Page 1

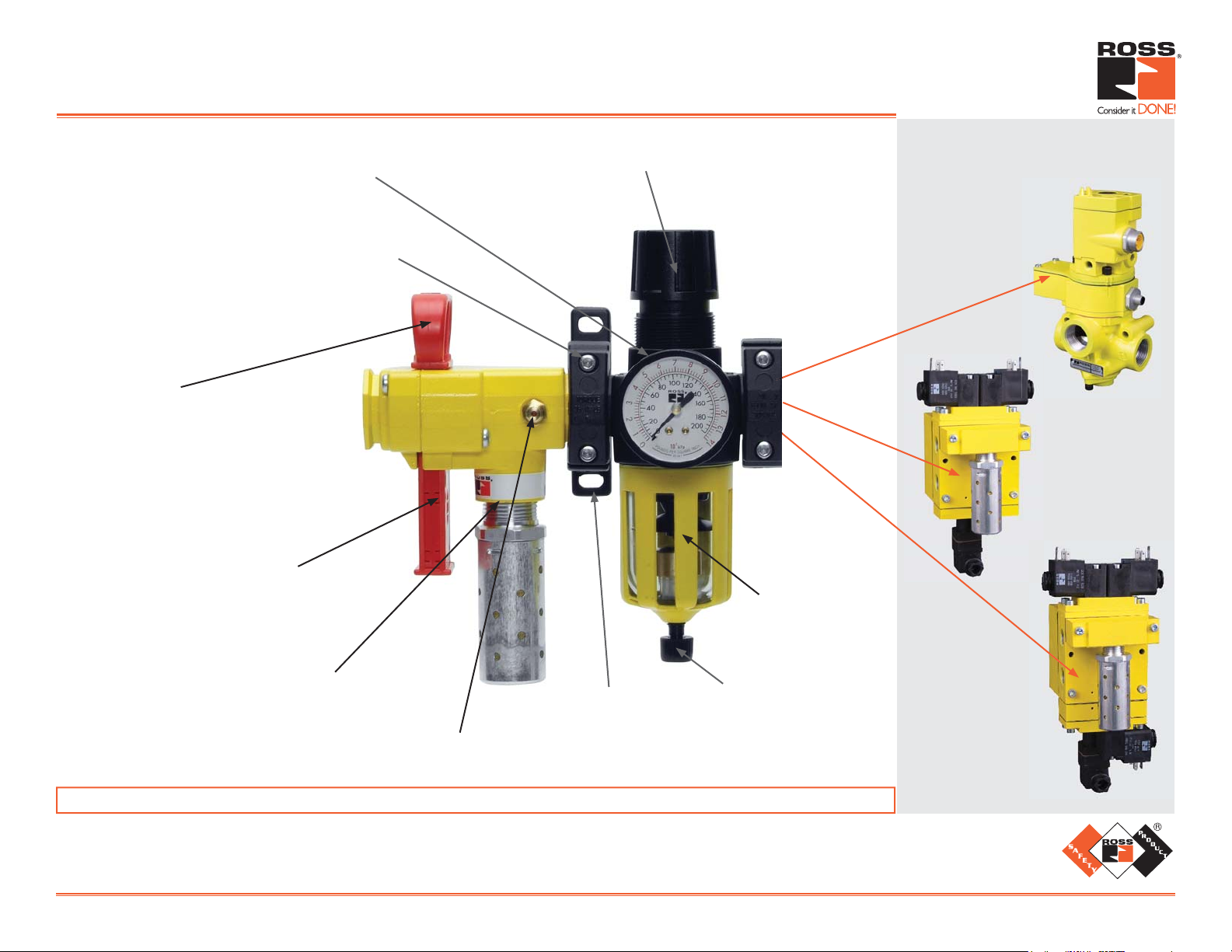

Modular L-O-X® Air Entry Combination

Lockout Valve with Integrated Filter/Regulator

Reverse fl ow self-relieving piston-type

for assured full fl ow exhaust.

Modular mounting for easy servicing.

Easy to operate

(positive push/pull operation-detented).

Only lockable in the off position.

Removable cap for tamper-resistant

pressure setting.

Combination Examples

Cat-2 Applications

SV Sensing Valve

Cat-3 Applications

DM1 Series E

Available in

polycarbonate or

metal bowl.

Has a full size exhaust port

(equal to or larger than supply).

Has a visible indicator of

Optional Mounting

Bracket

Manual or Auto Drain

(fl oat drain optional

with metal bowl).

Cat-4 Applications

DM2® Series E

pressure release (verifi cation port).

WARRANTY and CAUTIONS: Standard ROSS warranty and cautions apply, available upon request or at www.rosscontrols.com.

®

ROSS CONTROLS

U.S.A.

Customer Svs. 1-800-GET-ROSS

Technical Svs. 1-888-TEK-ROSS

www.rosscontrols.com

Printed in the U.S.A. – Rev. 05/09 © 2009, ROSS CONTROLS®. All Rights Reserved. Form PSI005

ROSS EUROPA GmbH

Germany

Fax: 49-6103-74694

info@rosseuropa.com

ROSS ASIA® K.K.

Japan

Fax: 81-427-78-7256

custsvc@rossasia.co.jp

ROSS UK Ltd.

United Kingdom

Fax: 44-121-559-5309

sales@rossuk.co.uk

ROSS CONTROLS® INDIA Pvt. Ltd.

India

Fax: 91-44-2625-8730

rossindia@airtelbroadband.in

ROSS SOUTH AMERICA Ltda.

Brazil

Fax: 55-11-4335-3888

vendas@ross-sulamerica.com.br

DIMAFLUID s.a.s.

France

Fax: 33-01-4945-6530

dimafluid@dimafluid.com

ROSS CONTROLS (CHINA) Ltd.

China

Fax: 86-21-6915-7960

alvinzhurong@vip.163.com

Page 2

Modular L-O-X®

New Product

Introduction

Lockout/Filter/Regulator

ISO

Symbol

Lockout

Automatic Drain

Self-relieving

STANDARD SPECIFICATIONS

Ambient/Media Temperature:

Plastic or Metal bowl: 40° to 125°F (4° to 52°C).

Body: Zinc.

Bonnet: Acetal.

Bowl: 4-oz (120-ml) polycarbonate plastic with zinc

shatterguard; optional zinc bowl with clear nylon sight glass

6-oz (178-ml).

Bowl Drain: Internal automatic drain; optional manual dr ain

or float drain (metal bowl only).

Cap Color: Black.

Filter Element: 5-micron rated polyethylene filter element;

optional 40-micron element.

Fluid Media: Compressed air.

Inlet Pressure: 15 psig (1 bar) minimum with automatic drain.

Plastic bowl: 150 psig (10 bar).

Metal bowl: 200 psig (14 bar).

Outlet Pressure: Adjustab le up to 150 psig (10 bar); o ptional

adjusting springs.

Pressure Adjustment: Removable, knob.

Pressure Gauge: 0 to 200 psig (14 bar); 1/4 NPT gauge

ports front and rear; 0-60 psig (4 bar) optional.

Panel Mounting: 1.56 inch (37.1 mm) hole required.

Ports: Tapped inlet, outlet and exhaust ports.

Seals/Elastomers: Carboxylated Nitrile (XNBR).

Valve: Zinc.

Valve Color: Yellow body, red lockout slide.

Slide: Acetal.

Threads: NPT standard, BSPP.

Referenced Standards:

All standards are subject to revision. Parties are

encouraged to investigate and apply the most recent

editions of the standards indicated below.

1

OSHA 29 CFR 1910.147

CSA Z142-02

CSA Z460-05

ISO 13849-1

ISO 14118:2000

EN 1037

ANSI/ASSE Z244.1- 2003 (R2010)

ANSI/PMMI B155.1- 2010

2

Air Entry Combination

Lockout Valve with

Integrated Filter/Regulator

GENERAL:

The Modular L-O-X® Air Entry is a combination Lockout

Valve with Integrated Filter/Regulator in a high flow,

compact space saving design. Full flow exhaust meets

all the applicable standards.

FEATURES:

• Filter and regulator consolidated into a single space-saving

assembly

• Modular mounting for easy servicing

• Internal automatic drain; optional manual drain or float drain

(metal bowl only)

• Reverse flow, self-relieving piston-type regulator; nonrelieving optional

• Tamper-resistant pressure setting

• Has a visible indicator of pressure release (verification port)

• Only lockable in the off position

• Has a full size exhaust port (equal to or larger than supply)

• Easy to operate (positive push/pull operation-detented)

• Optional EEZ-ON

• Packaging

• Conveyor panels

®

operation availab le

APPLICATIONS:

• Material handling

• All Air Entry points

www.rosscontrols.com

Page 3

Modular L-O-X® Air Entry Combination

250

010

scfm

FLOW

l/s

0 5

20

psi

100

OUTLET PRESSURE

1.4

2.8

4.2

5.6

bar

7.0

INLET PRESSURE: 91 psig (6.3 bar)

0

scfm

FLOW

l/s

0

00

20 30 40 50 60 70 80 90 100 110

10 15 20 25 30 35 40 45 50

1/2 Ports

1/4 Ports

3/8 Ports

40

60

80

20

psi

100

OUTLET PRESSURE

1.4

2.8

4.2

5.6

bar

7.0

00

40

60

80

20

psi

100

OUTLET PRESSURE

1.4

2.8

4.2

5.6

bar

7.0

00

40

60

80

Ports: 1/4, 3/8, 1/2

Flow to 105 scfm

DIMENSIONS inches (mm)

Bowl A B * C ** Depth † lb (kg)

Polycarbonate 7.7 (195.6) 4.81 (122.2) 3.23 (82.0) 2.9 (73.7) 3.12 (1.4)

Metal 7.7 (195.6) 6.43 (163.4) 3.23 (82.0) 2.9 (73.7) 3.18 (1.4)

* Bowl removal clearance: add 3.1 (79).

** Dome removal clearance: add 0.63 (16).

† Less gauge.

Inlet pressure psig (bar)

0.34

0.31

0.28

0.24

0.21

0.17

0.14

0.10

0.06

0.03

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

0

psid

bar

scfm

36 (2.5) 92 (6.3) 145 (10.0)

DIFFERENTIAL PRESSURE

050 100 150 200 250

l/s

0 25 50 75 100

1/4 Ports

A

Weight †

LOCKOUT VALVE FLOW CHARACTERISTICS

Inlet pressure psig (bar)

0.34

0.31

0.28

0.24

0.21

0.17

0.14

0.10

0.06

0.03

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

0

psid

bar

scfm

36 (2.5) 92 (6.3) 145 (10.0)

DIFFERENTIAL PRESSURE

050 100 150 200 250

0 25 50 75 100

l/s

FILTER/REGULATOR FLOW CHARACTERISTICS

C

B

Inlet pressure psig (bar)

36 (2.5) 92 (6.3) 145 (10.0)

1/2 Ports

DIFFERENTIAL PRESSURE

050 100 150 200

0 25 50 75 100

3/8 Ports

0.34

0.31

0.28

0.24

0.21

0.17

0.14

0.10

0.06

0.03

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

0

psid

bar

scfm

l/s

MD3 53P B A B 5 B B –

BOWL SIZE

53P - Polycarbonate Bowl (4 oz)

53M - Metal Bowl with sight gauge (6 oz)

ELEMENT TYPE

A - 40 Micron

B - 5 Micron; standard

Element Rating Kit Number

5-µm (Std. element) ................................936K77

40-µm ..........................................938K77

Accessories not included with the product, see page 4

for ordering information.

2 © 2012, ROSS CONTROLS

BOWL DRAIN

A - Auto Drain/Differential Pressure

M - Manual Drain

F - Float Drain (metal bowl only)

REPLACEMENT FILTER ELEMENT KITS

HOW TO ORDER

PIPE SIZE

2 - 1/4 NPTF

3 - 3/8 NPTF

4 - 1/2 NPTF

C - 1/4 BSPP

D - 3/8 BSPP

E - 1/2 BSPP

®

. All Rights Reserved.

GAUGE

A - No Gauge

B - (0-200 psig)

C - (0-60 psig)

D - No Gauge with Panel Mount Nut

E - (0-200 psig) Gauge with Panel Mount Nut

F - (0-60 psig) Gauge with Panel Mount Nut

ADJUSTMENT RANGE

A - 0-150 psig (0-10 bar); reverse flow

B - 0-100 psig (0-6.8 bar); standard, reverse flow

C - 0-50 psig (0-3.4 bar); reverse flow

ADD ON L-O-X

®

1 - Outlet Side

2 - Inlet Side

3 - L-O-X® with EEZ-ON

on Outlet Side

4 - L-O-X

on Inlet Side

X - no L-O-X

®

with EEZ-ON®

®

®

Page 4

Modular L-O-X® Air Entry Packages

Model Air Entry Port Size C

Number Type In-Out Exh. 1 to 2 2 to 3 Length Width Depth

Cat-2 with SV27 RC208-09 FR 1/2 1 6.3 9.2 14.80 (374.9) 11.00 (279.0) 6.60 (167.7)

Cat-2 with SV27 RC208L-09 FRL 1/2 1 6.3 9.2 14.80 (374.9) 11.00 (279.0) 6.60 (167.7)

Cat-3 with DM1 Series E RC304-09 FR 1/4 1/2 1.3 2.4 13.00 (330.0) 11.00 (279.0) 5.40 (134.7)

Cat-3 with DM1 Series E RC306-09 FR 3/8 1/2 1.9 2.4 13.00 (330.0) 11.00 (279.0) 5.40 (134.7)

Cat-3 with DM1 Series E RC304L-09 FRL 1/4 1/2 1.3 2.4 13.00 (330.0) 11.00 (279.0) 5.40 (134.7)

Cat-3 with DM1 Series E RC306L-09 FRL 3/8 1/2 1.9 2.4 13.00 (330.0) 11.00 (279.0) 5.40 (134.7)

Cat-4 with DM

Cat-4 with DM

Cat-4 with DM

Cat-4 with DM

* NPT port threads. Specify voltage and hertz when ordering.

2®

Series E RC404-09 FR 1/4 1/2 1.3 2.4 13.00 (330.0) 11.00 (279.0) 5.40 (134.7)

2®

Series E RC406-09 FR 3/8 1/2 1.9 2.4 13.00 (330.0) 11.00 (279.0) 5.40 (134.7)

2®

Series E RC404L-09 FRL 1/4 1/2 1.3 2.4 13.00 (330.0) 11.00 (279.0) 5.40 (134.7)

2®

Series E RC406L-09 FRL 3/8 1/2 1.9 2.4 13.00 (330.0) 11.00 (279.0) 5.40 (134.7)

V

Air Entry Package with 3/2 Normally Closed

Sensing V alve

• Pre-engineered panel-mounted design with air entry via filter and

regulator “FR”, or filter, regulator, and lubricator “FRL”.

• Includes 3/2 Normally Closed Sensing Valve which senses poppet position

and state. Electrical feedback via DPST switch (double-pole, single-throw).

• Applications include Air Dump and Trapped-Pressure Release.

Dimensions (inches/mm)

Air Entry Packages with Control Reliable

Energy Isolation

• Pre-engineered panel-mounted design with air entry

via a filter and regulator “FR”, or filter, regulator and

lubricator “FRL”.

• Includes DM

a) Self-contained dynamic monitoring system requires no further valve

monitoring controls.

b) Ready-to-run: If an abnormality clears itself upon the remo val of electricity to both

solenoids, it will be ready-to-run again. It does not remember the abnormality & stay

in a locked-out state until intentionally reset. Therefore, cumulative abnormalities

may go undetected.

c) Status indicator switch for valve condition (ready-to-run) feedback.

Do not use in power press clutch/brake applications.

• Pre-engineered panel-mounted design with air entry via a filter and

regulator “FR”, or filter, regulator and lubricator “FRL”.

• Includes DM

a) Self-contained dynamic monitoring system requires no further valve

monitoring controls.

b) Dynamic memory of abnormal function prevents unintentional reset with removal

of air or electricity.

• All necessary features for safety applications are included:

a) Electrical reset valve

b) Status indicator switch for valve condition (ready-to-run) feedback.

Do not use in power press clutch/brake applications.

1

Series E Double Valve with Monitoring:

2®

Series E Double Valve with Monitoring & Memory:

www.rosscontrols.com 3

Page 5

AIR ENTRY COMBINATION ACCESSORIES

Female

Male

Module

Connecting Clamp

Part No. R-A118-105

Combined

Clamp & Bracket

Part No. R-A118-105M

Mounting Bracket

Part No. R-A118-103

CLAMP for MODULE CONNECTIONS

Specially designed clamps provide a quick and easy assembly

or disassembly of MD3 modules. Two allen-head bolts quickly

tighten or loosen the clamp using a 5/32 or 4mm hex key.

The clamp contains a plate carrying two O-rings to provide

positive sealing between modules. Order clamp by part number

R-A118-105. Combined clamp and bracket (below) can be

ordered by part number R-A118-105M.

MOUNTING BRACKET

Two brackets are normally used to mount an FRL to a vertical

surface. The mounting bracket attaches to the moduleconnecting clamp (see above) with a single screw. Each

bracket then employs two bolts (1/4” or 6mm) to connect the

assembly to the mounting surface. Order bracket and screw

by part number R-A118-103. Combined bracket and

clamp

(above) can be ordered by part number R-A118-105M.

MALE and FEMALE END PORTS

Either male or female end ports can

be attached to threaded inlet and

outlet lines. This allows all mo dules

of an FRL assembly to be removed

easily and quickly without having

to unthread the end modules. The

end ports are attached to the modules with clamps (see at left).

End ports can be included in an assembled FRL or ordered

separately by the following part numbers:

Port Size Male Number Female Number

1/4 NPTF R-118-109-2F R-118-100-2

3/8 NPTF R-118-109-3F R-118-100-3

1/2 NPTF R-118-109-4F R-118-100-4

3/4 NPTF R-118-109-6F R-118-100-6

EXTRA PORT BLOCK

An extra port block can be placed between

modules to provide two auxiliary 1/4 NPTF

ports. Its mounting position can be rotated

to obtain the most convenient operating

orientation. If only one auxiliary port is to be

used, the unused port must be closed with

a pipe plug. (The inlet and outlet are not threaded.)

Port Size Part Number

1/4 NPTF ................R-118-106-2

3/8 NPTF ................R-118-106-3

1/2 NPTF ................R-118-106-4

MUFFL-AIR® Silencer

Port NPT Model Avg. Dimensions inches (mm) Weight

Size Threads Number C

V

A B lb (kg)

3/4 Male 5500A5013 7.0 1.3 (32) 3.8 (96) 0.5 (0.2)

* NPT port threads. For BSPP threads, add the letter “D” in front of the part number.

Pressure Range: 150 psig (10.3 bar) maximum.

Visual Pop-Up Indicator or Pressure Switch (electrical)

• May be installed on all L-O-X

®

valves and manual L-O-X® valves with EEZ-ON

operation with pressure sensing port

• Provides a means to verify the release of downstream pressure to next obstruction

Model Inlet Port Verification Dimensions inches (mm) Weight

Number Size* Option A B C lb (kg)

988A30 1/8 Pop-Up Indicator 0.55 (14) 0.98 (25) – 0.03 (0.01)

586A86 1/8 Pressure Switch 2.01 (51) 4.3 (110) 1.22 (31) 0.28 (0.12)

* NPT port threads.

®

Standard ROSS warranty and cautions apply, available upon request or at www.rosscontrols.com

ROSS UK Ltd.

United Kingdom

Fax: 44-121-559-5309

sales@rossuk.co.uk

ROSS CONTROLS

India

Fax: 91-44-2625-8730

rossindia@airtelmail.in

®

INDIA Pvt. Ltd.

WARRANTY and CAUTIONS

ROSS SOUTH AMERICA Ltda.

Brazil

Fax: 55-11-4335-3888

vendas@ross-sulamerica.com.br

ROSS EUROPA GmbH

Germany

Fax: 49-6103-74694

info@rosseuropa.com

ROSS CONTROLS

Customer Svs. 1-800-GET-ROSS

Technical Svs. 1-888-TEK-ROSS

Fax: 81-427-78-7256

custsvc@rossasia.co.jp

U.S.A.

www.rosscontrols.com

®

ROSS ASIA

K.K.

Japan

A

B

®

B

A

C

A

DIMAFLUID s.a.s.

France

Fax: 33-01-4945-6530

dimafluid@dimafluid.com

MUFFL-AIR® Silencer

B

Pop-Up

Indicator

Pressure Switch

ROSS CONTROLS

China

Fax: 86-21-6915-7960

alvinzhurong@vip.163.com

(CHINA) Ltd.

Printed in the U.S.A. – Rev. 07/12 © 2012, ROSS CONTROLS®. All Rights Reserved. Form NPS015

Loading...

Loading...