Page 1

BULLETIN 600T

ISO Valves and

Serial Bus Communication

with Turck

Modular I/O System

Premium Pneumatic Controls Since 1921

TM

ControlNet

TM

PROFIBUS

®

DeviceNet

TM

CANopen

Page 2

ROSS' website is the most complete and up-to-date source for product research and documentation.

Search results produce downloadable documentation or request for quote (RFQ).

Additional product information or CAD files are easily requested from Technical Service Team.

Additional information such as certifications, links and associations is also available.

Search for Products by Model Number,

descriptions or Search Repair Kits

by Product Model Number

Quick Order

by Part Number

Visit our website for

New released Products

Industry Solutions section includes white papers,

published articles, applications, and product

selection for specific industry segments

Download Catalogs, Bulletins,

find T echnical Documentation

and Information

Contact a ROSS

Inside Sales Team member

Sign Up for ROSS' e-News,

a Monthly Newsletter

Click on the ROSS Logo to

always return to Home Page

Find the right Electronic Data

Sheet (EDS) file for your

Serial Network

Standard Warranty and

Cautions

www.rosscontrols.com

2 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 3

Table of Contents

Standard Definitions .......................................................................................................................................4

Serial Bus Systems

ISO Size 00 & 0 Valves, Series W66 - Ordering Code

Plug-in, ISO Size 00 & 0 Valves Series W66 (15407-2)

Spool and Sleeve Valves for ISO Sub-Bases Size 1, 2 & 3 Valves, Series W65 (5599/II)

Plug-in, Series W66 (15407-2)

Size 00 & 0 Manifold & Sub-Base Kits .....................................................................................................10

Plug-in, Series W65 (5599-2)

Size 1, 2 & 3 Manifold & Sub-Base Kits ...................................................................................................11

End Plate Kits Size 00 & 0, Series W66

End Plate Kits Size 1, 2 & 3, Series W65

Accessories

Service & Repair Kits

Technical Information

.............................................................................................................................................13-15

........................................................................................................................................5

..................................................................................6

.................................................................................7

...........................8-9

.......................................................................................................12

.....................................................................................................12

...................................................................................................................................16

....................................................................................................................................17

TURCK Modular Industrial I/O System BL67

Overview .............................................................................................................................................18-19

Selection Guide .......................................................................................................................................20

Gateways

DeviceNet ...............................................................................................................................................21

Ethernet .............................................................................................................................................22, 23

Profibus-DP .............................................................................................................................................24

CANopen ...........................................................................................................................................25, 26

Modules

Discrete ..............................................................................................................................................29-36

Analog .....................................................................................................................................................42

Serial .......................................................................................................................................................41

Power Feed ..............................................................................................................................................43

Base Modules

Accessories ..................................................................................................................................................42

Standard Cautions

TURCK products Warranty, Terms and Conditions

ROSS products Standard Warranty

Global Locations

...............................................................................................................................................44

.......................................................................................46

..............................................................................................................47

...........................................................................................................................................48

3www.rosscontrols.com

Page 4

Standard Definitions

!

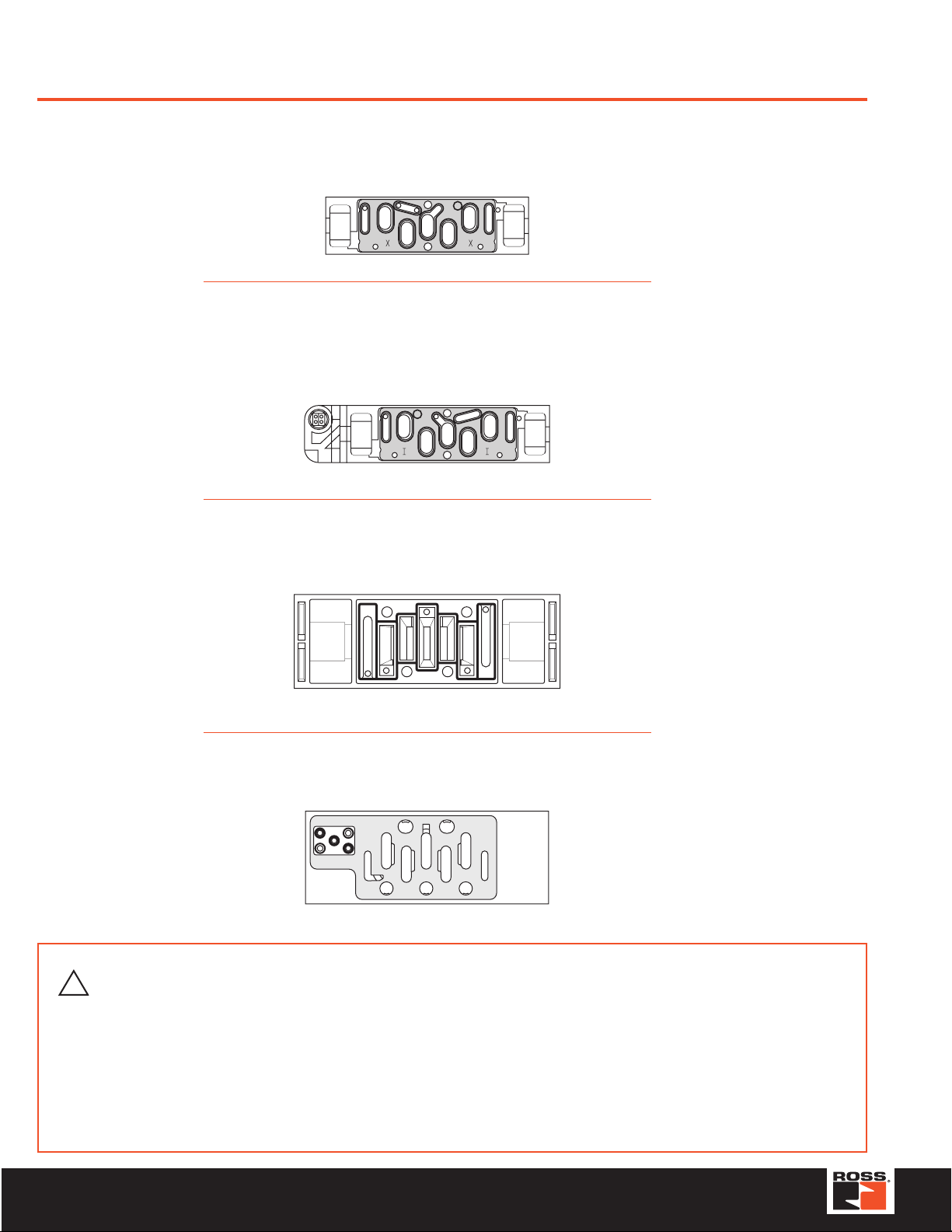

15407-1: Drop-cord Standards

for Size 0 (26mm) & Size 00 (18mm) Wide Valves

15407-2: Plug-in Standards

for Size 0 (26mm) & Size 00 (18mm) Wide Valves

5599-1: Drop-cord Standards for Sizes 1, 2, 3

5599-2: Plug-in Standards for Size 1, 2, 3

F AILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS

WARNING

This document and other information from ROSS CONTROLS®, its subsidiaries and authorized distributors provide product

and/or system options for further investigation by users ha ving technical expertise. It is important that you analyze all aspects

of your application including consequences of any failure , and review the information concerning the product or system in the

current product catalog. Due to the variety of operating conditions and applications for these products or systems, the user,

through its own analysis and testing, is solely responsible for making the final selection of the products and systems and

assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are

subject to change by ROSS CONTROLS and its subsidiaries at any time without notice.

DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

4 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 5

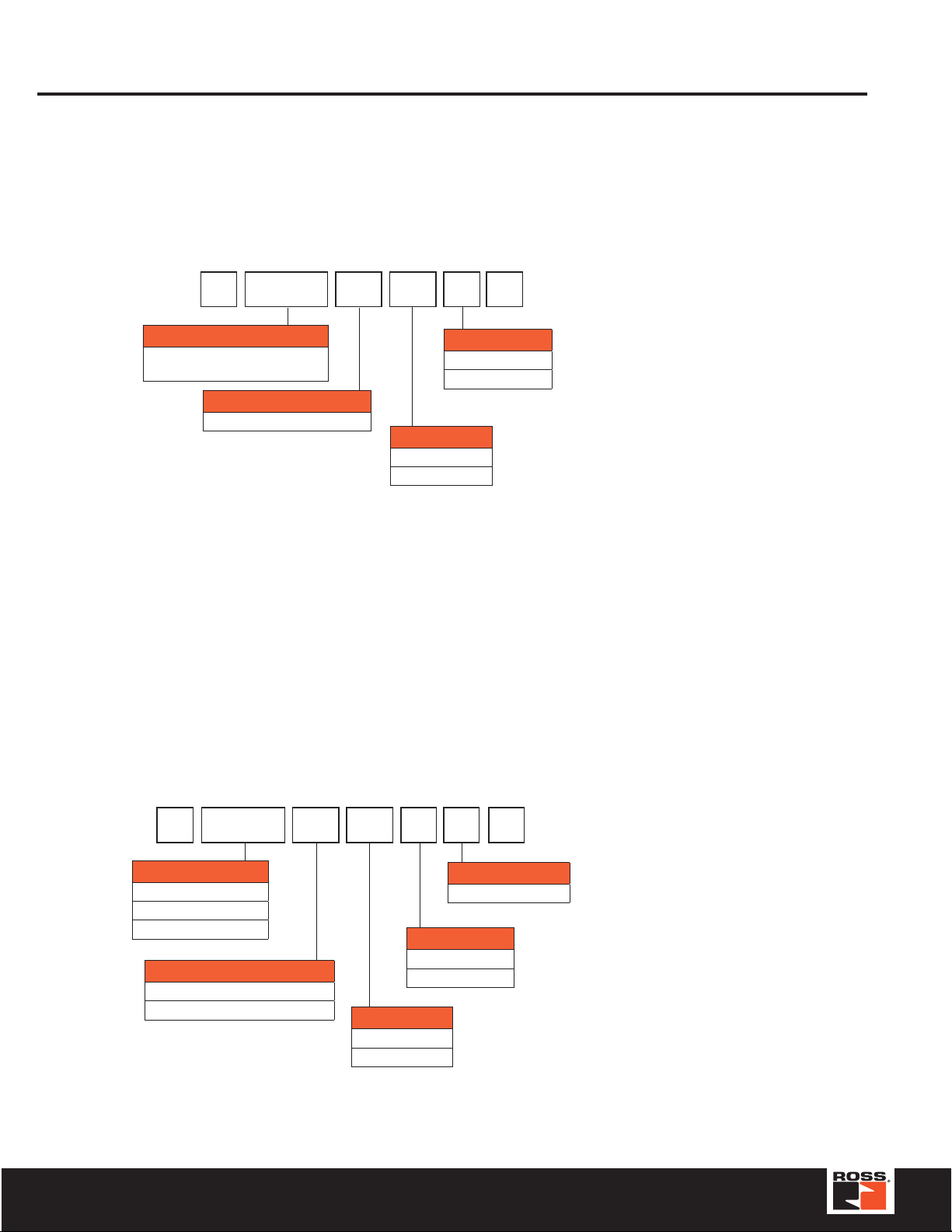

TM

• Centralized Serial Bus system

• Pneumatics and I/O are in close proximity to one another

• I/O density per module = 8

Series W66 18mm

ISO 15407-2 Valves

End Station Kit

• A complete Serial Bus communication offering for all ISO valves

Serial Bus System I/O - Centralized Configuration

• UL, CE, CSA certifications (as marked)

Adapter

Communication

www.rosscontrols.com

M12, Input or

Output Module

5

Page 6

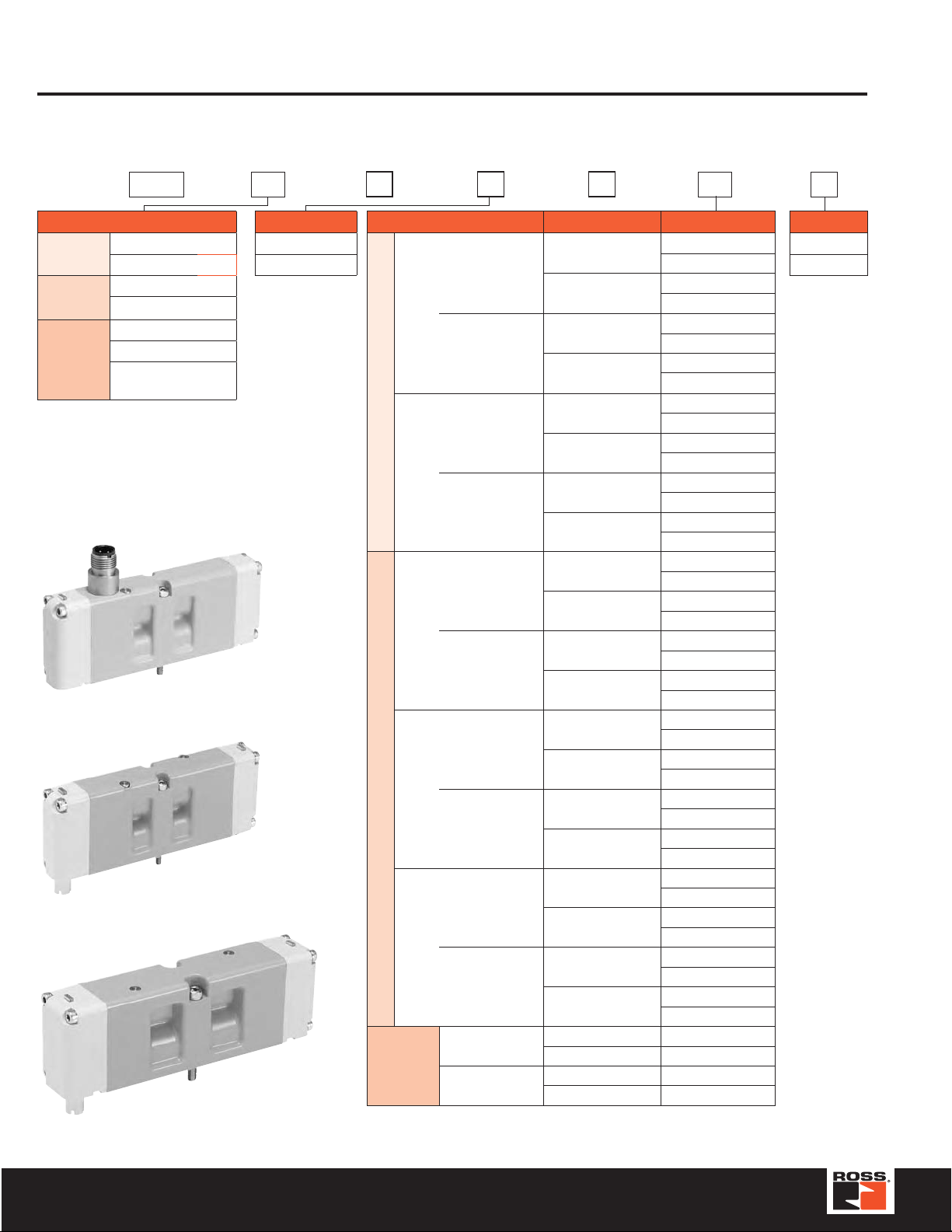

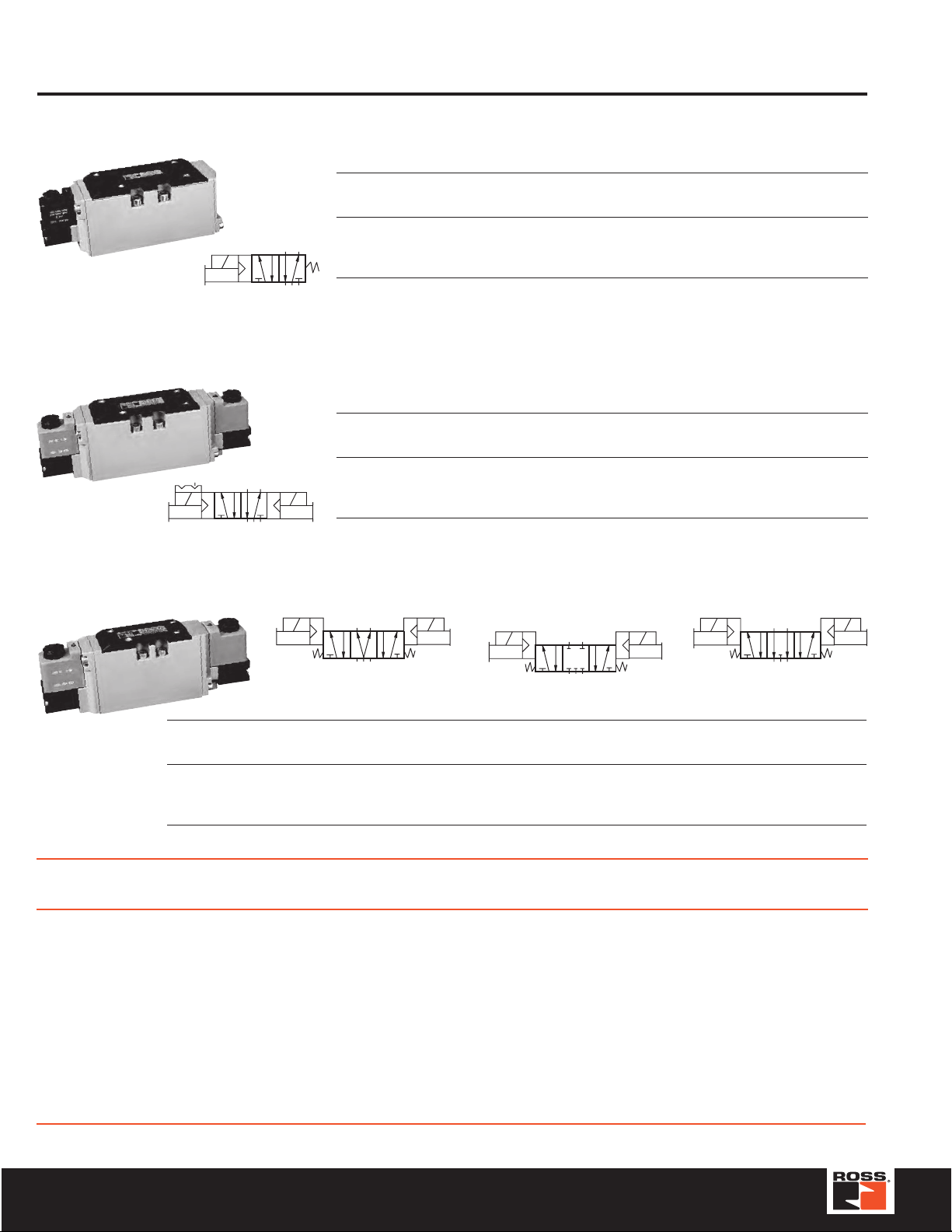

ISO Size 00 & 0 Valves Series W66

HOW T O ORDER

(Choose your options (in red) to configure your valve model number.)

W66 76 A 0 4 01 W

Function*

4-Way

2-Position

4-Way

3-Position

Dual

3-Way

2-Position

Remote Pilot 56

Solenoid Pilot 76

Remote Pilot 57

Solenoid Pilot 77

Normally Open 70

Normally Closed 75

NC / NO

NC - 14 End

78

Basic Size

Size 00 (18mm) 0

Size 0 (26mm) 1

* Be sure to choose Options from the correct list. For example,

if a Function of 4-Way 2-Position is chosen, then only choose

Options from the section listed for that function. See the light

gray-shaded columns of the Function and Options lists.

Size 00 (18mm), Single Solenoid (5/2)

Size 00 (18mm), Double Solenoid (5/2)

Size 0 (26mm), Double Solenoid (5/3)

Series W66 (15407-1)

Series W66 (15407-2)

Series W66 (15407-2)

Open Center

Options*

Single

4-Way 2-Position

Double

Closed

Center

Power

Center

4-Way 3-Position

Open

Center

2-Position

Dual 3-Way

Plug-In (15407-2)

Drop Cord (15407-1)

Plug-In (15407-2)

Drop Cord (15407-1)

Plug-In (15407-2)

Drop Cord (15407-1)

Plug-In (15407-2)

Drop Cord (15407-1)

Plug-In (15407-2)

Drop Cord (15407-1)

Plug-In (15407-2)

Drop Cord (15407-1)

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides

Locking Overrides

Non-Locking Overrides Internal Pilot - 07

Locking Overrides Internal Pilot - 17

Non-Locking Overrides Internal Pilot - 67

Locking Overrides Internal Pilot - 77

Internal Pilot - 01

External Pilot - 51

Internal Pilot - 11

External Pilot - 21

Internal Pilot - 61

External Pilot - 81

Internal Pilot - 71

External Pilot - 91

Internal Pilot - 07

External Pilot - 57

Internal Pilot - 17

External Pilot - 27

Internal Pilot - 67

External Pilot - 87

Internal Pilot - 77

External Pilot - 97

Internal Pilot - 01

External Pilot - 51

Internal Pilot - 11

External Pilot - 21

Internal Pilot - 61

External Pilot - 81

Internal Pilot - 71

External Pilot - 91

Internal Pilot - 03

External Pilot - 53

Internal Pilot - 13

External Pilot - 23

Internal Pilot - 63

External Pilot - 83

Internal Pilot - 73

External Pilot - 93

Internal Pilot - 07

External Pilot - 57

Internal Pilot - 17

External Pilot - 27

Internal Pilot - 67

External Pilot - 87

Internal Pilot - 77

External Pilot - 97

Voltage

24 VDC W

120 VAC Z

6 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 7

Size 00 (18mm) & Size 0 (26mm )

Open Center

Closed Center

Plug-in, Series W66 (15407-2)

5/2 Valves – Single Solenoid Pilot

ISO Port Valve Model Avg. Dimensions inches (mm) Weight

Size Size Number* C

Series W66, Size 00

Sol. 14

42

1

53

00 1/8 W6676A0401 0.55 4.43 (113) 0.72 (18) 1.98 (50)

0 1/4 W6676A1401 1.1 5.10 (130) 1.02 (26) 1.98 (50)

* Sub-base not included. See page 10-17 for sub-bases, manifolds and

accessories.

5/2 Valves – Double Solenoid Pilot

ISO Port Valve Model Avg. Dimensions inches (mm) Weight

Size Size Number* C

00 1/8 W6676A0407 0.55 4.43 (113) 0.72 (18) 1.98 (50)

0 1/4 W6676A1407 1.1 5.10 (130) 1.02 (26) 1.98 (50)

* Sub-base not included. See page 10-17 for sub-bases, manifolds and

Series W66, Size 00

42

Sol. 14 Sol. 12

1

53

accessories.

5/3 Valves – Double Solenoid Pilot

42

#12#14

53

1

Series W66, Size 00

Series W66, Size 0

ISO Port Valve Model Avg. Dimensions inches (mm) Weight

Size Size Number* C

Closed Center

00 1/8 W6677A0401 0.50 4.43 (113) 0.72 (18) 1.98 (50)

0 1/4 W6677A1401 1.0 5.10 (130) 1.02 (26) 1.98 (50)

00 1/8 W6677A0407 0.50 4.43 (113) 0.72 (18) 1.98 (50)

0 1/4 W6677A1407 1.0 5.10 (130) 1.02 (26) 1.98 (50)

Power Center

00 1/8 W6677A0403 0.50 4.43 (113) 0.72 (18) 1.98 (50)

0 1/4 W6677A1403 1.0 5.10 (130) 1.02 (26) 1.98 (50)

* Sub-base not included. See page 10-17 for sub-bases, manifolds and

accessories.

Length Width Height lb (kg)

V

Length Width Height lb (kg)

V

Power Center

42

#12#14

53

1

Length Width Height lb (kg)

V

Open Center

42

53

1

#12#14

Remote Pressure Control Models Available (2 & 3-Position) – Consult ROSS

STANDARD SPECIFICATIONS (for valves on this page):

Solenoids: Bi-polar, surge suppression (standard), indicator

lights.

Standard V oltages: 1.0, 24 volts DC; 2.0 VA, 120 volts AC.

Flow Media: Filtered air; 5 micron recommended.

Operating Pressure:

Vacuum to 145 psig (9.9 bar).

Minimum Operating Pressure:

2-position : 20 psig (1.37 bar).

3-position: 30 psig (2.07 bar).

Manifolds: Terminal Block Wiring (HA Only).

Collective Wiring: 25-Pin' D-Sub; 19-Pin Round; 16 Point

Terminal Strip; M23, 12-Pin; Isysnet Field Bus.

Construction:

Valve Body: Die Cast Aluminum.

Ens Caps: Polybutylene Terephthalate (PBT).

Fasteners: Zinc Plated Steel.

Coils: Thermoset Plastic.

Port Threads: NPT, BSPP. For BSPP threads add a “D” prefix to

the model number, e.g., DW6677A0401.

Manifolds: Terminal Block Wiring (HA Only).

7www.rosscontrols.com

Page 8

234

Spool and Sleeve Valves for ISO Sub-Bases (5599/II) Series W65

5/2 Valves – Single Solenoid Pilot Controlled, Spring Return

ISO Port Valve Model Avg. Dimensions inches (mm) Weight

Size Size Number* C

1 1/4 - 3/8 W6576A2401 1.0 6.3 (161) 1.6 (41) 2.7 (69) 1.5 (0.7)

14

5

2 3/8 - 1/2 W6576A3401 2.3 7.3 (186) 2.1 (52) 2.8 (71) 2.0 (1.0)

3 1/2 - 3/4 W6576A4401 3.4 8.5 (216) 2.6 (67) 3.1 (78) 3.5 (1.6)

1

* Sub-base not included. See page 11-17 for sub-bases, manifolds and accessories.

5/2 Valves – Double Solenoid Pilot Controlled, Detented

ISO Port Valve Model Avg. Dimensions inches (mm) Weight

Size Size Number* C

1 1/4 - 3/8 W6576A2407 1.0 8.8 (224) 1.6 (41) 2.7 (69) 2.0 (1.0)

14

2

345

1

2 3/8 - 1/2 W6576A3407 2.3 9.0 (228) 2.1 (52) 2.8 (71) 2.5 (1.2)

12

3 1/2 - 3/4 W6576A4407 3.4 10.0 (254) 2.6 (67) 3.1 (78) 4.0 (1.9)

* Sub-base not included. See pages 11-17 for sub-bases, manifolds and accessories.

Length Width Height lb (kg)

V

Length Width Height lb (kg)

V

5/3 Valves – Double Solenoid Pilot Controlled

2

14

4

5

3

1

Power Center

12

14

Closed Center

2

4

12

14

ISO Port Valve Model Number* Avg.

Size Size Power Center Closed Center Open Center CV

1

1/4 - 3/8 W6577A2902 W6577A2401 W6577A2407 1.0 8.8 (224) 1.6 (41) 2.7 (69) 2.0 (1.0)

Dimensions inches (mm) Weight

Length Width Height lb (kg)

2 3/8 - 1/2 W6577A3901 W6577A3401 W6577A3407 2.3 9.0 (228) 2.1 (52) 2.8 (71) 2.5 (1.2)

3 1/2 - 3/4 W6577A4900 W6577A4401 W6577A4407 3.4 10.0 (254) 2.6 (67) 3.1 (78) 4.0 (1.9)

* Sub-base not included. See pages 11-17 for sub-bases, manifolds and accessories.

The W65 Series has a base electrical connector whic h eliminates the need to disconnect wires to remove the valve. This eliminates dr op cords,

simplifies maintenance and connection to Serial Data Communication systems. For more information, refer to Bulletin 379B (form number A10090).

STANDARD SPECIFICATIONS (for valves on this page):

Solenoids: Rated for continuous duty.

Standard V oltages: 100-110 volts, 50 Hz; 100-120 volts, 60

Hz; 24 volts DC; 110 volts DC. For other voltages, consult

ROSS.

Power Consumption: Each solenoid. 6.5 VA holding on 50

or 60 Hz; 3.5 watts on DC (at 10 bar).

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air; 5 micron recommended.

Standard Inlet Pressure:

Size 1 models: 2-10 bar; Size 2 & 3 models: 1-10 bar.

All sizes also available up to 16 bar.

Pilot Supply: Internal/external supply selected automatically.

Required pressure at least 30 psig (2 bar).

Certification / Approval: CSA

Materials of Construction:

End Caps & Valve Body: Die Cast Aluminum

Fasteners: Zinc Plated Steel

Spool & Sleeve: Stainless Steel

Coils: Thermoset Plastic

234

5

1

Open Center

12

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

8 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 9

Spool and Sleeve Valves for ISO Sub-Bases (5599/II) Series W65

2

5/2 Valves – Single Pressure Controlled, Spring Return

ISO Port Valve Model Avg. Dimensions inches (mm) Weight

Size Size Number* C

1 1/4 - 3/8 W6556A2411 1.0 4.8 (121) 1.6 (41) 2.7 (69) 0.8 (0.4)

2 3/8 - 1/2 W6556A3411 2.3 5.8 (148) 2.1 (52) 2.8 (71) 1.5 (0.7)

3 1/2 - 3/4 W6556A4411 3.4 7.0 (178) 2.6 (67) 3.1 (78) 3.0 (1.4)

* Sub-base not included. See pages 11-17 for sub-bases, manifolds and accessories.

5/2 Valves – Double Pressure Controlled, Detented

ISO Port Valve Model Avg. Dimensions inches (mm) Weight

Size Size Number* C

1 1/4 - 3/8 W6556A2417 1.0 4.8 (121) 1.6 (41) 2.7 (69) 0.8 (0.4)

2 3/8 - 1/2 W6556A3417 2.3 5.8 (148) 2.1 (52) 2.8 (71) 1.5 (0.7)

3 1/2 - 3/4 W6556A4417 3.4 7.0 (178) 2.6 (67) 3.1 (78) 3.0 (1.4)

* Sub-base not included. See pages 11-17 for sub-bases, manifolds and accessories.

V

V

A B C lb (kg)

A B C lb (kg)

5/3 Valves – Double Pressure Controlled

Power Center

ISO Port Valve Model Number* Avg.

Size Size Power Center Closed Center Open Center CV

1

2 3/8 - 1/2 W6557A3901 W6557A3411 W6557A3417 2.3 5.8 (148) 2.1 (52) 2.8 (71) 1.5 (0.7)

3 1/2 - 3/4 W6557A4900 W6557A4411 W6557A4417 3.4 7.0 (178) 2.6 (67) 3.1 (78) 3.0 (1.4)

* Sub-base not included. See pages 11-17 for sub-bases, manifolds and accessories.

STANDARD SPECIFICATIONS (for valves on this page):

Ambient/Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air; 5 micron recommended.

Standard Inlet Pressure:

Size 1 models: 2-10 bar;

Size 2 & 3 models: 1-10 bar.

All sizes also available up to 16 bar.

1/4 - 3/8 – W6557A2411 W6557A2417 1.0 4.8 (121) 1.6 (41) 2.7 (69) 0.8 (0.4)

14

12

345

1

234

5

1

Closed Center Open Center

Dimensions inches (mm) Weight

A B C lb (kg)

Pilot Supply: Internal/external supply selected automatically.

Required pressure at least 30 psig (2 bar).

Materials of Construction:

End Caps & Valve Body: Die Cast Aluminum

Fasteners: Zinc Plated Steel

Spool & Sleeve: Stainless Steel

1214

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

9www.rosscontrols.com

Page 10

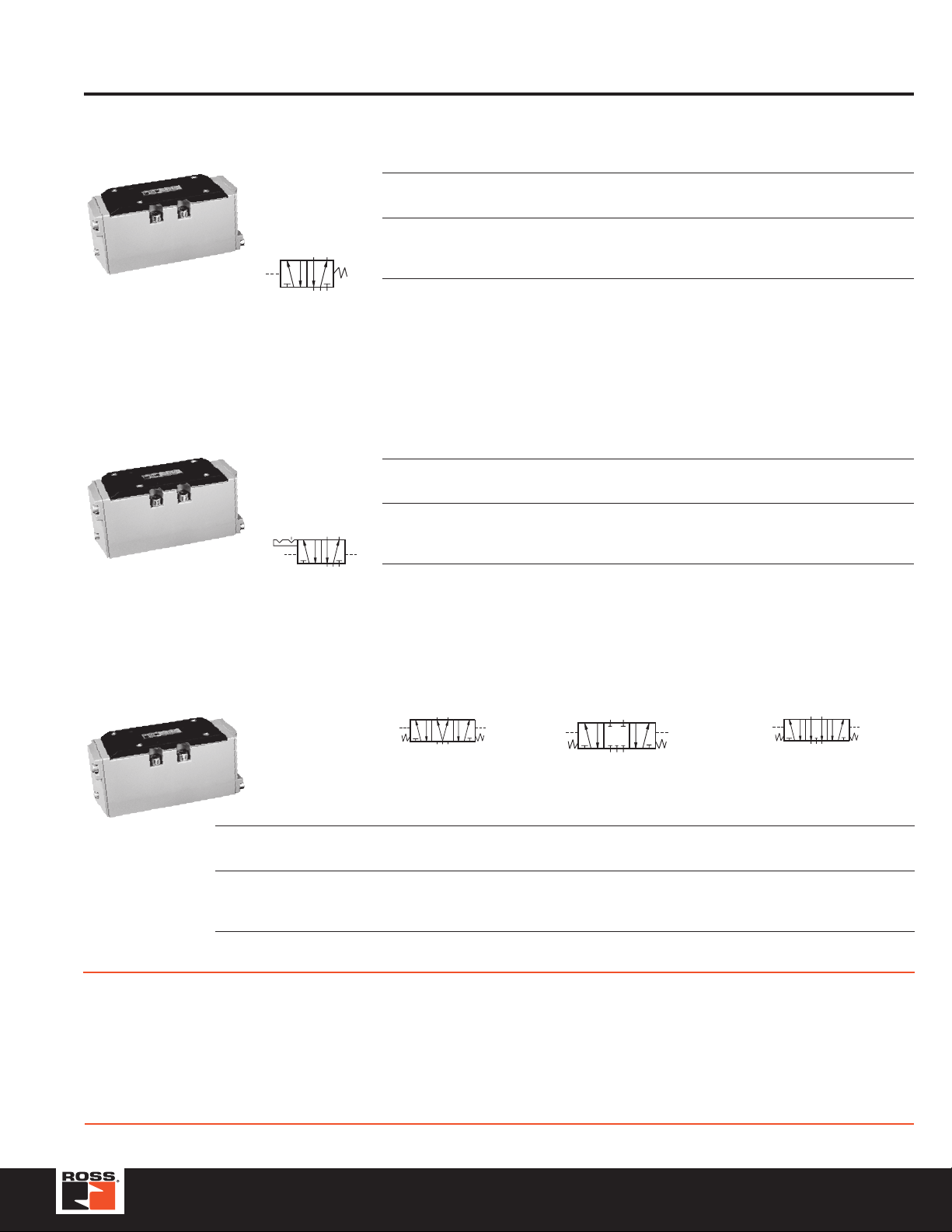

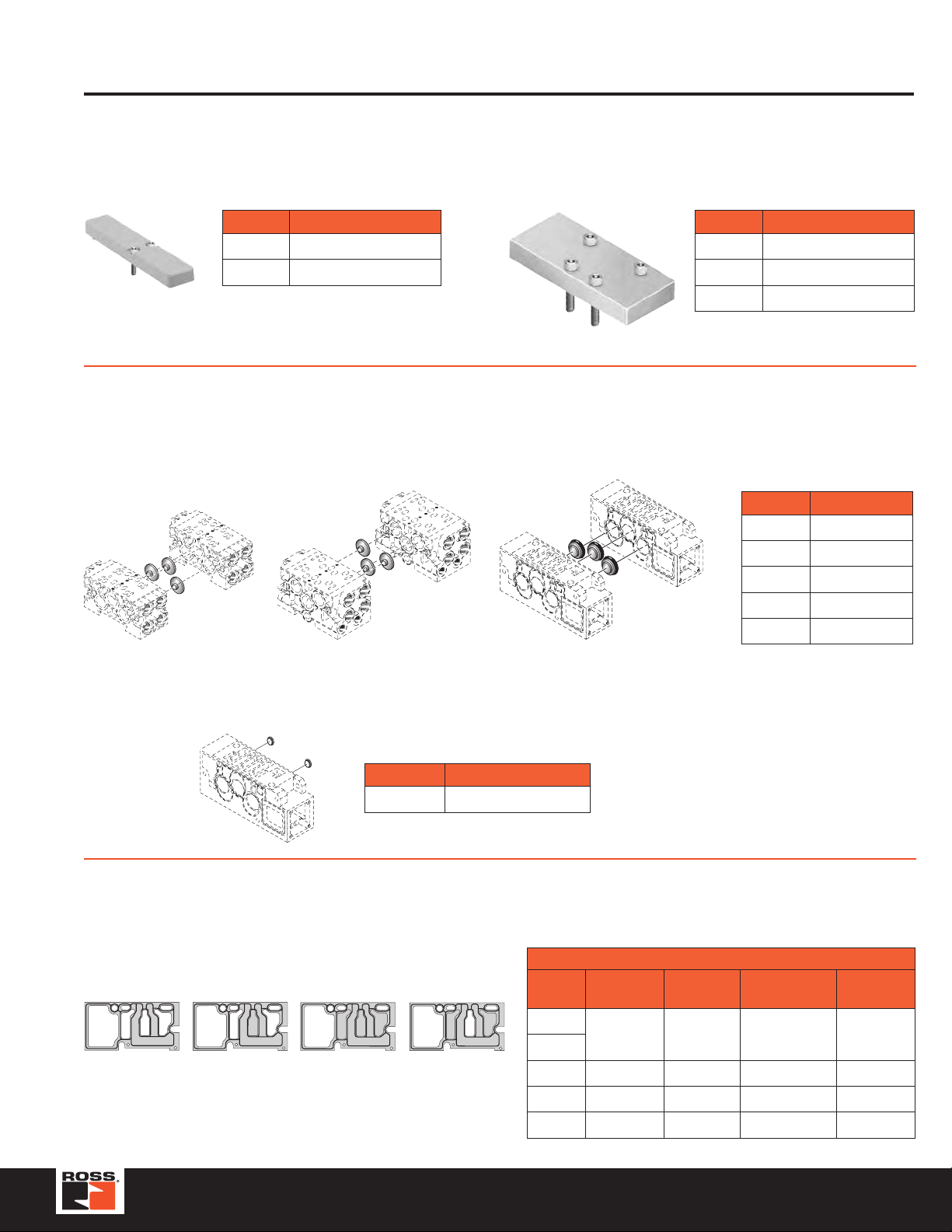

Plug-in, Series W66 (15407-2)

Size 00 & 0 Manifold / Sub-Base Kits

HOW T O ORDER

(Choose your options (in red) to configure your valve model number.)

R PS5511 13 M P

Basic Series

ISO 15407-2 18mm,

Series W66, Size 00

ISO 15407-2 26mm,

Series W66, Size 0

PS5611

PS5511

Mounting Style / Port Size

Series W66, Size 00

Manifold with 1/8 NPT End Ports 51

Manifold with 1/8 BSPP End Port 52

Manifold with 1/8 NPT Bottom / End Port 61

Manifold with 1/8 BSPP Bottom / End Port 62

Series W66, Size 0

Subbase with 1/4 NPT Side Ports 13

Subbase with 1/4 BSPP Side Ports 14

Subbase with 1/4 NPT Bottom / Side Port 23

Subbase with 1/4 BSPP Bottom / Side Port 24

Manifold with 1/4 NPT End Port 53

Manifold with 1/4 BSPP End Port 54

Manifold with 1/4 NPT Bottom / End Port 63

Manifold with 1/4 BSPP Bottom / End Port 64

Enclosures / Lead Length

J* Circuit Board, Single Address

M* Circuit Board, Double Address

Sub-Base Kits

Series W66, Size 0 Sub-Base

10 © 2012, ROSS CONTROLS

Series W66, Size 00 Series

2-Station Manifold

Manifold Kits

®

. All Rights Reserved.

Series W66, Size 0 Series

2-Station Manifold

Page 11

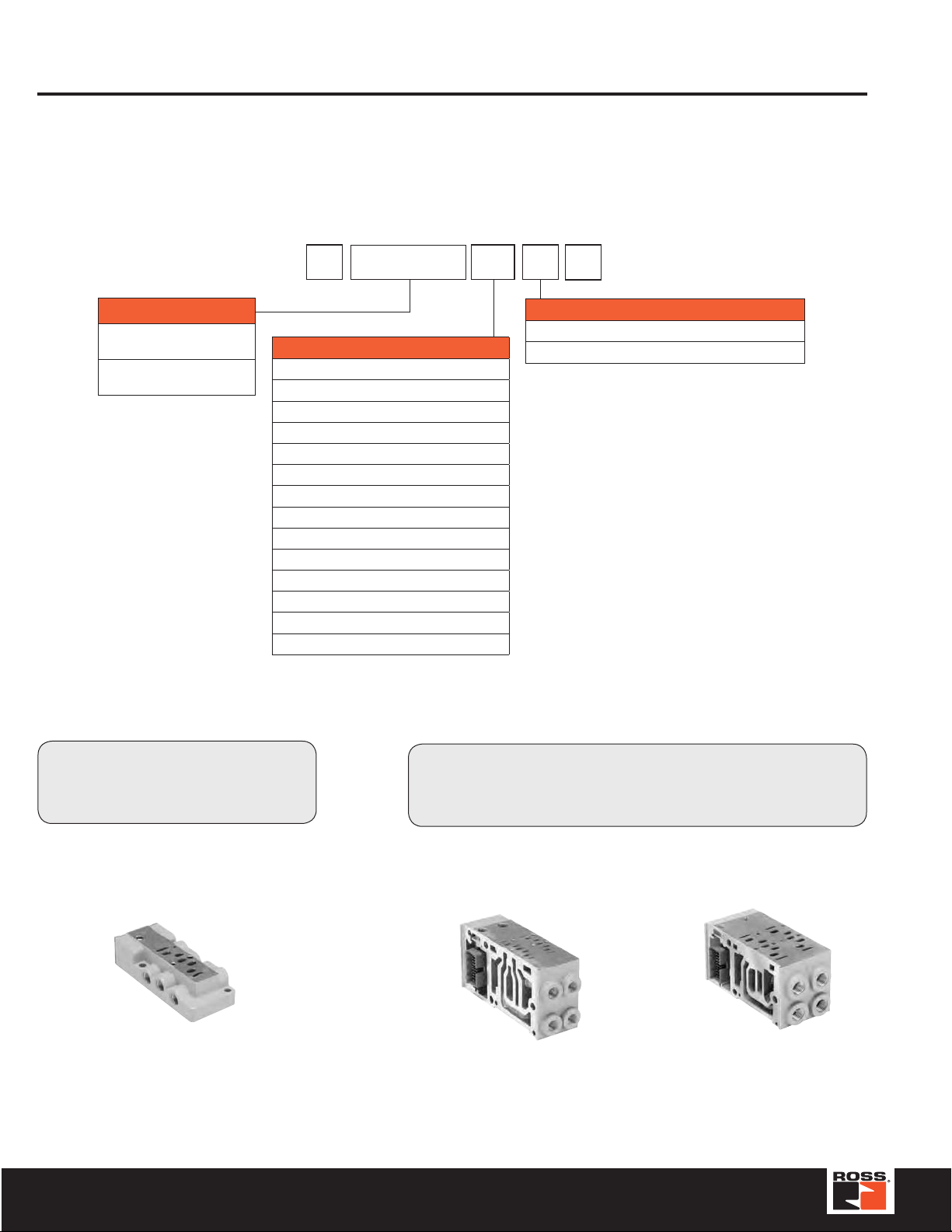

Plug-in, Series W65 (5599-2)

Size 1, 2, & 3 Manifold / Sub-Base Kits

HOW T O ORDER

(Choose your options (in red) to configure your valve model number.)

R PS4011 55 M C P

Basic Series

Size 1 PS4011

Size 2 PS4111

Size 3 PS4211

Note:

When using the Enclosure / Lead Length “J” or “M” option:

12 volts DC - Maximum number of coils is 13

24 volts DC - Maximum number of coils is 21

120 volts AC - Coils limited by the number of pins available in the connector

(25-Pin D-Sub = 24 coils, 19-Pin Brad Harrison = 16, 12-Pin M23 = 8)

240 volts AC - Must use “A” or “C” Option, Lead Wires or Terminal Blocks

Mounting Base Style / Port Size

Sub-base: 3/8 NPT Side Ports 15

Sub-base: 3/8 BSPP Side Ports 16*

Manifold: 3/8 NPT End Ports 55

Manifold: 3/8 NPT End Ports 56*

Size 1

Manifold: 3/8 NPT Bottom / End Port 65

Manifold: 3/8 BSPP Bottom / End Port 66*

* BSPP ISO 1179 Specifications.

† #1 Bottom Port - 1/4".

Sub-base: 1/2 NPT Side Ports 17

Sub-base: 1/2 BSPP Side Ports 18*

Sub-base: 1/2 NPT Bottom / End Port 27

Sub-base: 1/2 BSPP Bottom / End Port 28

Size 2

†

†

Manifold: 1/2 NPT Bottom / End Port 67

Manifold: 1/2 BSPP Bottom / End Port 68*

†

J

†

M

† Not Available with Subbase Kits.

Circuit Board, Single Address

Circuit Board, Double Address

Enclosures / Lead Length

Sub-base: 3/4 NPT Side Ports 19

Sub-base: 3/4 BSPP Side Port 10*

Sub-base: 3/4 NPT Bottom / End Port 29

Sub-base: 3/4 BSPP Bottom / End Port 20

Size 3

Manifold: 3/4 NPT Bottom / End Port 69

Manifold: 3/4 BSPP Bottom / End Port 60*

Sub-Base Kits

Automotive Connectors

Mounted in 1/2" Conduit Port

• 3-Pin-WiredforSingleSolenoid

• 4-Pin/5-Pin-WiredforDoubleSolenoid

Manifold Kits

Automotive Connectors

Mounted in Individual Manifold Conduit Cover

• 3-Pin - Wired for Single Solenoid

• 4-Pin / 5-Pin - Wired for Double Solenoid

Size 1

Size 1

Size 2 Size 3

Size 2 Size 3

11www.rosscontrols.com

Page 12

End Plate Kits, Series W66 & W65

Series W66

Size 00 & 0 End Plate Kits

HOW T O ORDER

(Choose your options (in red) to configure your valve model number.)

R PS56 20 T1 0 P

Basic Series

ISO 15407, Size 00 (18mm) &

Size 0 (26mm)

End Plate Kit Type

End Plate, Collective Wiring 20

PS56

Series W65

Size 1, 2, & 3 End Plate Kits

HOW T O ORDER

(Choose your options (in red) to configure your valve model number.)

0 NPT

1

Options

T1 16 Outputs

T2 32 Outputs

Thread Type

BSPP “G”

R PS40 20 T1 0 C P

Basic Series

ISO 5599, Size 1 PS40

ISO 5599, Size 2 PS41

ISO 5599, Size 3 PS42

End Plate Kit Type

End Plate, Collective Wiring 20

End Plate, Non-Collective Wiring 31

T1 16 Outputs

T2 32 Outputs

0 NPT

1

Options

12 © 2012, ROSS CONTROLS

Engineering Level

C Current

Thread Type

BSPP “G”

®

. All Rights Reserved.

Page 13

Blank Stations, Port Isolation , Gaskets

Blank Station Kits

Accessories

Size Kit Number 15407-2

RPS5634P

RPS5534P

15407-2

Size 00

Size 0

Kit includes: Blank Station Plate, Gasket,

and Mounting Bolts.

Manifold Port Isolation Kits

Main Galley (1, 3, 5)

2

4

2

4

Size 00

Main Galley

Size 0

Main Galley

5599

Size1, 2, 3

Main Galley

Size Kit Number 5599

Size 1

Size 2

Size 3

Kit includes: Blank Station Plate, Gasket,

and Mounting Bolts.

RPS4034CP

RPS4134CP

RPS4234CP

Size Kit Number

Size 00

Size 0

Size 1

Size 2

Size 3

Kit includes: Plugs with O-rings.

RD02BD0

RD01BD0

RPS4032CP

RPS4132CP

RPS4232CP

Pilot Galley

Size Kit Number

Size1, 2, 3

Pilot Galley

1, 2, & 3

Kit includes: Plugs with O-rings.

Manifold to Manifold Gasket Kits

RPS561AP RPS561CP RPS561DPRPS561BP

RPS4033CP

Size Standard

Size 00

Size 0

Size 1

Size 2

Size 3

15407-2

Blocked

#1 Port

RPS561AP RPS561BP RPS561CP RPS561DP

RPS4013P — — —

RPS4113P — — —

RPS4213P — — —

Blocked

#1, 3, 5 Ports

Blocked

#3, 5 Ports

13www.rosscontrols.com

Page 14

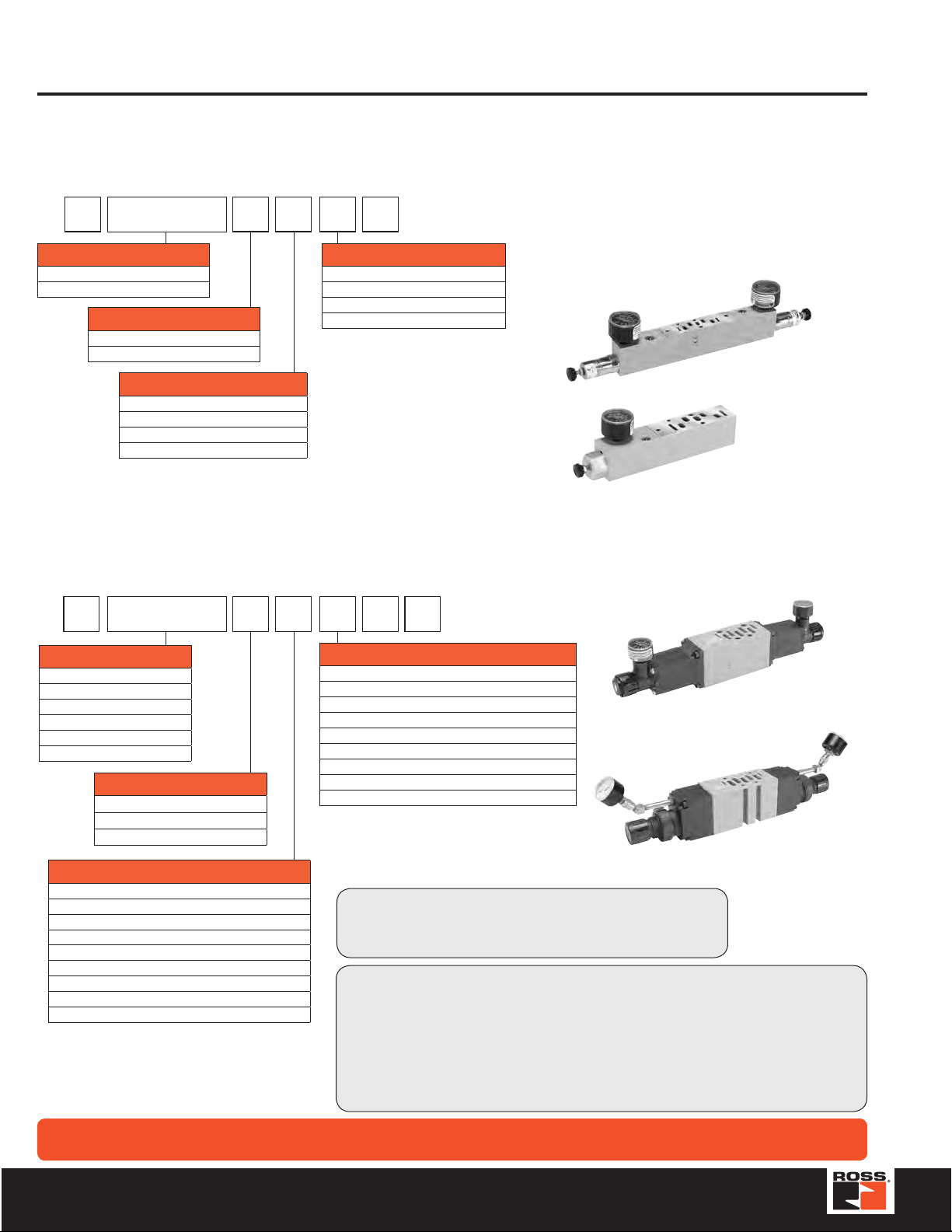

Accessories

Size 00 & 0

HOW T O ORDER

(Choose your options (in red) to configure your valve model number.)

R PS5637 1 6 6 P

Basic Series

Size 00 15407-2, 18mm PS5638

Size 0 15407-2, 26mm PS5538

Regulator Function

Common Pressure Regulator 1

Independent Pressure Regulator 2

#4 Port Regulator / Gauge*

2 2-60 PSIG w/o Gauge

3 5-125 PSIG w/o Gauge

5 2-60 PSIG w/Gauge

6 5-125 PSIG w/Gauge

* For Common Pressure Regulator Option, Regulator Gauge callout must

be the same number for both Port #4 and Port #2. (Example: 166)

* For Common Pressure Regulator Option, Regulator

Gauge callout must be the same number for both

Port #4 and Port #2. (Example: 166)

Size 1, 2 , & 3

HOW T O ORDER

(Choose your options (in red) to configure your valve model number.)

#2 Port Regulator / Gauge*

2 2-60 PSIG w/o Gauge

3 5-125 PSIG w/o Gauge

5 2-60 PSIG w/Gauge

6 5-125 PSIG w/Gauge

Interposed Regulators

Features:

• Remote Air Pilot Operated for hard-to-reach pressure

control

• Unregulated Pilot Pressure to valve for consistent

valve shifting reg ardl ess of pre ssure ad just ment

Size 00 - 18mm

(Dual Interposed Regulator Shown)

Size 0 - 26mm

(Single Interposed Regulator Shown)

R PS4037 1 6 6 C P

Basic Series

Size 1 5599-1 PS4037

Size 1 5599-2 PS4038

Size 2 5599-1 PS4137

Size 2 5599-1 PS4138

Size 3 5599-1 PS4237

Size 3 5599-1 PS4238

Regulator Function

Common Pressure Regulator 1

Independent Pressure Regulator 2

Selector Regulator 3

#4 Port Regulator / Gauge*

0** Line By-Pass Plate

1 1-30 PSIG w/o Gauge

2 2-60 PSIG w/o Gauge

3 5-125 PSIG w/o Gauge

4 1-30 PSIG w/Gauge

5 2-60 PSIG w/Gauge

6 5-125 PSIG w/Gauge

C Air Pilot w/60 PSIG Gauge

D Air Pilot w/160 PSIG Gauge

* For Common Pressure Regulator Option, Regulator Gauge callout must

be the same number for both Port #4 and Port #2. (Example: 166)

** Pressure Line By-Pass Option can only be used with Independent and

Selector Regulators (Option 2 & 3 in Interposed Block Function).

0** Line By-Pass Plate

1 1-30 PSIG w/o Gauge

2 2-60 PSIG w/o Gauge

3 5-125 PSIG w/o Gauge

4 1-30 PSIG w/Gauge

5 2-60 PSIG w/Gauge

6 5-125 PSIG w/Gauge

C Air Pilot w/60 PSIG Gauge

D Air Pilot w/160 PSIG Gauge

* For Common Pressure Regulator Option, Regulator Gauge callout must

be the same number for both Port #4 and Port #2. (Example: 166)

** Pressure Line By-Pass Option can only be used with Independent and

Selector Regulators (Option 2 & 3 in Interposed Block Function).

Ordering Components

• Manifold or Subbase Kit required

• Interposed Regulator Kit configured for Internal Pilot as standard

• Order valve as External Pilot

How to Configure Interposed Regulator / Valve Combinations

Internal Pilot Configuration - Pressure in Base Port 1 feeds regulator configured for

Internal Pilot which feeds valve configured for External Pilot.

External Pilot Configuration - Size 1, Size 2, Size 3

An External Pilot pressure in Port 12 or 14 of the base feeds thru the Interposed

Regulator 12 or 14 galley directly to the 12/14 pilot of the valve.

This configuration takes an External Pilot from the 12 port of the base and passes it thru

the regulator to feed the 12 galley of the valve.

#2 Port Regulator / Gauge*

Size 1

(Dual Interposed Regulator Shown)

Size 2

(Dual Interposed Regulator Shown)

WARNING

Double interposed regulators will reverse output ports, the 12 solenoid will pressurize the 4 port, the 14 solenoid will

pressurize the 2 port which may cause unexpected, potentially dangerous cylinder movement at valve pressurization.

14 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 15

Gauge Adapter Kit

Description Part Number

Gauge Kit RPS5651160P

1/8" Female to 1/8" Female Coupling R207P-2*

1/8" Male to 1/8" Male Long Nipple RVS215PNL-2-15*

* Included in Gauge Kit RPS5651160P

Included with all Size 00 Regulators. Both kits are

required on all Size 0 & 00 Regulators when the

Regulator is on the last Station on the Right (14) End.

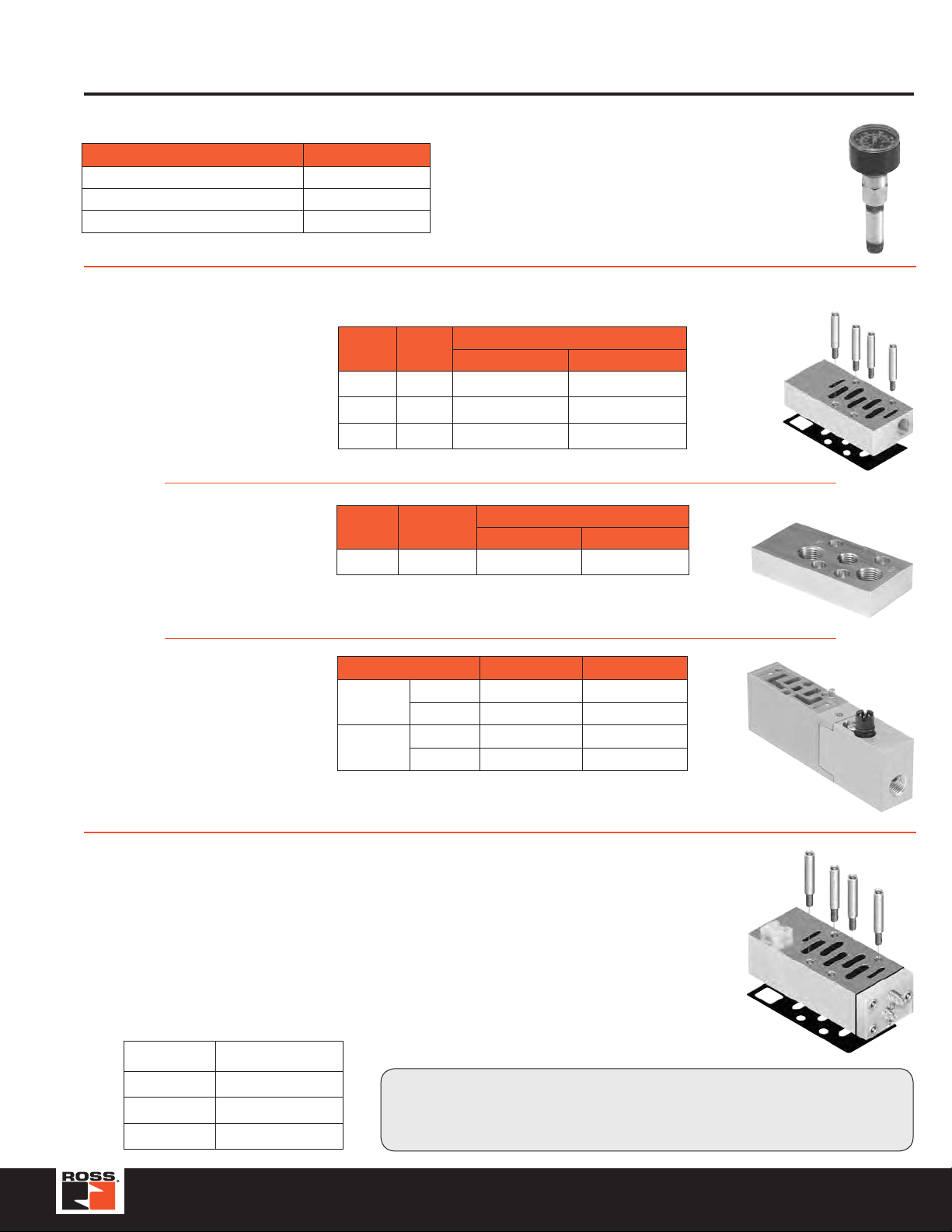

Remote Pilot Access Plates, Exhaust Modules, Air Supply Bases

Accessories

Remote Pilot

Access Plate Kits

Size 1

Auxiliary

Access Plate Kits

Interposed Supply &

Exhaust Modules

Size

Size 1 1/8" RPS401500CP RPS401501CP

Size 2 1/8" RPS411500CP RPS411501CP

Size 3 1/8" RPS421500CP RPS421501CP

Kit includes: Pilot Port Access Plate, Gasket and Mounting Studs.

Size Port Size

Size 1 1/4" & 3/8" RPS403000CP RPS403001CP

Kit includes: Pilot Port Access Plate, Gasket and Mounting Screws.

•UsedonSize1ManifoldstoprovideauxiliaryaccesstoPorts1,3&5.

•Port1:1/4",Ports3&5:3/8".

Size 00

(15407-2)

Size 0

(15407-2)

Quantity 1

•UsedonSize00&Size0valvestoprovideapressureorexhaust

path to individual valves.

Port

Size

Valve Size NPT BSPP “G”

Supply RPS561600P RPS561601P

Exhaust RPS561700P RPS561701P

Supply RPS551600P RPS551601P

Exhaust RPS551700P RPS551701P

Kit Number

NPT BSPP “G”

Kit Number

NPT BSPP “G”

Height: .72 Inch

5599-1 Shown

15407-2 Shown

Interposed Flow Controls

Features:

• Bothadjustmentscrewsarelocatedonthe12endoftheunit.

•

Interposed Flow Contr ol mounts with its own studs, w hich means the valve uses

standard bol ts for mo unti ng.

• InterposedFlowControlisnottobeused as a shutoffdevice andisnotbubble

tight when need le s are fully tur ne d d own.

Valve Size Plug-In 5599-2

Size 1 RPS4035CP

Size 2 RPS4135CP

Size 3 RPS4235CP

A Interposed Flow Control and Common Port Interposed Regulator may be

sandwiched together on a manifold or subbase. The Interposed Flow Control

MUST be located between the manifold/subbase and the Common Port

Interposed Regulator.

Plug-In 5599-2

Size 2 Shown

15www.rosscontrols.com

Page 16

Service & Repair Kits

Series W65 Replacement Pilot

Assembly & Coil

Description Model Number

Pilot Assembly 1149C79

Coil 334B33

Specify Voltage and Hz when ordering.

Manifold Hardware Kits

Valve Size Kit Number

Size 00 RPS5612P

Size 0 RPS5512P

Size 1 RPS4012P

Size 2 RPS4112P

Size 3 RPS4212P

Quantity 12

Valve Bolt Kits

Valve Size Kit Number

Size 00 RPS5687P

Size 0 RPS5587P

Quantity 12

Manifold to Manifold Gasket Kits

15407-2

Size Standard

Size 00

Size 0

Size 1 RPS4013P — — —

Size 2 RPS4113P — — —

Size 3 RPS4213P — — —

RPS561AP RPS561CP RPS561DPRPS561BP

RPS561AP RPS561BP RPS561CP RPS561DP

Blocked

#1 Port

Blocked

#1, 3, 5 Ports

Blocked

#3, 5 Ports

Regulator & Flow Control Mounting Studs

Type Size 00 Size 0

Flow Control

Regulator

Type Size 1 Size 2 Size 3

Flow Control RPS4036P RPS4136P RPS4236P

Regulator RPS4040P RPS4140P RPS4240P

Quantity 12

RPS5636P RPS5536P

RPS5636P RPS5536P

Regulator Kits

Valve Size Kit Number

Size 1 RPS4039P

Size 2 & 3 RPS4139P

Pilot Select Gasket Kits

Valve Size Kit Number

Size 00 RPS5605P

Size 0 RPS5505P

Quantity 10

Indicates External Pilot

Size 00 Shown

Indicates Internal Pilot

Valve to Base Gasket Kits

Valve Size Standard

Size 00 RPS5605P*

Size 0 RPS5505P*

Size 1 797B11

Size 2 828B11

Size 3 858B11

Quantity 1, * Quantity 10.

Regulator Gauge Kits – Size 1, 2 & 3

Gauge Type Kit Number

3/4" Face Air - Standard

0-60 PSIG RPS4051060BP

0-160 PSIG RPS4051160BP

1-1/2" Face Air - Large*

0-60 PSIG RPS4053060BP

0-160 PSIG RPS4053160BP

1-1/2" Face Liquid*

0-160 PSIG RPS4052160BP

* Includes brass pipe fitting extensions

Quantity 1

Body Service Kits

Valve

Size

Size 00

Size 0

Size 1 1422K77 1423K77 1424K77 1425K77 1424K77

Size 2 1467K77 1468K77 1469K77 1470K77 1469K77

Size 3 1471K77 1472K77 1473K77 1474K77 1473K77

Kit Includes: Spool assembly with seals, all piston seals, return spring, pilot selector

gasket, coil to end cap gasket.

Quantity 1

2

Position

Single

RPS5601P RPS5601P RPS5602P RPS5603P RPS5604P

RPS5501P RPS5501P RPS5502P RPS5503P RPS5504P

2

Position

Double

Closed

Center

3-Position

Open

Center

Power

Center

16 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 17

Service & Repair Kits

Regulator Conversion Kits Regulator Spring Range Kits

Valve

Size

Size 1 RPS4045BP RPS4047BP RPS4048BP

Size 2

Size 3

Quantity 1

Manual Bonnet

Assembly

(w/o Spring)

RPS4145BP RPS4147BP RPS4148BP

Air Pilot

Bonnet

Assembly

Independent

By-Pass

Plate

Technical Information

Temperature Rating

Size 00, 0, 1, 2, & 3

-15°C to 49°C (5°F to 120°F) Ambient.

Flow Rating (Cv)

Valve Size Port Size 2-Position 3-Position

Size 00 1/8" 0.55 0.50

Size 0 1/4" 1.1 1.0

Size 1 3/8" 1.0 1.0

Size 2 1/2" 2.3 2.3

Size 3 3/4" 3.4 3.4

Cv tested per ANSI / (NFPA) T3.21.3

Spring Range Size 1 Size 2 & 3

0 to 30 PSIG RPS4050030P RPS4150030BP

2 to 60 PSIG RPS4050060P RPS4150060BP

5 to125 PSIG RPS4050125P RPS4150125BP

Quantity 1

Response Time** (ms)

Valve

Size

Port

Size

Single Solenoid 2-Position - Air Return / Spring Assist

Size 00 1/8" 28 30 141 154

Size 0 1/4" 24 26 77 124

†

Size 1

Size 2

Size 3

##

Size 00 (12), Size 0 (25)

** With 100 PSIG supply, time (ms) required to fill from 0 to 90 PSIG and Exhaust

from 100 PSIG to 10 PSIG measured from the instant of energizing or deenergizing 24VDC solenoid.

† For valve response time information for Size 1, 2, & 3 valves, see ROSS Bulletin

379B - form # A10090.

Tested per ANSI / (NFPA) T3.21.8

3/8" — — — —

†

1/2" — — — —

†

3/4" — — — —

0 Cu. In. Chamber ## Cu. In. Chamber

Fill Exhaust Fill Exhaust

Operating Pressure

Size 00, 0, 1, 2, & 3

Maximum: 145 PSIG (1000 kPa)

Minimum:

Internal Pilot

Single Solenoid - 2-Position

Double Solenoid- 2-Position

Single Remote Pilot - 2-Position ** Vacuum Vacuum

Double Remote Pilot - 2-Position** Vacuum Vacuum

Double Solenoid - 3-Position (CC, OC, PC)

Double Remote Pilot - 3-Position** (CC, OC, PC) Vacuum Vacuum

Single Solenoid Pilot - 2-Position

Air Return / Spring Assist

Single Remote Pilot - 2-Position**

Air Return / Spring Assist

PSIG (Min. kPa)

Series W66, Size 00

30

(207)

35

(241)

30

(207)

External Pilot * * *

All Functions Vacuum Vacuum

* External Pilot Pressure / Remote Pilot Supply - 45-145 PSIG (310-1000 kPa).

** Must be equal to or greater than operating pressure.

PSIG (Min. kPa)

Series W66, Size 0

25

(173)

35

(241)

30

(207)

See pages 13 & 14 for

Sizes 1, 2 & 3

17www.rosscontrols.com

Page 18

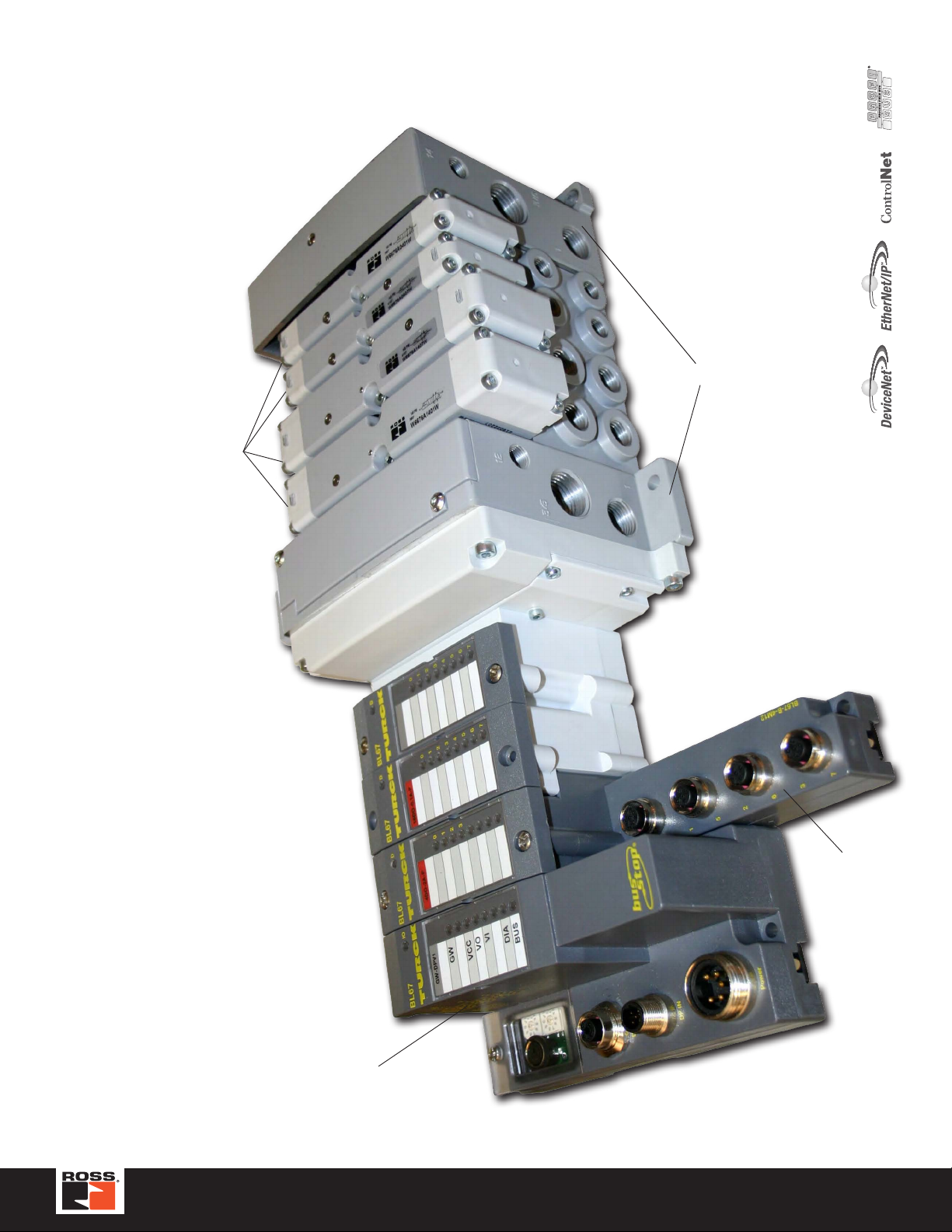

TURCK Modular Industrial I/O System BL 67

The BL67 Solution

BL67 combines all the flexibility of an in-the-cabinet PLC I/O

system with modularity, ruggedness and connectorization.

BL67 complements the AIM™, BL20 and piconet

families to meet the needs of unique applications, such as small

machine or conveyor systems requiring IP 67 protection.

The BL67 Concept

The BL67 modular concept is a very flexible approach to

connectorized I/O. The gateway, base and electronic modules

provide many benefits to the user.

• The gateway provides comm unication betw een the fieldbus

and I/O modules; modules are not dependent on the fieldb us

protocol.

• DIN-rail or frame mountable base modules are av ailable with

eurofast

®

(M12), minifast® (7/8-16UN), M23 and picofast®

(M8) connectors.

• Electronic modules are hot swappable.

• Power distribution module (24 volts DC) supplies the

connected I/O signals.

BL67’s openness, flexibility, connectorization, compact

housing and ruggedness provide a viable alternative to inthe-cabinet I/O.

Maximum Size of a BL67 Station

BL67 stations consist of a gateway and a maximum of 32

modules (equivalent to 1 m station length). Some high-tech and

analog I/O modules may consume or produce large amounts

of data, and therefore may limit the number of modules that

may be used per system. It is highly recommended that the I/

Oassistant software is used when planning and commissioning

BL67 systems. This prog ram allows you to b uild the BL67 node

on your computer and verify that all restrictions with regard

to power and size are met. The free I/O assistant software is

available for download from www.turck.com.

Addressing

As a node on a network, BL67 stations are addressed

dependent on the network system being used. Each network

gateway has a set of rotary switches used to set the address

for the node. DeviceNet™ and CANopen gateways may be

addressed between 0 and 63 via two switches (one f or the 10’s

digit and one for the 1’ s digit). For e xample, to set the address

to 37 you would set the 10’s switch to 3 and the 1’s switch to

7. The third switch on the gateway may be used to set the

communication rate of the network interface. PROFIBUS

gateways may be set from 1 to 125 by using three switches

(one for the 100’s, one for the 10’s and one for the 1’s).

Ethernet gateways allow different addressing schemes

depending on the Ethernet addressing method being used

in the overall system. Dynamic addressing schemes include

BootP and DHCP, while hard-coding a static address is also

allowed.

®

product

®

-DP

BL67 Power Distribution

Power Overview

The power supply for a BL67 station is fed via the power

connector on the PROFIBUS

network on the DeviceNet™ gateway. Power feeder modules

can be added to the system at any point to provide a fresh

isolated supply of power to all I/O connected to its right.

Internal Power Consumption via Module Bus

The amount of BL67 modules that may be supplied via the

internal module bus depends on the respective nominal current

IMB of the individual modules on the module bus. The sum of

the nominal current inputs of the connected BL67 module must

not exceed 1.5 A. If the I/O assistant software is used, an error

message is generated automatically via the <Station - Verify>

as soon as the system supply via the module bus is no longer

sufficiently guaranteed.

Module

BL67-GW-DPV1 – ≤150 mA

BL67-GW-DN – ≤100 mA

BL67-PF-24VDC ≤30 mA ≤9 mA

BL67-4DI-P ≤30 mA ≤9 mA ≤40 mA

BL67-8DI-P ≤30 mA ≤9 mA ≤40 mA

BL67-4DO-0.5A-P ≤30 mA ≤9 mA ≤100 mA

BL67-4DO-2A-P ≤30 mA ≤9 mA ≤100 mA

BL67-8DO-0.5A-P ≤30 mA ≤9 mA ≤100 mA

BL67-2AI-V ≤35 mA ≤10 mA ≤12 mA

BL67-2AI-I ≤35 mA ≤10 mA ≤12 mA

BL67-2AI-TC ≤35 mA ≤10 mA ≤30 mA

BL67-2AI-PT ≤45 mA ≤13 mA ≤45 mA

BL67-2AO-I ≤40 mA ≤12 mA ≤50 mA

BL67-2AO-V ≤60 mA ≤17 mA ≤50 mA

BL67-1RS232 ≤100 mA ≤28 mA ≤50 mA

BL67-8XSG-PD ≤30 mA ≤9 mA ≤100 mA

BL67-1SSI ≤50 mA ≤15 mA ≤50 mA

BL67-4DI-PD ≤30 mA ≤9 mA

BL67-8DI-PD ≤30 mA ≤9 mA ≤100 mA

To calculate current draw on DeviceNet: Add IMB(24) for all

modules. Then add VI and VO f or electronic modules to the left

of the first power feed module. Next, add the current draw of

the I/O devices.

To calculate current draw on PROFIBUS gateway power

connector for VI: Add IMB for all modules. Then add VI current

for all modules to the left of the first power feed module. Next,

add the current draw of the input devices.

For V O , add the VO current for all modules to the left of the first

power feed module. Next, add the current draw of the output

devices.

VMB = Module bus power

VI = Input power

VO = Output power

IMB = Module bus current

IMB(24) = Effective current dra w from gateway at 24 v olts DC supply

Nominal 1

Current

at 5 V I

®

gateway or directly from the

MB(24)

Nominal 3

Current

from V

Effective Draw 2

from Gateway at

24 VDC I

MB

Nominal 4

I

≤100 mA

Current

from V

O

18 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 19

TURCK Modular Industrial I/O System BL 67

Applying Power to BL67

PROFIBUS® , Ethernet and CANopen System

System Power

Isolation

Field Power

< 1.5A

I

MB(5V)

< 4A

I

I

(protected)

IO < 8A

V

MB(5V)

V

MB(24V)IMB(24V)

VOV

I

VI, VO, V

V

MB

V

V

4A

from Power on Gateway

MB

I

I

I

O

= Module Bus Power

= Input Power

I

= Output Power

O

I

MB(5V)

4A

VOV

I

Isolation of Field Power VI, V

I

I

I

O

O

A power feeder module provides

a new isolated segment for all

modules to its right.

System Power

Field Power

I

< 1.5A

MB(5V)

I

< 4A

I

(protected)

IO < 8A

V

MB(5V)

V

MB(24V)IMB(24V)

VOV

I

VI, VO, V

V

MB

V

I

V

O

4A

from DeviceNet™

MB

= Module Bus Power

= Input Power

= Output Power

TM

System

I

MB(5V)

DeviceNet

Isolation

4A

I

I

I

O

VOV

I

Isolation of Field Power VI’ V

I

I

I

O

O

A power feeder module provides

a new isolated segment for all

modules to its right.

19www.rosscontrols.com

Page 20

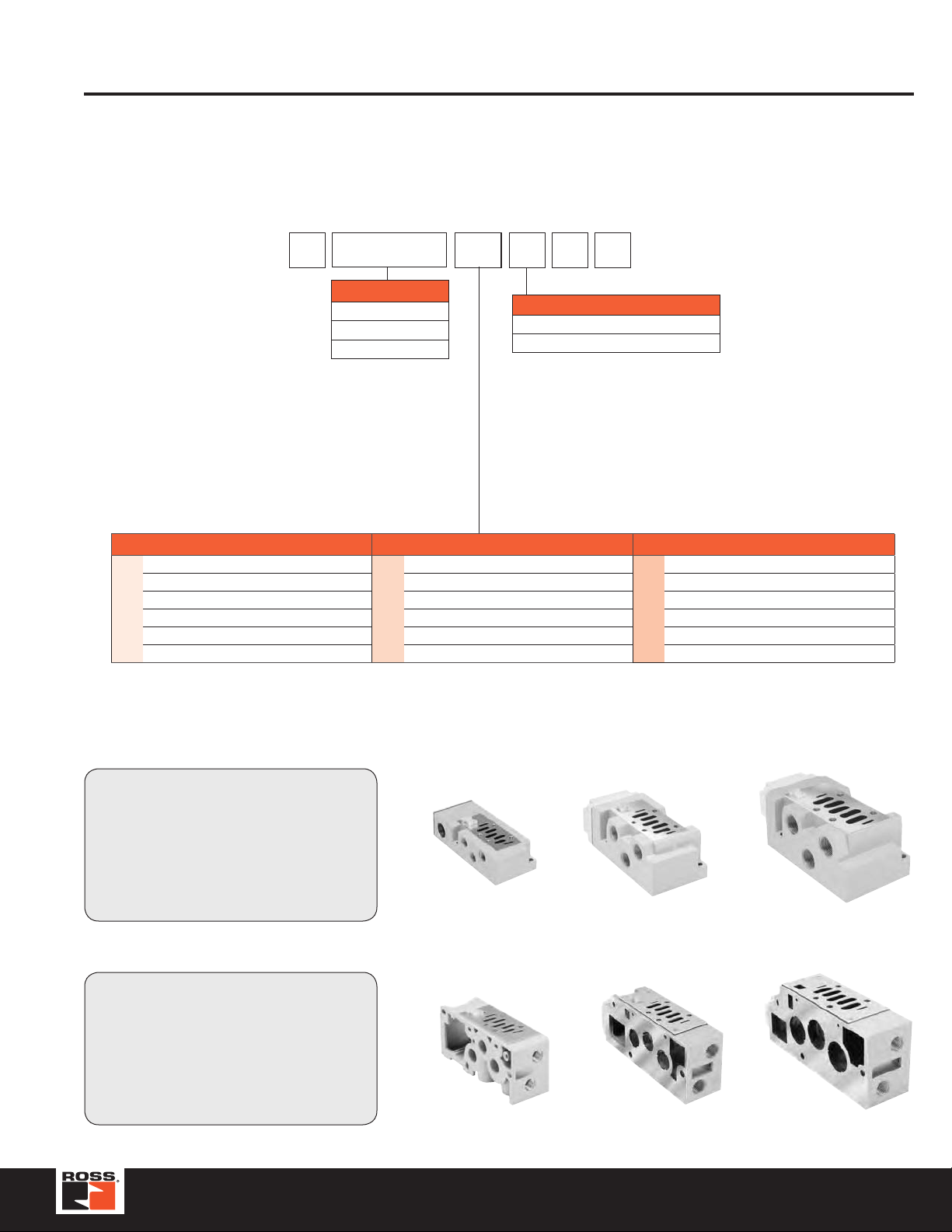

TURCK Modular Industrial I/O System BL 67

Environmental Conditions

Intended Application Environments

• BL67 does not need an enclosure

• Mount directly on machine or conveyor

•

Rugged design provides protection against dirt, dust and

liquids

Not intended for These Environments

• Continuous submersion

• 100 percent humidity

• High pressure washdown

Note:

For higher le vels of protection consider fully potted AIM stations .

BL 67 Selection Guide

General Environmental

Potential isolation Via optocoupler

Operating temperature 32° to +131°F (0° to +55°C)

Storage temperature -13° to +185°F (-25° to +85°C)

Relative humidity 5 to 95% (indoor), noncondensing

Vibration 1.0 g 5-10 Hz

Shock 15 g

Protection class

Electromagnetic

compatibility (EMC)

Housing material PC-V0 (Lexan), Nickel plated brass

Approvals CE

IP 67, NEMA 1, 3, 4, 12, 13

According to EN 61131-2

UL (pending)

CSA (pending)

Gateways Higher Level System Pages

DeviceNet

Ethernet

PROFIBUS-DP

CANopen

21

22, 23

24

25, 26

Modules Type I/O Direction Pages

Input 33-34, 36

Discrete

Analog

Serial

Output 29-31, 36

Input & Output 35

Input 40

Output 42

Input & Output 38-39

20 © 2012, ROSS CONTROLS

Power Feed

Base Modules

Accessories

®

. All Rights Reserved.

43

44

45

Page 21

TURCK Modular Industrial I/O System BL 67

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

DeviceNet Gateway

Electrical: • Operating Current: <600 mA from V

BL67-GW-DN

MB

• Supply Current: <8 A to I/O (from DeviceNet)

• Backplane Current: <1.5 A (from DeviceNet)

Mechanical: • Operating Temperature: 0 to +55°C (+32 to +131°F)

• Protection: IP 67

• Vibration: 5 g @ 10-500 Hz

Material: • Housing: PC-V0 (Lexan)

Diagnostics (Logical)

• Diagnostic information available through the DeviceNet I/O map

Diagnostics (Physical)

• LEDs to indicate status of DeviceNet and Module Bus communication

3.051 (77.5)

Service

Port and

Address

Switches

(91.0)

5.709

(145.0)

3.583

DeviceNet

2.913 (74.0)

BL67

GW-DN

GW

VCC

MNS

IO

Diagnostic

VO

VI

IO

LEDs

DeviceNet

Connector

DeviceNet

Connector

DeviceNet

1.260 (32.0)

DeviceNet minifast

®

Pinouts

Male Female

1 = Shield

2 = V+

3 = V4 = CAN_H

5 = CAN_L

3

2

2

4

1

5

1

3

4

5

5-Pin 5-Pin

Note: Power feeding modules may be used for I/O current supply to prevent overloading the DeviceNet power supply.

21www.rosscontrols.com

Page 22

TURCK Modular Industrial I/O System BL 67

3.051 (77.5)

Ethernet Pinout

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

ModBus TCP/IP

Ethernet Gateways

Ethernet IP

Ethernet Gateways

Electrical: • Operating Current: <600 mA from V

BL67-GW-EN

BL67-PG-EN

BL67-GW-EN-IP

BL67-PG-EN-IP

MB

• Input Supply Current: <4 A (from VI)

• Output Supply Current: <8 A (from VO)

• Backplane Current: <1.5 A (from V

MB)

Mechanical: • Operating Temperature: -12 to +55°C (-13 to +131°F)

• Protection: IP 67

• Vibration: 5 g @ 10-500 Hz

Material: • Housing: PC-V0 (Lexan)

Diagnostics (Logical)

• Diagnostic information available through the DeviceNet I/O map

Diagnostics (Physical)

• LEDs to indicate status of DeviceNet and Module Bus communication

Programmability

• PG in part number designates a programmable gateway

• Progammable according to IEC 61131.3 using CodeSys

(includes ladder logic)

• Use CodeSys to create logic programs to control local I/O

5.709

(145.0)

3.583

(91.0)

Service

Port and

Address

Switches

2.913 (74.0)

ETHERNET

POWER

BL67

GW-EN

VCC

LNK/ACT

GW

VO

VI

MS

1.260

(32.0)

Female

4

1 = TD+

2 = RD+

3

1

3 = TD-

IO

4 = RD-

2

4-Pin

Diagnostic

LEDs

Ethernet

Connector

5-pin minifast ® Power Pinout

Male

Power

Connector

1 = Gnd

2 = Gnd

3 = PE

4 = V

I

5 = V

O

3

2

4

5

1

5-Pin

22 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 23

TURCK Modular Industrial I/O System BL 67

3.051 (77.5)

2.913 (74.0)

Pinout

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

Profinet

Ethernet Gateways

BL67-GW-EN-PN

Electrical:

• Operating Current: <600 mA from V

MB

• Input Supply Current: <4 A (from VI)

• Output Supply Current: <8 A (from VO)

• Backplane Current: <1.5 A (from V

MB)

Mechanical: • Operating Temperature: -12 to +55°C (-13 to +131°F)

• Protection: IP 67

• Vibration: 5 g @ 10-500 Hz

Material: • Housing: PC-V0 (Lexan)

Diagnostics (Logical)

• Diagnostic information available through the DeviceNet I/O map

Diagnostics (Physical)

• LEDs to indicate status of DeviceNet and Module Bus communication

Service

Port and

Address

Switches

3.583

(91.0)

5.709

(145.0)

ETHERNET

BL67

GW-EN

GW

VCC

LNK/ACT

VO

MS

IO

Diagnostic

LEDs

VI

Ethernet

Connector

1 = TD+

2 = RD+

3 = TD4 = RD-

Ethernet Pinout

Female

4

3

2

4-Pin

Power

Connector

POWER

1.260

(32.0)

5-pin minifast

®

Power

Male

1 = Gnd

2 = Gnd

1

3 = PE

4 = V

5 = V

I

O

3

2

4

5

1

5-Pin

23www.rosscontrols.com

Page 24

2.913 (74.0)

1 = Gnd

2 = Gnd

TURCK Modular Industrial I/O System BL 67

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

PROFIBUS-DP Gateway

Electrical: • Operating Current: <50 mA from V

• Supply Current: <10 A to I/O (from V

• Backplane Current: <1.5 A (from V

BL67-PG-DP

I

)

I and VO

I)

Mechanical: • Operating Temperature: -25 to +55°C (+32 to +131°F)

BL67-GW-DPV1

• Protection: IP 67

• Vibration: 5 g @ 10-500 Hz

Material: • Housing: PC-V0 (Lexan)

Diagnostics (Logical)

• Diagnostic information available through the DeviceNet I/O map

Diagnostics (Physical)

• LEDs to indicate status of DeviceNet and Module Bus communication

Programmability

• PG in part number designates a programmable gateway

• Progammable according to IEC 61131.3 using CodeSys (includes ladder logic)

• Use CodeSys to create logic programs to control local I/O

3.051 (77.5)

Service

Port and

Address

Switches

3.583

(91.0)

5.709

(145.0)

PROFIBUS eurofast ® Pinouts

DP OUT

DP IN

POWER

Male Female

5

1

4

3

2

5-Pin 5-Pin

4

3

5

1

2

1 = 5 VDC*

2 = BUS _A

3 = Gnd

4 = BUS_B

5 = Shield

* Female connector only

Note: Power feeding modules may be used for I/O current supply to prevent overloading the DeviceNet power supply.

BL67 IO

GW-DP

GW

VCC

VO

VI

DIA

BUS

1.260

(32.0)

Diagnostic

LEDs

Profibus-DP

Connector

Power

Connector

minifast ® Power Pinouts

Male

3

4

5

5-Pin

2

3 = PE

4 = V

1

5 = V

I

O

24 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 25

TURCK Modular Industrial I/O System BL 67

3.051 (77.5)

2.913 (74.0)

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

CANopen Gateway

Electrical: • Operating Current: <600 mA from V

BL67-GW-CO

MB

• Supply Current: <8 A to I/O (from DeviceNet)

• Backplane Current: <1.5 A (from DeviceNet)

Mechanical: • Operating Temperature: -25 to +55°C (+32 to +131°F)

• Protection: IP 67

• Vibration: 5 g @ 10-500 Hz

Material: • Housing: PC-V0 (Lexan)

Diagnostics (Logical)

• Diagnostic information available through the DeviceNet I/O map

Diagnostics (Physical)

• LEDs to indicate status of DeviceNet and Module Bus communication

Service

Port and

Address

3.583

(91.0)

5.709

(145.0)

Switches

BL67

GW-CO

GW

VCC

VO

Bus

Error

IO

Diagnostic

LEDs

VI

CANopen

Connector

Power

Connector

1

CANopen eurofast ®Pinouts

Male Female

5

4

3

2

5-Pin 5-Pin

4

3

2

5

1

1 = Shield

2 = V+

3 = V-

4 = CAN_H

5 = CAN_L

* Female connector only

POWER

1.260

(32.0)

minifast ® Power Pinouts

Male

3

2

4

5

5-Pin

1

1 = Gnd

2 = Gnd

3 = PE

4 = V

I

5 = V

O

Note: Power feeding modules may be used for I/O current supply to prevent overloading the DeviceNet power supply.

25www.rosscontrols.com

Page 26

TURCK Modular Industrial I/O System BL 67

2.913 (74.0)

55

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

CANopen Gateway

Electrical: • Operating Current: <600 mA from V

BL67-GW-CO-T

MB

• Supply Current: <8 A to I/O (from DeviceNet)

• Backplane Current: <1.5 A (from DeviceNet)

Mechanical: • Operating Temperature: 0 to +55°C (+32 to +131°F)

• Protection: IP 67

• Vibration: 5 g @ 10-500 Hz

Material: • Housing: PC-V0 (Lexan)

Diagnostics (Logical)

• Diagnostic information available through the DeviceNet I/O map

Diagnostics (Physical)

• LEDs to indicate status of DeviceNet and Module Bus communication

3.051 (77.5)

Address

Service

Set

3.583

(91.0)

5.709

(145.0)

Service

Port and

Address

Switches

BL67 IO

GW-

GW

VCC

VO

VI

MNS

IO

Diagnostic

LEDs

CANopen

Connector

CANopen minifast ® Pinouts

Male Female

1 = Shield

2 = V+

3 = V4 = CAN_H

5 = CAN_L

4 4

22

11

5-Pin 5-Pin

26 © 2012, ROSS CONTROLS

POWER

1.260

(32.0)

33

®

. All Rights Reserved.

CANopen

Connector

Page 27

TURCK Modular Industrial I/O System BL 67

A B C

DD

S

4

5

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

4 Discrete Input Modules

Electrical: • Operating Current: <30 mA from V

<40 mA from V

Power Distribution:

• Logic: VMB and V

Material: • Connectors: Nickel-plated brass

• Housing: PC-VO (Lexan)

Diagnostics (Logical): • Diagnostic information available through the fieldbus gateway

Diagnostics (Physical): • LED to indicate module bus communication status as well as I/O diagnostics

• LEDs for each I/O point to indicate on/off status

23

5

1

Mating cordset: RK 4.4T-*-RS 4.4T

23

5

1

Mating cordset: RK 4.5T-*-RS 4.5T

6

8

BL67-4DI-P with BL67-B-4M12* A 4 0-3 S 1 PNP X 1

BL67-4DI-P with BL67-B-2M12* B 4 0-1 2S 2 PNP X 1

BL67-4DI-P with BL67-B-2M12-P* B 4 0-1 2S 2 PNP X 1

BL67-4DI-P with BL67-B-4M8* D 4 0-3 PI 1 PNP X 1

BL67-4DI-P with BL67-B-1M23* C 4 0 M23-4I 4 PNP X 1

BL67-4DI-N with BL67-B-4M12* A 4 0-3 S 1 NPN X 1

BL67-4DI-N with BL67-B-2M12* B 4 0-1 2N 2 NPN X 1

BL67-4DI-N with BL67-B-2M12-P* B 4 0-1 2N 2 NPN X 1

BL67-4DI-N with BL67-B-4M8* D 4 0-3 PI 1 NPN X 1

BL67-4DI-N with BL67-B-1M23* C 4 0 M23-4I 4 NPN X 1

BU

4

BK

BN

2N

Input (B)

WH

V-(A&B)

BU

4

Input (A)

BK

+(A&B)

V

I

BN

1

91011

Part Number Drawing

<1 mA from V

• Inputs: V

I

Input Connectors

V-

3

PE

Input

V

PE

2

+

I

1 = Input

2 = Input

3 = Input

4 = Input

23

5

1

Mating cordset: RK 4.4T-*-RS 4.4T

Splitter: VBRS 4.4-2RK 4T-*/*

3

4

1

Mating cordset: PSG 3M-*

1

2

3

4

I

4

PI

BU

BK

BN

M23-4I

5 = NC

6 = NC

7 = NC

8 = NC

MB

(...-P)

I

(...-N)

I

2S

Input (B)

WH

V-(A&B)

BU

PE

BK

Input (A)

BN

+(A&B)

V

I

V-

Input

+

V

I

9 = V

10 = V

11 = V

12 = V-

Input

Connectors Pinout

Count

BL67-4DI-P

BL67-4DI-N

3.583

(91.0)

7.677

(195.0)

+

I

+

I

+

I

Shown with

BL67-B-4MB base

D

1.654 (42.0)

BL67

1.260 (32.0)

5.709

(145.0)

BL67

BL67

BL67DD

I/O Data Map 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

n-1 (Data for modules to the left)

Out

n Data for next discrete modules I-1 I-2 I-3 I-0

n+1 (Data for modules to the right)

Inputs Data

Inputs per

Connector

Sensor

Style

Group

Diagnostics

Individual

Diagnostics

Wire-Break

Detection

Diagnostic

LEDs

I/O LEDs

I/O

Connector

I/O

Map

27www.rosscontrols.com

Page 28

TURCK Modular Industrial I/O System BL 67

DABC

2S

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

8 Discrete Input Modules

Electrical: • Operating Current: <30 mA from V

<40 mA from V

Power Distribution:

• Inputs: V

• Logic: V

<1 mA from V

I

MB

BL67-8DI-N

MB

(...-P)

I

(...-N)

I

Mechanical: • Operating Temperature: 0 to +55°C (+32 to +131°F)

• Protection: NEMA 1,3,4,12,13 / IEC IP 67

• Vibration: 5 g @ 10-500 Hz

Material: • Connectors: Nickel-plated brass

• Housing: PC-VO (Lexan)

Diagnostics (Logical):

• Diagnostic information available through the fieldbus gateway

Diagnostics (Physical):

• LED to indicate module bus communication status as well as I/O

diagnostics

BL67-8DI-P

• LEDs for each I/O point to indicate on/off status

7.677

(195.0)

3.583

(91.0)

1.654 (42.0)

Shown with

BL67-B-4M12 base

Diagnostic

LEDs

I/O LEDs

I/O

Connector

Input Connectors

Mating cordset: RK 4.4T-*-RS 4.4T

Splitter: VBRS 4.4-2RK 4T-*/*

2N

Mating cordset: RK 4.5T-*-RS 4.5T

Mating cordset: PSG 3M-*

PI

Application:

TURCK splitter box: 8MB12Z-4PZ-CS12

Cable: CSWM CKWM 12-10-*/S101/BL67

In

Part Number Drawing

BL67-8DI-P with BL67-B-4M12* A 8 0-3 2S 2 PNP X 1

BL67-8DI-P with BL67-B-4M12-P* B 8 0-3 2S 2 PNP X 1

BL67-8DI-P with BL67-B-8M8* B 8 0-7 PI 1 PNP X 1

BL67-8DI-P with BL67-B-1M23 D 8 0 M23-8I 8 PNP X 1

BL67-8DI-N with BL67-B-4M12* A 8 0-3 2N 2 PNP X 1

BL67-8DI-N with BL67-B-4M12-P* B 8 0-3 2N 2 NPN X 1

BL67-8DI-N with BL67-B-8M8* C 8 0-7 PI 1 NPN X 1

BL67-8DI-N with BL67-B-1M23 D 8 0 M23-8I NPN X 1

Input

Connectors Pinout

Count

1.260 (32.0)

4

5

6

7

12

8

3

1 = Input

2

2 = Input

3 = Input

4 = Input

1

91011

0

1

2

3

M23-8I

5 = Input

6 = Input

7 = Input

8 = Input

4

5

6

7

9 = V

10 = V

11 = V

12 = V-

I/O Data Map 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

n-1 (Data for modules to the left)

n I-7 I-6 I-5 I-4 I-3 I-2 I-1 I-0

n+1 (Data for modules to the right)

Inputs Data

Inputs per

Connector

Sensor

Style

Group

Diagnostics

Individual

Diagnostics

Wire-Break

Detection

Map

+

I

+

I

+

I

I/O

28 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 29

TURCK Modular Industrial I/O System BL 67

A B C

G

4

5

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

4 Discrete Output Modules

Electrical: • Operating Current: <30 mA from V

<100 mA from V

Power Distribution: • Inputs: V

• Logic: VMB and V

• Output Current: <0.5 A per output from V

O

O

BL67-4DO-0.5A-P

MB

O

O

Shown with

BL67-B-4M12 base

Material: • Connectors: Nickel-plated brass

• Housing: PC-VO (Lexan)

Diagnostics (Logical): • Diagnostic information available through the fieldbus gateway

Diagnostics (Physical): • LED to indicate module bus communication status as well as I/O diagnostics

• LEDs for each I/O point to indicate on/off status

1.654 (42.0)

Outputs Connectors

3.583

(91.0)

7.677

(195.0)

5.709

(145.0)

2G

Mating cordset: RK 4.4T-*-RS 4.4T

PO

D

Diagnostic

LEDs

I/O LEDs

Mating cordset: RK 4.4T-*-RS 4.4T

Splitter: VBRS 4.4-2RK 4T-*/*

6

7

12

8

91011

Part Number Drawing

BL67-4DO-0.5A-P with BL67-B-4M12* A 4 0-3 G 1 0.5 A Source 1

BL67-4DO-0.5A-P with BL67-B-2M12* B 4 0-1 2G 2 0.5 A Source 1

BL67-4DO-0.5A-P with BL67-B-2M12-P* B 4 0-1 2G 2 0.5 A Source 1

BL67-4DO-0.5A-P with BL67-B-4M8* D 4 0-3 PO 1 0.5 A Source 1

BL67-4DO-0.5A-P with BL67-B-1M23* C 4 0 M23-4O 4 0.5 A Source 1

I/O

Connector

Mating cordset: PSG 3M-*

1.260 (32.0)

0

1

2

3

M23-4O

5 = NC

6 = NC

7 = NC

8 = NC

9 = V

10 = V

11 = V

12 = V-

I/O Data Map 1

+

I

+

I

+

I

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

n-1 (Data for modules to the left)

Out

n Data for next discrete modules 0-3 0-2 0-1 0-0

n+1 (Data for modules to the right)

3

1 = Output

2

2 = Output

3 = Output

4 = Output

1

Outputs Data

Output

Count

Connectors Pinout

Outputs per

Connector

Current Style

Individual

Diagnostics

I/O

Map

29www.rosscontrols.com

Page 30

TURCK Modular Industrial I/O System BL 67

DA B C

H

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

4 Discrete Output Modules

Electrical: • Operating Current: <30 mA from V

<100 mA from V

Power Distribution: • Inputs: V

• Logic: VMB and V

Material: • Connectors: Nickel-plated brass

• Housing: PC-VO (Lexan)

Diagnostics (Logical):

• Diagnostic information available through the fieldbus gateway

Diagnostics (Physical):

• LED to indicate module bus communication status as well as

I/O diagnostics

• LEDs for each I/O point to indicate on/off status

• Output Current: <2 A per output from V

O

O

Input Connectors

Mating cordset: RK 4.5T-*-RS 4.5T

2H

BL67-4DO-2A-N

MB

O

O

PO

BL67-4DO-2A-P

7.677

(195.0)

3.583

(91.0)

1.654 (42.0)

5.709

(145.0)

Shown with

BL67-B-2M12 base

Diagnostic

LEDs

I/O LEDs

Mating cordset: RK 4.4T-*-RS 4.4T

Splitter: VBRS 4.4-2RK 4T-*/*

4

5

7

12

6

8

91011

3

2

1

Part Number Drawing

BL67-4DO-2A-P with BL67-B-4M12* A 4 0-3 H 1 2 A Source 1

Mating cordset: PSG 3M-*

M23-4O

1 = Output

2 = Output

3 = Output

4 = Output

0

1

2

3

5 = NC

6 = NC

7 = NC

8 = NC

Output

Count

9 = V

+

I

10 = V

+

I

11 = V

+

I

12 = V-

Connectors Pinout

1.260 (32.0)

I/O Data Map 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

n-1 (Data for modules to the left)

Out

n Data for next discrete modules 0-3 0-2 0-1 0-0

n+1 (Data for modules to the right)

Outputs Data

Outputs per

Connector Current

Style

Individual

Diagnostics

BL67-4DO-2A-P with BL67-B-2M12* B 4 0-1 2H 2 2 A Source 1

BL67-4DO-2A-P with BL67-B-2M12-P* C 4 0-1 2H 2 2 A Source 1

BL67-4DO-2A-P with BL67-B-4M8* D 4 0-3 PO 1 2 A Source 1

BL67-4DO-2A-P with BL67-B-1M23* C 4 0 M23-4O 4 2 A Source 1

BL67-4DO-2A-N with BL67-B-4M12* A 4 0-3 H 1 2 A Sink 1

BL67-4DO-2A-N with BL67-B-2M12* B 4 0-1 2H 2 2 A Sink 1

BL67-4DO-2A-N with BL67-B-2M12-P* C 4 0-1 2H 2 2 A Sink 1

BL67-4DO-2A-N with BL67-B-4M8* D 4 0-1 PO 1 2 A Sink 1

BL67-4DO-2A-N with BL67-B-1M23*

C 4 0 M23-4O 4 2 A Sink 1

I/O

Connector

I/O

Map

30 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 31

TURCK Modular Industrial I/O System BL 67

DABC

PO

4

5

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

8 Discrete Output Modules

Electrical: • Operating Current: <30 mA from V

<100 mA from V

Power Distribution: • Inputs: V

• Logic: VMB and V

Material: • Connectors: Nickel-plated brass

• Output Current: <0.5 A per output from V

O

O

BL67-8DO-0.5A-P

MB

O

O

BL67-B-8MB base

• Housing: PC-VO (Lexan)

Diagnostics (Logical): • Diagnostic information available through the fieldbus gateway

Diagnostics (Physical): • LED to indicate module bus communication status as well as I/O diagnostics

• LEDs for each I/O point to indicate on/off status

1.654 (42.0)

Outputs Connectors

2G

3.583

(91.0)

Shown with

Diagnostic

LEDs

I/O LEDs

Mating cordset: RK 4.4T-*-RS 4.4T

Splitter: VBRS 4.4-2RK 4T-*/*

6

7

12

8

3

1 = Output

2

2 = Output

3 = Output

4 = Output

1

91011

Application:

TURCK splitter box: 8MB12Z-4PZ-CS12

Cable: CSWM CKWM 12-10-*/S101/BL67

Mating cordset: PSG 3M-*

M23-8O

0

1

2

3

5 = Output

6 = Output

7 = Output

8 = Output

4

5

6

7

9 = VI+

10 = V

11 = V

12 = V-

7.677

(195.0)

1.260 (32.0)

+

I

+

I

I/O

Connector

I/O Data Map 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

n-1 (Data for modules to the left)

Out

n 0-7 0-6 0-5 0-4 0-3 0-2 0-1 0-0

n+1 (Data for modules to the right)

Outputs Data

Part Number Drawing

BL67-8DO-0.5A-P with BL67-B-4M12* A 8 0-3 2G 2 0.5 A Source 1

BL67-8DO-0.5A-P with BL67-B-4M12-P* B 8 0-3 2G 2 0.5 A Source 1

Output

Count

Connectors Pinout

Outputs per

Connector

Current Style

Individual

Diagnostics

I/O

Map

BL67-8DO-0.5A-P with BL67-B-8M8* C 8 0-7 PO 1 0.5 A Source 1

BL67-8DO-0.5A-P with BL67-B-1M23 D 8 0 M23-4O 4 0.5 A Source 1

31www.rosscontrols.com

Page 32

TURCK Modular Industrial I/O System BL 67

M23-16O

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

16 Discrete Output Modules

Electrical: • Operating Current: <30 mA from V

<100 mA from V

Power Distribution: • Inputs: V

• Logic: VMB and V

Material: • Connectors: Nickel-plated brass

• Output Current: <0.5 A per output from V

O

O

BL67-16DO-0.1A-P

MB

O

O

BL67-8-1M23 base

• Housing: PC-VO (Lexan)

Diagnostics (Logical): • Diagnostic information available through the fieldbus gateway

Diagnostics (Physical): • LED to indicate module bus communication status as well as I/O diagnostics

• LEDs for each I/O point to indicate on/off status

1.654 (42.0)

Outputs Connectors

15 6

7

8

16

9

10

17

11

5

19

4

14

3

2

13

1

18

12

1 = Output

2 = Output

3 = Output

4 = Output

5 = Output

6 = V7 = Output

8 = Output

9 = Output

14

10

6

3

2

1

5

9

10 = Output

13

11 = Output

12 = PE

13 = Output

14 = Output

15 = Output

16 = Output

17 = Output

18 = Output

19 = VI+

12

3.583

5.709

(145.0)

(91.0)

11

7

0

4

8

15

Shown with

Diagnostic

LEDs

I/O LEDs

I/O

Connector

1.260 (32.0)

Application:

•SMCValveBlocks;CSMDB2519-17-*/SMC

•MACValveBlocks;CSMDBK2519-17-*/MAC

•16MB12-4P2-CS191;CSMCKM19-19-0-*/S101

* Indicates lenght in meters.

1 Splitter box, refer to Connectivity Catalog for more information

Note: TURCK cannot guarantee pinout pinout of connecting de vices.

Please verify pinout is correct for your application.

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

n-1 (Data for modules to the left)

n 0-7 0-6 0-5 0-4 0-3 0-2 0-1 0-0

Out

n+1 0-15 0-14 0-13 0-12 0-11 0-10 0-9 0-8

n+2 (Data for modules to the right)

I/O Data Map 1

Outputs Data

Part Number Drawing

Output

Count

Connectors Pinout

BL67-16DO-0.1-P with BL67-B-1M23-19 A 16 0 M23-16O 16 0.1 A Source 1

32 © 2012, ROSS CONTROLS

Outputs per

Connector

®

. All Rights Reserved.

Current Style

Individual

Diagnostics

Map

I/O

Page 33

TURCK Modular Industrial I/O System BL 67

D

A B C

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

Deluxe 4 Discrete Input Modules

Electrical: • Operating Current: <30 mA from V

<100 mA from V

Power Distribution: • Inputs: V

• Logic: VMB and V

I

I

MB

I

BL67-4DI-PD

Material: • Connectors: Nickel-plated brass

• Housing: PC-VO (Lexan)

Diagnostics (Logical):

• Diagnostic information available through the fieldbus gateway

Diagnostics (Physical):

• LED to indicate module bus communication status as well as I/O diagnostics

• LEDs for each I/O point to indicate on/off status

1.654 (42.0)

3.583

(91.0)

S

5.709

(145.0)

Shown with

BL67-B-4M8 base

Diagnostic

LEDs

I/O LEDs

Input Connectors

7.677

(195.0)

Mating cordset: RK 4.4T-*-RS 4.4T

2S

PI

1.260 (32.0)

I/O Data Map 1

Mating cordset: RK 4.4T-*-RS 4.4T

Splitter: VBRS 4.4-2RK 4T-*/*

Part Number Drawing

BL67-4DI-PD with BL67-B-4M12* A 4 0-3 S 1 PNP X X 1

BL67-4DI-PD with BL67-B-2M12* B 4 0-1 2S 2 PNP X 1

BL67-4DI-PD with BL67-B-2M12-P* C 4 0-1 2S 2 PNP X 1

BL67-4DI-PD with BL67-B-4M8* D 4 0-3 PI 1 PNP X 1

Mating cordset: PSG 3M-*

Input

Count

Connectors Pinout

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

n-1 (Data for modules to the left)

In

n Data for next discrete modules I-3 I-2 I-1 I-0

n+1 (Data for modules to the right)

Note: I/O faults can be reported in the I/O map. Consult the product user

manual for details.

Inputs Data

Inputs per

Connector

Sensor

Style

Individual

Diagnostics

Wire-Break

Detection

I/O

Connectors

I/O

Map

33www.rosscontrols.com

Page 34

TURCK Modular Industrial I/O System BL 67

PI

2S

ABC

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

Deluxe 8 Discrete Input Modules

Electrical: • Operating Current: <30 mA from V

<100 mA from V

Power Distribution: • Inputs: V

• Logic: VMB and V

I

I

MB

I

BL67-8DI-PD

Material: • Connectors: Nickel-plated brass

• Housing: PC-VO (Lexan)

Diagnostics (Logical):

• Diagnostic information available through the fieldbus gateway

Diagnostics (Physical):

• LED to indicate module bus communication status as well as I/O diagnostics

• LEDs for each I/O point to indicate on/off status

Input Connectors

3.583

(91.0)

1.654 (42.0)

Shown with

BL67-B-4M12 base

Diagnostic

LEDs

I/O LEDs

7.677

(195.0)

Mating cordset: RK 4.4T-*-RS 4.4T

Splitter: VBRS 4.4-2RK 4T-*/*

Mating cordset: PSG 3M-*

1.260 (32.0)

I/O

Connectors

I/O Data Map 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

n-1 (Data for modules to the left)

Input

Count

Connectors Pinout

Part Number Drawing

BL67-8DI-PD with BL67-B-4M12* A 8 0-3 2S 2 PNP X X 1

BL67-8DI-PD with BL67-B-4M12-P* B 8 0-3 2S 2 PNP X 1

BL67-8DI-PD with BL67-B-8M8* C 8 0-7 PI 1 PNP X 1

In

n I-7 I-6 I-5 I-4 I-3 I-2 I-1 I-0

n+1 (Data for modules to the right)

Note: I/O faults can be reported in the I/O map. Consult the product user

manual for details.

Inputs Data

Inputs per

Connector

Sensor

Style

Individual

Diagnostics

Wire-Break

Detection

I/O

Map

34 © 2012, ROSS CONTROLS

®

. All Rights Reserved.

Page 35

TURCK Modular Industrial I/O System BL 67

CAB

4

5

2X

Modular I/O • Fieldbus Independent Configuration • IP 67 Protection • Various I/O Styles

Discrete Input/Output Module

Electrical: • Operating Current: <30 mA from V

<100 mA from V

Power Distribution: • Inputs: V

• Logic: VMB and V

• Output Current: <0.5 A per output from V

O

O

Material: • Connectors: Nickel-plated brass

• Housing: PC-VO (Lexan)

Diagnostics (Logical): • Diagnostic information available through the fieldbus gateway

Diagnostics (Physical): • LED to indicate module bus communication status as well as I/O diagnostics

• LEDs for each I/O point to indicate on/off status

Input/Output Connectors

Mating cordset: RK 4.4T-*-RS 4.4T

Splitter:

VBRS 4.4-2RK 4T-*/*

Mating cordset: PSG 3M-*

MB

O

PI

BL67-8XSG-PD

O