Page 1

Ports: 1/2 to 1

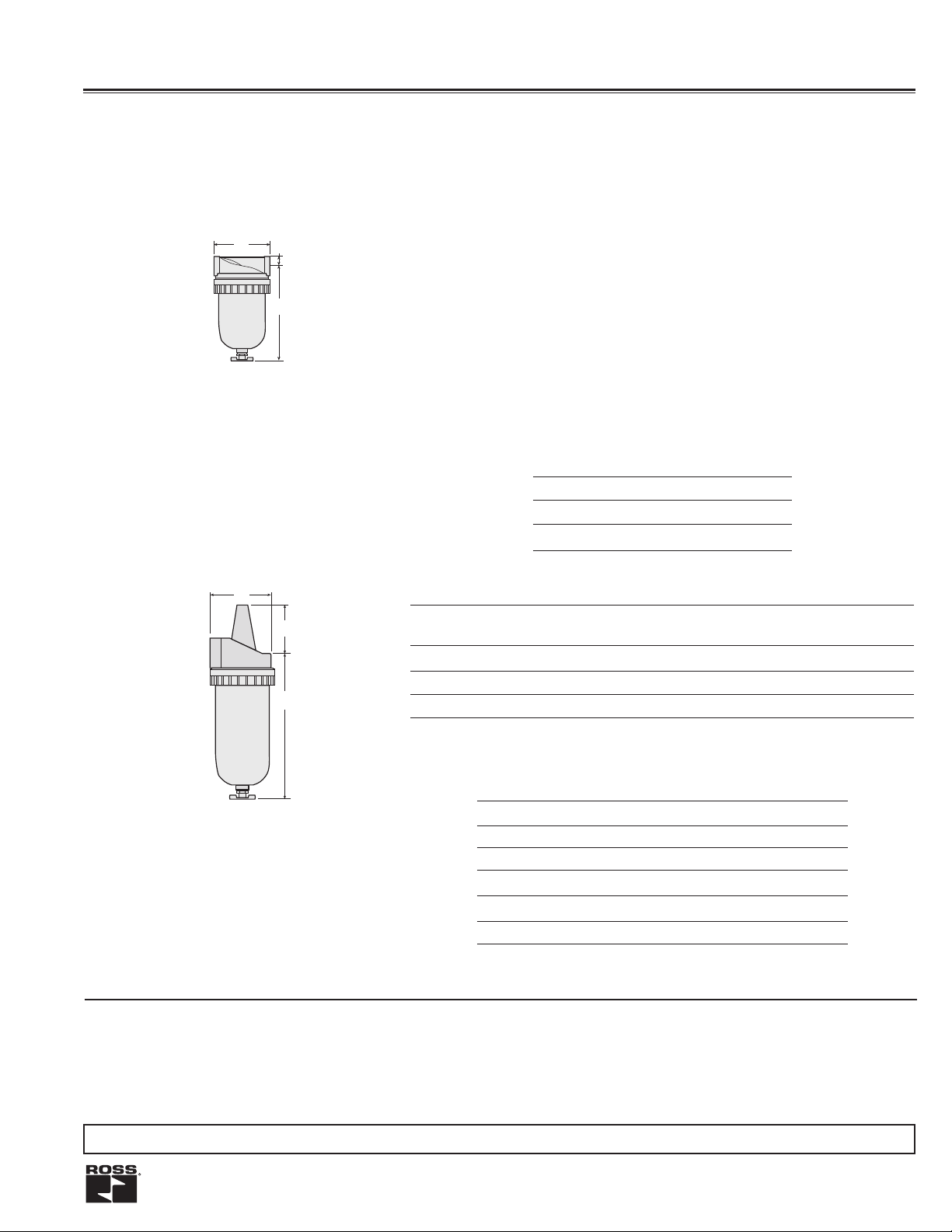

1/2 Model

SILENCERS/RECLASSIFIERS

Silencer/reclassifiers are integral silencer and oil separation devices.

When installed at the exhaust ports of pneumatic valves they reduce exhaust

noise and capture lubricants contained in the exhausting air.

A

C

B

They are used on valve-cylinder applications and on air tools with piped e xhausts.

FEATURES:

• Exhaust noise is reduced to 80 to 85 dBA under standard steady-state test

conditions

• Peak impact noise is reduced to 106 to 108 dBA

• Both a drain cock and a 1/8 tube tting are supplied for the manual or automatic

draining of accumulated liquids

Port Size Model Numbers

1/2 5055B4009

3/4 5055B5009

1 5055B6009

A

C

3/4 & 1 Model

STANDARD SPECIFICATIONS (for products on this page):

Ambient/Media Temperature: 40° to 125°F (4° to 51°C).

Bowl: Polycarbonate plastic.

Element: Sintered bronze.

Fluid Media: Compressed air.

B

Port Model DIMENSIONS inches (mm) Weight

Size Number A B C Depth lb (kg)

1/2 5055B4009 3.5 (89) 5.5 (140) 0.7 (18) 3.5 (89) 1.3 (0.59)

3/4 5055B5009 4.2 (107) 8.4 (213) 2.7 (69) 4.2 107) 2.8 (1.27)

1 5055B6009 4.2 (107) 8.4 (213) 2.7 (69) 4.2 (107) 2.8 (1.27)

REPLACEMENT FILTER ELEMENT KITS & BOWLS

Port Size Element Rating/Type Kit Number

1/2 20-µm - Standard 940K77

3/4 - 1 100-µm - Standard

Port Size

1/2 Polycarbonate 982K77

3/4 - 1 Polycarbonate 983K77

Inlet Pressure:

For automatic drain model: 5 to 150 psig (0.3 to 10.3 bar).

For manual drain model: 0 to 150 psig (0 to 10.3 bar).

Threads: NPT standard, BSPP. For BSPP threads, add a “C”

prefix to the model number, e.g., C5055B4009.

Bowl T ype Kit Number

981K77

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

www.rosscontrols.com 29

Page 2

0 10

0

20 30 40 50

0 10

0

20 30 40 50

Valve

Ports: 1/2 to 1

0 10

0

120

20

30 40 50

at flows over 70 scfm (33.0 l/s).

SILENCERS/RECLASSIFIERS

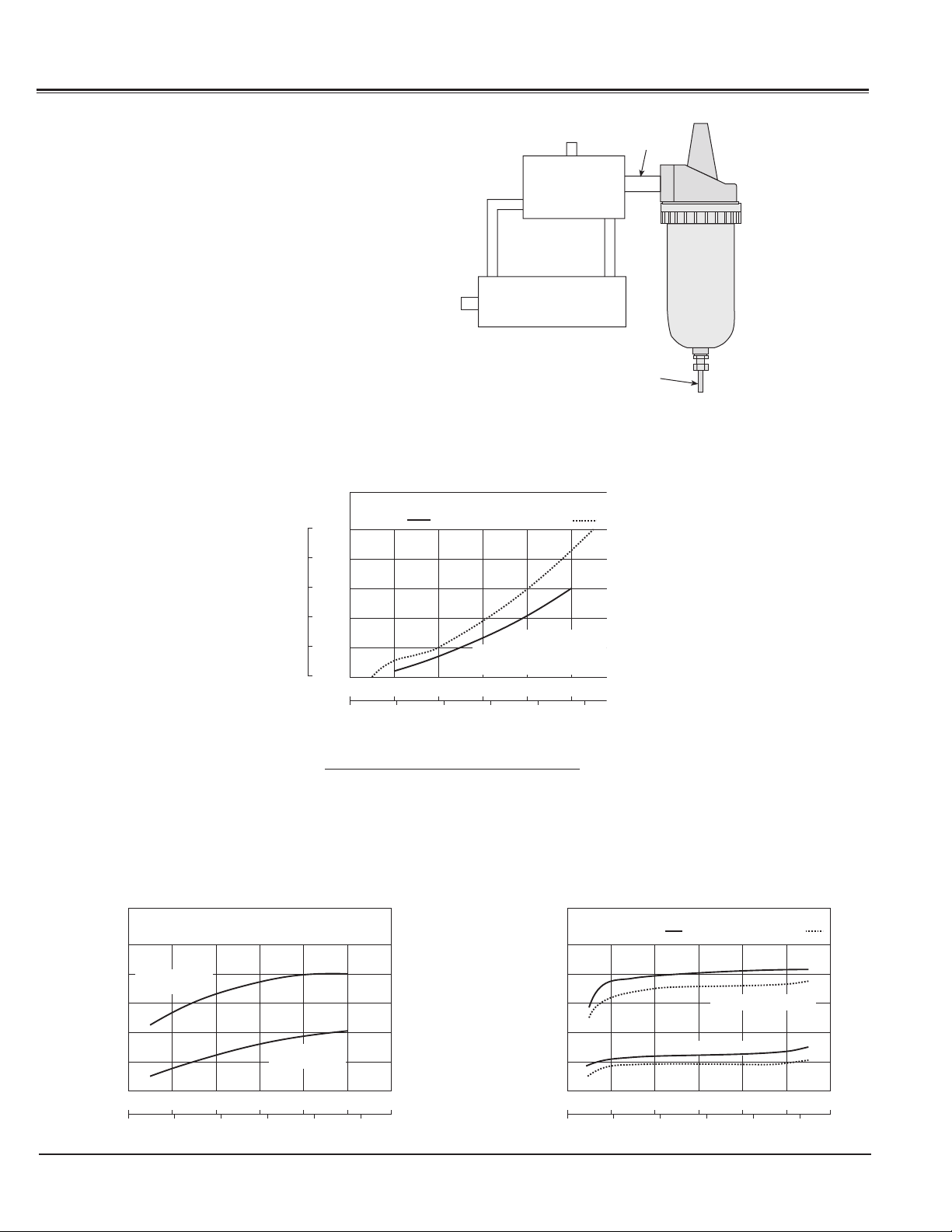

Typical Installation In A

Valve-Cylinder Circuit

bar

0.70

0.56

0.42

psi

10

8

6

Air Supply

Air Cylinder

FLOW CHART

Back Pressure Performance

1/2

Exhaust

Pneumatic

Valve

1/8” Drain Line

3/4 & 1

Constant-flow tests were conducted in a 14’ x 22’ room with a 14’ ceiling. Sound pressure levels

were recorded using a B & K precision impulse sound meter (model 22045), a 1-inch microphone

(DB0375), a flexible extension rod (UA0196), and a random incidence corrector (UA0055).

Test system as mounted on the 14-foot wall with exhaust port 4 feet from the 14-foot wall.

dBa

120

11 0

1/2” Open Port

(36” distance)

100

90

80

IN SLOW RESPONS E

SOUND PRESSURE LEVEL

70

scfm

02 0

FLO W

0

l/ s

0.28

0.14

0

0

scfm

scfm

FLOW

FLOW

1/2 Model Sound Attenuation

5055B4009

(36” distance)

40 60 80 100 120

4

2

BACK PRESSURE

0

0

02 0

0

l/ s

l/ s

On 1/2 models effluent

re-entrainment may occur

40 60 80 100

SOUND ATTENUATION DATA

dBa

120

11 0

100

90

80

IN SLOW RESPONS E

SOUND PRESSURE LEVEL

70

scfm

02 0

FLO W

0

l/ s

1 Inch Model Sound Attenuation

3 ft from exhaust 10 ft from exhaust

1” x 14” Open Pipe

5055B6009

40 60 80 100 120

30 © 2012, ROSS CONTROLS.

All Rights Reserved.

Loading...

Loading...