O

O

P

P

E

E

R

R

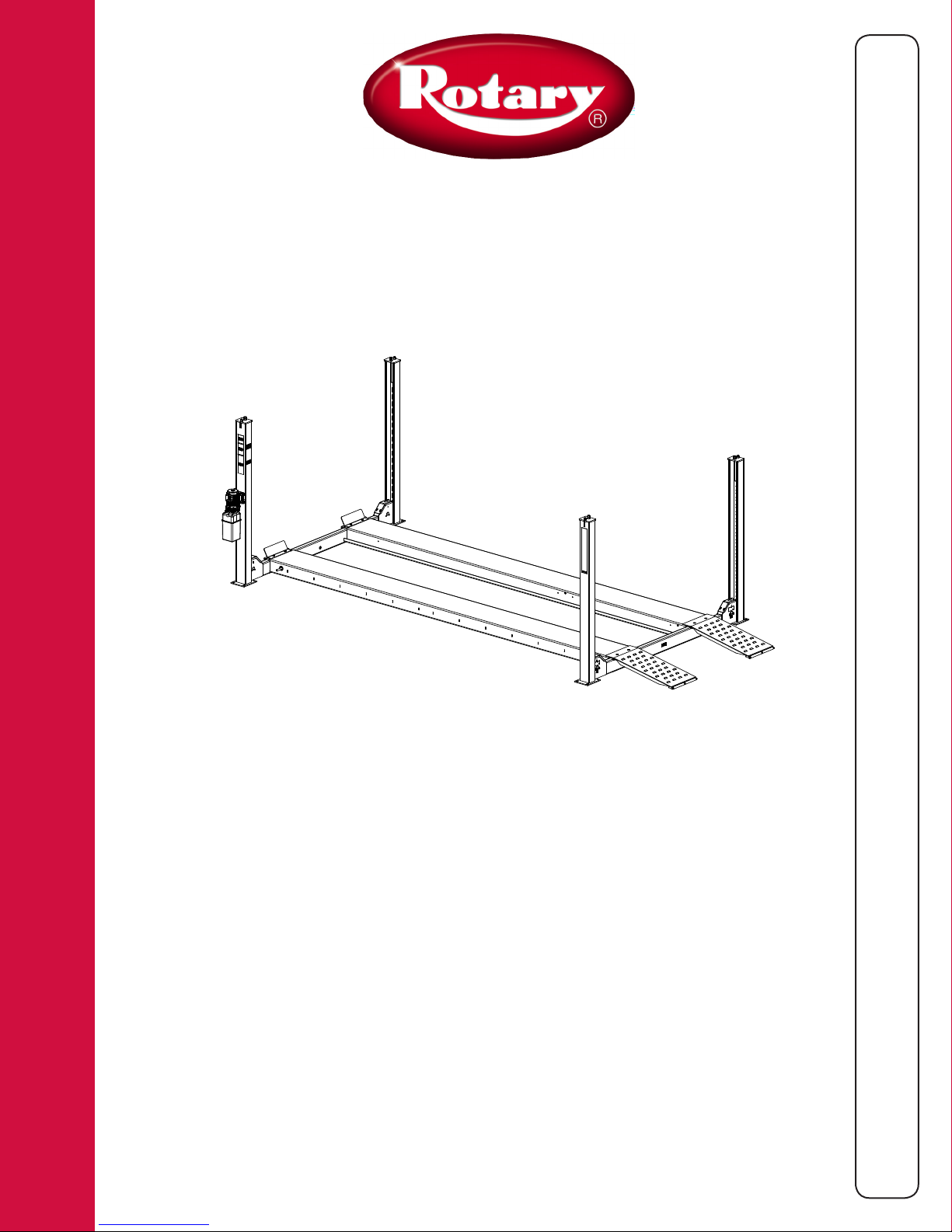

AR14/SM14/ARO14/SMO14

(100 Series) Four Post Surface Mounted Lift

Capacity 14,000 lb.

(6,350 kg.)

Español Página 13

(7,000 lbs.

(3,175 kg.)

per axle)

A

A

T

T

I

I

O

O

N

N

&

&

M

M

A

A

I

I

N

N

T

T

Français Page 25

Owner/Employer Responsibilities .............................2

Safety Instructions ......................................................3

Operating Instructions ................................................4

Maintenance Instructions ..........................................5

Trouble Shooting ..........................................................6

Lift Lockout/Tagout Procedure ..................................7

Operating Conditions ................................................... 12

Approved Accessories ...............................................12

© July 2017 by Vehicle Service Group. All rights reserved. CO10102

TABLE OF CONTENTS:

LP20610/LP20618

OM20220

Rev. C 7/21/2017

E

E

N

N

A

A

N

N

C

C

E

E

M

M

A

A

N

N

U

U

A

A

L

L

The Owner/Employer:

• The Owner/Employer shall ensure that lift operators are qualified and that they are

trained in the safe use and operation of the lift using the manufacturer’s operating

instructions; ALI/SM 10-1, ALI Lifting it Right safety manual; ALI-ST-10 ALI Safety

Tips card; ANSI/ALI ALOIM-2008, American National Standard for Automotive LiftsSafety Requirements for Operation, Inspection and Maintenance; ALI/WL Series, ALI

Uniform Warning Label Decals/Placards; and in the case of frame engaging lifts, ALI/

LP-GUIDE, Vehicle Lifting Points/Quick Reference Guide for Frame Engaging Lifts.

• The Owner/Employer shall establish procedures to periodically inspect the lift in

accordance with the lift manufacturer’s instructions or ANSI/ALI ALOIM-2008,

American National Standard for Automotive Lifts-Safety Requirements for Operation,

Inspection and Maintenance; and The Employer Shall ensure that lift inspectors are

qualified and that they are adequately trained in the inspection of the lift.

• The Owner/Employer shall establish procedures to periodically maintain the lift

in accordance with the lift manufacturer’s instructions or ANSI/ALI ALOIM-2008,

American National Standard for Automotive Lifts-Safety Requirements for Operation,

Inspection and Maintenance; and The Employer Shall ensure that lift maintenance

personnel are qualified and that they are adequately trained in the maintenance of

the lift.

• The Owner/Employer shall maintain the periodic inspection and maintenance records recommended by the manufacturer or ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection

and Maintenance.

• The Owner/Employer shall display the lift manufacturer’s operating instructions; ALI/

SM 10-1, ALI Lifting it Right safety manual; ALI-ST-10 ALI Safety Tips card; ANSI/ALI

ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements

for Operation, Inspection and Maintenance; and in the case of frame engaging lifts,

ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference Guide for Frame Engaging Lifts;

in a conspicuous location in the lift area convenient to the operator.

• The Owner/Employer shall provide necessary lockout/tagout means for energy

sources per ANSI Z244.1-1982 (R1993), Safety Requirements for the Lockout/Tagout

of Energy Sources, before beginning any lift repairs.

• The Owner/Employer shall not modify the lift in any manner without the prior written

consent of the manufacturer.

2

SAFETY INSTRUCTIONS

• Never allow unauthorized or untrained persons to operate lift or rolling jacks.

• Shop Policy should prohibit customers or non-authorized persons from being in shop area while lift is in use.

• Thoroughly train all employees in the use and care of lift and rolling jacks.

• Be Sure no one is standing in front or behind lift while vehicle is being driven onto or backed off the lift.

• DO NOT allow rear tires or portion of vehicle to interfere with ramp/chocks.

• Be Sure front wheel stops are in raised position before driving vehicle onto lift.

• Never allow front wheels to strike the front wheel stops.

• DO NOT permit employees or customers on lift when it is either being raised or lowered.

• Always stand clear of lift when raising or lowering and observe “Pinch Points” Warning.

• Never overload lift: capacity of lift is 14,000 lbs. (6,350 kg.) (7,000 lbs. (3,175 kg.) per axle). CAPACITY SHOULD

NOT BE EXCEEDED.

• Always engage parking brake and use the rear wheel chocks to keep the vehicle from rolling freely on the

runways.

• Always lower lift on locks before working on vehicle.

• Keep area around lift clean of tools, debris, grease, and oil.

• Always keep runway clean.

• Replace all caution, warning, or safety related decals on the lift when unable to read or missing.

• For Rolling Jack Safety Instructions see Rolling Jack Installation, Operation and Maintenance Instructions in

the rolling jack box.

• Never use work step while lift is in a raised position.

3

OPERATING INSTRUCTIONS

WARNING

WARNING

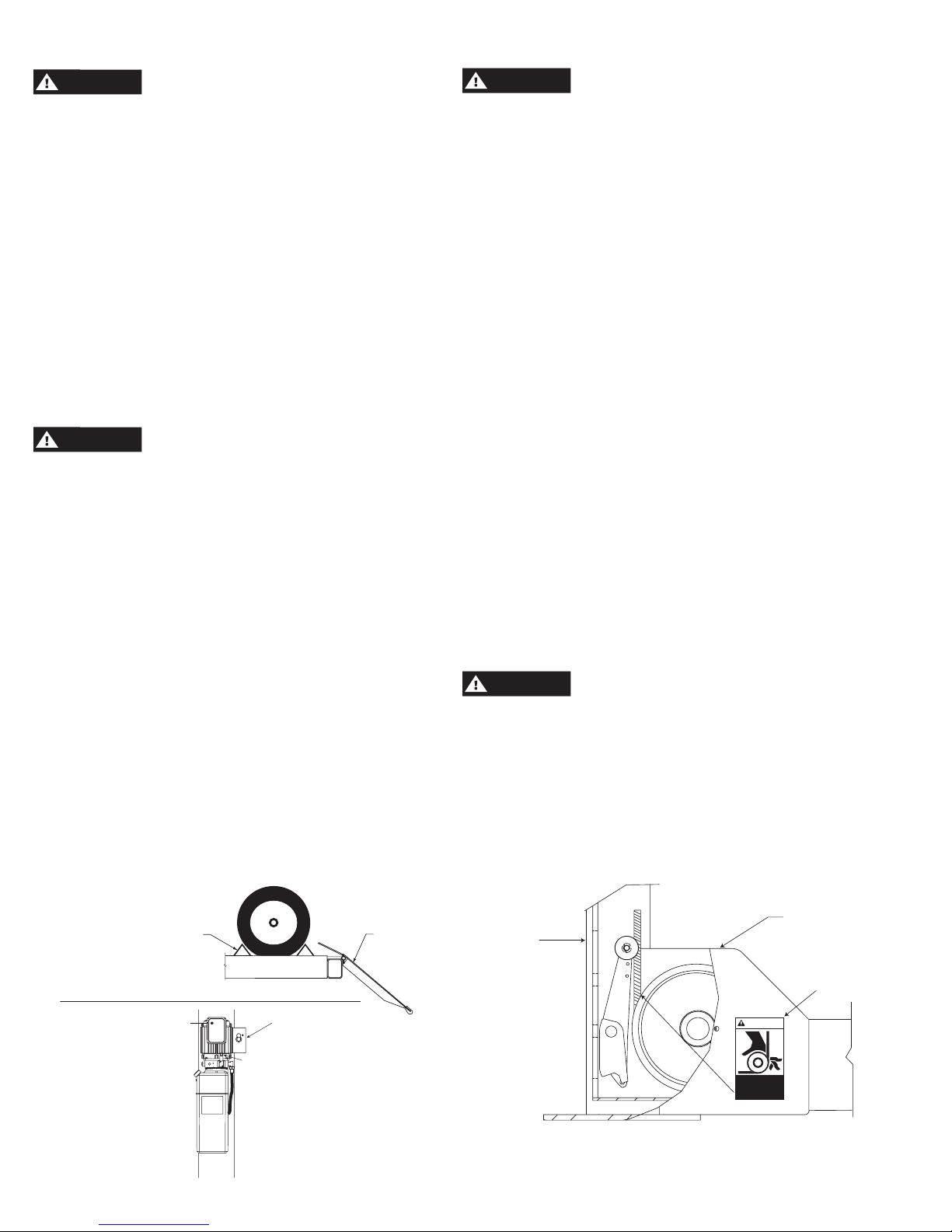

Fig. 2 Fig. 3

arning

WARNING

WARNING

To avoid personal injury and/or property dam-

age, permit only trained personnel to operate lift.

After reviewing these instructions, get familiar with lift con-

trols by running the lift through a few cycles before loading

vehicle on lift.

Observe and heed SAFETY and WARNING labels on the lift.

Note: The EL2 Model was designed for 131” (332.8 cm) or longer

wheelbase at the rated 14,000 lb. (6,350 kg.) capacity.

1. Loading: Lift must be fully lowered and no one in service

bay while the vehicle is brought on lift.

2. If lift is equipped with rolling jacks, jacks must be fully

lowered and the rear jack pushed toward center of lift to

provide under car clearance.

Engage runway locks before raising vehicle on

jacks! DO NOT operate lift while jacks are engaged with a

vehicle!

3. Stop vehicle when it contacts the front wheel stops. At all

times, be sure rear wheels are forward of the ramp/chocks

and the ramp/chocks will clear tires when the lift is raised,

Fig. 1. Driver and passengers must exit before raising.

The runways, ramps and connecting yokes at

each end of lift are designed to rest on the floor when fully

lowered. Observe pinch point warning decals, Fig. 3.

8. Repeat Step 2.

9. To Lower Lift: If lift has been resting on the locking latches,

lift must be raised high enough for all four latches to clear

the latch plate slots inside the columns.

10. Actuate the latch release valve on the power unit column to

disengage all four locking latches, Fig. 2. Hold actuator until

lift has fully lowered.

Note: If actuator on air valve is released, the latches will auto-

matically reset to the engaged position.

11. Push the lowering handle on the power unit to lower lift, Fig.

2. Lowering speed can be controlled by the force applied to

the lowering handle.

12. Observe lift and vehicle to be sure lift is level while being

lowered. If not, STOP repeat Steps 10 through 13.

13. Fully lower lift, remove the triangular wheel chocks and

check to be sure area is clear before removing vehicle from

lift, Fig. 1.

4. Place triangular wheel chocks on each side of one of the

rear tires, Fig. 1.

5. To Raise Lift: Push the “RAISE” button on the power unit.

Release button at desired height, Fig. 2.

6. For Rolling Jack Operating Instructions see Rolling Jack

Installation, Operation and Maintenance Instructions in the

rolling jack shipping carton.

7. Before Lowering Lift: Be sure no one is in the lift area and

that all tools, tool trays, etc. have been removed from under

the lift and vehicle.

Triangular

Wheel Stops

Rear Wheel

Chock

Fig. 1

RAISE

Button

Latch Release

Air Button

14. If your lift is not operating properly, DO NOT use until adjustments or repairs have been made by qualified lift service

personnel.

Keep hands clear of yoke ends while the lift is

being raised or lowered, Fig. 3.

*Maximum operation pressure is:

2755 psi (18995 kPa) for AR14

2973 psi (20498 kPa) for ARO14

2538 psi (17499 kPa) for SM14

2973 psi (20498 kPa) for SMO14

Yoke End

Column

Hands

Clear

W

CAUTION

LOWERING

Handle

Keep hands clear

of yoke ends

during lift

operation.

4

WARNING

MAINTENANCE INSTRUCTION

If you are not completely familiar with automotive lift maintenance procedures, STOP. Contact

factory for instructions.

To Avoid Personal Injury, permit only qualified lift service personnel to perform maintenance on this equipment.

• Periodically: Check all column, lift/runway attaching bolts for tightness.

• Always raise lift when cleaning floor area with solvents and/or cleaning compounds.

• Always keep runways and linkages clean. In salt belt or other corrosive environments, the lift must be

washed down weekly.

• Always: Replace slack cable device springs when replacing new cables.

• Never: Grease rollers or pins on open yoke lifts.

• Daily: Check cables and sheaves for wear. Observe for frayed cable strands. Wipe cables with a rag to detect hard to see small broken cable strands. Replace cables showing any broken strands. Replace worn parts

as required with genuine Rotary parts.

• Daily: Inspect front wheel stops and ramp/chocks for damage or excessive wear. Replace as required with

genuine Rotary parts.

• Daily: Check locking latch operation and reset. Adjust per instructions or repair if required with genuine

Rotary parts.

• Weekly: Clean foreign debris from rear wheel slip plates and turning radius gauges by blowing out with shop

air. DO NOT GREASE BALL BEARINGS.

• Weekly: Check torque on the column anchor bolts per specifications .

• Monthly: Clean wire rope cables with lift in both lowered and raised position by spraying with penetrating oil and

wiping the cable down.

• Monthly: Check cables for ware. Refer to 4-Post Inspection and Maintenance Guide for ware inspection informa-

tion.

• Monthly: Check level of runway. Adjust per instructions.

• Monthly: Lubricate Guide on each turning radius with a dry film lubricant. Clean and lubricate more often as

conditions warrant.

• Semi-Annually: Check fluid level of lift power unit and refill if required. If fluid is required, inspect all fittings,

hoses and seals. Repair as required.

• Semi-Annually: Lubricate front wheel stop and ramp/ chock hinge pins.

IMPORTANT

Cable adjustment should be checked by a Rotary Authorized Installer after the first 50 loaded lift

cycles and after 300 loaded lift cycles.

• For Rolling Jack Maintenance Instructions see Rolling Jack Installation, Operation and Maintenance Instructions in the rolling jack box.

5

Trouble

Motor does not run.

TROUBLE SHOOTING

Cause

1. Check fuse or circuit breaker.

2. Check for correct voltage to motor.

3. Inspect all wiring connections.

Remedy

1. Replace blown fuse or reset circuit

breaker.

2. Supply correct voltage to motor.

3. Repair and insulate all connections.

Motor runs but will not raise lift.

Motor runs—raises unloaded lift but will

not raise vehicle.

Lift slowly settles down.

Slow lifting speed or fluid blowing out filler

breather cap.

Lift going up unlevel.

4. Switch burned out.

5. Motor windings burned out.

1. Open lowering valve.

2. Pump sucking air.

3. Suction stub off pump.

4. Low fluid level.

1. Motor running on low voltage.

2. Trash in lowering valve.

3. Improper relief valve adjustment.

4. Overloading lift.

1. Trash in check valve seat.

2. Trash in lowering valve seat.

3. External fluid leaks.

1. Air mixed with fluid.

2. Air mixed with fluid suction.

3. Fluid return tube loose.

1. Cables out of adjustment.

2. Lift installed on unlevel floor.

4. Replace switch.

5. Replace motor.

1. Repair or replace lowering valve.

2. Tighten all suction line fittings.

3. Replace suction stub.

4. Fill tank with Dexron III ATF.

1. Supply correct voltage to motor.

2. Clean lowering valve.

3. Replace relief valve cartridge.

4. Check vehicle weight and/or balance

vehicle weight on lifts.

1. Clean check valve.

2. Clean lowering valve.

3. Repair external leaks.

1. Change hydraulic fluid to Dexron III

ATF.

2. Tighten all suction line fittings.

3. Reinstall fluid return tube.

1. Adjust slack out of cable.

2. Shim lift to level columns (Not to

exceed 1/2” (13mm) per column).

Lift stops short of full rise or chatters.

Anchors will not stay tight.

Lift will not lower.

1. Low on fluid.

1. Holes drilled oversize.

2. Concrete floor thickness or holding

strength not sufficient.

1. Insufficient air supply to lift.

2. Latches out of adjustment.

Note: Shim thickness of 2” (51mm) is

possible by using optional shim kit

#FC5393. Contact your authorized

Rotary Parts Distributor for ordering

information.

1. Check fluid level and bleed cylinder

If fluid is required inspect all fittings,

hoses, and seals. Repair as required.

Clean power unit pickup stub filter.

1. Use a fast setting cement to pour

into oversize holes and reset anchors

-or- relocate lift using a new bit to drill

holes.

2. Break out old concrete and repour

new pads for lift.

1. Check air pressure. Air supply to lift

should be between: min. 100 p.s.i. and

max. 120 p.s.i. (min. 690 kPa and max.

827 kPa). Check all lines and fittings

for leaks or crimps. Repair or replace

as required.

2. Check latches.

6

Trouble

Lift will not raise off of latches.

TROUBLE SHOOTING

Cause

1. Motor, pump, or cylinder failure.

Remedy

1. Contact lift manufacturer’s Customer

Service.

7

Purpose

LIFT LOCKOUT/TAGOUT PROCEDURE

This procedure establishes the minimum requirements for the lockout of energy that could cause injury to personnel by the operation of lifts in need of repair or being serviced. All employees shall comply with this procedure.

Responsibility

The responsibility for assuring that this procedure is followed is binding upon all employees and service personnel from outside service companies (i.e., Authorized Rotary Installers, contactors, etc.). All employees shall

be instructed in the safety significance of the lockout procedure by the facility owner/manager. Each new or

transferred employee along with visiting outside service personnel shall be instructed by the owner/manager (or

assigned designee) in the purpose and use of the lockout procedure.

Preparation

Employees authorized to perform lockout shall ensure that the appropriate energy isolating device (i.e., circuit

breaker, fuse, disconnect, etc.) is identified for the lift being locked out. Other such devices for other equipment

may be located in close proximity of the appropriate energy isolating device. If the identity of the device is in

question, see the shop supervisor for resolution. Assure that proper authorization is received prior to performing

the lockout procedure.

Sequence of Lockout Procedure

1) Notify all affected employees that a lockout is being performed and the reason for it.

2) Unload the subject lift. Shut it down and assure the disconnect switch is “OFF” if one is provided on

the lift.

3) The authorized lockout person operates the main energy isolation device removing power to the sub-

ject lift.

• If this is a lockable device, the authorized lockout person places the assigned padlock on the

device to prevent its unintentional reactivation. An appropriate tag is applied stating the person’s

name, at least 3” x 6” (76mm x 152mm) in size, an easily noticeably color, and states not to

operate device or remove tag.

• If this device is a non-lockable circuit breaker or fuse, replace with a “dummy” device and tag it

appropriately as mentioned above.

4) Attempt to operate lift to assure the lockout is working. Be sure to return any switches to the “OFF”

position.

5) The equipment is now locked out and ready for the required maintenance or service.

Restoring Equipment to Service

1) Assure the work on the lift is complete and the area is clear of tools, vehicles, and personnel.

2) At this point, the authorized person can remove the lock (or dummy circuit breaker or fuse) & tag

and activate the energy isolating device so that the lift may again be placed into operation.

Rules for Using Lockout Procedure

Use the Lockout Procedure whenever the lift is being repaired or serviced, waiting for repair when current

operation could cause possible injury to personnel, or for any other situation when unintentional operation could

injure personnel. No attempt shall be made to operate the lift when the energy isolating device is locked out.

8

Notes:

Notes:

Notes:

Loading...

Loading...