Rotary SL212i 400 Series, SL29i 400 Series Operation & Maintenance Manual

SL29i/SL212i

(400 Series)

SL29i Capacity 9,000 lbs.

SL212i Capacity 12,000 lbs.

O

O

P

P

E

E

R

R

A

A

T

T

I

I

O

O

N

N

&

&

M

M

Table Of Contents

Introduction ........................................................................ 2

Owner/Employer Responsibilities .................................... 3

Safety Instructions ............................................................. 4

Operating Instructions ...................................................... 6

Maintenance Instructions.................................................. 10

Trouble Shooting ................................................................ 11

Manual Lowering of Lift..................................................... 14

Date and Time Setting ....................................................... 16

Timer and Alarm Setting .................................................... 17

Rotary Contact Information ............................................... 18

Change Language .............................................................. 19

A

A

I

I

N

N

T

T

E

E

N

N

A

A

N

N

C

C

E

E

M

M

A

A

N

N

U

U

Installer: Please return this booklet to literature package and give to lift owner/operator.

© January 2003 by Rotary Lift.

LP20089

OM20120

Rev. B 01/28/03

A

A

L

L

INTRODUCTION

The Rotary inbay technology lift represents a

technological advancement that brings the power of

information right into the service bay.

• Bay management tools include owner and operator

instructions, maintenance reminders, troubleshooting

tips, date and time display and illustrated pickup

points.

• Convenience features include integrated air and

GFCI-protected electric connections at the control

panel, as well as a telephone/data port on the console.

• Ergonomics are improved by the use of soft touch

membrane controls for single-hand lift operation.

• On-board training is accessible at any time with the

touch of a button.

• Advanced safety include an OSHA compliant

lockable disconnect switch.

• Audible alarm, with an on/off option, signals when

the lowering button has been activated.

• Low voltage operation (24v) in the event of a shorted

or grounded circuit reduces the risk of shock.

• Liquid Detection System in the containment housing

and on-screen alerts help prevent accumulation of

water.

2

C

A

U

T

IO

?

?

Lift to be used

by trained operator

only.

SAFETY

INSTRUCTIONS

OWNER/EMPLOYER RESPONSIBILITIES

The Owner/Employer:

• Shall ensure that lift operators are qualified and that they are trained in the safe

use and operation of the lift using the manufacturer’s operating instructions;

ALI/SM 93-1, ALI Lifting it Right safety manual; ALI/ST-90 ALI Safety Tips

N

?

©

card; ANSI/ALI ALOIM-2000, American National Standard for Automotive

Lifts-Safety Requirements for Operation, Inspection and Maintenance; ALI/WL

Series, ALI Uniform Warning Label Decals/Placards; and in the case of frame

engaging lifts, ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference Guide

for Frame Engaging Lifts.

• Shall establish procedures to periodically inspect the lift in accordance with the

lift manufacturer’s instructions or ANSI/ALI ALOIM-2000, American National

Standard for Automotive Lifts-Safety Requirements for Operation, Inspection

and Maintenance; and The Employer Shall ensure that lift inspectors are quali-

fied and that they are adequately trained in the inspection of the lift.

Proper maintenance

and inspection

is necessary

for safe operation.

• Shall establish procedures to periodically maintain the lift in accordance with

the lift manufacturer’s instructions or ANSI/ALI ALOIM-1994, American

National Standard for Automotive Lifts-Safety Requirements for Operation,

Inspection and Maintenance; and The Employer Shall ensure that lift mainte-

©

nance personnel are qualified and that they are adequately trained in the maintenance of the lift.

• Shall maintain the periodic inspection and maintenance records recommended

by the manufacturer or ANSI/ALI ALOIM-2000, American National Standard

for Automotive Lifts-Safety Requirements for Operation, Inspection and Maintenance.

• Shall display the lift manufacturer’s operating instructions; ALI/SM 93-1, ALI

Lifting it Right safety manual; ALI/ST-90 ALI Safety Tips card; ANSI/ALI

ALOIM-1994, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and Maintenance; and in the case of

frame engaging lifts, ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference

Guide for Frame Engaging Lifts; in a conspicuous location in the lift area

convenient to the operator.

• Shall provide necessary lockout/tagout means for energy sources per ANSI

Z244.1-1982 (R1993), Safety Requirements for the Lockout/Tagout of Energy

Sources, before beginning any lift repairs.

• Shall not modify the lift in any manner without the prior written consent of the

manufacturer.

3

TAB CAN BE PULLED

OUT AND LOCKED

IN THE OFF POSITION

SAFETY INSTRUCTIONS

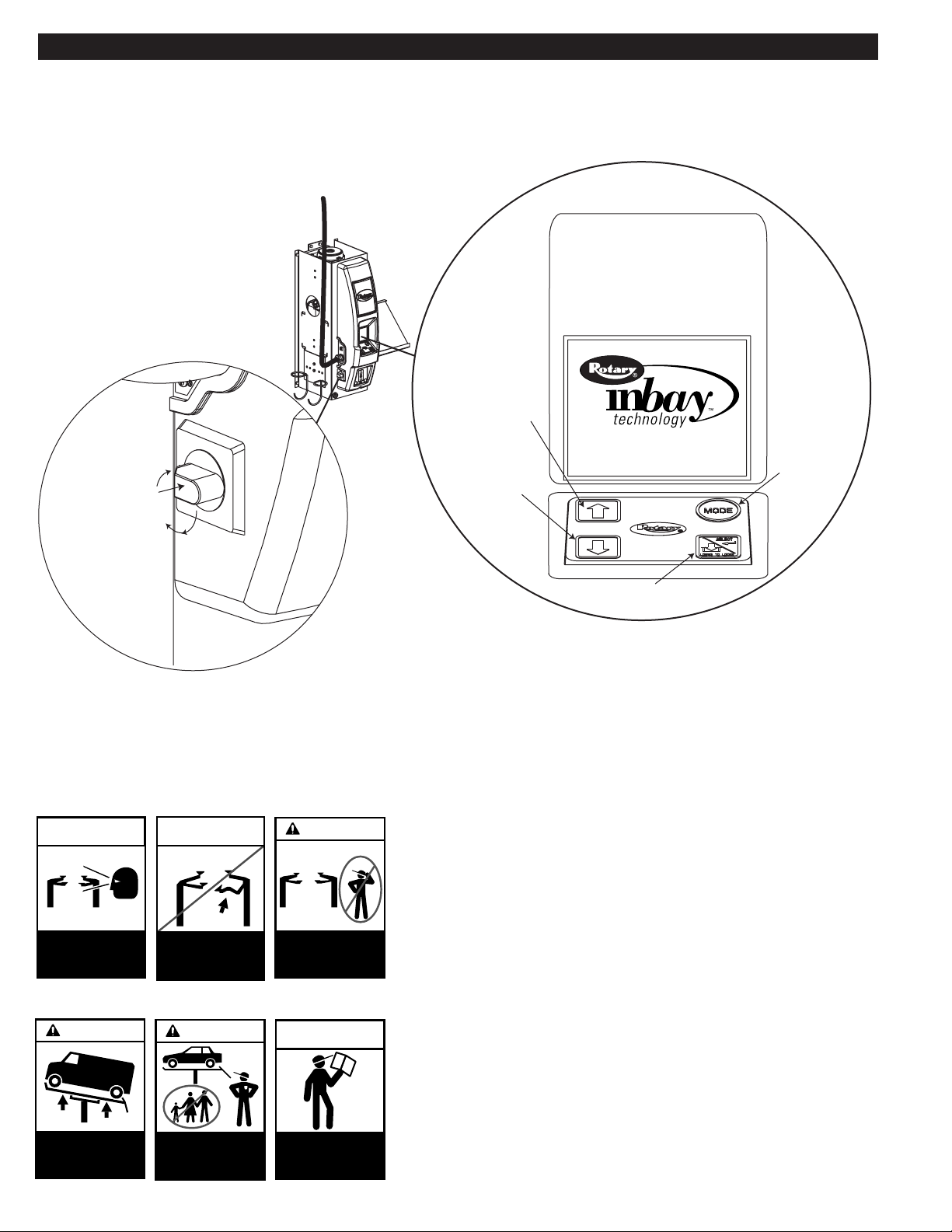

inbay Master Control Panel

Raise Lift / Scroll Up

1 O

N

FF

Lower Lift / Scroll Down

00/00/00 00:00

Mode Button

SAFETY

INSTRUCTIONS

Proper maintenance

and inspection

is necessary

for safe operation.

CAUTION

SAFETY

INSTRUCTIONS

Do not operate

a damaged lift.

©

CAUTION

CAUTION

Lift to be used

by trained operator

only.

©

SAFETY

INSTRUCTIONS

Menu Selection / Lower To Locks

• Daily inspect your lift. Never operate if it malfunctions or if it

has broken or damaged parts. Use only qualified lift service

personnel and genuine Rotary parts to make repairs.

?

?

?

• Thoroughly train all employees in use and care of lift, using

manufacturer’s instructions and Lifting It Right and Safety

Instructions supplied with the lift.

©

• Never allow unauthorized or untrained persons to position

vehicle or operate lift.

• Prohibit unauthorized persons from being in shop area while

lift is in use.

Auxiliary adapters

may reduce

load capacity.

Authorized personnel

only in lift area.

©

Read operating

and safety manuals

before using lift.

©

• Do Not permit anyone on lift or inside vehicle when it is

either being raised or lowered.

• Always keep area around lift free of tools, debris, grease and

©

oil.

4

SAFETY INSTRUCTIONS

WARNING

Keep feet

clear of lift

while lowering.

WARNING

Avoid excessive

rocking of vehicle

while on lift.

WARNING

CAUTION

Use vehicle

manufacturer’s

©

lift points.

©

WARNING

Clear area if vehicle

is in danger of falling.

©

WARNING

Remain clear of lift

when raising or

lowering vehicle.

Use height extenders

when necessary

to ensure

©

good contact.

• Never overload lift. Capacity of lift is shown on nameplate affixed to the lift.

• Do Not stand in front of the lift or vehicle while it is being positioned in the lift bay.

• Do Not hit or run over lift arms or adapters. This could damage lift or vehicle. Before

driving vehicle into bay, position arms and adapters to provide unobstructed entrance

onto lift.

©

• Always use all four adapters when raising vehicle. Never use just two adapters to raise

just one side or one end of the vehicle.

• Load vehicle on lift carefully. Position lift adapters to contact the vehicle at vehicle

manufacturer’s recommended lift points.

CAUTION

©

Position vehicle

center of gravity

over lift.

WARNING

Do not override

self-closing

lift controls.

CAUTION

IMPORTANT

CAUTION

©

• Remain clear of lift and vehicle when lowering.

The center cover is designed for foot traffic only.

DO NOT go under vehicle if locking latches are not engaged.

• Always use safety stands when removing or installing heavy components.

• Avoid excessive rocking of vehicle while on lift.

• Clear area if vehicle is in danger of falling.

• Remove tool trays, stands, etc. before lowering lift. Release locking latch before

attempting to lower lift.

©

• Position lift arms and adapters to provide an unobstructed exit before removing vehicle

from lift area.

• Do Not perform any maintenance on the power unit, control valves, air or fluid lines,

hydraulic cylinders, or check fluid level until lift has been fully lowered and all pressure

has been released from system. Follow OSHA Lockout/Tagout procedures as they apply;

reference ANSI Z244.1.

Always use

safety stands when

removing or installing

heavy components.

©

5

OPERATING INSTRUCTIONS

C

A

U

T

IO

N

Lift to be used

by trained operator

only.

©

?

?

?

C

A

U

T

IO

N

Authorized personnel

only in lift area.

©

WARNING

To avoid personal injury and/or property damage, permit only trained personnel to

operate lift. After reviewing these instructions, get familiar with lift controls by running

the lift through a few cycles before loading vehicle on lift.

IMPORTANT

Always lift the vehicle using all four adapters. NEVER raise just one end, one corner, or

one side of vehicle.

WARNING

If Lift is not operating properly, DO NOT use until adjustments or repairs are made by a

qualified lift service personnel.

Observe and heed SAFETY, CAUTION, and

WARNING labels on the lift.

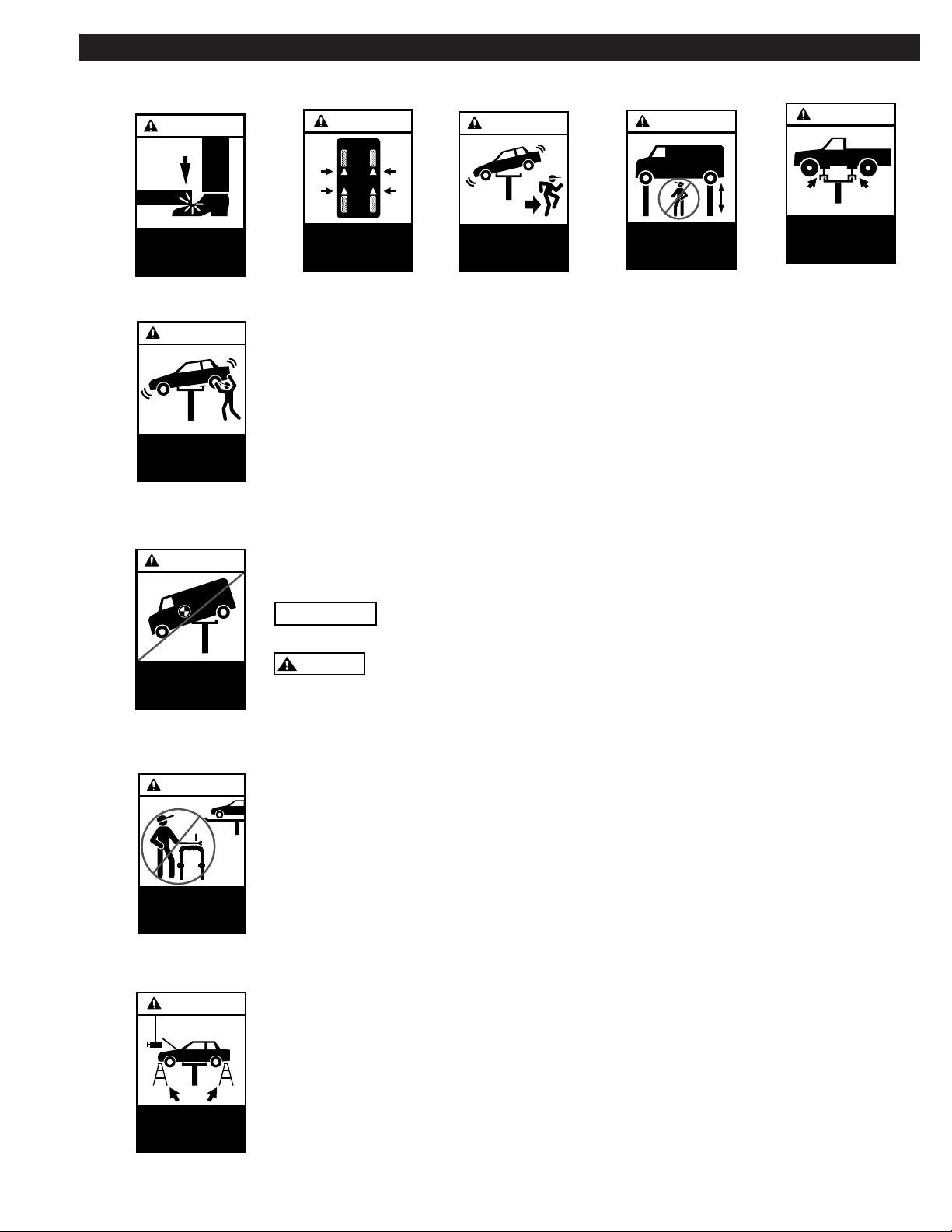

1. Lift must be fully lowered and service bay clear of all

personnel before the vehicle is brought on lift. Do not

stand in the front of a moving vehicle.

2. Position lift arms and adapters to provide unobstructed

entrance of vehicle onto lift.

3. Spotting: Spot vehicle on lift with left front wheel in

proper spotting dish position, Fig. 1.

Typical Wheel Spotting Positions

Less than 105"

wheelbase:

position left front

wheel on approach

side of wheel dish.

105"-127"

wheelbase:

position left front

wheel in wheel

dish.

Fig. 1

4. Lift Controls: The lift controls are on the touch pad,

Fig. 5. The lift will cease to run when you stop

pressing the buttons on the touch pad.

5. Loading: Position arms and adapters at the vehicle

manufacturer’s recommended lift points. Use

intermediate, high step or optional adapters/extensions

for under-body clearance when required, Fig. 3 and Fig. 4.

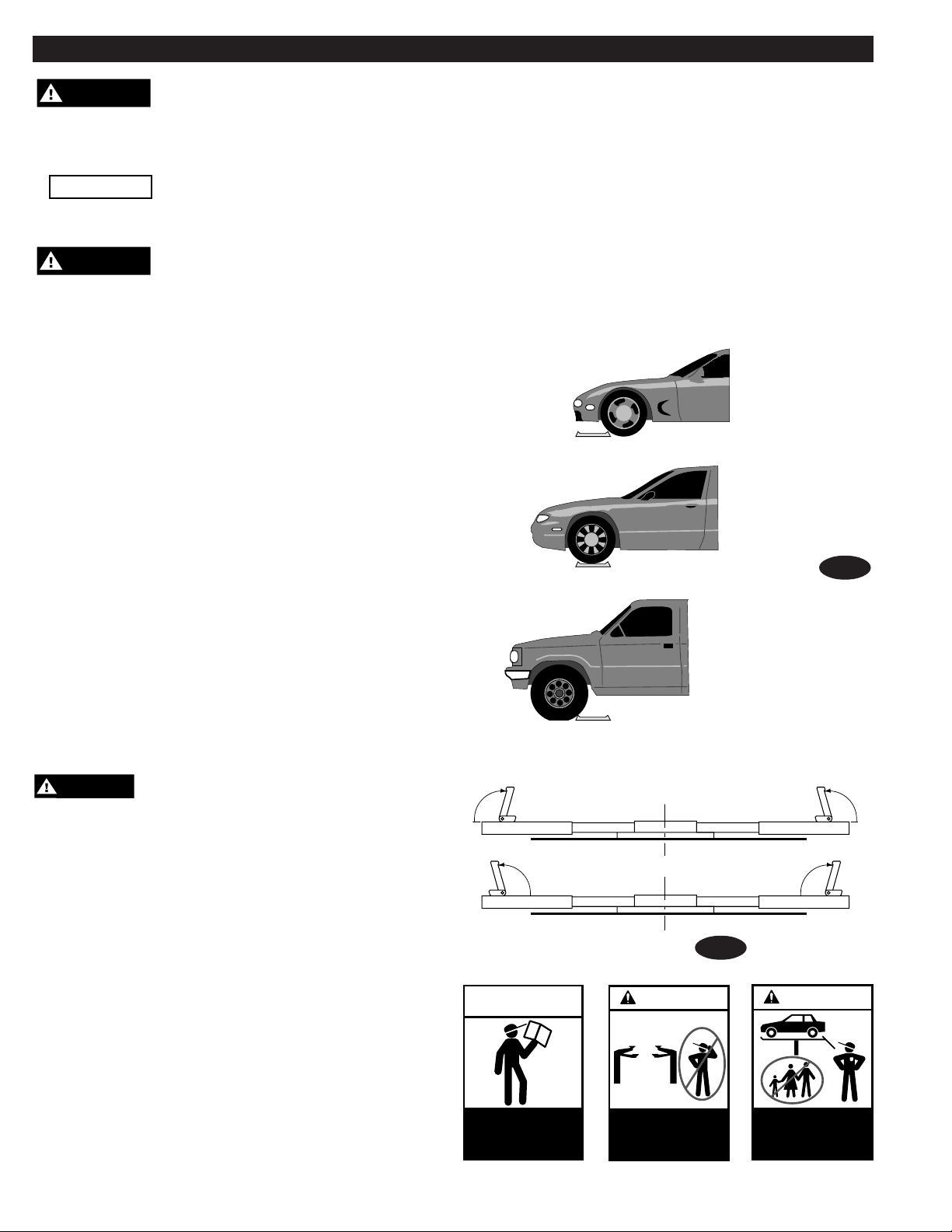

WARNING

Before attempting to lift pick-up trucks or

other truck frame vehicles, be sure that:

A. Vehicle individual axle weight does not exceed one-half

lift capacity.

B. Adapters are in secure contact with frame at vehicle

manufacturer’s recommended lift points, Fig. 3 and Fig. 4.

C. Vehicle is stable on lift and neither “front” nor “tail”

end heavy.

D. Adequate overhead clearance is provided to raise

vehicle to desired height.

E. Rotate front and rear adapter to oppose each other when

using the high step adapter and/or any auxiliary height

extending adapter, Fig. 2.

Larger than 127"

wheelbase:

position left front

wheel just forward

of wheel dish.

Center of Lift

Fig. 2

SAFETY

INSTRUCTIONS

Note: Allow 2 seconds between motor starts. Failure to

comply may cause motor burnout.

Read operating

and safety manuals

before using lift.

6

©

Loading...

Loading...