Rothenberger Industrial HS-060A-15, HS-060A-25, HS-060A-40, HS-060A-60 HS-060A-80, HS-060A-100 Operating instructions

8

GB

SYMBOLS USED IN THIS MANUAL

= Wear eye

protection

= Wear a dust

mask

= Wear

protective gloves

= Read the operating manual

- Soldering means fusing metallic materials by means of molten solder. Almost all metals and metal

alloys can be soldered, especially brass, copper and iron etc. A distinction can be made between soft

soldering and hard soldering (brazing).

- Hard soldering (brazing) is performed at temperatures over 450 degrees. Hard solders and silver

brazing solders

are made of metal alloys that melt only at temperatures which cannot be achieved using an electric

soldering iron. Soft soldering is performed at temperatures under 400 degrees. Soldering performed

with a soldering iron is soft soldering.

- Make certain that the rated power stated on the machine’s rating plate (230-240 V) agrees with the

local mains voltage before connecting the machine to the mains.

- Make sure that the tip is correctly fitted before heating the soldering iron It must be fastened tightly

with the clamping screw.

- We recommend that you work in the vicinity of the mains socket so that you can quickly pull the plug

from the socket in the event of an emergency.

- Be sure to disconnect the machine from the mains after finishing work.

- Allow the machine to cool down completely before storage! Rest the device on the stand provided or

on a non-flammable surface during breaks or after finishing work. Do not leave the soldering

unsupervised until it has cooled down completely.

- Do not use the soldering iron if the handle, the mains cable or the mains plug are damaged. Send the

device to an authorised workshop for repair. Never open the device yourself.

- Do not expose the device to water or moisture.

- The device may only be used indoors.

- Make sure that no liquids can enter the device.

- The soldering tip may only be removed when it is cool and when the soldering iron is off. Slide the new

soldering tip into the soldering iron as far as it will go and fasten it with the clamping screw. Do not use

unnecessary force.

- Never heat up the soldering iron without a soldering tip fitted.

- Do not touch the tip while operating the machine. Danger of burns!

- Use the device only in well ventilated rooms. Toxic fumes can be produced when soldering which can

lead to damage to the mucous membranes and/or chronic respiratory illness..

- Do not eat or drink whilst soldering as solder can contain lead. Always wash your hands thoroughly

after finishing work.

- The soldering iron is fitted with a special mains cable, which may not be damaged. When working,

take care not to touch the mains cable with the hot soldering iron. Damaged mains cables can not be

replaced. Never operate the soldering iron if the mains cable is damaged. Instead, dispose of it safely

as described in the ‘Recycling’ section of this manual.

- This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

Operational Safety Instructions for the

soldering iron

1

2

6

4

5

3

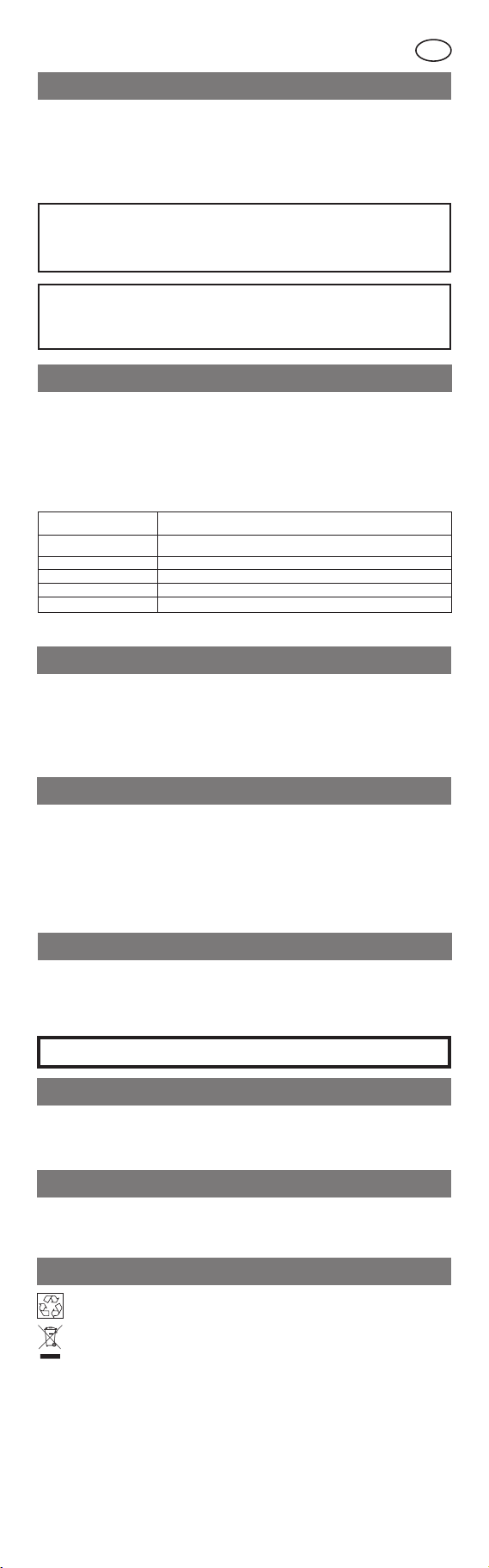

FEATURES

Model: HS-060A-15, HS-060A-25, HS-060A-40, HS-060A-60 HS-060A-80, HS-060A-100

Rated voltage 230-240 V~ / 50 Hz

Rated power: 15 W, 25 W, 40 W, 60 W, 80 W, 100 W

TECHNICAL SPECIFICATIONS

The machine is designed for use with single phase alternating current 230-240 V AC / 50 Hz and is doubleinsulated. Make certain that the rated voltage stated on the soldering irons’s rating plate matches the local

mains voltage.

If the work area is not close to the mains outlet, use an extension cable with sufficient conductor diameter

(min. 1.5 mm

2

).

The extension cable used should be as short as possible.

CONNECTING TO THE MAINS

The soldering irons are designed for joining metallic workpieces by means of molten solder.

Almost all metals and metal alloys can be soldered, especially brass, copper and iron etc.

Soldering performed with a soldering iron is soft soldering. Soft soldering is performed at temperatures

under 400 degrees.

SCOPE OF USE

The applicator wand is switched ON as soon as the plug (5) is connected to the mains.

Disconnect the machine from the mains to switch it OFF.

SWITCHING ON AND OFF

1 Soldering iron

2 Soldering tip

3 Fixing screw for tip

4 Handle

5 Cable with plug

6 Stand

Protection category I

9

GB

USING THE SOLDERING IRON

1. Ensure that the rated voltage stated on the rating label is the same as the local mains voltage.

2. Carefully check the tip (2) before switching the machine on. The tip fixing screw (3) must be tightly

fastened.

3. Connect the soldering iron to the mains.

4. Never heat up the soldering iron without a tip fitted.

5. The tip may only be removed from the machine when the machine is switched off. Never use force to

remove the tip. Insert the replacement tip as far as it will go into the tip holder.

6. Allow the soldering iron to cool down after finishing the job. Do not cool by rinsing under water.

7. Place the soldering iron on the stand (6) during breaks in your work.

Caution!

The soldering iron is fitted with a special mains cable. Do not use the soldering iron if this mains

cable is damaged. When working, take care not to touch the mains cable with the hot soldering

iron. Damaged mains cables can not be replaced. Never operate the soldering iron if the mains

cable is damaged. Instead, dispose of it safely as described in the ‘Recycling’ section of this

manual.

Caution!

- To prevent the risk of fire, always place the soldering iron on the stand provided or a similar

non-flammable surface after finishing work or during breaks.

- Always disconnect the soldering iron from the mains after finishing work. Allow the soldering

iron to cool down to room temperature before putting it away.

- Keep children out of the area.

Solder and flux

Solder for the DIY market is almost exclusively produced in the form of wire.

There are two types of solder wire on the market:

1. Simple, unfilled solder wire.

2. Solder wire with flux core

Fluxes remove oxide residue and prevent oxide residue forming on the workpiece during the soldering process.

Soldering greaseand liquid flux should be carefully removed from the workpiece after soldering using a

brush or cloth. Resin residue forms after soldering using solder wire with a flux core. Resin residue should

not be removed.

WORKING WITH THE MACHINE

Solder

Solder Melting temperature approx. 185°C

Good for electronical use.

Radio solder For model making or fine soldering

Melting temperature approx. 235°C

Soft solder For general purpose soldering.

Solder stone For cleaning the tip

Soldering grease Flux paste.

Liquid flux Flux for inaccessible workpieces

- The parts to be soldered must always be cleaned. Use a solvent solution to clean the parts. Remove any

oxidisation either chemically, or mechanically with a file or spatula.

- Do not use aggressive acids such as hydrochloric, sulphuric or nitric acid unless you are an expert. Instead a

10 % citric acid solution, warm or hot is usually suitable. Do not touch the workpiece with your fingers after

cleaning.

- When the right temperature is reached, the solder melts to a filmy consistency. If lumps are formed, the tip is

not yet hot enough. If beads are formed the tip should be cleaned.

The soldering iron may only be used indoors.

The soldering iron is designed for soldering electrical wires and circuit boards as well as repairing small

electronic appliances.

The soldering iron is for indoor use only and may not be used outdoors. The soldering iron cannot be used

for soldering large workpieces.

- Heat the joint with the soldering iron. Hold the solder to the joint until it is molten.

- Remove the soldering iron tip from the joint and allow the solder to set.

- Do not move the joint until the solder has set.

SOLDERING

- Dip the end of the de-soldering braid in flux.

- Heat the joint with the soldering iron. Hold the soldering braid to the molten solder.

- The molten solder flows onto the braid.

- Cut off the used part of the de-soldering braid.

DE-SOLDERING WITH DE-SOLDERING BRAID

The tip is a wear part and must be replaced from time to time.

Loosen the screw on the metal shaft of the soldering iron and remove the worn tip. Replace with a new tip.

Re-tighten the tip fixing screw.

MAINTENANCE

MAINTENANCE

This symbol indicates that this product may not be disposed of together with domestic waste in

compliance with the (2002/96/EC) Regulation pertaining to waste electrical and electronic devices

(WEEE). This product must be handed in at an designated collection point. This can occur, for

example, by returning it when a similar product is purchased or by handing it in at an authorised

collecting point for the recycling of waste electrical and electronic equipment. Owing to potentially

hazardous substances that are frequently contained in waste electronic equipment, incorrect

handling of waste equipment may have a negative impact on the environment and on the health of

human beings. By disposing of this product correctly, you are also contributing towards an efficient

use of natural resources. Information on collecting points for waste equipment can be obtained

from your local authority, the public waste disposal authority, an authorised institution for the

disposal of waste electrical and electronic equipment or the waste collection services.

RECYCLING

REPLACING THE MAINS CABLE

The soldering iron is fitted with a special mains cable, which may not be damaged. When working, take

care not to touch the mains cable with the hot soldering iron. Damaged mains cables can not be replaced.

Never operate the soldering iron if the mains cable is damaged. Instead, dispose of it safely as described in

the ‘Recycling’ section of this manual.

PREPARING THE SOLDERING IRON TIP AND THE JOINT

Loading...

Loading...