Page 1

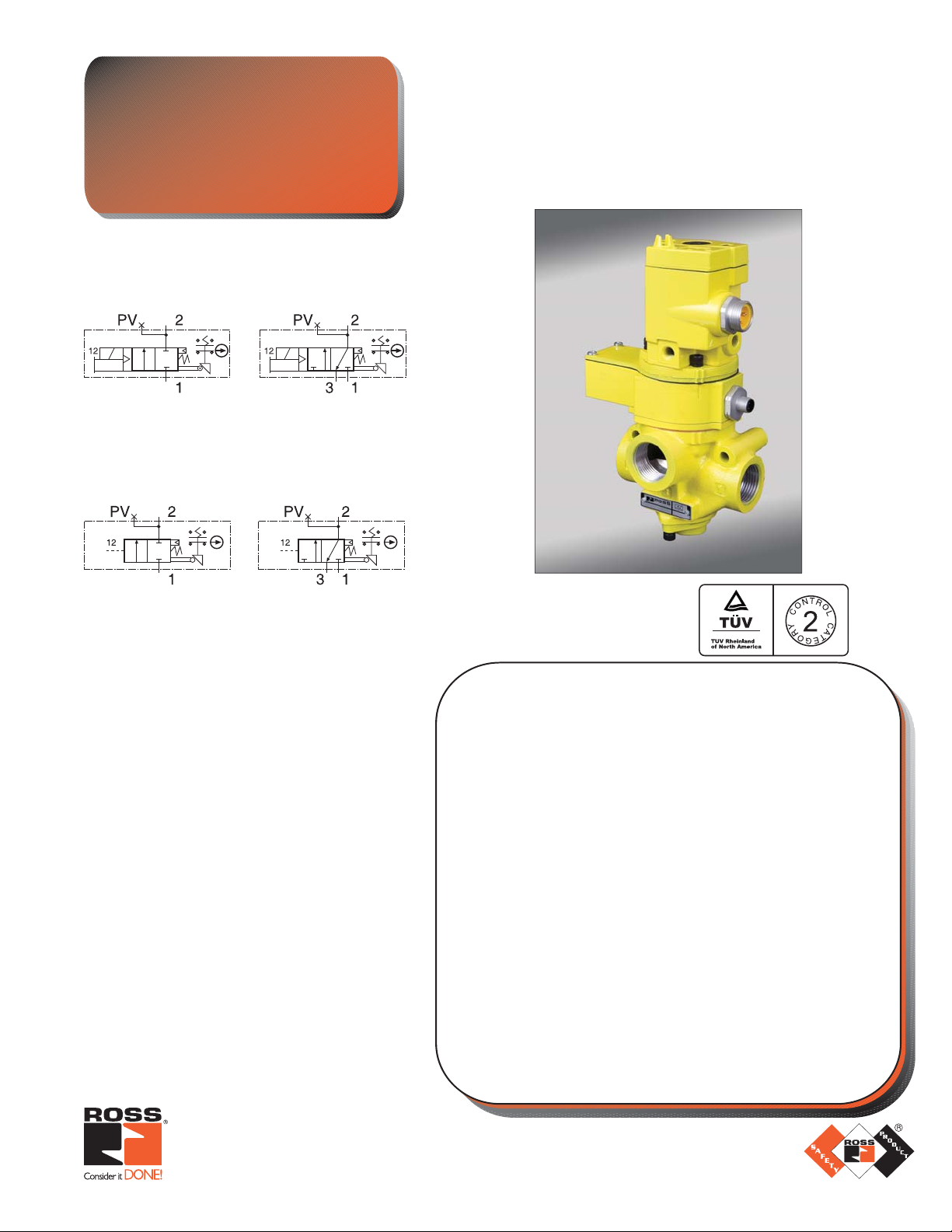

Series SV27 Sensing Valves

New Product

Information

Solenoid Pilot Controlled

2/2 3/2

Pressure Controlled

2/2 & 3/2 Normally Closed

with Position & State Sensing Feedback

for Category 2 Safety Applications

Air Dump/Release

3/2 Sensing Valve

(solenoid model shown)

2/2 3/2

Schematics shown for 3/4 and 1¼ bodies.*

STANDARD SPECIFICATIONS:

Pilot Solenoid: Rated for continuous duty.

Standard Voltages: 100–110 volts 50 Hz;

100–120 volts 60 Hz; 24, 110 volts DC.

Other voltages available.

Power Consumption: 87 VA inrush, 30 VA holding

on 50 or 60 Hz; 14 watts on DC.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air.

Inlet Pressure: 40 to 150 psig (2.8 to 10 bar).

Pilot Pressure: Equal to or greater than inlet

pressure.

Switch Current/Voltage Max.: 2.5 A/120 volts AC.

Switch Current/Voltage Min.: 50 mA/24 volts DC.

NOTE: Electrical life of switch varies with conditions

and voltage; rated in excess of 15 million cycles.

EN 954-1, ISO 13849-1,

& AS4024-1

(3/4 bodies only,

other sizes approval pending)

GENERAL:

ROSS’ new Series SV27 Sensing Valves, based upon the proven

Ser

ies 27 valve family, combine the tough, dirt tolerant characteristics

of poppet technology with sensing for actual internal position and state.

Electrical feedback is provided via a positively-driven, safety-rated

DPST (Double-Pole Single-Throw) switch with both normally open

(NO) and normally closed (NC) contacts. *For 3/4 and 1¼ bodies, the

DPST switch is actuated whenever the valve is not in the normal home

position. For size 2 body, the DPST switch is only actuated whenever

the valve IS in the normal home position.

An optional visual pressure indicator (988A30) or pressure switch

kit (608A86) can be installed into the 1/8 NPT pressure verifi cation

port (PV) for verifi cation of pressure release.

FEATURES:

• Solenoid pilot and pressure controlled versions

• Senses poppet position & state

• Electrical feedback via DPST switch (Double-Pole Single-Throw)

• Directly operated safety-rated force-guided status switch (DPST)

• Positive-break on 3/4 and 1¼ body valves

• Poppet construction for near zero leakage & high dirt tolerance

• Applications include Air Dump and Trapped-Pressure Release

www.rosscontrols.com

Page 2

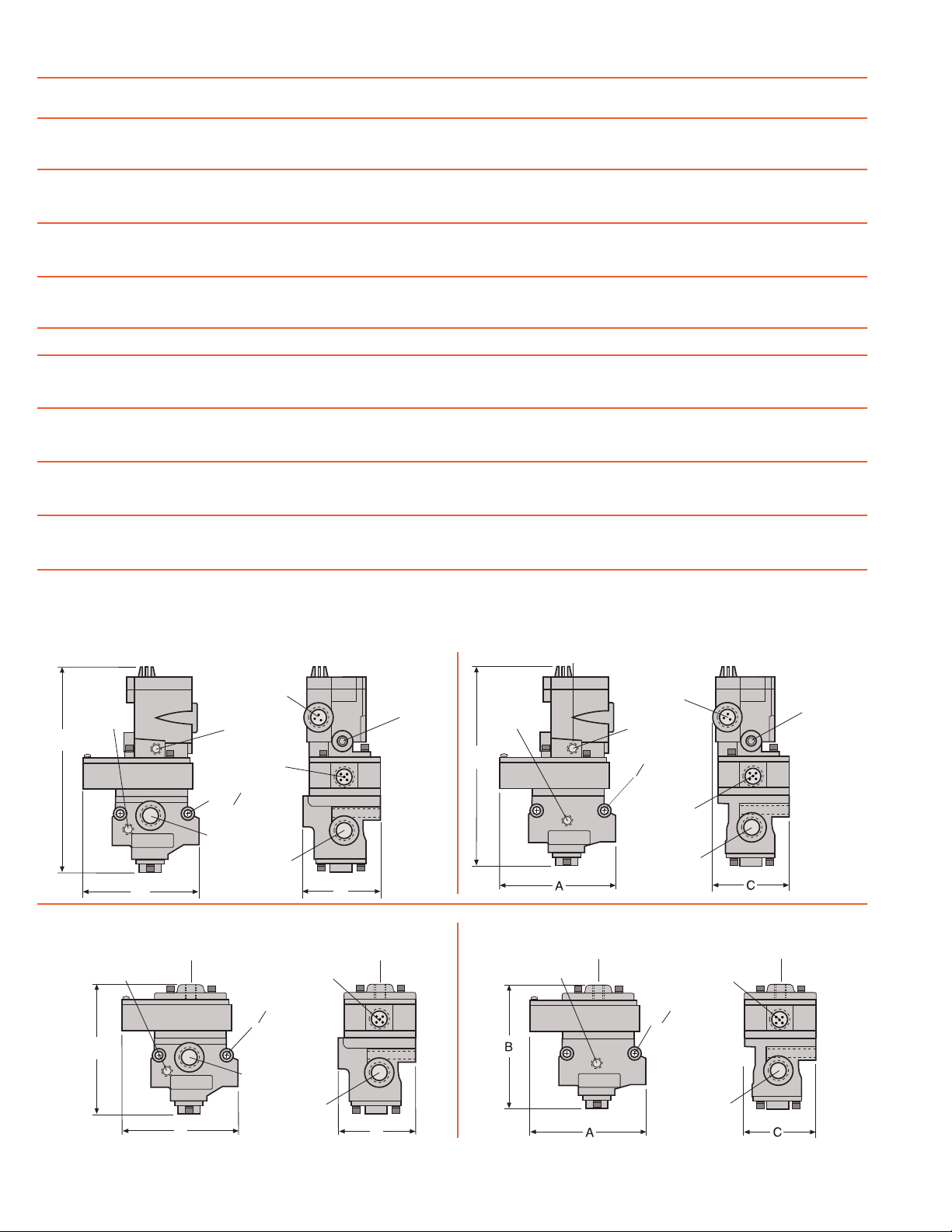

Model Numbers* Valve Port Size C

SV27NC305407PSAA1A** 3/2 1/2 1 6.3 9.2 5.7 (145) 9.6 (244) 3.1 (77) 4.5 (2.0)

Function

Solenoid Pilot Controlled Models

v

Dimensions inches (mm)

1, 2 3 1 - 2 2 - 3 A B C lb (kg)

Weight

SV27NC305507PSAA1A** 3/2 3/4 1 7.7 11 5.7 (145) 9.6 (244) 3.1 (77) 4.5 (2.0)

SV27NC305607PSAA1A** 3/2 1 1 8.0 12 5.7 (145) 9.6 (244) 3.1 (77) 4.5 (2.0)

SV27NC105407PSAA1A** 2/2 1/2 – 7.7 N/A 5.7 (145) 9.3 (235) 3.1 (77) 4.6 (2.1)

SV27NC105507PSAA1A** 2/2 3/4 – 9.0 N/A 5.7 (145) 9.3 (235) 3.1 (77) 4.6 (2.1)

SV27NC105607PSAA1A** 2/2 1 – 9.0 N/A 5.7 (145) 9.3 (235) 3.1 (77) 4.6 (2.1)

SV27NC307607PSAA1A** 3/2 1 1½ 23 34 6.8 (173) 12.0 (303) 4.9 (123) 7.8 (3.5)

SV27NC307707PSAA1A** 3/2 1¼ 1½ 30 32 6.8 (173) 12.0 (303) 4.9 (123) 7.8 (3.5)

SV27NC307807PSAA1A** 3/2 1½ 1½ 30 31 6.8 (173) 12.0 (303) 4.9 (123) 7.8 (3.5)

SV27NC107607PSAA1A** 2/2 1 – 24 N/A 6.8 (173) 12.0 (303) 4.9 (123) 8.1 (3.7)

SV27NC107707PSAA1A** 2/2 1¼ – 29 N/A 6.8 (173) 12.0 (303) 4.9 (123) 8.1 (3.7)

SV27NC107807PSAA1A** 2/2 1½ – 29 N/A 6.8 (173) 12.0 (303) 4.9 (123) 8.1 (3.7)

Pressure Controlled Models

SV27NC305405ASAA 3/2 1/2 1 6.3 9.2 5.7 (145) 6.4 (163) 3.6 (91) 3.3 (1.5)

SV27NC305505ASAA 3/2 3/4 1 7.7 11 5.7 (145) 6.4 (163) 3.6 (91) 3.3 (1.5)

SV27NC305605ASAA 3/2 1 1 8.0 12 5.7 (145) 6.4 (163) 3.6 (91) 3.3 (1.5)

SV27NC105405ASAA 2/2 1/2 – 7.7 N/A 5.7 (145) 6.1 (155) 3.1 (79) 3.4 (1.6)

SV27NC105505ASAA 2/2 3/4 – 9.0 N/A 5.7 (145) 6.1 (155) 3.1 (79) 3.4 (1.6)

SV27NC105605ASAA 2/2 1 – 9.0 N/A 5.7 (145) 6.1 (155) 3.1 (79) 3.4 (1.6)

SV27NC307605ASAA 3/2 1 1½ 23 34 6.8 (173) 8.8 (222) 4.9 (123) 6.4 (2.9)

SV27NC307705ASAA 3/2 1¼ 1½ 30 32 6.8 (173) 8.8 (222) 4.9 (123) 6.4 (2.9)

SV27NC307805ASAA 3/2 1½ 1½ 30 31 6.8 (173) 8.8 (222) 4.9 (123) 6.4 (2.9)

SV27NC107605ASAA 2/2 1 – 24 N/A 6.8 (173) 8.7 (220) 4.1 (105) 6.7 (3.0)

SV27NC107705ASAA 2/2 1¼ – 29 N/A 6.8 (173) 8.7 (220) 4.1 (105) 6.7 (3.0)

SV27NC107805ASAA 2/2 1½ – 29 N/A 6.8 (173) 8.7 (220) 4.1 (105) 6.7 (3.0)

*NPT port threads. For BSPP threads, replace “N” in the model number with a “D”.

** “1A”=120 volts 60 Hz, solenoids. For 240 volts 60 Hz, change “1A” to “2A”; for 24 volts 60 Hz, change to “3A” ; for 24 volts DC, change to “1D”.

Port PV

(pressure

verification)

B

Port PV

(pressure

verification)

B

3/2 Solenoid Pilot Controlled Model

3-pin Mini

connector

Por t Y-3

(pilot exhaust)

5-pin M12

connector

2X O 0.34 (8.0)

Port 3 (exhaust)

Port 1(inlet)

[Port 2 (outlet

A

on opposite site]

C

3/2 Pressure Controlled Model

1/4 Signal Port

5-pin M12

connector

2X O 0.34 (8.0)

Port 3 (exhaust)

1/4 Signal Port

Port X-1

(1/8 external

pilot supply)

Port PV

(pressure

verification)

B

Port PV

(pressure

verification)

2/2 Solenoid Pilot Controlled Model

3-pin Mini

connector

Por t Y-3

(pilot exhaust)

2X O 0.34 (8.0)

5-pin M12

connector

Port 1(inlet)

[Port 2 (outlet

on opposite site]

2/2 Pressure Controlled Models

1/4 Signal Port

5-pin M12

connector

2X O 0.34 (8.0)

1/4 Signal Port

Port X-1

(1/8 external

pilot supply)

Port 1(inlet)

[Port 2 (outlet

A

on opposite site]

C

2 ROSS CONTROLS

Port 1(inlet)

[Port 2 (outlet

on opposite site]

®

Page 3

Model Numbers* Valve Port Size C

Function

Solenoid Pilot Controlled Models

v

Dimensions inches (mm)

1, 2 3 1 - 2 2 - 3 A B C lb (kg)

Weight

SV27NC309807PSAA1A** 3/2 1½ 2½ 68 70 8.7 (219) 11.8 (300) 6.4 (161) 18.1 (8.2)

SV27NC309907PSAA1A** 3/2 2 2½ 70 70 8.7 (219) 11.8 (300) 6.4 (161) 18.1 (8.2)

SV27NC309957PSAA1A** 3/2 2½ 2½ 70 71 8.7 (219) 11.8 (300) 6.4 (161) 18.1 (8.2)

Pressure Controlled Models

SV27NC309805ASAA 3/2 1½ 2½ 68 70 8.7 (219) 11.8 (300) 6.4 (161) 17.2 (7.8)

SV27NC309905ASAA 3/2 2 2½ 70 70 8.7 (219) 11.8 (300) 6.4 (161) 17.2 (7.8)

SV27NC309955ASAA 3/2 2½ 2½ 70 71 8.7 (219) 11.8 (300) 6.4 (161) 17.2 (7.8)

*NPT port threads. For BSPP threads, replace “N” in the model number with a “D”.

** “1A”=120 volts 60Hz, solenoids. For 240 volts 60 Hz, change “1A” to “2A”; for 24 volts 60 Hz, change to “3A”; for 24 volts DC, change to “1D”.

3/2 Solenoid Pilot Controlled Models

PV

12

Por t 3

(exhaust)

Port 1(inlet)

[Port 2 (outlet

on opposite site]

Port X-1

(1/8 external

pilot supply)

5-pin M12

connector

2X O 0.53 (13.5)

B

3-pin Mini

connector

Port PV

(pressure

A

verification)

C

3/2 Pressure Controlled Models

1/8” Signal Port

Por t 3

(exhaust)

2

Port 1(inlet)

[Port 2 (outlet

on opposite site]

2X O 0.53 (13.5)

5-pin M12

connector

B

13

Port PV

(pressure

A

verification)

C

Wiring Kits

These kits are available in lengths of 4 or 10 meters, with

a cord grip on each cable. The kits for SV27 solenoid

pilot controlled models come with 2 cables; one with

a 3-pin MINI connector for the solenoid and one with

a 5-pin M12 (Micro) connector for the sensing switch.

The kits for the pressure controlled models include only

one cable with a 5-pin M12 connector for the sensing

switch. (Note: Each cable has one connector.)

Solenoid Cable with

3-pin MINI Connector

BRN

PIN 3

BRN

BLUE

GRN/YEL

BLUE

PIN 2

GRN/YEL

(GROUND)

PIN 1

Sensing Switch Cable

with 5-pin M12 Connector

for 3/4 and 1¼ bodies.

WHT

PIN 2

BLK

WHT

GRAY

BRN

PIN 1

BLK

PIN 4

BLUE

PIN 3

BLUE

BRN

Current/Voltage Max. 2.5 A /120 VAC

Sensing Switch Cable

with 5-pin M12

Connector for 2 inch body.

BLUE

PIN 3

BLK

PIN 4

GRY

PIN 5

Current/Voltage Max. 2.5 A /120 VAC

Kit Number Valve Type Length (meters) No. of Cables

2239H77 Solenoid Pilot 4 2

2240H77 Solenoid Pilot 10 2

2241H77 Air Pilot 4 1

2242H77 Air Pilot 10 1

*For 3/4 and 1¼ inch bodies, the DPST switch is actuated

whenever the valve is not in the normal home position. For 2

inch bodies, the DPST switch is only actuated whenever the

valve is in the normal home position.

www.rosscontrols.com 3

WHT

PIN 2

BRN

PIN 1

GRY

PIN 5

Page 4

DISCLAIMER

These circuits are illustrative only and not intended to be used literally for your application. Each machine

is unique and has individual characteristics that must be considered when designing a safety circuit. In

addition, the referenced standards are not an exhaustive list. There may be many additional local, state,

national, and international standards as well as machine function specifi c standards pertinent to your

machine. This document is not a substitute for a complete risk assessment of a machine’s hazards,

professional circuit design or acquiring an in depth understanding of standards/regulations relevant to

an application or machine.

Optional Pressure Switch Kit (608A86)

Schematic

Note: Pressure switch closes on falling pressure of 5 psig.

Integrated Double-Pole Single-Throw Switch (DPST)

Switch States

for 3/4 and

1¼ bodies

General Illustration Safety-Related Applications

ROSS Controls is the leader in safety-related pneumatic products.

Shown here are a few examples of the variety of ROSS’ safetyrelated products and their applications. Please contact us if you

are interested in or confused about safety for your pneumatically

operated equipment.

3

1

®

L-O-X

Cat 4 Alternative Method LOTO

Switch States

for 2 inch body

ROSS Safety-Related Applications

* Cylinder hazard in 2 directions

* Pinch points

* Tooling or product damage

* Single point Lockout

* Press clutch/brake

3-Way

Control Reliable

Double Valve

2

* Counterbalance

* Monitored power systems

* Partial de-energization

* Vertical loads

* Cylinder hazard

Referenced Standards:

All standards are subject to revision. Parties are

encouraged to investigate and apply the most recent

editions of the standards indicated below.

OSHA 29 CFR 1910.147

CSA Z142-02

CSA Z460-05

ISO 13849-1

ISO 14118:2000

EN 1037

ANSI/ASSE Z244.1- 2003

ANSI/PMMI B155.1- 2006

ROSS CONTROLS

Customer Svs. 1-800-GET-ROSS

Technical Svs. 1-888-TEK-ROSS

www.rosscontrols.com

ROSS EUROPA GmbH

Germany

Fax: 49-6103-74694

info@rosseuropa.com

ROSS ASIA

Japan

Fax: 81-427-78-7256

custsvc@rossasia.co.jp

U.S.A.

®

K.K.

®

ROSS UK Ltd.

United Kingdom

Fax: 44-121-559-5309

sales@rossuk.co.uk

DISCLAIMER

These circuits are illustrative only and not intended to be used literally for your application. Each machine

is unique and has individual characteristics that must be considered when designing a safety circuit. In

addition, the referenced standards are not an exhaustive list. There may be many additional local, state,

national, and international standards as well as machine function specifi c standards pertinent to your

machine. This document is not a substitute for a complete risk assessment of a machine’s hazards,

professional circuit design or acquiring an in depth understanding of standards/regulations relevant to

an application or machine.

Standard ROSS warranty and cautions apply, available upon request or at www.rosscontrols.com

Cat 2 Alternative Method LOTO

3

1

2

3-Way SV27

Sensing Valve

®

ROSS CONTROLS

Fax: 91-44-2625-8730

rossindia@airtelbroadband.in

INDIA Pvt. Ltd.

India

WARRANTY and CAUTIONS

ROSS SOUTH AMERICA Ltda.

Brazil

Fax: 55-11-4335-3888

vendas@ross-sulamerica.com.br

Redundant PO Check

®

EEZ-ON

DIMAFLUID s.a.s.

France

Fax: 33-01-4945-6530

dimafluid@dimafluid.com

PO Check

ROSS CONTROLS

Fax: 86-21-6915-7960

alvinzhurong@vip.163.com

(CHINA) Ltd.

China

Printed in the U.S.A. – Rev. 3/09 © 2009 ROSS CONTROLS®. All Rights Reserved. Form NPS279

Loading...

Loading...