Page 1

234

51

LIGHT LIGHT

SOL.

B

SOL.

A

234

51

LIGHT LIGHT

SOL.

B

SOL.

A

234

51

LIGHT LIGHT

SOL.

B

SOL.

A

234

51

LIGHT LIGHT

SOL.

B

SOL.

A

234

1

LIGHT LIGHT

SOL.

B

SOL.

A

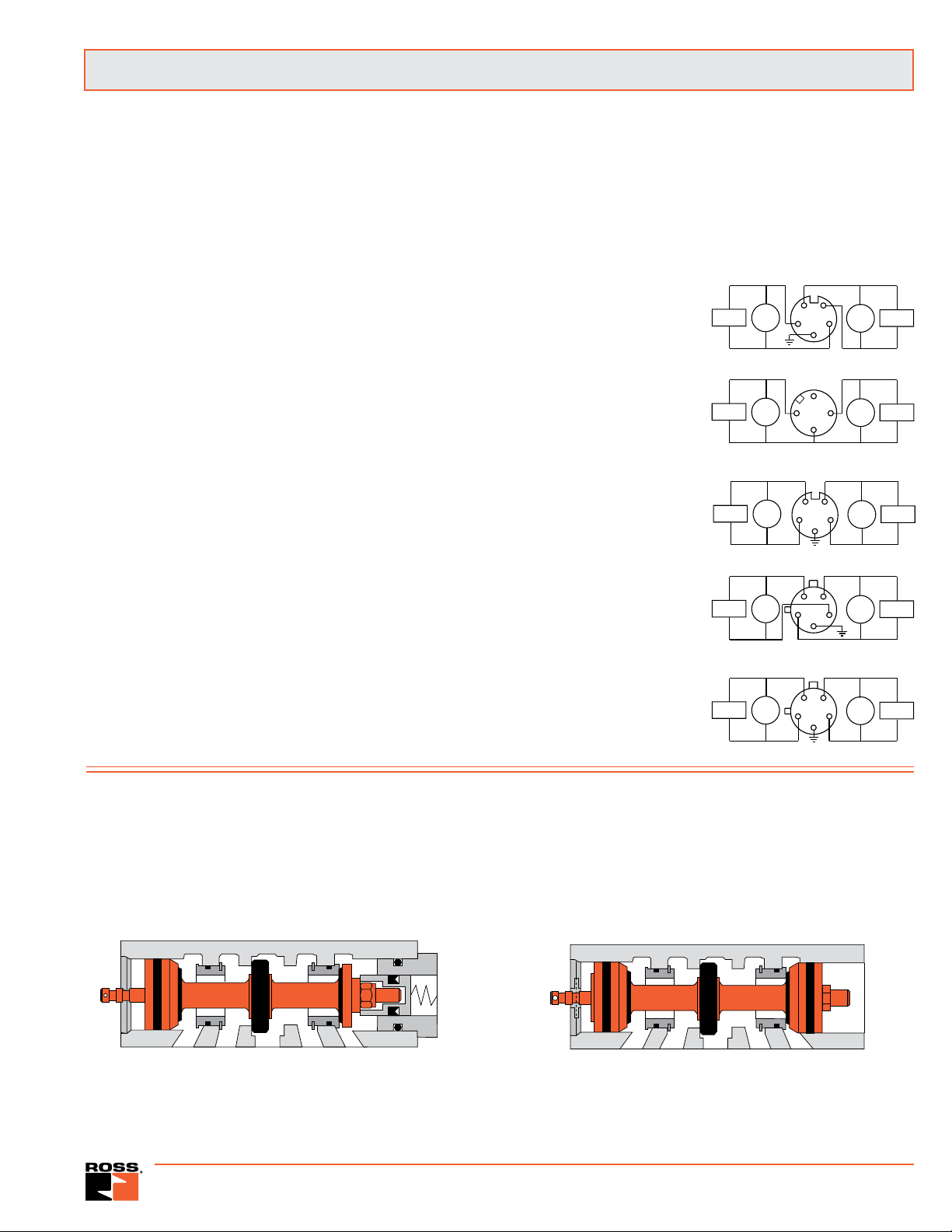

ROSS Valves for SAE Bases

The SAE Standard Interface, though originally developed by

U.S. auto companies in the early 1970s, has quickly gained wide

acceptance throughout the industry. Due to the design's ruggedness

and high-flow characteristics, the Society of Automotive Engineers

(SAE) established it as a new standard. This ensures that valves

designed to fit the SAE interface will be interchangeable, regardless

of manufacturer. In practical terms, the user can change from

one brand of valve to another without changing installed bases or

manifolds.

ROSS valves are available in SAE sizes 125, 250 and 500. Both

poppet and metal spool-and-sleeve construction are offered. The

valves described in this bulletin are all solenoid-pilot controlled.

SOLENOID PILOTS

Internal or External Pilot Supply. Valves in this bulletin are made

for internal pilot supply. However, they are easily converted for use

with an external pilot supply by moving a single pipe plug in the

bottom of the valve.

With solenoid pilot control, the main valve is shifted by applying air

pressure to an actuating piston or spool end. There is no mechanical

connection between the solenoid plunger in the pilot and the main

valve mechanism as there is in a valve actuated by a direct-acting

solenoid. If the valve mechanism were to stick, the plunger in a

solenoid-pilot-controlled valve could complete its travel and avoid

the high current flow which results when the travel is incomplete.

Thus overheating and solenoid burnout are avoided. Furthermore,

under average shop conditions, air pressure produces a valve-shifting

force much greater than that from a direct-acting solenoid, so that

the problem of valve sticking is minimized.

Indicator Lights. An indicator light is wired to each solenoid

circuit so that the light is illuminated whenever the solenoid is

energized.

Hard Wiring. An electrical opening, threaded 1/2 NPSC, is available

for use with conventional fittings.

ELECTRICAL CONNECTORS

Electrical connections to the valves can be made with sealed 4 or 5-pin

connectors (ANSI Standard B93.55) or by conventional hard wiring.

Sealed Connector. A 4 or 5-pin straight connector wired as required

by either the Ford Motor Company or the Chrysler Corporation

is available. Valves may be ordered with mini- or micro-change

connectors. See the wiring diagrams below for the various options

available.

Ford Wired 5-pin

mini-connector (all voltages)

Ford Wired 4-pin

micro-connector (24 vdc)

Chrysler Wired 5-pin

mini-connector (all voltages)

Chrysler Wired 5-pin

micro-connector (24 Volts DC)

Chrysler Wired 5-pin

micro-connector

(120 volts / 60 Hz)

Poppet Valve Construction

Single Control. 5-port, 2-position (5/2) valves that require a main-

tained signal to keep the valve in its shifted position. Internal air

pressure provides the force to return the valve when the signal is

removed.

Series 84

Poppets are face sealing valve elements which can open or close

passageways without sliding friction or the close tolerances required

of spool valves. Poppets don't build up breakaway resistance due

to varnish, and are highly tolerant of dirty air.

ROSS poppet valves have rugged internals and self-adjusting

exhaust poppet seats which equalize wear and promote long life.

Designed for use with or without air line lubrication.

Double Control. 5-port, 2-position (5/2) valves that require only a

momentary signal to shift the valve in either direction. A mechanical

detent and differential air pressure keep the valve in its shifted

postion.

www.rosscontrols.com

3

Page 2

MANUAL OVERRIDES

Each solenoid pilot has a non-locking override button for manual actuation of

the valve. For Size 500 valves, locking buttons and extended buttons are also

available. See page 9.

VALVE RESPONSE TIME

Average response constants for each valve are listed in the charts on pages

4 thru 6. These constants, designated M and F, can be used to determine the

amount of time required to fill or exhaust a volume of any size by using the

following formula:

ValveResponseTime(msec)=M+(F•V)

In this formula, M represents the average time in milliseconds (msec) for

the valve parts to move after the valve is energized. F is the average number

of milliseconds required for a flow of one standard cubic inch through the valve.

V is the number of cubic inches in the volume to be filled or exhausted.

The valve response time given by this formula is the average number of

milliseconds required to fill the volume V to 90 per cent of supply pressure, or

to exhaust the volume to 10 per cent of supply pressure. Response times will

be valid for any pressure in the range specified for the valve under "Standard

Specifications."

Note that F values are listed under two headings: "In-Out" and "Out-Exh."

The In-Out values are used to calculate fill times, and the Out-Exh. values are

used to calculate exhaust times.

SAMPLE PROBLEM. Using a ROSS double solenoid size 250 poppet valve,

how long will it take to fill a 250-cubic-inch chamber to 90% of supply pressure?

SOLUTION. The poppet valves are described on page 4 of this bulletin. From

the chart at the bottom of the page, we find that the response constants for a

size 250 valve are M = 20 and F = 0.54. Using these values in the response

time formula we have:

Valve Response Time (msec) = 20 + (0.54)(250)

= 20 + 135

= 155 msec

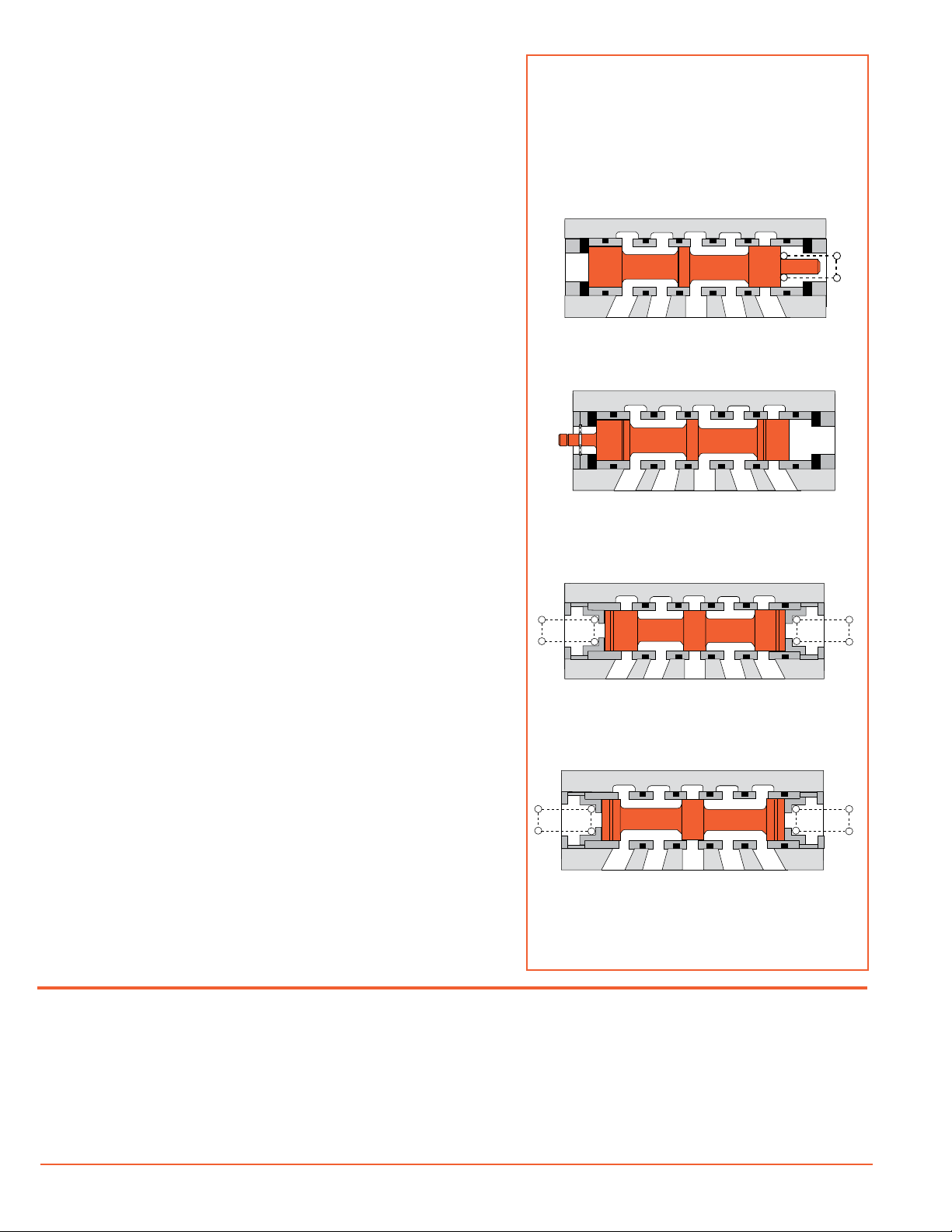

SERIES 80

Spool Valve Construction

The matched spool and sleeve used in each of these

valves is made of precision finished, hardened, stainless steel. The spool moves on a micro-inch film of air

between spool and sleeve so that wear is minimized.

For use in systems with or without air line lubrication.

Single Control. 5-port, 2-position (5/2) valves require

a maintained signal to keep the valve shifted. A spring

provides the return force after the signal is removed.

Double Momentary Control. 5-port, 2-position (5/2)

valves require only a momentary signal to shift the

valve in either direction. A mechanical detent keeps

the valve in its shifted position.

FLOW RATINGS

IMPORTANT NOTE. Widely different test standards are used by different

manufacturers in the determination of Cv ratings of valves. For this reason,

the Cv values given in the charts on pages 4, 5, and 6 should not be used in

comparing ROSS valves with those of other makers. These Cv values are

intended only for use with performance charts published by ROSS.

The Cv ratings in the charts on pages 4, 5, and 6 are averages for the various

flow paths through the valve and are for steady flow conditions.

PORT IDENTIFICATION

Ports on bases and in diagrams are designated by the following letters:

A: Outlet port

B: Outlet port

EA: Exhaust port (from port A)

EB: Exhaust port (from port B)

X: External pilot supply port

STANDARD SPECIFICATIONS (for valves on page 5):

Solenoids: AC or DC power. Rated for continuous duty.

Standard Voltages:

SAE Size 125, 250 models: 100-110 volts, 50 Hz; 100-120 volts, 60

Hz; 24 volts DC; 110 volts DC. For other voltages, consult ROSS.

SAE Size 500 models: 100-110 volts, 50 Hz; 100-120 volts, 60

Hz; 24 volts DC; 110 volts DC. For other voltages, consult ROSS.

Power Consumption: Each solenoid:

SAE Size 125, 250 models: 8 VA inrush; 6 VA holding on 50/60

Hz; 8 watts on DC.

P: Inlet port

SAE Size 500 models: 87 VA inrush; 30 VA holding on 50/60 Hz;

14 watts on DC.

Indicator Light: One for each solenoid.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air; 5 micron recommended.

Inlet Pressure: Vacuum to 150 psig (10 bar).

Pilot Pressure: At least 15 psig (1 bar).

Options: Pressure Controlled Valves–Interposed Pressure

Regulators.

Closed Center, Double Control. 5-port, 3-position

(5/3) valves require a maintained signal to shift the

valve in either direction from center. In the center

position all ports are closed.

Open Center, Double Control. 5-port, 3-position

(5/3) valves require a maintained signal to shift the

valve in either direction from center. In the center

position the outlet ports are connected to the exhaust

ports and the inlet port is closed.

4

© 2012, ROSS CONTROLS®. All Rights Reserved.

Page 3

AB

EA

P

EB

SOL

B

AB

EA

P

EB

SOL

B

SOL

A

C

A

B

C

A

B

C

A

B

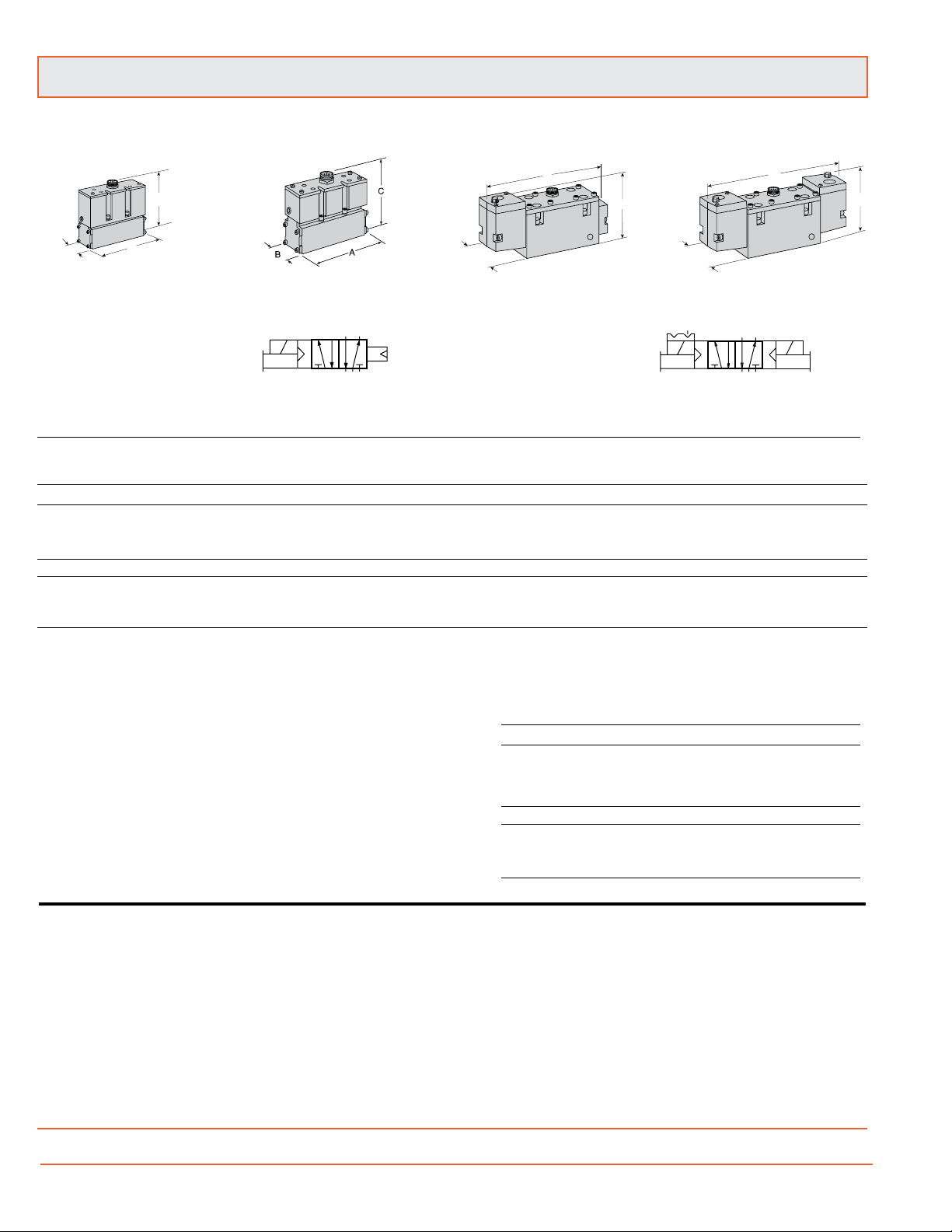

Series 84 Poppet Valves for SAE Bases

Series 84 Poppet Valves

SAE Size 125

Single or Double Solenoid

Single Solenoid

SAE Size 250

Single or Double Solenoid

SAE Size 500

Single Solenoid

Double Solenoid

SAE Size 500

Double Solenoid

Valve Model Numbers (Base not included)

SAE Chrysler Wired 5-pin Chrysler Wired 5-pin Ford Wired 5-pin Chrysler Wired 5-pin Ford Wired 4-pin Avg.

Size micro-connector micro-connector mini-connector mini-connector Hardwire micro-connector C

Single Solenoid Pilot Valves

(120 volts / 60 Hz) (24 Volts DC) (all voltages) (all voltages) (24 Volts DC)

125 8476C3311 8476C3321 8476C3331 8476C3341 8476C3351 8076C3361 1.8

250 8476C4311 8476C4321 8476C4331 8476C4341 8476C4351 8076C4361 5.5

500 8476B6311 8476B6321 8476B6331 8476B6341 8476B6351 8076B4361 7.9

Double Solenoid Pilot Valve

125 8476C3312 8476C3322 8476C3332 8476C3342 8476C3352 8476C3362 1.8

250 8476C4312 8476C4322 8476C4332 8476C4342 8476C4352 8476C4362 5.7

500 8476B6312 8476B6322 8476B6332 8476B6342 8476B6352 8476B6362 7.6

*Bases and manifolds on pages 7-9.

SAE Dimensions inches (mm) Weight

IMPORTANT NOTE:

The C

values given in this publication should not be used in

V

comparing ROSS valves with those of other makers. These

values are intended only for use with performance charts

C

V

published by ROSS. The C

ratings listed in this bulletin are

V

averages for the various flow paths through the valve and are

for steady flow conditions.

Size

Single Solenoid Pilot Valves

125 5.5 (140) 1.8 (45) 5.1 (129) 2.8 (1.3)

250 7.3 (185) 2.6 (65) 5.6 (142) 5.2 (2.4)

500 10.1 (257) 3.0 (76) 4.8 (121) 7.7 (3.5)

Double Solenoid Pilot Valves

125 5.5 (140) 1.8 (45) 5.1 (129) 3.3 (1.5)

A B C lb (kg)

250 7.3 (185) 2.6 (65) 5.6 (142) 5.7 (2.6)

500 11.2 (285) 3.0 (76) 7.1 (180) 8.9 (4.1)

V

STANDARD SPECIFICATIONS: For valves on this page.

Solenoids: AC or DC power. Rated for continuous duty.

Standard Voltages:

SAE Size 125, 250 models: 100-110 volts, 50 Hz; 100-120 volts, 60

Hz; 24 volts DC; 110 volts DC. For other voltages, consult ROSS.

SAE Size 500 models: 100-110 volts, 50 Hz; 100-120 volts, 60

Hz; 24 volts DC; 110 volts DC. For other voltages, consult ROSS.

Power Consumption: Each solenoid:

SAE Size 125, 250 models: 8 VA inrush; 6 VA holding on 50/60

Hz; 8 watts on DC.

SAE Size 500 models: 87 VA inrush; 30 VA holding on 50/60 Hz;

14 watts on DC.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

6

© 2012, ROSS CONTROLS®. All Rights Reserved.

Indicator Light: One for each solenoid.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air; 5 micron recommended.

Inlet Pressure: 30 to 150 psig (10 bar).

Pilot Pressure: Must be equal to or greater than inlet pressure.

Options: Pressure Controlled Valves–Interposed Pressure

Regulators.

Page 4

Port A

(outlet)

Port B

(outlet)

C

L

1.00

(25)

1.00

(25)

0.39 (10) dia.

2 places

6.25

(159

9

7.40

(188)

Port P

(inlet)

Port EA

(exhaust)

0.50

(13)

2.00

(51)

C

L

2.00

(51)

1/8 external

pilot supply

port X

0.32

(8)

1.17

(30)

1.92

(49)

Port EB

(exhaust)

1.48

(38)

2.52

(64)

1.17

(30)

Port A

(outlet)

1.38

(35)

C

L

1.36

(35)

3.06

(78)

2.32

(59)

1.36

(35)

0.50

(13)

Port EA

(exhaust)

Port P

(inlet)

9.00

(229)

2.75

(70)

0.63

(16)

2.75

(70)

C

L

1/8 external pilot

supply port X

Port EB

(exhaust)

8.25

(210)

1.38

(35)

0.41 (10) dia.

2 places

Port B

(outlet)

Sub-Bases for Series 80 & 84 SAE Valves

1.21

(31)

0.69

(18)

0.60

(16)

Port A

(outlet)

C

L

0.60

(16)

Port B

(outlet)

0.34 (8.6) dia.

2 places

4.05

(103

3

4.66

(118)

1.20

(31)

Port EB

(exhaust)

1/8 external

pilot supply

port X

Port P

(inlet)

C

L

0.54

(14)

Port EA

(exhaust)

0.41

(10)

0.67

(17)

1.20

(31)

0.82

(21)

1.75

(45)

Side-Ported

SAE Size 125

Sub-Base Port Size*

Number A, B P, EA, EB

577K91 1/8 1/4

578K91 1/4 3/8

579K91 3/8 3/8

*NPT threads. For SAE threads, consult ROSS.

SAE Size 250

Dimensions: inches (mm)

Sub-Base Port Size*

Number A, B P, EA, EB

539K91 1/4 3/8

540K91 3/8 1/2

541K91 1/2 1/2

542K91 3/4 3/4

*NPT threads. For SAE threads, consult ROSS.

SAE Size 500

Sub-Base Port Size*

Number A, B P, EA, EB

582K91 1/2 3/4

728K91 3/4 3/4

583K91 3/4 1

584K91 1 1

*NPT threads. For SAE threads, consult ROSS.

www.rosscontrols.com

7

Page 5

Manifolds for Series 80 & 84 SAE Valves

0.34 (8) dia.

SAE Size 125 Manifold Stations

Station Port Sizes*

Number A, B P, EA, EB

580K91 1/4 3/8

581K91 3/8 3/8

*NPT threads. For SAE threads, consult ROSS.

Each manifold station is supplied with all necessary

seals and hardware for assembly. End plates are

not required with these manifolds. Each station has

all ports threaded to accept piping.

Blanking Plate: For manifold stations not occupied

by a valve, blanking plates are available. These plates

block the unused air passages.

Order by part number 820K77.

0.28 (7) dia.

(2 places)

1/8 External pilot

supply port X

(both sides)

Port EB

(exhaust)

Port P

(inlet)

0.57

(14)

4.50 (114)

5.10 (130)

1.50

(38)

C

L

(exhaust)

0.37

(9)

1.50

(38)

2.53 (64)

Port EA

0.61

(15)

Dimensions: inches (mm)

2.06

(52)

Port A

2.44

(62)

0.50

(13)

(outlet)

0.44

(11)

0.50

(13)

1.08

(27)

C

L

C

L

Port B

(outlet)

0.50

(13)

1.82

(46)

SAE Size 250 Manifold Stations

Station Port Sizes*

Number A, B P, EA, EB

553K91 3/8 1/2

554K91 1/2 3/4

555K91 3/4 3/4

*NPT threads. For SAE threads, consult ROSS.

Each manifold station is supplied with all necessary

seals and hardware for assembly. End plates are

not required with these manifolds. Each station has

all ports threaded to accept piping.

Blanking Plate: For manifold stations not occupied

by a valve, blanking plates are available. These plates

block the unused air passages.

Order by part number 821K77.

(2 places)

1/8 External pilot

supply port X

(both sides)

Port EB

(exhaust)

Port P

(inlet)

Port B

(outlet)

2.52

(64)

6.31 (160)

7.18 (183)

C

2.00

(51)

2.00

(51)

L

Port EA

(exhaust)

0.50

(13)

2.00

(51 )

3.52 (89)

Port A

(outlet)

0.44

(11)

0.50

(13)

3.44

(87)

1.38

(35)

0.85

(22)

C

L

3.44

(87)

1.75

(45)

Port B

(outlet)

0.88

(22)

C

L

Port A

(outlet)

1.75

(45)

2.50

(64)

Port B

(outlet)

8

© 2012, ROSS CONTROLS®. All Rights Reserved.

Port A

(outlet)

Page 6

Manifolds for Series 80 & 84 SAE Valves

SAE Size 500 Manifold Stations

Station Port Sizes*

Number A, B P, EA, EB

585K91 1/2 3/4

586K91 3/4 1

587K91 1 1

*NPT threads. For SAE threads, consult ROSS.

Each manifold station is supplied with all necessary

seals and hardware for assembly. End plates are

not required with these manifolds. Each station has

all ports threaded to accept piping.

Blanking Plate: For manifold stations not occupied

by a valve, blanking plates are available. These plates

block the unused air passages.

Order by part number 822K77.

Port B

(outlet)

1.00

(25)

C

L

Port A

(outlet)

1.00

(25)

0.40 (10) dia.

(2 places)

2.38

(61)

1/8 External pilot

supply port X

(both sides)

Port EB

(exhaust)

Port P

(inlet)

3.44

(87)

Dimensions: inches (mm)

8.44 (214)

9.25 (235)

Port EA

(exhaust)

0.50

(13)

2.85

(72)

2.85

(72)

0.62

(16)

2.85

(72)

4.57

(116)

3.78

(96)

0.90

(23)

1.50

(38)

C

3.56

(90)

L

Accessories

Manual Override Kits for SAE Size 500 Valve

Flush metal buttons (shown at left as installed) are of either the locking or

non-locking type. The extended button (see below) is the non-locking type.

Order by the kit numbers below:

Flush Button

Non-locking 790K87

Locking 792K87

Extended Button

Non-locking 791K87

Port B

(outlet)

Port A

(outlet)

0.90

(23)

www.rosscontrols.com

9

Page 7

Interposed Regulators

Accessories

Both single and dual interposed regulators are available for SAE

sizes 125 and 250.

A regulator is sandwiched between the valve and sub-base or

manifold station and the valve is then bolted through the regulator

to the sub-base or manifold station with the longer bolts provided.

Single pressure regulators supply the same regulated pressure at

both outlet ports.

SAE Size 125 – Single: 593K91

SAE Size 250 – Single: 595K91

1.47 (37.3)

2.5 (63.5)

Dual pressure regulators allow the pressure at each outlet port to

be set independently.

Use dual pressure regulators with 80 Series valves only. When using

dual pressure regulators, the valve must be externally piloted.

Regulated pressure range:

10 – 130 psig (regulator-to-base gasket included).

6.19

(157.2)

SAE Size 125 – Dual: 873H91

SAE Size 250 – Dual: 816H91

11.0

(279.4)

1.47 (37.3)

8.63

(219.1)

2.5 (63.5)

16.5

(419.1)

10

© 2012, ROSS CONTROLS®. All Rights Reserved.

Loading...

Loading...