Page 1

Console

Consola

Console

Konsole

Console

Console

9

16

23

30

37

44

Gebrauchsanweisung

Mode d’emploi

Istruzioni per l’uso

Instrucciones de uso

Gebruiksaanwijzing

Kontakt den nærmeste Boston Scientific

kundeserviceafdeling, hvis en dansk kopi af

brugsanvisningerne ønskes. Spørg efter reservedel nr.:

90185046-02 Rev. B

ЕрйкпйнщнЮуфе ме фп гсбцеЯп еохрзсЭфзузт фзт

Boston Scientific бн пй ПдзгЯет ЧсЮузт брбйфеЯфбй нб

еЯнбй уфб ЕллзнйкЬ. ЖзфЮуфе фпн бсйимь бнфбллбкфйкпэ:

90185046-03 Rev. B

Entrar em contacto com o escritório para atendimento de

clientes da Boston Scientific se uma cópia das instruções

para utilização em português for necessária. Pedir pela

brochura número: 90185046-04 Rev. B

Kontakta Boston Scientific kundtjänst om ni behöver ett

exemplar av en svensk bruksanvisning. Fråga efter del

nummer: 90185046-05 Rev. B

3

Directions for Use

TM

Page 2

2

Page 3

Description

The Rotablator Rotational Angioplasty System is a catheter-based angioplasty

device utilizing a diamond-coated elliptical burr at the tip of a flexible drive

shaft. Tracking coaxially over a guide wire and rotating at up to 190,000 RPM,

the burr ablates plaque into fine particles that are disposed of by the body’s

reticuloendothelial system. The three main components included in the system

are the guide wire, control console system, and the advancer/catheter.

The Rotablator Console monitors and controls the rotational speed of the burr

and provides the operator with performance information throughout the

procedure. In the control console, the gas is filtered and then regulated by a

fixed-pressure regulator. The resultant pressure is gated by a pilot-actuated

valve, and gas flow is automatically adjusted by a proportional pneumatic valve

in order to maintain proper Rotablator System operating speed. The gas then

enters the gas turbine, and after expanding in the turbine, is exhausted at the

bottom of the Rotablator Rotational Angioplasty System advancer. Compressed

gas is also supplied to the foot pedal through a triple hose. When the foot pedal

is depressed, the gas is returned to the console, where it activates the pilot

valve, permitting flow of regulated compressed gas to the Rotablator Rotational

Angioplasty System advancer via the front panel turbine connector. With this

pilot valve arrangement, the gas flow to the Rotablator Rotational Angioplasty

System advancer cannot be throttled by using the foot pedal.

Intended Use

The Rotablator Console is intended for use with the Rotablator Rotational

Angioplasty System. Refer to guide wire and advancer package inserts for

specific information on the use of these components.

Restrictions, Warnings and Precautions

Restrictions

Caution: Federal (USA) law restricts this device to sale by or on the

order of a physician. For coronary use, federal (USA) law further

restricts this device to a physician trained and/or experienced in coronary

balloon angioplasty. Governing law outside the USA restricts this device to sale

by or on the order of a physician.

Warnings

• Never use oxygen as the propellant for the Rotablator Rotational

Angioplasty System. Never connect the regulator to an oxygen cylinder.

Oxygen combined with oil or other combustibles in the system can result in

an explosion.

• The use of accessories, transducers and cables other than those specified,

with the exception of transducers and cables sold by the manufacturer of the

Rotablator System as replacement parts for internal components, may result

in increased emissions or decreased immunity of the Rotablator System.

• The Rotablator System should not be used adjacent to or stacked with other

equipment and that if adjacent or stacked use is necessary, the Rotablator

System should be observed to verify normal operation in the configuration

in which it will be used.

• This device is not to be used in the presence of flammable anesthetics.

• If a hissing noise is detected from the console, check to make sure that the

pressure of the gas supplied to the air or nitrogen connector does not exceed

758.4 kPa (110 psi). The console is equipped with a pressure relief valve to

protect against excessive inlet pressure. Do NOT operate the Rotablator

Console with gas pressures in excess of 758.4 kPa (110 psi), as a gas hose

may burst.

• If patient defibrillation becomes necessary, the physician should take the

appropriate measures to protect himself against electrocution from the

defibrillator.

• Do not modify or repair. Modification or repair of the instrument by a

person other than an authorized Boston Scientific representative may

compromise the integrity of the device and/or lead to device failure

which, in turn, may result in patient injury or death. Boston Scientific

assumes no liability with respect to any instrument which has been

modified or repaired by a person other than an authorized Boston

Scientific representative and makes no warranties, express or implied,

including but not limited to merchantability or fitness for a particular

purpose, with respect to such instruments. If repair is needed, call your

Boston Scientific representative.

Precautions

• Care must be taken not to spill saline or other fluids on the console. Saline

spilled in the console may result in corrosion or electrical hazard.

• User should take precautions when using the console in conjunction with

other medical electrical equipment, as electromagnetic interference between

the equipment may affect the performance of the console or other devices.

The console complies with IEC 60601-1-2 regulations for radiation of and

immunity from electromagnetic energy.

• The Rotablator Console needs special precautions regarding EMC and needs

to be installed and put into service according to the EMC information

provided in Appendix D.

• Portable and mobile RF communications equipment can affect the

Rotablator Console.

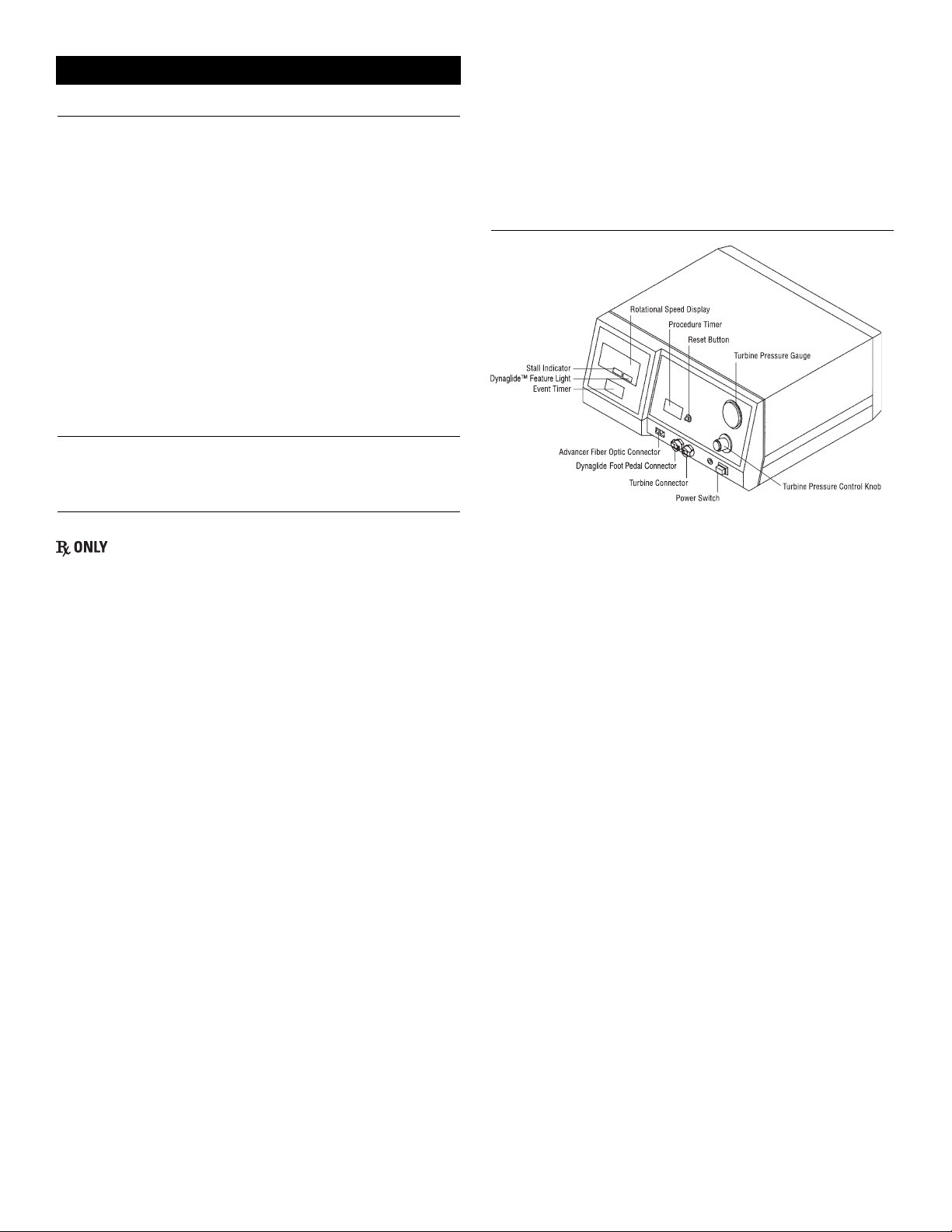

Description of the Rotablator Console

Figure 1

Control Console Front Panel

The symbols used on the console are listed in Appendix A. The main features

and functions of the console shown in Figure 1 are described below.

Front Panel

• Power Switch: Power is supplied to the console when the switch is in the

depressed position. The push button power switch is located in the lower

right corner of the front panel. The green light to the left of the switch

illuminates to indicate that the power has been turned on.

• Turbine Pressure Control Knob: The knob located above the power

switch is used to adjust the gas pressure to the turbine and consequently, the

rotational speed. Turning the knob clockwise increases the turbine pressure

(speed) as indicated on the turbine pressure gauge. Counterclockwise

rotation decreases the turbine pressure (speed).

• Turbine Pressure Gauge: Located above the turbine pressure control knob,

the pressure gauge displays the pressure of the compressed gas being

supplied to the advancer gas turbine. Generally the greater the gas pressure

to the gas turbine, the higher the rotational speed. The pressure should not

be allowed to exceed 482.6 kPa (70 psi) during normal operation. Flow

restrictions have been incorporated into the pneumatic system to prevent the

delivery of excessive energy to the advancer. For additional information on

operating range, accuracy and precision, see Table 1.

• Rotational Speed Display (Tachometer): The rotational speed display

located in the upper left corner of the console indicates the speed in RPM of

the burr and gas turbine. When the gas turbine is not operating, the display

is blank. When the foot pedal is depressed, the rotational speed is shown on

the rotational speed display. For additional information on operating range,

accuracy and precision, see Table 1.

• STALL Light: The STALL light is located directly below the rotational

speed display, and is visible only when illuminated. If the rotational speed of

an advancer falls below 15,000 RPM for more than 0.5 second, the red

STALL light is illuminated and delivery of compressed gas to the advancer

is discontinued. A stall condition may also be detected if the fiber optic

connection is not properly engaged. Stall detection is a safety feature

designed to discontinue delivery of compressed gas to the advancer in the

event of excessive mechanical loading or incorrect connection of the fiber

optic. Releasing the foot pedal will clear the stall condition and extinguish

the STALL light.

3

Rotablator™ Rotational Angioplasty System

Page 4

• DYNAGLIDE™ Feature Light: The DYNAGLIDE Feature light is

located adjacent to the STALL light, and is visible only when illuminated

indicating that the Dynaglide Feature is activated. The Dynaglide Feature

provides a controlled low speed rotation (approximately 50,000-90,000

RPM) of the Rotablator™ Burr for use during intraprocedure exchange of

Rotablator Rotational Angioplasty System advancer or catheter. The

Dynaglide Foot Pedal button is used to turn the Dynaglide Feature on or off.

• Event Timer: Located below the tachometer, the event timer records how

long the foot pedal has been continuously depressed with the air turbine and

burr spinning. When the foot pedal is released, the timer continues to

display the previous event time. Depressing the foot pedal resets and restarts

the timer. For additional information on operating range, accuracy and

precision, see Table 1.

• Procedure Timer: The procedure time is the sum of the individual event

times and indicates the total time the burr has been spinning during the

procedure. For additional information on operating range, accuracy and

precision, see Table 1.

Table 1

• Reset Button: Pushing the reset button resets the event and procedure

timers to zero.

• Turbine Connector: The gas line connector on the right-hand side receives

the advancer gas hose and supplies filtered, regulated compressed gas to the

advancer when the foot pedal is depressed.

• Dynaglide Foot Pedal Connector: The gas line connector on the left-hand

side receives the Dynaglide Foot Pedal pink hose, and is used to activate or

deactivate the Dynaglide Feature mode of operation.

• Fiber Optic Tachometer Cable Connector: These two female connectors

receive the mating male connectors from the fiber optic tachometer cable.

The orientation of the cable to the female connector is not important. The

fiber optic tachometer cable carries light pulses which the console uses to

determine the rotational speed of the gas turbine and burr.

Rear Panel

• Line Cord: This cable plugs into a conventional 100-120 V a.c. or

220-240 V a.c. receptacle (as indicated on the name plate located on the

rear of the console) and provides power to the console. In Germany, line

cord connections must be to a VDE 0107 compliant installation. The ground

wire of the line cord is internally connected to the console chassis.

• Fuses: The fuses protect the console’s electrical components in the event of

a serious electrical fault. If a fuse should fail, refer to Appendix B for

replacement instructions.

• Potential Equalization Connector: Located to the left of the fuse, the

potential equalization connector is provided to allow potential equalization

between various hospital electrical instruments. In Germany, the potential

equalization connections must be made to a VDE 0107 compliant installation.

•

Compressed Gas Inlet: This male connector, located in the top center of the

rear panel, mates to the corresponding connector on the supply line from the

compressed gas source. Pressure at this inlet should always be between 620.5

and 758.4 kPa (90 and 110 psi) with a minimum flow capacity of 140 l/min

(5 standard cubic feet per minute (scfm)). Pressure will be reduced by the

console to operating limits. An internal pressure-relief valve protects against

input pressures in excess of 792.9 kPa (115 psi) and creates a loud hissing

noise in the console when the pressure exceeds 792.9 kPa (115 psi).

• Dynaglide Foot Pedal Connectors: These two connectors receive the mating

pair of connectors from the Dynaglide Foot Pedal. The green hose connects to

the right-hand connector and the blue hose to the left-hand connector.

Other

• Dynaglide Foot Pedal: The foot pedal is used as an on/off control for the

advancer gas turbine. The foot pedal is also fitted with a valve which vents

any compressed gas in the foot pedal hose when the pedal is released,

permitting the burr to stop rapidly. The foot pedal is mounted in a protective

shroud which inhibits accidental actuation.

• The Dynaglide Foot Pedal button located on the right side of the foot pedal

housing is used as an on/off control for the Dynaglide Feature mode of

operation. When the Dynaglide Feature is on, the green DYNAGLIDE

Feature light is illuminated on the console front panel.

Assembly and Setup of the Rotablator Console

The recommended control console system, illustrated in Figure 2, consists of an air

or nitrogen pressure regulator mounted on a compressed gas cylinder, connected to

the Rotablator Console via a supply hose (provided with the console). The gas

cylinder is shown for illustration only, and is not of the recommended size. Gas

cylinders must be properly secured per standard procedures.

Note: It may also be possible to operate this system from a hospital (house) gas

system, as discussed in Appendix C. The Rotablator Console is not suitable for

use with in-hospital (house) compressed gas lines in Germany due to pressure

and flow incompatibilities, unless connections are made in accordance with

DIN 13 260.

Figure 2

Control Console System

To put the Rotablator Console into service, proceed as follows:

WARNING NEVER use oxygen as the propellant for the Rotablator

Rotational Angioplasty System. NEVER connect the

regulator to an oxygen cylinder. Oxygen combined with oil or

other combustibles in the system can result in an explosion.

WARNING This device is not to be used in the presence of

flammable anesthetics.

1. Procure a compressed gas cylinder containing either compressed air or nitrogen.

In Germany, only compressed air may be used, gas cylinder fittings must be

according to DIN 477 Teil 1 (Druckluft), and compressed gas cylinders must

be approved by the German government (Bauartzugelassen). A cylinder

capacity of at least 2250 l (79.46 standard cubic feet) is recommended, and

will provide approximately 20 minutes of service with the Rotablator

Rotational Angioplasty System advancer running at full speed. Larger

cylinders may be used. A fully charged spare cylinder should always be

available.

2. Secure the compressed gas cylinder in accordance with hospital procedures.

3. Obtain a cylinder regulator (relieving type is preferred) capable of

delivering at least 140 l/min (5 scfm) at 620.5-758.4 kPa (90-110 psi).

Make certain that the cylinder regulator fitting is compatible with the gas

cylinder being used. In Germany, only compressed air may be used, gas

cylinder fittings must be according to DIN 477 Teil 1 (Druckluft), and

compressed gas cylinders must be approved by the German government

(Bauartzugelassen).

4. Connect the supply hose gas coupling (provided with the Rotablator

Console) to the outlet port of the cylinder regulator.

Unless local government regulations require otherwise, the gas coupling

is configured with .6 cm (¼”) MNPT threads. Verify the type of gas

coupling provided with the Rotablator Console prior to procuring a

cylinder regulator.

If necessary, use suitable adapters to make the connection. In some

countries, the regulator end of the gas supply hose has a permanently

attached warning tag to remind users not to connect it to oxygen sources.

Do NOT remove this tag.

4

Display Operating Range Accuracy Precision

Turbine Pressure Gauge 0-689.5 kPa or 0-100 psi ± 5% 6.9 kPa or 1 psi

Rotational Speed Display 0-250,000 RPM ± 1.5% 1,000 RPM

Event Timer 00:00-59:59 ± 0.1% 1 second

Procedure Timer 00:00-59:59 ± 0.1% 1 second

Cylinder Regulator

Advancer Hose

Cylinder

Saline Infusion Port

Advancer

Catheter

Dynaglide Foot Pedal

Supply Hose

Console

Turbine Connector

Fiber Optic Connector

Foot

Pedal

Hose

Page 5

5

5. Remove the cylinder cap and attach the regulator, tightening the

cylinder fitting firmly.

The regulator should be adjusted so that the outlet pressure is in the range

620.5-758.4 kPa (90-110 psi).

6. Connect the supply hose to the inlet connector on the back of the console.

In most countries, the inlet connector is marked AIR OR NITROGEN. In

Germany, the inlet connector is marked ‘Druckluft’. Verify that the

compressed gas being placed into service is in accordance with the inlet

connector marking.

7. Connect the foot pedal to the console by first locating the three

connectors at the end of the foot pedal triple hose.

Insert the green hose connector in the right-hand and the blue hose

connector in the left-hand mating receptacles on the rear of the Rotablator™

Console. These receptacles are labeled FOOT PEDAL or marked with a foot

pedal symbol. Connect the pink hose connector to the left-hand connector

on the front panel.

8. Connect the power cord to a properly rated hospital grade receptacle

(as indicated on the nameplate located on the rear of the console).

In Germany, power connections must be made to a VDE 0107 compliant

installation, and the potential equalization stud must be connected.

9. Open the compressed gas cylinder valve, or line valve if running on

house air (see Appendix C), to supply compressed gas to the console.

Note that the cylinder regulator gauge indicates the pressure of the gas

remaining in the cylinder. The regulator should be adjusted so that it never

supplies more than 758.4 kPa (110 psi) to the console, and no less than

620.5 kPa (90 psi). Do not initiate the procedure if less than 3,447 kPa

(500 psi) of gas remains in the tank.

WARNING If a hissing noise is detected from the console, check to make

sure that the gas pressure supplied to the air or nitrogen

connector does not exceed 758.4 kPa (110 psi). The console

is equipped with a pressure relief valve to protect against

excessive inlet pressure. Do NOT operate the Rotablator

Console with gas pressures in excess of 758.4 kPa (110 psi),

as a compressed gas hose may burst.

10.Push the console power switch and confirm that the green light

illuminates indicating power is on.

The Rotablator Console is now ready for use. Console placement,

ventilation, splash protection and cleaning instructions may be found below

in the section entitled: “Operation, Cleaning and Disposal Instructions.”

Operation, Cleaning and Disposal Instructions

1. Ventilation

The Rotablator Console uses natural convection cooling to maintain the

proper operating temperature for internal components. Cooling vents are

located on the bottom and rear of the console enclosure. In order to ensure

proper ventilation of the console, it must be placed on a hard, flat surface

with a minimum of 2.5 cm (1”) clearance maintained around all sides and

bottom of the enclosure. Do not set on drapes or bedding.

2. Splash

The Rotablator Console is designed to be placed outside of the sterile field.

Care should be taken to protect the console from splash and ingress of

liquids which may cause damage to internal components.

3. Cleaning

The Rotablator Console and Dynaglide™ Foot Pedal should be cleaned

regularly by wiping with a soft cloth dampened with a mixture of water

and mild detergent. Never immerse in fluids. The use of solvents or

abrasive cleaners may cause damage to the plastic parts of the console and

should be avoided.

4. Disposal

The user should follow local and national regulations for disposal of

electronics when disposing of this unit. The console contains no batteries or

heavy metals.

References

For coronary use, please refer to the Rotablator Rotational Angioplasty System

physician training program course materials for a listing of publications, or

contact your local sales representative. Additional articles, including

publications on the use of the Rotablator Rotational Angioplasty System in the

peripheral vasculature are available upon request. Please contact your local

sales representative to obtain a listing.

The symbols shown below may be present when required by specific safety

testing agencies such as Underwriters Laboratories (UL), Canadian Standards

Association (CSA), etc.

Dangerous voltage. To reduce risk of electric shock, do NOT

remove cover. Refer servicing to qualified service personnel.

Potential equalization connector. Provides means of achieving potential

equalization between hospital instruments. In Germany, connection

must be to a VDE 0107 compliant installation.

Indicates that a fire hazard may exist if fuses are not replaced as

marked.

Indicates type CF equipment.

Attention! Consult Accompanying Documents.

Console power is OFF when the power switch is in

the OUT position.

Console power is ON when the power switch is in the IN position.

Rotational Speed. Displays speed of the burr in RPM.

Event Time. Displays the length of time the foot pedal

has been continuously depressed.

Procedure Time. Displays the sum of the individual event times.

Reset. Resets the event and procedure timers to zero.

Turbine Pressure. Displays the pressure of the compressed

gas being supplied to the advancer gas turbine.

Turbine pressure increases with clockwise rotation.

Fiber optic connector.

Turbine. Connector for the advancer gas hose.

Compressed Gas Inlet. Connector for the supply line

from the compressed gas source.

Foot pedal connectors.

Proper disposal of electronic equipment is required according to

EN directive 2002/96/EC, Waste of Electrical and Electronic

Equipment (WEEE).

Contents of Package.

Appendix A - Symbol Translation Key

Page 6

6

Product Number.

The product has been tested for compliance with the applicable

requirements of UL 60601-1:2003. Safety approval for the US has

been granted by Underwriters Laboratories.

The product has been tested for compliance with the applicable

requirements of CAN/CSA C22.2 No. 601.1. Safety approval for

Canada has been granted by CSA.

Electrical safety testing was performed by TUV

Rheinland.

Danger - Explosion Hazard.

Do not use in the presence of flammable anesthetics.

Store within the given relative humidity upper and lower

limitations.

Technical Specifications

Electrical Selectable 100-120 V a.c. or 220-240 V a.c.

Specifications: Voltage:

Frequency: 50-60 Hz

Power: 70 VA

Fuses: 2 x F2.0A, 250V

Pneumatic Input Gas: Compressed Air or Nitrogen

Specifications: Pressure: 620.5-758.4 kPa (90-110 psi)

Flow: Minimum, 140 l/min (5 scfm) at rated pressure.

Operating Ventilation: Minimum 2.5 cm (1”) clearance on all sides,

Conditions: with console on a hard flat surface.

Temperature: +10º to +40ºC

Humidity: 10% to 90% non condensing

Storage Temperature: -30º to +60ºC

Conditions: Humidity: 10% to 95% non condensing

Safety Agency Underwriters Laboratory (UL) Classified to UL60601-1/Can/

Registration: CSA C22.2 No. 601.1 Medical Device Class I per UL 60601-1

National Australia Testing Agency (NATA) Type CF

equipment (IEC 601).

TUV certifications to IEC 601, EN550011, Class B and

EN60601-1-2.

Quarterly Inspections

These inspections should be performed once per quarter. If console fails any of

the inspections listed below, contact your Customer Service representative.

1. Check the physical condition of the power cable, strain relief, and plug.

Make sure that there are no frayed ends on the power cable connector, the

strain relief is attached, the plug has no bent prongs, and the ground prong

in the plug is present and secure. Verify that there are no unacceptable

scratches or punctures on the exterior of the AC cord set.

2. Check for loose or missing screws, sharp edges, or loose connectors.

By hand, check the console pneumatic connectors and verify that they are

not loose. Verify that all screws are in place on covers. Hold console in both

hands and shake in two different directions to verify that there is no loose

hardware inside the console.

3. Perform an external visual inspection for mechanical damage.

Verify that there are no unacceptable chips, dents, scratches, or marks on

the console enclosure or foot pedal. Verify that the knobs are secured

properly and are not loose. Tighten any loose knobs. Make sure that the

pneumatic connectors are in working order, not stuck open, and are tight

against the console.

4. Check the front panel indicators.

With the console connected to AC power and compressed gas, cycle the

Power switch to apply power to the console and verify that:

a) The green Power LED illuminates.

b) The EVENT TIME display reads 00:00.

c) The PROCEDURE TIME display reads 00:00.

d) The RPM display is blank.

e) The STALL display is blank.

5. Check the operation of the turbine pressure gauge.

Connect the console to AC power and compressed gas. Starting with the

SPEED ADJUST knob fully counterclockwise, verify that clockwise rotation

of the SPEED ADJUST knob results in an increased reading on the console

TURBINE PRESSURE gauge.

6. Check the operation of the DYNAGLIDE™ Foot Pedal display.

With the console connected to AC power and compressed gas, and with the

Dynaglide Foot Pedal connected, turn on the unit, cycle the DYNAGLIDE

Feature button on the foot pedal, and verify that the DYNAGLIDE Feature

indicator illuminates and goes blank.

7. Check the operation of the STALL display.

Without connecting the advancer (i.e., no fiber optic connector plugged in),

activate the foot pedal and check for stall light illumination. Verify that the

stall light goes blank when foot pedal is released.

Service Information

Fuse: In the event of a fuse failure, turn off the power and unplug the line cord

from the power outlet. The power cord may also be unplugged from the rear of

the console to improve fuse access. Using a tool such as a screwdriver, remove

the fuse drawer by depressing the locking tab. See Figure 3 below.

Figure 3

Fuse Replacement

Replace both fuses with the same type and rating as specified on the rear of

the console. Reinsert the fuse drawer until the locking tab snaps into place.

Reconnect the power cord and restore power to the console. If a fuse fails

again, disconnect all power to the console and contact your Customer Service

representative.

All other service must be performed by Boston Scientific Corporation personnel.

Field repair, other than the console’s external fuse replacement, voids all

warranties and may not be performed without express authorization from

Customer Service.

Note: This appendix does NOT apply to TUV Rotablator™ Consoles.

The Rotablator Rotational Angioplasty System is designed to be operated from

compressed gas cylinders via a cylinder regulator. However, if a house air or

nitrogen system is available, the control console can be supplied directly,

eliminating the need for a cylinder and cylinder regulator. The requirements are

as follows:

1. The compressed gas must be air or nitrogen only.

2. The gas must be clean, dry, and oil free.

3. The gas pressure must be between 620.5 kPa (90 psi) and 758.4 kPa

(110 psi) at the inlet to the control console.

4. The system must be capable of supplying gas at a rate of 140 l/min

(5 scfm) or more.

Appendix B - Service and Maintenance Information

Appendix C - Running the System

From Low Pressure (House) Lines

Power Cord

Receptacle

Locking T

Fuse Drawer

Page 7

7

An adapter fitting is available for the Rotablator™ Console. This fitting has a

female quick-connect on one end and .6 cm (¼”) MNPT threads on the other.

The .6 cm (¼”) MNPT end is a standard .6 cm (¼”) pipe male fitting and will

readily fit most gas handling equipment or connectors on the house lines. The

quick-connect mates directly to the connector on the end of the supply hose

which normally would attach to a regulator.

Appendix D - Electronic and

Electromagnetic Guidance

Guidance and manufacturer’s declaration - electronic emissions

The Rotablator System is intended for use in the electromagnetic environment specified below. The customer or the user of the Rotablator System should assure that it

is used in such an environment.

Emission Test Compliance Electromagnetic Environment - Guidance

RF emissions

CISPR 11

Group 1 The Rotablator System uses RF energy only for its internal function. Therefore, its RF emissions

are very low and are not likely to cause any interference in nearby electronic equipment.

RF emissions

CISPR 11

Class A The Rotablator System is suitable for use in all establishments other than domestic and those

directly connected to the public low-voltage power supply network that supplies buildings used

for domestic purposes.

Harmonic emissions

IEC 61000-3-2

Class A

Voltage fluctuations / flicker emissions

IEC 61000-3-3

Complies

Guidance and manufacturer’s declaration - electromagnetic immunity

The Rotablator System is intended for use in the electromagnetic environment specified below. The customer or the user of the Rotablator System should assure that it

is used in such an environment.

Immunity Test IEC 60601

Test Level

Compliance Level Electromagnetic Environment - Guidance

Electrostatic discharge (ESD)

IEC 61000-4-2

+

6 kV contact

+ 8 kV air

+

6 kV contact

+ 8 kV air

Floors should be wood, concrete or ceramic tile. If floors are covered

with synthetic material, the relative humidity should be at least 30%.

Electrical fast transient / burst

IEC 61000-4-4

+

2 kV for power supply lines

+ 1 kV for input / output lines

+

2 kV for power supply lines

+ 1 kV for input / output lines

Mains power quality should be that of a typical commercial or

hospital environment.

Surge

IEC 61000-4-5

+

1 kV differential mode

+ 2 kV common mode

+

1 kV differential mode

+ 2 kV common mode

Mains power quality should be that of a typical commercial or

hospital environment.

Voltage dips, short

interruptions and voltage

variations on power supply

input lines

IEC 61000-4-11

<5% UT(>95% dip in UT)

for 0,5 cycle

40% UT(60% dip in UT)

for 5 cycles

70% UT(30% dip in UT)

for 25 cycles

<5% UT(>95% dip in UT)

for 5 seconds

<5% UT(>95% dip in UT)

for 0,5 cycle

40% UT(60% dip in UT)

for 5 cycles

70% UT(30% dip in UT)

for 25 cycles

<5% UT(>95% dip in UT)

for 5 seconds

Mains power quality should be that of a typical commercial or

hospital environment. If the user of the Rotablator System requires

continued operation during power mains interruptions, it is

recommended that the Rotablator System be powered from an

uninterruptible power supply or a battery.

Power frequency (50/60 Hz)

magnetic field

IEC 61000-4-8

3 A/m 3 A/m Power frequency magnetic fields should be at levels characteristic of

a typical location in a typical commercial or hospital environment.

NOTE: UTis the a.c. mains voltage prior to application of the test level.

Page 8

8

Guidance and manufacturer’s declaration - electromagnetic immunity

The Rotablator™ System is intended for use in the electromagnetic environment specified below. The customer or the user of the Rotablator System should assure

that it is used in such an environment.

Immunity Test IEC 60601

Test Level

Compliance Level Electromagnetic Environment - Guidance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2,5 GHz

3 V

3 V/m

Portable and mobile RF communications equipment should be used no closer to

any part of the Rotablator System, including cables, than the recommended

separation distance calculated from the equation applicable to the frequency of the

transmitter.

Recommended separation distance

d = 1,2 √P

d = 1,2 √P 80 MHz to 800 MHz

d = 2,3 √P 800 MHz to 2,5 GHz

where P is the maximum output power rating of the transmitter in watts (W)

according to the transmitter manufacturer and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as determined by an electromagnetic

site surveya, should be less than the compliance level in each frequency range.

b

Interference may occur in the vicinity of equipment marked with the following

symbol:

NOTE 1: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and FM radio

broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an

electromagnetic site survey should be considered. If the measured field strength in the location in which the Rotablator System is used exceeds the applicable RF

compliance level above, the Rotablator System should be observed to verify normal operation. If abnormal performance is observed, additional measures may be

necessary, such as re-orienting or relocating the Rotablator System.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

Recommended separation distances between portable and mobile RF communications equipment and the Rotablator System

The Rotablator System is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of the

Rotablator System can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications equipment

(transmitters) and the Rotablator System as recommended below, according to the maximum output power of the communications equipment.

Rate Maximum Output Power of

Transmitter

W

Separation Distance According to Frequency of Transmitter

m

150 kHz to 80 MHz

d = 1,2 √P

80 MHz to 800 MHz

d = 1,2 √P

800 MHz to 2,5 GHz

d = 2,3 √P

0,01 0,12 0,12 0,23

0,1 0,38 0,38 0,73

1 1,2 1,2 2,3

10 3,8 3,8 7,3

100 12 12 23

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be estimated using the equation

applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and people.

Warranty

Boston Scientific Corporation (BSC) warrants that reasonable care has been

used in the design and manufacture of this instrument. This warranty is in lieu

of and excludes all other warranties not expressly set forth herein, whether

express or implied by operation of law or otherwise, including, but not

limited to, any implied warranties of merchantability or fitness for a

particular purpose. Handling, storage, cleaning and sterilization of this

instrument as well as other factors relating to the patient, diagnosis, treatment,

surgical procedures and other matters beyond BSC’s control directly affect the

instrument and the results obtained from its use. BSC’s obligation under this

warranty is limited to the repair or replacement of this instrument and BSC

shall not be liable for any incidental or consequential loss, damage or expense

directly or indirectly arising from the use of this instrument. BSC neither

assumes, nor authorizes any other person to assume for it, any other or

additional liability or responsibility in connection with this instrument.

Page 9

Boston Scientific International S.A.

55 avenue des Champs Pierreux

TSA 51101

92729 NANTERRE CEDEX

FRANCE

Boston Scientific Corporation

One Boston Scientific Place

Natick, MA 01760-1537

USA

USA Customer Service 888-272-1001

© 2007 Boston Scientific Corporation or its affiliates.

All rights reserved.

90185046-01

Loading...

Loading...