Rotary SPOA7, SPO9, SPOA9 Installation Instruction

SPOA7, SPOA9, SPO9

Two Post Surface Mounted Lift

(200 Series Lifts)

I

I

N

N

R

O

T

A

R

Y

I

L

A

V

CERTIFIED

B

Y

SPOA7 Capacity 7,000lbs. SPOA9 Capacity 9,000lbs.

1750 lbs. per arm 2250 lbs. per arm

SPO9 Capacity 9,000lbs.

2250 lbs. per arm

A

D

T

E

D

L

T

E

S

S

T

T

A

A

L

L

L

L

A

A

T

T

I

I

O

O

N

N

L

I

F

T

I

I

N

N

S

S

T

T

R

R

U

U

C

C

T

T

I

I

O

O

Entire contents © October 2000 by Rotary Lift. All rights reserved. IN20008

Rev. P 10/04/00

N

N

S

S

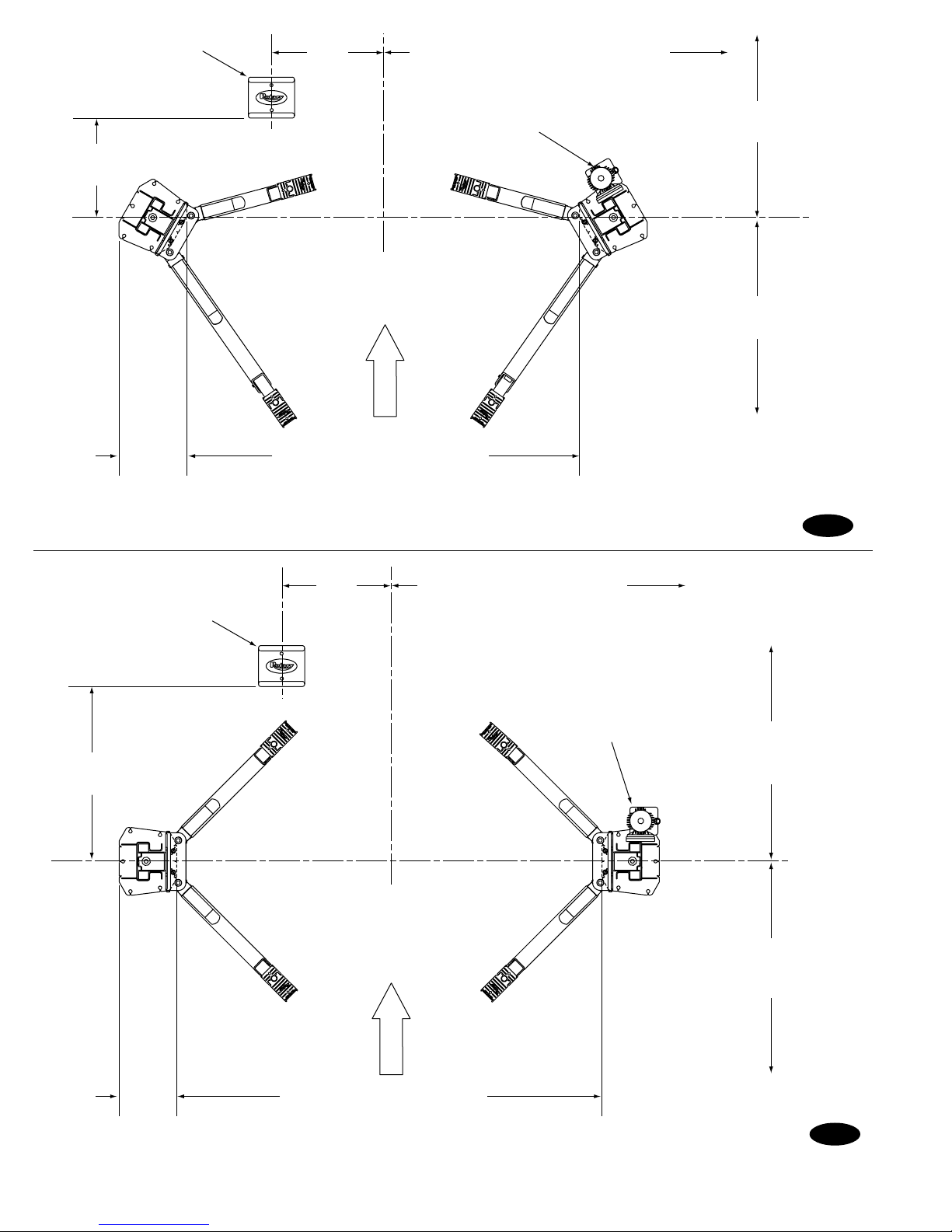

Wheel Spotting Dish

2' 2"

(657mm)

2' 5"

(737mm)

6' 0" (1829mm) minimum to nearest

obstruction or bay. 7' 0" (2134mm)

minimum to nearest wall.

Power Unit

(Passenger Side)

APPROACH

9' 0" (2743mm) minimum

to nearest obstruction

15' 0" (4572mm) minimum

to nearest obstruction

18"

(457mm)

*NOTE: Dimension is from Inside of Baseplate to Inside of Baseplate.

Wheel Spotting Dish

3' 10"

(1178mm)

7' 11-3/8" (2423mm) SPOA7*

7' 3-3/8" (2219mm) SPOA7NB (Narrow Bay)*

8' 5-3/8" (2575mm) SPOA9*

2' 5"

(737mm)

6' 0" (1829mm) minimum to

nearest obstruction or bay.

7' 0" (2134mm) minimum to

nearest wall.

Power Unit

(Passenger Side)

Fig. 1a

11' 0" (3353mm)

minimum to nearest

obstruction

15"

8' 11-5/8" (2734mm) SPO9*

(381mm)

*NOTE: Dimension is from Inside of Baseplate to Inside of Baseplate.

13' 0" (3963mm)

minimum to nearest

obstruction

APPROACH

Fig. 1b

2

1. Lift Location: Use architects plan when

available to locate lift. Fig. 1a & Fig. 1b shows

dimensions of a typical bay layout.

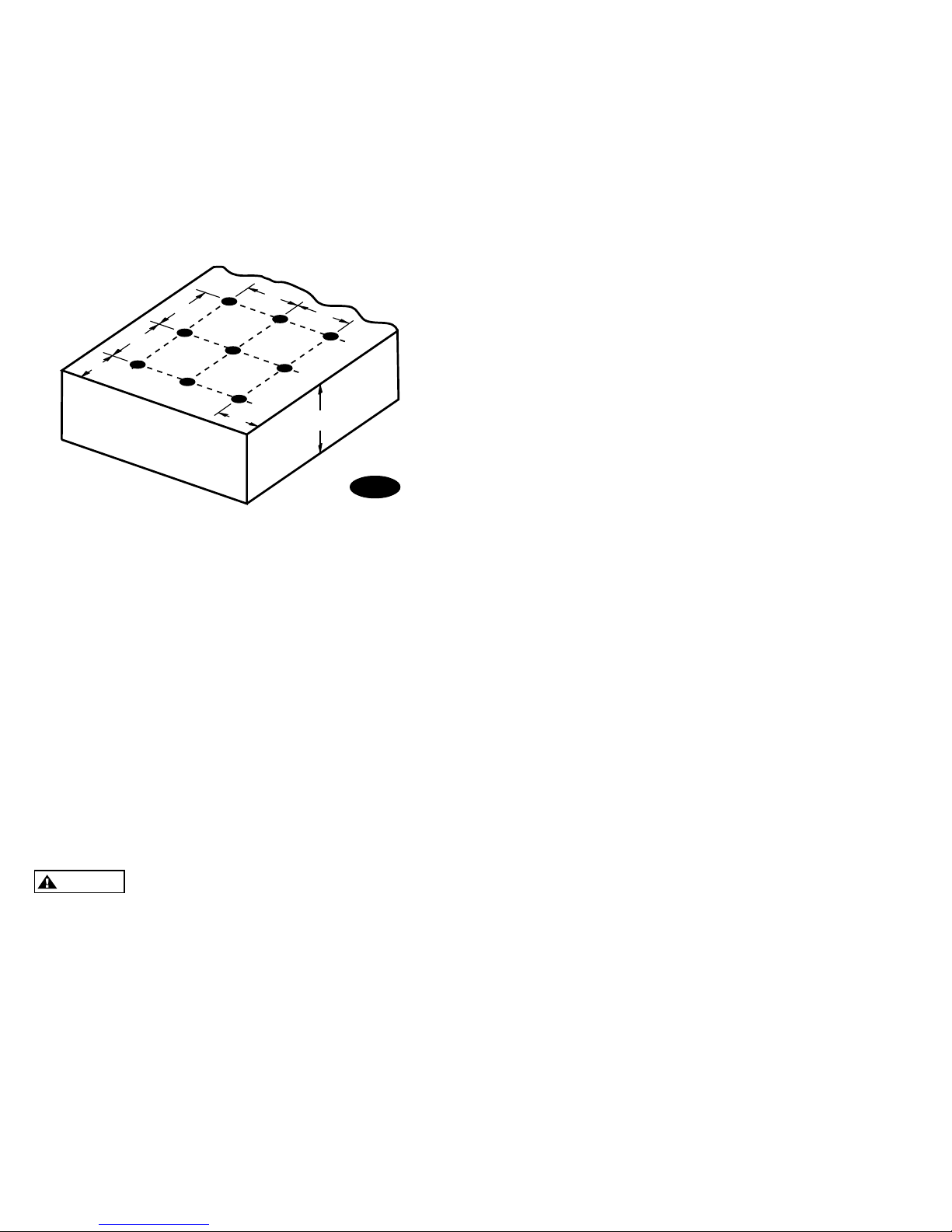

2-1/4"

2. Lift Height: See Fig. 4 for overall lift height of

each specific lift model. Add 1 min. to overall

height to lowest obstruction.

WARNING

DO NOT install this lift in a pit

or depression due to fire or explosion risks.

3. Column Extensions: Before standing columns

upright, install the column extensions using (12)

3/8-16NC x 1/2 Flanged HHCS, Fig. 4.

4. Latch Cable Guides: Install the latch cable

guides to column extensions with (4) 1/4-20NC x

1 HHCS and 1/4-20NC Flanged Locknuts, Fig. 1c,

Fig. 1d, & Fig. 10b.

NOTE: Latch cable guide must be toward approach

side of the column extension. Coat the cable contact

surface with a light grease such as TUFOIL.

SPOA7/SPOA9

Column

Extension

4-1/4"

Drill holes using

3/4" carbide

tipped masonary

drill bit per ANSI

standard

B94.12.1977

Clean hole.

Run nut down just

below impact section

of bolt. Drive anchor

into hole until nut and

washer contact base.

4-1/4"

Tighten nut with

Torque wrench to

150 ft.-lbs.

3-1/4"

Fig. 2

Installation torque of 150 ft-lbs. is required for all anchor bolts.

NOTE: Use

rectangular shims at

inside edge of

baseplate. Use

constructions

adhesive or silicon

cement to hold shim

in place. INSURE

shims are held tightly

between base plate

and floor after

torquing anchors.

Anchor

Shims

(1/2" Max.)

Fig. 3

Nut

Flat

Washer

NOTE: If more than 2 horse shoe shims are used at any of the column

anchor bolts, pack non-shrink grout under the unsupported area of the

column base. Insure shims are held tightly between the baseplate and

floor after torquing anchors.

Overhead Assembly

1/4"-20NC x 1"

HHCS & 1/4"

Flanged Locknut

Latch Cable

Guide

Latch Cable

Guide

1/4"-20NC x 1"

HHCS & 1/4"

Flanged Locknut

SPO9

Extension

Column

APPROACH

APPROACH

Fig. 1c

Fig. 1d

3/8"-16NCx1" HHCS

& Flanged Locknut

12' 0" (3658mm)

Top of Cylinder

11' 8" (3556mm)

Top of Overhead

Assembly(std.)

11' 4" (3454mm)

Top of Overhead

Assembly

(Low Ceiling)

All above for

both SPOA7

and SPOA9

(Low Ceiling is

N/A for SPO9)

(2)3/8" Star Lockwashers

on right side only

Use (4) 3/8"-16NCx1/2"

Flanged HHCS in front

and (2) in the back

Use (1) 3/8" Star

Lockwasher on right extension

Fig. 4

IMPORTANT: All star washers are to be mounted on the right

side column to ensure grounding of overhead limit switch. Star

washers are not needed when mounting to left side column.

Notice the column extension mounting, Fig. 4 and overhead limit

switch mounting as well in Fig. 6.

3

5. Lift Setting: Position columns in bay using

dimensions shown in Fig. 1a & Fig. 1b. Place column

with power unit mounting bracket on vehicle passenger

side of lift. Both column base plate backs must be square

on center line of lift. Notches are cut into each base plate

to indicate center line of lift.

Use appropriate equipment to raise carriage to first latch

position. Be sure locking latch is securely engaged.

C

C

B

C

C

B

A

Fig. 5

A) Concrete Thickness &

Hole Depth 4-1/4" (108mm)

B) Edge Distance 4-3/4" (121mm)

C) Hole Spacing 6-1/2" (165mm)

If anchors do not tighten to 150 ft-lbs. installation torque,

replace concrete under each column base with a 4' x 4' x

6" thick 3000 PSI minimum concrete pad keyed under and

flush with the top of existing floor. Let concrete cure

before installing lifts and anchors.

7a. Overhead Assembly: Fig. 6: Adjust overhead to

appropriate dimension. Install (4) 3/8"-16NC x 3/4"

HHCS & 3/8-16NC Flanged Locknuts, do not tighten.

Mount switch assembly towards power unit column as

shown, using (2) 1/4"-20NC x 3/4" lg. HHCS, 1/4-20NC

Nuts and 1/4" Star Washers. For Narrow Bay installation,

see step 7b, all others go to step 7c.

7b. For Narrow Bay installation only: Cut off 11 from

the length of the bar and cushion on the end opposite the

1/4 mounting hole. Continue to step 7c.

7c. Continued Overhead Assembly: Insert 1/4"-20NC

x 2" HHCS through pivot hole in end of switch bar. Insert

opposite end of bar through slot in switch mounting

bracket. Then secure HHCS and Switch Bar to overhead

as shown, using 3/4" spacer and 1/4-20NC Locknut.

Tighten Hex bolt leaving 1/16 gap between the spacer

and the overhead assembly.

8. Overhead Installation: Install overhead assembly to

column extensions with (2) star washers and (8) 3/8" x 1"

HHCS and 3/8 Flanged Locknuts, Fig. 4. Tighten bolts

at center of overhead assembly.

Concrete and Anchoring: Concrete shall have a

compression strength of at least 3,000 PSI and a minimum

thickness of 4-1/4" in order to achieve a minimum anchor

embedment of 3-1/4". When using the standard supplied

3/4 x 5-1/2 lg. anchors, if the top of the anchor exceeds

2-1/4 above the floor grade, you DO NOT have enough

embedment.

Drill (10) 3/4" dia. holes in concrete floor using holes in

column base plate as a guide. See Fig. 2 and Fig. 5 for

hole depth, hole spacing, and edge distance requirements.

CAUTION

DO NOT install on asphalt or other

similar unstable surfaces. Columns are

supported only by anchors in floor.

6. IMPORTANT: Using the horse shoe shims

provided, shim each column base until each column is

plumb. If one column has to be elevated to match the

plane of the other column, full size base shim plates

should be used (Reference FA5112 Shim Kit). Recheck

columns for plumb. Tighten anchor bolts to an

installation torque of 150 ft-lbs. Shim thickness MUST

NOT exceed 1/2 when using the 5-1/2 long anchors

provided with the lift. Adjust the column extensions

plumb.

9. Power Unit: First install (1) star washer onto one of

the (4) 5/16"-18NC x 1-1/2" HHCS. This is very

important for grounding. Put the (4) 5/16"-18NC x 1-1/2"

HHCS thru holes in power unit bracket using Push-Nuts

to hold in place, Fig. 7a & Fig. 7b. Mount unit with motor

up to column bracket and install (4) 5/16 star washers

and 5/16 Nuts. Install and hand tighten Branch Tee to

pump until O-ring is seated. Then tighten locknut to 35-40

ft-lbs, and connect supply hoses to Tee, Fig. 8a or Fig. 8b.

NOTE: Over tightening locknut may tear O-ring.

4

3/8"-16NC x 3/4" HHCS

& Flanged Locknut

SPOA9

7-3/4"

Spacer

Spacer

1/4"-20NC x 2" HHCS

& 1/4" Locknut

3/8"-16NC x 3/4" HHCS

& Flanged Locknut

1/4"-20NC x 2" HHCS

& 1/4" Locknut

1/4"-20NC x 3/4" HHCS, Star Lockwasher, and Nut

111-3/8"

SPO9

1/4"-20NC x 3/4" HHCS, Star Lockwasher, and Nut

114"

11-3/4"

Spacer

Spacer

3/8"-16NC x 3/4" HHCS

& Flanged Locknut

1/4"-20NC x 2" HHCS

& 1/4" Locknut

1/4"-20NC x 3/4" HHCS, Star Lockwasher, and Nut

3/8"-16NC x 3/4" HHCS

& Flanged Locknut

1/4"-20NC x 2" HHCS & 1/4" Locknut

1/4"-20NC x 3/4" HHCS, Star Lockwasher, and Nut

105-3/8"

97-3/8"

SPOA7

SPOA7 Narrow Bay

7-3/4"

7-3/4"

Fig. 6

5

Loading...

Loading...