User Instructions

Release n. 03/eng- June 11th, 2016

Table of contents

Warnings and handbook keeping pag. 01

Safety pag. 02

Techincal data pag. 05

Labels and plates pag. 07

How is made pag. 08

Lifting and carrying pag, 08

Indoor oven installation pag. 09

First start pag. 11

Lightings and baking pag. 12

Cleaning pag. 13

Scheme and list of the components ( forced convection ovens

exept “Garden”)

Scheme and list of the components of “Garden” model pag. 16

Scheme and list of the components (static ovens) pag. 18

Electrical diagram pag. 20

Bulb replacement pag. 20

troubleshooting pag. 21

Warranty pag. 23

Declaration of CE conformity pag. 25

pag. 14

NOTICE

This manual provides information for the transport, installation, correct use and

maintenance of the Rossofuoco’s ovens; it is aimed at people involved in the installation,

use and maintenance of the equipment.

Before carrying out any operation, read carefully these instructions.

In case of doubts about the correct interpretation of the instructions, contact the

manufacturer or the reseller to obtain the clarications that you need.

it is forbidden to carry out any operation without having read and understood the

contents of this manual.

non-compliance, even partial, of the recommendations contained in this handbook

may lead to dangers for the user, the irregular operation of the oven and possible

damage to the equipment.

The manufacturer is not liable for damages or injury resulting from failure to observe

this prohibition.

HANDBOOK KEEPING

This manual is an integral part of the product.

It must always accompany the oven even in case of trasfert to other people.

This document should always be available for sta enabled to install, for the use and to

perform the maintenance of the oven.

It must be kept in the immediate vicinity thereof.

The document must be preserved in good condition and easily readable during the all

lifetime of the oven.

Consequently:

• keep this manual in a place protected from heat and moisture, away from liquids.

• use the document without damaging it.

• do not tear the pages and don’t modify the contents of this handbook.

In the event that this booklet has damages that may impair its legibility, or is lost, you

will immediately request a replacement copy from the manufacturer or from the reseller.

01 of 26

SAFETY AND E CONTRAINDICATIONS

Read carefully the entire manual.

01) The oven is designed exclusively for cooking food and should not be used for any other

purpose.

02) The oven is intended for domestic use only. The operator before using the equipment must

read and know all the safety precautions outlined in this document.

03) All local regulations, including those that refer to national and European laws must be

respected when installing or using the unit.

04) The oven must be placed on a oor or platform leveled, with load-bearing capacity appropriated

to substain the weight of the oven declared by the manufacturer (for built-in ovens also see

pag.08).

If you install the oven on the cart supplied by the manufacturer use a proper equipment for

lifting and handling the equipment (also see pag. 08); the oor or the platform must be

appropriated to sustain the weight of the equipment in the support points of the cart.

If the characteristics of the oor or of the platform where you intend to place the oven are not

responding to the needs use approriated load distribution plates.

05) When you install the oven remove all the protective lms, the internal and the external

packagings.

06) The outdoor oven must be placed in a suitable position so that the smoke does not create

any damage or trouble.

07) The oven must be installed to provide access to clean the ue.

08) The connection to the mains must be carried out in accordance with the safety standards in

force in the country of use.

09) The socket which connect the oven must be:

• Complies with the type of plug installed in the same.

• Sized to comply with the nameplate data for power equipment.

• Connected to an ecient earthing system.

• Connected to a power supply system with a protecting device against overload and discharge

currents (breaker / dierential or similar devices) in accordance with the rules laid down by the

European and national laws.

10) The power cord must not:

• come in contact with any type of liquid.

• come in contact with hot surfaces or parts of the equipment.

• be crushed and / or come in contact with sharp surfaces.

• be used to move the equipment.

• be used if damaged.

• be handled with damp or wet hands.

• be wrapped in coil when the oven is working.

• be manipulated.

11) Place any furniture at a distance greater than 15 cm from the oven walls, and 50 cm from the

radiation area of the front doors.

12) Use the oven only when equipped with oven mitts able to provide adequate protection

against heat.

13) Do not touch the oven during normal operation without these protections.

14) WARNING: Accessible parts may become hot during use. Children should be kept away.

15) The oven should be fuelled only with dry virgin wood of small size; it is forbidden to burn any

other material as (for example) pieces of chipboard, “medium density”, pieces of painted wood

panel pieces that may contain resins, foils ant or other media nishing of wood.

17) The use of types of wood dierent from virgin wood can generate toxic combustion gas

and cause damage to the structure of the oven.

The combustion of materials dierent from virgin wood is also prohibited by law.

02 of 26

18) The oven must be steadily controlled by the user during its normal operation.

19) The combustion chamber must always remain closed during operation of the oven, except

during the charging of the wood.

20)The oven must not exceed a temperature of 400 °C (752 F) , beyond this temperature the yield

is not optimal and the equipment can be damaged.

To avoid exceeding this threshold, do not introduce wood in quantities greater than 5 kg at

power up.

21) Never introduce paper, plastic or siliconic materials in order to avoid possible generations of

ames.

22) If you see smoke, turn o the power or unplug the appliance and keep the door closed in order

to extinguish any ames.

23) Follow the detailed instructions for cleaning door seals, cavities and adjacent parts.

24) Clean the oven regularly and remove any residual food. Neglecting to clean the oven could

cause a deterioration of the surface that could adversely aect the life of the device and lead

to dangerous situations.

In addition, where possible, periodically, before switching the oven clean the smoke duct and

the ue, in particular to check for obstructions, especially after a long period of inactivity of the

equipment.

Before cleaning the oven be sure to disconnect the plug from the socket.

Clean the equipment thoroughly following the procedures indicated in this manual.

25) After each use the temperature of the oven remains at high values for a long time.

Make sure that the temperature of the inner and outer walls has reached room temperature

before acting on the oven without the necessary protections.

26) It is recommended to discharge the ashes each time, before the use of the equipment.

When you do it check that there are not burning or hot coals, to avoid burns and / or re and,

however, put the ashes in a steel bin or made with similar material.

27) Any repair, replacement or maintenance must be performed by qualied technician

authorized by the manufacturer.

28) Please contact your dealer or the manufacturer directly for the resolution of any problem.

29) Any type of work on the domestic system that may be necessary to install and use the oven,

should be performed by qualied technician and in accordance with the laws in force in the

country where you live and where you intend to use the equipment.

30) WARNING: IN you need to replace the lamp, to avoid the possibility of electric shock, make

sure that the appliance is switched o and disconnected from the power supply before doing it.

Follow the replacement instructions mentioned in the section “Electrical System” of this manual.

31) In case of re, use carbon dioxide (CO2) extinguishers ; do not use water or powder extinguishers.

32) It is also strictly prohibited:

• Install the unit in a manner dierent from how in this manual.

• Install the equipment in presence of sources that can cause possible combustion (ames,

cigarettes, sparks, etc.).

• Install the unit in areas where there is the possibility of water jets.

• Install and use the equipment close to combustible materials, ammable and / or explosive, or

in places with hazardous atmospheres of re.

• Smoke while using the device, or get closer with devices that can generate combustion, such as

cigarettes or lighters lit, any kind of ames, scintillators.

33) Do not modify the equipment or perform technical operations that are not authorized by the

manufacturer. Each technical maintenance or repairs should always be carried out at specialized

centers authorized by the manufacturer.

34) Do not use any accessories other than those supplied with the oven.

03 of 26

35) Do not use the device in dierent ways and / or for purposes other than those specied in this

manual.; in particular, the appliance should not be used as an incinerator.

36) Don’t use fuels other than those recommended, including liquids.

37) Do not use the unit in physical and mental condition impaired, or under the inuence of

alcohol, narcotics or psychotropic drugs.

38) Do not cover, damage or remove the license and/or techincal plates appliated on the oven

and on it’s accessories.

WARNING

In case of improper use any form of guarantee is void and the manufacturer declines any

responsibility for damages to persons and / or things.

Improper use means:

• any use other than that specied in this manual.

• any use made with ways or techniques other than those permitted in this manual.

• any work on the apparatus in contrast with the instructions provided in this manual.

• any use after tampering of components and / or after alteration of the safety devices.

• any use after repairs performed with unauthorized components.

04 of 26

TECHNICAL DATA AND LABELING

technical data

Table 1 – technical data of the equipment

General Descrizione

Manufacturer ROSSOFUOCO s.r.l. unipersonale

manufacturer’s brand Rossofuoco

Model see rating plate on the oven

Serial number see rating plate on the oven

ELECTRICAL SPECIFICATIONS

Rated supply voltage 230 V

Rated supply frequency 50 Hz

Rated output power 60 W

Secondary supply voltage of the transformer 12 V

Insulation class II

IP Degree of protection IP X4

Width x Length x Height; Weight(*); *

(height of the outdoor models without chimney; height of the indoor models expet smoke pype(15mm))

Outdoor oven ECO 50 with trolley

Outdoor ovens type 65

Outdoor ovens type 80

Outdoor oven SEDICINONI

Outdoor ovens type 100

DIMENSIONS AND WEIGHT OF THE OVENS

with trolley

with trolley

with trolley

with trolley

( for outdoor models is intended with trolley)

Via Cavaleri di Vittorio Veneto, 21

61045 PERGOLA (PU) - ITALY

Tel. +39 0721/735926

fax +39 0721/737107

840x890x1745 mm; 154 kg

1000x1050x1770 mm; 234 kg

1060x1180x1770 mm; 271 kg

1250x1070x1820 mm; 277 kg

1060x1380x1770 mm; 325 kg

Indoor oven ECO 50

Indoor ovens type 65

Indoor ovens type 80

Indoor oven SEDICINONI

Indoor ovens type100

610x690x850 mm; 115 Kg

750X810X970 mm; 178 Kg

800x970x970 mm; 205 Kg

1000X820X1000 mm; 205 Kg

800X1170X970 mm; 253 Kg

05 of 26

CLIMATE CONDITIONS OF USE

Temperature: 5 – 40 °C

Relative humidity 20 – 90 %

FEATURES OF THE LAMP

Type Halogen

Voltage 12 V ac

Power 20 W

THERMAL FEATURES

Maximum load of rewood 4 Kg max

Caloric Value low. Ki 3500 Kcal/Kg

Usefule Thermal Energy (Q) 8500 Kcal/load

Maximum temperature of the oven (Tf) 400 °C

Maximum temperature of the combustion chamber

(Tcc)

Mass ow of combustion gases 7,5 g/s

Flue gas temperature after the stub pipe 270 °C

Minimum supply pressure to the rated thermal

output

850 °C

0,10 mBar

06 of 26

Included Accessories with the oven

Oven mitts - User and installation handbook

Labeling

Fig. 1 - data label installed on the oven

ROSSOFUOCO srl unipersonale

Via Cavalieri di Vittorio Veneto, 21 - 61045 PERGOLA (PU)

ITALY

Model:

Voltage:

Read and follow the operating instructions

Fig. 2 - Security labels installed on the oven

Frequency: Power:

Use only recommended fuels

WARNING: high temperatures

do not touch with hands

07 of 26

TECHNICAL DESCRIPTION OF THE OVEN

The oven consists essentially of a metal casing (or container), of an internal chamber

called cooking chamber and another separated chamber airtight called combustion

chamber that is connected directly to a particular ue for the output of the smoke. In

the lateral spaces between the side panels and the cooking chamber, has been applied

an additional layer of thermal insulation (rock wool) to better protect the outer walls of

the oven by the heat and improve the maintenance of right temperature in the cooking

chamber, that so will last longer constant.

The cooking chamber is all made with hi quality polished stainless steel, specically

suitable for food; the interior thereof, is assembled “cold”, with screws and slots capable

of absorbing without deformations the thermal expansion due to heat.

All materials that remain in contact with atmospheric agents are treated with additional

protection against corrosion that prolongs the durability.

The exclusive system for conveying fumes has also allowed us to create a totally square

cooking chamber, without the usual vault;

so our oven has more space to contain and cook everything well, on any hob, ensuring

on each level the same volume of air and an almost identical amount of heat.

In the cooking chamber it’s possible to accommodate in the same time three shelves

at dierent heights; in the lower part of the room is positioned a refractory plate which

also has the function of allowing a more uniform distribution of the internal heat.

On most of our ovens are installed two valves: one for adjusting the smoke outlet and

one to adjust the output of the steam from the cooking chamber.

The oven is equipped with a thermometer to check the temperature inside the cooking

chamber, a timer, interior lighting, ventilation, chrome grilles, trays, poker and pan

holder.

LIFTING AND CARRYING

For lifting and moving the oven use an appropriate equipment able to substain its

weight.

The oven can be lifted using the appropriate engagement (pos. 20) located inside the

outlet duct of the fumes.

Once unpacked, never lift the oven using systems forks; it ‘s absolutely forbidden to lift

the oven by hand.

The oven can be equipped, where not supplied as standard, with our cart (supplied

separately on request), with

extractable handles (position 3)

and with wheels (position 2) .

The cart is made for small

shifts of the oven in the area

where you are using it. Avoid

to move the oven on inclined

planes. Avoid to move the oven

when it is working.

08 of 26

HOW TO INSTALL THE BUILT-IN OVEN

For the installation of the built-in oven, in addition to what is indicated in other parts of

this manual, the following is recommended:

1. To place the oven prepare a compartment with two supporting walls with longitudinal

length equal to that of the oven and with a recommended height of about 60/70

centimeters, or use our specic metal support (optional); the oven should be installed

so that it can be moved easily for any maintenance if necessary;

2.Depending on the location (near or far from ammable materials) follow the minimum

requirements set out in the diagram on the next page;

3.Connect the smoke pipe of the oven to the chimney with a stainless steel tube

(130mm diameter);

4. Check that the ue is sized appropriately for the draft in compliance with the

regulations in force in the country where the oven is installed;

The section must be no less than 120x120mm (if square) or with a diameter of at least

150mm (if round);

5. In case of realization of a counterhood above the oven, in order to facilitate any

maintenance, it is essential to make it removable or equip it with an opening part (see

scheme 1 and 2 in the next page);

6. if it is not already present in the oven, apply a damper (this could be useful in

chimneys over 2m.); make sure that the chimney is free from obstructions. The damper

shall be of the type that does not totally block the smoke even in case of accumulation

of combustion residues. The damper must be easy to handle and with an opening in

the plate which, in a continuous area, occupies at least 20cm ² or 3% of the section of

the plate if this is larger;

7. Channelized output of the vapors, from the control valve to the outside, or in any case

in an area not watertight;

8. The AC adaptor supplied with the oven must remain accessible for any check

and maintenance, so install it in a xed position outside the masonry wall of the

compartment that houses the oven;

9.Ensure that the ventilation engine on the rear of the oven has always enough space

for the ow of the air required to keep it cool;

10.Make sure that the room where you instal installation the oven has a proper air

exchange (refer to the relevant laws in force in your country).

NB: an installation that does not comply with even one of the above conditions cause

the void of the warranty and exempts the manufacturer from any liability for any

consequence.

09 of 26

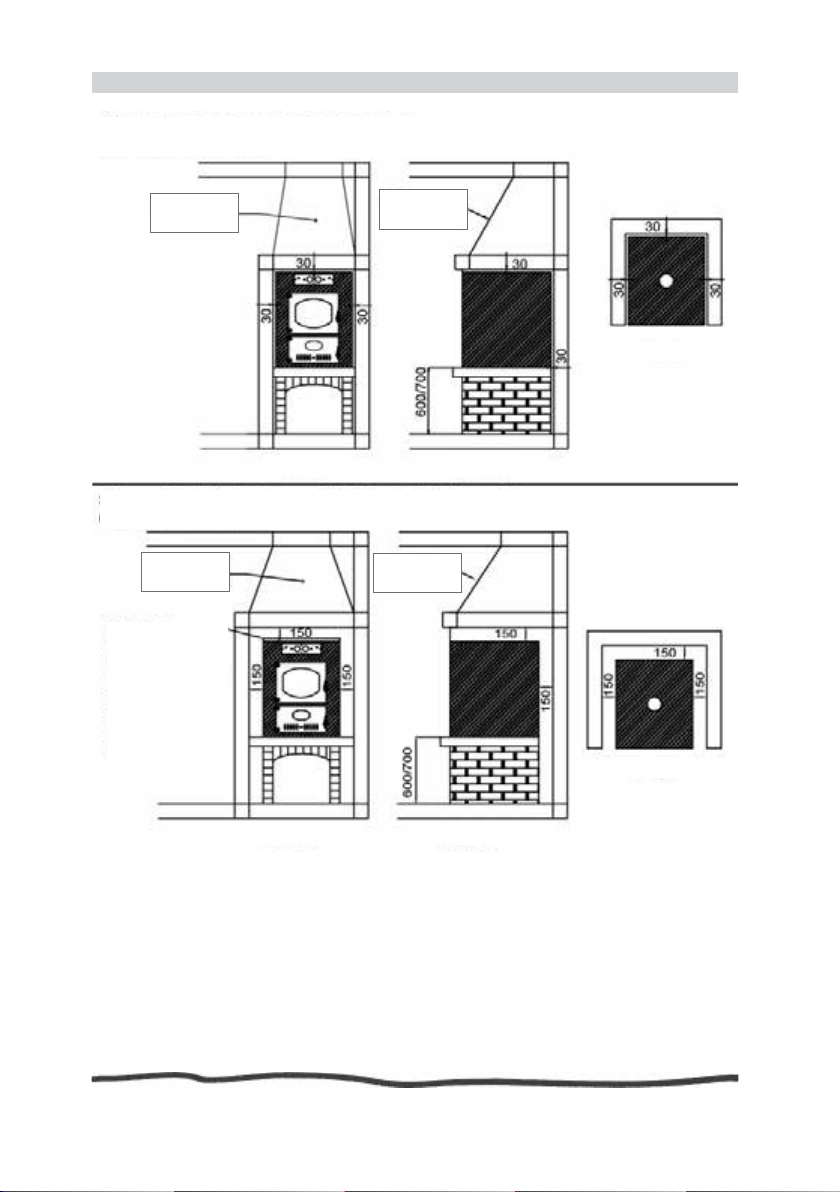

Fig. 3 - Scheme for mounting the built-in oven

Diagram 1: standard installation in masonry

(dimensions in millimeters)

Removable

counterhood

Front view

Diagram 2: installation near inammable materials

(dimensions in millimeters)

Removable

counterhood

In the case of coating with removable

ange, for a proper

circulation of air,

leave a slot of at

least 270 cm ².

Removable

counterhood

Removable

counterhood

Plant

Side view

Plant

Front view

Side view

An installation that does not comply with even one of the above conditions cause

the void of the warranty and exempts the manufacturer from any liability for any

consequence.

10 of 26

FIRST START OF THE OVEN

The rst lighting of a new oven must be done without cooking any of food.

Proceed as follows:

Load the combustion chamber (the lower door with louvers to adjust the air - page. 14

- Pos. 26 or page 16 - Pos. 14) with small pieces of dry virgin wood putting it above the

grid; for the rst lighting 2/3 kg of wood are enough.

Make sure that everything is set for the correct functioning; open the smoke valve

(where applicable) and then light the re using some very small pieces of wood or some

few little pieces of paper.

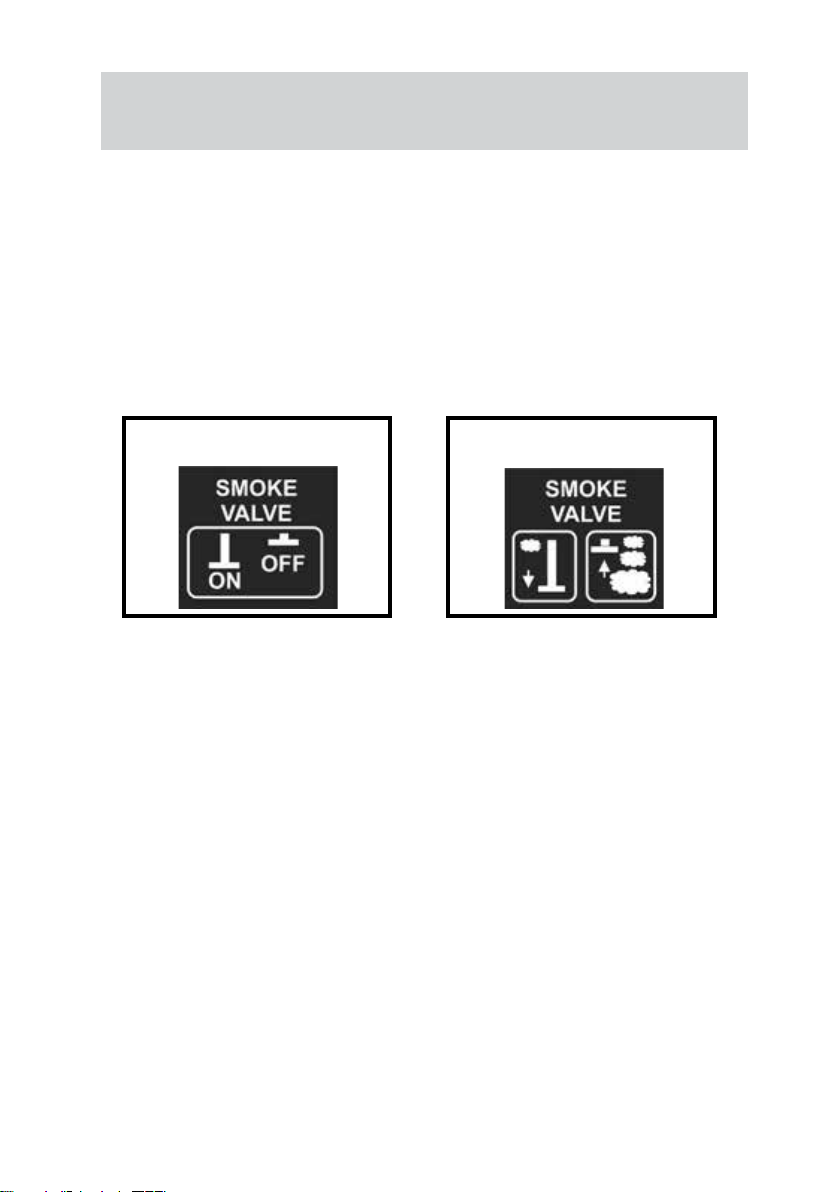

Warning: the action of the knob on the valve fumes was reversed on models produced from 1 January 2013 where,

to open the valve and increase the output of the fumes, the knob must be pushed towards the oven.

Position of the smoke valve knob for models

manufactured before January 1st. 2013

(Be careful to never use any type of liquid or gaseous fuel or explosive mixtures as well

as chemicals or petroleum-based, or alcohol or gasoline or anything not made for these

purposes.)

Position of the smoke valve knob for mo-

dels manufactured after January 1st. 2013

After starting the re close the door leaving fully open the slots for the airow so that

the wood burns well to turns into burning coals.

In this rst ignition phase heat the oven over 150 °C (302°F), but without reaching the

maximum temperature, and leave it on for an hour; this will eliminate the residual of

moisture from the rebricks.

Do not worry if you see whitish smoke and feel unpleasant smells; it is normal at the rst

heating of the new materials.

Please remember that the release of whitish smoke and unpleasant smells may

continue for 5/6 ignitions; this does not means a malfunction.

If the temperature inside the cooking chamber rises too, you can momentarily open

the door of the cooking chamber to let out a bit of hot air, or you can act on the slits on

the door of the combustion chamber to decrease the air ow on the coals in order to

reduce the combustion.

After this rst start the oven is ready for normal use.

11 of 26

LIGHTING THE OVEN AND COOKING FOODS

Repeat the lighting procedure as described on the previous page, but changing the

amount of wood to be inserted in relation to what you are going to cook (the scheme

on the next page will help you).

During the lighting phase open the valve that regulates the output of fumes and

adjustable slots on the door of the combustion chamber.

It is important to keep in mind that the oven should work with burning coals and not

with vivid ame inside the combustion chamber.

The amount of wood recommended is approximate and calculated to reach the right

operating temperature of the oven in the same time in wich the burning wood turns to

hot coals; hot coals instead of vivid ames will give to the cooking chamber the right

heat for all the time of cooking.

In this condition the oven will almost never need to be furter fed except when the

cooking times are particularly long or when you open many times the door of the

cooking chamber, such as when baking pizzas; in this case if necessary add more wood,

but only small pieces, each once.

If it happens that the operating temperature in the cooking chamber is reached when

the ame is still alive inside the combustion chamber, cool the cooking chamber

opening its door; the next time you turn on the oven, reduce the amount of wood

introduced.

When, after turning on the oven, the desired temperature has been reached and the re

will be turned into hot coals insert into the cooking chamber the food to cook, keeping

the door open less time as possible.

Thanks to the glass on the door and the internal lighting (that can be activated with the

switch that gives the symbol), you can easily control the food while cooking.

Since the oven is provided with ventilation system, have the foresight to disable it

before opening the door of the cooking chamber, to avoid a more consistent dispersion

of heat to the outside.

If you want to cook food directly on the grill it is reccomended to put under it a baking

pan, large enough, with a small amount of water in which will drop the fat of the food;

so the bottom of the oven does not get dirty and will not be produced unpleasant

fumes and smells.

In all operations with hot oven, checks continuously it and it’s functioning; always use

protections to avoid burns.

The temperatures and cooking times given in the table on the next page, or in the

brochures of our oven, or in the cookbook or in our web site, are for guidance only and

must be directly evaluated and adjusted by the oven’s user according to common sense

and to the specic conditions of the moment.

After each use (but when the oven is cold) it is recommended to thoroughly clean

the ioven and to empty the combustion chamber from the ashes, following the

reccomendations given in this booklet.

If combustion ends before you have nished cooking, in order to preserve for longer

a high temperature, close the fumes valve (but not totally) and close the adjustable

aerator of the combustion chamber too.

If you want drier air inside the cooking chamber open the steam valve (if available).

12 of 26

Fig. 4 - Table of cooking times and temperatures

Cooking times and temperatures

Food TemperatureC°Heating time

(minutes)

Pizza 350-380 60 07-10 6

Bun 320-350 45 15-20 4-5

Bread 300-330 54 70-90 4-5

Lasagna 280-300 40 30-40 3-4

Roast meat 300-350 45 60-90 4-5

Grilled sh 230-250 35-40 20-30 3-4

Grilled vegetables 230-270 35-40 20-30 3

Cakes 180-220 30-35 20-30 3

The charge of wood indicated in the table refers to the total of the initial amount and that estimated to be

added while baking in order to maintain the right temperature for all the time of cooking.

Cooking time

(minutes)

Wood load

(Kg.)

CLEANING OF THE OVEN

To clean the oven do not use abrasive cleaners, scouring pads, steel wool, acids or

rough cloths because these products may permanently compromise the aesthetics of

the oven.

Clean the inside of the cooking chamber, when the oven is o and cool, using a soft

cloth with warm water and mild soap, then dry it with a soft cloth or chamois leather.

Remove each time any possible residue of the food to prevent its burning the next time

you use the oven.

Also clean the painted parts and the glass with a soft cloth, mild soap and water.

Thoroughly clean the combustion chamber from the ashes and empty the ash pan

following the recommendations already given in other sections of this manual.

13 of 26

SCHEME OF THE OVEN

models with forced convection system, exept “Garden” and “Garden Plus”

14 of 26

LIST OF PARTS

models with forced convection system, exept “Garden” and “Garden Plus”

POS. DESCRIPTION CODE

1 Cart (**) 03_01_01

2 Cart wheels (**) 03_02_02

3 Cart extractable handles (**) 03_03_02

4 Cart door (**) 03_04_01

5 Knobs for cart door and for air regulator 03_05_02

6 Stainless steel hinges for combustion chamber and cooking chamber doors 03_06_04

7 Cooking chamber door 03_07_01

8 Central faceplate 03_01_04

9 Combustion chamber door 03_09_01

10 Air regulation slits for combustion chamber 03_10_01

11 Ergomonic “cool-grip” handle 03_11_02

12 Company Logo 03_12_01

13 Doors subframe 03_13_01

14 Front panel 03_14_01

15 Tools faceplate 03_15_01

16 Smoke valve and steam valve knobs 03_16_02

17 Fan and lamp switches 03_17_02

18 Timer 03_18_01

19 Thermometer 03_19_01

20 Front and rear under-roof panels - tympanums (*) 03_20_02

21 Smoke pipe ange (*) 03_21_01

22 Chimney (*) 03_22_01

23 Roof (*) 03_23_01

24 Top panel 03_24_01

25 Base structure 03_25_01

26 Combustion chamber 03_26_01

27 Ash pan 03_27_01

28 Fire grate 03_28_01

29 Refractory plate 03_29_01

30 Refractory plate slit 03_30_02

31 Plain chrome plated grid 03_31_03

32 Supports for grids 03_32_02

33 Cooking chamber 03_33_01

34 Steam valve 03_34_01

35 Smoke valve 03_35_01

36 lift engagement 03_36_01

37 Lamp holder 03_37_01

38 Lamp 03_38_01

39 Right and left panels 03_39_02

40 Rockwool 03_40_01

41 Rear panel 03_41_01

42 AC adapter 03_42_01

43 Air conveyor 03_43_01

44 Fan system cover 03_44_01

45 Fan system kit 03_45_01

46 Air ow grid 03_46_01

47 Fume duct 03_47_01

48 Metal springs and Locking spring hooks 03_48_02

49 Tempered Glass 03_49_01

(*) = only for outdoor versions (**)= optional

15 of 26

SCHEME OF THE OVEN

“Garden” and “Garden PLus” with forced convection system

16 of 26

LIST OF PARTS

“Garden” and “Garden Plus” with forced convection system

POS. DESCRIPTION CODE

1 Chimney wind cap (*) 04_02_01

2 Rear under-roof panel - tympanum(*) 04_02_02

3 Front under-roof panel - tympanum (*) 04_02_03

4 Roof (*) 04_02_04

5 Steam valve 04_01_01

6 Flue 04_01_02

7 Lamp 04_01_03

8 fan system 04_01_04

9 AC adapter 04_01_05

10 Air conveyor 04_01_06

11 Cooking chamber 04_05_01

12 Fume duct 04_01_08

13 Supports for grids 04_05_02

14 Combustion chamber 04_06_01

15 Plain chrome plated grid 04_05_03

16 Fire grate 04_06_02

17 Ash pan 04_06_03

18 Doors subframe 04_01_14

19 Smoke valve knob (*) 04_03_01

20 Fan switch 04_03_02

21 Thermometer 04_03_03

22 Lamp switch 04_03_04

23 Steam valve knob (*) 04_03_05

24 Tools faceplate 04_03_06

25 Stainless steel hinges for cooking chamber door 04_04_02

26 Cooking chamber door 04_04_04

27 Tempered Glass 04_04_03

28 Central faceplate 04_04_05

29 Company Logo 04_04_06

30 Stainless steel hinges for combustion chamber door 04_04_07

31 Air regulation slits for combustion chamber 04_04_08

32 Knob for air regulator 04_04_09

33 Combustion chamber door 04_04_10

34 Knob for lower compartement door 04_01_15

35 Lower compartment door 04_01_16

36 Base structure 04_01_17

37 Wheels 04_01_18

38 Right side panel 04_01_19

39 Left side panel 04_01_20

40 Extractable handles 04_01_21

41 Ergomonic “cool-grip” handle 04_04_11

(*) “Garden Plus” only

17 of 26

SCHEME OF THE OVEN

Models without forced convenction system

1

3

5

2

4

6

12

7

10

9

15

13

11

18

16

17

14

23

24

25

8

19

20

21

22

26

18 of 26

LIST OF PARTS

Models without forced convenction system

POS. DESCRIPTION CODE

1 Chimney wind cap (*) 05_02_01

2 Rear under-roof panel - tympanum (*) 05_02_02

3 Front under-roof panel - tympanum (*) 05_02_03

4 Roof (*) 02_02_04

5 Internal Roof 05_01_01

6 Lamp 05_01_02

7 Firebrick 05_01_03

8 Machine body 05_01_04

9 Cooking chamber door 05_03_01

10 Handle of the cooking chamber door 05_03_02

11 Tempered Glass 05_03_03

12 Combustion chamber door 05_04_01

13 Company Logo 05_04_02

14 Handle of the combustion chamber door 05_04_03

15 Central faceplate 05_01_05

16 Ash pan and re grate with barbeuce

function

17 Thermometer 05_01_06

18 Chrome plated grid 05_05_02

19 AC adapter 05_01_07

20 External casing 05_01_08

21 Lamp switch 05_01_09

22 Cart 05_06_00

23 Extractable handles 05_06_01

24 Cart door 06_06_02

25 Door’s cart knob 05_06_03

26 Cart wheels 05_06_04

(*) only for outdoor models

05_05_01

19 of 26

ELECTRICAL SYSTEM

The oven may work well even without electricity that is necessary only for the lamp and

for the ventilation.

Note tha even turning o the ventilation you get a good cooking.

As told before the electrical system of the oven has the function to supply the internal

fan of the ventilation system and the halogen bulb used to illuminate the inside of the

cooking chamber.

The oven is equipped with a secure power supply adapter which outputs a safety low

voltage (12 V ac) for supplying electrical components inside.

ELECTRICAL DIAGRAM

M = Cooling fan engine

L1 = Lamps of the cooking chamber

P1 = Lamps switch

P2 = Fan Switch

T1 = AC adapter 220-230V 50Hz / 12V 60 Va

PLEASE NOTE: In the outdoor models, the AC Adapter is placed by the manufacturer on

the back of the oven.

In the built-in versions the AC Adapter must remain accessible for maintenance; therefore

it must be xed externally to the masonry walls that house the oven

ELECTRICAL COMPONENTS

Domestic power supply

18a = Cooling fan engine

18b = Cooling fan

19 = Lamp holder + glass cover + Lamp (12V -20W)

23a = Lamps Switch

23b = Fan Switch

39 = AC adapter 220-230V 50Hz / 12V 60 Va

47 = Electric cable

Electric cable (leght 2 mt.)

(for built-in ovens)

LAMPS REPLACEMENT

This operation must always be performed when the oven is cold:

1 Disconnect the oven from the power supply;

2 Unscrew the glass cover that protects the lamp;

3 Remove the old lamp by pulling it out and replace it with another of the same

characteristics as the original (see Table 1 of Technical Data page 06), being careful to

do not touch directly the new lamp with your ngers;

4 Screw the glass cover of the lamp and then reconnect the oven to the mains.

Warning: The lamps are halogen bulbs, so in case of replacement, the new lamps can

not be touched with the ngers; use a handkerchief (for example) to handle them.

20 of 26

TROUBLE SHOOTING

TROUBLE POSSIBLE REASON SOLUTION

The electrical system of the oven

does not work

The interior light does not work Lamp to be replaced or not fully

The internal fan does not work fan damaged Contact the manufacturer or an

The timer does not work The timer is damaged Contact the manufacturer or an

The thermometer does not work The thermometer is damaged Contact the manufacturer or an

The re don’t lights Damp wood and / or closed

The oven does not reach the right

temperature

Improper release of smoke Failure to follow the prescrip-

The power plug not properly

inserted in the socket.

Electrical cable frayed and

broken. Contact the manufacturer or an

Failure of the electronic control

circuit.

inserted into the holder.

The power switch is not

working

Fan switch not working

valves

Amount of wood insucient or

unsuitable

tions about the installation and

the use of the oven

Check the connection and the

functioning of the outlet.

authorized service center.

Replace the lamp, or push it

further into its holder following

the directions given in this

manual

Contact the manufacturer or an

authorized service center.

authorized service center.

authorized service center.

authorized service center.

Use appropriate wood and / or

check the correct opening of

the valve.

Add more wood (within the

limits recommended) and check

that it is of a type suitable.

Please read again carefully this

manual and correct any dierences in the installation or use,

according to the recommendations given in it.

21 of 26

22 of 26

Model Serial

To be completed and stored by the customer

WARRANTY CARD

Date of purchase

Stamp and signature of the dealer

Attention, this part of the

warranty card must be stored

by the costumer, while the part

below, completed with all the

required data, must ber cut and

sent to the manufacturer at the

address indicated on the back.

Customer’s data

Name Surname

Address

Post code City Region/ prov/county

State Phone number (with international code)

e mail

WARRANTY CARD

To be completed and sent to the manufacturer

Model Serial Date of purchase

Stamp and signature of the dealer

Attention, this part of the war-

ranty card must be completed

with all the required data, cut

and sent, to the manufacturer

at the address indicated on

the back.

section for the customer

section to be sent to the manufacturer

Customer’s data

Name Surname

Address

Post code City Region/ prov/county

State Phone number (with international code)

e mail

Customer’s signature

Warnign, the Warranty cards incomplete, or without the stamp and the signature of the dealer will be

not considered valid.

WARRANTY CARD

The oven is guaranteed for 2 years from the date of purchase shown on the back of this card and

axed by the dealer at the time of sale along with stamp and signature.

The manufacturer’s warranty covers the cost of the parts, while the costs of transportation, labor,

technician, or any other costs shall be borne by the customer as any works of demolition and / or

restoration.

The electrical system is not covered by the guarantee; will also not be covered by warranty faults

or failures due to neglect, improper handling, installation, normal wear and tear, acts of God, re,

vandalism, tampering, damage during installation or transport and in any case everything is a result

of misuse of the oven, with particular regard to breaches of the limits of temperature (400 C°), the use

of non-approved fuels and non-compliance with the instructions regarding installation and housing

(with particular reference to the built-in models).

The manufacturer does not assume any further liability or other than those mentioned here.

For the request of such work and / or repairs we reccomend that you contact the retailer from whom

section for the customer

the oven has been purchased.

Attention, this part of the warranty card must be stored by the costumer, while the

part below, completed with all the required data, must ber cut and sent to the manu-

facturer at the address indicated on the back.

WARRANTY CARD

The oven is guaranteed for 2 years from the date of purchase shown on the back of this card and

axed by the dealer at the time of sale along with stamp and signature.

The manufacturer’s warranty covers the cost of the parts, while the costs of transportation, labor,

technician, or any other costs shall be borne by the customer as any works of demolition and / or

restoration.

The electrical system is not covered by the guarantee; will also not be covered by warranty faults

or failures due to neglect, improper handling, installation, normal wear and tear, acts of God, re,

vandalism, tampering, damage during installation or transport and in any case everything is a result

of misuse of the oven, with particular regard to breaches of the limits of temperature (400 C°), the use

of non-approved fuels and non-compliance with the instructions regarding installation and housing

(with particular reference to the built-in models).

The manufacturer does not assume any further liability or other than those mentioned here.

For the request of such work and / or repairs we reccomend that you contact the retailer from whom

the oven has been purchased.

section to be sent to the manufacturer

Warning: this part of the warranty card must be completed with all the required data,

cutted and sent to the manufacturer at the following address:

ROSSOFUOCO srl - Via Cavalieri di V. Veneto, 21 - 61045 PERGOLA (PU) - ITALY

DECLARATION OF CONFORMITY - CE

ROSSOFUOCO S.r.l. unipersonale

Via Cavalieri di Vittorio Veneto, 21 – 61045 PERGOLA (PU)- ITALY

declares under its own responsability that the following products:

• SERIES: STEEL, outdoor and built-in models 65 - 80 -100

• SERIES: ECO, outdoor and built-in 50 - 65 - 80 -100

• SERIES: FIAMMA, outdoor and built-in 65 - 80 -100

• SERIES: EFFE, outdoor and built-in models 65 - 80 -100

• SERIES: GARDEN, GARDEN PLUS all models

• SERIES MINUTINO, QUATTROSTAGIONI

• SERIES: RED, built-in models 65 - 80 -100

• SERIES: SEDICINONI, outdoor and built-in models 80

complies with the following product’s standards and subsequent amendments

Rule European references Description

CEI EN 60335-1(2008) EN 60335-1 (2002)

CEI EN 60335-2-102 (2007)

A1(2011)

CEI EN 62233 (2009) EN 62233 (2008) Methods of measurement

CEI EN 55014-1 (01-2008)

A1 (2010)

A2 (2012)

CEI EN 55014-2 (2015) EN 55014-2 (2015) Electromagnetic compatibility

CEI EN 61000-3-2 (2015) EN 61000-3-2 (2014) Electromagnetic compatibility

EN 63335-1/A1 (2004)

EN 60335-1/A11 (2004)

EN 60335-1/A2 (2006)

EN 60335-1/A12 (2006)

EN 60335-1/A1/EC (2007)

EN 60335-2-23 (2006) Safety of household and similar

EN 55014-1 (12-2006)

A1 (2009)

A2 (2011)

Safety of household and similar

devices nature

Part 1: General requirements

electrical.

Part 2: Particular requirements

for appliances with gas burners,

gas oil and solid fuel tted with

electrical connections.

for electromagnetic elds of

household appliances and similar

apparatus with regard to human

exposure.

Electromagnetic compatibility - prescription for household appliances, electric tools and similar

apparatus.

Part 1: Emission.

- Requirements for household

appliances, electric tools and

similar apparatus.

Part 2: Immunity - Product family.

(EMC)

Part 3-2: Limits - Limits for harmonic current emissions (equipment

input current <= 16 A per phase)

25 of 26

Rule European references Description

CEI EN 61000-3-3 (2014)

EC 1(2014)

UNI EN 13229 (2006) EN 13229 (2001) Inset appliances including open

UNI EN 12815 (2006)

EC 1 (2008)

EC 2 (2011)

CEI EN 50581 (2013) EN 50581 (2011) Technical documentation for

EN 61000-3-3 (2013) Electromagnetic compatibility

(EMC)

Part 3-3: Limits - Limitation of

voltage changes, voltage uctuations and icker in low-voltage

supply systems for equipment

with rated current <= 16 A per

phase and not subject to conditional connection.

res red by solid fuels - Requirements and test methods

EN 12815 (2001) Residential cookers red by solid

fuel - Requirements and test

methods.

the assessment of electrical and

electronic products with respect

to the restriction of hazardous

substances

... and in accordance with the provisions of the following EC directives and following

amendments:

Directive/Regulation Description

Directive 2014/30/UE Directive 2014/30/UE of the European parliament and of the Council

Directive 2014/35/UE Directive 2014/35/UE of the European parliament and of the Council

Regulation1935/2004 Regulation (EC) No 1935/2004 of the European parliament and of

Directive 2011/65/UE Directive 2011/65/EU of the European parliament and of the Council of

Directive 2012/19/CE Directive 2012/19/CE of the European parliament and of the Council

of 26 February 2014 on the approximation of the laws of the Member

States relating to electromagnetic compatibility.

of 26 February 2014 on the harmonisation of the laws of Member

States relating to electrical equipment designed for use within certain

voltage limits.

the Council of 27 October 2004 on materials and articles intended to

come into contact with food and repealing Directives 80/590/EEC and

89/109/EEC.

8 June 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment (recast).

of 04 July 2012 on waste electrical and electronic equipment (WEEE)

(RAEE).

Pergola (Italy) , June 11th 2016

26 of 26

(ROSSOFUOCO s.r.l. unipersonale)

The legal representative

manufactured by:

ROSSOFUOCO srl unipersonale

Via Cavalieri di Vittorio Veneto, 21

61045 Pergola (PU) - ITALY

P.Iva: 02443170416

tel. +39 0721 735926 - fax +39 0721 737107

mail: info@rossofuoco.com

www.rossofuoco.com

Loading...

Loading...