sss1. Introduction

2-Post Vehicle Lift

SGL35

O

O

PP

EE

RR

AA

TT

II

N

N

GG

aa

n

n

dd

M

M

AA

II

NN

TT

EE

NN

AA

© Rotary Lift, 03/2013 ● 117592 ● Rev. C

NN

CC

EE

M

M

AA

N

N

U

U

AA

LL

EC Declaration of Conformity

according to EC directive 2006/42/EC on machinery (Annex II A)

Name and address of the manufacturer:

BlitzRotary GmbH

Hüfinger Str.55

78199 Bräunlingen, Germany

This declaration relates exclusively to the machinery in the state in which it was placed on the market, and excludes

components which are added and/or operations carried out subsequently by the final user. The declaration is no more

valid, if the product is modified without agreement.

Herewith we declare, that the machinery described below

Product denomination: 2-post vehicle lift

model / type: SGL35

Capacity 3500 kg

machinery / serial number: ………………..

Year of manufacture: 20…

Complies with all essential requirements of the Machinery Directive2006/42/EC

In addition the partly completed machinery is in conformity with the EC Directives 2004/108/EC relating to

electromagnetic compatibility and 2006/95/EC relating to electrical equipment

met in accordance with Annex I No. 1.5.1 of the Machinery Directive 2006/42/EC).

(Protection objectives have been

Harmonised Standards used:

EN 1493: 2010 Vehicle lifts

EN ISO 12100-1 : 2003 Safety of Machinery- Basic concepts

EN ISO 12100-2 : 2003 Safety of Machinery- Basic concepts

EN 60204-1:2006+7/2007 Electrical equipment of machines

EN 349:1993+A1:2008 Safety of machinery - Minimum gaps

EN ISO 13850:2008 Safety of machinery – Emergency stop

EN ISO 14121-1:2007 Safety of machinery - Risk assessment

Other technical standards and specifications used:

BGG 945 inspection of vehicle lifts

BGR 500 management of working appliances

BGV A3 Accident prevention regulation of electric facilities and equipment

The person authorised to compile the relevant technical documentation:

Herr Pohl; Hüfinger Str. 55; 78199 Bräunlingen

Place : Bräunlingen

Date : 19.03.2013

______________________

Frank Scherer

Managing Director

Reg-Nr. 042_2006/42/EG

Contents

1. Introduction

6.4 Recommissioning the lift after incorrect

alignment of the slider blocks .............. 18

1. Introduction .................................................. 2

1.1 About this operating manual ................. 2

1.2 Important information for the machine

operator ................................................. 2

1.3 Specialist for safety related work .......... 3

1.4 In-house accident, health & safety and

environmental information ..................... 3

1.5 Warning and information symbols ......... 3

2. Intended use ................................................ 4

2.1 General .................................................. 4

2.2 Incorrect use .......................................... 4

3. The lift ........................................................... 4

3.1 Functionality .......................................... 4

3.2 System overview ................................... 5

3.3 Technical data ....................................... 6

3.4 Identification of lift.................................. 6

3.5 Permitted weight distribution ................. 7

3.6 Safety mechanisms ............................... 8

3.7 Control box ............................................ 9

4. Safety regulations ..................................... 10

4.1 General operation................................ 10

4.2 Operational safety, breakdowns .......... 10

4.3 Picking up loads .................................. 10

4.4 Up /down ............................................. 10

4.5 Installation, maintenance, servicing .... 10

5. Operation .................................................... 11

5.1 Emergency stop .................................. 11

5.2 Before use ........................................... 11

5.3 Switching on the equipment ................ 11

5.4 Driving the vehicle onto the lift ............ 11

5.5 Up / down ............................................ 11

5.6 Using the lift ......................................... 12

5.7 Before lowering the lift ......................... 12

5.8 Driving the vehicle from the lift ............ 12

5.9 Switch off the system .......................... 13

6. Action in the event of a fault .................... 14

6.1 Operator troubleshooting .................... 14

6.2 Troubleshooting for competent persons15

6.3 Emergency lowering ............................ 17

7. Maintenance ............................................... 19

7.1 Maintenance staff qualification ............ 19

7.2 Safety regulations ................................ 19

7.3 Maintenance schedule ......................... 19

7.4 Cleaning ............................................... 20

7.5 Check the hydraulic oil level ................ 20

7.6 Approved hydraulic oils ........................ 20

7.7 Check the hydraulic component seals . 20

7.8 Inspect and adjust the synchronisation

cables ................................................... 20

7.9 Carry out a function test ....................... 21

8. Repairs ........................................................ 21

9. Safety inspections ..................................... 21

10. Transport, storage ..................................... 21

10.1 Storage ................................................ 21

10.2 Trans port .............................................. 21

10.3 Unpacking ............................................ 22

11. Installation .................................................. 23

11.1 Installation guidelines .......................... 23

11.2 Mechanical installation ......................... 24

11.3 Hydraulic installation ............................ 26

11.4 Electrical connection ............................ 26

11.5 Final assembly of the mechanical unit . 27

12. Commissioning .......................................... 30

13. Disassembly ............................................... 32

14. Disposal ...................................................... 32

14.1 Packaging ............................................ 32

14.2 Environmental procedures for disposal32

14.3 Metals / Electronic waste ..................... 32

ANNEX ................................................................. 33

Diagrams, Spare parts lists, supplementary

instructions

Electrical Circuit diagram

Hydraulic diagram

Spare parts lists

Hydraulic power unit

117592 ● 03/2013

1

1. Introduction

g

1. Introduction

1.1 About this operating manual

The post lift conforms to state of the art technology

and complies with the applicable occupational

health & safety and accident prevention regulations.

Notwithstanding, improper use or use other than

that which is intended may result in a risk of fatal or

physical injury to the user or third parties and may

also result in damage to property.

It is therefore imperative that the relevant people

carefully read and understand this operating

manual.

Read the instructions carefully to prevent incorrect

use, potential hazards and damage. The post lift

should always be operated according to regulations.

Please note the following:

The operating manual must be kept close to the

lift and be easily accessible for all users.

Make sure that you have read and

understood Chapter 4, Safety Instructions

and also the operating instructions on the

machine.

We assume no liability for damage and

operational breakdowns which may occur as a

result of non-compliance with the instructions

contained within this operating manual.

Installation and commissioning of the lifts is

described in detail in Chapters 11 to 13.

Installation may only be carried out by

authorised installation specialists (trained by the

manufacturer) and qualified electricians.

If you should run into difficulties please contact a

specialist, our customer service.

Illustrations may differ from the supplied version

of the machine. Functions or processes to be

carried out remain the same.

Disclaimer:

We assume no responsibility for printing errors,

mistakes and technical changes.

The brands and trade marks mentioned in this

document refer to their owners or the products

thereof.

This is the ori

inal manual in German.

1.2 Important information for the

machine operator

The operating manual contains important

information for safe operation and for the functional

reliability of the lift.

The signed form “Installation record“ must be

sent to the manufacturer to verify the installation

of the lift.

The “Inspection logbook“ contains forms for

verifying the initial, regular, and unscheduled

safety inspections. Use the forms to record the

inspections and add the completed forms to the

inspection logbook.

Design modifications must be entered in the

“Machine master data sheet“.

The machine operator is responsible for ensuring

that the lift is always operated in a safe manner and

the following requirements are met or regularly

carried out.

The operators must be qualified through specialist

training and experience.

The operator must be familiar with the

applicable occupational health & safety and

accident prevention regulations and be

instructed and trained to operate the lift.

The operator must have read and understood

the safety regulations chapter and verified this

with his signature.

If several people work on the post lift, a foreman

must be appointed.

The post lift may only be operated in technically

sound condition with regard to safety.

Maintenance and servicing must be performed

regularly according to the defined schedule.

Safety inspections must be conducted regularly,

and at least once annually in accordance with

chapter 9.

The inspection logbook must be kept up-to-date.

This operating manual as well as the annexed

instructions must always be kept with the lift.

This also applies if the lift is sold or re-installed

at a new location.

For safety reasons, unauthorised modifications

or alterations to the lift are not permitted. In case

of an unauthorised modification, the operating

permit is cancelled, and the Declaration of

Conformity becomes null and void.

2

117592 ● 03/2013

1. Introduction

1.3 Specialist for safety related

work

The post lift must be inspected after commissioning

and at regular intervals but at least annually.

as well as after the replacement of safety-related

parts during maintenance work.

Safety-related work and safety inspections on the lift

may only be carried out by people trained to do so.

These people are generally known as certified

experts and competent persons.

Certified experts are persons who may inspect

and assess lifts (freelance specialist engineers,

TÜV certified experts), based on their training

and experience.

They are familiar with the relevant occupational

health & safety and accident prevention

regulations.

Competent persons (skilled people) are

persons who have sufficient knowledge and

experience of lift systems. They have attended

a special training course at the lift manufacturer.

Competent persons are customer service fitters

for the manufacturer or authorised dealer.

people. Non-compliance may lead to

death or serious injury.

Risk of death or injury

Potential risk to life and health of

WARNING

CAUTION

ATTENTION

people. Non-compliance may lead to

serious or critical injury.

Risk of injury

Potentially hazardous situation.

Non-compliance may lead to minor

or moderate injury.

Damage to property

Potentially hazardous situation. Noncompliance may lead to damage to

property.

Other Symbols

INFO-Symbol Useful information and tips.

i

Bullet point:

For lists with key information on the

respective subject.

1. Action:

Carry out the detailed steps in order.

1.4 In-house accident, health &

safety and environmental

information

This operating manual does not contain information

and instructions with actions in the event of

accidents and health risks.

The in-house operating instruction must be supplied

by the operator of the lift.

1.5 Warning and information

symbols

Warnings are identified by the following symbols,

depending on the hazard classification.

Be especially aware of safety and hazards when

working in situations identified by warning symbols.

Comply with the occupational health & safety and

accident prevention regulations which are applicable

in your country.

Risk of death or injury

Direct threat to life and health of

Action symbol

Carry out the detailed steps in order.

DANGER

117592 ● 03/2013

3

2. Intended use

2. Intended use

2.1 General

Risk of injury!

WARNING

To prevent injury to persons or property, the

lift should only be operated by trained

operators.

After reading this manual, become familiar

with operating the lift by conducting several

trial runs before loading a vehicle onto the lift.

The lift is designed to raise and lower cars and

delivery vehicles for repair, maintenance, and

cleaning in a normal workshop environment.

The lift may only be used according to regulations,

in a fully functional condition according to the

technical data in chapter 3.3.

The manufacturer assumes no liability for

damage of any kind which arises through

incorrect, erroneous, or unreasonable use.

3. The lift

3.1 Functionality

The lift is designed to raise vehicles to the

optimum height for maintenance, cleaning, or

repair work.

The lift is operated by pressing buttons on the

control unit which is attached to one of the

posts.

The vehicle is raised and lowered in jog mode.

Steel cables ensure that the vehicle is raised

horizontally.

The max load capacity of the whole lift is 3500 kg

and may not be exceeded.

Operators may stand under the raised load.

Risk of injury if used incorrectly.

DANGER

ALWAYS raise the vehicle with all four (4)

adapters! Never lift only one end, one corner

or one side of the vehicle.

2.2 Incorrect use

Incorrect use presents a residual risk to the life and

health of the people working in the lift zone.

The manufacturer assumes no liability for damage

resulting from use other than the intended purpose

and misconduct.

The following is prohibited:

Climbing onto or riding on the load or pick-up

equipment.

Loitering under the load when raising or

lowering.

Raising vehicles loaded with hazardous

substances.

Installing the lift in areas at risk from explosion.

Using the lift for washing vehicles and under any

other conditions not expressly specified in the

operating manual,

4

117592 ● 03/2013

1

3. The lift

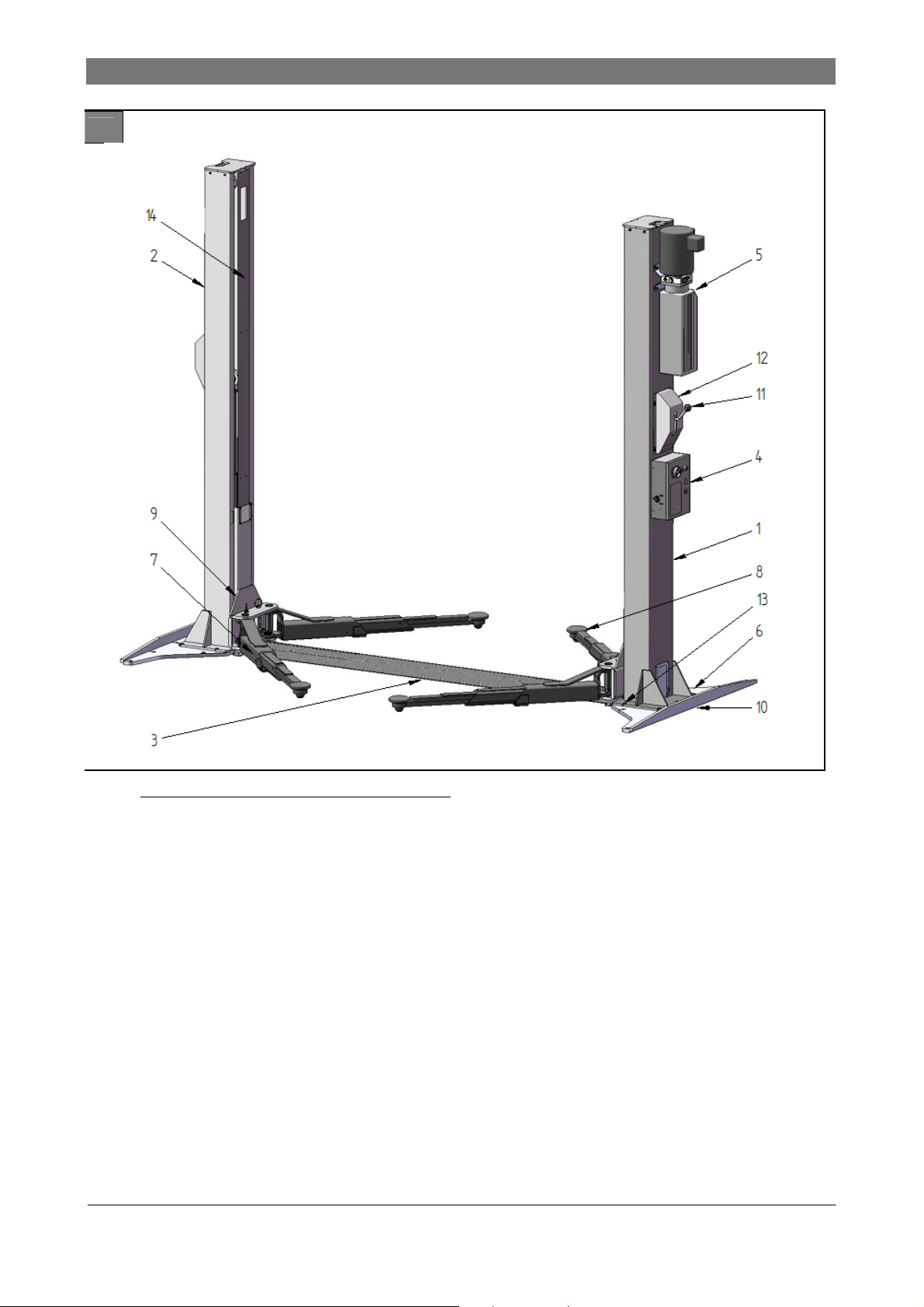

3.2 System overview

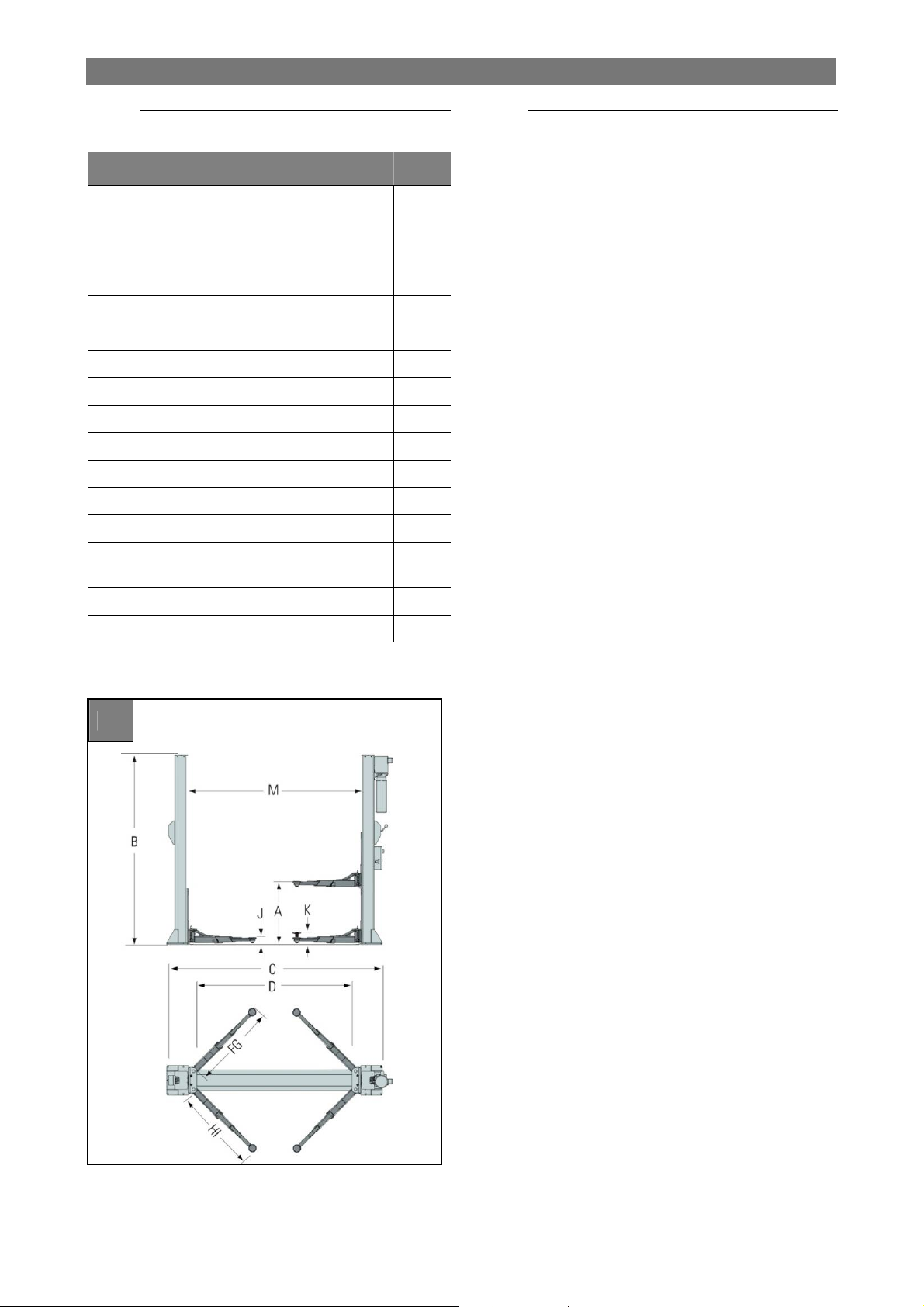

Figure 1: Example of a post lift

1 Primary column

2 Secondary column

3 Drive-through ramp

4 Control unit

5 Hydraulic unit

6 Column base plate

7 Arm

8 Adapter

9 Slide

10 Base plate support (optional extra)

11 Lever for latch mechanism

12 Latch mechanism cover

13 Hole for anchor bolts

14 Cover plate

117592 ● 03/2013

5

3. The lift

3.3 Technical data

SGL35

Load capacity / Lift cylinder [kg] 3500

A Rise [mm] 1828

B Overall height [mm] 3160

C Overall width [mm] 3320

D Drive-through clearance [mm] 2388

F Reach front arm min. [mm] 600

G Reach front arm max. [mm] 1280

H Reach rear arm min [mm] 600

I Reach rear arm max. [mm] 1280

J Adapter height min. [mm] 110

K Adapter height max. [mm] 166

L Inside columns [mm] 2688

M Motor [kW] 2.2

Electrical connection

(3 phases)

Rise time [sec] 40

Required ceiling height [mm] 3170

400 V

50 Hz

3.4 Identification of lift

The customer service department of your authorised

dealer can react quicker to your maintenance

queries if you specify the lift, serial number, and any

possible accessories.

The information below is given on the information

plates:

BlitzRotary GmbH

Hüfinger Str.55

78199 Bräunlingen

Deutschland

Telephone: +49 771 9233 0

Fax: +49 771 9233 10

Model SGL 35

Model year 20__

Serial number _____________

Load capacity (kg) 3500

Power supply (V) 230 / 400

Power consumption (kW) 2.3

Actuating power (kW) 2.2

Phases 3 + PE

Frequency (Hz) 50 / 60

Specified hydraulic pressure (bar) 205

2

6

117592 ● 03/2013

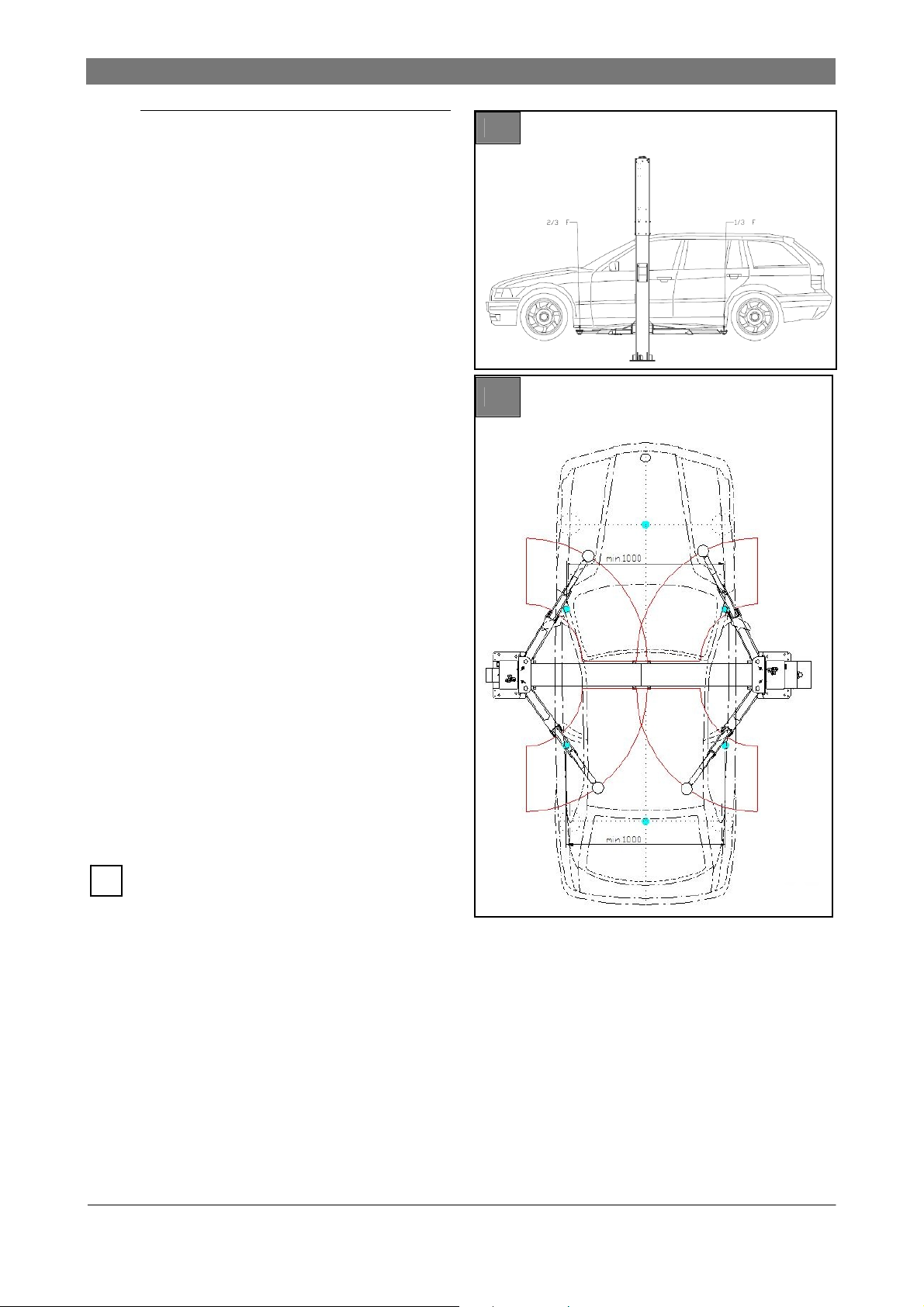

3.5 Permitted weight distribution

Figure 3: Vehicle centre of gravity

The weight distribution on the adapters is

reversible for this post lift: The heavy load can

either be placed on the long or the short arms

P1 (1/3) - P2 (2/3) of the maximum load.

3

3. The lift

Figure 3: Minimum distance between two

adapters

Not less than 1000 mm

If the distance is less, the load capacity of the lift

will be reduced

4

The weight distribution must match the

i

guidelines specified in this chapter. We

therefore recommend distributing the weight

as centrally as possible in relation to the axis

of the posts.

117592 ● 03/2013

7

3. The lift

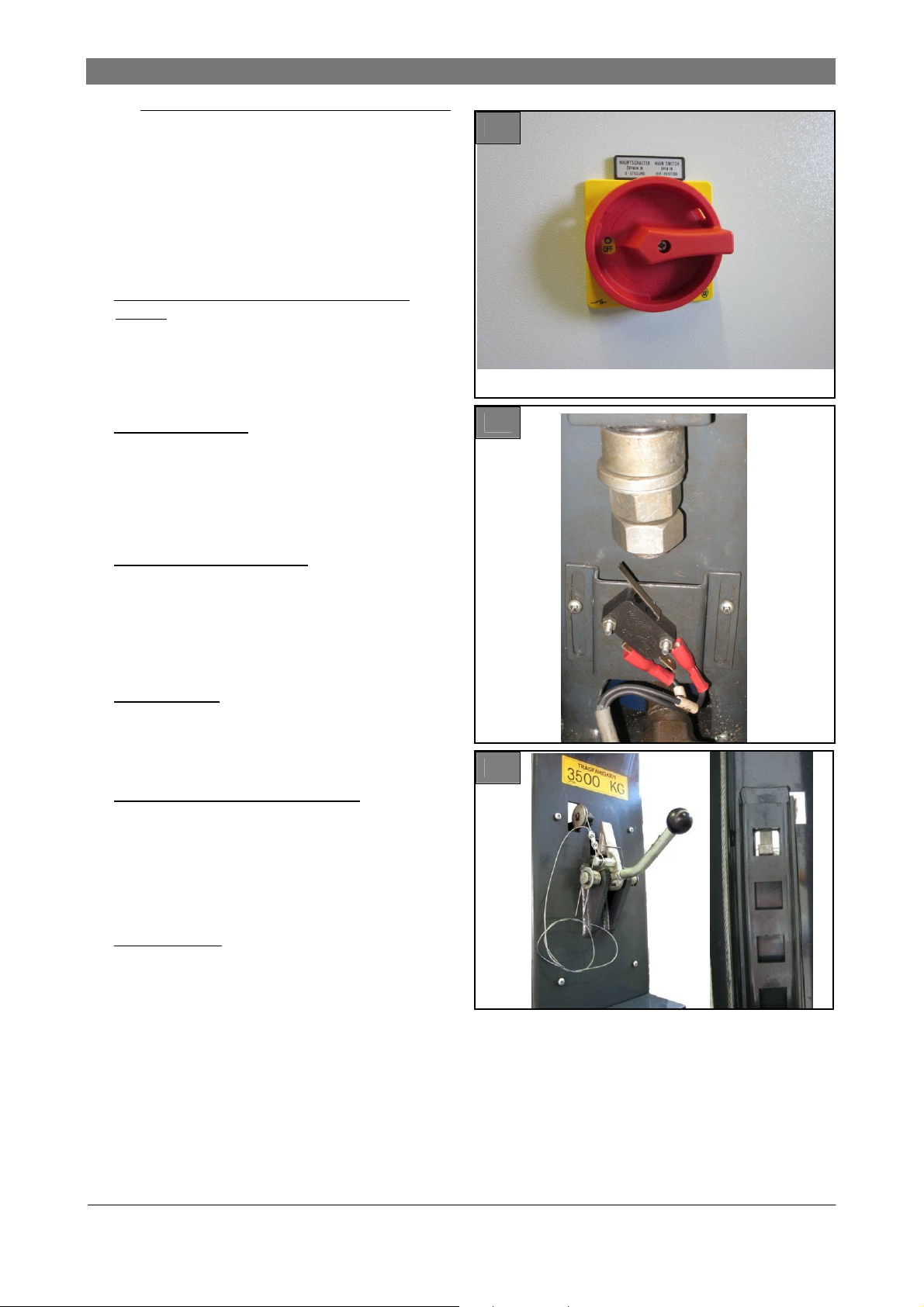

3.6 Safety mechanisms

Figures 5 ... 9: Safety mechanisms

Electrical

Emergency stop button on the control unit

(Figure 5)

Broken chain and slack chain switch (lifting

chain): consists of a micro switch, which is fitted

in each column at the bottom. This module

permits any movement of the lift to be halted if a

chain is broken or unusually slack. (Figure 6)

Hydraulic

Broken line switch: consists of a valve in a

hydraulic cylinder. This valve is designed to limit

the lowering rate if the hydraulic line fails

(breaks). It is set so that the lowering rate does

not exceed the nominal rate by more than 1.5 x.

Mechanical

Mechanical latching system: consists essentially

of a spring-loaded latch which is fitted on each

column, as well as a bar with notches on each

slider block. This latch and bar assembly stops

the lift from accidentally dropping in the event of

a leak in the hydraulic system or breaks in the

system components (Figure 7)

Arm restraints: consist of a ring gear on the end

of the arm which engages the pinion of the lift

slide. This assembly is activated as soon as the

slide leaves its lowest point to prevent the arms

from slewing. (Figure 8)

Mechanical synchronisation control: consists of

two synchronisation cables which connect the

slider blocks to each other. The cables prevent

incorrect alignment of one slider in relation to

the other slider if the weight is unevenly

balanced crosswise. (Figure 9)

Ergonomics

5

6

7

Foot protection: metal plates on both sides of

the base plate of both columns and a metal

baffle plate in the outside of the arms which

prevent a foot becoming trapped under the

slider block or arm(s).

8

117592 ● 03/2013

3. The lift

8

3.7 Control box

(see figure 11)

1 Main switch, emergency stop

To connect the lift to the mains supply, turn the

switch to ”1", to disconnect from the power

supply turn it to ”0".

2 Control box key

Opens the control box for maintenance

purposes.

3 Up button

9

Press this button to actuate the hydraulic power

unit and raise the slider block. This works on the

dead man’s switch principle, meaning that when

the button is released, raising of the lift is halted

immediately.

4 Down button

When this button is pressed and the latching

system lever is activated at the same time (s.

Figure 7), the slider block is lowered. This

works on the dead man’s switch principle,

meaning that when the button is released,

lowering of the lift is halted immediately. The

system is also locked by the latching

mechanism. Before lowering, the latching

mechanism must first be released. If the lever

cannot be released, the latch has engaged.

The lift must first be raised a little to finally

release the system. Only then can you lower

the lift.

11

117592 ● 03/2013

9

4. Safety regulations

4. Safety regulations

Comply with the following regulations!

4.1 General operation

Only operate the lift if you have read and

understood this operating manual. Also refer to

the brief operating instructions on the lift.

The total permitted weight is 3,500 kg .

Only persons who are 18 years old, are trained

in operating the lift, and have signed the

handover sheet are permitted to operate the lift.

Vehicles with low ground clearance or with

optional extras should be checked beforehand.

They can only be lifted if no damage can be

caused.

Work on the lift may only be carried out if the

main switch is turned off and locked.

Do not:

● Carry people on the lift.

● Climb onto the lift or the load.

● Ride on the lift with equipment.

Emergency lowering of a vehicle may be done

only by competent persons.

Switch off equipment when not in use.

Do not use the lift in proximity to a potentially

combustible or flammable atmosphere.

4.2 Operational safety,

breakdowns

The operational safety of the lift must be

inspected regularly.

If breakdowns occur or if there are missing

safety components, shut down the lift

immediately. Inform the supervisor or customer

service.

During the raising and lowering process, no-one

should loiter within range of the moving load

and the pick-up points.

Briefly raise the lift to check that the vehicle

pick-up points are secure. The latches must be

properly engaged. Only then lift the vehicle to

the desired height. The lift and the vehicle may

otherwise become dangerously unstable.

The area within range of moving loads and pick-

up points must be free of obstacles.

4.5 Installation, maintenance,

servicing

Installation, maintenance, and servicing work

may only be carried out by trained and

authorised specialists, with the system switched

off and made safe.

Electrical work may only be carried out by

qualified electricians.

Only specialist staff with specialist knowledge

and experience may work on hydraulic

equipment.

Repairs on the safety equipment of the lift may

only be carried out by competent persons.

Follow the maintenance schedule, document

maintenance work.

Only use OEM parts.

Following design modifications or repair work on

safety relevant parts, the lift must be inspected by

a certified expert.

4.3 Picking up loads

Before lifting with the arms, check the pick-up

points on the vehicle for load capacity,

corrosion, damage, and modifications.

Only lift vehicles at the points approved by the

manufacturer.

Do not carry out any work on a raised vehicle

which may affect the stability of the pick-up

points.

4.4 Up /down

Only operate the lift if it poses no danger to

people.

10

117592 ● 03/2013

5. Operation

Risk of injury if an incorrect

procedure is followed during

DANGER

If there are indications of faults such as

unusual noise or leaks, shut down the lift

immediately, secure it, and inform the

supervisor.

To prevent any movement of the lift in an

i

emergency (malfunction or defect), set the

main switch to ”0" and lock it with the key

switch.

DANGER

No one may loiter under the vehicle when the

lift is moving, clamber onto the lift, or climb

into the car. The movement of the slider block

and the arms must not be hampered by

objects (e.g. tools), before they have reached

their end position.

Inspect the lift - see ”Inspection and

maintenance instructions for operators". Never

activate the lift if it is showing a malfunction or

damaged parts.

Before the vehicle is placed on the lift, it must be

fully lowered and everyone must move away

from the work area.

If problems occur, set the main switch to ”0“.

The lift may only be inspected by authorised

and qualified staff. Before all maintenance or

repair work, lock the main switch with the key

switch and if necessary, disconnect the lift from

the power supply.

Do NOT use the lift as a crane or jack for other

lifting mechanisms!

breakdowns.

5.1 Emergency stop

5.2 Before use

Risk of injury if an incorrect

procedure is followed before use

5. Operation

5.4 Driving the vehicle onto the

lift

Unauthorised or untrained persons may NOT

operate the lift and may NOT lift the vehicle.

Do NOT drive against or over the arms

Do NOT overload the lift: Refer to the load

capacity plate on the lift

Refer to the weight distribution details in

the ”Area of use" chapter. Never exceed the

figures in this chapter in order not to expose

the operator to danger.

Make sure that the vehicle is centred

according to the longitudinal axis of the lift

and that the pick-up points of the vehicle

chassis are correctly positioned in relation to

the adapters.

Make sure that the arms do not directly touch

the vehicle chassis. Before lifting, check again

that all adapters are correctly positioned

below the pick-up points.

Check that the arm restraints are properly

engaged before lifting the vehicle.

Make sure that no danger arises from lifting

the load, and after lifting the load for a few

centimetres, check that the vehicle is correctly

positioned and secure.

It is essential that the vehicle is lifted at the

points indicated by the manufacturer for this

purpose and only accessories supplied by the

manufacturer of the lift.

When raising and lowering, ensure that the

motion of the lift is smooth and does not

chatter and that the load is always stable. If a

vehicle is unstable or the operation of the lift

does not appear normal, halt operation of the

lift immediately. If possible, lower the lift again

with extreme care. If necessary, check and

correct the vehicle position. If the vehicle

continues to be unstable, set the main switch

to ”0“ and contact the maintenance technician

at your authorised dealer.

5.5 Up / down

The lift must be lowered and raised steadily,

i

so that the load does not shift.

5.3 Switching on the equipment

To connect the control unit to the power supply,

set the main switch to ”1".

117592 ● 03/2013

If the vehicle does not remain stable, halt all

i

lift movement immediately.

Then turn the main switch to ”0“ and lock it.

11

5. Operation

The vehicle must now be lowered by an

i

authorised competent person.

ONLY use adapter extensions from the lift

manufacturer. DO NOT use wood or concrete

i

blocks or other improvised extensions.

Check the condition of the pick-up points on the

i

vehicle. These should be free of grease, oil and

dirt. Arms swing under the vehicle and position the

adapter on the pick-up points recommended by the

vehicle manufacturer (Fig. 4). Bring the adapter to

the corresponding height to stop the car straight

and properly balanced.

When raising and lowering, monitor the lifted

i

vehicle constantly. If the lift is not synchronised,

pause the movement and determine the cause.

Monitor the tension of the synchronisation cables

i

through the inspection window in the plate frame,

and if there are irregularities, shut down the lift

and contact the service department.

Raising

1. Press the Up button. Raise the vehicle

slightly.

2. Check that the vehicle pick-up points are

secure.

3. Press the Up button. Raise the vehicle to the

desired height.

4. Make sure that each pinion engages the ring

gear as soon as the slider block loses contact

with the floor.

lever and push the DOWN button to lower the

lift to the required level.

2. If you cannot pull the lever down, the latching

mechanism has engaged. Press the UP and

DOWN buttons at the same time so that the

slider block rises and the lever is released. Then

lower the vehicle.

The latch mechanism, the lever, and the "Up"

and "Down" switches are dead man’s

i

switches. The lift is raised and lowered as

long as the buttons and the lever are

engaged.

3. Set the main switch to “0“.

5.6 Using the lift

Prevent extreme vibrations from the vehicle

whilst it is positioned on the lift

If required, always use safety stands as

stabilisers when removing or fitting heavy

components (i.e. engines, gearboxes etc). Use

4 safety stands

When lowering, stay outside the range of the lift.

Do not stand in the lowering zone.

Wear protective goggles when working

underneath the vehicle

If necessary, also use support straps to stabilise

the vehicle on the arm when disassembling

parts.

5. If one of the pinions does not engage the ring

gear, the bolt with the pull ring at the top can be

seen to protrude further than normal at the top

on the guide shaft of the pinion (Fig. 8, in

normal position). In this case, lower the slider

block and re-position the problematic arm.

6. Release the SAFETY lever and the Up button

as soon as the working height has been

reached.

7. When the required height has been reached,

the lift can engage the safety latch.

8. Set the main switch to ”0", as soon as the

necessary working height has been reached.

Down

1. Connect the control unit to the power supply

and set the main switch to “1“, pull the SAFETY

12

5.7 Before lowering the lift

Remove all tools and other objects from the lift

zone.

Ensure that no-one is in the lift zone.

Ensure that there are no people or objects in the

drive-off zone before driving the vehicle from the

lift.

5.8 Driving the vehicle from the

lift

1. Secure the vehicle against rolling.

2. Ensure that the arms are in their outermost

position on full drive-thru position before driving

the vehicle from the lift.

117592 ● 03/2013

Loading...

Loading...