Page 1

SA-02 Instruction Manual - Version 1.0 (Page 1/2)

1

Supervised Wireless Magnetic

Contact Sensor

This product may be sold in the following

member states of the European Community:

Austria Germany Norway

Belgium Greece Portugal

Denmark Holland Spain

Finland Ireland Sweden

France Italy United Kingdom

!

INSTALLATION INSTRUCTIONS

AND IMPORTANT INFORMATION

9J-REL-001/0706-0670001-00

4

FEATURES OF SA-02 - Performance

Magnetic Contact Sensor

The SA-02 Supervised Wireless Magnetic Contact

Sensor is a high-performance intrusion sensor

developed with the highest level of technology to make

it ideal for residential and commercial applications.

Following features standard.

Supervisor

Case & Back Tamper Detectors

ASIC and Microprocessor Technology

Up to 3-yr. Battery Life with SPS

Ultra-low Current Consumption

Readily Replaceable 3.6V- 1/2 AA Lithium Battery

SMD Component technology

L.E.D. Test Function

P/N:

2 3

INTRODUCTION (FAQ's)

Q: What is a Magnetic Contact Sensor ?

A: A Magnetic Contact Sensor is a sensor which

detects the opening and closing of doors or

windows protected by the sensor.

Q: What is WIRELESS and how can it benefit me ?

A: Wireless is the use of radio signals to transmit a

signal from any sensor to a security panel,

eliminating the need for setting wire ducts, extra

cabling materials or drilling, saving time and money.

Q: What is SUPERVISOR or SUPERVISED sensor ?

A: A Supervised sensor continuously reports to the

receiver or security panel to confirm status of the

sensor and its presence. If the receiver fails to hear

from a sensor within a pre-programmed time, it

will presume a sensor is missing or malfunctioning

and notify the user. This provides added security.

5 6

INSTALLATION - Performance Criteria

The SA-02 Magnetic Contact Sensor detects the opening

and closing of doors and windows and transmits this

information to the receiver panel.

- AVOID: Placing the Magnetic Contact Sensor near

strong magnetic or electrical fields other than the

magnet with which it is intended to be used. Otherwise,

performance could be affected and false alarms could

occur.

- AVOID: Mounting on or near large metal surfaces and

multiple concrete/steel walls. This may interfere or block

the wireless signals. Make sure to test the range from

any location by using the RF Test Procedure to ensure

reception.

- IMPORTANT NOTE: Install the Magnetic Contact

Sensor on windows or doors that have firm hinges and

firm locking action to prevent false alarms associated

with wind or bumping.

INTRODUCTION (FAQ's) - continued;

Q: What is LOW BATT detection ?

A: For all supervised sensors, LOW BATT detection is

when a sensor continuously measures its battery

state and transmits a low battery signal to the

security panel when the battery's voltage drops

below a certain level. This alerts the user in advance

to replace a weak battery.

Q: What is a CASE TAMPER detector?

A: A Case Tamper detector monitors any unauthorized

opening of the unit housing. A signal will be

transmitted to the security panel to notify the user of

such tampering.

Q: What is a BACK TAMPER detector?

A: Once the sensor is mounted and activated, the Back

Tamper detector ensures that the sensor is not

removed or vandalized by detecting any removal of

the unit from a wall or corner. The Back tamper

detector will alert the security panel in such cases.

STEP-1 INSTALLING THE BATTERY (Fig 1)

Use only the specified 3.6 V Lithium Battery.

(See block 22)

1) Unscrew the case locking screw and remove the front

cover. CAUTION Do not touch the magnetic element

or the electronic components inside as this may

cause damage.

2) For a new unit, simply remove the plastic strip

contact breaker. For replacement, remove the battery

by using a small screwdriver. CAUTION: Notice

the polarity. Replace with a fresh battery.

3) Dispose of the old battery properly. Do not

incinerate, heat, disassemble, recharge.

4) To test, press in both the back-tamper and the case tamper buttons, or use a magnet to simulate a door

opening and closing. The LED will light to indicate

an RF transmission.

5) Close the front cover and replace the locking screw

7

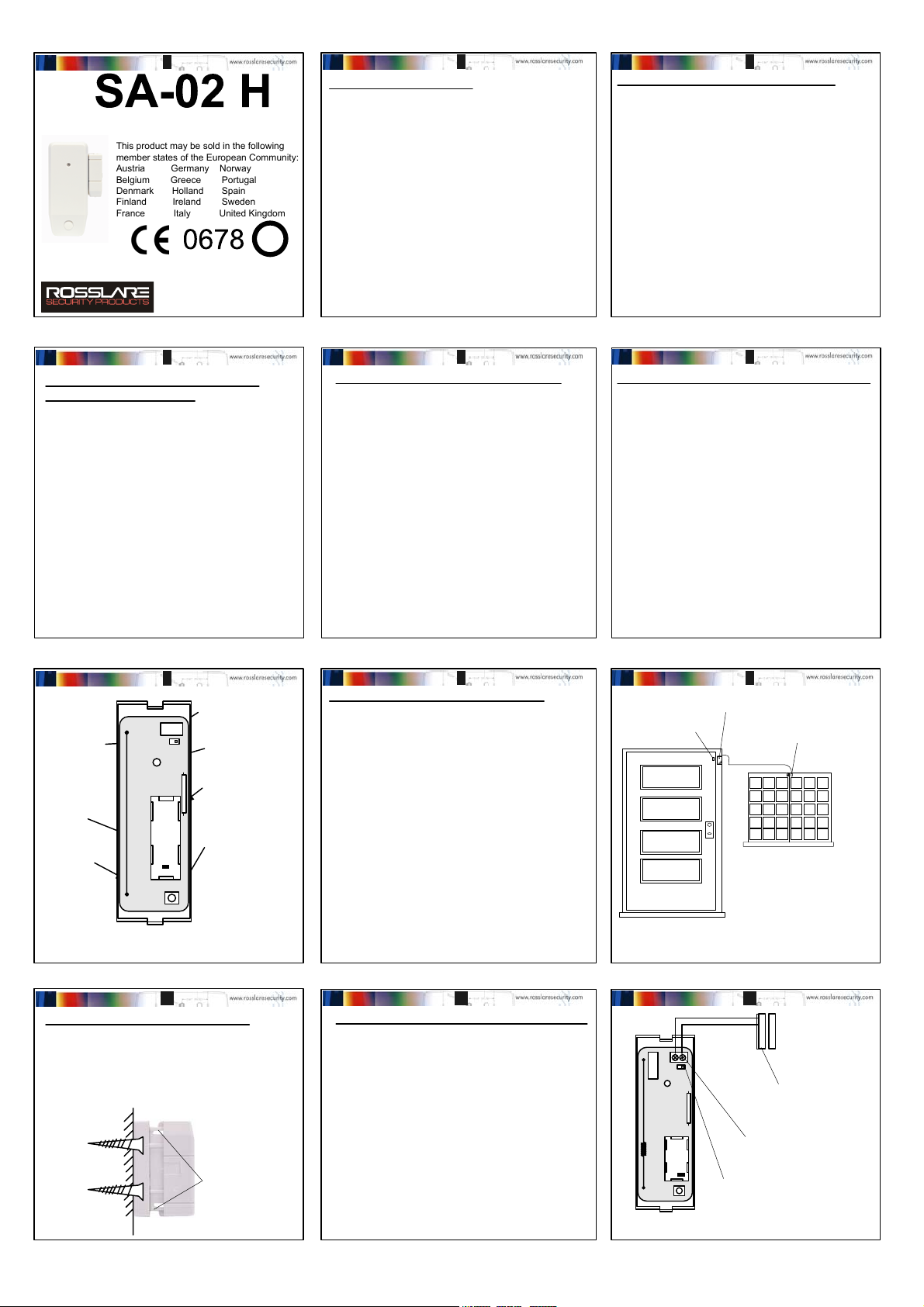

TERMINAL BLOCK FOR

WIRED CONTACTS

JUMPER FOR

EXTERNAL

SENSOR

BATTERY

HOLDER

ANTENNA

+

FRONT OF PCB

RF TRANSMISSION

INDICATION LED

MAGNETIC CONTACT

INTERNAL SENSOR

CASE TAMPER

BUTTON

(NORMALLY CLOSED)

FIG 1: Front of PCB

10

STEP-3 SELECT MAGNET HEIGHT

The SA-02 comes equipped with a standard magnet with

adjustable height, suitable for most applications When

there is a special need, select the appropriate height for

the magnet assembly that will suit the location of the

sensor. (FIG 3)

To adjust for a

possible mismatch in

height, between the

door and the frame,

the magnet part has a

mechanism to adjust

it's height. Simply

press on the sides

and adjust the

FIG 3: Magnet

height.

8 9

STEP-2 SELECTING THE LOCATION

The location and mounting of the SA-02 affects both the

transmission range and wear and tear of the transmitter.

Preferably the transmitter should be installed as close

as possible to the receiver and mounted in a high

location so that the transmission will have less

interference.

1) Select a DOOR OR WINDOW within a room or hallway

that best matches the criteria in section 5. (Fig 2):

2) Make sure that the Magnetic Contact Sensor will be

mounted on a sturdy, non-vibrating door or

window frame. Note: Following this instruction will

reduce bumping and vibration effects on the

sensor, and will extend the life of the product.

3) Perform the RF Test from the proposed mounting

location to ensure that the sensor can be received.

4) Select the appropriate height for the magnet

assembly that will suit the location of the sensor.

11 12

STEP- 4 WIRING THE EXTERNAL SENSOR

When the internal magnetic sensor in the SA-02 is not

applicable, or an additional set of contacts are needed

for the SA-01, the following procedure is required:

The maximum distance that an external contact can be

away from the SA-02 is about 8.5 meters or 25 feet.

1) This step is not necessary unless installing a remote

external magnetic contact sensor with a wire to the

SA-02.

2) Remove the case locking screw and front cover.

3) Connect the external magnet(s) in series to the wired

input terminal block of the magnetic contact sensor.

4) Move the jumper cover to the two right-most pins to

activate the external magnetic contact input.

5) Replace the front cover and locking screw.

Please see FIG 4.

Mount the SA-02

onto the stationary

Mount the Magnet

onto the door

door-frame

FIG 2: Selecting a Location

Terminal Block

for External Magne tic

+

Contact.

Jumper for activating the

external contacts.

FIG 4: Wiring an External Sensor

Connect additional

external contacts

by wire to the

SA-02

Wired External Magnetic

Contact.

Page 2

SA-02 Instruction Manual - Version 1.0 (Page 2/2)

13

STEP-5 ACTIVATING THE BACK TAMPER

Each Magnetic Contact Sensor SA-02 is equipped with

both a Back and Case Tamper detector. The case tamper

detector is always active, however the wall tamper

detector (normally inactive) is optionally activated by

cutting a Jumper.

For additional protection against the theft or removal of

the sensor from the mounting location, the back tamper

can be activated to work in unison with case tamper by

cutting the jumper R18 which is on the top side of the

PCB.

1) Remove the case locking screw and front cover.

Look at the front of the PCB with the antenna

showing (FIG 5)

2) To activate the back tamper switch, locate and cut

the jumper

3) Replace the front cover and locking screw. The Back

tamper will be active.

16

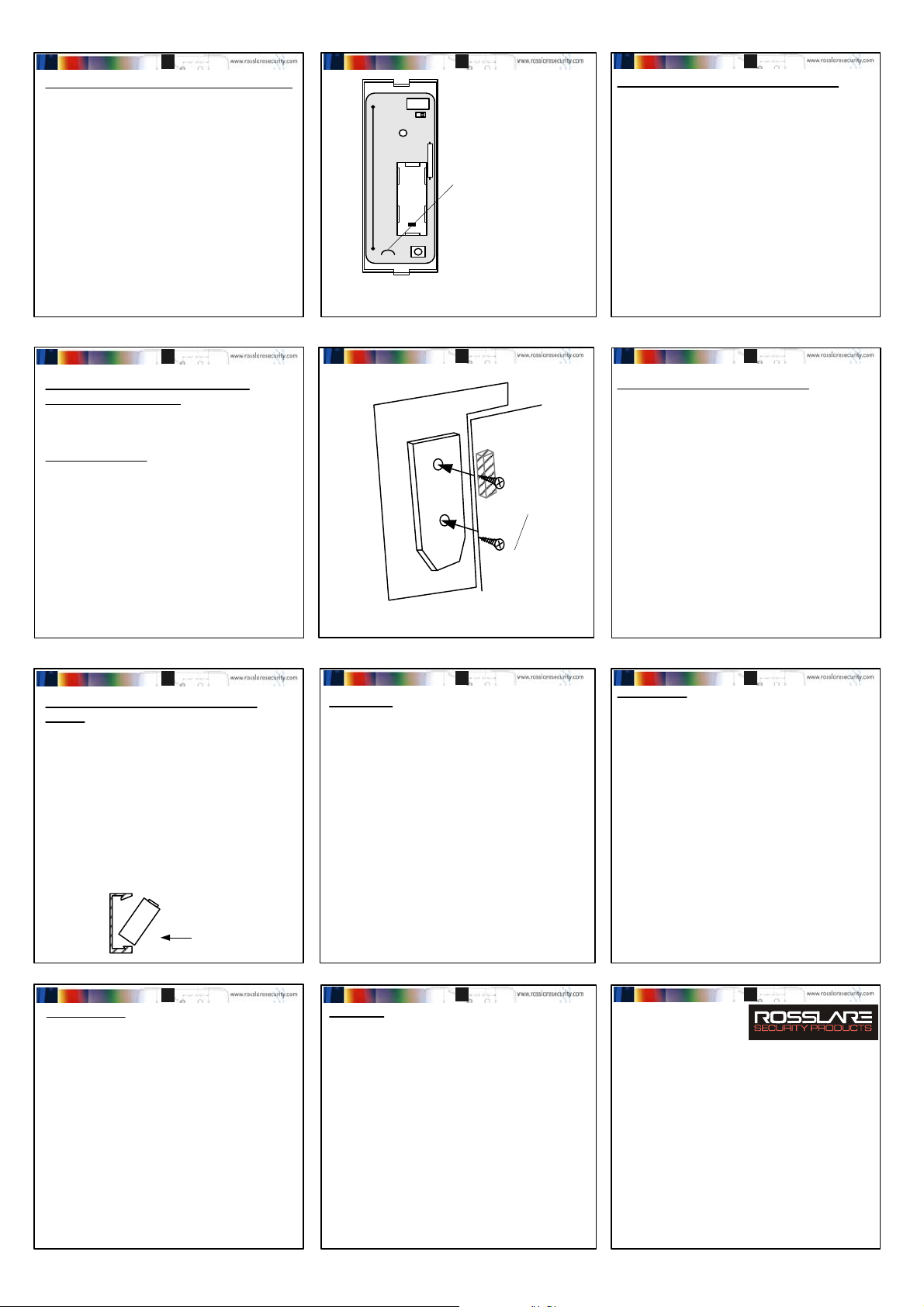

STEP-7 MOUNTING THE Magnetic

Contact Sensor (FIG 6)

The SA-02 Magnetic Contact Sensor is designed to be

Mounted onto a flat wooden or stucco surface.

Flat Surface Mounting:

1) Remove the PCB from the back case.

1) Remove the knockouts from the back case labeled B

by using a sharp tool or using a nail.

2) Affix the two screws onto the wall, so that the Back

Tamper arm is pressed in.

3) Replace the PCB and tighten the PCB locking screw.

4) Replace the top cover of the Magnetic Contact

Sensor.

Important: When mounting the SA-02 to the surface, it

is important to see that the surface is flush with the back

tamper device.

14 15

Jumper wire for activating the

+

R-18

back tamper switch.

Cut the jumper R-18 to activate

the back tamper.

FIG 5: Activation of the Back Tamper

17 18

Door

Frame

B

Affix the

B

back case

to the wall

firmly with

two screws

STEP-6 RADIO TRANSMISSION TEST

This test is used to check the range and the reception of

the sensor to the control panel receiver. If reception is

poor, try to change the location of the Magnetic Contact

Sensor.

1) Ensure that all the settings of the Magnetic Contact

Sensor are adjusted as necessary for the location

according to STEPS 1 to 5, and that the Magnetic

Contact Sensor case is closed, with the locking

screw firmly secured.

2) Hold the sensor close as possible to the

mounting location, and transmit using the magnet.

3) During this mode, each time the LED flashes, the

sensor transmits to the panel. If the panel is armed,

this will cause an alarm. If the panel is in test mode,

then the signal strength can be measured.

4) It is recommended to try several locations until the

best reception is attained.

STEP-8 Post-Installation Testing

After mounting the back of the sensor housing to the

window or door frame, it is important to check the

reliability of the RF transmission to the receiver or

security panel.

Perform a range test as indicated in STEP 6.

If the sensor is used with a receiver, check to see that

the receiver is receiving the sensor.

It is suggested that you arm the system and test that the

SA-02 transmits to the desired control panel.

Important: If the back tamper has been activated in

previous steps, check the security panel to ensure that

there is no tamper signal, and that the sensor is properly

installed.

19

STEP-9 Replacing the Battery in the

SA-02.

Batteries in the SA-02 should be replaced following a

Low Battery indication on the receiver or security panel.

PLEASE: Dispose of the old battery properly, do not recharge, disassemble, heat or incinerate.

1) Open the SA-02 sensor, and observe the correct

polarity labeled on the PCB and the holder.

2) Remove the old battery and dispose of it properly.

3) Insert the new battery (Model numbers shown in

specifications below)

SPECIFICATIONS

Battery:

Pulse Count: Fixed at single pulse.

Detect Range: Sensitivity of up to 2 cm from magnet.

Operating Temp: - 20

Operating Humidity: Up to 95% Non-Condensing (max.)

Alarm Transmit: 1 second.

RF Frequency: Available in 433.92 or 868.35 MHz, with 1m Watt

Installation: Indoor

Magnet: Standard magnet with plastic housing and wall spacer,

Tamper Switch 1: Removal of Magnetic Contact Sensor Front Cover (Protected

Tamper Switch 2: Removal of Magnetic Contact Sensor from the wall or f rom

Supervisor: The supervisory signal is routinely transm itted to the panels

Current: Standby - 23uA

Size: 87mm (h) x 35mm (w) x 25 mm (d)

Weight: 37 grams ( 1.30 oz) without battery.

Lithium Primary cell.

3.6-volt Lithium 900 mAh

Tadiran / Varta / Tekcell (SB-AA-02)

1/2 AA Size. (Low Battery Signal when V-2.5V)

CAUTION! Dispose of Properly, do not re-charge,

o

C to +50oC

- 4oF to + 122oF

adjustable height.

by case tamper switch)

corner mount (protected by rear tamper switch)

every 20 minutes, advising the Tamper Status,

Battery Status, Event Activation Status to the panel.

Transmit - 5 mA

(3.5 " x 1 3/8 " x 1 ")

3.6 -volt Lithium 900 mAh

Lithium Primary cell.

3.6-volt Lithium 900 mAh

+

Tadiran / Varta / Tekcell (SB-AA-02)

1/2 AA Size.

-

22

disassemble, heat or incinerate.

Insert the NEGATIVE ( - )

side of battery first.

FIG 6: Mounting the SA-02

20 21

CE Notice:

The model SA-02 Wireless Magnetic Contact Sensor

generates and uses radio frequency energy. If not

installed in accordance with the manufacturer's

instructions it may cause interference.

If this equipment causes interference to radio or

television reception-which can be determined by turning

the equipment on and off - the installer is encouraged to

correct the interference by one or more of the following

measures: 1) Reorient the antenna of the radio/

television, 2) Connect the AC transformer to a different

outlet so the control panel or television are on different

branch circuits, 3) Relocate the control panel with

respect to the radio/television.

This device complies with the applicable ETSI/CE rules.

Operation is subject to the following two conditions :

1) This device nay not cause harmful interference, and 2)

this device must accept any interference received,

including interference that may cause undesired

operation.

23 24

WARRANTY

The Manufacturer's warranty on this product is for a period of one year from the date

of purchase against defects in materials and workmanshi p. Manufacturer's warranty

hereunder is limited to repair or replacement, at the manufacturer's sole option, if the

product is found to be defective in normal use during the warranty period. The

warranty is given in favour of the origina l purchase only. Subject to the above

warranty, manufacturer's liability and that of it's dist ributors, re-sellers and agents and

is wholly limited to the original purchase price and no payment will be made for

related or consequential loss including but not limited to labour costs incurred in

inspection, replacement or repair of defective products. This warranty is given

expressly and in place of all other expressed or implied warranties of mer chantibility

and fitness for a particular purpose and this warranty is the only warranty made by the

manufacturer. No agent, representatives or employee of the manufacturer has the

authority to waive, alter or add to the printed provisions of this warranty, to make

representation of warranty not contained herein or to extend this warranty to anyone

other than the original purchaser of the product. The SA-02 Magnetic Contact Sens or

is guaranteed against defects in workmanship and material for a period of 12 (Twelve)

months from date of purchase. Return the fault y product with a dated proof of

purchase to your dealer for replacement.

NOTICE

The SA-02 Magnetic Contact Sensor is designed to send an electronic signal to alar m

control system, should intrusion occur, the warranty does not make the manuf acturer

or the distributor of the SA-02 Magnetic Contact Sensor held liable for consequential

damages resulting from any breech of warranty, expressed or impl ied, applicable to

their use.

Important !:

Rosslare radio control panels provide a reliable

communications link and fill an important need in

portable wireless signalling. However, there are some

limitations that must be observed.

For US installations only: The radios are required

to comply with FCC rules and regulations as part

15 devices. As such they have a limited

transmitter power and therefore limited range.

A receiver cannot respond to more than one

transmitted signal at a time and may be blocked

by two simultaneous signals that occur near their

operating frequencies, regardless of the individual

sensor code.

Any changes to this circuit or device may void

FCC compliance.

Infrequently used radio links should be tested

regularly to protect against unintended

interference or fault.

A general knowledge of radio and it's properties

should be gained prior to acting as a wholesale

distributor or dealer, and these facts should be

communicated to the ultimate users.

INTERNATIONAL OFFICES

U.S.A.: Rosslare America Inc.

ISRAEL Rosslare Israel Ltd (Center Office)

Hong Kong: Rosslare Enterprises Ltd.

Westlake, Los Angeles, CA 91632 U.S.A

Tel: (818) 707 2974 Fax: (818) 7070543

Rosslare America Inc.

2001 Reliance, Packway, Suite D

Bedford, Texas 76021 U.S.A

Tel: (817) 685 9100 Fax: (817) 685 9188

Rosslare Powerpath NAPDC.

North America Product Development

22e. Howard St, # 238 Des Plaines, IL60018, U.S.A

Tel: (847) 827 6330 Fax: (847) 8276433

22 Hamelacha St, PO BOX 11407, Rosh Ha-Ayin, 48091,

905-912 Wing Fat Industrial Building

12 Wang Tai Road, Kowloon Bay,

Hong Kong. Tel (852) 2795 5630 Tel (852) 2795 1508

www.rosslaresecurity.com

Loading...

Loading...