Installation instructions and

Operator‘s Manual

for ROTAX®-engines type

125 MAX DD2 evo

Part no.: 297733 Edition: 10/2019

BRP-Rotax GmbH & Co KG | Rotaxstrasse 1 | 4623 Gunskirchen, Austria | T: +43 7246 601 0 | F: +43 7246 6370

www.rotax.com | www.rotax-kart.com

Genera

BRP-Rotax recommends products of the following companies:

l information

For inf

center or consult the workshop manual (available on the internet at www.rotax-kart.com).

We ask to hand over this manual, the engine identity card and the product and service

registration document to the new owner in case of a change of ownership.

ormation regarding the repair of the engine 125 MAX DD2 evo contact an authorized service

Preface

This document and all technical data and procedures therein are property of BRP-Rotax GmbH &

Co KG and based on the state of knowledge at the time of publication. The manual has been

drawn up to the best of our knowledge. However, we exclude any liability.

We reserve all rights including technical modification and possibility of errors.

Reprinting, translation or copies in whole or in part, are authorized only after written permission by

BRP-Rotax GmbH & Co KG.

BRP-Rotax GmbH & Co KG reserves the right at any time to discontinue or change specifications,

prices, designs, features, models or equipment without incurring any obligations.

Engine performance may vary depending on, among other things, general conditions, ambient

temperature and altitude.

BRP-Rotax

INSTALLATION MANUAL

Table of Content

Chapter INTRO –

Chapter 1 – Engine installation

Chapter 2 – Fuel system

Chapter 3 – Electric system

Chapter 4 – Cooling system

Chapter 5 – Exhaust system

Chapter 6 – Installation of the accessories

Chapter 7 – Finishing work

Effectivity: 125 MAX DD2 evo

Content

Page 1

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

NOTES

Notes

Page 2

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

Edition /Rev. 0

Preface

Contents

General

BRP-Rotax

INSTALLATION MANUAL

Chapter: INTRO

For information regarding repair of the engine 125 MAX DD2 evo contact an authorized

service center or consult the workshop manual

(available on internet under www.rotax-kart.com).

We ask to hand over this manual, the engine identity card and the product and

service registration document to the new owner in case of a change of ownership.

This Installation Manual contains instructions for all the installation work on the ROTAX®Engine Type 125 MAX DD2 evo.

This document and all technical data and procedures therein are property of

BRP-Rotax GmbH & Co KG and based on the state of knowledge at the time of

publication The Manual has been drawn up to the best of our knowledge. However,

excluding any liability.

We reserve all rights including technical modification and possibility of errors. Reprinting,

translation or copies in whole or in part, are authorized only after written permission by

BRP-Rotax GmbH & Co KG.

BRP-Rotax GmbH & Co KG reserves the right at any time to discontinue or change

specifications, prices, designs, features, models or equipment without incurring obligation.

Engine performance may vary depending on, among other things, general conditions,

ambient temperature and altitude.

NOTE

The registration document and engine identity card must be provided to the final

consumer upon delivery by the authorized service center with handover date and

company stamp.

NOTE

The data entered in the registration document and/or engine identity card is

required for the verification of a warranty claim. Without a completely filled-in

engine identity card, no warranty claim will be granted.

NOTE

In case of participating in the ROTAX® MAX CHALLENGE (RMC) the engine

must be verified for conformity with the technical regulations and sealed. The

serial number of the seal must be entered in the engine identity card.

Effectivity: 125 MAX DD2 evo

INTRO

Page 1

Edition: September 01 2019

Symbols used

BRP-Rotax

INSTALLATION MANUAL

This Manual uses the following symbols to emphasize particular information. This

information is important and must be observed.

m WARNING

Identifies an instruction, which if not followed may cause injury or endanger the

life of the driver, mechanic or third party.

ATTENTION

Identifies an instruction which, if not followed may cause injury or endanger the

life of the driver, mechanic or third party.

ENVIRONMENTAL NOTE

Environmental notes give you tips on environmental protection.

NOTE

Indicates supplementary information which may be needed to fully complete or

understand an instruction.

✔

TIP

Denotes a checking operation

This information gives you additional advice and tips

INTRO

Page 2

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

Safety information

BRP-Rotax

INSTALLATION MANUAL

m WARNING

Non-compliance can result in serious injuries or death!

For the best possible engine operation, compliance with the following advice regarding

installation of engine and equipment is required.

m WARNING

Non-compliance can result in serious injuries or death!

Engine operation is permitted only with equipment supplied by ROTAX®

m WARNING

Non-compliance can result in serious injuries or death!

Besides the engine-specific installation advice, also take note of information from the

respective chassis manufacturer.

Introduction

Congratulations on choosing the ROTAX engine Type 125 MAX DD2 evo.

The ROTAX® engine Type 125 MAX DD2 evo has been developed exclusively for use in

Go-karts, which must only be run on specified tracks. This product has numerous

technical innovations.

m WARNING

Non-compliance can result in serious injuries or death!

Before starting with installation and operation of the engine, observe the installation

instructions and Operator’s Manual and follow all instructions.

m WARNING

Non-compliance can result in serious injuries or death!

This engine performs better as comparable products

Effectivity: 125 MAX DD2 evo

INTRO

Page 3

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

UNBOXING AND PURCHASED PARTS PACKAGE

By buying a ROTAX Engine, you will receive two boxes. The engine box and the accessory box.

Figure 1.1: Unboxing

Engine box

The engine box contains the pre-assembled engine with the secure sticker, which describes the run-in procedure. Take the engine out of the box.

Accessory box

The accessory box contains all required parts for running the engine. Lay down all parts,

so you have a good overview of the parts. Check, if all parts of the following table are

delivered.

INTRO

Page 4

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Effectivity: 125 MAX DD2 evo

INTRO

Page 5

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

Figure 1.2: Accessory box

Pos. Description

1 Radiator with coolant hoses

2 Mounting plate with ignition coil, solenoid valve and spark plug cap

3 Battery box and wiring harness

4 Battery charger

5

6

7

8 Manuals and engine identity card

9

10

11 ECU O

12 Carburetor O

13 Paddle shift system O

Intake silencer

Fuel pump with fuel hose O

Exhaust system

Several small parts (spark plug, screws,...) O

Hose package for RAVE control unit O

Check mark

O

O

O

O

O

O

O

INTRO

Page 6

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

ENGINE INFORMATION

Engine serial number

The engine serial number is stamped on the clutch side housing-half.

BRP-Rotax

INSTALLATION MANUAL

Figure 1.3: Serial number of the engine, TYPICAL

Effectivity: 125 MAX DD2 evo

INTRO

Page 7

Edition: September 01 2019

Information sticker

BRP-Rotax

INSTALLATION MANUAL

The information sticker is glued to the intake socket. It does not only prevent dust from

coming inside the engine during the transport, it also provides you with information about

the run-in procedure and general tasks you must do at the initial run of the engine.

Figure 1.4: Information sticker

Gear oil and fuel specifications

See the latest Operators Manual.

Equipment and modifications

Modifications to engine and/or equipment are not allowed.

INTRO

Page 8

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Chapter: 1

ENGINE INSTALLATION

TOPICS IN THIS CHAPTER

Installation of overload clutch and engine with rear axle .........................................................................2

Engine installation with engine brackets .................................................................................................3

Direct attachment of the engine to chassis..............................................................................................5

Effectivity: 125 MAX DD2 evo

1

Page 1

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION OF OVERLOAD

CLUTCH AND ENGINE WITH REAR

AXLE

NOTE

The overload clutch is the link between the engine and the rear axle of the kart. In case that

the rear axle has been blocked by (e.g. breaking), the overload clutch is slipping slightly and

is not transferring the peak load from the rear

axle to the engine.

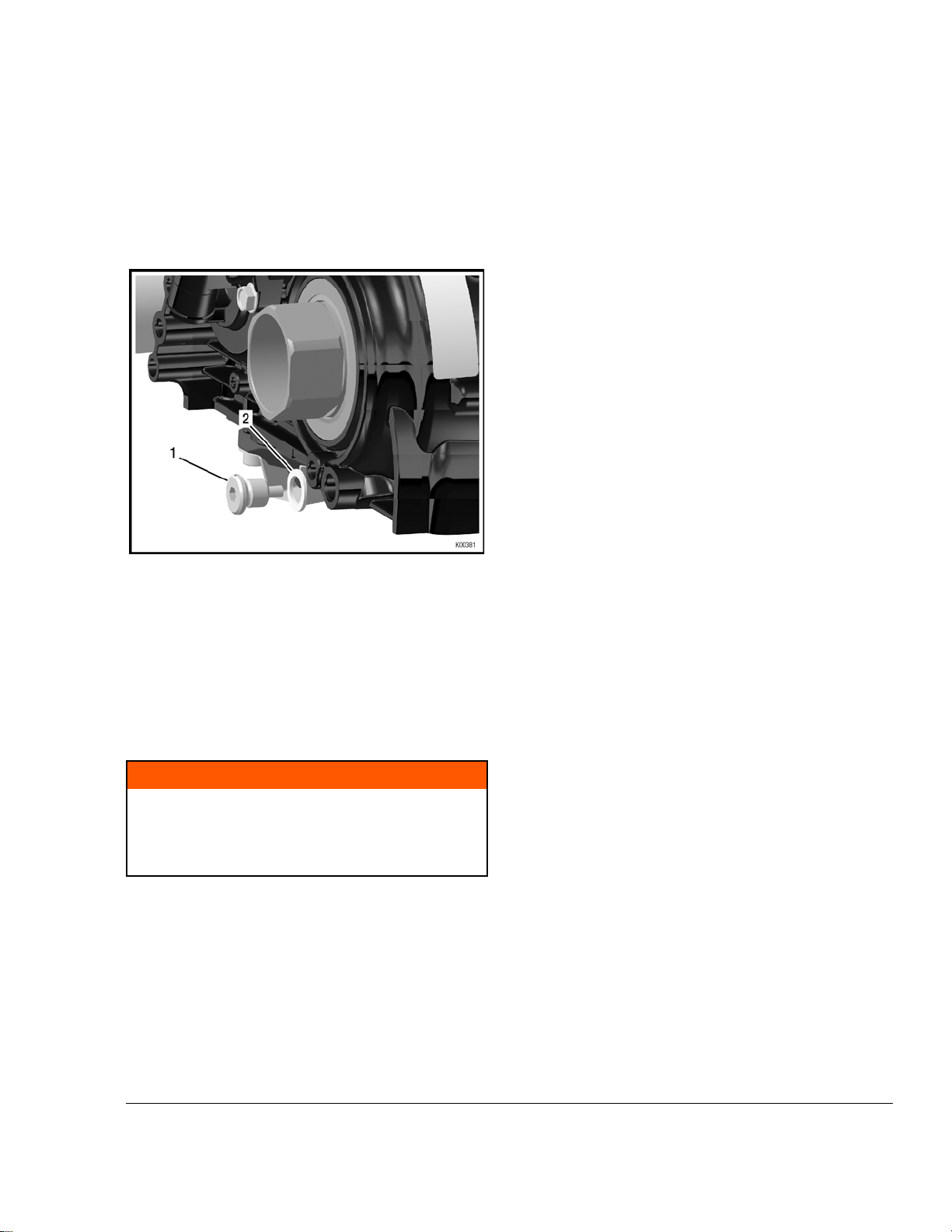

The plain bearings (pos. 2) are inside of the

overload clutch (pos. 1).

NOTE

Do not tighten the overload clutch and clamp

ring yet (see section Engine attachment with engine brackets).

Figure 2.1

Plain bearings

1 Overload clutch

Step

1

Procedure

Slide the clamp ring (pos. 1, following

figure ) the thrust washer (pos. 2) and

the overload clutch (3) to the middle of

the rear axle.

2

NOTE

The rear axle of the kart must have a smooth

surface (no grooves for keys) in the area of the

4 plain bearings of the overload clutch.

1

Page 2

Edition: September 01 2019

Figure 2.2: Overload clutch

Clamping ring

1

3 Overload clutch

5 Allen screw M5x30

2

Thrust washer

4

Allen screw M6x25

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

ENGINE INSTALLATION WITH

ENGINE BRACKETS

Tools required:

• Allen key 8mm

• Allen key 5 mm

• Allen key 4 mm

• Torque wrench

See Figure: Tightening sequence and Engine

brackets.

The engine has to be fixed to the chassis by means

of 2 engine brackets (pos. 1). Due to different distances of the 2 main rails of various chassis brands, the

engine bracket is not included in the scope of supply.

Step

1

2 After engine alignment, tighten the 4

Procedure

Slide the engine onto the rear axle and

align the rear axle and the engine by

measuring the distance between the

front and the rear axle

Allen screws M8 x 25 to fix the upper

engine bracket to the engine with 28

Nm (20.65 ft. lb). Fix and tighten the

lower engine bracket to the upper

bracket with 4 Allen screws M8 x 30

with 22 Nm (16.22 ft. lb). Secure the

Allen screws with LOCTITE 243

blue.

NOTE

The minimum screw in length of the screws fixing the engine brackets onto the crankcase is

16 mm to 20 mm (0.6 - 0.95 in.).

Step

3

Procedure

Slide the overload clutch, thrust washer and clamp ring along the axle to the

hollow shaft and then fix to the rear

axle. Tighten the screw on the clamping ring with 10 Nm (89 in. lb).

Figure 2.3: Engine brackets

FIGURE SIMILAR

NOTE

The 125 MAX DD2 engine can only be mounted

on specially prepared chassis for this engine

type.

m WARNING

Non-compliance can result in serious injuries

or death!

For engine attachment to the chassis, please fol-

low the instruction of the chassis manufacturer.

Effectivity: 125 MAX DD2 evo

4

Tighten the 6 Allen screws (pos. 1, Figure Tightening sequence) on the overload clutch with 7 - 8 Nm (62 - 71 in.

lb). Make sure that every screw is

tightened with the right tightening torque, repeat procedure if necessary.

1

Page 3

Edition: September 01 2019

Figure 2.4: Tightening sequence

1 Allen screws

BRP-Rotax

INSTALLATION MANUAL

1

Page 4

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

DIRECT ATTACHMENT OF THE

ENGINE TO CHASSIS

If the frame of the chassis is specially prepared for installation of the ROTAX® 125 MAX DD2 evo, then 2

sheet metal brackets with holes are welded onto the

two frame tubes. The engine is clamped between the

two brackets with 4 bolts.

NOTE

The minimum screw in length of the screws fixing the engine brackets onto the crankcase is

16 mm to 20 mm (0.6 - 0.95 in.).

NOTE

Secure bolts with bolt adhesive e.g. LOCTITE

243.

Step

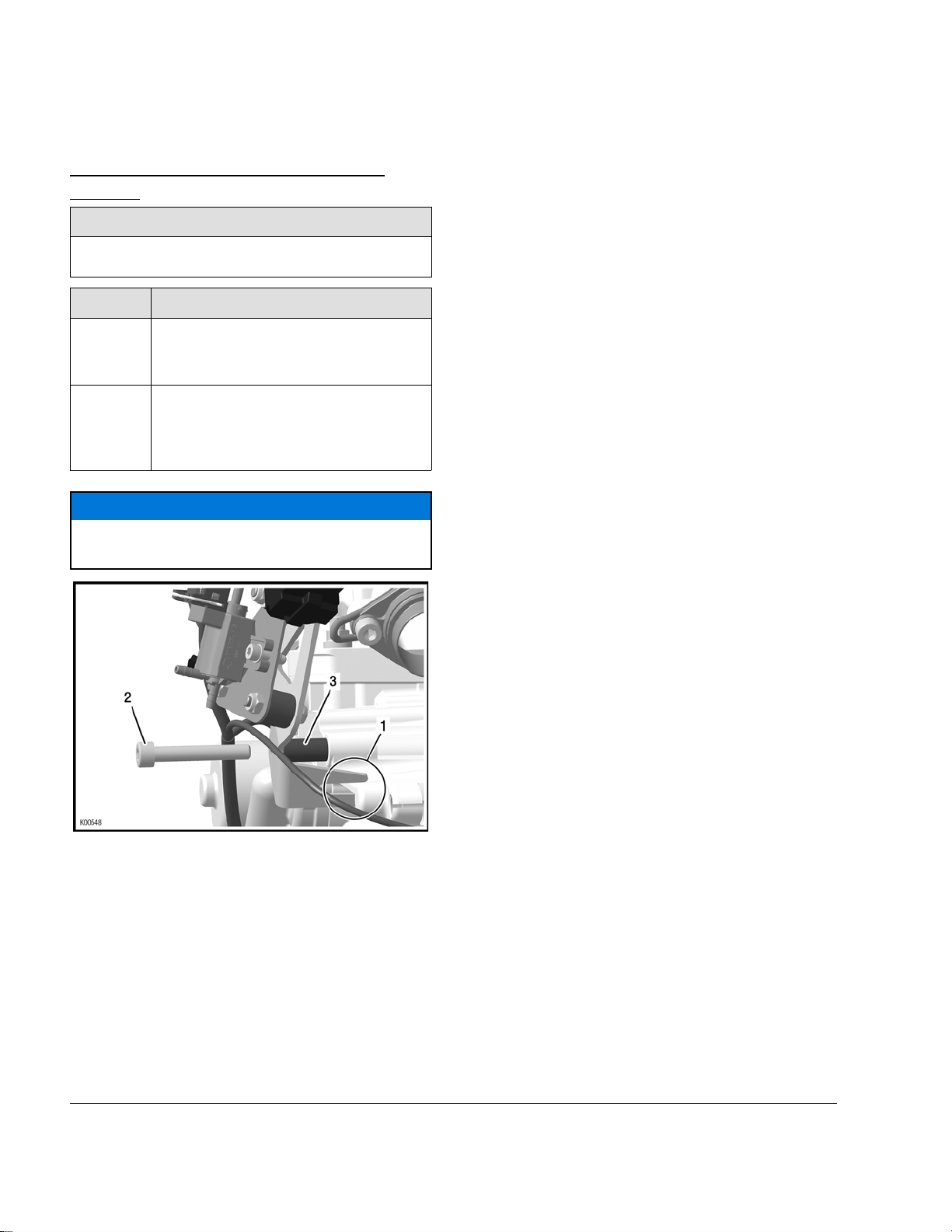

Procedure

Figure 2.5

Pick-up sensor

1

1 Mount engine directly on the brackets.

NOTE

Check for easy access to the pick-up sensor

(pos. 1). There are two options to install the

pick-up sensor. Choose the orientation which

gives you the best fit for your chassis

installation.

m WARNING

Non-compliance can result in serious injuries

or death!

For engine attachment to the chassis, please fol-

low the instruction of the chassis manufacturer.

Effectivity: 125 MAX DD2 evo

1

Page 5

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

NOTES

Notes

Page 6

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

Edition /Rev. 0

BRP-Rotax

INSTALLATION MANUAL

Chapter: 2

FUEL SYSTEM

TOPICS IN THIS CHAPTER

Installation and connection of the fuel pump...........................................................................................2

Installation of the Bowden cable for carburetor control...........................................................................4

Installation and connection of the carburetor ..........................................................................................6

Effectivity: 125 MAX DD2 evo

2

Page 1

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION AND CONNECTION

OF THE FUEL PUMP

Tools required:

• Allen key 5 mm

• Circlip pliers

Step

1

Figure 3.1

Step

2

Procedure

The retaining plate, rubber buffers, fuel

pump, fuel hose (with 230 mm and

1800 mm length) is already preassembled.

Procedure

Install the retaining plate with fuel

pump (pos. 1) on the gearbox cover by

using 2 screws M6x30 (pos. 3) and

washers (pos. 2).

Figure 3.2

Fuel pump

1

3 Screws M6x30

Figure 3.3

TIP

Facilitate the assembly of fuel hose by

slightly widening the hose end with a pair

of circlip pliers.

2

Washer

ATTENTION

2

Page 2

Edition: September 01 2019

Fuel hose can be damaged!

Avoid excessive widening of the fuel hose.

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Step

Procedure

3

4

The fuel hose with 230 mm length will

be connected later to the carburetor,

see carburetor installation.

The larger fuel hose (pos. 1) should be

connected to the fuel filter (pos. 2) and

to the fuel tank.

Figure 3.4

Large fuel hose

1

ATTENTION

Pay attention to the direction of the arrow on

the fuel filter.

This must point towards the fuel pump.

ATTENTION

Route the fuel line from the fuel tank to the fuel fil-

ter so that it does not touch any moving parts of

the track and attach the fuel line onto the top side

of the chassis tube.

ATTENTION

The flow in the impulse hose and fuel lines

must not be restricted by the use of cable ties.

2

Fuel filter

Effectivity: 125 MAX DD2 evo

2

Page 3

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION OF THE BOWDEN

CABLE FOR CARBURETOR

CONTROL

Tools required:

• Open-end wrench 10 mm

Step

1

Reset spring of carb piston presses against

carburetor cover and might eject carburetor

Step

2 Remove nipple screw (pos. 5) with

3

4 Fit nipple screw in carburetor piston

5

Procedure

Carefully remove carburetor cover with

rubber ring (pos. 7, 8).

ATTENTION

cover at removal.

Procedure

open-end wrench 10 mm from carburetor piston (pos. 2).

Engage nipple of Bowden wire (pos. 9)

in nipple screw (pos. 5).

and hand tighten with open-end

wrench 10 mm.

Insert carburetor piston (pos. 2) into

carb body with recess of piston towards intake silencer.

Figure 3.5

1 Carburetor

3 Jet needle K57

Nipple screw

5

7 Carb cover

9 Bowden cable

Carburetor piston

2

Clip

4

Compression spring

6

Rubber ring

8

Restrictor (Mini, Micro

10

MAX evo)

6 Pass Bowden wire through compres-

sion spring (pos. 6) and through cover

with rubber ring (pos. 7, 8) of

carburetor.

7

8 Pass Bowden wire through Bowden

9 Connect Bowden cable to throttle

Fit carb cover (pos. 7) on carburetor.

conduit and through adjustment screw

on chassis (throttle pedal).

pedal.

2

Page 4

Edition: September 01 2019

NOTE

Shorten Bowden cable as required.

Step

10 Route carburetor Bowden cable on the

Procedure

top side of the chassis tubes and attach with the cable ties supplied. Make

sure that the Bowden cable does not

touch any moving parts or the track.

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

m WARNING

Non-compliance can result in serious injuries

or death!

The carburetor Bowden cable must not be kinked

or restricted as the carburetor piston might get

stuck in full throttle position.

Step

11 Set and secure the adjustment screw

12 Set and secure the stop screw for

Procedure

for Bowden cable on chassis so that

the carburetor piston will remain in

closed position when throttle pedal is

not activated.

throttle pedal so that, with pedal completely pressed down, the carburetor

piston will be in the full open position.

The Bowden cable must not be under

full tension when the throttle is in fully

open position.

Effectivity: 125 MAX DD2 evo

2

Page 5

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION AND CONNECTION

OF THE CARBURETOR

Tools required:

• Ratchet wrench with socket 7 mm

• Phillips screwdriver

Step

1

2 Connect the outlet hose of the fuel

Procedure

Fit carburetor (pos. 1) into carburetor

socket and secure with hose clamp

(pos. 2) in vertical position.

pump with fuel inlet (pos. 3) on the

carburetor.

Figure 3.6

1 Carburetor

3 Fuel inlet

2

Page 6

Edition: September 01 2019

Hose clamp

2

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Chapter: 3

ELECTRIC SYSTEM

TOPICS IN THIS CHAPTER

Electric system overview.........................................................................................................................2

Installation ECU into the battery clamp assy............................................................................................3

Installation of the battery clamp assy. .....................................................................................................5

Installation of the wiring harness ............................................................................................................7

Effectivity: 125 MAX DD2 evo

3

Page 1

Edition: September 01 2019

INSTALLATION MANUAL

ELECTRIC SYSTEM OVERVIEW

BRP-Rotax

Figure 4.1

Connector pickup sensor

1

Connector battery

3

5 Connector ECU 6

7 Connector shift contact 8

Tie wrap 142x3.2

9

3

Page 2

Edition: September 01 2019

2 Connector starter

Connector RAVE (only applicable 125 MAX evo)

4

Connector ignition coil

Tie wrap 250x4.8

Effectivity: 125 MAX DD2 evo

INSTALLATION MANUAL

INSTALLATION ECU INTO THE

BATTERY CLAMP ASSY.

BRP-Rotax

Step

1 Prepare rubber pad (consists of two

Figure 4.2

Rubber pad

1

Procedure

halves) (pos. 1) and the ECU (pos. 2)

for installation.

2

ECU

Figure 4.3

Rubber pad

1

Step

3 Insert the complete unit into the battery

Procedure

clamp assy..

NOTE

Step

2

TIP

Effectivity: 125 MAX DD2 evo

Procedure

Install the rubber pad (pos. 1) onto the

ECU.

Align at the triangular bottom of the ECU.

It fits only in one position to the rubber

pad.

If difficulties at insertion occur, the inside of the

battery clamp assy. can be easily bent inward

so that the distance increases slightly.

ATTENTION

Make sure that the connection cable has been

installed between the two pads.

The connection of the ECU is on the rear side

(against the driving direction).

3

Page 3

Edition: September 01 2019

Figure 4.4

Rubber pad

1

BRP-Rotax

INSTALLATION MANUAL

2 Connection cable

3 ECU connector

3

Page 4

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION OF THE BATTERY

CLAMP ASSY.

Tools required:

• Allen key 4 mm

• Ratchet wrench with socket 8 mm or Phillips

screwdriver

m WARNING

Non-compliance can result in serious injuries

or death!

Make absolutely sure to avoid short-circuiting of

battery terminals. A short circuit will ruin the bat-

tery and could cause an explosion.

Step

1

Procedure

Attach the battery fixture (pos. 5) with

the two pipe clamps (pos. 1 – 4) on the

left side box beside the driver’s seat.

NOTE

The clamps (pos. 2, 3) are designed for chassis

tubes of 30 - 32 mm (1.18 – 1.26 in) diameter.

ATTENTION

Risk of clamp fracture!

Do not over tighten the screw of the pipe clamps.

Step

2

3 Put the battery (pos. 7) into the fixture

Procedure

Install rubber pad (pos. 6) with battery

(pos. 7) into the battery holder (pos.

5).

and install the cover (pos. 8) with preassembled wiring harness using the

Allen screw with rounded flange head

(pos. 9).

Figure 4.5

Pipe clamps

1–4

Rubber pad

6

Battery cover

8

O-ring

10

Battery fixture

5

Battery

7

Flange head screw

9

Multiple function switch

11

TIP

The battery fixture (pos. 5) can be fixed

with one screw on one side of the clamp

(pos. 3).

Effectivity: 125 MAX DD2 evo

3

Page 5

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

Figure 4.6

NOTE

The battery terminals must point in the direction

of the control unit.

Figure 4.8

Figure 4.7

Battery terminals

1

Step

3

Procedure

Connect the positive terminal (red) of

the battery.

Step

5

Procedure

Install the battery cover onto the battery holder.

NOTE

Make sure that the two retaining lugs (pos. 1)

are in the notches of the battery cover!

Step

6

Procedure

Tighten flange head screw (pos. 2) of

the battery cover.

4

Connect the negative terminal (black)

of the battery.

3

Page 6

Edition: September 01 2019

Figure 4.9

Retaining lugs

1

Flange head screw

2

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION OF THE WIRING

HARNESS

Tools required:

• Torx screwdriver T30

The wiring harness is delivered partly pre-assembled

to facilitate the installation. This means that the relay,

the master switch and the battery cover are already

pre-assembled and wired.

NOTE

The connector assignment is shown on the following pages. Details on the assignment of cables and pins are given in the wiring diagram.

NOTE

Cable lugs may break after repeated bending.

Step

1 Place the wiring harness loosely on

Procedure

the chassis.

NOTE

When unplugging connections on ignition pick

up and ignition coil, press the integrated catch

first.

NOTE

Disconnect any electrical plug connection only

by pulling on the plugs.

Step

2 Pre-mount cable tie large through the

Procedure

two holes provided on the mounting

plate.

NOTE

Always start the installation at the engine side to

work without tension on the wiring harness.

ATTENTION

Strain relief of the plug connections must be

ensured.

NOTE

Compensate excessive length of wiring harness

by routing cables in loops.

m WARNING

Non-compliance can result in serious injuries

or death!

The wiring harness must not touch moving

parts of the track.

Figure 4.10: Installation

1 Cable tie

Step

3

4 Fasten cables with cable ties on the

Procedure

Connect solenoid valve and ignition

coil. Attach both connectors (signed

green) on the two components.

mounting plate.

Effectivity: 125 MAX DD2 evo

3

Page 7

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

Figure 4.11

1 Solenoid valve

Connectors (signed

3

green)

Step

5

Procedure

Remove isolation tape from the shift

contact wire (pos. 1) and loosely fasten with a tie wrap (pos. 2) (about 130

mm from the cable lug).

Ignition coil

2

4

Cable tie

Step

6

Procedure

Fasten the cable lug (pos. 3) to the

shift contact assy. using the Plastite

screw M6x25 (pos. 4). Pay attention to

correct sequence of the components!

See following Figures.

For correct adjusting of the plastite

screw find the according section inside

the latest Operators Manual.

NOTE

Fasten the cable lug (pos. 3) between the fuel

tube 8 mm (pos. 2) and the Plastite screw

M6x25 (pos. 4). See following Figure.

Figure 4.12

Tie wrap

1 Contact wire

2

NOTE

Do not tighten tie wrap yet in order to be able to

change its position later on.

3

Page 8

Edition: September 01 2019

Figure 4.13

Shift contact assy.

1

Cable lug

3

2

Fuel tube

4

Plastite screw M6x25

NOTE

The correct adjustment of the shift contact is described in the Operators Manual, section “Adjustment of gear shifting”.

Step

7

Procedure

Fasten the wire of the shift contact

assy. with a tie wrap (pos. 1) on the

bottom of the engine.

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Figure 4.14

Tie wrap

1

Step

8 Connect pick up connector to pick up

Procedure

sensor (pos. 1). Pay attention to the

engagement of the connector. See also section: Direct attachment of the

engine to chassis.

Step

9 Attach ignition cables to the spark

Procedure

plug.

Figure 4.15

Pick up sensor

1

NOTE

If it's not possible to plug in the connector of the

pick-up sensor, unscrew the pick-up sensor and

change the angle or direction. See also section:

Direct attachment of the engine to chassis.

Effectivity: 125 MAX DD2 evo

3

Page 9

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

NOTES

Notes

Page 10

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

Edition /Rev. 0

BRP-Rotax

INSTALLATION MANUAL

Chapter: 4

COOLING SYSTEM

TOPICS IN THIS CHAPTER

Cooling system overview ........................................................................................................................2

Installation of the radiator .......................................................................................................................3

Intake silencer .........................................................................................................................................4

Installation of the intake silencer with integrated airfilter ........................................................................5

Effectivity: 125 MAX DD2 evo

4

Page 1

Edition: September 01 2019

INSTALLATION MANUAL

COOLING SYSTEM OVERVIEW

BRP-Rotax

Figure 5.1

1 Radiator 2

3 Lower coolant water hose 4

Rubber puffer

5

7 Washer 8 Lock nut

Allen screw — rounded flange head

9

4

Page 2

Edition: September 01 2019

Upper coolant water hose

Clamp 16–25

Rubber puffer

6

Hose clamps

10

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION OF THE RADIATOR

Tools required:

• Ratchet wrench with socket 7 mm or Phillips

screwdriver

Step

1

2 Mount the radiator support with the

NOTE

For an optimum of cooling efficiency, we recommend to install the radiator in an angle of 25° +/5° tilted backwards.

Non-compliance can result in serious injuries

For radiator installation to the chassis, please fol-

low the instruction of the chassis manufacturer.

Step

3 Put the four supplied hose clamps

Procedure

Mount radiator (pos. 1) using the provided rubber buffer (pos. 5) and lock

nut (pos. 8) with washer (pos. 7) on

the lower support bracket on the

chassis.

rubber buffer (pos. 6) and lock nut

(pos. 8) with washer (pos. 7) on the

upper radiator mount and onto the

chassis.

m WARNING

or death!

Procedure

(pos. 10) on the coolant hoses.

Step

6 Secure the coolant hoses with the

7

The coolant water hose between radiator and

engine must not rub with the drivers seat.

Arrange the routing of the coolant water hose

Step

8 Secure the lower coolant water hose

Non-compliance can result in serious injuries

Please follow the instruction of the chassis manu-

facturer for mounting the lower coolant water hose

Step

9 Establish connection between over-

Procedure

hose clamps (pos. 10).

Secure the upper coolant water hose

to the driver's seat (pos. 2) using the

provided cable tie.

ATTENTION

accordingly.

Procedure

(pos. 3) using two of the provided cable ties to the chassis.

m WARNING

or death!

to the chassis.

Procedure

flow socket on radiator filling socket

and the overflow bottle with an appropriate piece of hose.

4 Push the upper coolant water hose

(pos. 2) onto the upper socket of the

radiator as well onto water socket of

the cylinder head cover.

5

Effectivity: 125 MAX DD2 evo

Push the lower coolant water hose

(pos. 3) onto the lower socket of the

radiator as well onto the water socket

of the water pump housing.

ATTENTION

Warrant the best possible engine cooling.

Ensure that the air stream covers the complete ra-

diator area.

4

Page 3

Edition: September 01 2019

INTAKE SILENCER

BRP-Rotax

INSTALLATION MANUAL

Figure 5.2: Overview

1 Intake silencer case 2 Intake silencer cover

3 Filter element 4 Holder for filter element

5 Intake silencer tube 6

7 Carburetor socket 8

9 Lock nut M6 10

O-ring

Clamp 50–70

Allen screww. rounded flange head

4

Page 4

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

INSTALLATION MANUAL

INSTALLATION OF THE INTAKE

SILENCER WITH INTEGRATED

AIRFILTER

Tools required:

• Allen key 4 mm

• Ratchet wrench with socket 7 mm or Phillips

screwdriver

BRP-Rotax

Step

1 Install the rubber intake pipe (pos. 5)

2

3

4

5

Procedure

in a vertical position into the bottom

half (pos. 2) of the intake silencer so

that the rounded intake openings point

outwards.

Fit the carburetor socket (pos. 7) into

the inner side half of silencer (pos. 1)

so that the arrow on the socket points

towards the carburetor.

Install the filter element (pos. 3) with

holder (pos. 4).

Assemble filter box and filter insert as

shown in the intake silencer overview

figure. Make sure that the locking is interlocked properly.

Attach the intake silencer with the supplied hose clamps (pos. 8) to the

carburetor.

NOTE

The carburetor socket (pos. 7) is slightly tilted in

one direction and can be turned so that the best

possible position between carburetor and intake

silencer can be achieved.

Step

6 Attach the intake silencer on the chas-

Effectivity: 125 MAX DD2 evo

Procedure

sis using the M6 Allen screw with

rounded flange head (pos. 10).

4

Page 5

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

NOTES

Notes

Page 6

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

Edition /Rev. 0

BRP-Rotax

INSTALLATION MANUAL

Chapter: 5

EXHAUST SYSTEM

TOPICS IN THIS CHAPTER

Exhaust system overview........................................................................................................................2

Installation of the exhaust system ...........................................................................................................3

Effectivity: 125 MAX DD2 evo

5

Page 1

Edition: September 01 2019

INSTALLATION MANUAL

EXHAUST SYSTEM OVERVIEW

BRP-Rotax

Figure 6.1

Exhaust system

1

Tension spring

3

Exhaust gasket

5

7 Rubber buffer 8

9 Rubber buffer 10 Washer 8.4

11 Lock nut M8 12

Exhaust gasket

13

2

4

6

14

5

Page 2

Edition: September 01 2019

Silencer assy.

Spring stainless

Retaining plate

Spring stainless

Exhaust socket assy.

Spring stainless

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION OF THE EXHAUST

SYSTEM

Tools required:

• Open-end wrench 13 mm

• Spring hook

NOTE

On the underside of the exhaust system, two different mounting mechanisms are provided. At

the front, the assembly is carried out with rubber

buffers (pos. 7) between the retaining plate

(pos. 6) and the exhaust system and attached

by extension springs (pos. 8). At the rear, the

exhaust system is mounted directly using a rubber mount M8 (pos. 9).

ATTENTION

A rigid suspension of the exhaust system

could result in fractures in the exhaust system.

NOTE

For easier installation use the special tool

"Spring hook" part no. 251680.

ATTENTION

Do not over-stress the springs when fitting

them.

Step

5 Attach the exhaust system on the

Procedure

chassis supports such that the sealing

of the ball joint between cylinder and

exhaust system will not be impaired.

Step

1 Attach the heat-resistant rubber mount

2

3

Step

4

Procedure

(pos. 9) to the support lug on the

underside of the exhaust.

Arrange the chassis-specific supports

so that the exhaust system follows the

straightest possible course from the

exhaust socket on the cylinder to the

muffler.

The gasket (pos. 13) is the only sealing between engine and the exhaust

system. Additional heat-resistant LOCTITE is not necessary anymore.

Procedure

Secure the exhaust system on the exhaust socket using the two supplied

exhaust springs (pos. 14).

Effectivity: 125 MAX DD2 evo

5

Page 3

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

NOTES

Notes

Page 4

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

Edition /Rev. 0

BRP-Rotax

INSTALLATION MANUAL

Chapter: 6

INSTALLATION OF THE ACCESSORIES

TOPICS IN THIS CHAPTER

Installation of mounting plate ..................................................................................................................2

Fitting of the spark plug...........................................................................................................................3

Installation and connection of the RAVE control unit ..............................................................................4

Assembly of paddle shift system.............................................................................................................7

Effectivity: 125 MAX DD2 evo

6

Page 1

Edition: September 01 2019

INSTALLATION MANUAL

INSTALLATION OF MOUNTING

PLATE

Tools required:

• Allen key 6 mm

BRP-Rotax

Step

1 The holding bracket, the mounting

2 Install whole bracket kit with Allen

Slot of mounting plate has to be installed in

Procedure

plate, the solenoid valve and the ignition coil are already pre-assembled.

screw M8x50 (pos. 2) and distance

sleeve 8.2/12/25.5 (pos. 3) onto the

engine.

ATTENTION

the correct position.

Figure 7.1

2

1 Slot

Distance sleeve 8.2/

3

12/25.5

Allen screw M8x50

NOTE

Distance sleeve (pos. 3) has to be install between engine housing and retaining plate. Distance sleeve can be replaced by fitting of an

additional seat stay.

6

Page 2

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

INSTALLATION MANUAL

FITTING OF THE SPARK PLUG

The engine will be supplied with a spark plug.

Tools required:

• Feeler gauge

• Socket 21 mm

• Torque wrench

BRP-Rotax

Step

1 Remove the transport plug from the

2

Procedure

cylinder head.

Check electrode gap of spark plug. Adjust as required.

NOTE

Check technical regulations to assure conformity when setting the electrode gap.

Step

3 Fit supplied spark plug (pos. 1) and

4

Procedure

tighten 25 Nm (221 lbf in) to 27 Nm

(239 lbf in).

Install the spark plug connector (pos.

2), ensure correct engagement.

Figure 7.2

Spark plug

1

Spark plug connector

2

Effectivity: 125 MAX DD2 evo

6

Page 3

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

INSTALLATION AND CONNECTION

OF THE RAVE CONTROL UNIT

NOTE

The hose package of the RAVE control is already pre-assembled.

NOTE

The impulse restrictor is offered optionally.

Step

1

Procedure

Insert impulse nozzle (pos. 6) about 25

mm into the 420 mm pressure line

(pos. 7) using an Allen key SW4. Pay

attention to the mounting direction! It

also works without an impulse nozzle,

this only serves to choke the opening

of the exhaust valve.

NOTE

In order to prevent the displacement of the impulse nozzle (pos. 6), a small cable tie (pos. 8)

should be attached directly afterwards to the

pressure line. Do not tie up the pressure line

completely!

Figure 7.3

4 Check valve

7 Pressure line

Step

2

Impulse nozzle

6

Tie wrap small

8

Procedure

Attach the black hose of the hose

package (pos. 1) to the metal connector (pos. 2) of the magnetic valve

6

Page 4

Edition: September 01 2019

Figure 7.4

Hose package

1

Step

3

2

Metal connector

Procedure

Attach the other end of the hose package (pos. 1) (short end with T-piece) to

the fuel pump.

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Figure 7.5

Hose package

1

Step

4

Procedure

Attach the fuel line of the hose package (pos. 1) to the impulse nipple on

the engine housing..

NOTE

Check that valve is not the lowest point of the

impulse circuit to prevent that condensation affects a proper operation.

Step

5

Figure 7.7

1 Cable tie

Step

6

Procedure

Attach cable tie with mount (pos. 1) to

the housing.

Impulse nipple

2

Procedure

Secure both lines with cable tie, ensuring that the black hose is on top.

Figure 7.6

Hose package

1

Effectivity: 125 MAX DD2 evo

ATTENTION

Do not tighten cable ties too tight, because

constricted lines can lead to loss of function.

Step

7

Procedure

Attach an additional cable tie (pos. 3)

as shown in figure.

Edition: September 01 2019

6

Page 5

Figure 7.8: Cable tie

1 Cable tie

3 Cable tie

2

Black hose

BRP-Rotax

INSTALLATION MANUAL

Step

8

Figure 7.9

Procedure

Attach the 220 mm pressure line (pos.

1) to the magnetic valve (pos. 3). Secure the pressure line on the magnetic

valve with a tie wrap (pos. 4). Attach

the other end of the pressure line to

the exhaust valve (pos. 2).

1 Pressure line

Magnetic valve

3

6

Page 6

Edition: September 01 2019

2

Exhaust valve

4

Cable tie

Effectivity: 125 MAX DD2 evo

INSTALLATION MANUAL

ASSEMBLY OF PADDLE SHIFT

SYSTEM

Tools required:

• Allen key 6 mm

• Allen key 5 mm

BRP-Rotax

Step

1 Install spacer (pos. 1) into the appro-

Figure 7.10

Spacer

1

Procedure

priate bore (pos. 2) of the engine

housing.

Appropriate bore

2

Figure 7.11

2

1 Washer

Step

3 Mount Bowden cable (pos. 2) with

Procedure

washer (pos. 1) onto the shift contact

guidance (pos. 3).

Bowden cable

Step

2

Effectivity: 125 MAX DD2 evo

Procedure

Install washer (pos. 1) on one of the

two Bowden cables (pos. 2).

Figure 7.12

1 Washer

Shift contact

3

guidance

Step

4

2

Bowden cable

Procedure

Mount Bowden cable with shift contact

guidance (pos. 1) to the retaining plate

(pos. 2).

Page 7

Edition: September 01 2019

6

Figure 7.13

BRP-Rotax

INSTALLATION MANUAL

Shift contact

1

guidance

Step

5

Figure 7.14

Retaining plate

2

Procedure

Mount Allen screw (pos. 1), lock washer (pos. 2) and spacer (pos. 3) together with the shift contact guidance (pos.

4) to the engine housing. Tightening

torque 22 Nm.

Figure 7.15

1 Point 1

Step

7

Figure 7.16

2

Point 2

Procedure

Mount sleeve (pos. 1) onto the retaining plate (pos. 2).

2

1 Allen screw

Spacer

3

Step

Procedure

Lock washer

Shift contact guidance

4

6 The alignment between point -1- and

point -2- must be given. Otherwise it

can cause increased friction, which

has a negative impact on shifting

behavior.

6

Page 8

Edition: September 01 2019

1 Mount sleeve

Step

8

Procedure

Mount second Bowden cable (pos. 1)

through shift contact guidance and

sleeve onto the retaining plate (pos.

2).

No washer is necessary on this Bowden cable.

Retaining plate

2

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Figure 7.17

1 Bowden cable

3 Guidance

Step

9

Retaining plate

2

Procedure

Install Bowden cables (pos. 1) into the

support on the back of the engine.

Figure 7.19

Cable support

1 Bowden cables

3 Set screw

Step

11 Hand-tighten both Bowden cables

Procedure

(pos. 1) onto the control whip (pos. 2),

using M6. Allen screws (pos. 3) and

washers (pos. 4). Pay attention to the

correct installation of the control whip!

2

NOTE

The oblique millings (pos. 5) of the control whip

serve to guide the cables. The cable ends must

look away from the center of the control whip.

The Bowden cables can be attached to the control

whip in two different ways:

• Version 1:

Figure 7.18

1 Bowden cable

Step

10

Effectivity: 125 MAX DD2 evo

Procedure

Thread both ends of the Bowden cables (pos. 1) through the cable support

(pos. 2). Install the set screw (pos. 3)

onto the cable support – just pre-assemble it, do not tighten yet.

Fasten Bowden cable to position 5 inside.

Feature: Shift travel longer, but less effort.

• Version 2

Fasten Bowden cable to position 5 outside.

Feature: Short shift, but higher effort.

6

Page 9

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

NOTE

The control lever can also be attached on the

back, depending on how it is more ergonomic

for the driver.

Figure 7.20

Control whip

1 Bowden cable

3 Allen screw

Oblique millings

5

Step

12 Hand-tighten control lever left and right

Procedure

(pos. 1) onto the control whip (pos. 4),

using M6 Allen screws (pos. 2) and

washers (pos. 3).

2

4

Washer

Step

13

Procedure

Install spacer (pos. 1) with washer

(pos. 2) onto the bottom side of the

control whip (3).

NOTE

The bottom side is, where the screws of the

Bowden cables are fixed.

Figure 7.21

1 Control lever

3 Washer

6

Page 10

Edition: September 01 2019

2

Allen screw

Control whip

4

Figure 7.22

Spacer

1

Control whip

3

Step

14 Tighten Allen screw M6x60 (pos. 1)

Procedure

and washer (pos. 2) onto the top of the

control whip (pos. 3).

2

Thrust washer

NOTE

Top is the opposite side, where the screws of

the Bowden cables are attached.

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Figure 7.23

2

1 Allen screw M6x60

Control whip

3

Step

15

Procedure

Place the entire shifting unit onto the

steering wheel and tighten it using Allen screw M6x 60 (pos. 3), M6 lock nut

(pos. 1) with washer (pos. 2).

Washer

NOTE

Control whip must run smoothly.

NOTE

Spacer must fit into the bore provided on the

steering wheel.

Figure 7.24

2

1 Lock nut M6

3 Allen screw M6x60

Step

16 The setting of the shifting is carried out

17

Procedure

in neutral gear, which means that the

control whip must be in horizontal

position.

Tighten screw (pos. 2) of the cable

abutment (pos. 1) and the screws of

the Bowden cables on the control whip

(pos. 3).

Washer

NOTE

At full steering angle, no gear must engage. If a

gear engages by itself, the distance between

control whip and cable abutment must be

adjusted.

Effectivity: 125 MAX DD2 evo

Step

18

Procedure

Finally, the length of the Bowden cables can be adjusted so that they do

not disturb the driver when shifting.

6

Page 11

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

Figure 7.25

1 Cable abutment

Control whip

3

2

Screw

6

Page 12

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

Chapter: 7

FINISHING WORK

TOPICS IN THIS CHAPTER

Check oil level in gearbox........................................................................................................................2

Venting of the gear compartment ............................................................................................................4

NOTE

To determine the best possible transmission ratio, the use of a rev-counter is required for observation

of the speed limits.

NOTE

To warrant engine operation within temperature limits of the coolant, a temperature sensor for

observation of the coolant temperature is required.

NOTE

Refer to Operators Manual for operating limits.

Effectivity: 125 MAX DD2 evo

7

Page 1

Edition: September 01 2019

BRP-Rotax

INSTALLATION MANUAL

CHECK OIL LEVEL IN GEARBOX

The gearbox is already filled with the appropriate

amount of oil by the engine manufacturer. However,

before the engine is installed in the frame, the oil level must be verified or replenished.

Step

1 Place engine on a horizontal surface

When placing the engine on a horizontal sur-

face, take care not to damage the crankcase

sensor, which is mounted on the bottom of the

Step

2 The oil level can be checked on in-

Procedure

and/or assembling trestle.

ATTENTION

crankcase.

Procedure

spection glass (pos. 1). It should reach

approximately to one-third of the inspection glass, see following figure. If

the oil level is not sufficient, replenish

oil as described in the following steps.

NOTE

For gearbox oil specifications and oil capacity

(total) see the latest Operators Manual.

Figure 8.1

Inspection glass

1

Step

3 Remove the air vent screw (pos. 1)

4

Procedure

and slowly fill in oil until oil level is in

the middle of the inspection glass.

Hand-tighten air vent screw (pos. 1).

7

Page 2

Edition: September 01 2019

Figure 8.2

1 Air vent screw

Effectivity: 125 MAX DD2 evo

BRP-Rotax

INSTALLATION MANUAL

NOTE

For draining the oil from the gear case, remove

the magnetic oil drain plug (pos. 1) and sealing

ring (pos. 2). Clean the oil drain plug before installation. Always use a new sealing ring.

Figure 8.3

Magnetic oil drain

1

plug

Sealing ring

2

NOTE

Tighten magnetic oil drain plug (pos. 1) to 20

Nm (177 lbf.in.).

m WARNING

Non-compliance can result in serious injuries

or death!

Do not run the engine without gear oil. This will

lead to engine failure.

Effectivity: 125 MAX DD2 evo

7

Page 3

Edition: September 01 2019

VENTING OF THE GEAR

COMPARTMENT

BRP-Rotax

INSTALLATION MANUAL

Step

1

2 Establish a connection between the

Procedure

Remove cap from the venting screw.

venting screw and a collecting reservoir using a piece of the supplied fuel

hose of an appropriate length.

NOTE

The venting hose must not reach all the way to

the bottom of the collecting reservoir.

ATTENTION

Do not attach the venting hose on the bottom

of the collecting reservoir, if only one reservoir

is in use.

7

Page 4

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

Index

BRP-Rotax

INSTALLATION MANUAL

B

Battery, installation ................................................5

Bowden cable, installation......................................4

C

Carburetor, connection ..........................................6

Carburetor, installation...........................................6

Cooling system .....................................................1

Cooling system overview .......................................2

D

Direct attachment of the engine to chassis ..............5

E

ECU, Installation ...................................................3

Electric system......................................................1

Electric system overview........................................2

Engine information ................................................4

Engine, installation ................................................3

Exhaust system ....................................................1

Exhaust system overview ......................................2

Exhaust system, installation ...................................3

O

Oil level, check in gearbox .....................................2

Overload clutch, installation ...................................2

P

Paddle shift system, assembly ...............................7

R

Radiator, installation ..............................................3

RAVE control unit, installation ................................4

S

Spark plug, fitting ..................................................3

U

Unboxing..............................................................1

V

Venting of the gear compartment............................4

F

Finishing work.......................................................1

Fuel pump, connection ..........................................2

Fuel pump, installation...........................................2

Fuel system, installation ........................................1

I

Intake silencer ......................................................4

Intake silencer, installation .....................................5

INTRO .................................................................1

M

Mounting plate, installation.....................................2

Effectivity: 125 MAX DD2 evo

W

Wiring harness, installation ....................................7

Index

Page 5

Edition: September 01 2019

Operator‘s Manual

BRP-Rotax

Operators Manual

Table of Content

Chapter INTRO – GENERAL INFORMATION

Chapter 1 – Technical Description

Chapter 2 – Operating fluids and battery

Chapter 3 – Engine calibration

Chapter 4 – Engine operation

Chapter 5 – Preservation and transport

Effectivity: 125 MAX DD2 evo

Content

Page 1

Edition: September 01 2019

BRP-Rotax

Operators Manual

NOTES

Page 2

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

Operators Manual

Chapter: INTRO

GENERAL INFORMATION

Preface Before operating the engine, read the Operators Manual carefully.

If any passages of the Manual are not clearly understood or if you have questions, please

contact an authorized Distribution or Service Center for ROTAX®-kart engines.

This document and all technical data and procedures therein are property of BRP-Rotax

GmbH & Co KG and based on the state of knowledge at the time of publication The

Manual has been drawn up to the best of our knowledge. However, excluding any liability.

We reserve all rights including technical modification and possibility of errors. Reprinting,

translation or copies in whole or in part, are authorized only after written permission by

BRP-Rotax GmbH & Co KG.

BRP-Rotax GmbH & Co KG reserves the right at any time to discontinue or change

specifications, prices, designs, features, models or equipment without incurring obligation.

Engine performance may vary depending on, among other things, general conditions,

ambient temperature and altitude.

Contents This Operators Manual contains instructions about how to operate the ROTAX®-Engine

Type 125 MAX DD2 evo.

Symbols used This Manual uses the following symbols to emphasize particular information. This

information is important and must be observed.

m WARNING

Identifies an instruction, which if not followed may cause injury or endanger the

life of the driver, mechanic or third party.

ATTENTION

Denotes an instruction which if not followed may severely damage the engine.

Noncompliance might lead to health hazards under certain conditions.

ENVIRONMENTAL NOTE

Environmental notes give you tips on environmental protection.

NOTE

Indicates supplementary information which may be needed to fully complete or

understand an instruction.

✔

TIP

______________________________________________________

Denotes a checking operation

This information gives you additional advice and tips

Effectivity: 125 MAX DD2 evo

INTRO

Page 1

Edition: September 01 2019

BRP-Rotax

Operators Manual

NOTES

Page 2

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

Operators Manual

Chapter: 1

TECHNICAL DESCRIPTION

TOPICS IN THIS CHAPTER

Design of the ROTAX engine 125 MAX DD2 evo.......................................................................................2

General ................................................................................................................................................2

Cooling circuit .......................................................................................................................................2

Balance gear.........................................................................................................................................3

Ignition unit ...........................................................................................................................................3

Electric starter .......................................................................................................................................3

Electro pneumatically exhaust timing control ...........................................................................................3

Intake silencer.......................................................................................................................................3

Exhaust system.....................................................................................................................................4

Gearbox ...............................................................................................................................................4

Electronic Shifting Assistant (ESA) .........................................................................................................4

Fuel pump ............................................................................................................................................4

Carburetor ............................................................................................................................................4

Centrifugal clutch ..................................................................................................................................5

Overload clutch .....................................................................................................................................5

Effectivity: 125 MAX DD2 evo

1

Page 1

Edition: September 01 2019

BRP-Rotax

Operators Manual

DESIGN OF THE ROTAX ENGINE 125 MAX DD2 EVO

Figure 1.1

GENERAL

The Rotax 125 MAX DD2 evo engine is a single cylinder two stroke engine with reed valve

controlled inlet and 125 cm

the gasoline in a specified mixing ratio.

The power transmission to the rear axle takes place via a manually shift able integrated 2speed gearbox.

________________________________________________________________

COOLING CIRCUIT

The coolant is pumped from the radiator to the water pump which is driven by the clutch

shaft. The water pump conveys the coolant through cylinder and the cylinder head back to

the radiator.

The cooling circuit is equipped with a thermostat (opening point 45 °C / 113 °F). It assures

that the engine reaches its operating temperature quickly and keeps it at a relatively constant level.

The thermostat is integrated in the cylinder head cover.

________________________________________________________________

3

displacement. Mixture lubrication is achieved by adding oil to

1

Page 2

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BALANCE GEAR

IGNITION UNIT

BRP-Rotax

Operators Manual

The balance gear is mounted on the primary shaft and rotates counter-wise to the crankshaft to reduce engine vibration.

________________________________________________________________

The control of the ignition system is exercised by the ECU (Engine Control Unit). To calculate the ignition timing, an engine speed sensor is needed, which is installed on the bottom

of the engine housing. There is no manual adjustment of the ignition system necessary

and/or possible.

If the power button is pressed once, the ignition is activated and the button lights up. To

start the engine, it only needs to be pressed once again. To turn off the engine as well as

the ignition, proceed in reverse order.

________________________________________________________________

ELECTRIC STARTER

By pressing the "START" button, the circuit between the battery and the electric starter will

be closed by a relay. The electric starter drives the starter gear on the crankshaft via an intermediate gear with free wheeling, until the engine starts to run. An automatic switch reset from "START" to "ON" is integrated.

________________________________________________________________

ELECTRO PNEUMATICALLY EXHAUST TIMING CONTROL

The engine type 125 MAX DD2 evo is equipped with an electro-pneumatic exhaust control. The E-RAVE (Electronic ROTAX Adjustable Variable Exhaust) system is controlled by

an electro-pneumatic valve via the ECU. The vacuum required is provided by the engine

crankcase.

If the engine is running at idle speed or below the opening point of the E-RAVE system

(between approximately 8000-9000 rpm) the exhaust valve is closed. With the engine running, it closes or opens the electro-pneumatic valve of the exhaust depending on the

speed and, therefore it provides optimum performance characteristics.

________________________________________________________________

INTAKE SILENCER

The intake silencer incorporates an air filter to clean the intake air. The intake silencer has

been designed for optimum reduction of air intake noise level and represents a tuned system with the engine.

The air filter consists of several layers and has been optimized in the area of air passage

and filter efficiency. If soiled or during engine maintenance work, clean the filter with biodegradable products.

Effectivity: 125 MAX DD2 evo

1

Page 3

Edition: September 01 2019

________________________________________________________________

EXHAUST SYSTEM

The exhaust system is designed as resonance system with an after-muffler and represents a tuned system with engine.

________________________________________________________________

GEARBOX

The power transmission to the rear axle takes place via manually shiftable integrated 2speed gearbox and not as usual, via a maintenance intensive chain drive. Changing the

gear activates the gear shift fork as well as a shifting sleeve, which slides on the hollow

shaft between the 1

BRP-Rotax

Operators Manual

st

and 2ndgear and then engages in the respective idle gear.

The gear is kept in position by an index pin, which keeps the gearshift fork in the selected

position, 1

To allow shifting into 2

off for a moment when actuating the shifting paddle.

________________________________________________________________

st

gear, neutral or 2ndgear.

nd

gear without lifting the foot from the gas pedal, the ignition is cut

ELECTRONIC SHIFTING ASSISTANT (ESA)

To optimize the shifting from 1stto 2ndgear, the ignition is interrupted for a short time. This

releases load from the gearset and, gear shifting is faster and less stressful for the

gearset.

________________________________________________________________

FUEL PUMP

The fuel pump functions due to the alternating negative pressure and overpressure in the

crankcase and sucks fuel from the fuel tank into the carburetor via the fuel pump.

In the suction side of the fuel pump (between fuel tank and fuel pump) a fuel filter is installed to prevent contamination of the fuel pump and carburetor.

________________________________________________________________

CARBURETOR

The carburetor (DELL’ORTO VHSB 34) is a slide type carburetor with float system. The

standard main jet is suitable for almost all operating conditions. For extreme operating

conditions, the main jet size must be adjusted to the actual conditions according to this

manual.

1

Page 4

Edition: September 01 2019

________________________________________________________________

Effectivity: 125 MAX DD2 evo

CENTRIFUGAL CLUTCH

The engine is equipped with a centrifugal clutch operating in an oil bath. This clutch separates the engine from the gearbox at less than 2.500 rpm. Only at an engine speed of approx. 4.000 rpm. the centrifugal clutch is completely engaged.

________________________________________________________________

OVERLOAD CLUTCH

The engine has a mechanical overload clutch, which is installed on the rear axle. It is to

protect the crankshaft from hard shocks from the drive components which are not usual

during normal operation (e.g. the blocking of the rear axle).

BRP-Rotax

Operators Manual

Effectivity: 125 MAX DD2 evo

1

Page 5

Edition: September 01 2019

BRP-Rotax

Operators Manual

NOTES

Page 6

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

Operators Manual

Chapter: 2

OPERATING FLUIDS AND BATTERY

TOPICS IN THIS CHAPTER

Coolant....................................................................................................................................................2

Battery.....................................................................................................................................................3

Battery charging unit ...............................................................................................................................4

Fuel .........................................................................................................................................................6

See also table “important information (summary)” in Chapter 5.

Effectivity: 125 MAX DD2 evo

2

Page 1

Edition: September 01 2019

BRP-Rotax

Operators Manual

COOLANT

Use only distilled water as engine coolant. If the kart is stored below the freezing temperature of water, make sure to drain the water from the cooling radiator and engine

completely.

Step

1

2 Close radiator cap.

Storage below the freezing temperature of water could lead to a damage of the cooling

______________________________________________________

Procedure

Open radiator cap and fill the system with coolant.

Small radiator: approx. 0.52 liter / 0.137 gal for the complete cooling system

Big radiator: approx. 0.7 liter / 0.185 gal for the complete cooling system

ATTENTION

Observe the storage conditions.

system and the engine.

ATTENTION

Exceeding the engine temperature could lead to serious engine failure.

The engine temperature should not exceed 85 °C / 185 °F.

2

Page 2

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

Operators Manual

BATTERY

See Fig. Pos. 1: Charging connector.

The power for the ignition unit and electric starter is only supplied from the battery. With a

fully charged battery of 12 V and 6.5 Ah, the engine can be started approximately one hundred times and operated over a period of approximately five hours. With the battery voltage decreasing to approximately 11 V the point will be reached when the battery voltage

is too low to generate a spark for ignition.

ATTENTION

The lifespan of the battery will be drastically reduced by exhausting the battery

completely.

Fully re-charge the battery before and after any operation of the kart.

NOTE

It is recommended to always carry a charged spare battery. The installed battery

should be replaced with a fully charged battery before it is completely exhausted.

NOTE

If the spark plug is removed, to check if the battery still generates a spark, consider the following: with the spark plug removed it is easier for the electric starter to

crank the engine, which reduces current absorption of the electric starter, resulting in battery voltage adequate to generate a spark. If the spark plug is fitted

again, it may happen that the engine does not start.

NOTE

To charge a battery, the delivered battery charging unit specified by ROTAX®

should be utilized (battery charger part no. 265148). When using the lithium battery available as spare part, the battery charger Optimate Lithium (part no.

581325) is mandatory.

NOTE

To be able to use the battery charger in your home country, please contact your

nearest authorized ROTAX® distributor or one of their ROTAX® Service Centers

to receive an adapter plug or adapter cable, respectively.

NOTE

This battery charger will switch over automatically to maintenance charge as soon

as the target voltage is reached. Therefore overcharging with the result of ruining

the battery will be impossible.

Use of any other battery charger can impair the battery life or may ruin the battery.

Effectivity: 125 MAX DD2 evo

ATTENTION

2

Page 3

Edition: September 01 2019

BRP-Rotax

Operators Manual

BATTERY CHARGING UNIT

When charging the battery take note of the following:

Step

1

Figure 2.1: Pos. 1: Charging connector

Step

2 Connect the battery charging unit on 110-230V, 50 - 60Hz power supply.

Procedure

Connect battery charger to the charging connector (pos. 1).

Procedure

During the charging procedure, the charge indicating lamp will light up red.

NOTE

The battery charger may be connected to the battery for a longer period, as the

battery takes just the current required to be fully charged.

NOTE

A non-extinguishing red control lamp, even after 24 hours of charging, indicates

that the charging capacity of the battery is diminishing.

NOTE

A red/green blinking of the charging control lamp indicates transition from main

charging to additional charging and does not signal a faulty battery charger.

2

Page 4

Edition: September 01 2019

3

4 The charging time amounts to approx. 12 hours.

At completion of the charging process, the control lamp will change to

green, but the charging current will remain, thus warranting a fully charged

battery.

Effectivity: 125 MAX DD2 evo

BRP-Rotax

Operators Manual

Step

5

6

7

Procedure

Unplug power supply to battery charging unit.

Remove output wires of the battery charger from the battery.

The battery is ready again for use.

ATTENTION

In addition to these directives, follow the advice of the battery charging unit

manufacturer.

NOTE

When the battery is charged while not mounted on the kart, use the connector cable (part no. 266022). If needed, contact your authorized distributor or one of their

ROTAX® Service Centers.

The charging condition of the battery can be estimated by using a commercially available

measuring instrument.

______________________________________________________

Effectivity: 125 MAX DD2 evo

2

Page 5

Edition: September 01 2019

BRP-Rotax

Operators Manual

FUEL

For engine operation, a mixture of unleaded gasoline of at least ROZ

+MON) / 2 and fully synthetic two-stroke oil, mixed at ratio 1: 50 (2% oil) has to be used.

ATTENTION

Carry out a correct running-in procedure.

See Chapter 4 section: Running-in procedure for the engine.

m WARNING

Non-compliance can result in serious injuries or death!

When mixing fuel and fuelling do not smoke or allow open fire. Gasoline is highly flam-

mable and explosive under certain conditions.

m WARNING

Non-compliance can result in serious injuries or death!

Never perform mixing and fuelling in closed rooms, handle fuel in well ventilated areas

only.

m WARNING

95 / 91 (RON

min.

Non-compliance can result in serious injuries or death!

Fuel the kart only when engine is not running and the combination switch is at OFF

position.

m WARNING

Risk of fire and explosion!

Make sure that fuel will not splash onto hot engine components or equipment.

m WARNING

Non-compliance can result in serious injuries or death!

Pay attention to the safety advice of the kart manufacturer.

ATTENTION

Possible engine trouble!

Too much oil in the fuel mixture (more than 2%) could lead to engine trouble (e.g. coking

of the exhaust valve, piston ring sticking).

2

Page 6

Edition: September 01 2019

Effectivity: 125 MAX DD2 evo

BRP-Rotax

Operators Manual

ATTENTION

Possible engine blow-up!

Insufficient amount of oil in the fuel mixture (less than 2%) could result in e.g. piston

seizure.

ATTENTION

Engine damage and damage to the intake system may occur.

Do not try any different sorts of fuel.

ATTENTION

Before each fuelling, shake fuel container well to ensure adequate mixing of the gaso-

line with the oil.

ATTENTION

Ensure that no contamination enters the fuel tank and the carburetor.

ATTENTION

Unleaded fuel has a limited storage life.

Store only the quantity of fuel in a container which will be needed in the near future.

ENVIRONMENTAL NOTE

Don’t spill fuel. Absorb spilled fuel with appropriate drying agent and ensure ecological

disposal.

______________________________________________________

Effectivity: 125 MAX DD2 evo

2