Rotor ROT115 User Manual

COPYRIGHT NOTICE

All rights reserved.

No part of this manual may be reproduced, copied,

transmitted, disseminated, downloaded or stored in any

storage medium, for any purpose, without the express prior

written consent of ROTOR.

ROTOR grants permission to download a single copy of

this manual onto a hard drive or other electronic storage

medium to be viewed and to print one copy of this manual

or of any revision hereto, provided that said electronic or

printed copy contain the complete text of this copyright

notice and that it is further indicated that any unauthorized

commercial distribution of this manual or any revision

hereto is strictly prohibited.

The information in this document is subject to change

without notice. ROTOR reserves the right to change or

improve its products and to make changes in the content

without obligation to notify any person or organization of

such changes or improvements.

Visit ROTOR’s website (www.rotorbike.com) for updates and

supplemental information concerning the use and operation

of this and other ROTOR products.

This manual was publis ed: 0 /1h 1 8

Model#: ROT115

FCC ID:R3AROT115

20 -3 JN0556

INSID E

SN

12345

ROTOR ROT115

FCC ID: R3AROT115

www.rotorbike.com

PN

ROT115

ES

EN

33Copyright notice

CONTENTS

1. Product description ............................................................................................................................... 35

2. Crank installation ................................................................................................................................... 36

3. Pairing ........................................................................................................................................................ 43

4. Calibration / Zeroing............................................................................................................................. 45

5 2 ®. First steps with your ROTOR INpower .........................................................................................

6. Battery ........................................................................................................................................................ 48

7 2 ®. ROTOR INpower training use......................................................................................................... 49

8. Maintenance ............................................................................................................................................ 52

9. Frequently asked questions ................................................................................................................ 53

10. Safety warning ....................................................................................................................................... 60

ROTOR Warranty policy ........................................................................................................................... 60

Regulatory statements .............................................................................................................................. 61

CEE Regulation ............................................................................................................................................ 61

47

34 Contents

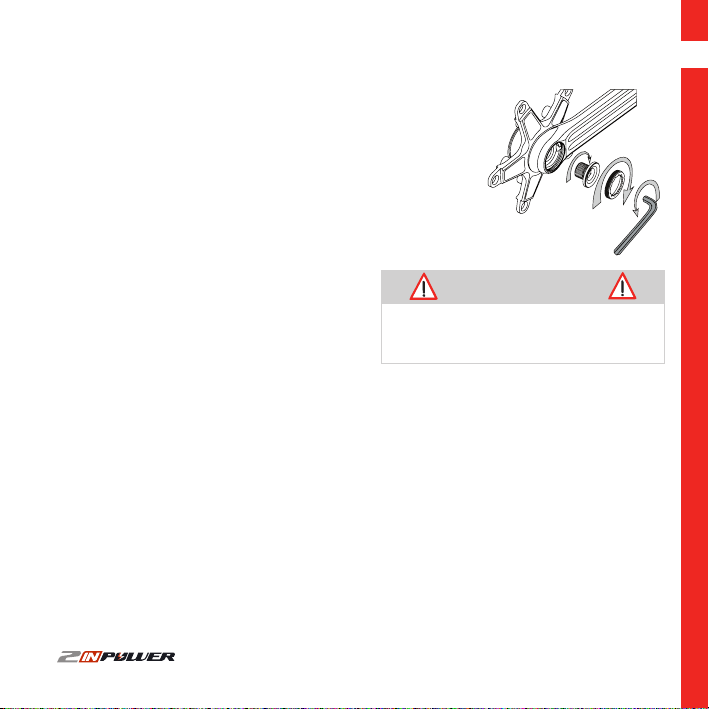

1. PRODUCT DESCRIPTION

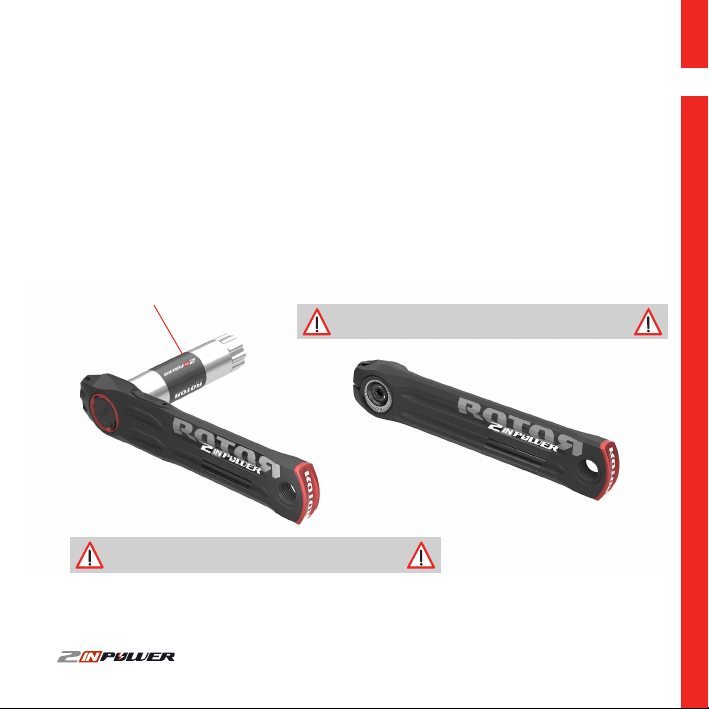

1.1. 2INpower® CRANKSET

Drive-side crank assembly (crank+axle+spider) contains the power meter unit and specific

Bluetooth® Smart / ANT+ sensor ID number.

Non-d includes bolt and DTT insert.rive-side crank assembly

ATTENTION: DO NOT REMOVE THE BOLT AND THE DTT INSERT IN THE LEFT SIDE.

TOOLS NEEDED: left and right INpower crank assembly requires the use of the following2 ®

tools:

- mm allen wrench.5

TM

ES

EN

Power meter RIGHT

Drive-side crank assembly

WARNING: DO NOT DISASSEMBLE

Non-drive-side crank assembly

WARNING: DO NOT DISASSEMBLE

35Product description

1. . COMPATIBILI2 TY

2 ®INpower cranks use a 30 mm Universal

Bottom Bracket (UBB) system and the BOOST

standard in the MTB version that’s compatible

with BB30, PF30, BBright, BSA30, ITA30, BB86,

386 EVO, BB89, BB92 and BOOST frames.

For more information consult your ROTOR

Authorized Dealer or bike dealer to ensure

correct compatibility of 2INpower® with your

frame.

Visit our website:www.rotorbike.com

Read and understand this manual carefully

before installing your cranks. Improvements

of product specifications may occur without

any prior notification.

WARNING!

2. CRANKS INSTALLATION

When installing your ROTOR 2INpower® for the first time, complete the following steps:

2.1. Spacer verification (page 37).

2. .2 Uninstall your old cranks (page 39).

2. .3 Drive-side crank assembly installation (page 41).

2. .4 Left-side crank assembly spacer selection (page 41).

2. .5 Left-side crank assembly installation (page 42).

2. .6 Fine-tuning adjustment (page 42).

2. .7 Uninstalling 2INpower® cranks (page 42).

WARNING!

Ensure there is no interference between

the cranks and the frame or any other

component part.

36 Cranks installation

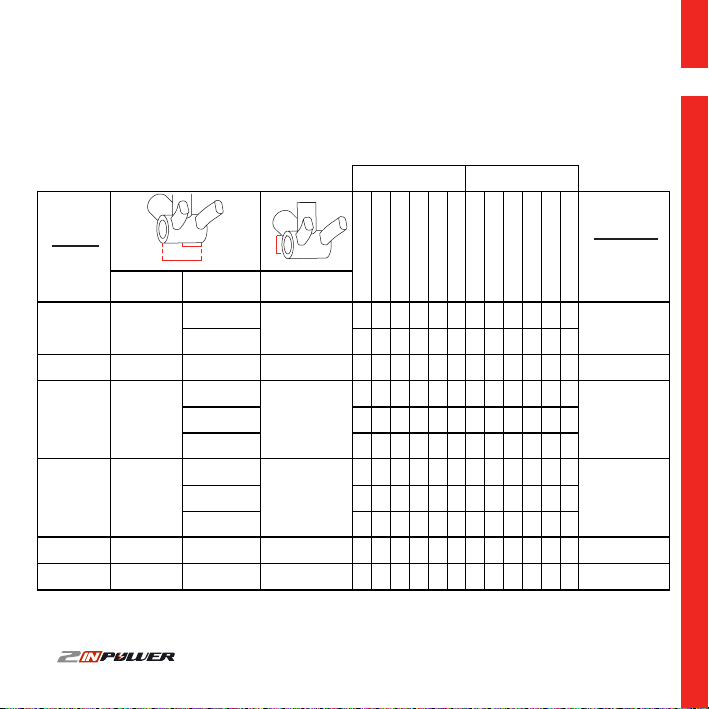

2.1. SPACER VERIFICATION FOR CRANKS1. MTB

Width (mm) WR (mm) Inner diam (mm)

48.5 Asym X

47.25 Asym X X X

BB89 89.5 44.75 Sym 41 X X X X PF4130

39 Asym X X

37.75 Asym X X X X

36.5 Sym X X X

39 Asym X X

37.75 Asym X X X X

36.5 Sym X X X

BSA - 68 68 34 Sym BSA Thread X X X BSA30

PF30 - 68 68 34 Sym 46

X X X

UBB PF30

PF30 - 73 73 46

Type B: 5.5 mm

Type C: 8.5 mm

BSA - 73 73 BSA Thread

BB92 92 41

Frame

Cuadro

Type D: 11.5 mm

Type E: 0.5 mm

Type A: 2.5 mm

Type B: 5.5 mm

Type C: 8.5 mm

Type D: 11.5 mm

Type E: 0.5 mm

Type F: 3.0 mm

Type A: 2.5 mm

PF4130

BSA30

UBB PF30

Compatible BB

Pedalier

compatible

Type F: 3.0 mm

To correctly use your 2 ® appropriate spacersROTOR INpower , it is necessary to select the

for your frame.

NOTE: if different bearings are used, spacing may differ.

Select your frame and spacers from the below:MTB table

Seleccione su cuadro y espaciadores de la siguiente:de montaña tabla

NDS - L DS - R

ES

EN

W

R

W

Nds - L: Non-Drive side - Left; Ds - R: Drive side - Right; Asym: Asymmetric; Sym: Symmetric

Read your bottom bracket manual to verif y compatibility with your frame.

D

37Cranks installation

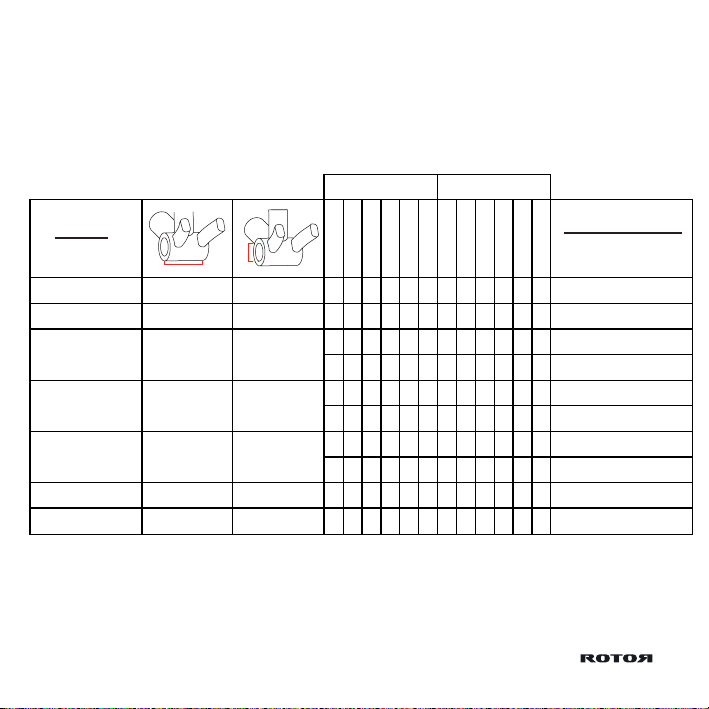

2. . SPACER VERIFICATION FOR CRANKS1 2. ROAD

Frame

Cuadro

Type A: 2.5mm

Type B: 5.5mm

Type C: 8.5m m

Type D: 11.5 mm

Type E: 0.5mm

Type F: 3.0mm

Type A: 2.5mm

Type B: 5.5mm

Type C: 8.5m m

Type D: 11.5 mm

Type E: 0.5mm

Type F: 3.0mm

Compatible BB

Pedalier

compatible

BB86 86,5 mm 41 mm

X X

Press Fit 4130

BB30 - 68 68 mm 42 mm

X X X X

BB30

X X X X

Press Fit 4630

X X

UBB PF30

X X X

Press Fit 4630

X X

UBB BBright

X X X X

Press Fit 4630

X X

UBB 386

BSA 68 mm BSA Thread

X X

BSA30

ITA 70 mm ITA Thread

X X

BSA30

PF30 - 68 68 mm 46 mm

PF30 - BBright 79 mm 46 mm

BB386 86 mm 46 mm

To correctly use your 2 ® appropriate spacersROTOR INpower , it is necessary to select the

for your frame.

NOT :E if different bearings are used, spacing may differ.

Select your road frame and spacers from the table below:

NDS - L DS - R

D

W

NDs - L: Non-Drive side - Left; Ds - R: Drive side - Right

Read your bottom bracket manual to verify compatibility with your frame.

38 Cranks installation

2. . UNINSTALL YOUR OLD CRANKS2

2. .a. If you already have a ROTOR crankset2

1*. Remove drive-side bolt using an 8 mm allen wrench.

2*. Remove drive-side nut using a cassette lockring tool (Shimano

TL-FW30 or similar).

3*. Screw the drive-side bolt clockwise into the spindle.

4*. Flip the drive-side nut over and screw it clockwise into the crank

arm to be used as a selfextracting cap. It must be flush with the

outer face of the arm and all of its threads must be engaged.

5*. Unscrew the drive-side alloy bolt counterclockwise using an

8 mm allen wrench until the drive-side

assembly disengages from the spindle.

2. .b. If you have a crankset from2

another manufacturer

Read the corresponding instructions to correctly

remove cranks from another manufacturer.

Do not follow steps . to . if you want1* 5*

to remove INpower cranks. In this case

go to page 45 of the INpower manual.

WARNING!

ES

EN

TL-FW30

Cranks installation

39

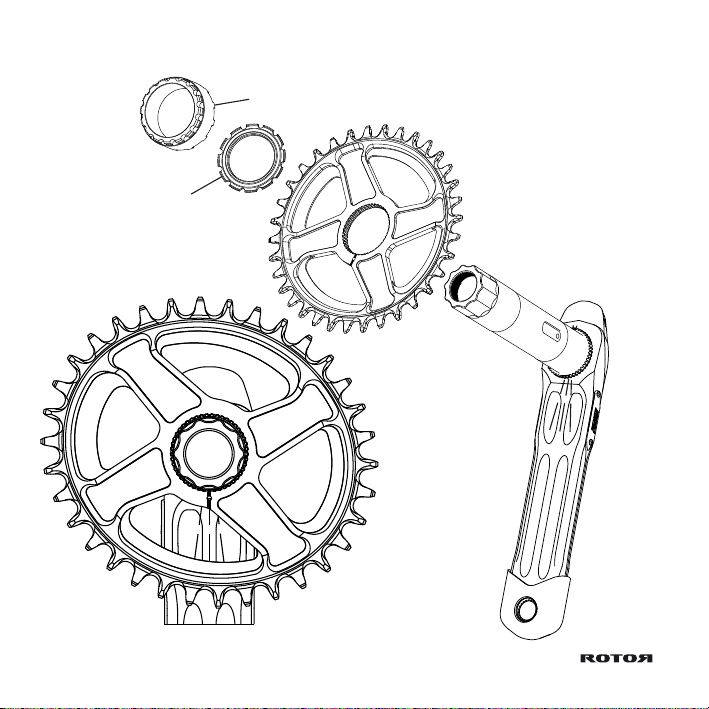

2. .3 DIRECT MOUNT INSTALLATION IN DRIVE-SIDE CRANK

*Use a BB

wrench that is

Shimano®

Hollowtech® II

compatible

DM chainring nut

DM chainring in

position OCP #3

DM nut tool

OCP

OCP

1

5

3

Introduce the Direct Mount

chainring through the axle and

position it over the drive-side

crank. To properly regulate the

OCP position of your chainring,

align the correspondent

number in the crank with the

OCP mark on the chainring.

Once the chainring is

correctly positioned,

tighten the Direct

Mount nut into the

crank to 35-40 Nm*.

2

4

5

3

1

40 Cranks installation

2.4. DRIVE-SIDE CRANK ASSEMBLY INSTALLATION

2. .1.4 Place a 0.5 mm plastic washer on

the axle next to the chainring.

2. . .4 2

S forelec t the appropriate spacer(s)

the drive-side on page 37 or 38 and pass

it through the axle next to the 0.5 mm

washer.

2. . .4 3 Lightly grease the outside of the

axle to facilitate passage through the

bearings. Insert the drive-side crank

assembly through the andbearings

frame.

For MTB cranks installation, make sure

that the bearings are situated more to

the outside than the limit lines marked

on the axle.

Spacer selected

from page 37 or 38

Do not strike or force the cranks to avoid

damaging the product.

0.5 mm plastic washer

Grease

WARNING!

2. -SIDE CRANK ASSEMBLY SPACER SELECTION5. LEFT

2. .1.5 Grease the end of the axle.left

2. .2.5 S forelect the appropriate spacer(s)

the left-side on page 37 or 38 and place

it between the frame and the left crank.

2. . .5 3 The DTT bolt comes from issue in

dead point.It is necessary to unscrew it

1.5 turns counterclockwise to open the

crank and introduce it onto the left end

of the axle. Do not remove the DTT bolt.

If it is removed it will break and this will

void the warranty.

ES

EN

Spacer selected

from page 37 or 38.

41Cranks installation

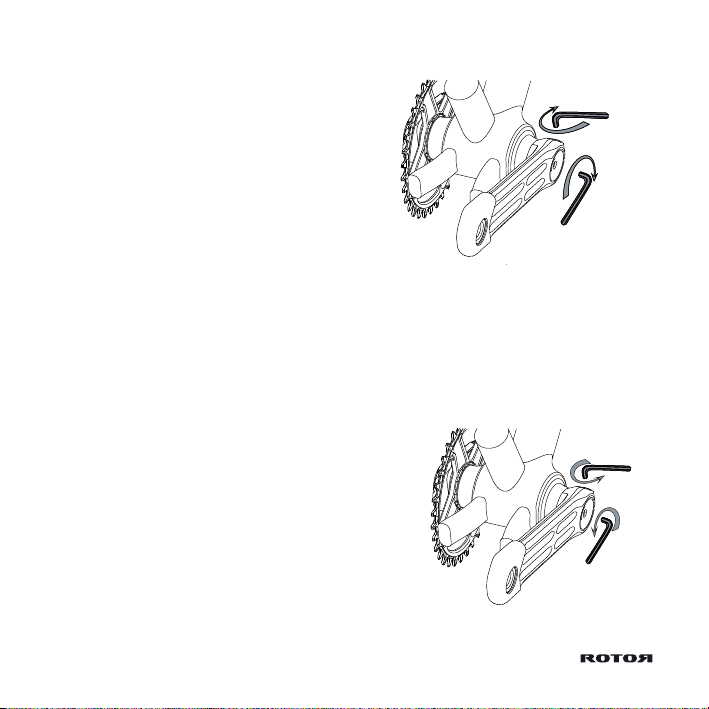

2.6. 2INpower® LEFT-SIDE CRANK ASSEMBLY INSTALLATION

Tighten the left-side bolt (1) using a 5 mm allen wrench

in order to approach the crank to the frame, placing

it in its position. Tighten the DTTbolt in the left crank

(2) to 7 Nm using a 5 mm allen wrench. This allows

the crank to be fixed to the axle. Finally tighten the

left-side bolt (1) to 5 Nm to make sure that it is not lost.

Do not overtighten the bolts.

(2)

7 Nm

5 Nm

(1)

2.7. FINE TUNE ADJUSTMENT

2. .7 1. If the crank does not turn smoothly even with the left-side bolt not tightened,remove the

0.5 mm washer from the left side and repeat the installation.

2.7.2. If you see that there is lateral play even with the left-side bolt completely tightened,use an

additional 0.5 mm plastic washer on the left side and repeat the installation steps.

2.8 UNINSTALLING 2 ® CRANKS. INpower

2.8.1.

Counterclockwise turn the DTT bolt (1) in the

left-side crank using a 5 mm allen wrench.Afterwards,

unscrew the left-side bolt (2) using a 5 mm allen

wrench unitl it is removed. Take the left crank out of

the axle.

Do not remove the DTT bolt. If it is removed it will

break and this will void the warranty.

perderá la garantía.

(1)

(2)

42 Cranks installation

Loading...

Loading...