Rotary SPO12 Standard, SPO12 Hummer, SPO12 Sprinter Installation Instructions Manual

I

N

N

S

S

I

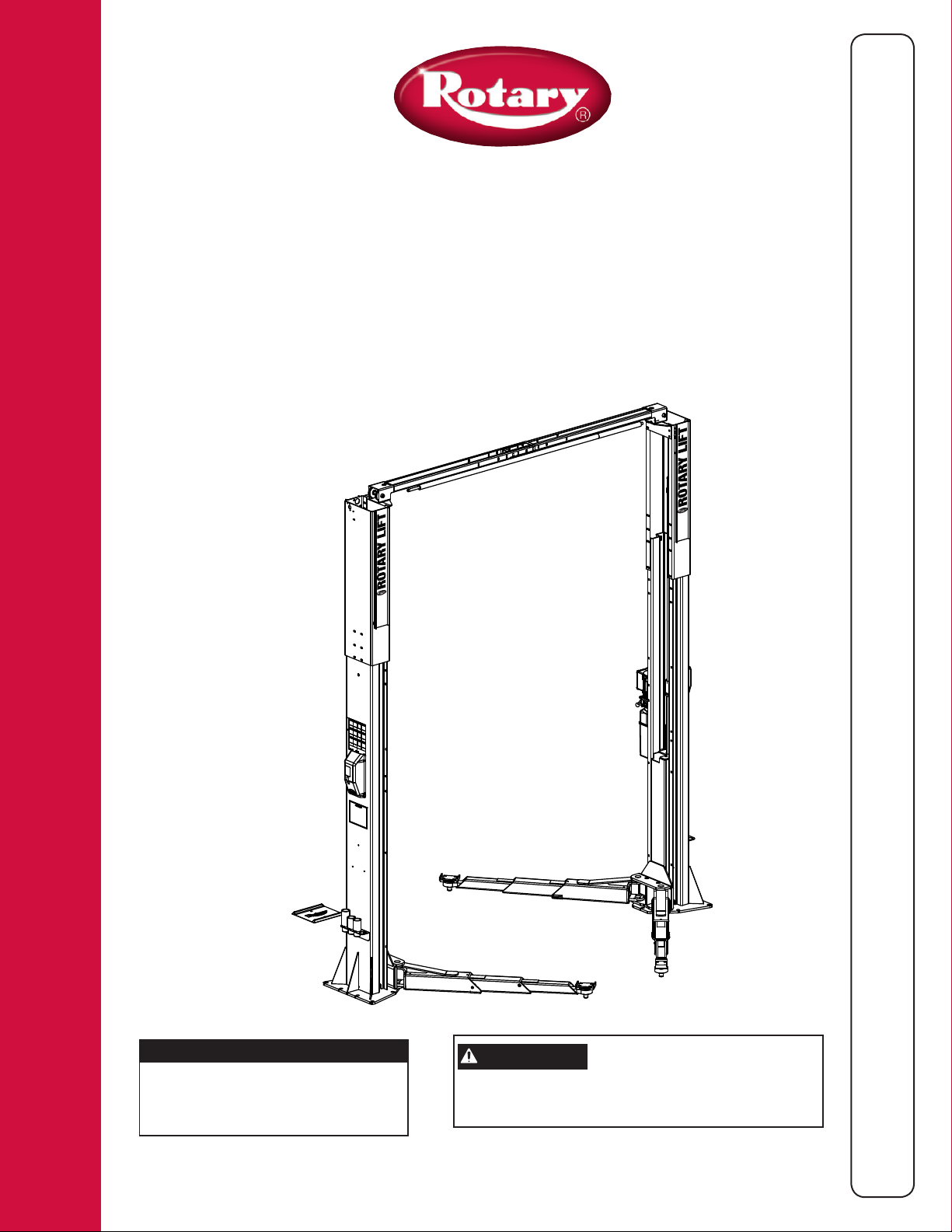

SPO12

Standard/Hummer/Sprinter

Two Post Surface Mounted Swing Arm Frame Engaging Lift

Standard (500/700 Series) Capacity: 12,000 lbs.

Hummer (5W0/7W0 Series) Capacity: 12,000 lbs.

Sprinter (5A0/7A0 Series) Capacity: 9,000 lbs.

Español Página 25

Le Français La page 49

T

T

A

A

L

L

L

L

A

A

T

T

I

O

O

N

N

I

OPERATING CONDITIONS

Lift is not intended for outdoor use

and has an operating ambient temperature

range of

41°-104°F (5°-40°C)

IMPORTANT

Installation and Service of Automotive Lifts

before installing lift.

Reference ANSI/ALI ALIS,

Safety Requirements for

I

N

N

S

S

T

T

R

R

U

U

C

C

T

T

I

O

O

N

N

I

I

© May 2019 by Vehicle Service Group. All rights reserved. CO10473

IN20272

Rev. AC 5/22/2019

S

S

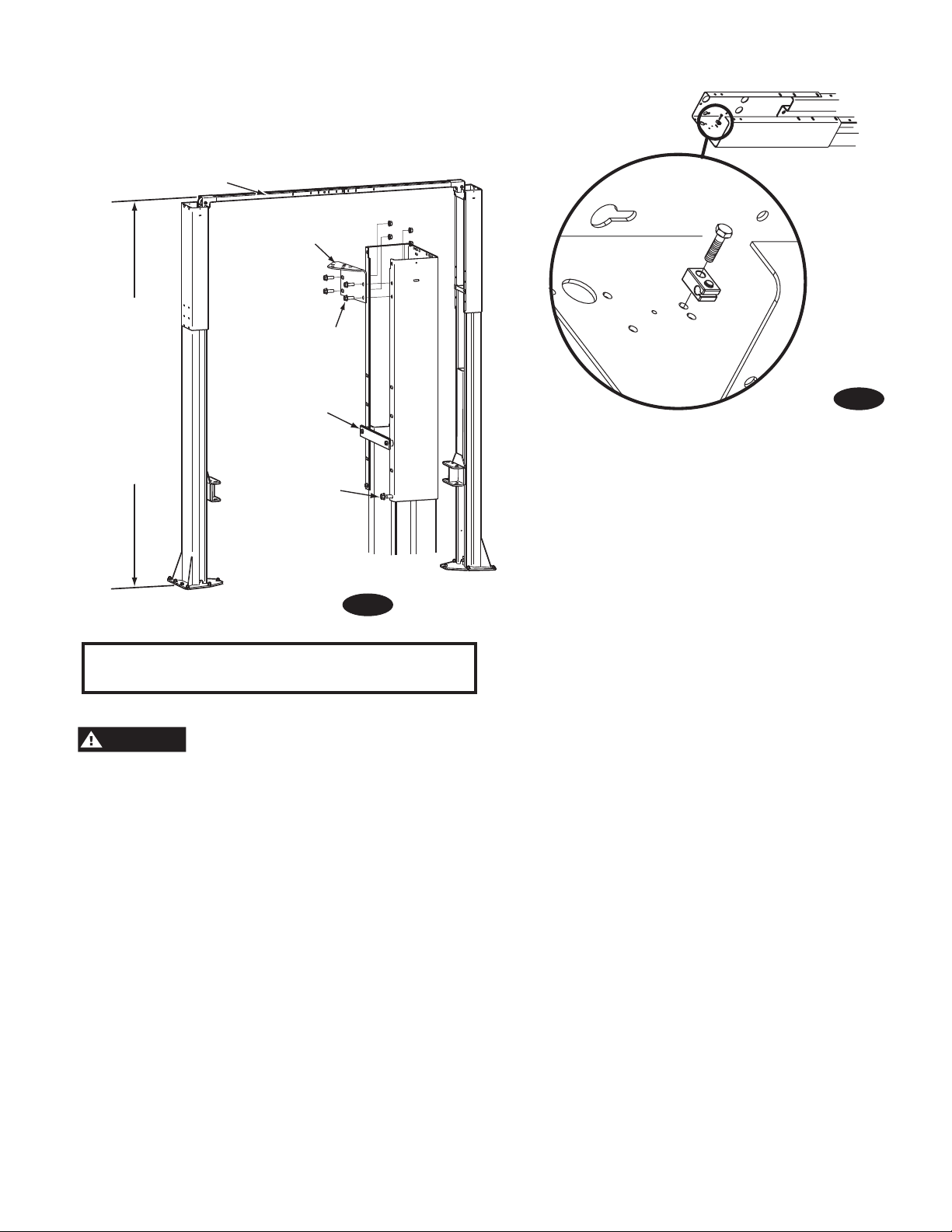

INSTALLATION INSTRUCTIONS

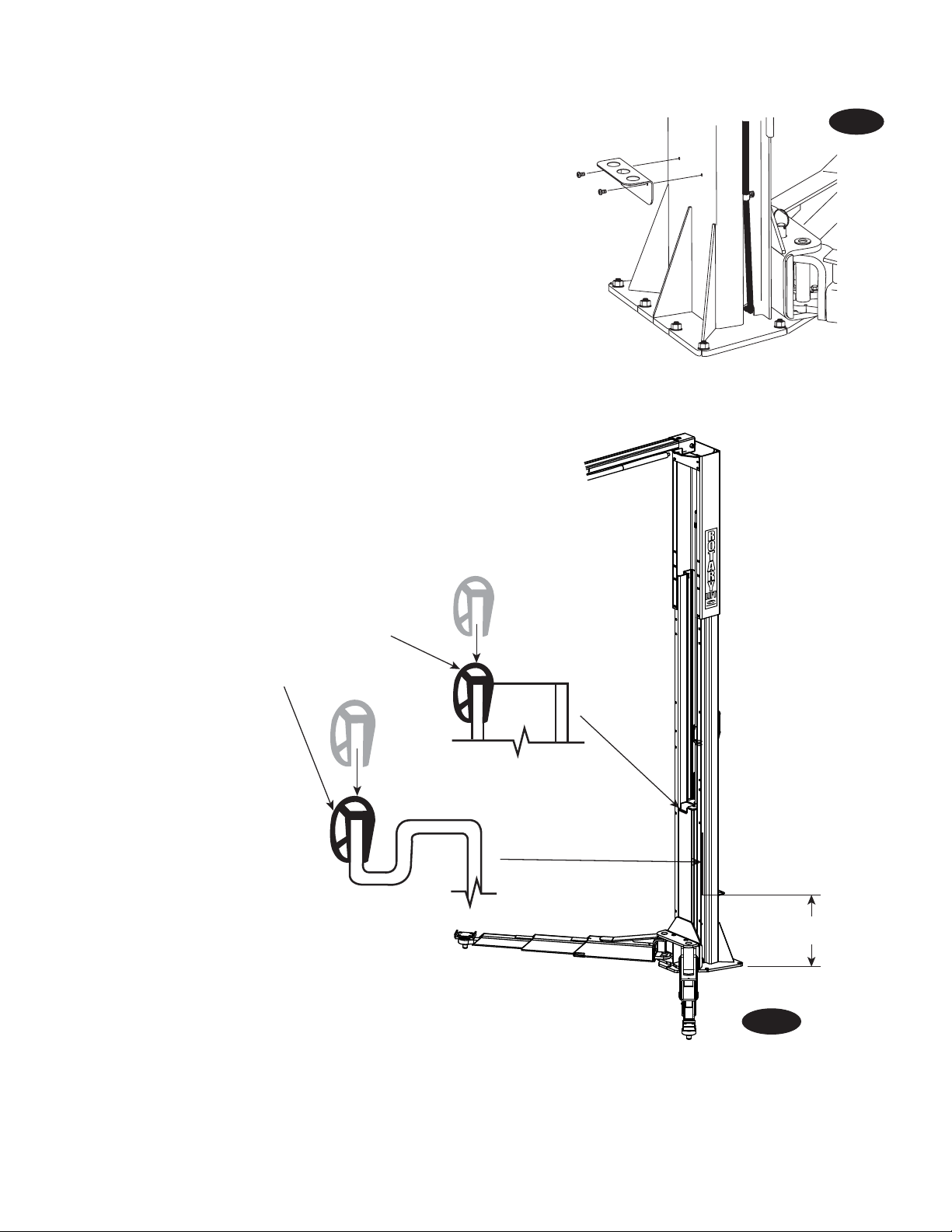

8-1/2" LOWER HEIGHT

SETTING

STANDARD HEIGHT

SETTING

4" LOWER HEIGHT

SETTING

(14) 3/4” Anchors

56”

Left Rear

2’-5”

11’-5 5/8” SPO12

6’-0” minimum to nearest

obstruction or bay. 7’-0”

minimum to nearest wall.

Right Front

13’ minimum to

nearest obstruction

13’ minimum to

nearest obstruction

APPROACH

SPO12 Standard (500 Series) & SPO12 Sprinter (5A0 Series)

SPO12 Standard (700 Series) & SPO12 Sprinter (7A0 Series)

Note: See Pg. 3 for Hummer (5W0/7W0 Series) Lifts.

Fig. 1a

ATTENTION

: Continue to

page 7 for SPO12 standard

installation.

Fig. 1b

2

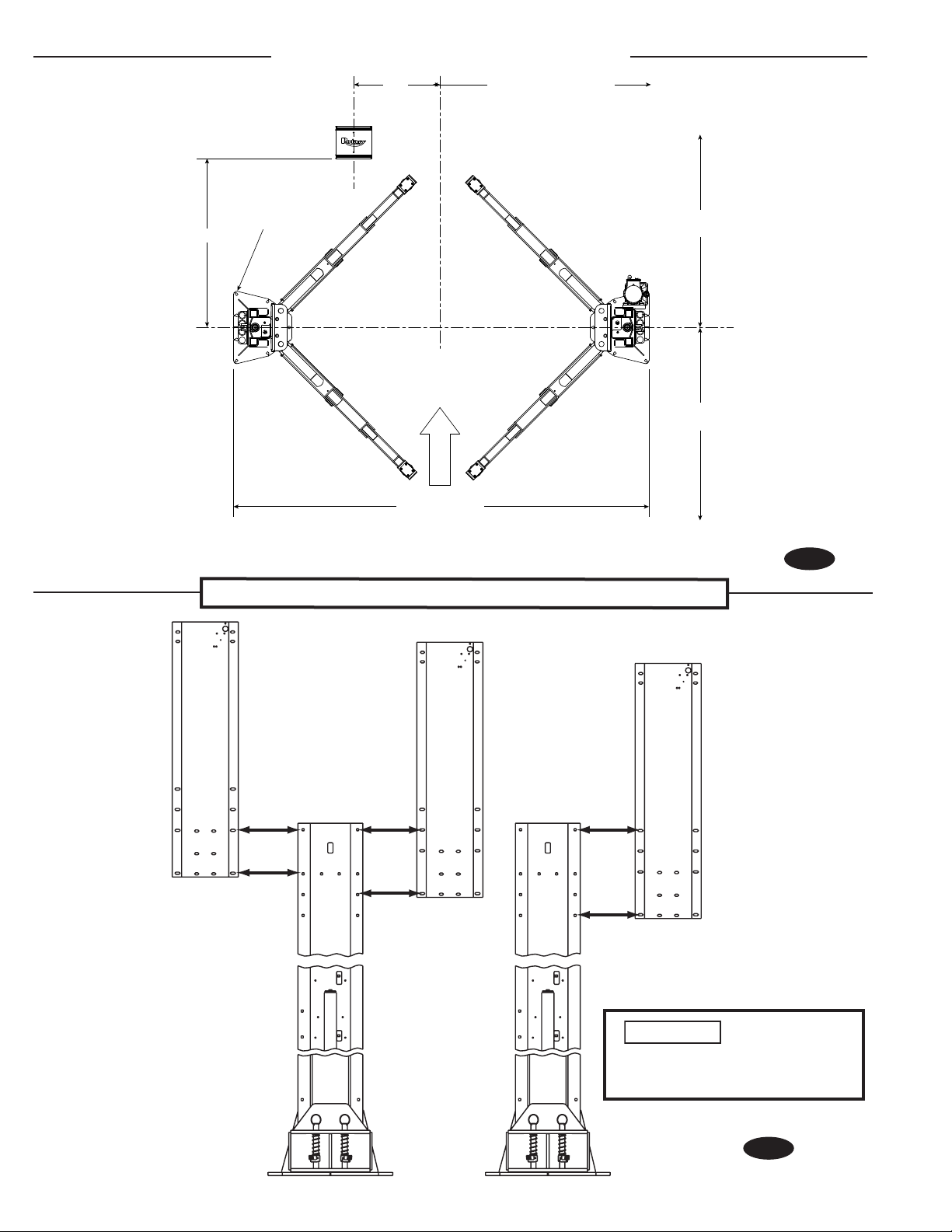

SPO12 Hummer Supplement Instructions

IMPORTANT

If you have ordered a SPO12 Hummer Lift (5W0/7W0 Series) these figures

MUST be used in place of the standard instruction figures on page 2.

56”

(14) 3/4” Anchors

Left Rear

2’-5”

7’-0” minimum to nearest

obstruction or bay. 8’-0”

minimum to nearest wall.

Right Front

13’ minimum to

nearest obstruction

13’ minimum to

nearest obstruction

APPROACH

12’-10 5/8”

SPO12 Hummer Lift (5W0 Series)

SPO12 Hummer Lift (7W0 Series)

Fig. 1a

Fig. 1b

3

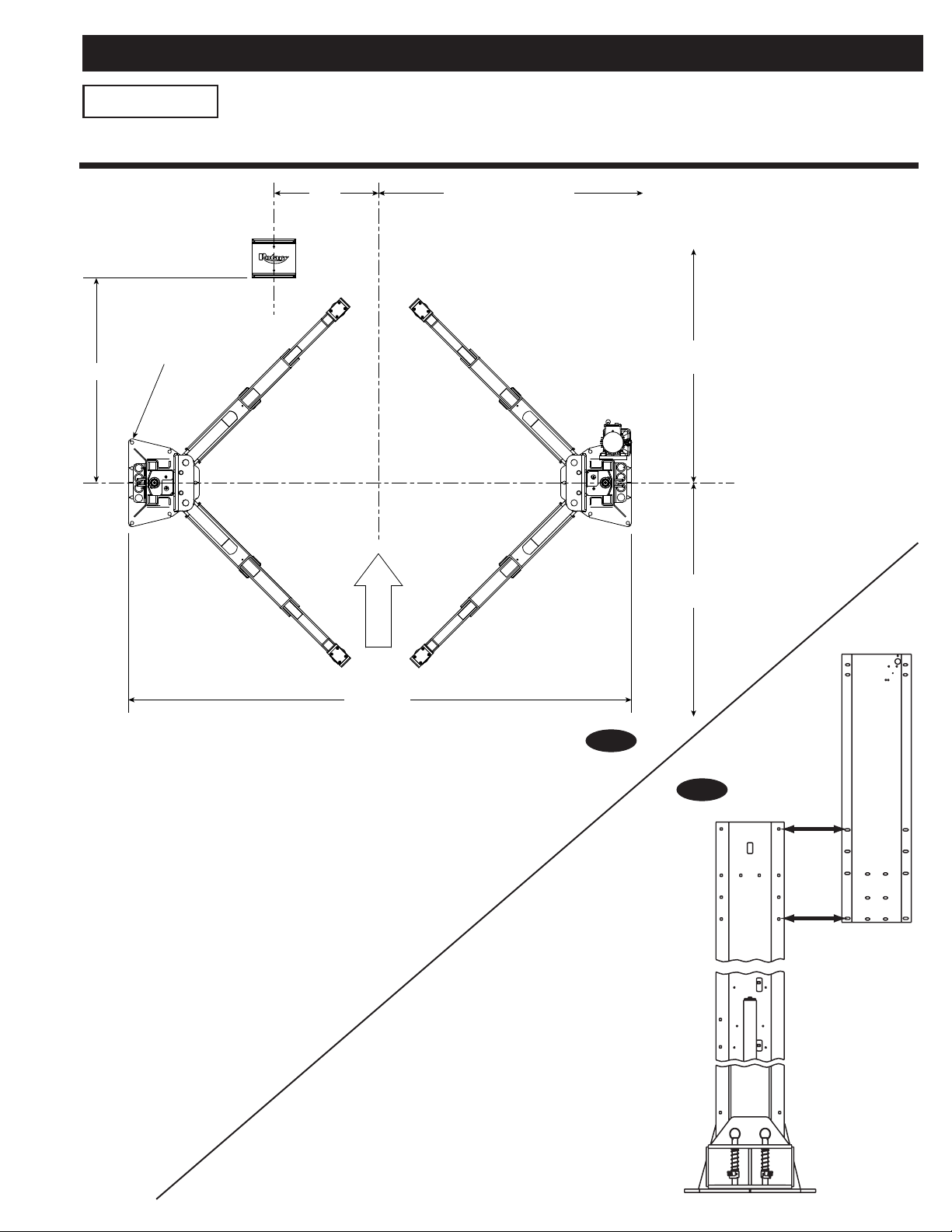

Overhead Assembly

13'-11 1/2"

To p

Overhead

Assembly

(14'-11 1/2" EH1)

Tie Bar & Spacers -use

(2)3/8"-16NCx 2-1/2"

Carriage Bolts

And Flanged Lock Nuts

Use (2) 3/8"-16NCx1"

Carriage Bolts

In Front And

(2) In the Back

3/8"-16NCx3/4" HHCS

& Flanged Locknut

Mounting

Bracket

SPO12 Hummer Supplement Instructions

WARNING

IMPORTANT

131"

11-3/4"

(2)3/8"-16NC x 3/4" HHCS & Flanged Locknut

(4)3/8"-16NC x 1" Flanged HHCS and Flanged Nuts

1 Phase Lifts

1/4"-20NC x 2-3/4" HHCS

& 1/4" Locknut

1/4"-20NC x 2-3/4" HHCS,

Flat Washer, Spacer, and Nut

Spacer

Star

Washer

This Side

2 Spacers

If you have ordered a SPO12 Hummer Lift (5W0/7W0 Series) these figures MUST

be used in place of the standard instruction figures on pages 7 & 8.

DO NOT install this lift in a pit or

depression due to fire or explosion risks.

Fig. 2

Fig. 6

4

1. Lift Location: Use architects plan when available

WARNING

to locate lift. Fig. 1a shows dimensions of a typical bay

layout.

Lift Height: See Fig. 2 for overall lift height of each

specific lift model. Add 1” min. to overall height to

lowest obstruction.

Overhead Assembly

Mounting

Bracket

SPO12 (500/700) &

SPO12 (5A0/7A0)

13'-8"

[4166mm]

STD. Top

Overhead

Assembly

EH-1 14’-8” [4470mm]

EH-2 15’-8“ [4775mm]

EH-3 16’-8” [5080mm]

(SPO12LC

11’-8”

[3556mm])

3/8"-16NCx3/4" HHCS

& Flanged Locknut

Tie Bar & Spacers -use

(2) 3/8"-16NCx2-1/2"

Carriage Bolts and

Flanged Locknuts

Use (2) 3/8"-16NCx1"

Carriage Bolts and

Flanged Locknuts in

front and (2) in the back

Fig. 2

Overhead Mounting Bracket: Install Mounting Brackets

to column extensions as shown, Fig. 2.

Fig. 3

3. Column Extensions: While column is on the ground,

install column extensions using (4) 3/8”-16NC x 1” lg.

Carriage Bolt and Flanged Locknut, Fig. 3 & Fig. 1b. Use (2)

3/8”-16NC x 2-1/2” lg. Carriage Bolt and Flanged Locknut to

attach the tie bar and the column extension together at the

column’s uppermost holes, Fig. 3. The tie bar is positioned

on the outside of the column extension. Adjust the column

extensions plumb.

Note: See Pg. 3 for Hummer (5W0/7W0 Series) Lifts.

DO NOT install this lift in a pit or

depression due to fire or explosion risks.

2. Latch Cable Guides: Install the latch cable conduit guide

brackets to column extensions with (1) 1/4”-20NC x 1” HHCS

and 1/4”-20NC Flanged Locknuts, Fig. 3. HHCS should go

through hole nearest the edge as shown, Fig. 3.

4. Lift Setting: Position columns in bay using dimensions

shown in Fig. 1a. Place column with power unit mounting

bracket on vehicle passenger side of lift. Both column base

plate backs must be square on center line of lift. Notches

are cut into each base plate to indicate center line of lift.

Use appropriate equipment to raise carriage to first latch

position. Be sure locking latch is securely engaged.

IMPORTANT: All star washers are to be mounted on the

right side column to ensure grounding of overhead limit

switch. Star washers are not needed when mounting to left

side column. Notice the column extension mounting, Fig. 3

and overhead limit switch mounting as well in Fig. 3 & Fig. 6.

5

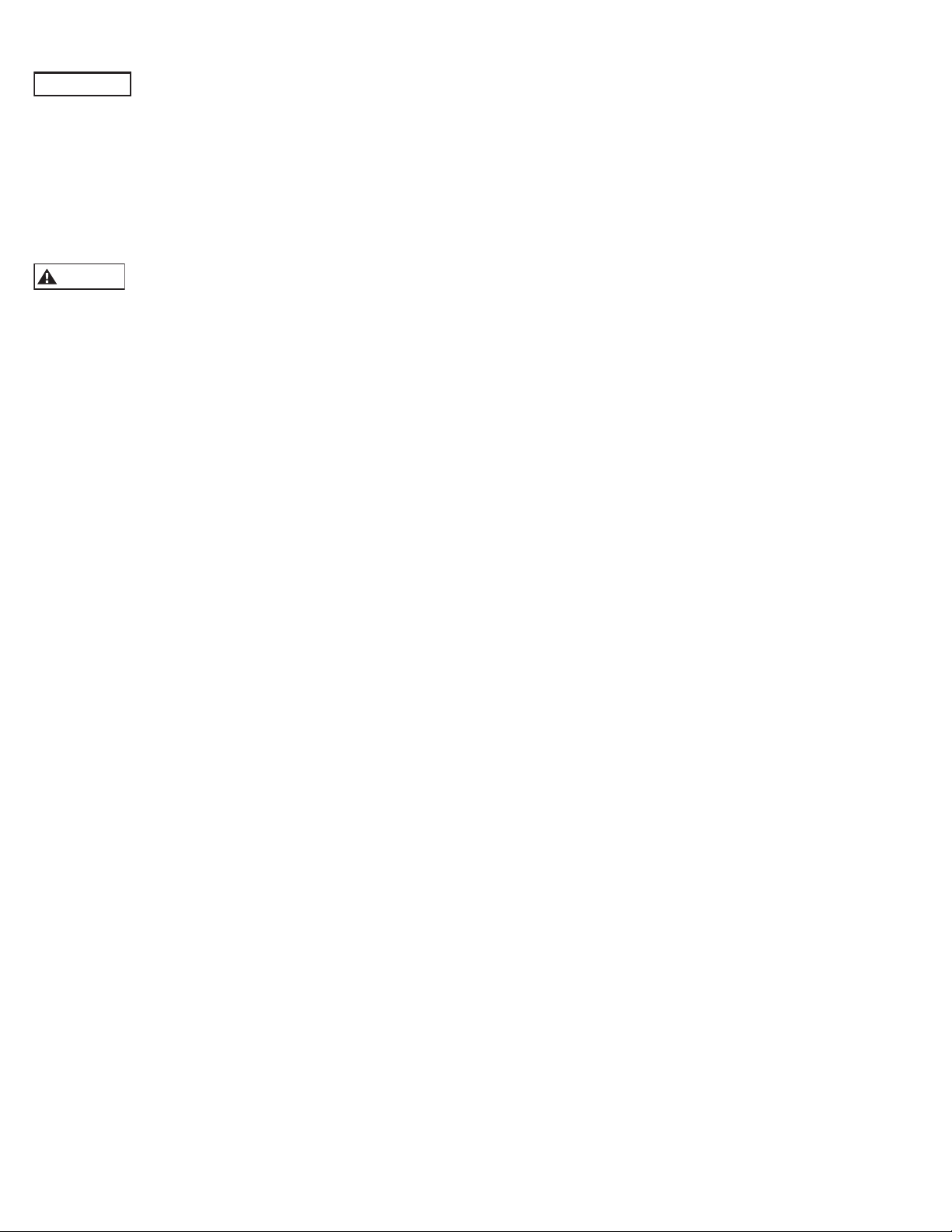

5. Concrete and Anchoring:

IMPORTANT

CAUTION

Reference IN20294 if Sprinter long arms

are going to be used for this installation or if the lift will

possibly be retro-fit with them in the future. Different

concrete and anchoring requirements are required.

Drill (14) 3/4” dia. holes in concrete floor using holes in

column base plate as a guide. See Figs. 4 and 5 for hole

requirements.

DO NOT install on asphalt or other similar

unstable surfaces. Columns are supported only by

anchors in floor.

IMPORTANT: Using the horse shoe shims provided,

shim each column base until each column is plumb. If

one column has to be elevated to match the plane of

the other column, full size base shim plates should be

used (Reference Shim Kit). Recheck columns for plumb.

Tighten anchor bolts to an installation torque of 110 ft-lbs.

Shim thickness MUST NOT exceed 1/2” when using the

5-1/2” long anchors provided with the lift.

If anchors do not tighten to 110 ft-lbs. installation torque,

replace concrete under each column base with a 4’ x 4’

x 6” thick 3000 PSI minimum concrete pad keyed under

and flush with the top of existing floor. Let concrete cure

before installing lifts and anchor.

6

Fig. 4

Shims (1/2"(12.7mm) Max.)

Nut

Flat Washer

Anchor

Anchor: Min

Concrete

Thickness

Hilti Kwik

Bolt III (3/4" x

5-1/2")

Hilti HY200

(with HAS

threaded rod)

4-1/4"

(108mm)

5-1/4"

(134mm)

Min Edge

Distance

3-3/8"

(86mm)

1-3/4"

(45mm)

*The supplied concrete fasteners meet the criteria of the American National Standard

“Automotive Lifts - Safety Requirements for Construction, Testing, and Validation” ANSI/ALI ALCTV-2011,

and the lift owner is responsible for all charges related to any additional anchoring requirements as

specified by local codes. Contact customer service for further information at: 800.640.5438

Drill holes using 3/4” carbide

tipped masonry drill bit per

ANSI B212.15-1994 (R2000).

Construction dust collected

Run nut down just below impact

section of bolt. Drive anchor

into hole until nut and washer

contact base.

Tighten nut with Torque

wrench to 110 ft.-lbs.

(149 Nm).

per OSHA 29 CFR 1926.1153.

12K 2-Post Lift Anchor Installation Reference Guide

Min Anchor

Embedment

3-1/4" (83mm) 110 3000 4'x4'x6" 65 Varies by

3-1/2" (89mm) 100 / less than 3-3/4"

Installation Anchor

Torque Ft-lbs

edge distance use

Torque Value of 30

FT/LBS

Min Concrete PSI

Strength - For All

Standards

3000 4'x4'x6" N/A

Concrete pad

Size If Concrete

Does Not Meet

Requirements

Maintenance

Torque

Values

SEISMIC

location consult

with your

structural engineer

and manufacturer’s

representative.

Fig. 5

NOTE: If more than 2 horse shoe shims are used at any of the

column anchor bolts, pack non-shrink grout under the unsupported

area of the column base. Insure shims are held tightly between the

baseplate and floor after torquing anchors.

7

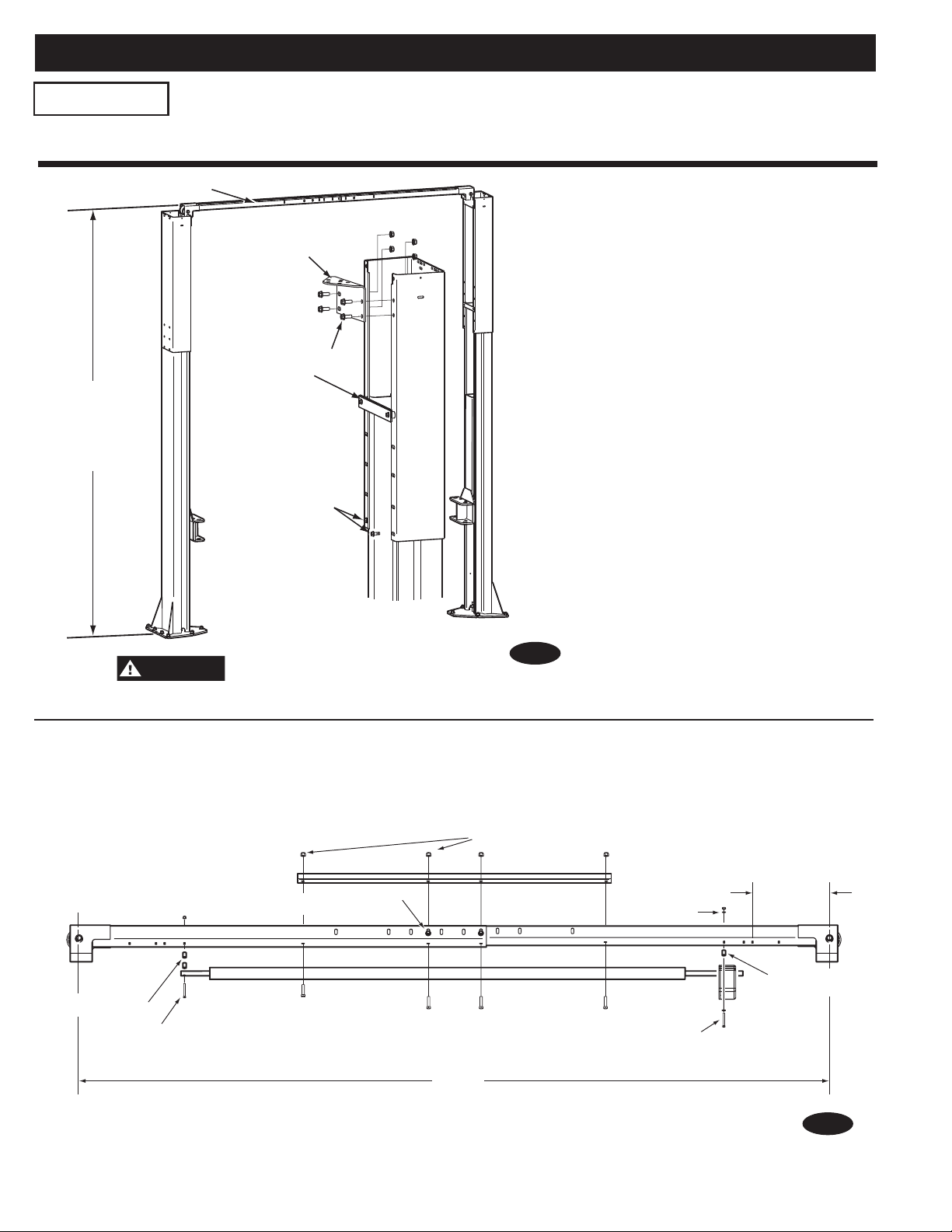

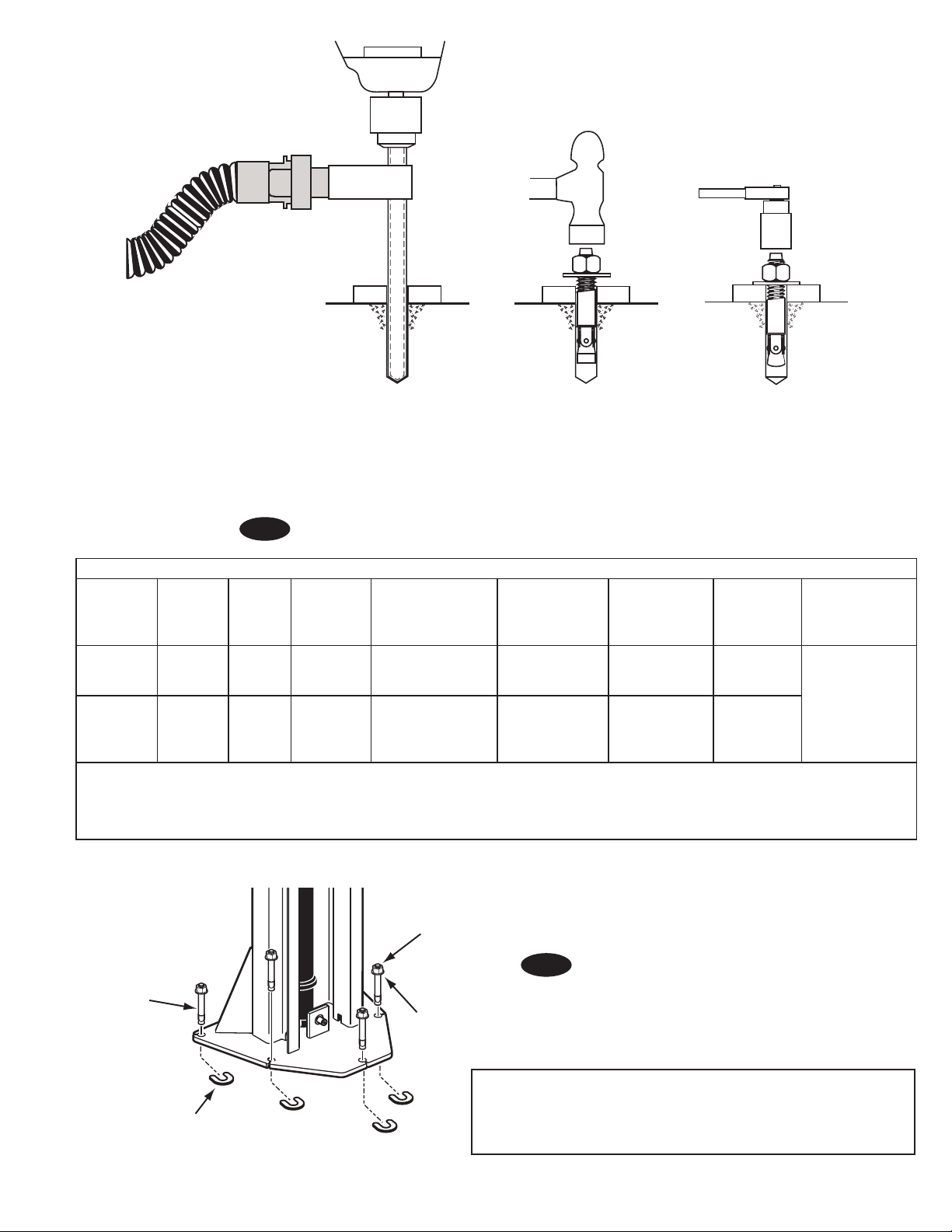

Hardware Detail For Overhead Assembly

1/4"-20NC x 2-3/4" HHCS

2 Spacers

Spacer

1/4" Lock Nut

Open Bar Side

HOLE

DETAIL

SPO12

1/4"-20NC x 2-3/4" HHCS

1/4" Lock Nut

1/4" Star Lock

Washer

1/4" Flat

Washer

Switch Box Side

(2)3/8"-16NC x 3/4" HHCS & Flanged Locknut

1/4"-20NC x 2-3/4" HHCS & 1/4" Locknut

114"

11-3/4"

(2)Spacers

(4)3/8"-16NC x 1" Flanged HHCS and Flanged Nuts

1 & 3 Phase Lifts

1/4"-20NC x 2-3/4" HHCS, Flat Washer, and Nut

Spacer

Star

Washer

This Side

6. Overhead Assembly: Adjust overhead to 114”

between centerline of sheave pins, Fig. 6. Install (4)

3/8”-16NC x 2-3/4” Flanged HHCS & Flanged Locknuts, do

not tighten. Install overhead stiffener angle inside center

of overhead using (4) 3/8”-16NC x 1” Flanged HHCS and

Flanged Locknuts, see Fig. 6. Slide switch box over switch

bar ensuring lockout holes face the power unit column.

Use (2) 1/4”-20NC x 2-3/4” lg. HHCS, (2) flat washers, (2)

3/4” spacers, and (2) 1/4” star washers and nuts to mount

switch box to overhead, Fig. 7a and Fig. 7b.

Note: For Fig. 6, see Pg. 4 for Hummer (5W0/7W0 Series) Lifts.

7. For single phase and three phase lifts with push

button control box: Insert (2) 1/4”-20NC x 2-3/4” HHCS

through pivot hole in end of switch bar. Insert opposite

end of bar through slot in switch mounting bracket. Then

add spacers between the limit switch box and the

overhead, Fig. 6, using (2) spacers and

1/4”-20NC Locknut. Tighten Hex bolt leaving 1/16” gap

between the spacer and the overhead assembly.

Fig. 6

8

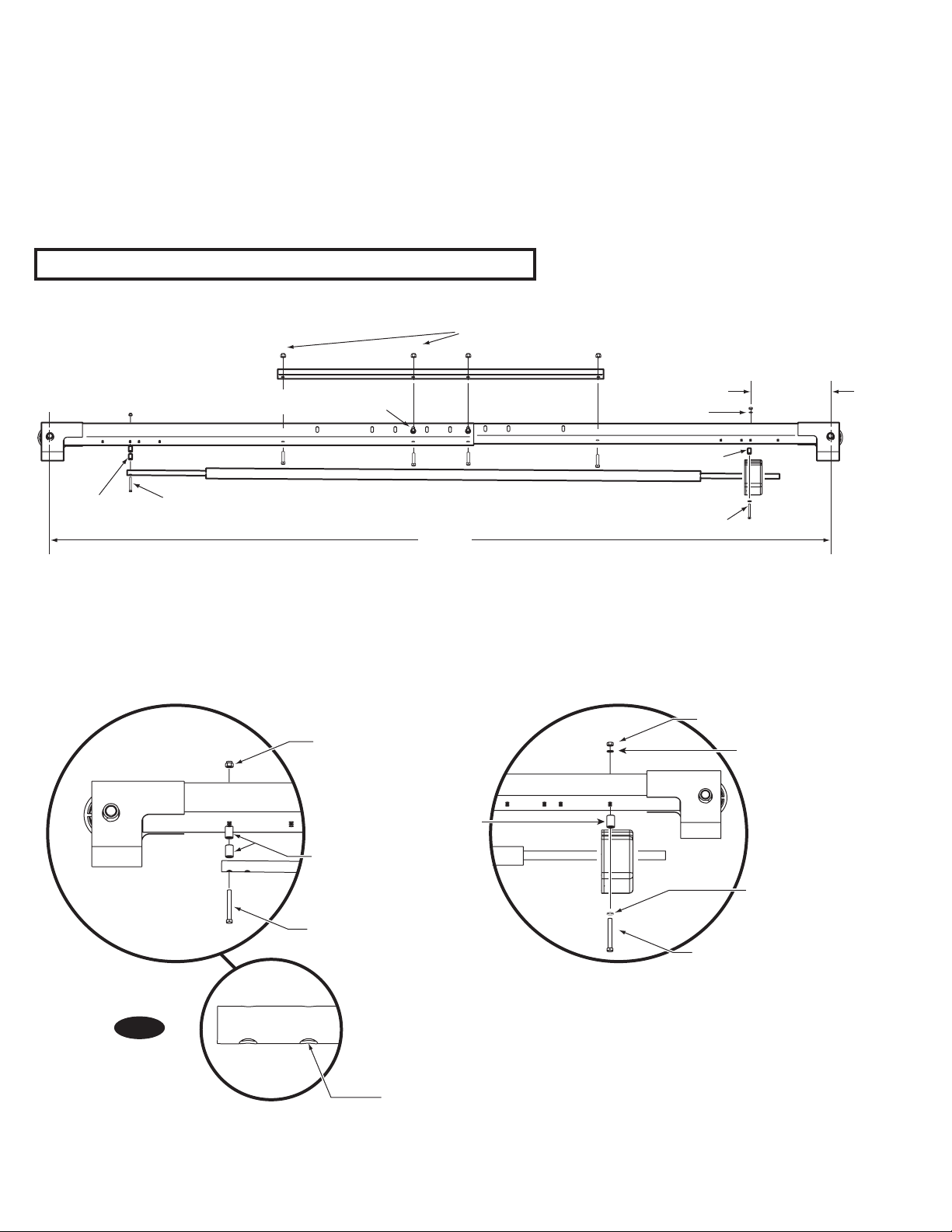

Use 3/8"-16NC x 3/4"

Flanged HHCS and

Flanged Locknuts

CAUTION

IMPORTANT

CAUTION

8. Overhead: Install overhead assembly to Mounting

Bracket with (2) 3/8”-16NC x 3/4” Flanged HHCS, (2) 3/816NC flanged locknut, Fig. 7c. Ensure limit switch box is

mounted on power unit side. Tighten bolts at center of

overhead assembly.

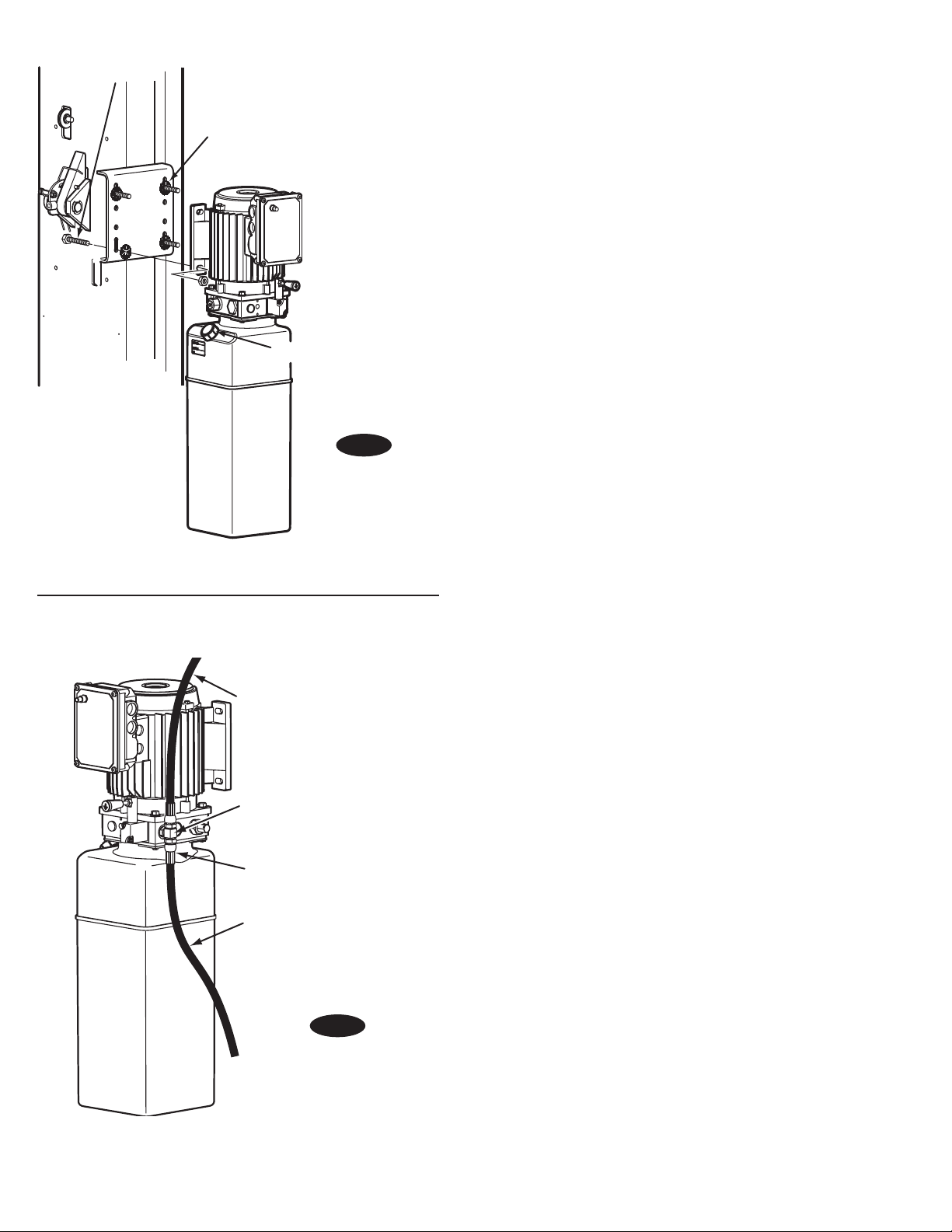

9. Power Unit: Put the (4) 5/16”-18NC x 1-1/2” flanged

locking HHCS thru holes in power unit bracket using PushNuts to hold in place, Fig. 8a. Mount unit with motor up to

column bracket and install (2) 5/16” Flanged locking Nuts.

Install and hand tighten Branch Tee to pump until O-ring

is seated. Continue to tighten the locknut to 10-15 ft-lbs.,

or until the nut and washer bottom out against the pump

manifold. NOTE: You may still be able to rotate the Branch

Tee. This is acceptable unless there is seepage at the

O-ring. If so, slightly tighten the locknut.

Over tightening locknut may tear O-ring or

distort threads in pump manifold outlet.

Fig. 7a

10. Hoses: Clean adapters and hose. Inspect all threads

for damage and hose ends to be sure they are crimped,

Fig. 8b. Install hose and hose clamps, Fig. 9a & Fig. 9d.

Flared Fittings Tightening Procedure

1. Screw the fittings together finger tight. Then, using the

proper size wrench, rotate the fitting 2-1/2 hex flats.

Flare seat MUST NOT rotate when

tightening. Only the nut should turn.

2. Back the fitting off one full turn.

3. Again tighten the fittings finger tight; then using a

wrench, rotate the fitting 2-1/2 hex flats. This will

complete the tightening procedure and develop a

pressure tight seal.

Overtightening will damage fitting resulting

in fluid leakage.

Fig. 7b

COVER NOT SHOWN

Fig. 7c

9

Push nuts hold bolts to brackets.

Fill Breather Cap

Use (4)5/16"-18NC

x1-1/2" lg. Flanged

Locking HHCS

and Nuts

Overhead

Hose

Power Unit

(Short) Hose

Crimped Hose

Sleeve (Typical)

Branch Tee

Fig. 8a

Adapter & Hose Installation (see Fig. 9a)

1. Install Pc. (2) with metal hose clamps, on power unit

column side connecting it to the cylinder (1) first.

2.

Install Pc. (3) with plastic hose clamps starting at

opposite column cylinder (1) and working toward the

power unit column. All excess hose should be at bends

& inside overhead assembly.

3. Install Pc. (4) into power unit.

4. Connect Pc. (2) & Pc. (3) to Tee (4).

NOTE: Route Power Unit hose inside columns using slots

provided at column base, Fig. 9b. Route Overhead Hose in

column channel on outside of column, Fig. 9b. Overhead

hose goes over top end of overhead assembly, Fig. 11a.

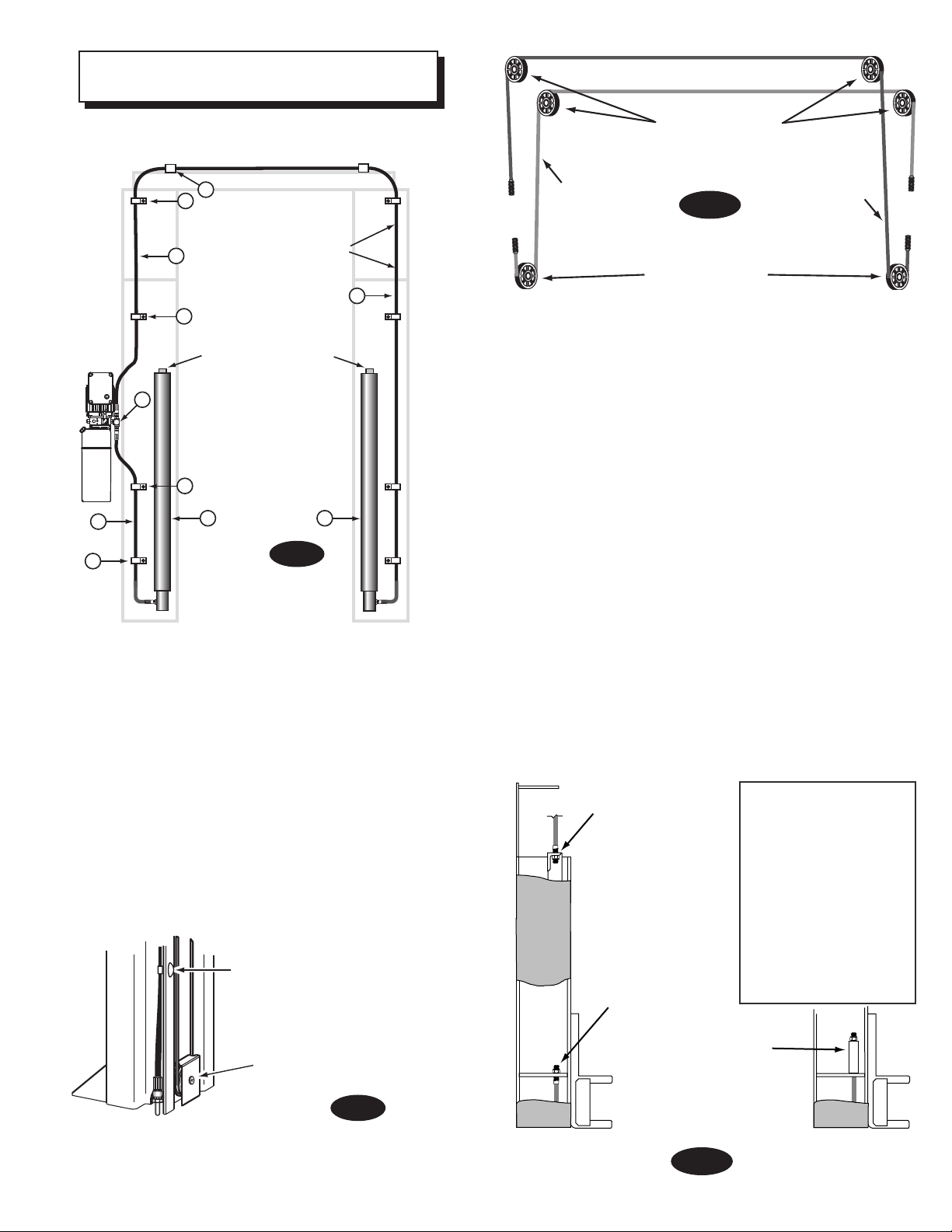

11. Equalizing Cables

A) Refer to Fig. 10a for the general cable arrangement.

First, run a cable end up through the small hole in the

lower tie-off plate. Fig. 10b.

B) Push the cable up until the stud is out of the carriage

top opening.

C) Run a nylon insert locknut onto the cable stud so 1/2”

(13mm) of the stud extends out of the locknut.

D) Pull the cable back down. Fig. 10b

E) Run cable around the lower sheave, then up and

around overhead sheave and across and down to the

opposite carriage. Fig. 10a.

F) Fasten the cable end to the carriage upper tie-off

bracket. Tighten the locknut enough to apply light

tension to the cable.

G) Repeat procedure for the second cable. Complete lift

assembly. Adjust the tension of both cables during the

final adjustments.

Fig. 8b

10

Attach hose to column

using 3/8"-16NC x 3/4"

Carriage Bolts, Flanged

Locknuts, and Hose Clips

Sheave Cover

1 1

2

6

4

6

FRONT

Hose runs down

approach side to

cylinder on left column.

Cylinder bleeders

Torque values

15 ft. lbs. Minimum

20 ft. lbs. Maximum

6

5

3

3

5

*

*

*

*

**

##

# #

NOTE: Overhead hose crosses and runs down

1st Cable

2nd Cable

Upper Sheaves

Lower Sheaves

approach side of left column to cylinder.

Fig. 10a

Fig. 9a

ITEM QTY. DESCRIPTION

1 2 Hydraulic Cylinder

2 1 Power Unit Hose

3 1 Overhead Hose

4 1 Branch Tee

5 2 Metal Hose Clips

6 8 Plastic Hose Clips

*6 3/8-16NC x 3/4” lg. Carriage Bolts

*6 3/8”-16NC Flanged Locknuts

#4 3/8-16NC x 3/4” lg. Flanged HHCS

#4 3/8”-16NC Flanged Locknuts

Upper Cable Tie Off

& 5/8" Nylon Insert

Locknut

Lower Cable Tie Off

& 5/8" Nylon Insert

Locknut

To set up cables for a low

ceiling(LC), use 3/4" SCH

80 steel pipe spacers (not

included) at the lower

cable tie off. The lengths

required are as follows:

4" Lower Height = 8"

(203mm) long pipe

8-1/2" Lower Height = 17"

(432mm) long pipe

3/4"(19mm)

SCHEDULE 80

Fig. 9b

11

steel pipe spacer

for Low Ceiling

Fig. 10b

IMPORTANT

Latch cable runs

along approach

side of overhead

Cable Guide

runs UNDER

hydraulic hose

Attach to extension using

wire tie. Use hole closest

to OUTSIDE edge and on

NON-APPROACH side.

1/4"-20NC x 1" HHCS

and Flanged Locknut

3/8"-16NC x 3/4" HHCS

and Flanged Locknut

3/8"-16NC x 3/4" HHCS

and Flanged Locknut

APPROACH

Attach Hose Clamps Here

Attach Latch Cable Conduit

Guide Bracket Here. Always

use two holes on approach

side of extension to attach bracket.

Always put HHCS through hole

closest to center of overhead.

IMPORTANT

Fig. 11a

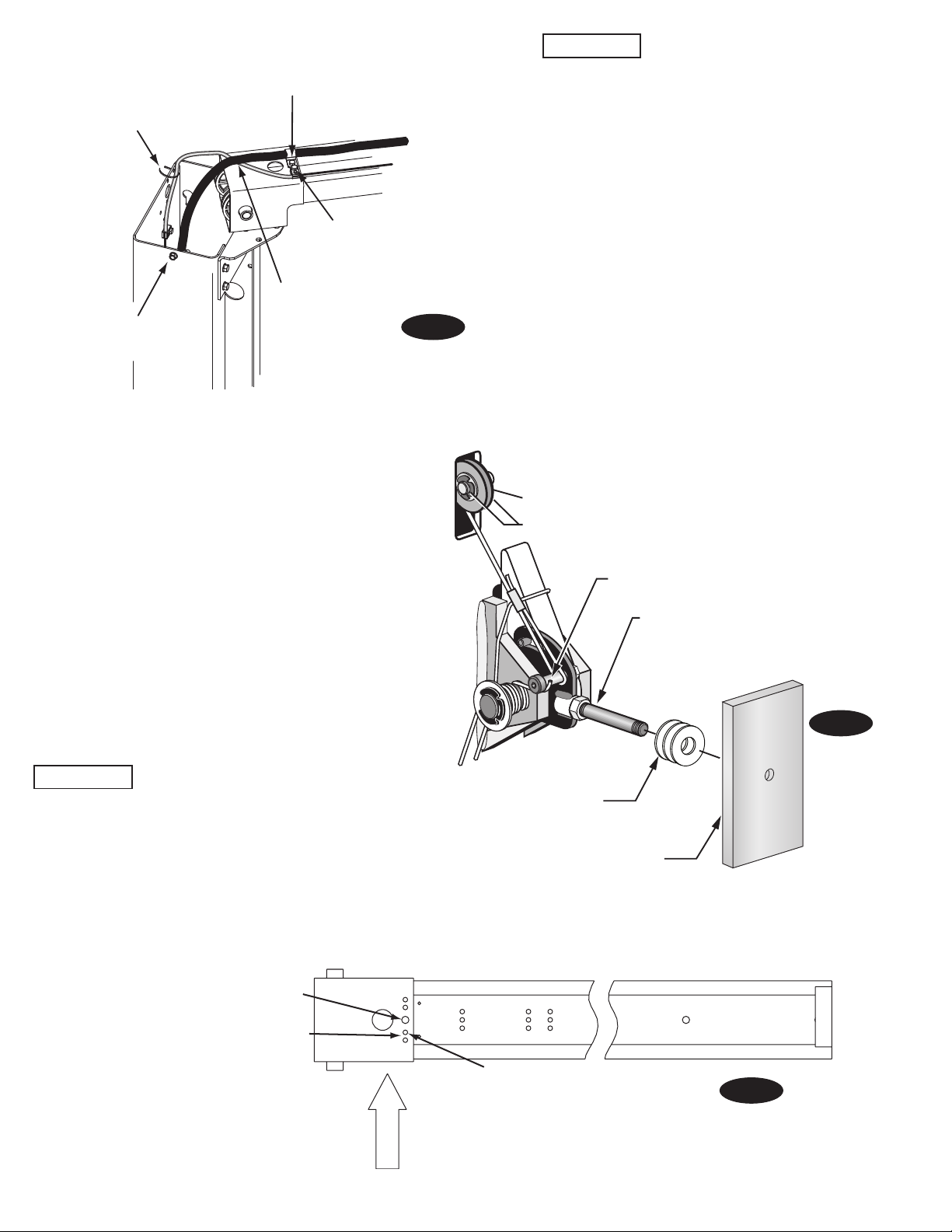

12. Locking Latch Cable

A) Install latch cable sheave and retaining rings in upper

slot of power unit column as shown, Fig. 11c.

B) Slip loop end of cable over end of shoulder screw on

right side latch control plate, Fig. 11c.

C) Feed the other end of the cable through the latch cable

sheave slot making sure that the cable is running

under the bottom side of the latch cable sheave and

inside the right column, Fig. 11c.

D) Attach latch cable conduit guide brackets to overhead

as shown, Fig. 11a & Fig. 11b. Always use the holes on

the approach side of the lift. HHCS should be in hole

nearest the center of the overhead, Fig. 11b.

E) Route cable up inside column and through the latch

cable guide, Fig. 11a & Fig. 12.

Using wire ties provided, tie off

cable guide to column extension as shown,

Fig. 11a. Guide must be attached in hole

closest to the outside edge of the column on

the NON-APPROACH side.

G) Bring the cable down inside the left column

and feed the end of the cable through the

lower latch cable sheave slot so that the

cable is now back outside the column, Fig.

13.

H) Install latch cable sheave and retaining

rings in lower slot of non-power unit column

as shown, Fig. 13.

I) Route cable under the bottom side of the

latch cable sheave, Fig. 13.

J) At this point you MUST install the latch

handle, jam nut, and right column latch

cover Fig. 11c & Fig. 14. Install latch handle

ball, Fig. 14.

Latch Cable Sheave

(2) 3/8" Retaining Rings

Shoulder Bolt

Install Latch Handle using a 3/8"

hex jam nut to lock in place. Then

install flat washers and slot cover.

Fig. 11c

Using wire ties provided, tie off cable guide

to column extension as shown, Fig. 11a. Guide must

be attached in hole closest to the outside edge of the

column on the NON-APPROACH side.

F) Continue routing cable to the left column latch cable

guide, Fig. 11a & Fig. 12, routing the cable through the

left column latch cable guide, Fig. 11a.

(3) 3/8” Flat Washers

Slot Cover

Fig. 11b

12

Shoulder Bolt

Cable Clamp

Feed cable up through Cable

Clamp, loop over end of

shoulder bolt and feed back

down through Cable Clamp.

(2) 3/8" Retaining

Rings

Latch Cable Sheave

5/16-18NC x 3/8" lg. PHMS

Latch handle MUST be

positioned at the top of

the latch control cover.

Ball Handle

Fig. 12

Latch Cable Guide

Right Column

Latch Cable

Notice the clearance

removed between

Control Plate Slot

and Latch Dog Pin.

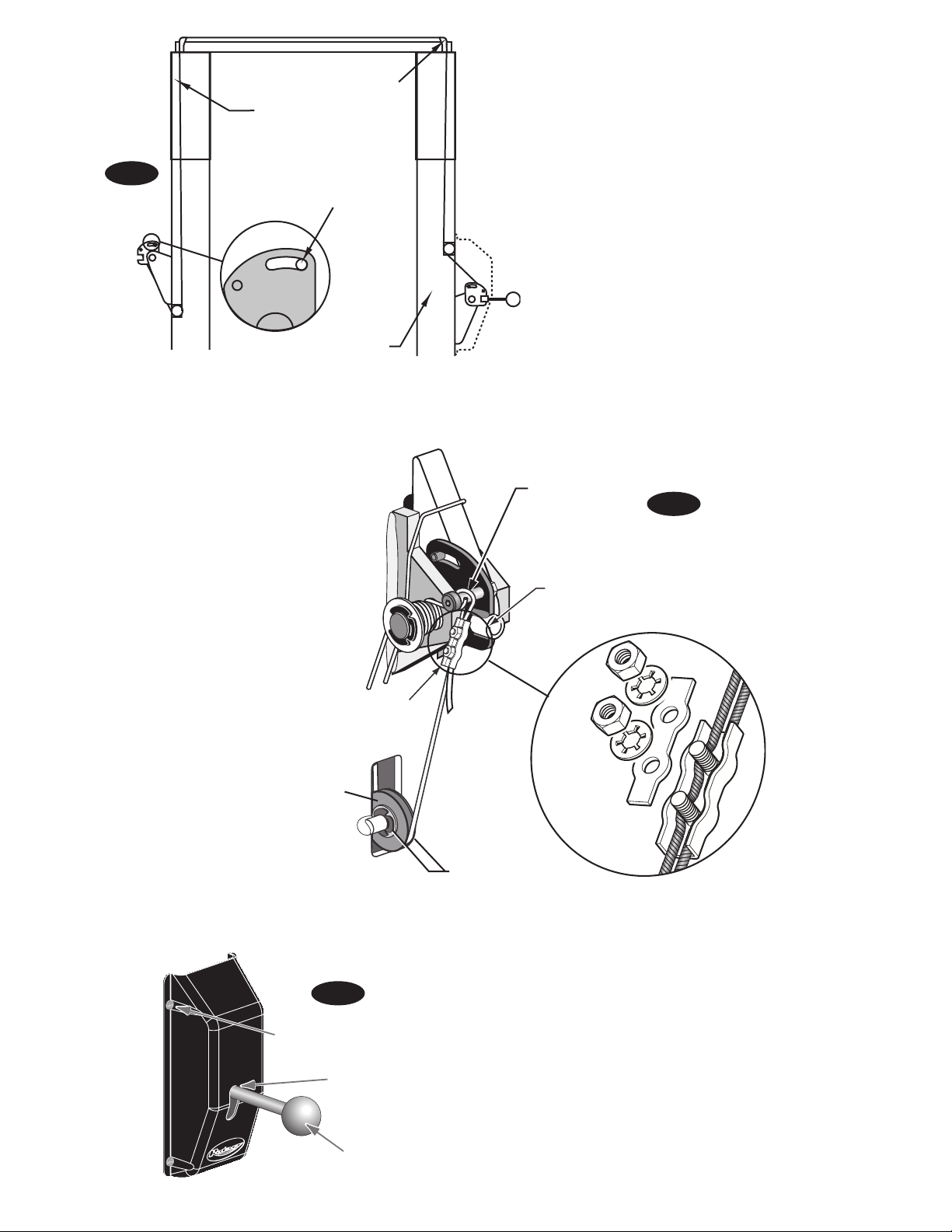

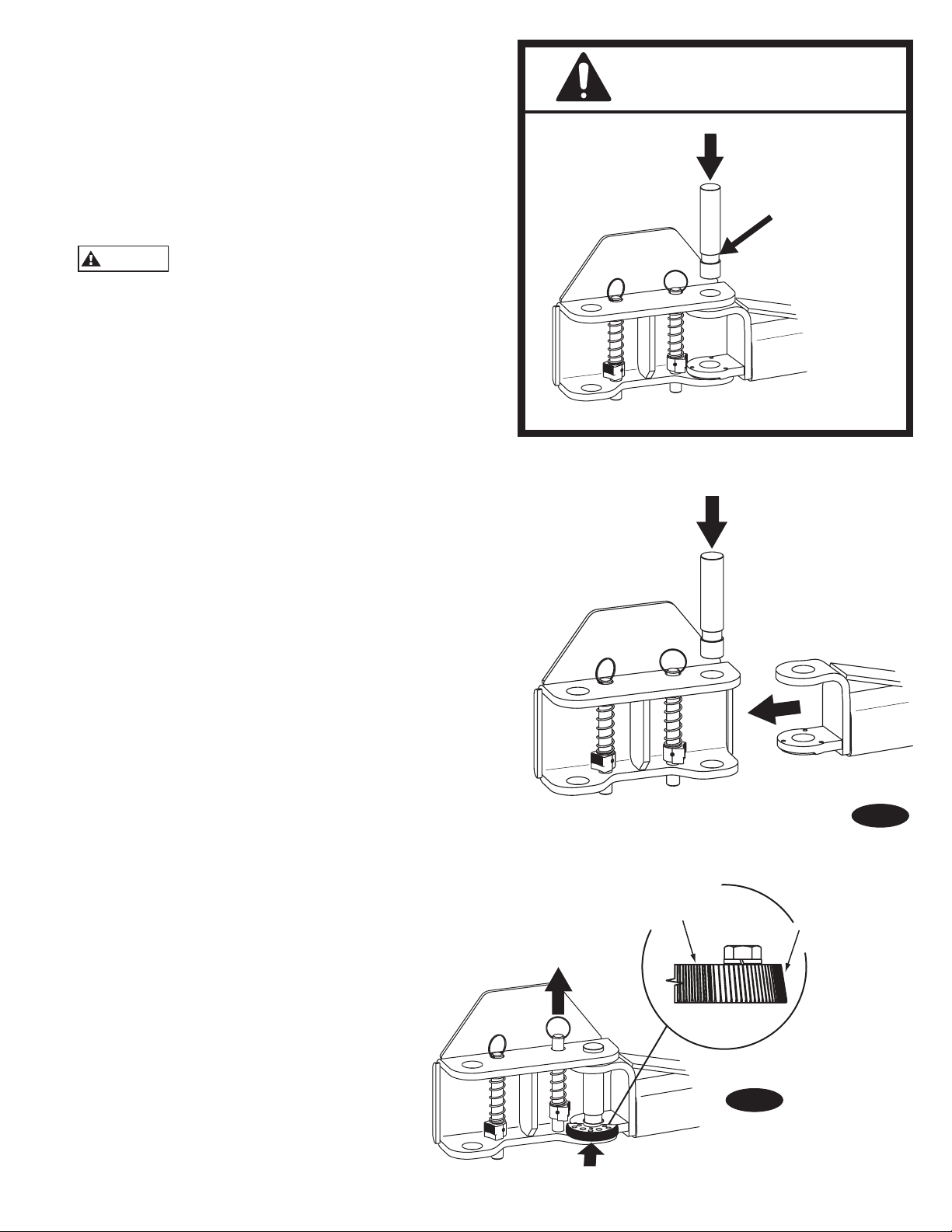

K) Insert cable in cable clamp along one side, loop

around shoulder screw and back down, inserting

cable along other side of cable clamp, Fig. 13. Place

top back on clamp, barely tightening.

L) Next, pull the control plate down, Fig. 12 & Fig. 13, to

eliminate any clearance between the control plate slot

and the latch dog pin, Fig. 12.

M) Using Pliers, pull cable tight and secure the clamp

close to the shoulder screw. Tighten clamp.

Fig. 13

Fig. 14

13

M

230V

60Hz

1 Ø

Black

Green

White

Overhead

Limit Switch

Up

Switch

White

Black

Black

Ov

Max.

Max.

Attach white

White

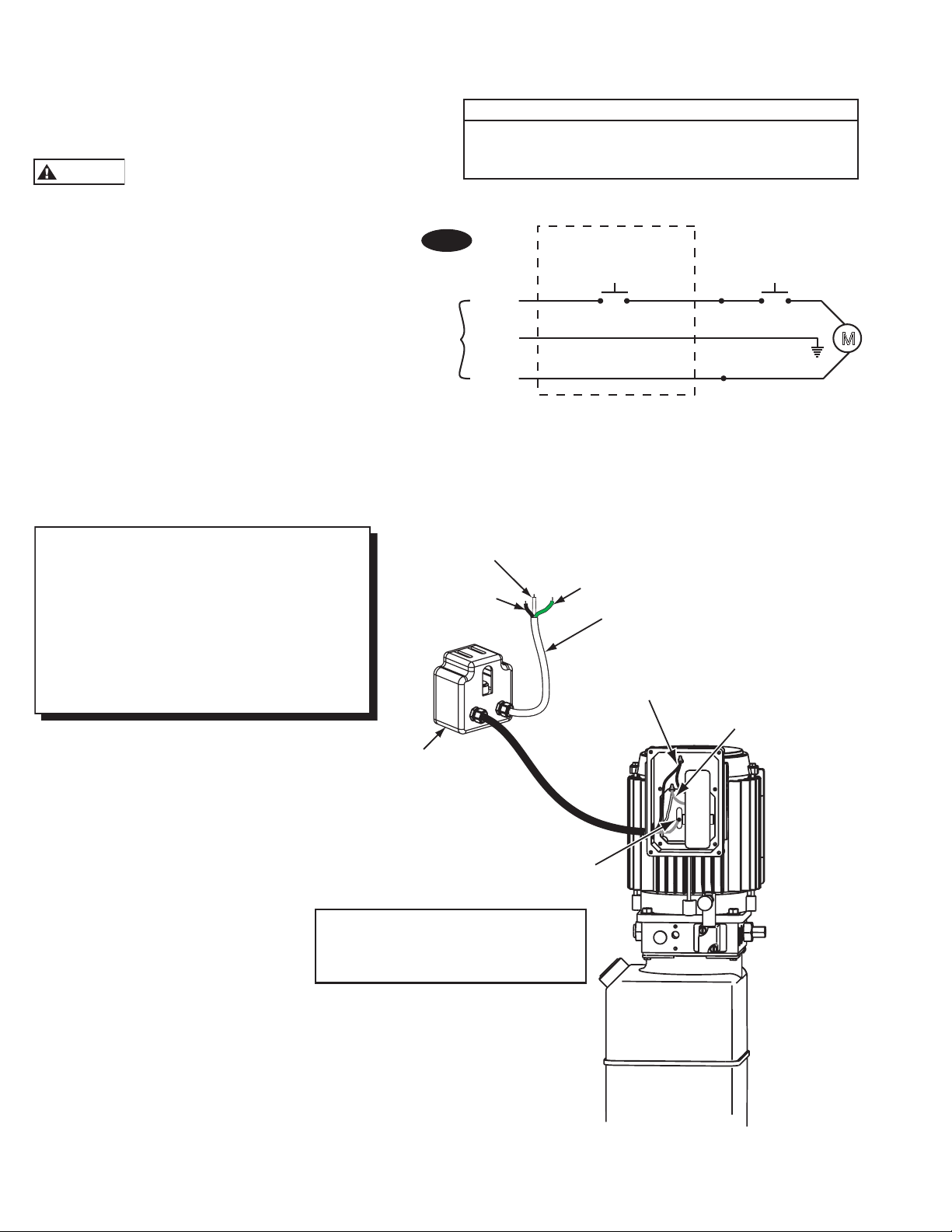

13. Electrical: Have a certified electrician run

CAUTION

NOTE: Assure cord used for connection

between the overhead switch and power

unit is of the type specified in:

UL201, Sections 10.1.1.3 & 10.1.1.4

(Example: SO, G, STO) Size for 25 amp

circuit. See UL 201, Section 15 for proper

wiring requirements for this connection.

appropriate power supply to motor, Fig. 15 & 16.

Size wire for 20 amp circuit. For single phase

4HP motor wire for 30 amp circuit. See Motor

Operating Data Table.

Never operate the motor on line

voltage less than 208V. Motor damage may occur.

Single Phase Power Unit

MOTOR OPERATING DATA TABLE - SINGLE PHASE

LINE VOLTAGE RUNNING MOTOR VOLTAGE RANGE

208-230V 50Hz. 197-253V

208-230V 60Hz. 197-253V

IMPORTANT: Use separate circuit for each power

unit. Protect each circuit with time delay fuse or

circuit breaker. For single phase 208-230V, use 20

amp fuse. For single phase 4HP motor use 30 amp

fuse. Three phase 208-240V, use 20 amp fuse. For

three phase 400V and above, use 10 amp fuse. For

wiring see Fig. 15, Fig. 16, and Fig.16b. All wiring

must comply with NEC and all local electrical

codes.

Note: 60Hz. single phase motor CAN NOT be run

on 50Hz. line without a physical change in the

motor.

Fig. 15

Note: 60Hz. Single phase motor CAN NOT be run on 50Hz. line

without a physical change in the motor.

Black

Green

208-230V 60Hz

Single Phase

Attach black wire

to one motor wire.

wire to one

motor wire.

erhead Switch

Voltage: 277V

Current: 25A

Attach ground wire here.

Connect supply to wires in box as

per Fig. 16. Attach ground wire to

screws provided.

14

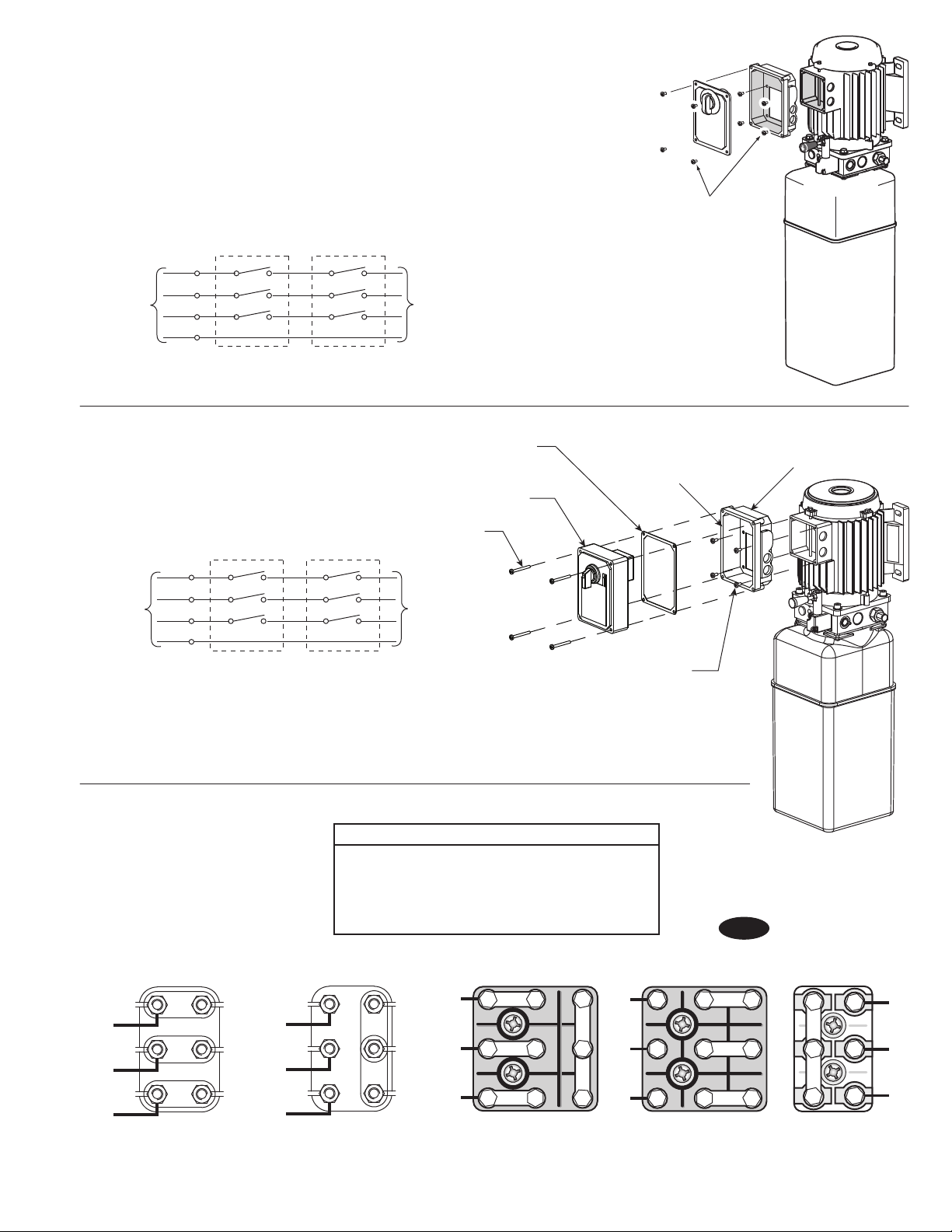

NOTE: Two Different Drum Switches were used

please select one of the two options below.

Newer model three phase lifts use the push button

control box with contactor. Its instructions follow

the Drum Switch instructions.

NOTES:

1. Unit not suitable for use in unusual conditions. Contact

Rotary for moisture and dust environment duty unit.

2. Control Box must be field mounted to power unit.

3. Motor rotation is counter clockwise from top of motor.

L1

3 Phase

Supply

L2

L3

1

2

3

4

5

6

1

2

5

6

7

8

MOTOR

PE

FOR 3 Ø POWER

UNITS: Attach Box using

M5 x 10 PHMS, Plated

Capacitor Box Attachment

Option One

3 Phase

Supply

OVERHEAD SWITCH

(WHERE APPLICABLE)

L1

1

2

3

L2

L3

4

5

6

PE

OVERHEAD SWITCH

(WHERE APPLICABLE)

DRUM

SWITCH

Gasket

Drum Switch

And Cover

(4) M5 x 45 PHMS, Plated

1

2

3

5

DRUM

SWITCH

4

6

MOTOR

(4) M5 x 10 PHMS, Plated

Capacitor Box To Power Unit

Capacitor Box Attachment

Option Two

Three Phase Power Unit

MOTOR OPERATING DATA TABLE - THREE PHASE

LINE VOLTAGE RUNNING MOTOR VOLTAGE RANGE

208-240V 50/60Hz. 197-253V

400V 50Hz. 360-440V

440-480V 50/60Hz. 396V-528V

575V 60Hz. 518V-632V

Re-seal Between

Box And Spacer

With Silicone

Sealer

Fig. 16

Capacitor

Box

L3

L2

L1

U1

V1

W1

50/60Hz. 3Ø

208-240V

Current Pin Layouts Older Pin Layouts

W2

U1

W2

T9

T3

L3

T6

L3

T3

L3

U2

V1

U2

T8

T2

L2

T5

L2

T2

L2

V2

W1

V2

L1

T7

T1

T4

L1

T1

L1

440-480V 50/60 Hz. 3Ø

380-400V 50 Hz. 3Ø

208-240V

50/60Hz. 3Ø

440-480V 50/60 Hz. 3Ø

380-400V 50 Hz. 3Ø

15

T9

T8

T7

T6

T5

T4

W2

V2

W1

T3

T2

V1

U2

U1

T1

575V 60 Hz. 3Ø

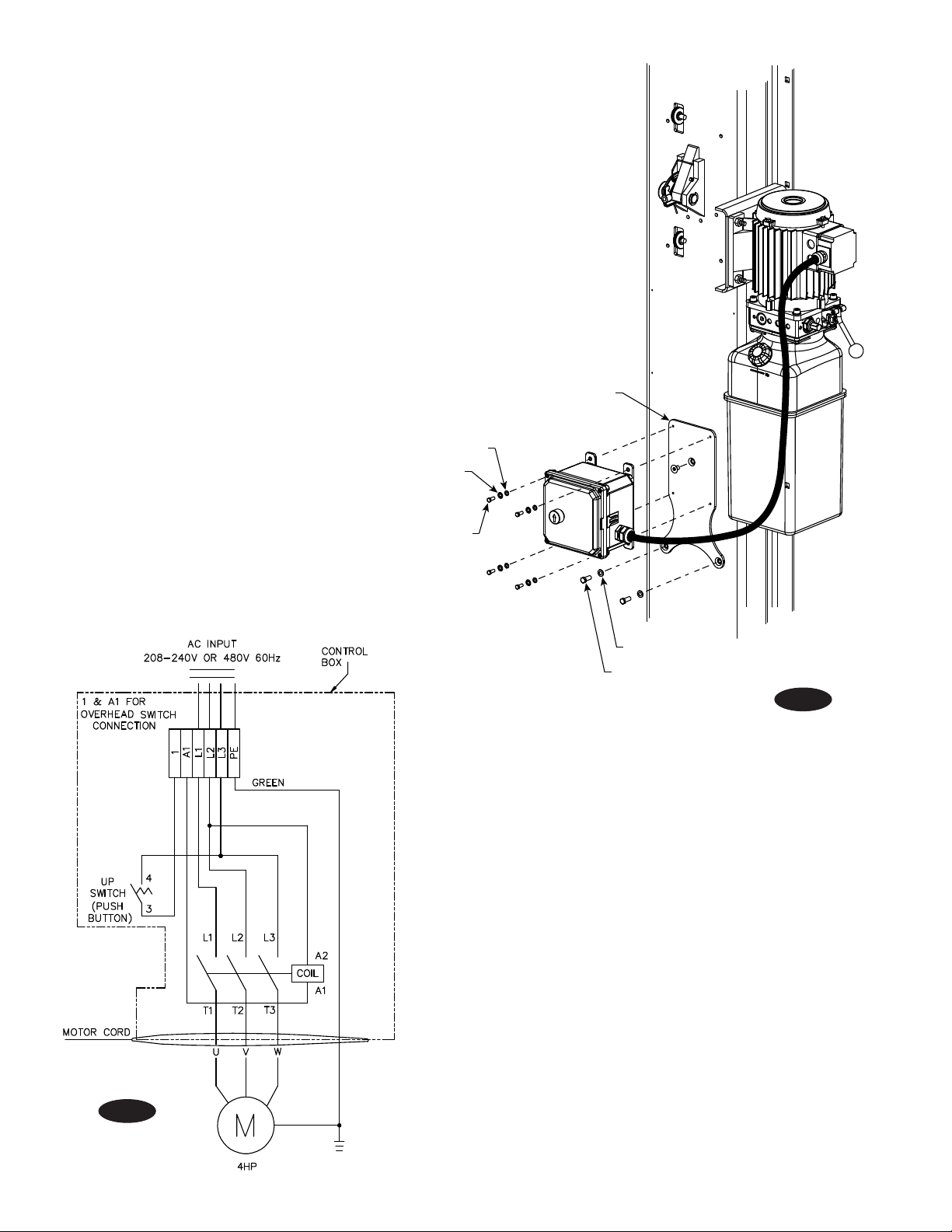

14. 3ø Control Box Installation:

Note:

The contactor in the control box has a 480V coil.

For installations where the electric supply is 230V,

the coil must be replaced with the extra 230V coil

shipped with the control box. For 575V electric

supply, the coil must be replaced with the extra

575V coil shipped with the lift.

A) Attach Mounting Bracket on column, as shown in Fig.

16a, using (1) 5/16”-18NC x 1/2” Socket Head Counter

Sunk Machine Screw, (2) 5/16”-18NC x 1/2” HHCS, and

(2) 5/16” Flat Washers.

B) Attach Control Box to Bracket using (4) 1/4”-20NC

x 1/2” HHCS, (4) 1/4” Flat Washers, and (4) 1/4” Star

Washers.

C) Route cord through strain relief on motor and connect

per table on the bottom of page 15.

1/4” Flat Washer

1/4” Star Washer

Mounting Bracket

1/4”-20NC x 1/2” HHCS

5/16” Flat Washer

5/16”-18NC x 1/2” HHCS

Fig. 16a

Fig. 16b

16

NOTE beveled

gear orientation

TOP

will be

marked on top side

of restraint gear

15. Oil Filling & Bleeding: Use Dexron III ATF, or

CAUTION

Installation

Pinch Point

Keep Hands

Above Groove

CAUTION

Hydraulic Fluid that meets ISO 32 specifications. Remove

fill-breather cap, Fig. 8a. Pour in (8) quarts of fluid.

Start unit, raise lift about 2 ft. Open cylinder bleeders

approximately 2 turns, Fig. 9a.

Close bleeders when fluid streams. Torque values for the

bleeders are 15 ft. lb. minimum and 20 ft lb. maximum.Fully

lower lift. Add more fluid until it reaches the

MIN_____ mark on the tank. Replace fill-breather cap.

If fill-breather cap is lost or broken, order

replacement. Reservoir must be vented.

16. Overhead switch: Check overhead switch assembly

to assure that switch bar is depressing switch plunger

sufficiently to actuate the switch. The overhead switch is

wired normally open, see Fig. 15, Fig. 16, and Fig. 16b. Lift

will not operate until weight of switch bar is depressing

switch plunger. Verify that Power Unit stops working when

switch bar is raised, and restarts when the bar is released.

17. Arms & Restraints: Before installing arms, raise

carriages to a convenient height. Grease swivel arm pins

and holes with Lithium grease. Slide arm into yoke, Fig.

17a. Install 1-3/4” diameter arm pin(s), Fig. 17a.

After installing arms and pins, install arm Restraint Gears

as follows: Install Restraint Gear onto arm clevis, as

shown, Fig. 17b. Ensure side of gear marked TOP is facing

upward, Fig. 17b.

NOTE: TOP is stamped on top side of gear. You may

need to pull up on the pin-ring to allow enough room to

install Restraint Gear.

Then, install the (2) 3/8”-16NC x 1-1/2” HHCS (8 total for

all 4 arms) and 3/8” Spring Lockwashers into the gear and

arm, but do not tighten. Reference Fig. 17c, Fig. 18, and Fig.

19.

Torque the Restraint Gear bolts to 30-34 ft.-lbs.

Fig. 17a

Fig. 17b

17

Use holes marked with arrow for Right Front

and Left Rear.

Use holes marked with arrow for Left Front

and Right Rear.

Fig. 17c

DO NOT use holes marked with arrows.

NOTE: To check operation of arm restraints, raise carriage

1” min. from full down position. Pull up on pin-ring and

adjust arms to desired position. To engage restraint, let

pin-ring down allowing gear teeth to mesh together. It may

be necessary to rotate arm slightly to engage gear teeth.

NOTE: Pin & Ring, Spring, & Gear Block are all

preassembled.

NOTE: Once arm is installed in yoke, pull up

actuator pin and swing arm fully around, being

sure that the Restraint Gear and Gear Block always

stay aligned. If they do not stay aligned, remove

restraint gear and install in the opposite position.

Fig. 18

Fig. 19

18

18. Installation of Rack for Adapter Extensions: Install

racks as shown, Fig. 20, using 5/16”-18NC x 3/8”

PHMS.

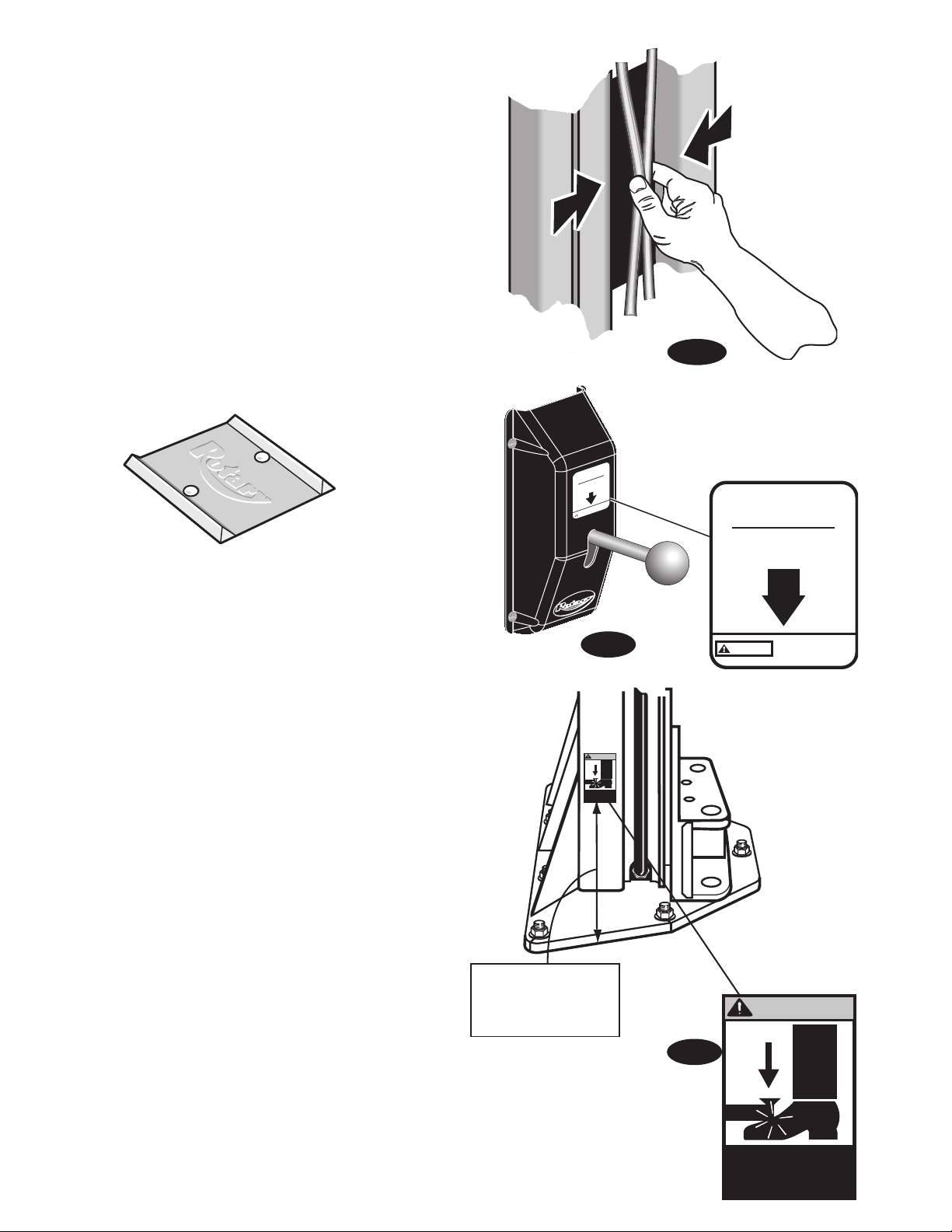

19. Door Bumper Installation:

1) Press long bumper on column edge, Fig. 21a.

2) Press short bumper on top edge of carriage

tube, Fig. 21a.

20. Latch Cable Adjustment:

A) Check to make sure the latch will properly engage and

disengage. Slowly release the latch handle. A 1/8”

gap between the top of the latch dog and the column

is allowable.

B) When raising, listen to latches to be sure that both

latch dogs fall into latch slots. If they do not, loosen

clamp and adjust tension as necessary.

C) Install left latch cover using 5/16-18NC x 3/8” lg PHMS.

21. Pressure Test: Run lift to full rise and keep motor

running for 5 seconds. Stop and check all hose

connections. Tighten or reseal if required. Repeat air

bleeding of cylinders.

Fig. 20

Padded section

of door bumper

faces out.

Short

Bumper

Long Bumper

21” (533mm)

Fig. 21a

19

WARNING

Keep feet

clear of lift

while lowering

Place WARNING decal

a minimum of 8" from

the bottom of the decal

to the ground.

WARNING

Keep feet

clear of lift

while lowering

Raise Lift Off

Latches

Actuate To Release

Latches

Pinch Point

CAUTION

NP266 Rev C

Raise Lift Off

Latches

Actuate To Release

Latches

Pinch Point

CAUTION

NP266 Rev C

22. Equalizer Cable Adjustments: Raise lift to check

equalizer cable tension. Below carriage, grasp

adjacent cables between thumb and forefinger, with

about 15 lbs. effort you should just pull the cables

together. Adjust at upper tie-offs Fig. 21b.

23. Latch Release Decal: Install latch release decal on

cover above latch release handle, Fig. 22.

24. Pinch Point Decal Location: Install enclosed pinch

point decals. Place (1) decal on each column, Fig. 23.

25. Wheel Spotting Dish: Position wheel spotting dish as

illustrated in Fig. 1. Drill (2) 3/8” holes 2-1/2” deep in

concrete floor using holes in wheel spotting dish as

guide. Drive both anchors, provided, into concrete to

secure dish.

Fig. 21b

26. Upon completion of the assembly of the lift, the lift is

to be operated to assure proper function. Observe for

locks operating in all locking positions, each side lifts

equally, hydraulics do not leak, all electrical controls

function as labeled, all pneumatics are functional

and leak free, ramps rotate freely (if applicable), and

proper clearances with all items in bay have been

maintained.

Operate the lift with a typical vehicle and observe to

assure the same items for proper functioning.

Fig. 22

Fig. 23

20

NOTES

21

NOTES23NOTES

22

Loading...

Loading...