SM30/RFL25

SM30 Capacity 30,000 lbs. (15,000 lbs. per axle)

140” Minimum Wheelbase

I

N

N

S

S

T

T

A

A

L

L

I

RFL25 Capacity 25,000 lbs. (12,500 lbs. per axle)

L

L

A

A

T

T

I

O

O

N

N

I

N

N

S

S

I

I

© July 2018 by Vehicle Service Group. CO10598.0 IN20490

Rev. J 7/24/2018

LP20460

T

T

R

R

U

U

C

C

T

T

I

O

O

N

N

S

S

I

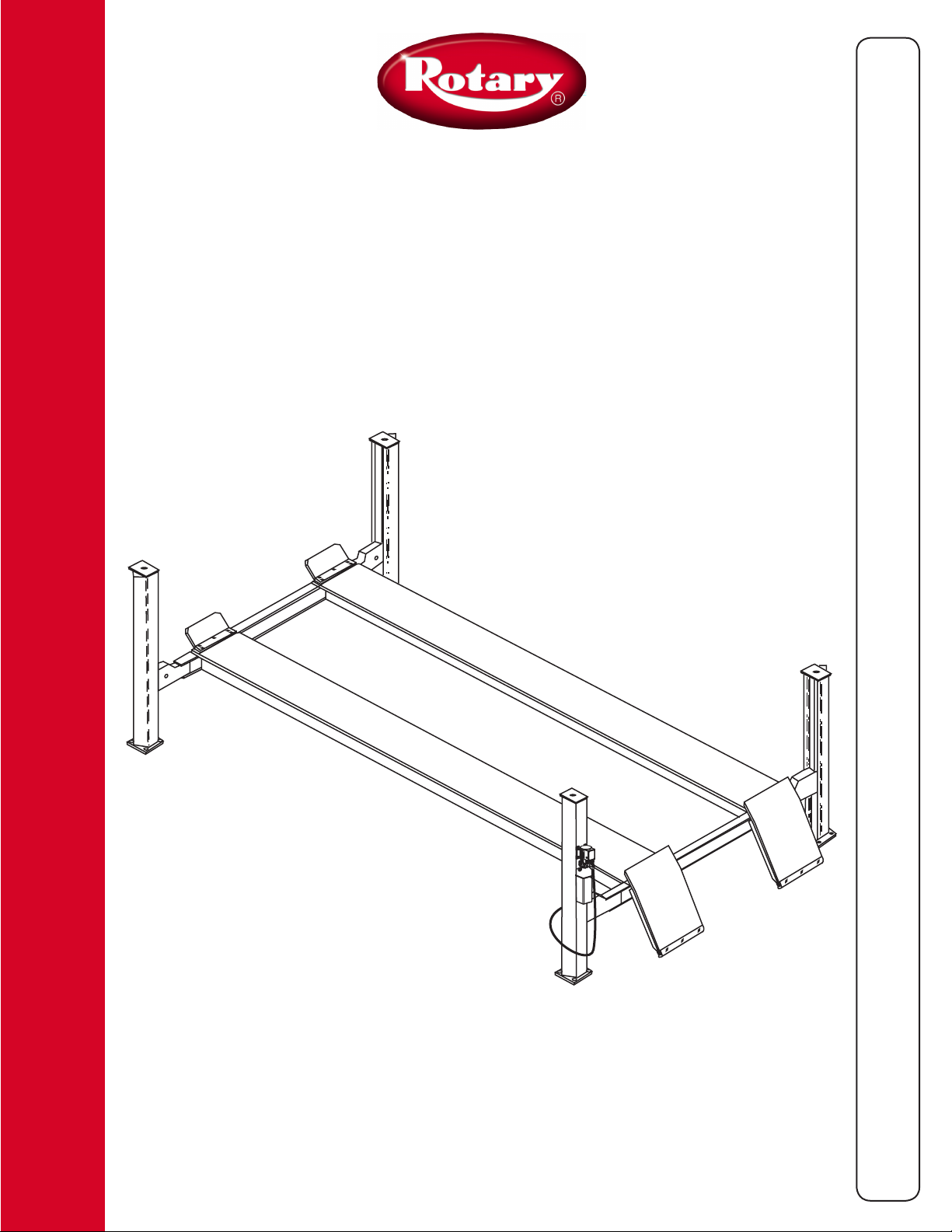

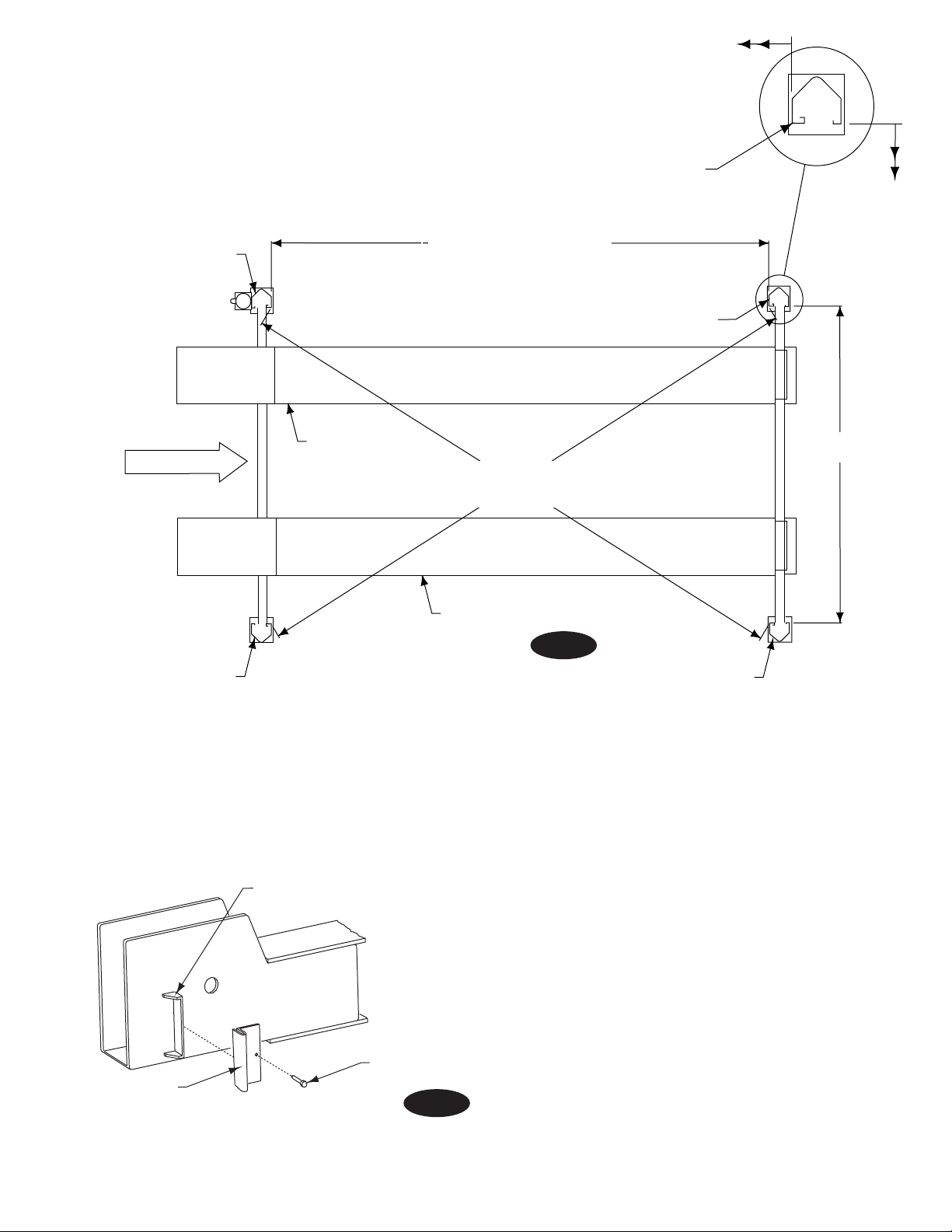

Required Clearances

WARNING

Estimation Shim Requirements

Dimension at highest position minus other

APPROACH

Rear Clearance

Rear Clearance (Min. 5'-6" for SM30's, 8'-6" for

RFL25's) = rear overhang of longest vehicle + required

work space

Fig. 1

Read and understand Installation Instructions completely

before starting with lift installation.

1. Lift Location: Use architects plan when available to locate lift.

Fig. 1 shows dimensions of a typical bay layout. For power

unit at right front, rotate lift 180°, leaving ramp/chocks and

wheel stops in original position. Lift floor area should be

level.

DO NOT install on asphalt or other similar

unstable surfaces. Columns are supported only by anchors in

floor.

Note: If runway extensions are used, an additional 3’–0” of

clearance must be added to end with extensions.

Left

Runway

Right

Runway

C

L

8'–0" Min. To

Nearest

Obstruction

8'–0" Min. To

Nearest

Obstruction

Front Clearance

Front Clearance = front overhang of

longest vehicle + required work space

2. Ceiling or overhead clearance must be 80” plus height

of tallest vehicle.

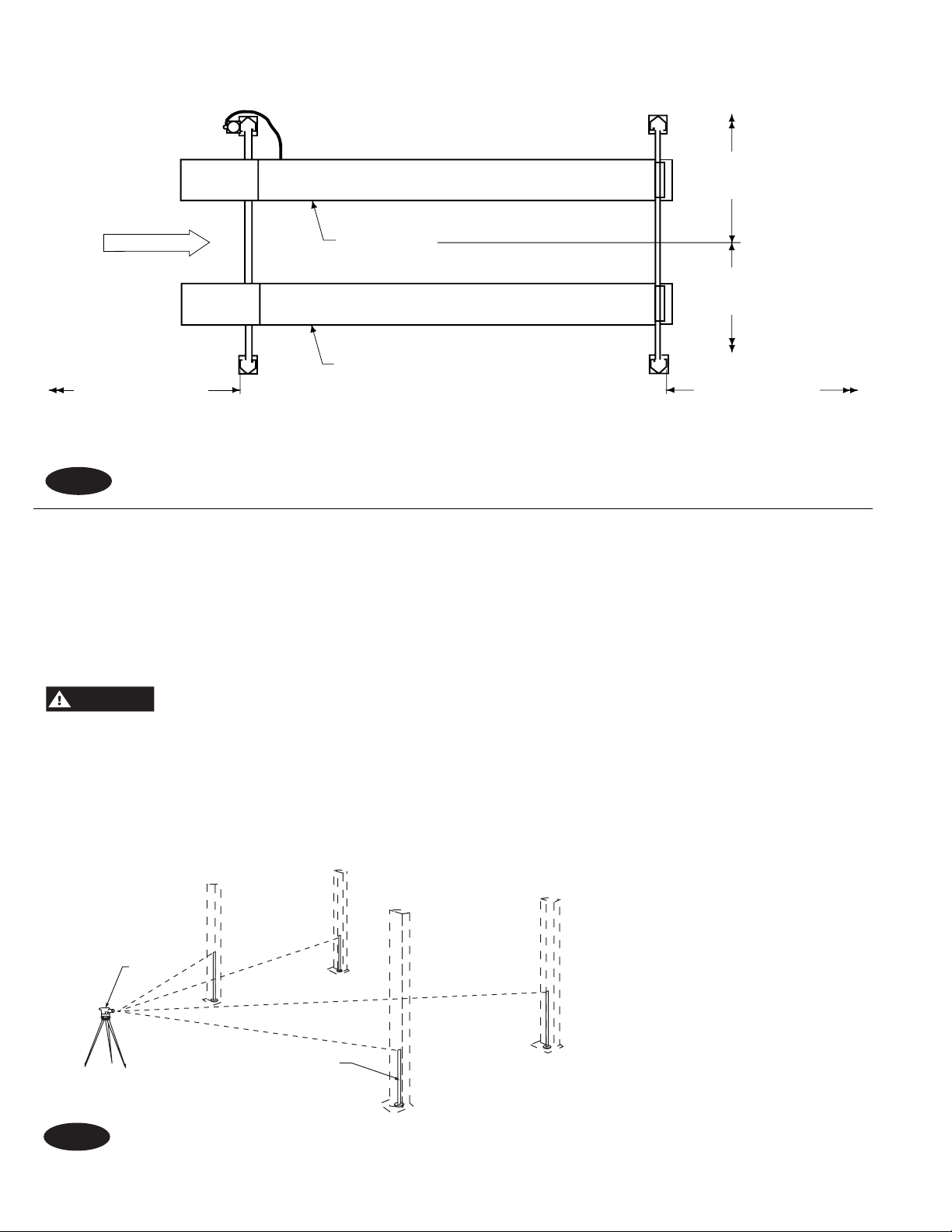

3. Estimating Column Shim requirements:

In the following section, the terms “highest” and

“lowest” refer to elevation of floor.

A. Mark locations where lift columns will be

positioned in bay.

B. Place target at column positions and record

readings, Fig. 2.

C. Find the highest of the four (4) locations. Find the

difference between the reading at each of the

remaining three (3) columns and the highest

reading.

D. The difference is the estimated amount of shim

thickness needed at each column.

FRONTREAR

Fig. 2

Transit

Target

position = shim thickness required

2

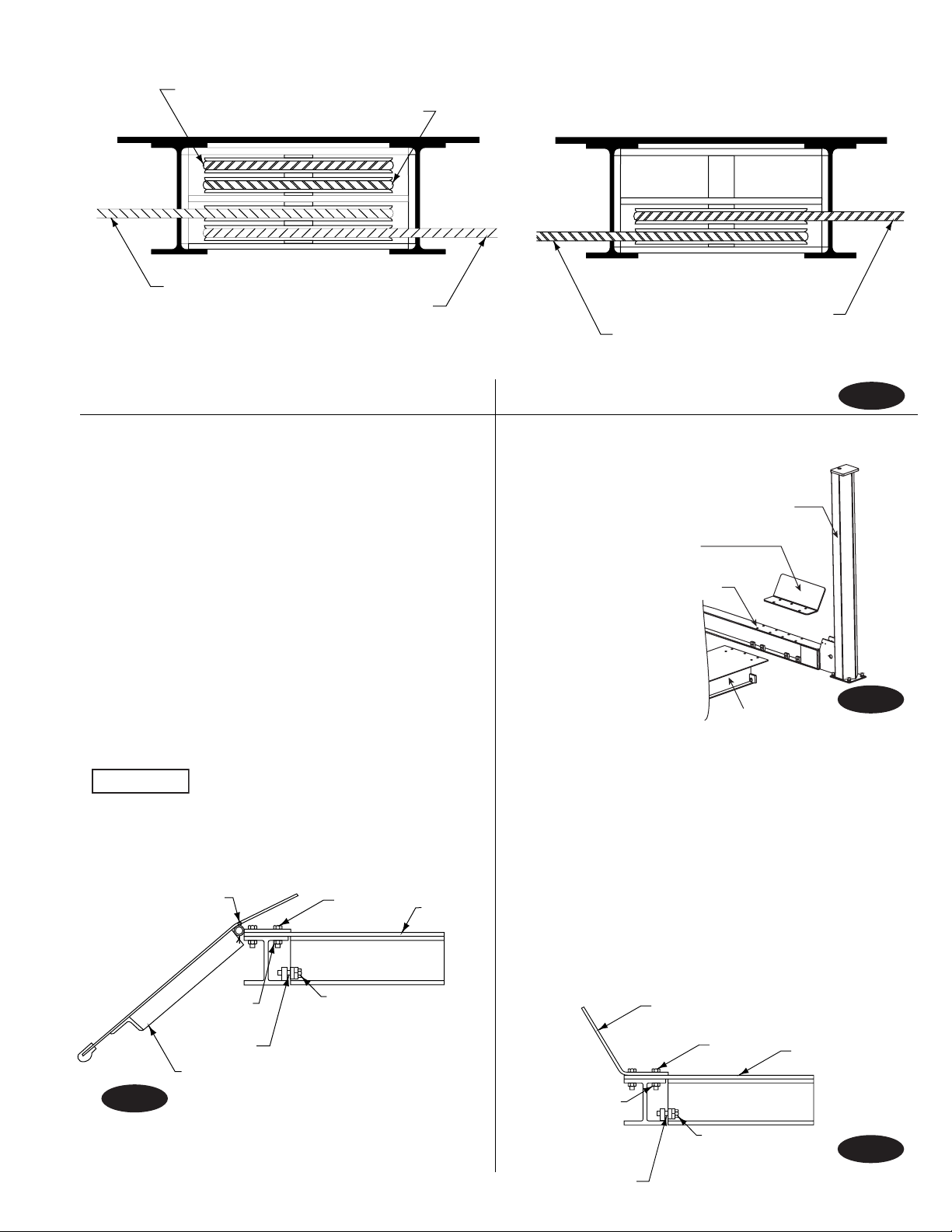

Cable Seating in Sheave Grooves

Fron

(V

Right Rear

IMPORTAN T

Feed Cable Ends Through Yoke End

Ramp/Chock

Ramp/chock

Wheel Stop

Flange

Nuts

Cable (#4)

Left Rear

Cable (#3)

Right Front

Cable (#2)

Left Front

Cable (#1)

t

iewed from front)

E. Maximum shim thickness of 2” is possible by using shims

and anchors provided with lift. If more shimming is required,

consult factory for different shim package including longer

anchor bolts.

4. Runway and Yoke Assembly:

A. Determine direction of approach in bay.

B. Position left runway in bay with hydraulic cylinder hose

connection to rear of bay. Cables and sheaves are preassembled in runway. Runway needs to be up off floor so

shipping restraints can be removed from cable ends, air

and hydraulic lines, and cylinder rod. Pull cables, air and

fluid lines out for assembly. Make sure cables are in proper

sheave grooves, Fig. 3.

C. Position front and rear yokes at respective ends of

runway, Fig. 1. Feed cable ends through yoke end, Fig. 4. Do

not assemble sheaves in yoke ends at this time.

Be sure cables are not crossed inside yoke.

Cotter Pin Should Be

On Outside Of

Runway

Bolts

Runway

Right Rear

Left Rear

Cable (#4)

Cable

Rear

(Viewed from rear)

(#3)

Fig. 3

Right Front Column

Permanent

Wheel Stop

Alignment Holes

For Runway Adjustment

Right Runway

Fig. 4

D. Lay right runway in place on yoke. Slide right runway toward

outside of lift until holes in yoke and runway line up, Fig. 4.

Hold runway in place and bolt on ramp/chock and wheel

stops to runway using ten 5/8” x 2 1/2” bolts and flange nuts.

Square up yokes with runways using four 3/4”-10NC x 2” lg.

bolts, 3/4” flat washers, 3/4” lock washers, and shims. Ramp/

chocks go on rear, Fig. 5. and Fig. 6. Repeat for left runway.

E. Insert each end of the left runway’s 1/4” air line into the Tee’s

connecting the locking latch air cylinders in each yoke, Fig. 7.

Fig. 5

Flange

Nuts

Shim

3/4" x 2" lg. Bolts

3/4" Lock Washers

3/4" Flat Washers

Permanent

Wheel Stop

Bolts

3/4" x 2" lg. Bolts

3/4" Lock Washers

3

Shim

3/4" Flat Washers

Runway

Fig. 6

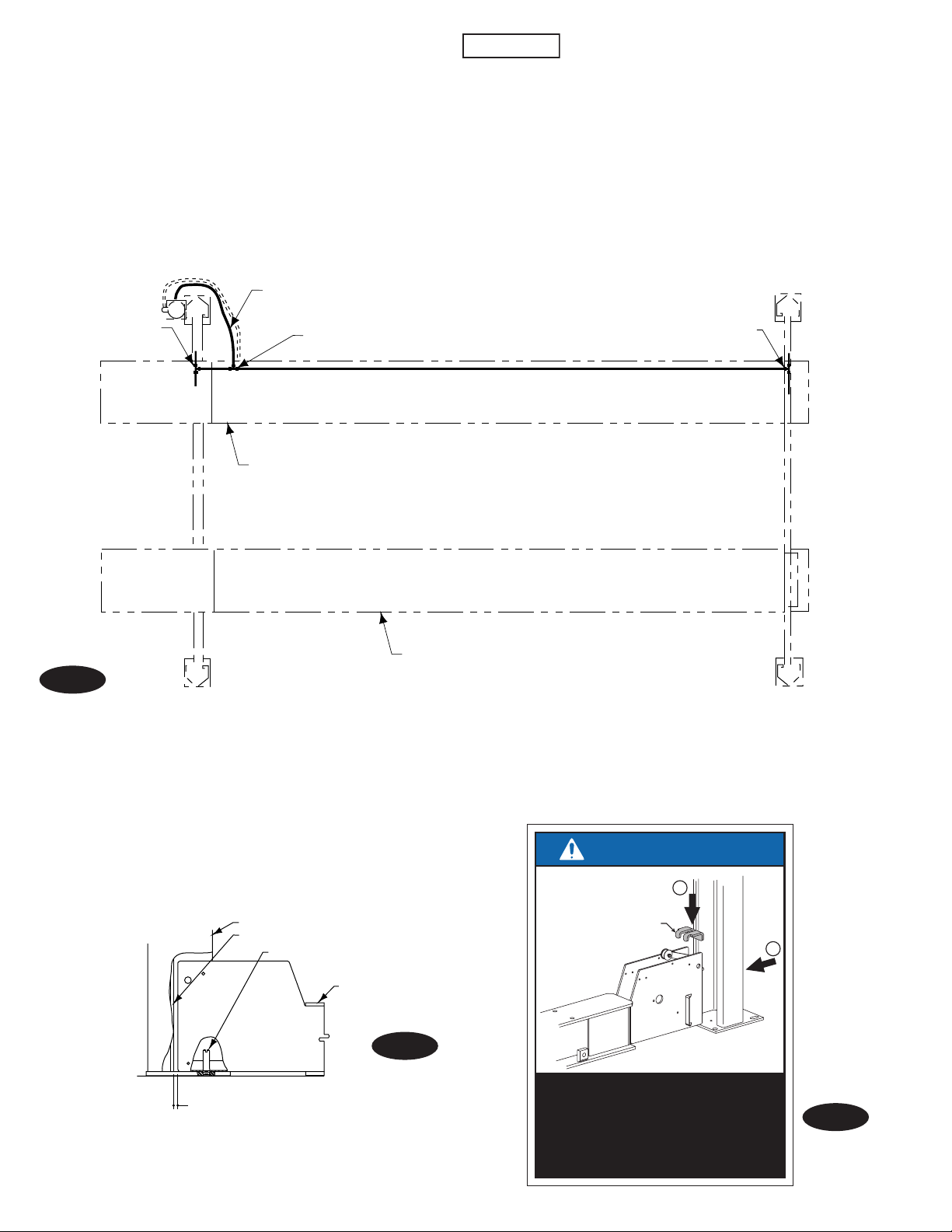

5. Columns:

IMPORTAN T

Note: Columns are not interchangeable. They must be set at their

respective corner of the lift. Column double return bend is always

to inside of lift, Fig. 9. Place the power unit column at the left

rear corner of the lift. The point where the hydraulic hose passes

through side of left runway should be visible from this corner.

Insert alignment stud through hole in yoke end and thread into

base plate of column, Fig. 8. Repeat for other columns.

The yoke/column alignment studs MUST be used

for proper centering of columns to yokes, Fig. 8. A gap of

5/16” must be maintained between column and yoke.

See step 6 B. Note: It may be necessary to remove Plastic Slider

from Column Stop on yoke end, Fig. 10, before aligning yoke

in column. After yoke is in column, reinstall Plastic Slider and

secure with 5/16” button head screw.

Fig. 7

Tee

Air Line To

Lift

Tee

Left Runway

Air Line in Runway

Tee

Right

Runway

Alignment Stud

Column

Latch Bar

Alignment Stud

Yoke Assembly

Fig. 8

5

/

" REF. Between Yoke End and Latch Bar

16

IMPORTANT

1

Ears Of

Spacer

2

Use Yoke Spacer As Shown To

Maintain 5/16" Of Gap From End

Of Yoke To Front Of Latch Bar.

Be Sure To Remove Spacer

After Installation.

4

Fig. 8a

Power Unit Column

Tapping

Plastic Slider

Plastic Slider

Check Lift Dimensions

Double Return Bend always

to the Inside of Lift.

RFL25 ....... 177 1/8" Ref.

SM30S ........ 249 1/8" Ref.

SM30L ........ 285 1/8" Ref.

SM30EL......321 1/8" Ref.

Between Columns

Width and length measurements are made from column

sides, NOT column base plate. Diagonals are measured from

inside corner of column.

Left Front

Column

APPROACH

Right Rear Column

Left Runway

Column Stop

Diagonals

Within

Right Runway

1

133 1/4" Ref.

/ 4 "

Fig. 9

Right Front Column

1

/4"

Screw

Fig. 10

5

Loading...

Loading...