displayed through the web page.

c. check the WIFI signal is strong enough.

9.6 Problem During Inverter Generation

9.6.1 Power generation lower than expect

a. check if the panel surface need to be clean;

b. check if the panel have shading problem;

c. check all of the DC wiring is well connected;

d. check if the wiring connection point have been oxidized;

e. check the cable used for DC and AC is right size, and the length of the cable not excess the recommend

length.

35

Page 36

9.6.2 Generation difference between two or among three MPPT channels.

a. check each MPPT channels’ input voltage not higher than 30%;

b. check PV array’s tilt and azimuth angle is the same;

c. check if the PV array have shading problem.

9.6.3( Grid line Voltage Fault) Fault Report

a. due to the grid fluctuate, if the fault report occasionally, you can ignore this fault report, and the inverter

could recover automatically after the grid back to the normal;

b. if this fault frequently report, we recommend to upgrade the firmware of DSP.

9.6.4 E17(Grid Voltage Fault) Fault Report

a. check the safety/country code is correct;

b. check all of the AC wiring point is well connected;

c. measure the AC voltage is within normal range;

d. re-setting the AC output range(maximum volt. Is 519Vac).

9.6.5 E29(M Grid Freq Fault) Fault Report

a. check the safety/country code is correct;

b. check all of the AC wiring point is well connected;

c. measure the AC frequency is within normal range;

d. re-setting the AC frequency range(49.0 ~ 51.0Hz).

9.6.6 Other Fault Report

9.6.6.1 Inverter report the same Fault Code during the same time of the day

Check if the AC output point nearby have the big power load. When the load start, the grid voltage or

frequency will be affect.

9.6.6.2 Inverter report over current or over voltage fault code

a. check the cable used for DC and AC is right size, and the length of the cable not excess the recommend

length;

b. check local load consumption is low, grid voltage is high;

c. switch the output line to the lower voltage phase if possible.

9.6.6.3 Circuit breaker trip during frog, cloudy and rainy day

check the resistance between PV(+) and ground, PV(-) and ground lower than 2MΩ.

9.6.6.4 Daily generation date cannot count from zero

check the date and time setting is correct.

9.7 Power Components Inspection(without DC power supply)

9.7.1 Power diode

a. single diode

b. dual-diode

36

Page 37

Switch to the diode position of multimeter, please notice the ‘+’ and ‘-‘. The normal value is 0.33~0.37V(‘+’

with ‘-‘), ∞ (‘-‘ with ‘+’). And specific value could compare with normal inverter. Value close to the zero or

bigger than normal range stands the diode is damaged.

For the 5thgeneration models(total 4 measure positions)

37

Page 38

38

Page 39

9.7.2 IGBT / MOSFET

a. IGBT

b. MOSFET

a. switch to the diode position of multimeter, and measure the value between Pin 3 and Pin 2, normal value

is 0.3~0.4V. Value close to the zero stands the component is damaged;

b. the normal resistance between Pin 2 and Pin 3 should be infinity(∞), value close to the zero stands the

component is damaged;

c. check if the short-circuit between Pin 1 and Pin 2, Pin 2 and Pin 3.

For the 5thgeneration models(total 8 measure positions)

39

Page 40

9.7.3 Component Position Number

Power Diode Position Number

5thGeneration Single MPPT

D1

5thGeneration Dual-MPPT

D9, D13, D30, D31

IGBT/MOSFET Position Number

5thGeneration Single MPPT

Q2, QA1, QA2, QA3, QB1, QB2, QB3

5thGeneration Dual-MPPT

Q2, Q4, QA1, QA2, QA3, QB1, QB2, QB3

40

Page 41

9.8 MOSFET Driver Inspection(for 5th generation models)

Remove the control board and control board mounting pad. Power the inverter with 100Vdc source and

wait about 15 seconds. Measure the voltage of all of the MOSFET Pin 1 and Pin 3 separately, the normal

driver voltage is -5Vdc. If the voltage abnormal, it stands the power PCB is damaged.

9.9 Inverter Frequently Tripping Due to Grid Fluctuation

9.9.1 Check the grid voltage with multimeter if voltage range goes below or beyond of -20% to +10% then

check the Vac.Min and Vac.Max setting in inverter by selecting SET menu as mention below.

9.9.2 Press enter key for two time and menu is open which shows Error record (Fig.1)and by up-down key

select the SET menu (Fig.2).

Fig.1 Fig. 2

41

Page 42

9.9.3 Select the SET menu by enter key and you will get the display as mention in Fig. 3 and Fig. 4.

Fig.3 Fig.4

9.9.4 Press enter key to set the voltge range and enter the password as shown in Fig.5.

Fig. 5

9.9.5 Adjust the voltage range of Vac.Min and Vac.Max by up-down key and set it at Vac. Max:450V and Vac. Min:339V as

shown in Fig.6 and Fig.7.

Fig.6 Fig.7

Note:- Display screen menu change according to rating of the Inverter.

42

Page 43

10 Contact

Please do not hesitate to contact us for any technical problems you have. Please be sure to provide the

following information in order to obtain necessary assistance:

Inverter type

Inverter serial number

Inverter SN Number

Customer Information

The contents of this manual are subject to change without further notice. For Rotosol latest product

information, please visit our website www.rotosol.solar

Rotosol Solar(Division of Solar – Rotomag motors and controls pvt ltd.)

www.rotosol.solar

ADD: 2102/3 & 4 ,Vitthal Udhyognagar

Near Anand, Gujarat – 388121 , India

Phone : +91-9227110023/24/25

E-MAIL: invert@rotosol.solar

Website : www.rotosol.solar

Annex Warranty Terms (Overseas)

Rotosol Solar(Division of Solar – Rotomag motors and controls pvt ltd.) Product Warranty Terms

1.Product Quality Standards and Warranty

Rotosol inverters comply with local safety regulations related to the national grid and grid

standards.

The inverter warranty is decided by Rotosol and its distributor.

Spare parts warranty is valid 3 months (beginning from the date of shipment), during the warranty

period, Rotosol is responsible for the replacement.

43

Page 44

Spare Parts

NO.

Item

1

DC PV Connector (MC4)

2

AC Connector

3

Fuse

4

Enclosure

The monitoring module warranty is valid for 12 months (beginning from the date of shipment).

After the products leaving the factory, the appearance damage (scratches, rust, chemical damage) is

beyond warranty.

2.Warranty Exceptions

Damage or lose to inverter or accessory caused by logistics.

Inverter failure caused by non-compliance with national utility grid standard which lead to eg.

abnormal grid voltage, grid frequency etc.

Inverter malfunction or damage caused by non-professional or non-qualified personnel

Failure to observe the user manual, the installation guide, and the maintenance regulations

Remove or damage warranty seal

Change or remove specification label, serial number (SN)

Product malfunction or damage due to disobey to relevant laws and regulations or technical

requirements in power plant design, construction or installation works

Solar panels' input parameters exceed the inverter's allowed range

Product malfunction or damage due to installation on movable device or in vibration occasions

Failure or damage caused by corrosion, lightning and other natural damage or force majeure

Unauthorized alteration or disassembly of the product

Damage or malfunction caused by other facilities eg. Surge damage caused by switching on/off high

power generator

Low electricity generation because of inverter self-protection caused by environmental reasons (such

as the installation environment, natural environment, grid environment, etc.) is not a quality problem.

3.Repair and Replacement

3.1 When a failure occurs, the user should check and record from the screen display the error code, DC

voltage, AC voltage dataor phenomena ect., then contact your local dealer.

When the dealer or Rotosol confirm that it is the product quality problem ,the faulty product will

be replaced.

For the product has been replaced or repaired, the remaining warranty entitlement will be transferred to the

replacement or repaired device

44

Page 45

Rotosol is only responsible for the company's products troubleshooting, repair and replacement, but

doesn't assume any other special damages, consequential damages, incidental damages (including loss of

profits, loss of goodwill, loss of business reputation loss or delay, etc.).

This warranty does not affect the customer's enjoyment of any other rights laws and regulations relating to

sales of consumer goods provided for in the host country or region.

4.Service Contact

Customers could contact local dealer or distributor to discuss how to proceed. Please visit

www.rotosol.solar for dealer/installer's contact details. Of course, customers may also contact Rotosol f they

need help or advice.

5. Force Majeure

Force majeure is not artificially unavoidable and insurmountable objective conditions. In addition, it is the

loss that even if the use of methods of prevention and attention, cannot prevent. It includes the following:

earthquakes, floods, fires, storms and other natural disasters.

war, invasion, blockade and other hostile armed actors.

revolution, rebellions, riots.

strike.

collection, prohibition, and other provisions of the government's actions.

infectious diseases.

third-party negligence and wrongdoing which Manufacturers cannot control

h) others

6. For above, Rotosol will not bear any responsibility. Please be noted.

45

Page 46

Rotosol Solar(Division of Solar – Rotomag motors and controls pvt ltd.)

www.rotosol.solar

ADD: 2102/3 & 4 ,Vitthal Udhyognagar

Near Anand, Gujarat – 388121 , India

Phone : +91-9227110023/24/25

Customer Care Number : 1800-123-4412

E-MAIL: invert@rotosol.solar

Website : www.rotosol.solar

46

Loading...

Loading...