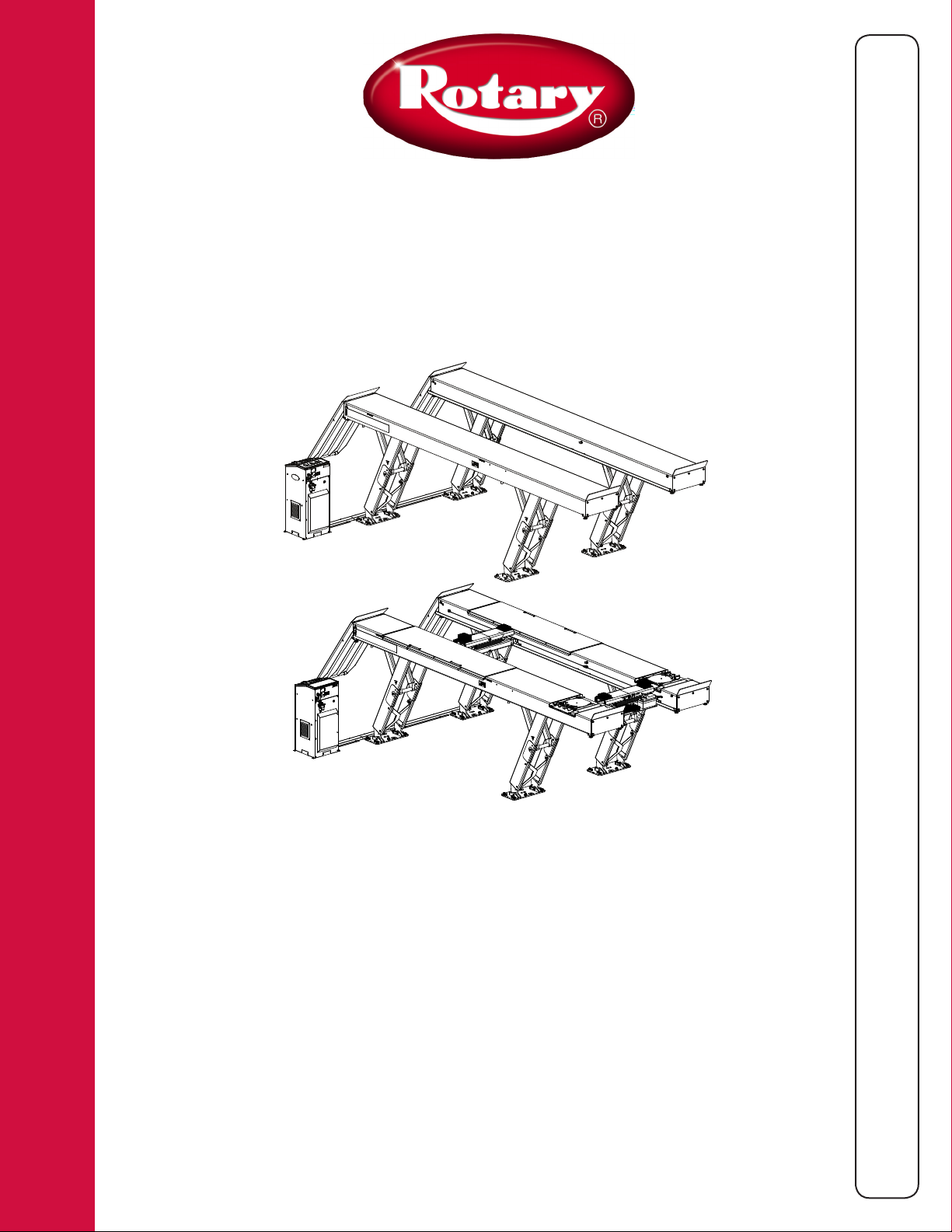

Rotary 1000 SERIES, Y12, YA12 Operation & Maintenance Manual

Y12/YA12

SURFACE AND FLUSH MOUNTED LIFT

(1000 SERIES)

12000 lb. Capacity

(6000 lbs. per axle)

O

O

P

P

E

E

R

R

A

A

T

T

I

I

O

O

N

N

&

&

M

M

TABLE OF CONTENTS:

Owner/Employer Responsibilities ...................................................... 2

Safety Instructions ............................................................................... 2

Operating Instructions ......................................................................... 4

Maintenance Instructions ................................................................... 6

Trouble Shooting ................................................................................... 7

Manual Raising & Lowering Runways .............................................. 12

Calibration Procedure .......................................................................... 15

Lift Lockout/Tagout Procedure ........................................................... 18

Operating Conditions ............................................................................ 19

Approved Accessories......................................................................... 19

LP20576

© April 2013 By Vehicle Service Group. All rights reserved. CO8571.1

OM20215

Rev. C 4/11/2013

A

A

I

I

N

N

T

T

E

E

N

N

A

A

N

N

C

C

E

E

M

M

A

A

N

N

U

U

A

A

L

L

TheOwner/Employer:

• TheOwner/Employershall ensure that lift operators are qualified and that they are trained in the safe use and operation of the lift

using the manufacturer’s operating instructions; ALI/SM 93-1, ALI Lifting it Right safety manual; ALI/ST-90 ALI Safety Tips card;

ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and Maintenance; ALI/WL Series, ALI Uniform Warning Label Decals/Placards; and in the case of frame engaging lifts, ALI/LP-GUIDE, Vehicle

Lifting Points/Quick Reference Guide for Frame Engaging Lifts.

• TheOwner/Employershall establish procedures to periodically inspect the lift in accordance with the lift manufacturer’s instructions or ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and

Maintenance; and The Employer Shall ensure that lift inspectors are qualified and that they are adequately trained in the inspection

of the lift.

• TheOwner/Employershall establish procedures to periodically maintain the lift in accordance with the lift manufacturer’s instructions or ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and

Maintenance; and The Employer Shall ensure that lift maintenance personnel are qualified and that they are adequately trained in

the maintenance of the lift.

• TheOwner/Employershall maintain the periodic inspection and maintenance records recommended by the manufacturer or ANSI/

ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and Maintenance.

• TheOwner/Employershall display the lift manufacturer’s operating instructions; ALI/SM 93-1, ALI Lifting it Right safety manual; ALI/

ST-90 ALI Safety Tips card; ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and Maintenance; and in the case of frame engaging lifts, ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference

Guide for Frame Engaging Lifts; in a conspicuous location in the lift area convenient to the operator.

• TheOwner/Employershall provide necessary lockout/tagout means for energy sources per ANSI Z244.1-1982 (R1993), Safety Requirements for the Lockout/Tagout of Energy Sources, before beginning any lift repairs.

• TheOwner/Employershallnot modify the lift in any manner without the prior written consent of the manufacturer.

SAFETY INSTRUCTIONS

•Daily inspect your lift. Never operate if it malfunctions or if it

has been broken or damaged parts. Use only qualified lift service

personnel and genuine Rotary parts to make repairs.

•Thoroughly train all employees in the use and care of lift and

wheels free device, using manufacturer’s instructions and “Lifting

It Right” and “Safety Instructions” supplied with the lift.

•DONOT permit employees or customers on lift when it is either

being raised or lowered.

•Neverallow unauthorized or untrained persons to operate lift or

wheels free device.

•Prohibit customers or non-authorized persons from being in

shop area while lift is in use.

•DONOTstand in front or behind lift while vehicle is being driven

onto or backed off the lift.

•DONOT allow rear tires or portion of vehicle to interfere with

ramp/chocks.

•Never allow front wheels to strike the front wheel stops.

•Never raise or lower the lift while the vehicle is supported by the

wheels free device. Only raise or lower the lift when all 4 tires of

the vehicle are supported by the runway.

•Always stand clear of lift when raising or lowering and observe

“Pinch Points” Warning.

•Never overload lift: capacity of lift is 12,000 lbs. (6,000 lbs. per

axle.) CAPACITY SHOULD NOT BE EXCEEDED.

•Always engage parking brake and use the rear wheel chocks to

keep the vehicle from rolling freely on the runways.

•Always lower lift on locks before working on vehicle.

•Loadvehicle on lift carefully, align vehicle with runways before

driving on.

CAUTION

raised high enough for locking latches to engage.

2

If you are working under vehicle, lift should be

SAFETY INSTRUCTIONS

•Alwayskeep area around lift clean of tools, debris, grease, and

oil.

•Always keep runway clean.

•Replace all caution, warning, or safety related decals on the lift

when unable to read or missing.

•ForWheelsFreeDeviceSafetyInstructions see Wheels Free

Device Installation, Operation and Maintenance Instructions in

the wheels free device box.

•Neveruse work step while lift is in a raised position.

•DONOT perform any maintenance on the power unit, control

valves, air or fluid lines, hydraulic cylinders, or check fluid level

until lift has been fully lowered and all pressure has bee released

from system. Follow OSHA Lockout/Tagout procedures as they

apply, reference ANSI Z244.1.

•DONOT block open or override self-closing lift controls, they are

designed to return to the off or neutral position when released.

•Cleanarea if vehicle is in danger of falling.

•Remove tools, and other equipment from on or below lift before

lowering lift.

CAUTION

Lowering lift legs onto an obstruction may cause

damage to lift.

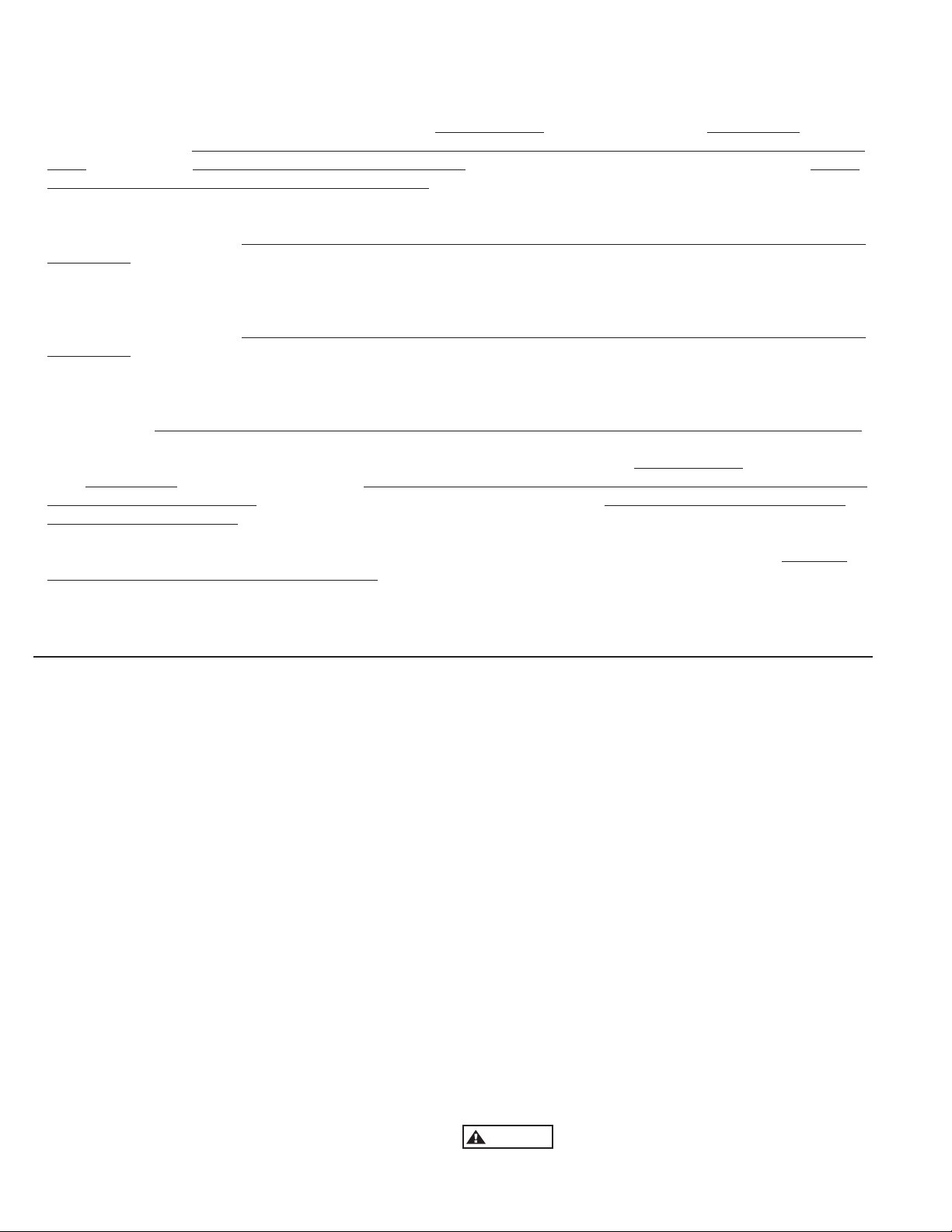

SAFETY

INSTRUCTIONS

Read operating

and safety manuals

before using lift.

CAUTION

?

?

?

Lift to be used

by trained operator

ONLY.

WARNING

SAFETY

INSTRUCTIONS

Do not operate

a damaged lift.

©

WARNING

Remain clear of lift

when raising or

lowering vehicle.

©

SAFETY

INSTRUCTIONS

Proper maintenance

and inspection

is necessary

for safe operation. ©

©

WARNING

Keep clear

of pinch points

when lift is moving.

©

WARNING

Clear area if vehicle

is in danger of falling.

WARNING

Keep feet

clear of lift

while lowering.

©

CAUTION

Authorized personnel

only in lift area.

©

WARNING

Do not override

self-closing

lift controls.

©

©

©

Chock wheel

to prevent

vehicle movement.

©

3

OPERATINGINSTRUCTIONS

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

To avoid personal injury and/or property dam-

age, permit only trained personnel to operate lift.

IMPORTANT

raise just one end, corner or one side of vehicle.

After reviewing these instructions, get familiar with lift controls by

running the lift through a few cycles before loading vehicle on lift.

til adjustments or repairs are made by a qualified lift service

technician.

Observe and heed SAFETY and WARNING labels on the lift.

NOTE: This lift was designed for 121-1/2” or longer wheelbase at

the rated 12,000 lb.

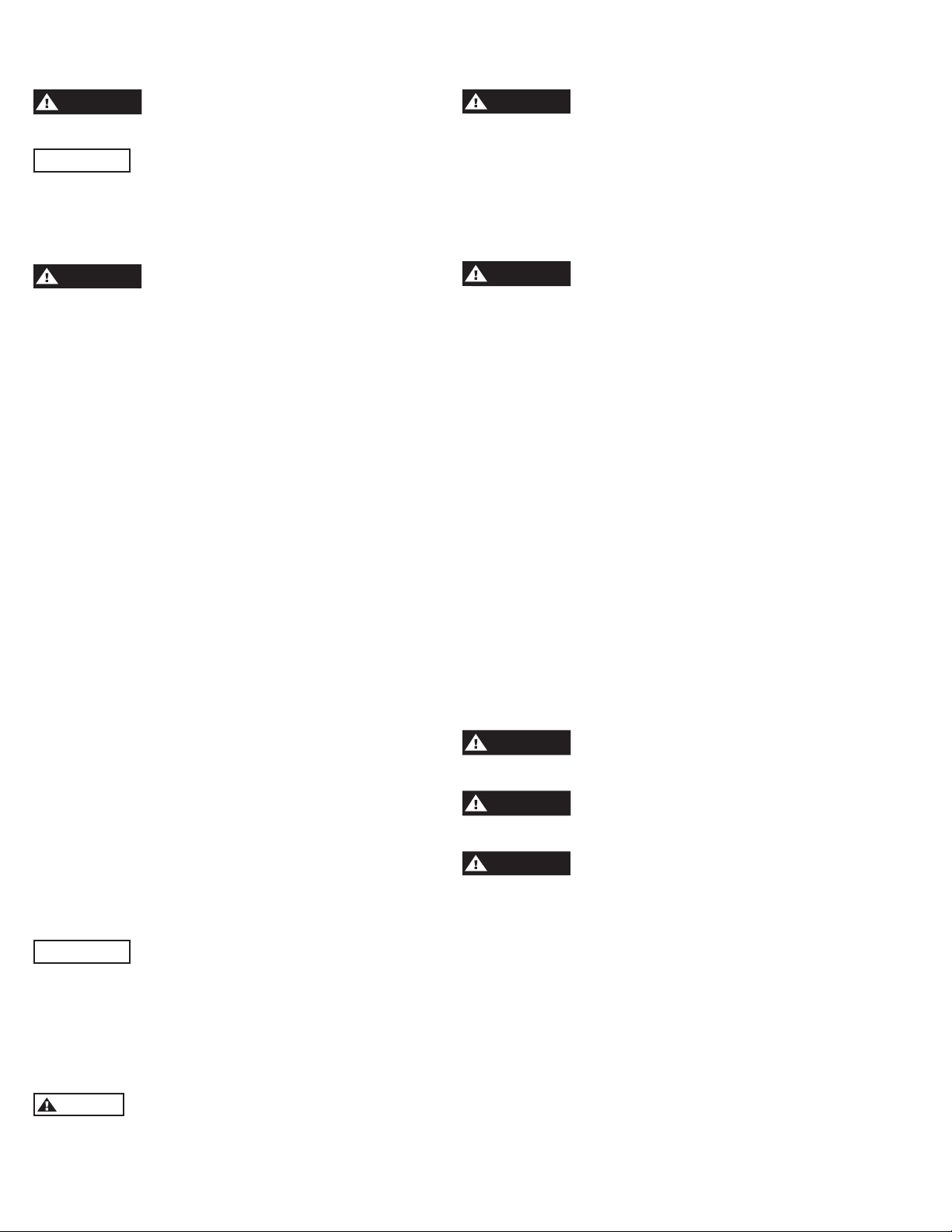

1. Loading:

A. Lift must be fully lowered and service bay clear of all

personnel before the vehicle is brought on lift. Do not

stand in front of a moving vehicle.

B. If lift is equipped with wheels free device, it must be fully

lowered and the rear wheels free device pushed toward

center of lift to provide under car clearance.

C. Stop vehicle when it contacts the front wheel stops.

At all times, be sure rear wheels are forward of

the ramp/chocks and the ramp/chocks will clear tires

when the lift is raised, Fig. 1. Driver and passengers

must exit before raising.

Always lift vehicle using all four tires. Never

If lift is not operating properly, DONOT use un-

WARNING

above the runway by the wheels free device.

3. BeforeLoweringLift:

A. Be sure no one is in the lift area and that all tools, tool

trays, etc. have been removed from under the lift and

vehicle.

B. If lift is equipped with wheels free device, it must be fully

lowered and the rear wheels free device pushed toward

center of lift to provide under car clearance.

4. ToLowerLift:

A. Raise lift off locking latches by pushing the “RAISE”

button, Fig. 2.

Note: If actuator on air valve is released, the latches will auto-

matically reset to the engaged position.

B. Push the “Lowering” button to lower lift, Fig. 2.

C. Observe lift and vehicle to be sure lift is level while being

lowered. If not, STOP raise lift by pressing the “Raise”

button until runways are level and repeat the lowering

process.

D. Fully lower lift, remove the triangular wheel chocks and

check to be sure area is clear before removing vehicle

from lift, Fig. 1.

Never raise lift while vehicle is supported

Observe pinch point warning decals, Fig. 3.

D. Place triangular wheel chocks on each side of one of the

rear tires, Fig. 1.

2. ToRaiseLift:

A. Push the “RAISE” button on the control panel. Release

button at desired height, Fig. 2.

B. Lower lift to locking latches by pushing the “LOWERTO

LOCKS” button until light turns off, Fig. 2.

IMPORTANT

ment readings are measured.

C. For Wheels Free Device Operating Instructions see

Wheels Free Device Installation, Operation and Mainte nance Instructions in the wheels free device shipping

carton.

CAUTION

are not engaged.

Always lower lift on locking latches before align-

DONOT go under vehicle or lift if locking latches

Keep hands clear of linkages while the lift is

being raised or lowered, Fig. 3.

Never lower lift while vehicle is supported

above the runway by the wheels free device.

Before attempting to lift pick-up trucks or other

truck frame vehicles, be sure that:

A. Vehicle individual axle weight does not exceed one-half

lift capacity.

B. Adequate overhead clearance is provided to raise

vehicles to desired height.

Note: Allow 2 seconds between motor starts. Failure to comply

may cause motor burnout.

*Maximum operation pressure is:

3250 psi for Y12/YA12

4

OPERATINGINSTRUCTIONS

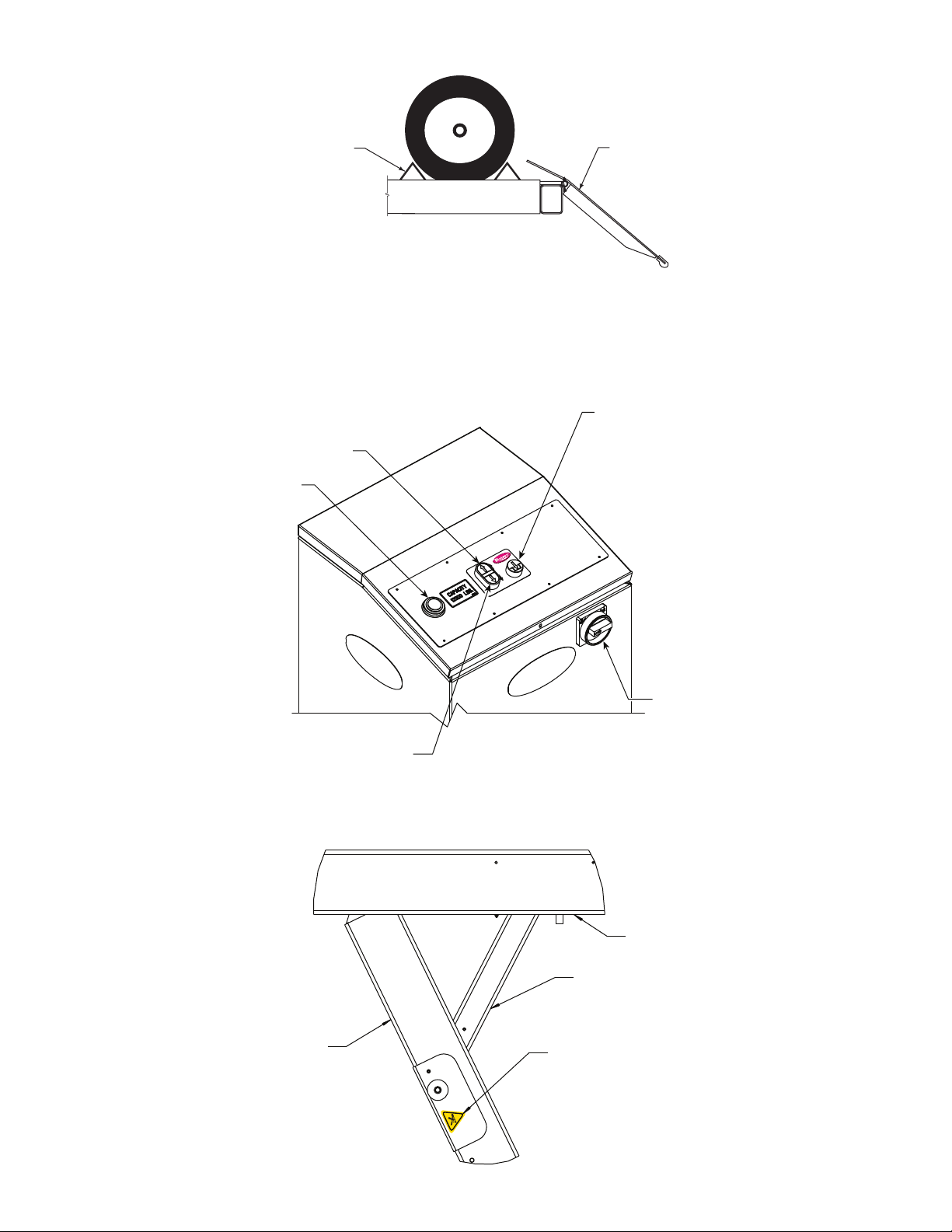

Triangular

Wheel Stops

Raise Button

Control Fault

Beeper

Rear Wheel

Chock

Fig. 1

Lower To Locks Button

(Blinks When Lift Is Not

Resting On Locks)

LIFT ON

LOCKS

WHEN LIT

LOWER TO LOCKS

Leg Link

Lower Button

Disconnect Switch

Fig. 2

Runway

Arm Link

Hands Clear Warning

NP945 REV.-

Fig. 3

5

WARNING

MAINTENANCEINSTRUCTION

If you are not completely familiar with automotive lift maintenance procedures, STOP. Contact factory for

instructions.

ToAvoidPersonalInjury, permit only qualified lift service personnel to perform maintenance on this equipment.

•Always: Keep attaching bolts tight.

•Always: Keep locking latches free and oiled.

•Always: Raise lift when cleaning floor area with solvents and/or cleaning compounds.

•Always: Always keep runways and linkages clean. In salt belt or other corrosive environments, the lift must be washed down

weekly.

•Daily: Inspect front wheel stops and ramp/chocks for damage or excessive wear. Replace as required with genuine Rotary Lift

parts.

•Daily: Check locking latch operation and reset. Adjust per instructions or repair if required with genuine Rotary parts.

If locking latch is not heard when lift is raised:

A. Lower loaded lift onto lock, to check if lock is functioning. If lock is functioning, stop. If not, continue on

to “Step B”.

B. Check locking latch for damage or air line problem.

C. Repair and lubricate locking latch pivot points.

D. Lower lift about half way. Then raise lift and watch locking latch operation.

E. The air cylinder should allow locking latch to pivot in and out of the latch bar.

F. Push the “LOWER” button. This should retract air cylinder and locking latch from latch bar in-order to lower

lift.

•Weekly: Clean foreign debris from rear wheel slip plates and turning radius gauges by blowing out with shop air. DONOTGREASE

BALLBEARINGS.

•Monthly: Check anchor bolts to ensure they are torqued to 65 ft. lbs .

•Monthly: Check level of runway. Adjust per instructions.

•Monthly: Check position sensor cables. Replace if damaged.

•Monthly: Lubricate Guide on each turning radius with a dry film lubricant. Clean and lubricate more often as conditions warrant.

•Semi-Annually: Check fluid level of lift power unit and refill if required. If fluid is required, inspect all fittings, hoses and seals. Repair

as required.

•Semi-Annually: Spray inside of slider and lock tracks with Teflon (PTFE) lubricate with a paraffin wax additive. Clean and lubricate

more often as conditions warrant.

•Semi-Annually: Lubricate ramp/ chock hinge pins.

•ForWheelsFreeDeviceMaintenance Instructions see Wheels Free Device Installation, Operation and Maintenance Instructions in

the wheels free device box.

•Replaceall caution, warning, or safety related decals on the lift if unable to read or missing. Reorder labels from Rotary Lift - see

parts breakdown.

•OilFilterControlManifold: Replace filter after the first 6 months of operation and every 2 years thereafter. Installation torque is hand

tight.

6

Loading...

Loading...