Page 1

Explosion-Proof

1

2

3

4

14

1

2

12

1

2

10

1

2

3

1

2

10

3

New Product

Information

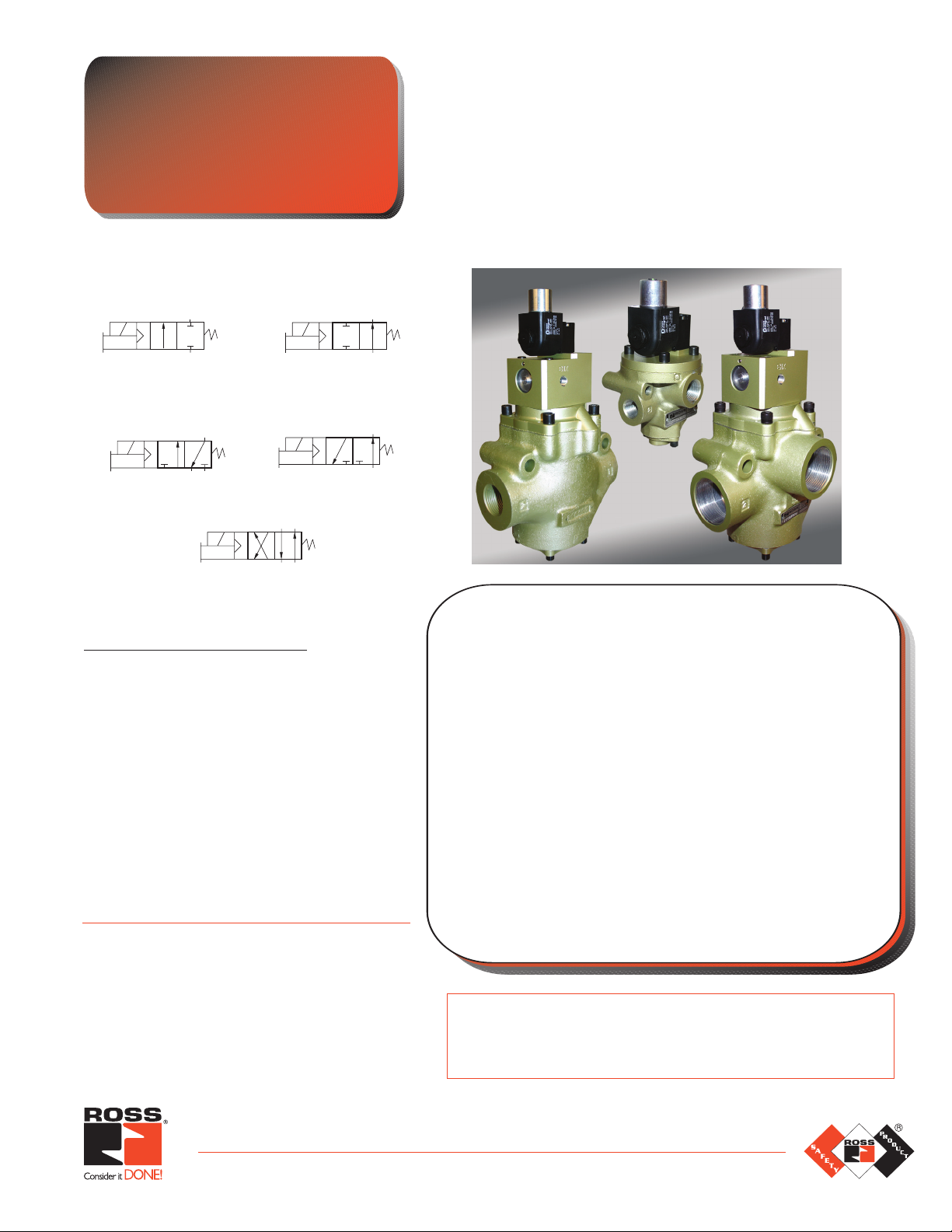

Solenoid Pilot Controlled

2/2 Valves

Normally Closed (NC) Normally Open (NO)

3/2 Valves

Normally Closed (NC)

12

4/2 Valves

Normally Open (NO)

Solenoid Pilot Poppet Valves

for Line Mounting

2/2, 3/2 & 4/2

Normally Closed & Normally Open

Series 27

STANDARD SPECIFICATIONS:

Solenoids: AC or DC power.

Standard Voltages: 24 volts DC.

Power Consumption: 4.6 watts.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Solenoid Temperature: -4° to 140°F (-20° to 60°C).

Flow Media: Filtered air.

Inlet Pressure:

1/4 to 1½ Port Sizes: 15 to 150 psig (1 to 10 bar);

1½ to 2½ Port Sizes: 30 to 150 psig (2 to 10 bar).

Threads: NPT, BSPP port threads.

CSA APPROVED, for use in the following

hazardous locations:

CLASS I, Zone 1

CLASS I, Div. 1, Group A, B, C and D

CLASS I, Div. 2, Group A, B, C and D

CLASS II, Group E, F and G

CLASS III

Ex m II, T4

GENERAL:

Explosion-proof solenoid pilot controlled valves are ideal for

applications in a wide range of industries and environments

where safety from electrical ignition of flammable gases,

vapors, flammable liquids, combustible dust, or easily ignitable

fibers is a concern.

FEATURES:

• Solenoidpilotcontrolled

• Poppet construction for near zero leakage & high dirt tolerance

• Self-cleaning

• Wear compensating

• Repeatability throughout the life of the valve

External pilot supply option available, consult ROSS.

Explosion-Proof solenoid pilot valves for use

in High Temperature and Low Temperature Service

also available, consult ROSS.

For additional information consult your ROSS distributor or call ROSS Technical Services

in the U.S.A. at 1-888-TEK-ROSS (835-7677).

www.rosscontrols.com

Page 2

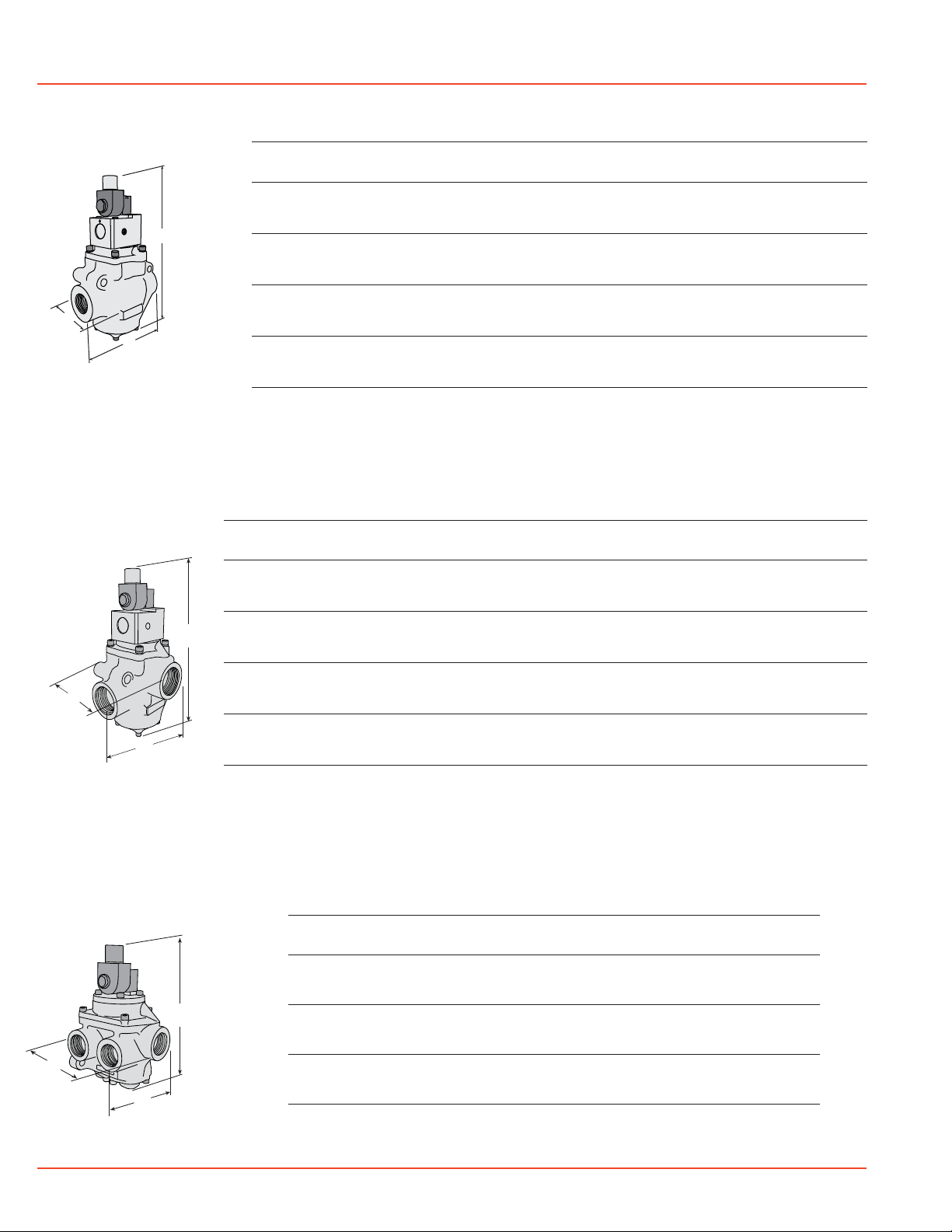

2/2 Valves

Single Solenoid Pilot Controlled

B

3/2 Valves

B

Port Valve Model Number* Avg. CV Dimensions inches (mm)

Size NC NO NC NO A B C lb (kg)

Weight

1/4 2771B2002 2772B2002 2.3 2.3 3.6 (91) 3.2 (79) 9.0 (229) 3.0 (1.4)

3/8 2771B3002 2772B3002 3.8 3.3 3.6 (91) 3.2 (79) 9.0 (229) 3.0 (1.4)

C

1/2 2771B4012 2772B4012 4.0 3.5 3.6 (91) 3.2 (79) 9.0 (229) 3.0 (1.4)

1/2 2771B4002 2772B4002 7.7 6.5 4.6 (116) 3.2 (79) 9.0 (229) 3.6 (1.6)

3/4 2771B5002 2772B5002 9.0 7.3 4.6 (116) 3.2 (79) 9.0 (229) 3.6 (1.6)

1 2771B6012 2772B6012 9.0 7.9 4.6 (116) 3.2 (79) 9.0 (229) 3.6 (1.6)

1 2771B6002 2772B6002 24 21 6.7 (169) 4.1 (104) 12.0 (305) 7.5 (3.4)

1¼ 2771B7002 2772B7002 29 20 6.7 (169) 4.1 (104) 12.0 (305) 7.5 (3.4)

1½ 2771B8012 2772B8012 29 21 6.7 (169) 4.1 (104) 12.0 (305) 7.5 (3.4)

A

1½ 2771B8002 2772B8002 49 49 8.7 (219) 5.2 (131) 13.0 (330) 16.0 (7.3)

2 2771B9002 2772B9002 57 57 8.7 (219) 5.2 (131) 13.0 (330) 16.0 (7.3)

2½ 2771B9012 2772B9012 64 72 8.7 (219) 5.2 (131) 13.0 (330) 16.0 (7.3)

* NPT pressure port threads, for BSPP threads add a “D” prefix to the model number e.g., D2771B2002.

Port Sizes Valve Model Number Avg. CV Dimensions inches (mm)

Weight

In-Out Exh. NC NO NC NO A B C lb (kg)

1/4 1/2 2773B2002 2774B2002 2.8 2.5 3.6 (91) 3.2 (79) 9.0 (229) 2.5 (1.2)

3/8 1/2 2773B3002 2774B3002 4.0 3.0 3.6 (91) 3.2 (79) 9.0 (229) 2.5 (1.2)

1/2 1/2 2773B4012 2774B4012 3.8 3.0 3.6 (91) 3.2 (79) 9.0 (229) 2.5 (1.2)

1/2 1 2773B4002 2774B4002 7.8 7.2 4.6 (116) 3.6 (92) 9.0 (229) 3.3 (1.5)

3/4 1 2773B5002 2774B5002 9.4 7.2 4.6 (116) 3.6 (92) 9.0 (229) 3.3 (1.5)

C

1 1 2773B6012 2774B6012 10 7.2 4.6 (116) 3.6 (92) 9.0 (229) 3.3 (1.5)

1 1½ 2773B6002 2774B6002 29 21 6.7 (169) 4.9 (123) 12.0 (305) 7.0 (3.2)

1¼ 1½ 2773B7002 2774B7002 31 22 6.7 (169) 4.9 (123) 12.0 (305) 7.0 (3.2)

1½ 1½ 2773B8012 2774B8012 31 21 6.7 (169) 4.9 (123) 12.0 (305) 7.0 (3.2)

1½ 2½ 2773B8002 2774B8002 69 58 8.7 (219) 6.4 (161) 13.0 (330) 16.5 (7.4)

A

2 2½ 2773B9002 2774B9002 70 60 8.7 (219) 6.4 (161) 13.0 (330) 16.5 (7.4)

2½ 2½ 2773B9012 2774B9012 71 55 8.7 (219) 6.4 (161) 13.0 (330) 16.5 (7.4)

* NPT pressure port threads, for BSPP threads add a “D” prefix to the model number e.g., D2773B2002.

4/2 Valves

Port Sizes Valve Model Avg. Dimensions inches (mm) Weight

In-Out Exh. Number C

1/4 1/2 2776B2002 2.5 4.0 (100) 3.9 (97) 8.0 (203) 1.9 (0.9)

3/8 1/2 2776B3002 3.6 4.0 (100) 3.9 (97) 8.0 (203) 1.9 (0.9)

1/2 1/2 2776B4002 3.7 4.0 (100) 3.9 (97) 8.0 (203) 1.9 (0.9)

C

1/2 1 2776B4002 6.9 4.7 (118) 5.3 (135) 10.0 (254) 4.2 (1.9)

3/4 1 2776B5002 8.2 4.7 (118) 5.3 (135) 10.0 (254) 4.2 (1.9)

1 1 2776B6012 8.9 4.7 (118) 5.3 (135) 10.0 (254) 4.2 (1.9)

B

1 1½ 2776B6002 23 6.5 (166) 8.3 (211)

1¼ 1½ 2776B7002 24 6.5 (166) 8.3 (211)

A

1½ 1½ 2776B8012 25 6.5 (166) 8.3 (211)

* NPT pressure port threads, for BSPP threads add a “D” prefix to the model number e.g.,

D2771B2002.

2 ROSS CONTROLS

V

A B C lb (kg)

12.0 (305)

12.0 (305)

12.0 (305)

®

11.0 (5.0)

11.0 (5.0)

11.0 (5.0)

Page 3

Technical Drawings Specifications

2/2 Solenoid Pilot Controlled Models

Port Sizes 1/4 to 1 OT (Overtap)

B

2X O 0.34 (8.0)

B

Port 1(inlet)

[Port 2 (outlet

on opposite site]

A

C

A

Port Sizes 1 to 2½

2X O 0.53 (13)

Port 1(inlet)

[Port 2 (outlet

on opposite site]

C

3/2 Solenoid Pilot Controlled Models

Port Sizes 1/4 to 1 OT (Overtap)

Port Sizes 1 to 2½

Port 3

(exhaust)

Port 3

(exhaust)

B

A

2X O 0.34 (8.0)

Port 1(inlet)

[Port 2 (outlet

on opposite site]

C

B

A

2X O 0.53 (13)

Port 1(inlet)

[Port 2 (outlet

on opposite site]

C

4/2 Solenoid Pilot Controlled Model

Port Sizes 1/4 to 1 OT (Overtap)

Port 2 (outlet)

Port 3 (exhaust)

2X O 0.34 (8.0)

B

B

Port Sizes 1 to 2½

Port 3

(exhaust)

2X O 0.34 (8.0)

Port 2

(outlet)

Port 4 (outlet)

Port 1 (inlet)

A

C

A

Port 4

(outlet)

Port 1

(inlet)

C

www.rosscontrols.com 3

Page 4

Conversion Kit

ROSS Controls standard poppet solenoid pilot controlled valves for line

mounting can be easily field-converted into an explosion-proof solenoid

pilot poppet valve.

Listed on the right are the conversion kit part numbers to replace the

obsolete ROSS explosion proof pilot, or to convert a standard in-line valve

to an explosion-proof valve.

Applicable Requirements

C22.2 No. 0-10 - General Requirements - Canadian Electrical Code, Part II

CSA C22.2 No. 25-1966 - Enclosures for use in Class II Groups E, F and G Hazardous Locations

CSA C22.2 No. 142-M1987 - Process Control Equipment

C22.2 No. 213-M1987 - Non-Incendive Electrical Equipment for Use in Class I, Division 2 Hazardous Locations

CAN/CSA E79-0-95 - Electrical apparatus for explosive atmospheres, Part 0: General requirements

CAN/CSA E79-18-95 - Electrical apparatus for explosive atmospheres, Part 18: Encapsulation "m"

Part Number

1/4" - 1" OT (Overtap) 2370K77W

1" - 2½" 2371K77W

Referenced Standards

All standards are subject to revision. Parties are encouraged to investigate and apply the most recent editions of the standards indicated below.

Various Safety-related Standards that Apply to Air Systems:

ANSI/ASSE Z244.1-2003 (R2008) – Lockout/Tagout Control of Hazardous Energy

OSHA 29 CFR 1910.147, ANSI B11.0-2010, RIA 15.06, ISO13849 – Machine Safeguarding

ANSI/PMMI B155.1-2010 – Safety Requirements for Packaging Machinery

ANSI B11.1 – Safety Requirements for Mechanical Power Presses

ANSI B11.2 – Safety Requirements for Hydraulic Power Presses

ANSI B11.3 – Safety Requirements for Power Press Brakes

ANSI B11.19-2010 – Performance Requirements for Safeguarding (Stop Time)

ANSI B11.TR6-2010 – Safety Control Systems for Machine Tools

OSHA 29 CFR 1910.211-219 – Safeguarding Mechanical Power Presses

®

ROSS UK Ltd.

United Kingdom

Fax: 44-121-559-5309

sales@rossuk.co.uk

WARRANTY and CAUTIONS

Standard ROSS warranty and cautions apply, available upon request or at

www.rosscontrols.com

ROSS CONTROLS® INDIA Pvt. Ltd.

India

Fax: 91-44-2625-8730

rossindia@airtelbroadband.in

ROSS SOUTH AMERICA Ltda.

Brazil

Fax: 55-11-4335-3888

vendas@ross-sulamerica.com.br

DIMAFLUID s.a.s.

France

Fax: 33-01-4945-6530

dimafluid@dimafluid.com

ROSS CONTROLS (CHINA) Ltd.

China

Fax: 86-21-6915-7960

alvinzhurong@vip.163.com

ROSS EUROPA GmbH

Germany

Fax: 49-6103-74694

info@rosseuropa.com

ROSS CONTROLS

Customer Svs. 1-800-GET-ROSS

Technical Svs. 1-888-TEK-ROSS

ROSS ASIA® K.K.

Fax: 81-427-78-7256

custsvc@rossasia.co.jp

U.S.A.

www.rosscontrols.com

Japan

Printed in the U.S.A. – Rev. 10/12 © 2012 ROSS CONTROLS®. All Rights Reserved. Form NPS035

Loading...

Loading...