Page 1

Ports: 1/8 & 1/4

A

Flow to 22 scfm

120

80

68

4

10

16

0

40

2

12

0

14

2

00

BAR

0

100 x kPa

psi

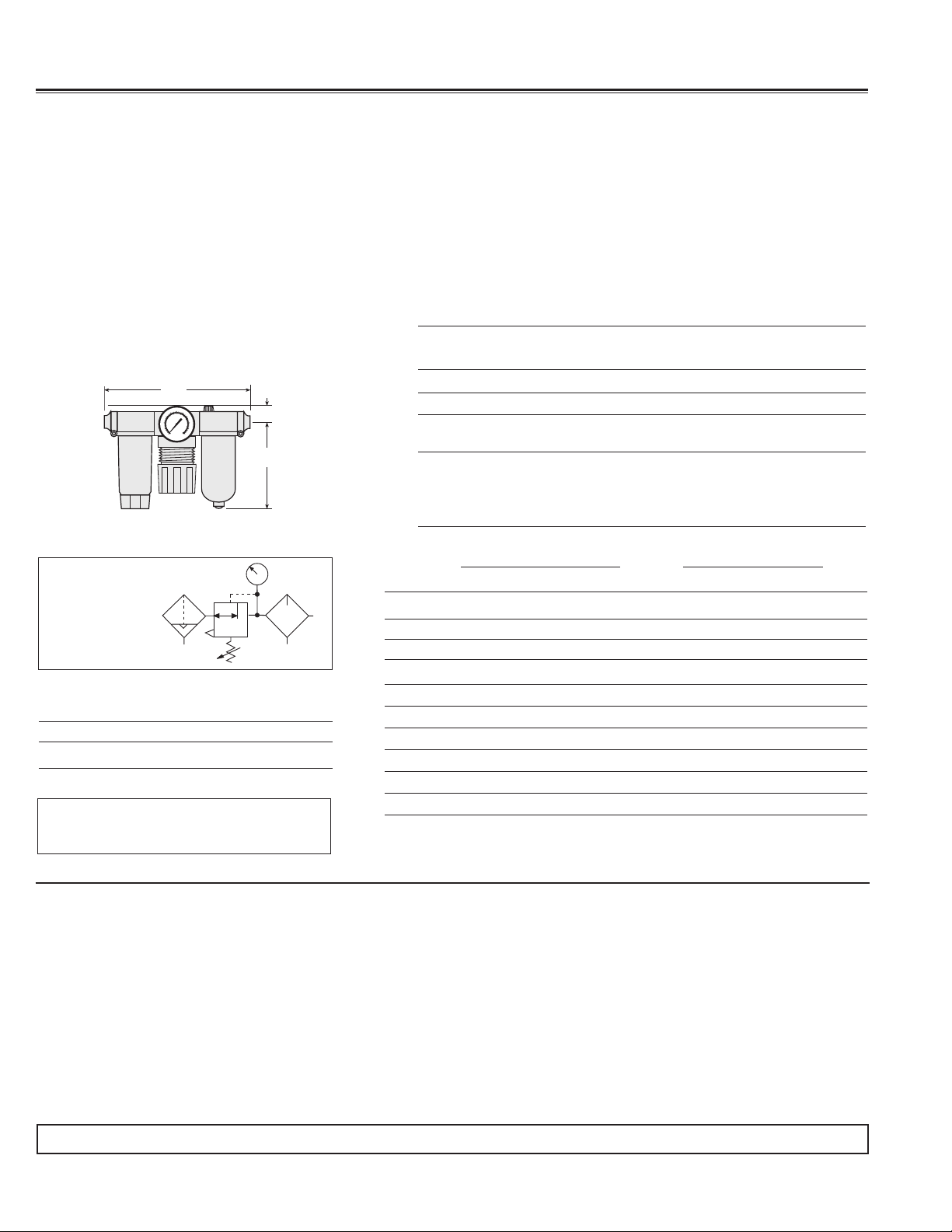

BANTAM Modular FRLs

FEATURES:

• Individual lter, piston-type regulator or diaphragm-type, wick-feed lubricator

• Modular assembly and mounting

• Threaded ports or quick-connect ttings for tubing up to 10 mm in diameter

• 5-micron rated polyethylene lter element

• High-strength polycarbonate plastic bowls or aluminum bowls

• Internal automatic lter drain; optional manual drain

• Self-relieving regulator; optional non-relieving

• Pressure gauge

Port

Size A B C Depth lb (kg)

C

1/8, 1/4 6.3 (160) 3.6 (92) 1.7 (43) 3.6 (92) 0.53 (0.24)

Models below have quick-connect fittings for tubing.

1/4 6.7 (170) 3.6 (92) 1.7 (43) 3.6 (92) 0.50 (0.23)

3/8 7.2 (183) 3.6 (92) 1.7 (43) 3.6 (92) 0.50 (0.23)

B

4 mm 6.7 (170) 3.6 (92) 1.7 (43) 3.6 (92) 0.50 (0.23)

6 mm 6.7 (170) 3.6 (92) 1.7 (43) 3.6 (92) 0.50 (0.23)

8 mm 6.4 (163) 3.6 (92) 1.7 (43) 3.6 (92) 0.50 (0.23)

10 mm 7.2 (183) 3.6 (92) 1.7 (43) 3.6 (92) 0.50 (0.23)

DIMENSIONS inches (mm)

Weight

Port Automatic Drain Models Manual Drain Models

ISO Symbol

FRL

1

2

Automatic Drain

Self-relieving

REPLACEMENT FILTER ELEMENT KIT

Element Rating/Type Kit Number

0.5 µm polyethylene - Standard 933K77

AIR FLOW DATA

See Flow Charts for individual assembly

components on preceding pages.

STANDARD SPECIFICATIONS (for products on this page):

Ambient/Media Temperature:

Polycarbonate plastic bowl: 40° to 125°F (4° to 52°C).

Metal bowls: 40° to 175°F (4° to 79°C).

Bodies: Acetal.

Bowls: 2-ounce (60-ml) capacity polycarbonate plastic bowls or

aluminum bowls.

Filter Drain: Internal automatic drain; optional manual drain.

Filter Element: 5-micron rated polyethylene.

Fluid Media: Compressed air.

Size Plastic Bowl Metal Bowl Plastic Bowl Metal Bowl

THREADED

1/8 5B01C0115 5B01C0216 5B01C0315 5B01C0416

1/4 5B02C0115 5B02C0216 5B02C0315 5B02C0416

TUBE FITTINGS

1/4 5B03C0115 5B03C0216 5B03C0315 5B03C0416

3/8 5B04C0115 5B04C0216 5B04C0315 5B04C0416

4mm 5B05C0115 5B05C0216 5B05C0315 5B05C0416

6mm 5B06C0115 5B06C0216 5B06C0315 5B06C0416

8mm 5B07C0115 5B07C0216 5B07C0315 5B07C0416

10mm 5B08C0115 5B08C0216 5B08C0315 5B08C0416

For quick fill cap on lubricator, change the last digit to a seven (7), e.g., 5B08C0216

becomes 5B08C0217.

For diaphragm regulator, change eighth digit to a two (2), e.g., 5B01C0115 becomes

5B01C0125.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

PISTON TYPE

Inlet Pressure:

For automatic drain model:

With polycarbonate plastic bowl: 15 to 150 psig (1.0 to 10.3 bar).

With metal bowl: 15 to 200 psig (1.0 to 13.8 bar).

For manual drain model:

With polycarbonate plastic bowl: 0 to 150 psig (0 to 10.3 bar).

With metal bowl: 0 to 200 psig (0 to 13.8 bar).

Oil Adjustment: External, no shutoff.

Outlet Pressure: Adjustable up to 100 psig (6.9 bar).

Panel Mounting: 1-3/16 inch (30 mm) hole required.

Regulator Dome and Knob: Acetal.

Seals: Nitrile.

Threads: NPT standard, BSPP. For BSPP threads, add a “C” prefix

to the model number, e.g., C5B01C0115.

68 © 2012, ROSS CONTROLS.

All Rights Reserved.

Page 2

Ports: 1/8 & 1/4

A

Flow to 19 scfm

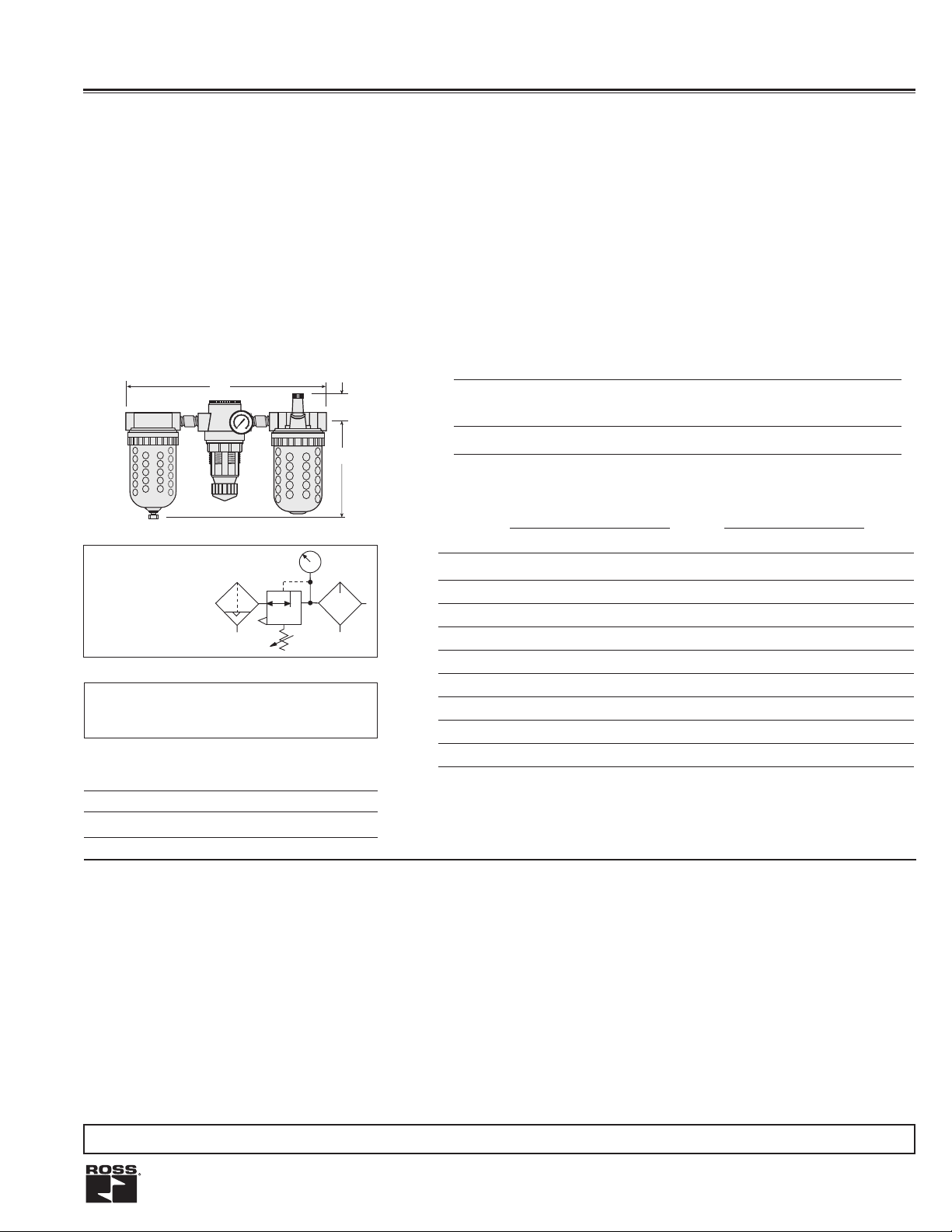

MINIATURE FRLs

FEATURES:

• Individual lter, piston-type or diaphragm-type regulator, wick-feed lubricator

• Inline mounting

• 5-micron rated polyethylene lter element

• High-strength polycarbonate plastic bowls or aluminum bowls

• Internal automatic lter drain; optional manual drain

• Self-relieving regulator; optional non-relieving

• Pressure gauge

120

80

68

4

10

1

60

0

4

2

12

0

14

2

0

BAR

0

0

100 x kPa

psi

C

B

REPLACEMENT FILTER ELEMENT KIT

Element Rating/Type Kit Number

0.5 µm polyethylene (Std. element) 933K77

ISO Symbol

FRL

1

2

Automatic Drain

Self-relieving

AIR FLOW DATA

See Flow Charts for individual assembly

components on preceding pages.

DIMENSIONS inches (mm)*

Weight †

Bowl A B C Depth † lb (kg)

Plastic 5.5 (140) 3.6 (90) 0.7 (17) 1.6 (41) 0.76 (0.34)

Metal 5.5 (140) 4.3 (109) 0.7 (17) 1.6 (41) 0.76 (0.34)

* Dimensions do not include pressure gauges.

† Less gauge.

Port Automatic Drain Models Manual Drain Models

Size Plastic Bowl Metal Bowl Plastic Bowl Metal Bowl

COMBINATION FILTER & REGULATOR* (diaphragm type)

1/8 5321C1027 5322C1024 5321C1026 5322C1025

1/4 5321C2027 5322C2024 5321C2026 5322C2025

COMBINATION FILTER & REGULATOR* (diaphragm type)

1/8 5321C1037 5322C1034 5321C1036 5322C1035

1/4 5321C2037 5322C2034 5321C2036 5322C2035

COMBINATION FILTER & LUBRICATOR ** (High flow)

1/8 5311C1012 5312C1012 5311C1011 5312C1011

1/4 5311C2012 5312C2012 5311C2011 5312C2011

1/8 5331C1006 5332C1006 5331C1005 5332C1005

1/4 5331C2006 5332C2006 5331C2005 5332C2005

*Regulated pressure 0 – 100 psig (0 - 6.9 bar); gauge included.

**To order the lubricator with a quick-fill cap, change the third digit from the end of

the model number from “0” to “1,” e.g., model 5311C1012 with quick-fill cap becomes

model 5311C1112.

COMBINATION FILTER, REGULATOR*

(diaphragm type) & LUBRICATOR** (High flow)

STANDARD SPECIFICATIONS (for products on this page):

Ambient/Media Temperature:

Polycarbonate plastic bowl: 40° to 125°F (4° to 52°C).

Metal bowls: 40° to 175°F (4° to 79°C).

Bowls: 2-ounce (60-ml) capacity polycarbonate plastic bowls or

aluminum bowls.

Filter Drain: Internal automatic drain; optional manual drain.

Filter Element: 5-micron rated polyethylene.

Fluid Media: Compressed air.

Heads: Aluminum.

Inlet Pressure:

For automatic drain model:

With polycarbonate plastic bowl: 15 to 150 psig (1.0 to 10.3 bar).

With metal bowl: 15 to 200 psig (1.0 to 13.8 bar).

Inlet Pressure:

For manual drain model:

With polycarbonate plastic bowl: 0 to 150 psig (0 to 10.3 bar).

With metal bowl: 0 to 200 psig (0 to 13.8 bar).

Oil Adjustment: Internal; tamper-resistant.

Outlet Pressure: Adjustable up to 100 psig (6.9 bar).

Pressure Gauge: 0 to 160 psig (0 to 11.0 bar); 1/8 NPT gauge

ports front and rear.

Panel Mounting: 1-3/16 inch (30 mm) hole required.

Regulator Dome and Knob: Acetal.

Seals: Nitrile.

Threads: NPT standard, BSPP. For BSPP threads, add a “C” prefix

to the model number, e.g., C5321C1027.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

www.rosscontrols.com 69

Page 3

Ports: 1/4, 3/8, 1/2

A

MID-SIZE Modular FRLs

FEATURES:

• Individual lter, piston-type regulator, sight-feed lubricator

• Modular or inline mounting

• 5-micron rated polyethylene lter element

• High-strength zinc bowl or polycarbonate plastic bowl with shatterguard

• Internal automatic lter drain; optional manual drain

• Self-relieving regulator; optional non-relieving

• Pressure gauge

120

0

8

68

4

10

160

40

2

12

0

14

200

BAR

0

100 x kPa

psi

C

B

ISO Symbol

FRL

1

2

Automatic Drain

Self-relieving

REPLACEMENT FILTER ELEMENT KIT

Element Rating/Type Kit Number

0.5 µm polyethylene (Std. element) 936K77

AIR FLOW DATA

See Flow Charts for individual assembly

components on preceding pages.

DIMENSIONS inches (mm)

Weight

Bowl A B C Depth † lb (kg)

Plastic 8.5 (215) 4.6 (117) 1.8 (46) 2.8 (71) 3.75 (1.70)

Metal 8.5 (215) 4.7 (119) 1.8 (46) 2.8 (71) 3.75 (1.70)

† Less gauge.

Port Automatic Drain Models Manual Drain Models

Size Plastic Bowl** Metal Bowl Plastic Bowl** Metal Bowl

COMBINATION FILTER & REGULATOR* (Includes 2 female port kits.)

1/4 5M11B2110 5M11B2210 5M11B2310 5M11B2410

3/8 5M11B3110 5M11B3210 5M11B3310 5M11B3410

1/2 5M11B4110 5M11B4210 5M11B4310 5M11B4410

COMBINATION FILTER & LUBRICATOR (Includes 2 female port kits.)

1/4 5M11B2101 5M11B2202 5M11B2301 5M11B2402

3/8 5M11B3101 5M11B3202 5M11B3301 5M11B3402

1/2 5M11B4101 5M11B4202 5M11B4301 5M11B4402

1/4 5M11B2111 5M11B2212 5M11B2311 5M11B2412

3/8 5M11B3111 5M11B3212 5M11B3311 5M11B3412

1/2 5M11B4111 5M11B4212 5M11B4311 5M11B4412

*Piston type; regulated pressure 0-100 psig (0-6.9 bar); gauge included.

**Plastic bowl includes metal bowl guard.

Note: Each regulator comes complete with a gauge.

COMBINATION FILTER, REGULATOR* & LUBRICATOR

(Includes 2 female port kits.)

STANDARD SPECIFICATIONS (for products on this page):

Ambient/Media Temperature:

Polycarbonate plastic bowl: 40° to 125°F (4° to 52°C).

Metal bowls: 40° to 175°F (4° to 79°C).

Bowls: 4-ounce (120-ml) capacity zinc bowls or polycarbonate

plastic bowls with zinc shatterguards.

Filter Drain: Internal automatic drain; optional manual drain.

Filter Element: 5-micron rated polyethylene.

Fluid Media: Compressed air.

Heads: Zinc.

Inlet Pressure:

For automatic drain model:

With polycarbonate plastic bowl: 15 to 150 psig (1.0 to 10.3 bar).

With metal bowl: 15 to 200 psig (1.0 to 13.8 bar).

Inlet Pressure:

For manual drain model:

With polycarbonate plastic bowl: 0 to 150 psig (0 to 10.3 bar).

With metal bowl: 0 to 200 psig (0 to 13.8 bar).

Oil Adjustment: External; tamper-resistant.

Outlet Pressure: Adjustable up to 100 psig (6.9 bar).

Pressure Gauge: 0 to 200 psig (0 to 14 bar); 1/4 NPT gauge ports

front and rear.

Panel Mounting: 1-9/16 inch (40 mm) hole required.

Regulator Dome and Knob: Acetal. Optional metal regulator dome.

Seals: Nitrile.

Sight Dome: Clear nylon.

Threads: NPT standard, BSPP, SAE. For BSPP threads, add a

“C” prefix to the model number, e.g., C5M11B2110.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

70 © 2012, ROSS CONTROLS.

All Rights Reserved.

Page 4

FULL-SIZE FRLs

Ports: 1/4, 3/8, 1/2, 3/4

Flow to 138 scfm

A

12

0

80

68

4

10

1

6

0

0

4

2

12

0

14

200

BAR

0

100 x kPa

psi

REPLACEMENT FILTER ELEMENT KIT

Element Rating/Type Kit Number

0.5 µm polyethylene (Std. element) 939K77

ISO Symbol

FRL

1

Automatic Drain

Self-relieving

AIR FLOW DATA

See Flow Charts for individual assembly

components on preceding pages.

C

B

FEATURES:

• Individual lter, diaphragm-type regulator, sight-feed lubricator

• Modular or inline mounting

• 5-micron rated polyethylene lter element

• Zinc bowl with clear nylon sight glass or polycarbonate plastic bowl with

steel shatterguard

• Internal automatic lter drain; optional manual drain or electronic drain

• Self-relieving regulator; optional non-relieving

• Pressure gauge

DIMENSIONS inches (mm)

Weight †

Bowl A B C Depth † lb (kg)

8-oz Plastic 10.1 (256) 5.8 (147) 1.3 (33) 2.8 (71) 7.06 (3.20)

8-oz Metal 10.1 (256) 6.4 (163) 1.3 (33) 2.8 (71) 7.06 (3.20)

† Less gauge.

Port Automatic Drain Models Manual Drain Models

Size Plastic Bowl** Metal Bowl Plastic Bowl** Metal Bowl

COMBINATION FILTER & REGULATOR* (Includes 2 female port kits.)

1/4 5F11B2120 5F11B2220 5F11B2320 5F11B2420

3/8 5F11B3120 5F11B3220 5F11B3320 5F11B3420

1/2 5F11B4120 5F11B4220 5F11B4320 5F11B4420

3/4 5F11B5120 5F11B5220 5F11B5320 5F11B5420

COMBINATION FILTER & LUBRICATOR (Includes 2 female port kits.)

1/4 5F11B2101 5F11B2202 5F11B2301 5F11B2402

3/8 5F11B3101 5F11B3202 5F11B3301 5F11B3402

1/2 5F11B4101 5F11B4202 5F11B4301 5F11B4402

3/4 5F11B5101 5F11B5202 5F11B5301 5F11B5402

2

1/4 5F11B2121 5F11B2222 5F11B2321 5F11B2422

3/8 5F11B3121 5F11B3222 5F11B3321 5F11B3422

1/2 5F11B4121 5F11B4222 5F11B4321 5F11B4422

3/4 5F11B5121 5F11B5222 5F11B5321 5F11B5422

*Piston type; regulated pressure 0-100 psig (0-6.9 bar); gauge included.

**Plastic bowl includes metal bowl guard.

For pipe nipple version, change the third and fourth digit to zero (0),

e.g., 5F11B2321 becomes 5F00B2321.

COMBINATION FILTER, REGULATOR* & LUBRICATOR

(Includes 2 female port kits.)

STANDARD SPECIFICATIONS (for products on this page):

Ambient/Media Temperature:

Polycarbonate plastic bowl: 40° to 125°F (4° to 52°C).

Metal bowls: 40° to 175°F (4° to 79°C).

Bowls: 8-ounce (240-ml) capacity zinc bowl with clear n ylon sight

glass or polycarbonate plastic bowl with steel shatterguard.

Bowl Rings: Aluminum.

Filter Drain: Internal automatic drain; optional manual drain or

electronic drain.

Filter Element: 5-micron rated polyethylene.

Fluid Media: Compressed air.

Heads: Zinc.

Inlet Pressure:

For automatic drain model:

Inlet Pressure:

For manual drain model:

With polycarbonate plastic bowl: 0 to 150 psig (0 to 10.3 bar).

With metal bowl: 0 to 200 psig (0 to 13.8 bar).

Oil Adjustment: External; tamper-resistant.

Outlet Pressure: Adjustable up to 125 psig (8.6 bar).

Pressure Adjustment Locking Key: Removable.

Pressure Gauge: 0 to 200 psig (0 to 14 bar); 1/4 NPT gauge

ports front and rear.

Regulator: Nylon dome; acetal knob.

Seals: Nitrile.

Sight Dome: Clear nylon.

Threads: NPT standard, BSPP, SAE. For BSPP threads, add a

“C” prefix to the model number, e.g., C5F11B2120.

With polycarbonate plastic bowl: 15 to 150 psig (1.0 to 10.3 bar).

With metal bowl: 15 to 200 psig (1.0 to 13.8 bar).

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

www.rosscontrols.com 71

Page 5

Ports: 3/8, 1/2, 3/4

Flow to 205 scfm

MD4TM FRLs

A

12

0

0

8

68

4

10

1

60

0

4

2

12

0

14

2

0

BAR

0

0

100 x kPa

psi

Metal Bowls

C

B

FEATURES:

• Individual lter, regulator, lubricator

• Modular or inline mounting

• 5-micron rated polyethylene lter element; optional 40-micron

element

• Aluminum bowl with clear nylon sight glass or polycarbonate

plastic bowl with steel shatterguard

• Internal automatic lter drain; optional manual or electronic drain

• Optional extended aluminum lubricator bowl with sight glass

• Self-relieving diaphragm-type regulator; optional non-relieving

• Pressure gauge; two gauge ports

ISO Symbol - FRL

Automatic Drain - Self-relieving

1

2

A

12

0

80

68

4

10

1

60

40

2

12

0

14

200

BAR

0

100 x kPa

psi

Bowl A B* C Depth † lb (kg)

C

DIMENSIONS inches (mm)

9 oz Plastic 10.9 (276) 7.7 (195) 2.2 (56) 2.9 (73) 6.94 (3.15)

9 oz Metal 10.9 (276) 7.6 (193) 2.2 (56) 3.1 (79) 6.94 (3.15)

15 oz Metal 10.9 (276) 10.6 (269) 2.2 (56) 3.1 (79) 7.13 (3.24)

B

* Bowl removal clearance: For 9-ounce bowls add 3.4 (86).

For extended bowl add 6.1 (155).

† Less gauge.

Extended Metal

Lubricator Bowl

AIR FLOW DATA

See Flow Charts for individual assembly components on preceding pages.

REPLACEMENT FILTER ELEMENT KIT

Element Rating/Type Kit Number

0.5-µm polyethylene - Standard R-A115-106PE5

40-µm bronze R-A115-106PE3

HOW T O ORDER

MD4 53P B A 5 5 2 S *

BOWL SIZE

53P - Two 9 oz Polycarbonate Bowls

53M - Two 9 oz Metal Bowls

53E - 9 oz metal bowl on filter

15 oz metal bowl on lubricator

53F - 9 oz polycarbonate bowl on filter

15 oz metal bowl on lubricator

FILTER

ELEMENT TYPE

A - 40-µm

B - 5-µm (standard)

REGULATOR ADJUSTMENT RANGE

A - 0-175 psig (0-12.1 bar) with 0-200 psig (0-13.8 bar) gauge

B - 0-125 psig (0-8.6 bar) standard with 0-200 psig (0-13.8 bar) gauge

C - 0-50 psig (0-3.4 bar) with 0-60 psig (0-4.1 bar) gauge

D - 0-20 psig (0-1.3 bar) with 0-60 psig (0-4.1 bar) gauge

E - no regulator with 0-60 psig (0-4.1 bar) gauge

For mounting bracket options, see page 77.

B

PIPE SIZE

3 - 3/8 NPTF

4 - 1/2 NPTF

5 - 3/4 NPTF

C - 3/8 BSPP

D - 1/2 BSPP

E - 3/4 BSPP

F - 3/4-16 SAE

G - 7/8-14 SAE

FIL TER REGULA TOR TYPE

5 - Side by side (two piece) with auto drain

6 - Side by side (two piece) with manual drain

7 - Side by side (two piece) with electronic drain - manual drain only

8 - Side by side (two piece) with automatic external drain - manual drain only

LUBRICA TOR TYPE

S - Standard

Q - Quick-Fill Cap

N - No Lubricator

COLOR

G - Gray

Y - Yellow

R - Red

B - Blue

2 - Gold (standard)

ADD ON L-O-X

Weight †

®

1 - Outlet Side

2 - Inlet Side

3 - L-O-X

®

with EEZ-ON

on Outlet Side

4 - L-O-X® with EEZ-ON®

on Inlet Side

- Blank for no L-O-X®

®

STANDARD SPECIFICATIONS (for products on this page):

Ambient/Media Temperature:

Polycarbonate plastic bowl: 40° to 125°F (4° to 52°C).

Metal bowls: 40° to 175°F (4° to 79°C).

Bowls: 9-ounce (270-ml) capacity aluminum bowl with clear nylon

sight glass or polycarbonate plastic bowl with steel shatterguard.

Optional 15-ounce (450-ml) extended aluminum lubricator bowl with

two clear nylon sight glasses.

Bowl Rings: Nylon.

Cap Color: Gold standard; optional gray, yellow, red, blue.

Filter Drain: Internal automatic drain; optional manual drain or

electronic drain.

Filter Element: 5-micron rated polyeth ylene; optional 40-micron element.

Fluid Media: Compressed air.

Heads: Zinc.

Inlet Pressure:

For automatic drain model:

With polycarbonate plastic bowl: 15 to 150 psig (1.0 to 10.3 bar).

With metal bowl: 15 to 200 psig (1.0 to 13.8 bar).

For manual drain model:

With polycarbonate plastic bowl: 0 to 150 psig (0 to 10.3 bar).

With metal bowl: 0 to 200 psig (0 to 13.8 bar).

Oil Adjustment: External; tamper-resistant.

Outlet Pressure: Adjustable up to 125 psig (8.6 bar).

Pressure Adjustment Locking Key: Removable.

Pressure Gauge: 0 to 200 psig (0 to 14 bar); 1/4 NPT gauge

ports front and rear.

Seals: Nitrile.

Sight Dome: Clear nylon.

Threads: NPT standard, BSPP, SAE.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

72 © 2012, ROSS CONTROLS.

All Rights Reserved.

Page 6

Ports: 3/4 & 1

A

Flow to 270 scfm

HIGH-CAPACITY FRLs

FEATURES:

• Individual lter, piston-type regulator, wick-feed lubricator

• Inline mounting

• 5-micron rated polyethylene lter element

• Metal bowls with clear nylon sight glass or polycarbonate plastic bowls

with steel shatterguard

• Internal automatic lter drain, optional manual drain, external automatic

drain, or electronic drain

• Self-relieving regulator; optional non-relieving

• Pressure gauge

12

0

80

68

4

10

160

40

2

12

0

14

20

BAR

0

0

100 x kPa

psi

C

B

ISO Symbol

FRL

1

Automatic Drain

Self-relieving

AIR FLOW DATA

See Flow Charts for individual assembly

components on preceding pages.

REPLACEMENT FILTER ELEMENT KIT

Element Rating/Type Kit Number

0.5-µm polyethylene (Std. element) 1010K77

DIMENSIONS inches (mm)*

Weight

A B C Depth lb (kg)

15.8 (401) 8.0 (204) 1.2 (31) 4.3 (108) 8.00 (3.64)

*Dimensions do not include pressure gauges.

Port Automatic Drain Models Manual Drain Models

Size Plastic Bowl** Metal Bowl Plastic Bowl** Metal Bowl

COMBINATION FILTER & REGULATOR*

2

3/4 5H00C5110 5H00C5210 5H00C5310 5H00C5410

1 5H00C6110 5H00C6210 5H00C6310 5H00C6410

COMBINATION FILTER & LUBRICATOR

3/4 5H00B5101 5H00B5202 5H00B5301 5H00B5402

1 5H00B6101 5H00B6202 5H00B6301 5H00B6402

COMBINATION FILTER, REGULATOR* & LUBRICATOR

3/4 5H00C5111 5H00C5212 5H00C5311 5H00C5412

1 5H00C6111 5H00C6212 5H00C6311 5H00C6412

*Piston type; regulated pressure 0-100 psig (0-6.9 bar); gauge included.

**Plastic bowl includes metal bowl guard.

Note: Each regulator comes complete with a gauge.

Note: For BSPP threads, add the letter “C” in front of the part number.

STANDARD SPECIFICATIONS (for products on this page):

Ambient/Media Temperature:

Polycarbonate plastic bowl: 40° to 125°F (4° to 52°C).

Metal bowls: 40° to 175°F (4° to 79°C).

Bowls: 16-ounce (480-ml) capacity aluminum bowls with sight glass

or polycarbonate plastic bowls with steel shatterguard.

Bowl Rings: Aluminum.

Filter Drain: Internal automatic drain; optional manual drain,

external automatic, or electronic drain.

Filter Element: 5-micron rated polyethylene.

Fluid Media: Compressed air.

Heads: Aluminum.

Inlet Pressure:

For automatic drain model:

With polycarbonate plastic bowl: 15 to 150 psig (1.0 to 10.3 bar).

With metal bowl: 15 to 200 psig (1.0 to 13.8 bar).

For manual drain model:

With polycarbonate plastic bowl: 0 to 150 psig (0 to 10.3 bar).

With metal bowl: 0 to 200 psig (0 to 13.8 bar).

Oil Adjustment: External; tamper-resistant.

Outlet Pressure: Adjustable up to 100 psig (6.9 bar).

Pressure Adjustment Locking Key: Removable.

Pressure Gauge: 0 to 200 psig (0 to 14 bar);

1/4 NPT gauge ports front and rear.

Seals: Nitrile.

Threads: NPT standard, BSPP . For BSPP threads, add a “C” prefix

to the model number, e.g., C5H00C5110.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

www.rosscontrols.com 73

Page 7

Ports: 1¼ & 1½

A

Flow to 495 scfm

12

0

80

68

4

10

1

60

0

4

2

12

0

14

200

BAR

0

100 x kPa

psi

See Flow Charts for individual assembly

AIR FLOW DATA

components on preceding pages.

HIGH-CAPACITY FRLs

FEATURES:

• Individual lter, piston-type regulator, sight-feed

• Inline mounting

• 5-micron rated lter element; optional 40-micron lter element

• Aluminum bowls with clear nylon sight glass

• Internal automatic lter drain; optional manual drain

• Self-relieving regulator

• Pressure gauge

ISO Symbol

Automatic Drain

Self-relieving

C

DIMENSIONS inches (mm)

B

A B* C Depth lb (kg)

15.8 (401) 10.6 (268) 2.1 (54) 4.3 (108) 8.00 (3.64)

REPLACEMENT FILTER ELEMENT KIT

Element Rating/Type Kit Number

0.5-µm polyethylene - Standard 1656K77

40-µm bronze - Optional R-A114-106E3

FRL

1

Weight

2

HOW T O ORDER

HIGH-CAPACITY Model No. 5H 00C

PIPE SIZE

7 = 1¼

8 = 1½

STANDARD SPECIFICATIONS (for products on this page):

Ambient/Media Temperature:

Polycarbonate plastic bowl: 40° to 125°F (4° to 52°C).

Metal bowls: 40° to 175°F (4° to 79°C).

Bowls: 35-ounce (1 liter) capacity aluminum bowls with clear nylon

sight glasses.

Bowl Rings: Aluminum.

Filter Drain: Internal automatic drain. Optional manual drain.

Filter Element: 5-micron or 40-micron rated filter element availab le.

Fluid Media: Compressed air.

Heads: Aluminum.

Inlet Pressure:

For automatic drain model:

With polycarbonate plastic bowl: 15 to 150 psig (1.0 to 10.3 bar).

With metal bowl: 15 to 200 psig (1.0 to 13.8 bar).

FILTER

0 = None

1 = Automatic drain, metal bowl, 40 micron

2 = Automatic drain, metal bowl, 5 micron

3 = Manual drain, metal bowl, 40 micron

4 = Manual drain, metal bowl, 5 micron

NOTE: Polycarbonate plastic bowls for 1¼ and 1½ units not available.

* * * *

LUBRICATOR

0 = None

2 = Sight-feed, metal bowl

4 = Sight-feed, metal bowl, quick-fill cap

REGULATOR

0 = None

1 = Piston, 0-100 psig (0-6.9 bar)

8 = Internal pilot, 15-200 psig (1.0-13.8 bar)

Inlet Pressure:

For manual drain model:

With polycarbonate plastic bowl: 0 to 150 psig (0 to 10.3 bar).

With metal bowl: 0 to 200 psig (0 to 13.8 bar).

Oil Adjustment: External; tamper-resistant.

Outlet Pressure: Adjustable up to 100 psig (6.9 bar).

Pressure Adjustment Locking Key: Removable.

Pressure Gauge: 0 to 200 psig (0 to 14 bar); 1/4 NPT gauge

ports front and rear.

Regulator: Nylon dome; acetal knob.

Seals: Nitrile.

Sight Dome: Clear nylon.

Threads: NPT standard, BSPP. For BSPP threads, add a “C” prefix

to the model number, e.g., C5H00C7112.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

74 © 2012, ROSS CONTROLS.

All Rights Reserved.

Page 8

Components for Modular Assembly

MID-SIZE and FULL-SIZE Units

The modular designs of the MID-SIZE and FULL-SIZE series offer

maximum flexibility in customizing FRL assemblies. As shown at the

right, connector kits are required to interconnect units. Various port

kits (shown below) can be used to connect the assemblies to the

inlet and outlet piping. Note that all FRL components have threaded

ports so that conventional pipe fittings may be used where desired.

Female Port Kits

Used to connect to piping at

inlet or outlet.

Port Size Part Number

1/4 897K77

3/8 898K77

1/2 899K77

3/4 900K77

Male Port Kits

Used to connect modular to

non-modular units. Also allows

90-degree connections using

side, bracket, or extra port kits.

Port Size Part Number

1/4 893K77

3/8

894K77

1/2

895K77

3/4 896K77

Side Port Kits

Functions as a 90-degree female port.

Three types:

(1) port at front or back; (2) port at top; (3) port at bottom.

Port Size Part Number

Front/Back Top Bottom

1/4 902K77 906K77 1000K77

3/8 903K77 907K77 1001K77

1/2 904K77 908K77 1002K77

3/4 905K77 909K77 1003K77

Female Port Kits or

other port kits shown below

Connector

Kits 892K77

7

8

6

9

5

100

1

120

80

0

4

fi

140

60

11

3

160

40

1

2

2

180

20

1

200

3

0

1

2

lb/in

1

4

0

bar

MID-SIZE and FULL-SIZE Modular Assembly

Connector Kit 892K77

Used to connect units to one another as well

as to any of the ports shown on this page.

Mounting Bracket Kit 915K77

L-shaped metal brackets (not illustrated) are used f or wall mounting

modular assemblies. Kit contains two brackets and four screws for

attaching brackets to tops of modular units.

BANTAM Units

BANT AM modular units use end plates secured with scre ws to hold

the pipe or tubing ports (see below), and also to serve as mounting

brackets. Shor t screws are used to secure the end plates when a

Pipe or

Tubing Port

single BANT AM unit is used. If two or more units are combined, long

screws extend through an end plate and thread into the next unit.

Screw kits required are as follows:

End Plate

Single Unit: Two short screw kits.

Two-Unit Combination: One each short screw kit and long

screw kit.

Three-Unit Combination: Two long screw kits.

Part Number

Port Size Part Number

1/8 NPT 862K77

Pipe Ports

1/8 BSP D864K77

1/4 NPT 863K77

1/4 BSP D865K77

END PLATE (1): 857K77

Short Screw (2): 858K77

Long Screw (2): 859K77

Small O-Rings: 860K77

(for inlet or mating ports)

Large O-Rings: 861K77

(for outlet or mating ports)

www.rosscontrols.com 75

Port Size Part Number

1/4 866K77

3/8 867K77

Tube Ports

6 mm 869K77

4 mm 868K77

8 mm 870K77

10 mm 871K77

7

8

6

9

5

100

1

120

80

0

4

fi

140

60

1

1

3

160

40

1

2

2

180

20

1

200

3

0

1

2

lb/in

1

4

0

bar

Page 9

Series MD4TM Modular Assemblies

Female

Male

Dimensions: inches (mm)

0.88 (22.4)

3.71 (94.2)

(327.41)

12.89

11.13 (282.7)

3.71 (94.2)

3.71 (94.2)

0.88 (22.4)

3.24

(82.3)

1.79

(45.5)

1.5

(38.1)

3.00

(76.2)

Remove clamp with

5/32 or 4mm hex key

Mount with 1/4”

or 6 mm bolt

Combined Clamp & Bracket

Module Connecting Clamp

Part No. R-A118-105

Part No. R-A118-105M

Mounting Bracket

Part No. R-A118-103

2.19

0.20

(5.1)

(55.6)

7.36

(186.9)

7.56

(192.0)

120

80

68

4

10

160

40

2

12

0

14

2

00

BAR

0

100 x kPa

psi

Male and Female End Ports

Either male or female end ports can be attached to threaded inlet

and outlet lines. This allows all modules of an FRL assemb ly to

be removed easily and quickly without having to unthread the

end modules. The end ports are attached to the modules with

clamps (see at left). End ports can be included in an assembled

FRL or ordered separately by the following part numbers:

Clamp for Module Connections

Port Size Male Part Number* Female Part Number*

1/4 NPTF R-118-109-2F R-118-100-2

Specially designed clamps provide a quick and easy assembly

or disassembly of MD4

TM

modules. Two allen-head bolts quickly

tighten or loosen the clamp using a 5/32 or 4mm hex key. The

clamp contains a plate carrying two O-rings to provide positive

sealing between modules.

3/8 NPTF R-118-109-3F R-118-100-3

1/2 NPTF R-118-109-4F R-118-100-4

3/4 NPTF R-118-109-6F R-118-100-6

For BSPP threads, add a “W” suffix to the model number,

e.g., R-118-109-2FW.

Order clamp by part number R-A118-105.

Combined clamp and bracket (below) can be ordered by part

Extra Port Blocks

number R-A118-105M.

An extra port block can be placed between modules to provide

Mounting Brackets

Two brackets are normally used to mount an FRL to a vertical

surface. The mounting bracket attaches to the module

connecting clamp (see above) with a single screw . Each brack et

then employs two bolts (1/4” or 6mm) to connect the assembly

to the mounting surface.

Order bracket and screw by part number R-A118-103.

Combined bracket and

number R-A118-105M.

clamp (above) can be ordered by part

two auxiliary 1/4 NPTF ports. Its mounting position can be

rotated to obtain the most convenient operating orientation. If

only one auxiliary port is to be used, the unused port must be

closed with a pipe plug. (The inlet and outlet are not threaded.)

Port Size

1/4 NPTF R-118-106-2

3/8 NPTF R-118-106-3

1/2 NPTF R-118-106-4

For BSPP threads, add a “W” suffix to the model number,

e.g., R-118-109-2FW.

76 © 2012, ROSS CONTROLS.

Part Number*

All Rights Reserved.

Page 10

Mounting Accessories

Regulator Mounting Brackets

Regulators and integral filter/regulators can be mounted

E

C

D

to a surface with a bracket that attaches to the regulator.

Brackets and mounting nuts can be ordered separately or

in a kit which includes both bracket and mounting nut.

Usage Kit Bracket Nut A B C D E Diameter inches (mm)

MINIATURE 873K77 872K77 874K77 1.375 (35) 1.125 (29) 0.31 (8) 0.31 (8) 0.69 (17) 1.19 (30)

MID-SIZE 876K77 875K77 877K77 2.38 (60) 1.00 (25) 1.50 (38) – – 1.56 (40)

MD4TM & FULL-SIZE 879K77 878K77 880K77 2.38 (60) 1.00 (25) 1.50 (38) – – 2.06 (52)

Part Numbers Dimensions inches (mm) Panel Mounting Hole

MINIATURE

B

A

MID-SIZE & MD4

TM

C

B

A

Modular Mounting Brackets

Two L-shaped metal brackets as shown at the right can be used for wall mounting of modular

FRLs or Clean Air Packages . A single br acket can be used to mount individual filters or lubricators.

Kits include two brackets and four screws for attaching the brackets to the modules.

Kit Dimensions inches (mm)

Usage Number A B C D

BANTAM - Mounts with long screws that extend through end plates,

number 859K77 (two required).

MID-SIZE & FULL-SIZE 915K77 3.0 (76) 0.88 (22) 1.00 (25) 1.20 (31)

MID-SIZE, & FULL-SIZE

A

C

B

FRL Inline Mounting Pipe Brackets

A

Two pipe brackets can be used for wall

mounting of FRL assemblies that use

pipe nipples to join the components. The

bracket kits listed below include two sets

of brackets.

Bracket Assembly Kit for HIGH-RELIEF Pilot

Operated Regulator

High-Relief Pilot Operated Regulator with 1/4- thru 1¼ inch

ports can be mounted to a vertical surface using the bracket

assembly kit listed below.

Bracket Assembly Kit

Model Number R-A37-381

Nipple Kit Dimensions inches (mm)

Size Number A B C

1/4 887K77 2.72 (28) 0.50 (13) 1.00 (25)

C

3/8 888K77 2.72 (28) 0.50 (13) 1.00 (25)

B

1/2 889K77 2.72 (28) 0.50 (13) 1.00 (25)

3/4 890K77 3.69 (94) 1.13 (29) 1.25 (32)

1 891K77 3.69 (94) 1.13 (29) 1.25 (32)

www.rosscontrols.com 77

Loading...

Loading...