Rothenbuhler Engineering 1673 2 User Manual

ROTHENBUHLER

ENGINEERING

®

1673 REMOTE FIRING DEVICE

OPERATION MANUAL

ROTHENBUHLER ENGINEERING

P.0. BOX 708

524 RHODES ROAD

SEDRO WOOLLEY, WA 98284

1673-A16A

1/17/2014

©2014 Rothenbuhler Engineering

All Rights Reserved

ii

TABLE OF CONTENTS

Chapter

Page

TABLE OF CONTENTS .................................................................................................. II

LIST OF ILLUSTRATIONS ............................................................................................. V

SAFETY WARNINGS ................................................................................................... VII

LIMITED WARRANTY ................................................................................................. VIII

REGULATORY INFORMATION .................................................................................... IX

RADIATION HAZARD WARNING ................................................................................. XI

1. INTRODUCTION .................................................................................................. 1

1.1. Theory of Operation .......................................................................................... 1

1.2. Storage and Environmental Conditions ............................................................. 1

2. RFD SYSTEM COMPONENTS ............................................................................ 3

2.1. Controller unit .................................................................................................... 3

2.2. Remote Unit ...................................................................................................... 5

2.3. Battery Chargers ............................................................................................... 6

2.4. Enable Keys ...................................................................................................... 6

2.5. Controller Unit External Features ...................................................................... 7

2.6. Controller Unit Panel Display ............................................................................ 8

2.7. Controller LCD Display ................................................................................... 10

2.8. Remote Unit External features ........................................................................ 15

2.9. Remote Unit Panel Display ............................................................................. 17

2.10. Remote Unit LCD Display............................................................................ 19

2.11. Shock Tube Firing TIp ................................................................................. 22

3. PREOPERATIONAL PROCEDURES ................................................................ 24

3.1. Physical Inspection ......................................................................................... 24

1673 OPERATION MANUAL REV A

iii

3.2. Charging the Batteries .................................................................................... 24

3.3. Power On Test ................................................................................................ 25

3.4. Testing the Electric Detonator Mode ............................................................... 25

3.5. Testing the Shock Tube Initiator Mode ........................................................... 27

4. RFD OPERATIONAL PROCEDURES ............................................................... 30

4.1. Setting up the RFD ......................................................................................... 30

4.2. Firing the RFD ................................................................................................. 33

5. RFD SYSTEM CONFIGURATION –MENUS ..................................................... 38

5.1. Start Menu ...................................................................................................... 38

5.2. Normal User .................................................................................................... 38

5.3. Controller Advanced User ............................................................................... 39

5.4. Remote Normal User ...................................................................................... 39

5.5. Remote Unit Advanced User........................................................................... 40

5.6. Service Menu .................................................................................................. 41

5.7. Factory Menu .................................................................................................. 41

5.8. Programming Electronic Keys ......................................................................... 41

6. 1673 CONFIGURATION SOFTWARE ............................................................... 44

6.1. About the Configuraton Software .................................................................... 44

6.2. Running the Configuration Software ............................................................... 44

6.3. Reading the Event History Log ....................................................................... 45

7. CONFIGURATION SOFTWARE INSTALLATION ............................................. 48

7.1. 1673 RFD Conguration Software .................................................................... 48

7.1. Installing the USB Cable Drivers ..................................................................... 48

8. MAINTENANCE ................................................................................................. 53

8.1. Maintenance Procedures ................................................................................ 53

9. BASIC TROUBLESHOOTING IN THE FIELD ................................................... 55

9.1. Remote Unit .................................................................................................... 55

1673 OPERATION MANUAL REV A

iv

9.2. Controller Unit ................................................................................................. 55

10. RFD SPECIFICATIONS ..................................................................................... 56

1673 OPERATION MANUAL REV A

v

LIST OF ILLUSTRATIONS

Figure 2-1 Controller Unit ................................................................................................ 3

Figure 2-2 Remote Unit ................................................................................................... 5

Figure 2-3 Controller External Features .......................................................................... 7

Figure 2-4 Controller Panel ............................................................................................. 8

Figure 2-5 Controller Unit Default Screen ..................................................................... 10

Figure 2-6 Controller Armed Screen ............................................................................. 12

Figure 2-7 Motion Detect Screen .................................................................................. 13

Figure 2-8 Remote Unit External Features .................................................................... 16

2-9 Remote Unit Display Panel ..................................................................................... 17

Figure 2-10 Remote Unit Default Screen ...................................................................... 19

Figure 2-11 Remote Unit Electric Detonator Armed Screen .......................................... 20

Figure 2-12 Remote Unit Shock Tube Initiator Armed Screen ...................................... 21

Figure 2-13 Firing Tip, Shock Tube ............................................................................... 22

Figure 4-1 Raising the Controller Antenna .................................................................... 30

Figure 4-2 Raising the Remote Antenna ....................................................................... 31

Figure 4-3 Activating the Remote Unit........................................................................... 32

Figure 4-4 Controller Unit Face Panel ........................................................................... 33

Figure 4-5 Controller Default Screen ............................................................................. 34

Figure 4-6 Status Check Results on Controller ............................................................. 35

Figure 4-7 Arm the SELECTED Remote Units .............................................................. 35

Figure 4-8 Motion Detect Screen .................................................................................. 36

Figure 4-9 Verify the green READY Lights are on steady ............................................. 36

1673 OPERATION MANUAL REV A

vi

Figure 5-1 Start Menu ................................................................................................... 38

Figure 5-2 Advanced User Menu .................................................................................. 42

Figure 5-3 Choose System # (1-8) ................................................................................ 42

Figure 5-4 Choose the Number of Remotes in the System ........................................... 42

Figure 5-5 Program Remote Keys ................................................................................. 43

Figure 6-1 1673 RFD Configuration – Main Screen ...................................................... 45

Figure 6-2 Event History Log for Controller ................................................................... 46

Figure 6-3 Event History Log for Remote ...................................................................... 47

Figure 7-1 Figure 7-2 ............................................... Error! Bookmark not defined.

Figure 7-3 ........................................................................ Error! Bookmark not defined.

Figure 7-4 ........................................................................ Error! Bookmark not defined.

Figure 7-5 ........................................................................ Error! Bookmark not defined.

Figure 7-6 ........................................................................ Error! Bookmark not defined.

Figure 7-7 Select Setup.exe ............................................ Error! Bookmark not defined.

Figure 7-8 Install 1673 RFD Configuration Software ....... Error! Bookmark not defined.

Figure 8-1 Battery Condition (Discharge Battery) .......................................................... 53

1673 OPERATION MANUAL REV A

vii

SAFETY WARNINGS

1) Always follow your local safety regulations. This manual and its procedures are

secondary to governmental regulations, local regulations or company safety

regulations and procedures. The operation procedures in this manual are only

suggestions and should be checked against the above safety regulations and

procedures. Company training should include the proper use of this machine and

only trained personnel should use it.

2) Never rely on this equipment or any equipment totally for your safety. All

mechanical and electronic equipment can fail. Always have a safety procedure

that will protect you and minimize hazards of such failure.

3) High power radio transmissions can cause electric blasting caps to detonate. Store

the Controller and Remote Units 25 or more feet (8 meters) from electric

detonators.

4) The Shock Tube Initiator on the Remote Unit can develop up to 3,000 Volts. Do

not touch the firing tip or the firing tip jacks while arming or firing the unit.

5) The Electric Detonator generates up to 400V. Do not touch the two firing terminals

when arming or firing the unit.

6) Do not connect the shock tube or electric detonator leg wires or firing cable to a

Remote Unit unless its green READY light is on, the red ARMED light is off, and

the ON light is on steady.

7) Do not use the system if any of the units show damage to the point that failure is

suspected. Thoroughly test the system prior to use.

8) Never approach the Remote Unit if it is attached to live explosives unless you have

a confirmed READY status back to the Controller AND you have waited at least 20

minutes for the automatic disarm AND you have followed proper safety wait times.

1673 OPERATION MANUAL REV A

viii

LIMITED WARRANTY

The 1673 Remote Firing Device is guaranteed for 2 years (batteries –1 year, spark tips

excluded) against defects in workmanship or materials. If the equipment should fail

during this period, we will repair it at our factory or at the nearest authorized service

facility. Warranty service on this equipment must be performed only by an authorized

service center. Unauthorized service procedures or parts will void and cancel your

warranty, and may cause radio equipment to fail, resulting in accidents and/or personal

injury. This is a limited warranty and is given in places of legally implied warranties of

merchantability and fitness for a particular purpose. Our liability is expressly limited to

the cost of repair or replacement of the RFD under this guarantee, and does not extend

to additional or consequential damages resulting from the operation of equipment.

1673 OPERATION MANUAL REV A

ix

REGULATORY INFORMATION

UNITED STATES

This device complies with Part 15 of the FCC regulations. Operation is subject to the

following two conditions: (1) That this device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may

cause undesired operation.

The radio contained in this device operates in FCC regulated frequency bands. This

device must be licensed by the FCC before use. Because this device contains a

transmitter, federal law prohibits unauthorized use or adjustments of this radio.

Note: The Grantee is not responsible for any changes or modifications not expressly

approved by the party responsible for compliance. Such modifications could void the

user’s authority to operate the equipment.

CANADA

**This Class B digital apparatus meets all requirements of the Canadian Interference-

Causing Equipment Regulations.

Cet appareil nume’rique de la classe B respecte toutes les exigences du Re’glement sur

le mate’riel brouilleur du Canada.

This device complies with Industry Canada licence-exempt RSS standard(s). Operation

is subject to the following two conditions: (1) this device may not cause interference,

and (2) this device must accept any interference, including interference that may cause

undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables

aux appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de 'appareil

doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible

d'en compromettre le fonctionnement

Under Industry Canada regulations, this radio transmitter may only operate using an

antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry

Canada. To reduce potential radio interference to other users, the antenna type and its

gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not

more than that necessary for successful communication.

These radio transmitters (IC: 2758A-167301 & 2758A-167302) have been approved by

Industry Canada to operate with the antenna types listed below with the maximum

permissible gain and required antenna impedance for each antenna type indicated.

1673 OPERATION MANUAL REV A

x

Antenna types not included in this list, having a gain greater than the maximum gain

indicated for that type, are strictly prohibited for use with this device.

Antenna: ¼ wave whip, gain 2.15 dBi

Only Factory accessories are approved for use with this device – e.g. third party

holsters, belt clips etc. are not approved for use.

Contact information where the user can obtain Canadian information on RF exposure

and compliance.

1. Health Canada Safety Code 6:

http://www.hc-sc.gc.ca/ewh-semt/pubs/radiation/radio_guide-lignes_direct-eng.php

2. RSS-102:

http://www.ic.gc.ca/eic/site/smt-gst.nsf/eng/sf01904.html

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut

fonctionner avec une antenne d'un type et d'un gain maximal (ou inférieur) approuvé

pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage

radioélectrique à l'intention des autres utilisateurs, il faut choisir le type d'antenne et son

gain de sorte que la puissance isotrope rayonnée équivalente (p.i.r.e.) ne dépasse pas

l'intensité nécessaire à l'établissement d'une communication satisfaisante.

Le présent émetteur radio (IC: 2758A-167301 & 2758A-167302) a été approuvé par

Industrie Canada pour fonctionner avec les types d'antenne énumérés ci-dessous et

ayant un gain admissible maximal et l'impédance requise pour chaque type d'antenne.

Les types d'antenne non inclus dans cette liste, ou dont le gain est supérieur au gain

maximal indiqué, sont strictement interdits pour l'exploitation de l'émetteur.

Stabantenne: ¼ longueur d'onde, gain 2.15 dBi

Seuls les accessoires d'usine sont approuvés pour une utilisation avec cet appareil - par

exemple étuis de tiers, ceinture clips, etc ne sont pas approuvés pour l'utilisation.

Les coordonnées où l'utilisateur peut obtenir de l'information canadienne sur l'exposition

aux radiofréquences et la conformité.

1. Santé Canada Code de sécurité 6:

http://www.hc-sc.gc.ca/ewh-semt/pubs/radiation/radio_guide-lignes_direct-eng.php

2. RSS-102:

http://www.ic.gc.ca/eic/site/smt-gst.nsf/eng/sf01904.html

AUSTRALIA

The radio transmitters contained in this equipment are approved by the Australian

Communications Authority (ACA). Frequency assignment/licensing must be obtained

from the ACA before use.

This device is has been determined to be in compliance with AS2187.2 for underground

and surface mines.

1673 OPERATION MANUAL REV A

xi

RADIATION HAZARD WARNING

This radio shall only be used during the course of employment by individuals aware of

the hazards of radio frequency (RF) radiation exposure, and the ways to minimize such

hazards. This radio is not intended for use by the "General Population." Further, this

radio must not be co-located or operated in conjunction with any other antenna or

transmitter. User should not allow antennas to come within 20 cm (8 inches) of the body

during use.

Cette radio ne doit être utilisé au cours de l'emploi par des individus conscients des

dangers de la fréquence radio (RF) l'exposition aux radiations et les façons de

minimiser ces risques. Cette radio n'est pas destiné à être utilisé par la «population

générale». En outre, cette radio ne doit pas être co-localisé ou exploité en conjonction

avec une autre antenne ou transmetteur. L'utilisateur ne devrait pas permettre antennes

à venir dans les 20 cm (8 po) du corps pendant l'utilisation.

1673 OPERATION MANUAL REV A

1

1. INTRODUCTION

1.1. THEORY OF OPERATION

1.1.1. The Remote Firing Device (RFD) is used to activate both electric and non-

electric detonator devices. The system is strictly an electronic device, containing no

explosive. The Remote Unit is placed at the explosive site, with a shock tube or the

electric detonator firing cable running to the detonator(s). The Controller is placed at

the intended firing position.

1.1.2. Using remote control technology allows the blaster to increase his standoff

distance for maximum safety. With the blaster unconnected to the firing line, he is free

to move around to achieve both the safest firing position, as well as the preferred

viewing position. Blast efficiency is improved as the consumption of non-electric leadin-line is reduced by as much as 90%. In subsurface operations, safety is achieved

when all headings are fired from one position with all personnel above ground.

Significant cost savings may be found in comparison to expensive mains firing systems.

1.1.3. Critical features of this Remote Firing Device over other systems are the two-

way communication link and the timed automatic-disarming function. The two-way

communication feature provides a high degree of safety, by allowing the blaster to verify

that each Remote Unit is disarmed before approach. The automatic-disarming function

ensures that the unit returns to a safe state in the event of a loss of communications,

after a time out period.

1.1.4. In subsurface operations, safety is achieved when all headings are fired from

one position with all personnel above ground. Significant cost savings may be found in

comparison to expensive mains firing systems. The motion detection feature can be

used to help determine if the blast has been initiated successfully.

1.2. STORAGE AND ENVIRONMENTAL CONDITIONS

1.2.1. The Controller Unit and the Remote Unit cases (with lids closed) are airtight,

watertight, and dustproof. The Remote Unit should normally be operated with the lid

closed and fastened. The internal case contains the circuit electronics and should

remain sealed.

1.2.2. The Controller and the Remote Units are shock resistant and will handle

considerable abuse. They have been drop tested from 6 feet (1.8 m) onto concrete.

1.2.3. The Remote Unit firing terminals are electrically isolated from the firing energy

at all times except when firing.

1.2.4. The RFD system should be stored in a cool, dry place. The storage

temperature range is -4 to 86 F (–20 to 30 C). Exceeding the storage temperature

range may result in damage to the internal battery packs.

1673 OPERATION MANUAL REV A

2

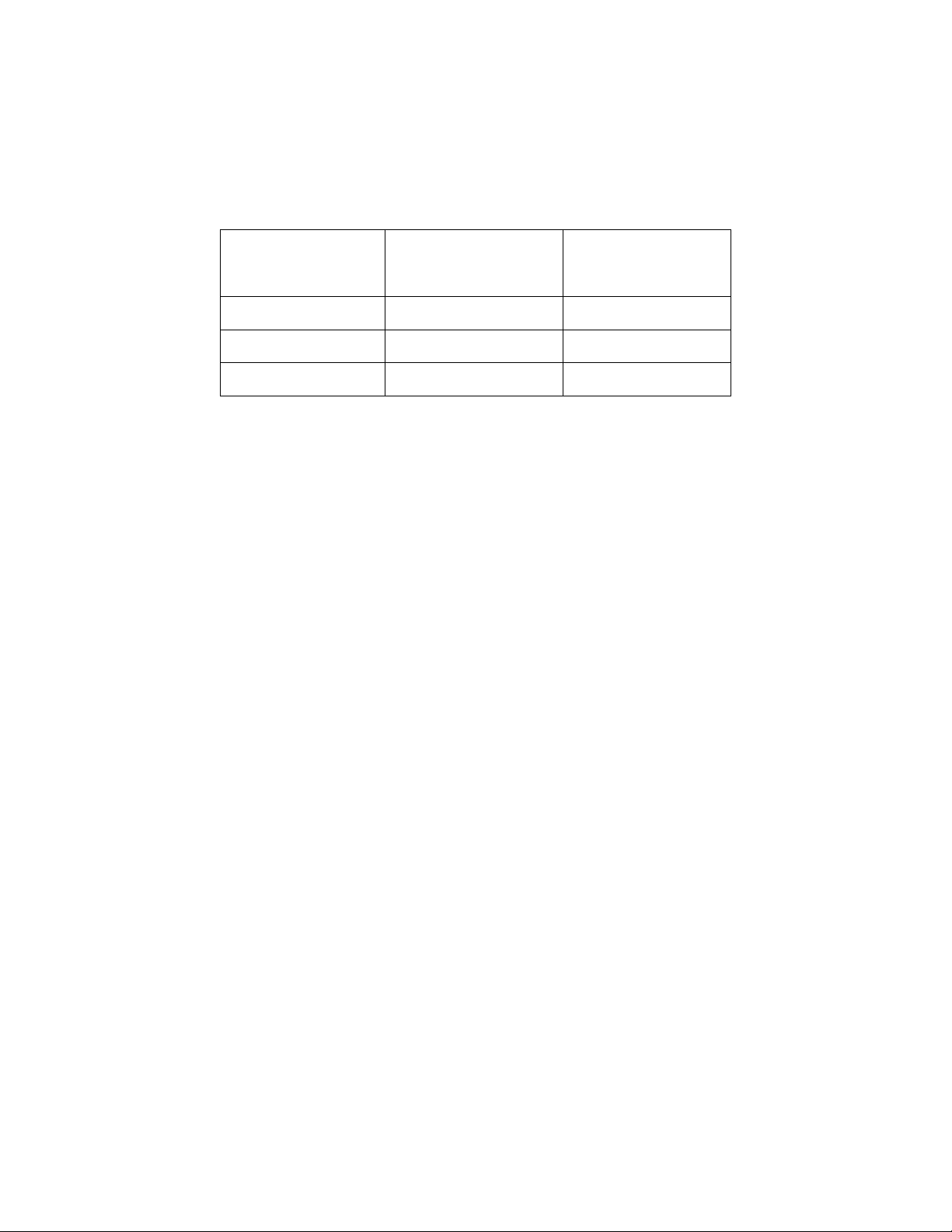

1.2.5. The maximum operating temperature range of the RFD is –22 to 140 F (-30

Minimum

Temperature

Maximum

Temperature

Operate

-22 F (-30 C)

140 F (60 C)

Store*

41 F (5 C)

77 F (25 C)

Charge

32 F (0 C)

104 F (40 C)

to 60 C).

1.2.6. The battery chargers are for indoor use only. Charge time is approximately 3

hours.

Table 1-1 RFD Temperature Ranges

*Exposure outside of this temperature range may result in decreased battery life or

damage to the internal battery packs.

1673 OPERATION MANUAL REV A

3

2. RFD SYSTEM COMPONENTS

2.1. CONTROLLER UNIT

Figure 2-1 Controller Unit

2.1.1. Figure 2-1 shows the Controller Unit. The Controller Unit is responsible for

initiation of all communications with the Remote Unit(s). The Controller Unit’s case is

yellow for easy identification.

2.1.2. The Controller has an electronic key that must be installed before Arming and

Firing is allowed.

1673 OPERATION MANUAL REV A

4

2.1.3. The Controller Unit is capable of commanding up to 64 Remote Units, in 8-

Remote groups that are hereafter referred to as “Systems”.

2.1.4. The Controller can operate in standby for typically 12-16 hours before

recharging is required. The Controller’s charger is internal and is capable of worldwide

operation. Typical charge time is 3 hours. The battery system features test and

discharge functions.

2.1.5. The Controller features an internal history event log which stores 1024 events

in non-volatile memory. The history log can be used to obtain information on the

operation and performance of the RFD. Each event is logged with the current date and

time along with GPS coordinates (if available).

2.1.6. When the Electric Detonator circuit has been selected on the Controller,

transmission signal levels from responding Remote Units are automatically reduced for

safety around blasting caps. The Controller’s transmission signal level remains

unchanged.

1673 OPERATION MANUAL REV A

5

2.2. REMOTE UNIT

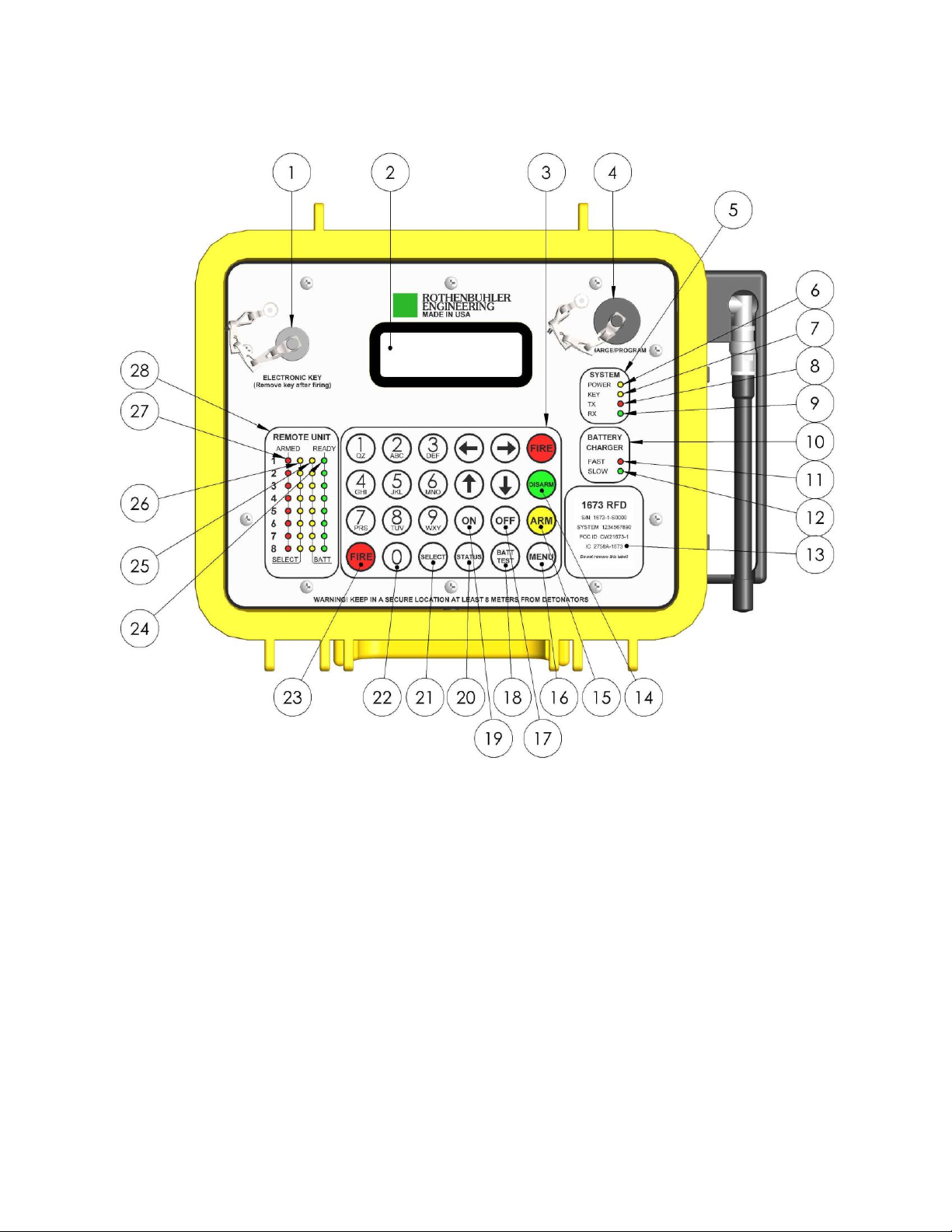

Figure 2-2 Remote Unit

2.2.1. Figure 2-2 shows the Remote Unit. The Remote Unit contains the fire circuits

used for the initiation of detonators. The Remote Unit is normally positioned at a

protected location relatively close to the blast area.

2.2.2. The electronic keys used in the Remote Unit are matched to the Controller

and must be installed for communication, arming and firing.

2.2.3. The Remote Unit’s electric detonator circuit develops a minimum of 350V DC

@ 5J with 27Ω of internal impedance. The maximum recommended series firing

resistance (firing cable plus detonators) is 150Ω for group 1A detonators. Consult the

specifications for the specific detonator that you are using.

1673 OPERATION MANUAL REV A

6

2.2.4. The Remote Unit’s shock tube circuit develops a high voltage spark to initiate

non-electric shock tube.

2.2.5. The Remote Unit can run on standby for typically 12-16 hours before

recharging is required. The Remote Unit’s charger is internal and is capable of

worldwide operation. Typical charge time is 3 hours. The battery system features test

and discharge functions.

2.2.6. The Remote Unit features an internal history event log which stores 1024

events in non-volatile memory. The history log can be used to obtain information on the

operation and performance of the RFD. Each event is logged with the current date and

time along with GPS coordinates (if available).

2.3. BATTERY CHARGERS

2.3.1. Both Controller and Remote Units use internal battery chargers which are

powered by +12VDC from an external AC adapter. The AC adapter operates from 100–

240VAC, 50-60 Hz, and has changeable pins for worldwide operation. Typical charge

time is 3 hours. Charging should be conducted indoors. Do not attempt to substitute

another power supply or equipment damage may occur.

2.3.2. For battery charging procedure, refer to Section 3.2.

2.4. ENABLE KEYS

2.4.1. Each system is supplied with a unique group of enable keys. The enable

keys contain the encoded information required for operation.

2.4.2. The Controller Unit has a unique enable key, and will only arm and fire with

this specific key installed. The Controller Unit will perform status and disarm functions

without the key installed. The Controller Unit automatically disarms all Remote Units

upon key removal. The Controller key is labeled with a ‘C’ to distinguish it from the

Remote keys.

2.4.3. The Remote Units’ use of the enable key can be configured for one of two

operation modes.

2.4.3.1. In generic (default) mode, the Remote unit assumes its System and Unit

numbers from the key installed. Any key can work in any Remote unit (as long as that

Remote is on the correct frequency assignment). Generic mode allows the flexibility to

move Remote Units within different systems and units within those systems by changing

the keys.

2.4.3.2. In dedicated mode, The Remote Unit is setup to only work with one specific

key; for example a Remote Unit setup in dedicated to be Remote #3 from System #8

can only work with a key that matches these values. Dedicated mode can help when a

very strict key control plan is required.

1673 OPERATION MANUAL REV A

7

2.5. CONTROLLER UNIT EXTERNAL FEATURES

Item

Item Name

Description

1

RETRACTABLE ANTENNA

Raised vertically during operation, retracted for protection during transport and storage.

2

ANTENNA GUARD

Protects the Antenna from damage. Holds the antenna in position.

3

CARRY HANDLE

Normal carry point for individual unit.

4

AUTOMATIC VENT

The vent allows for automatic pressure equalization inside the case ensuring proper function of the membrane keypad. The vent is

waterproof.

5

CONDENSED INSTRUCTIONS

Basic instructions for operation of this equipment. Refer this manual for compete instructions.

6

LID

The lid should be closed and during transport, storage or when the unit is exposed to the elements for full protection.

2.5.1. Figure 2-3 and Table 2-1 show the external features of the Controller Unit.

Figure 2-3 Controller External Features

Table 2-1 Controller External Features

1673 OPERATION MANUAL REV A

8

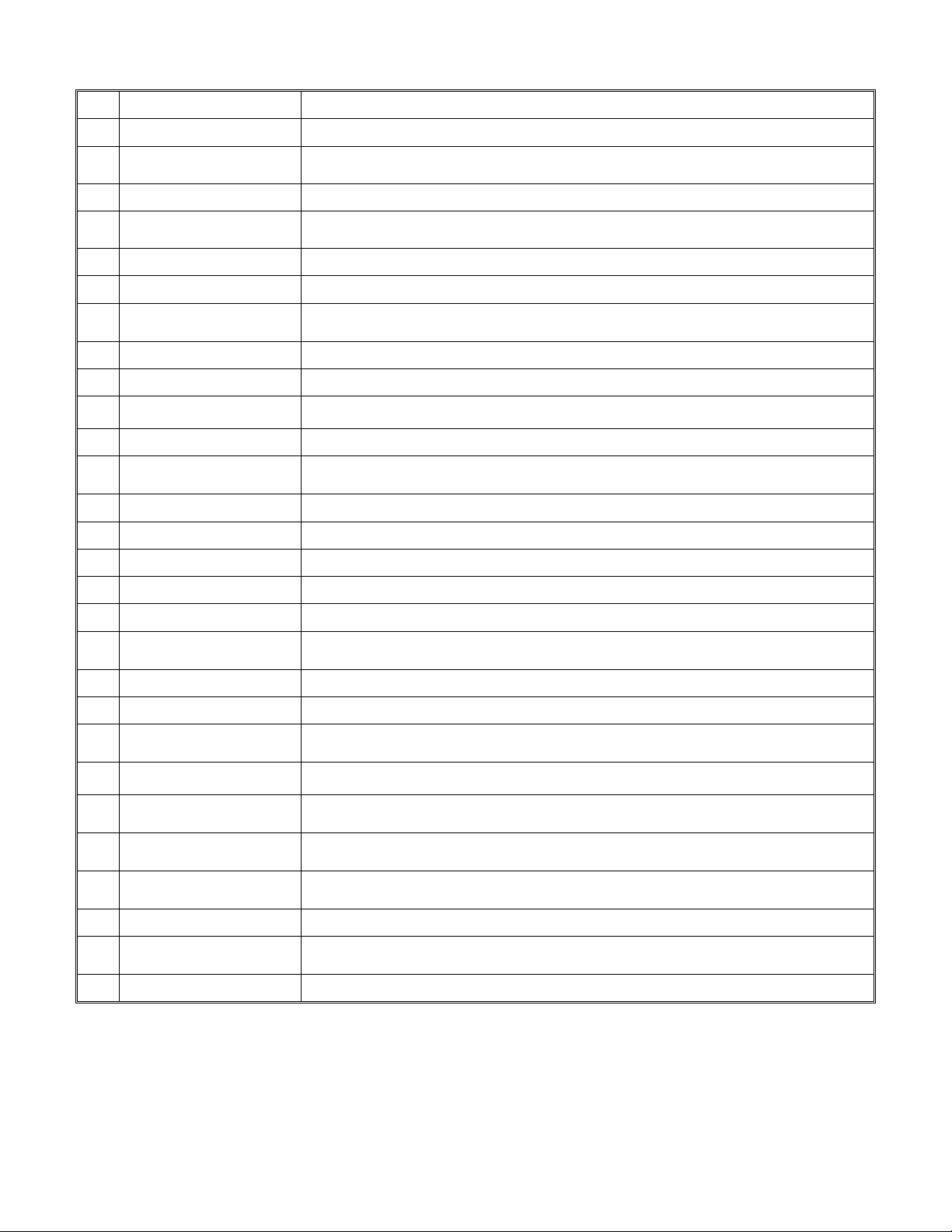

2.6. CONTROLLER UNIT PANEL DISPLAY

Figure 2-4 Controller Panel

Figure 2-4 and Table 2-2 illustrate the panel indicators, and switch locations on the

Controller Unit.

Always press one switch at a time unless firing, and hold each switch for at least ½

second.

1673 OPERATION MANUAL REV A

9

Item

Item Name

Description

1

ELECTRONIC KEY PORT

Electronic key must be installed to Arm and Fire Remote units.

2

LIQUID CRYSTAL DISPLAY

The LCD displays information to the user such as battery charge, operation mode, etc. Backlights when switches are pressed.

3

KEYPAD AREA

24 switches used to control the unit through various modes of operation.

4

CHARGE/PROGRAM PORT

Used to supply power to the internal charger and provides a serial connection for reading the history log and changing settings.

5

SYSTEM INDICATORS

Displays information related to system operation.

6

POWER LIGHT

Solid yellow indicates the unit is on. Flashes yellow to indicate the battery must be recharged.

7

KEY LIGHT

Solid yellow indicates the correctly programmed Controller key is installed and working. Flashes when a faulty or incorrect key is

installed.

8

TX LIGHT

Lights red when unit is transmitting.

9

RX LIGHT

Lights green to indicate an on channel carrier or when receiving a message from a Remote unit.

10

BATTERY CHARGER INDICATORS

Displays battery charging status.

11

FAST CHARGING LIGHT

Lights red to indicate the battery is being fast charged. Blinks red when charge is pending.

12

SLOW CHARGING LIGHT

Lights green to indicate battery charging is complete and the battery is receiving a slow maintenance charge. Blinks green to indicate a

charging error has occurred.

13

INFORMATION LABEL

Shows model number, serial number, system number, and regulatory information.

14

DISARM SWITCH

When pressed, sends a Disarm command to all selected Remote Units.

15

ARM SWITCH

When pressed and held for ½ second, sends the Arm command to all selected Remote Units.

16

MENU SWITCH

Brings up the main menu screen, or returns to the default screen.

17

OFF SWITCH

Turns power off to the unit when not in use or when charging.

18

BATTERY TEST SWITCH

Pressing causes a 10 second loaded battery test. Holding for 5 seconds causes unit to discharge the battery completely for long term

storage and battery conditioning.

19

ON SWITCH

Turns power on to the unit.

20

STATUS SWITCH

Requests status response from Remote Units.

21

SELECT SWITCH

Pressing once allows up to 8 Remote Units to be selected with switches (1-8). Pressing a second time locks the selection into the unit.

22

NUMERIC SWITCHES (x10)

Used for selection of Remote units and various menu options and settings.

23

FIRE SWITCH (x2)

When both FIRE switches are pressed and held simultaneously for ½ second, all Remote Units that are both selected and armed will

be fired.

24

REMOTE READY LIGHT (x8)

Lights solid green to indicate the corresponding Remote Unit’s status is confirmed disarmed. Blinks green to indicate the corresponding

Remote Unit’s status is assumed to be disarmed (unconfirmed).

25

REMOTE BATTERY LIGHT (x8)

Lights solid yellow after receiving a status response from a corresponding Remote whose battery is ok. Blinks yellow to indicate the

corresponding Remote unit has a low battery and should be recharged.

26

REMOTE SELECT LIGHT (x8)

Lights yellow to indicate the corresponding Remote Unit has been selected for communications with the Controller.

27

REMOTE ARMED LIGHT (x8)

Solid red indicates the corresponding Remote Unit is confirmed to be armed. Blinks red when the corresponding Remote unit is

assumed to be armed but has not been confirmed as armed.

28

REMOTE UNIT DISPLAY AREA

Displays basic information related to the operation of up to 8 Remote Units.

Table 2-2 Controller Unit

1673 OPERATION MANUAL REV A

10

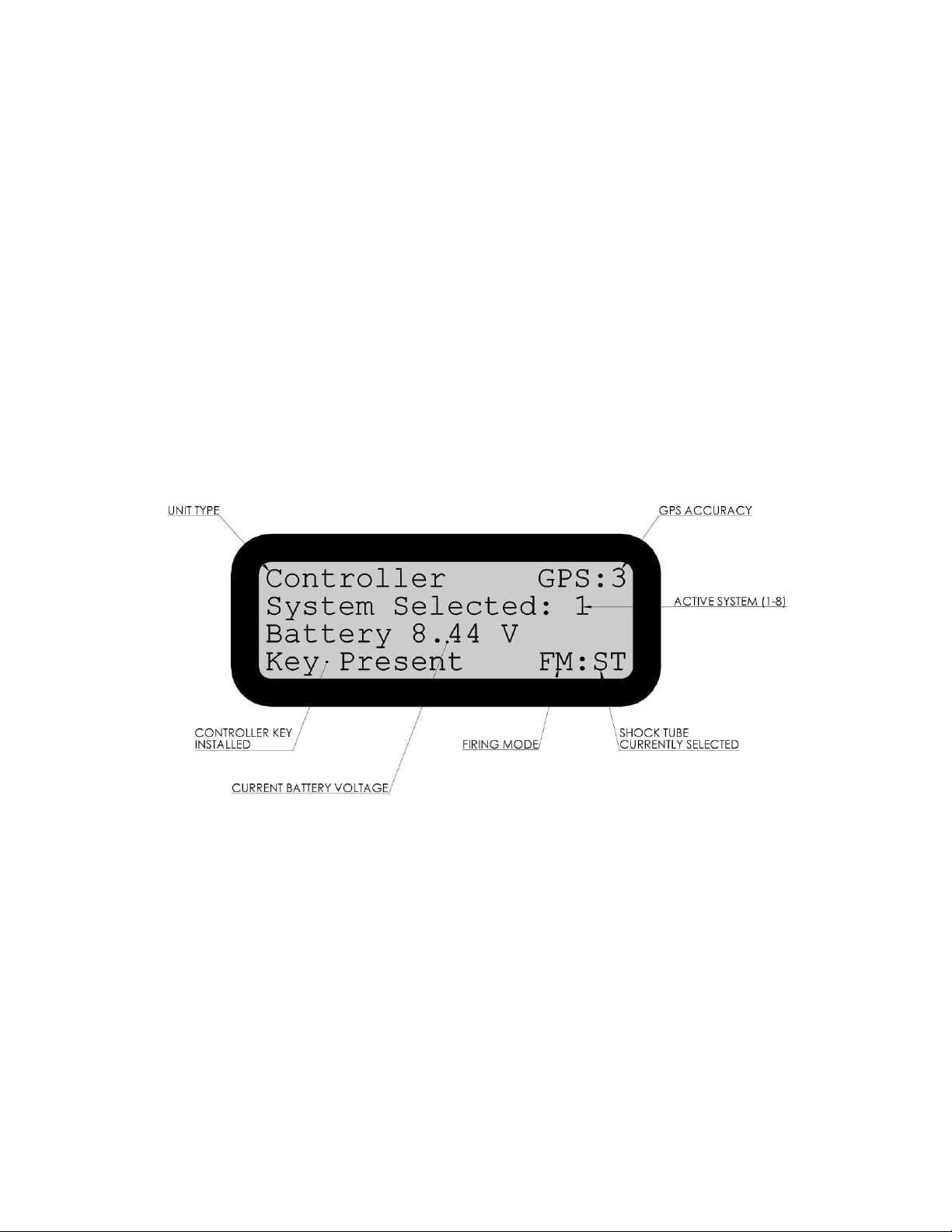

2.7. CONTROLLER LCD DISPLAY

2.7.1. The LCD display provides information that is supplemental to the basic

operation of the 1673 RFD. The LCD is rated for -20 to 70 ºC (-4 to 158 ºF). At low

temperatures, the LCD may unreadable. In most cases, the standard LED indicators are

sufficient to complete blasting operations. In the event the display becomes unreadable

due to low temperature, normal display operation should be restored as the unit comes

back within the normal temperature range.

2.7.2. Whenever a switch is pressed, the LCD display’s backlighting function will be

enabled. After 30 seconds of inactivity, the backlighting will automatically turn off to

save battery power.

2.7.3. When the Controller is turned on by pressing the ‘ON’ switch, The Controller

goes through a series of self-tests. Once the self-testing is complete, The Controller will

show the default screen of Figure 2-5.

Figure 2-5 Controller Unit Default Screen

2.7.4. UNIT TYPE: This informs the user this is a Controller Unit (yellow box).

2.7.5. GPS ACCURACY: If the unit is equipped with GPS, data received from

satellite signals are used to record date, time, and positional information in the history

log. The GPS accuracy is a number (0-3) which represents the calculated accuracy of

the reported data. A GPS rating of ‘0’ indicates GPS has not been acquired. The highest

rating of ‘3’ indicates an accuracy of approximately 3 meters (10 feet) and the recorded

positional data is considered ‘data ok’. GPS takes approximately 1 minute to acquire

after the unit is turned on. GPS signals are not available in underground installations,

inside vehicles, or where the unit is surrounded by metal. The GPS unit will remember

the date and time when no signal is available. You can check the actual GPS

1673 OPERATION MANUAL REV A

Loading...

Loading...