Page 1

Bulletin E383Bulletin E383

5/2-W ay Double Valves with

5/2-W ay Double Valves with

®

ROSSMIRROR

C

C

ROSSMIRROR

®

Sensing

Sensing

1www.rosseuropa.com

Page 2

ROSS safety-related technology

has a long tradition...

ROSS 5/2-way Double Valves with

CROSSMIRROR®-Sensing

For almost 40 years ROSS has been developing double

valves which have made a significant contribution to the

operating safety of pneumatically controlled presses. During this period our range of double valves has been developed continuously in response to the needs of press

manufacturers and users. Monitoring devices have also

been offered in a variety of designs to satisfy different requirements.

The range of double valves in 5/2-way configuration featuring the all-new CROSSMIRROR® -sensing system presented

in this leaflet incorporates all our experience and represents the state-of-the-art in ROSS double valves.

Selecting the double valve best suited to each application

requires considerable technical knowledge. If you need

further information or technical advice, please contact

ROSS or your nearest ROSS distributor or sales office.

CAUTION: On mechanical presses and other hazardous

machines with pneumatically operated clutches and brakes double valves at least should be used. Double valves

without self-monitoring should be used only if current regulations permit.

If the valves are used on presses in Germany, the

„Safety Regulations For Control Systems On Power-driven Presses for Metalworking zH 1/457“ must be observed.

For applications not covered by standard valves, please

consult ROSS. We reserve the right to make technical modifications in the course of further product development.

This all-new ROSS-Crossflow double valve with CROSSMIR-

®

-sensing is a 5/2-way valve with two individual soleno-

ROR

id pilot valves each actuating its own individual metalspool-sleeve valve element.

The spool-and-sleeve valve elements are arranged in parallel design and - as a safety-related feature - they are connected by „crossflow“ channels. In case of normal valve

operation both spools move synchronously; when de-actuated, the spools are in the upper position; and when actuated, they are in the lower position. Because of their redundant design and their self-monitoring capabilities, ROSS

5/2-way-Crossflow double valves with C

sing provide a very high safety standard for the control of

single- or double acting cylinders or rotary drives.

Additional safety features are incorporated in the base. In

the event of loss of air pressure at the inlet port a check

valve is installed to trap the downstream air, a small bleed

orifice slowly relieves the trapped air. Additionally a small

two-way valve provides safety in the case where inlet pressure is restored whilst the solenoids are still energized. To

guard against any sudden cylinder movement, this valve

provides a path to exhaust for one of the pilot valves which

puts the valve into an inoperable state until both solenoids

have been de-energized.

The new ROSS C

gned to exhaust the pilot supply to one solenoid pilot when

only one half of the valve is in an actuated position. This is

accomplished by connecting the pilot air supply system to

the main valve spool and sleeve. The connection is made

such that as the spool moves toward the actuated position

the pilot supply is vented to exhaust via the second valve

element. When the second valve element moves to the actuated position, it blocks the exhausting pilot air thereby

maintaining a constant supply. Pilot supply to the opposite

pilot is connected in a mirror image of the first pilot supply,

hence the name „cross mirror“.

ROSSMIRROR

®

-sensing system is desi-

ROSSMIRROR

®

-sen-

CONTENTS:

Product description........................................ Page 2

Specifications, model numbers ..................... Page 3

Dimensions ................................................... Page 4

Replacement parts ........................................Pages 5, 6

Flow characteristics, valve response times ...Page 7

General information....................................... Page 8

Cautions........................................................ Pages 9, 11

Operating instructions ................................... Page 10

2www.rosseuropa.com

Page 3

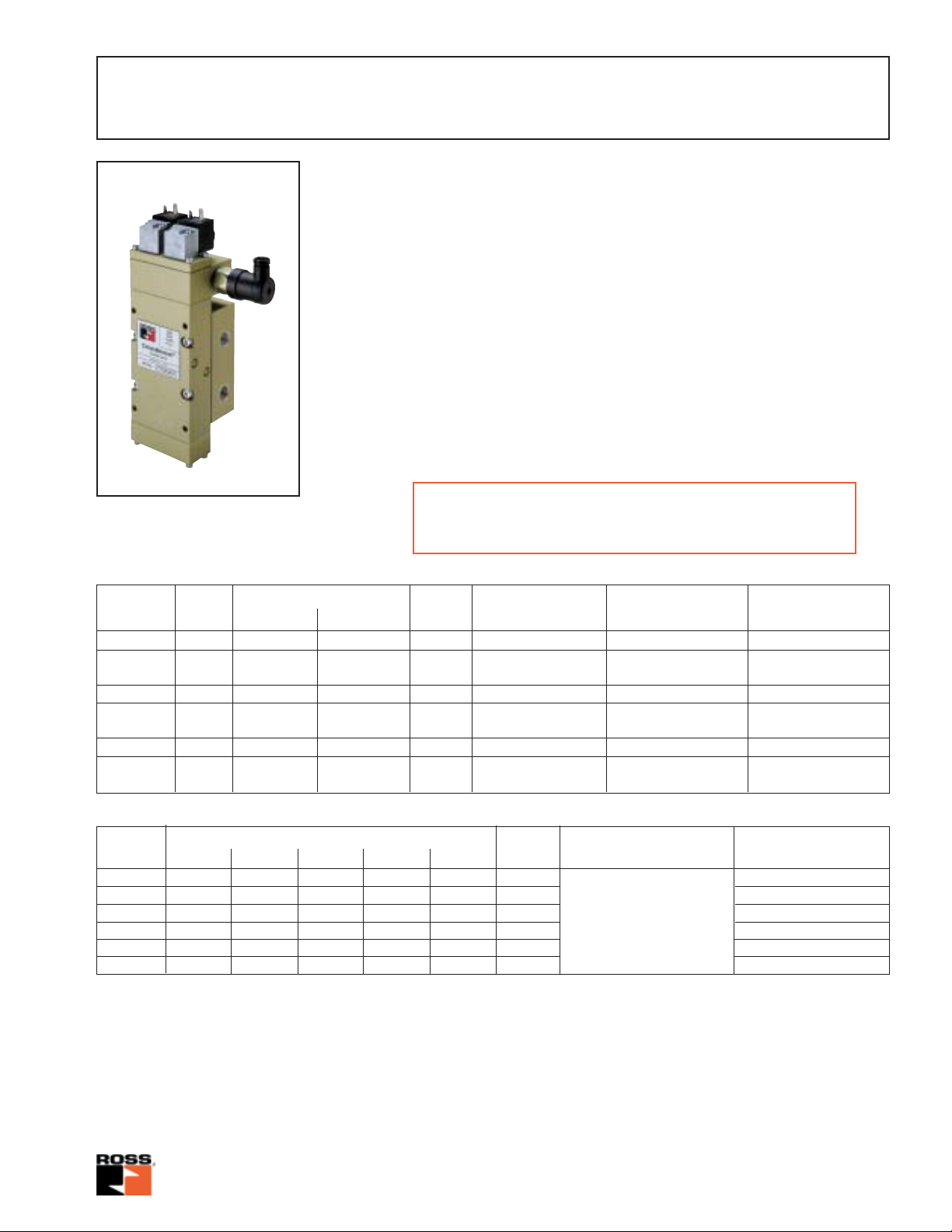

5/2-Way Double V alves

with CROSSMIRROR®-Sensing

SPECIFICATIONS

Design: Metal-to-metal spool-and-

sleeve valves, pressure-operated.

Air and spring returned.

Operation: Solenoid-operated airpiloted valves, 3/2-way-spring-return.

2)

Media

: compressed air,

dehydrated, filtered (5 µm),

lubricated or unlubricated.

Operating pressure: 2,5 to 10 bar.

Temperature range: 4° C to 50° C.

Mounting orientation: preferably

Pilot solenoid: according to VDE 0580.

Enclosure rating acc. to DIN 400 50 IP

65. Connector socket according to DIN

43650 Form A.

Solenoids rated for continuous duty.

Standard voltages:

24 V DC 110 V DC

24 V 50 Hz, 110 V 50 Hz, 230 V 50 Hz;

24 V 60 Hz, 110 V 60 Hz, 240 V 60 Hz.

Power consumption:

DC solenoids - 5,3 W

AC solenoids - 8,5 VA

vertically.

1)

Monitoring

: dynamically, cyclically,

internally.

The double valves listed have been approved by the following testing

and certificating authority:

BG-Fachausschüsse Eisen und Metall III und Hebezeuge II,

Deutschland: Certificate No. 99035

Double Valve

Nominal Size Operating pressure (bar) Weight Type Model Number3)Replacement valve

Diameter min. max. (kg) (with sub-base) (without sub-base)

10 G 3/8 2,5 10 3,8 CM 5/2 D7776A3410 7776A3400

10 G 3/8 2,5 10 3,9 CM 5/2 D7776A3411 7776A3401

with pressure switch

15 G 1/2 2,5 10 4,8 CM 5/2 D7776A4420 7776A4400

15 G 1/2 2,5 10 5,1 CM 5/2 D7776A4421 7776A4401

with pressure switch

15 G 3/4 2,5 10 4,8 CM 5/2 D7776A5410 7776A4400

15 G 3/4 2,5 10 5,1 CM 5/2 D7776A5411 7776A4401

with pressure switch

3)

Sub-base

Nominal Pipe size Weight Design Model Number

Diameter 1 2 3 4 5 (kg) Feature

10 G 1/2 G 3/8 G 3/8 G 3/8 G 3/8 1,1 D996C91

10 1/2 NPT 3/8 NPT 3/8 NPT 3/8 NPT 3/8 NPT 1, 1 996C91

15 G 3/4 G 1/2 G 1/2 G 1/2 G 1/2 1,6 D1049C91

15 3/4 NPT 1/2 NPT 1/2 NPT 1/2 NPT 1/2 NPT 1,6 1049C91

15 G 3/4 G 3/4 G 3/4 G 3/4 G 3/4 1,6 D1153C91

15 3/4 NPT 3/4 NPT 3/4 NPT 3/4 NPT 3/4 NPT 1,6 1153C91

Notes

1) In addition, a pressure-switch-monitored model of this valve is available. In case of a malfunction or pressure failure, the pressure

switch can be used for signaling abnormal operation. Important Note: The pressure switch is not designed to be integrated in a safety

circuitry as its response may be delayed, depending on the type of malfunction.

2) It is recommended to use compressed air, filtered and unlubricated. If lubricated air must be used, we recommend oils conforming to

ISO viscosity classes 32-46 (DIN 51519).

3) When ordering the valve, specify AC or DC voltage and frequency for operating the pilot solenoids (see Specifications above).

Sub-base is equipped

with check valve in

pipe connection 1 and

2/2-way valve as reset

after pressure energy

failure

3www.rosseuropa.com

Page 4

5/2-Way Double V alves

with CROSSMIRROR®-Sensing

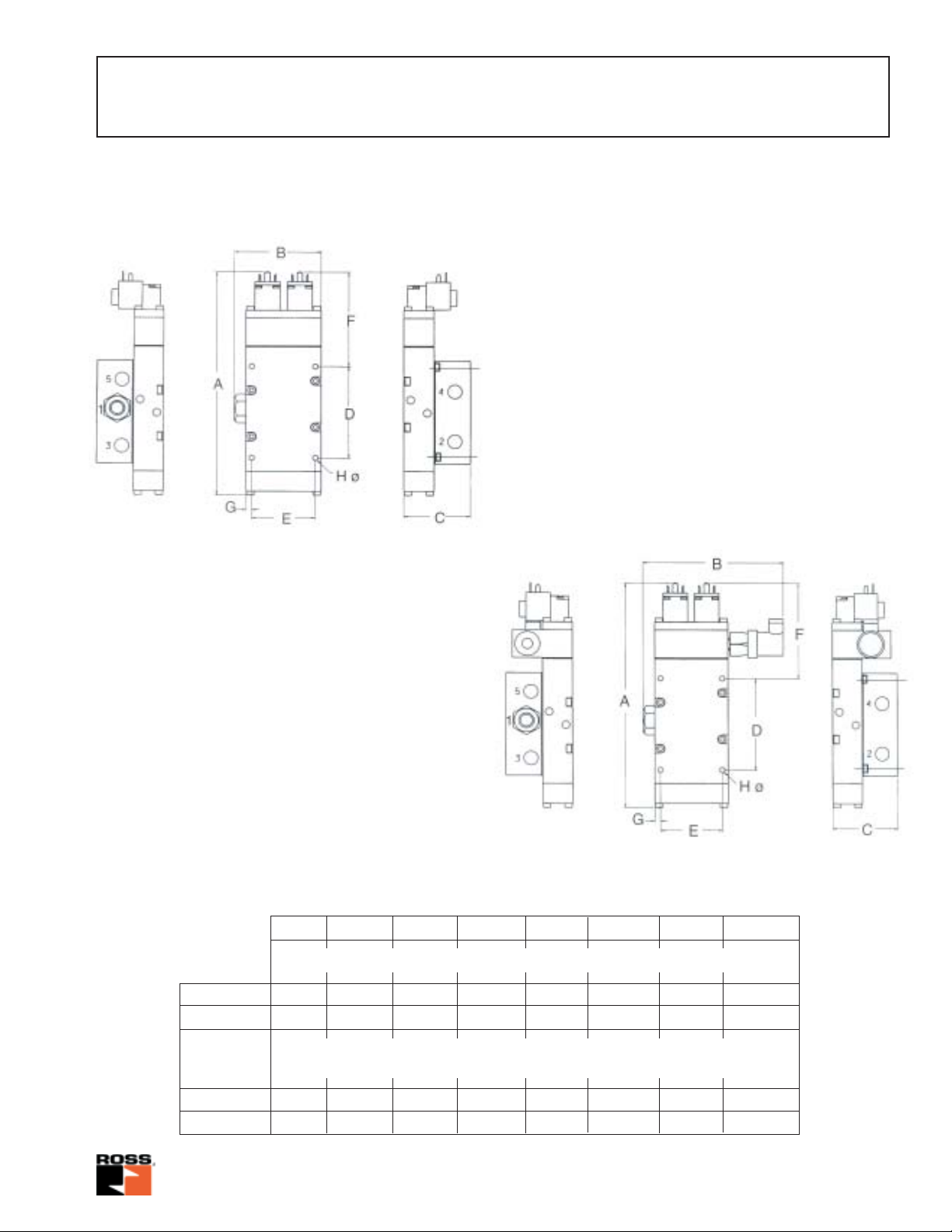

Dimensions –

Valve with ported sub-base

Dimensions –

Valve with ported sub-base and

pressure switch

Dimensional drawings:

Mounting interface sub-base to machine

dimensions: D; E; F; G and H

Dimensions in mm

ND 10 282 104 81 115,6 75 119,5 7 7 or M 6

ND 15 310 108 106 136 81 122 7 7 or M 6

ND 10 282 172 81 115,6 75 119,5 7 7 or M 6

ND 15 310 175 106 136 81 122 7 7 or M 6

ABCDEFGH ø

Double valve with ported sub-base

Double valve with ported sub-base

and pressure switch

4www.rosseuropa.com

Page 5

5/2-Way Double V alves

with CROSSMIRROR®-Sensing

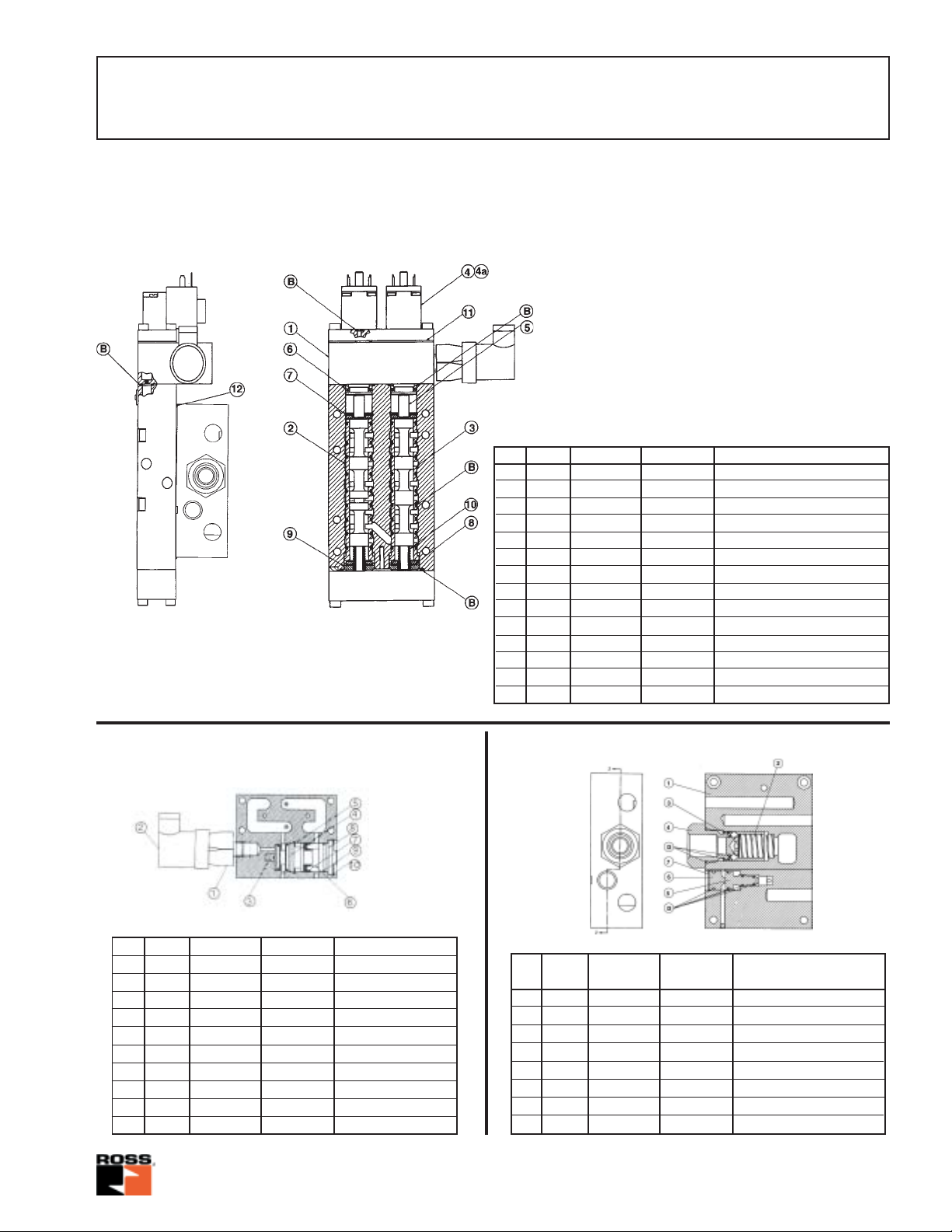

Replacement parts –

Valve with pressure switch

Valve Numbers

7776A3401

7776A4401

Pos. Qty. 7776A3401 7776A4401 Description

1 1 854C89 883C89 Sensing as semb ly

2 1 420H90 418A90 Inlet spool/sleeve

3 1 421H90 419A90 Outlet spool/sleeve

4 2 1044H79 1044H79 Pilot assembly

4a 2 – – Coil

5 2 577A09 603A09 Actuation piston

6 2 583A32 503A32 Seal

7 2 139J22 143J22 Retaining ring

8 4 288A32 289A32 Bumper

9 2 1460A25 1585A25 Spacer

10 2 478A13 497A13 Compression spring

11 1 860A11 886A11 Gasket (pilot-to-body)

12 1 861A11 885A11 Gasket (body-to-sub-base)

B 1 1575K77 1577K77 Seal kit

Pressure switch assembly Sub-base assembly

Pos. Qty. 854C89 883C89 Description

1 1 518E30 518E30 Pressure switch

2 1 522E30 522E30 Connector socket

3 1 207A13 207A13 Spring

4 1 200A97 200A97 Insert assy.

5 1 144J22 144J22 Retaining ring

6 1 580A09 580A09 Piston

7 1 768J32 768J32 U-cup seal

8 1 678B25 678B25 Stem guide

9 1 207J15 207J15 O-Ring

10 1 131J22 131J22 Retaining ring

Pos. D996C91Qty. Description

1 1 D1048B91 D1130B91 Valve body assembly

2 1 488A13 222A13 Spring

3 1 185A88 351A88 Valve poppet assembly

4 1 D332B85 D334B85 Check valve assembly

5 1 147A90 147A90 Spool assembly

6 1 157A85 157A85 Plug assembly

7 1 133J22 133J22 Retaining ring

D 1 1576K77 1578K77 Seal kit

D1049C91

D1153C91

5www.rosseuropa.com

Page 6

Replacement parts –

Valve without pressure switch

Valve Numbers

7776A3400

7776A4400

5/2-Way Double V alves

with CROSSMIRROR®-Sensing

Sub-base assembly

Pos. Qty. 7776A3400 7776A4400 Description

1 1 853C89 884B89 Sensing assembly

2 1 420H90 418A90 Inlet spool/sleeve

3 1 421H90 419A90 Outlet spool/sleeve

4 2 1044H79 1044H79 Pilot valve assembly

4a 2 – – Coil

5 2 577A09 603A09 Actuating piston

6 2 583A32 503A32 Seal

7 2 139J22 143J22 Retaining ring

8 4 288A32 289A32 Bumper

9 2 1460A25 1585A25 Spacer

10 2 478A13 497A13 Compression spring

11 1 860A11 886A11 Gasket (pilot-to-body)

12 1 861A11 885A11 Gasket (body-to-sub-base)

B 1 1575K77 1577K77 Seal kit

Pos. D996C91Qty. Description

1 1 D1048B91 D1130B91 Valve body assembly

2 1 488A13 222A13 Spring

3 1 185A88 351A88 Valve poppet assembly

4 1 D332B85 D334B85 Check valve assembly

5 1 147A90 147A90 Spool assembly

6 1 157A85 157A85 Plug assembly

7 1 133J22 133J22 Retaining ring

D 1 1576K77 1578K77 Seal kit

D1049C91

D1153C91

6www.rosseuropa.com

Page 7

5/2-Way Double V alves

with CROSSMIRROR®-Sensing

Flow characteristics (kv-values)

kv - values

Valve No.: 7776A3400 & 7776A3401

with sub-base D996C91

Inlet G 1/2; Outlet G 3/8

Flow direction Function Function

Normal Abnormal Normal Abnormal

Side „A“ Side „B“ Side „A“ Side „B“

1 to 2 1,8 1,4 1,8 2,78 2,0 2,78

1 to 4 1,5 – – 2,95 – –

2 to 3 1,4 – – 2,34 – –

4 to 5 2,4 1,8 1,8 6,26 3,65 3,13

Valve No.: 7776A4400 & 7776A4401

with sub-base D1049C91

Inlet G 3/4; Outlets G 1/2 - G 3/4

V alve response times

Valve No.: 7776A3400 and 7776A3401 5/2 Nominal diameter 10

7776A4400 and 7776A4401 5/2 Nominal diameter 15

Solenoid operated: 230V / 50Hz

T est pressure: 3; 6 bar

Work ports 2 and 4 are closed without volume.

Response times in ms

Flow direction Pressure 7776A.... 7776A....

3400 3401 3400 3401 4400 4401 4400 4401

3 bar 6 bar 3 bar 6 bar

ENERGIZED 1 to 4 rising 34 40 25 28 47 41 34 35

Normal function 2 to 3 falling 30 34 26 27 45 38 35 31

DE-ENERGIZED 1 to 2 rising 29 44 44 39 61 62 60 60

Normal function 4 to 5 falling 38 39 40 37 59 57 62 62

ENERGIZED

Abnormal function 1 to 2 rising 50 47 53 46 54 59 70 63

Side A

2)

4 to 5 falling 45 50 52 49 50 56 56 57

ENERGIZED

Abnormal function 1 to 2 rising 41 47 46 57 64 56 52 52

3)

Side B

4 to 5 falling 28 54 47 53 61 57 55 67

1)

1) Response time: ENERGIZED - average time required to fill volume to 90% of supply pressure.

DE-ENERGIZED - average time required to exhaust volume to 10% of supply pressure.

2) 3) In case of malfunctions due to differing actuation functions of pilot valves or/and the main v alv e systems of v alv e side A or B.

7www.rosseuropa.com

Page 8

5/2-Way Double V alves

with CROSSMIRROR®-Sensing

GENERAL INFORMA TION

The new ROSS 5/2-way

CROSS MIRROR

®

double

valve is designed as a self-monitoring valve. It can

be used for controlling pneumatic presses for coldforming of metal (optionally in connection with additional devices such as pilot-operated check valves),

if the electric control of the valve is designed in

accordance with prEN..."Pneumatic Presses" (June

1998). The mirror-image-type air flow pattern in the

CROSS MIRROR® double valve allows an alternating

pressure buildup from the de-actuated (pressure

port 1 to work port 2) to the actuated mode (pressure

port 1 to work port 4) only if the following conditions

are fulfilled:

1. The solenoid control signals must actuate the

solenoid pilot valves synchronously or with a time

difference of < 0,5 sec.

2. Both main valve systems must be in the at-rest

position before the valve is actuated.

3. Both main valve systems must have moved into

the actuated position within a defined time span of

< 0,5 sec.

Pressure Switch Unit (optional)

In case of a valve malfunction, the standard valve

shifts back to the at-rest-position; i.e. pressure

from port 1 to port 2. By actuating the valve again,

the cause of the malfunction (dirt or asynchronous

signals) can be eliminated and the valve can

operate normally again. In order to detect such a

malfunction, a valve with pressure switch unit is

available.

This pressure switch unit can be used to signal a

malfunction and to interrupt valve piloting. Properly

wired into the electric circuit, the pressure switch

can prevent a new valve cycle until the malfunction

has been analyzed and eliminated.

Pressure switch unit

Q

O

AB

12

(optional)

N

P5

12

Additional work-safety features are incorporated in

the base:

1 . A check valve in the inlet port prevents the cylinder from falling abruptly when a loss of pressure

occurs. In such a case a small bypass will allow the

cylinder to move gradually into the at-rest-position.

2

. When an unexpected loss of pressure occurs with

the electric pilot signal still being present, another

valve integrated in the sub-base is designed to

prevent any uncontrolled valve shifting and cylinder

movement that might occur when the pressure

returns. In case of a pressure loss this valve opens

the pilot air line and thereby prevents the main valve

system from shifting when pressure returns. All pilot

valves and main valve systems must be in the atrest-position before a restart of the system after a

pressure loss.

OUTLET 4

3

1

2

CHAMBER "A" CHAMBER "B"

2A

EXH. 5

OUTLET 2

A5

A2

A4

A8

A3

A7

A1

A6

1A

AIR SUPPLY

3

1

2

2B

B2

B8

B7

B6

1B

Pressure Port 1

EXH. 3

B4

B3

B1

B5

Sub-base with

pressure failure

monitoring

Schematic

(V alve in the de-actuated position)

8www.rosseuropa.com

Page 9

5/2-Way Double V alves

with CROSSMIRROR®-Sensing

CAUTIONS

Installation

Double valves should be installed only by persons

trained and experienced in the installation of such

equipment.

Lines

Air supply directed through air preparation units and

pressure regulator to pressure por

t 1 requires

minimum line capacity of pressure port 1.

Lines and line connections must be in accordance

with relevant safety regulations, e.g. prEN...

Pneumatic Presses“ (June 1998).

Cylinder speed regulation

When installing components between the double

valve and the work element, the relevant safety

regulations e.g. prEN... Pneumatic Presses“ (June

1998) need to be observed.

Air preparation

An efficient filter unit (at least 5 µm) must be mounted

before the valve. Use of a lubricator is not necessary

if the work element is designed for non-lube

operation.

Silencers

Silencers can be mounted to ports 3 and 5 of the

doub

le valve . These must be in accordance with the

relevant safety regulations, as for instance prEN...

Pneumatic Presses“ (June 1998). Restricting the

exhaust port of a double valve can adversely affect

its proper operation. Silencers must be resistant to

clogging and have a flow capacity larger than the

exhaust capacity of the valve.

Piloting

Electrical piloting of the double valve must be in

accordance with the relevant (application-specific)

safety regulations.

SAFETY-RELEV ANT CAUTIONS:

• The use of surge suppressors in the solenoid

circuits may slow down the de-energisation of the

solenoid coils and thereby may delay response of

the valve elements which may increase exhaust time.

Depending on the application, the electrical

•

connection with the valve may have to be secured

separately.

• In case of machine vibration > 25g a suitable

shock absorbing mounting device has to be provided

for the valve.

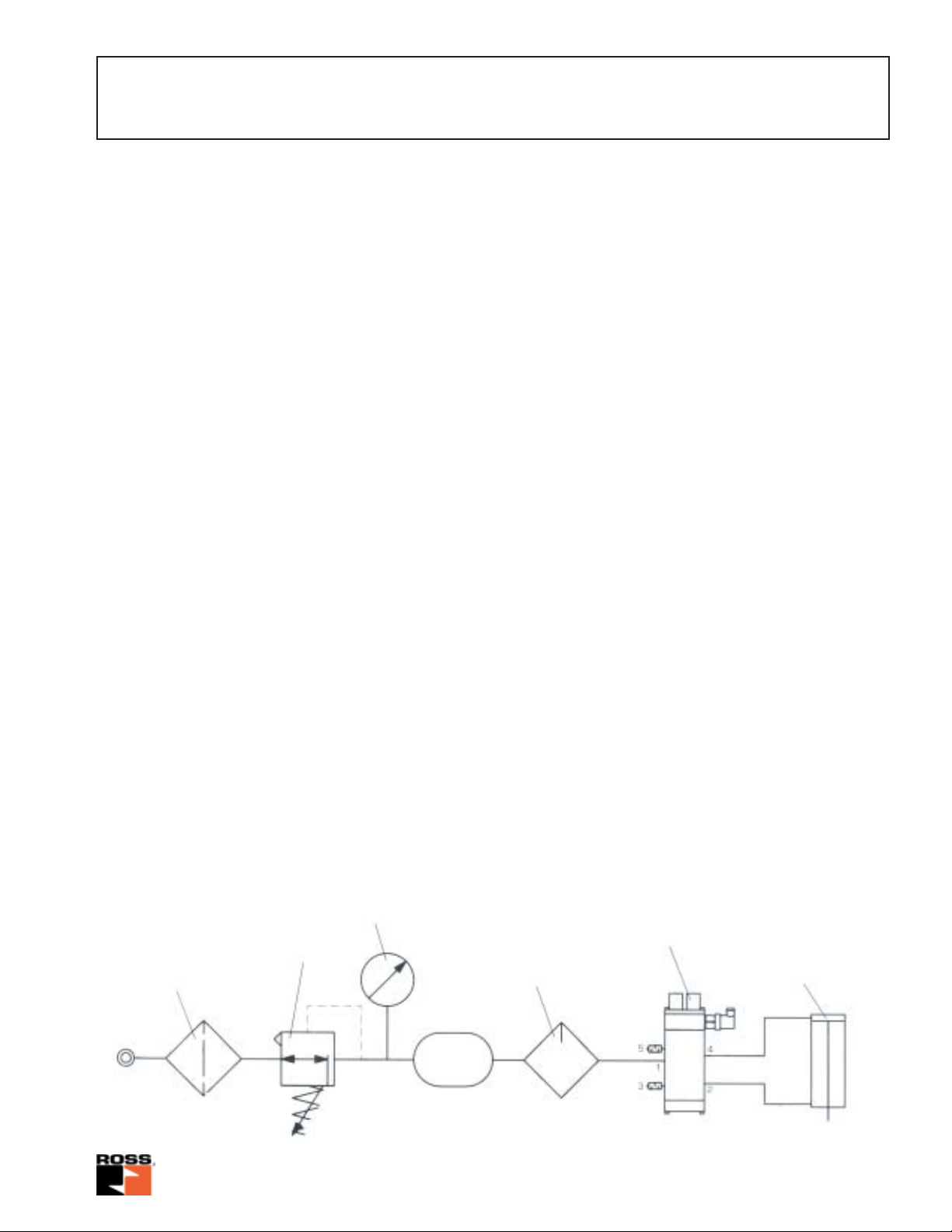

Mounting schematic (example)

Pressure reducing

Filter and

water separator

valve

Pressure gauge

Volume

Lubricator

5/2-CROSSMIRROR

double valve

Pressure switch

®

Double-acting

cylinder

9www.rosseuropa.com

Page 10

5/2-Way Double V alves

with CROSSMIRROR®-Sensing

OPERATING INSTRUCTIONS

Start-up

Prior to start-up, the installation must be checked thoroughly by persons trained and experienced in the

operation of pneumatic equipment. Make sure that the maximum operating pressure specified on the valve

label will not be e

rest-position. For further testing, a functional test as well as a pressure failure test must be performed.

Functional test

T

est Result

1. Actuate solenoid A Piston does not move

2. Actuate solenoid B Piston does not move

3. Actuate solenoid A, then actuate

solenoid B after t > 0,5s Piston does not move

4. Actuate solenoid B, then actuate

solenoid A after t > 0,5s Piston does not move

5. Actuate solenoids A and B after t < 0,5s

then de-energize solenoid A and Piston moves, but returns to at-rest-position after solenoid A

re-actuate after t > 0,5s is de-energized, and remains in that position

6. As under 5., however, test to be

performed with solenoid B See result 5

xceeded. When operating pressure is applied, the cylinder piston must move into the at-

Pressure failure test

The valve is in the at-rest position. T urn off operating

pressure at port 1 and exhaust the operating

pressure line. Actuate the valve in the normal way

(solenoids A and B in t < 0,5s), and keep the

solenoids energized. Then apply operating pressure

to port 1 again. The piston is not supposed to lea ve

its position. For checking the check v alv e in port 1,

close and exhaust the operating pressure line. If

the check valves close properly, the piston will not

move downward quic kly . Depending on the intensity

of usage, the check valves should be checked at

three month’ intervals.

Malfunctions

In case of malfunctions, we recommend to check/

e

xchange the double valve immediately.

Maintenance, testing

Maintenance and testing procedures must follow

the rules and guidelines set by the respective nati-

onal w

should only be performed by persons trained and

experienced in the use of pneumatic equipment. It

is recommended that maintenance and test

procedures be performed at least once a year,

unless otherwise specified.

Repair

It is recommended that double valves which need

to be serviced be handed over to a ROSS service

point. Customers maintaining their own repair

service have to make sure that only original spare

par

Pneumatic equipment should be repaired only by

persons trained and experienced in the repairing of

such equipment, guided by these operating

instructions. Information about valve repair and/or

the exchange of a valve must be written down in

the machine operation documentation.

ork-safety institutions. These procedures

ts (as specified in the ROSS parts lists) be used.

10www.rosseuropa.com

Page 11

with CROSSMIRROR®-Sensing

A

B

Male thread

5/2-Way Double Valves

MUFFL-AIR® -Silencers

Pipe ø k

size value number A B

R 3/8 5,0 D5500A3003 32 96

R 1/2 6,1 D5500A4003 32 96

R 3/4 6,1 D5500A5013 32 96

Cautions

- Model Dimensions - mm

v

PRE-INSTALLATION or SERVICE

1. Before servicing a valve or other pneumatic component, be sure

that the electrical supply is turned off and that the entire pneumatic

system is shut off and exhausted.

2. All ROSS products, including service kits and parts, should be

installed and/or serviced only by persons having training and

experience with pneumatic equipment. Because any installation can

be tampered with or need servicing after installation, persons

responsible for the safety of others or the care of equipment must

check every installation on a regular basis and perform all

necessary maintenance.

3. All applicable instructions should be read and complied with before using any fluid power system in order to prevent harm to persons and/or equipment. In addition, overhauled or serviced valves

must be functionally tested prior to installation and use.

4. Each ROSS product should be used within its specification limits.

In addition, use only ROSS parts to repair ROSS products. Failure

to follow these directions can adversely affect the performance of

the product or result in the potential for human injury.

FILTRATION and LUBRICATION

5. Dirt, scale, moisture, etc. are present in virtually every air sys-

tem. Although some valves are more tolerant of these contaminants

than others, best performance will be realized if a filter is installed to

clean the air supply, thus preventing contaminants from interfering

with the proper performance of the equipment. ROSS recommends

a filter with a 5-micron rating for normal applications.

6. All standard ROSS filters and lubricators with polycarbonate

plastic bowls are designed for compressed air applications only. Do

not fail to use the metal bowl guard, where provided, to minimize

danger from high pressure fragmentation in the event of bowl failure. Do not expose these products to certain fluids, such as alcohol

or liquified petroleum gas, as they can cause bowls to rupture,

creating a combustible condition, hazardous leakage, and the

potential for human injury. Immediately replace a crazed, cracked

or deteriorated bowl. When the bowl gets dirty, replace it or wipe it

with clean dry cloth.

7. Only use lubricants which are compatible with materials used in

the valves and other components in the system. Normally,

compatible lubricants are petroleum base oils with oxidation

inhibitors, an aniline point between 82°C and 104°C, and an ISO 32,

or lighter, viscosity. Avoid oils with phosphate type additives which

can harm polyurethane components, potentially leading to valve

failure and/or human injury.

AVOID INTAKE / EXHAUST RESTRICTION

8. Do not restrict the air flow in the supply line. To do so could re-

duce the pressure of the supply air below the minimum requirements for the valve and thereby cause erratic action.

9. Do not restrict a poppet valve's exhaust port as this can adversely affect its operation. Exhaust silencers must be resistant to clogging and have flow capacities at least as great as the exhaust capacities of the valves. Contamination of the silencer can result in

reduced flow and increased back pressure. ROSS expressly dis-

claims all warranties and responsibility for any unsatisfactory performance or injuries caused by the use of the wrong type, wrong

size, or inadequately maintained silencer installed with a ROSS

product.

DOUBLE VALVES

10. Mechanical power presses and other potentially hazardous ma-

chinery using a pneumatically controlled clutch and brake mechanism must use a press control double valve with a monitoring device. A double valve without a self-contained monitoring device

should be used only in conjunction with a control system which assures monitoring of the valve. All double valve installations involving

hazardous applications should incorporate a monitoring system

which inhibits further operation of the valve and machine in the

event of a failure within the valve mechanism.

11www.rosseuropa.com

Page 12

ROSS

Robert-Bosch-Strasse 2

D-63225 Langen / Germany

Phone: +49-6103-7597-0

Fax: +49-6103-74694

www.rosseuropa.com

EUROPA GmbH

ROSSROSS

ROSS

ROSSROSS

P.O. Box 7015,

Troy, Michigan 48007 U.S.A.

Phone: +1-248-764-1800

Fax: +1-248-764-1850

www.rosscontrols.com

CONTROLS

®

ROSS SOUTH AMERICA Ltda.

Rua Olavo Goncalves, 43/47 - Centro

Sao Bernardo do Campo - Sao Paulo

Brazil - CEP 09725-020

Phone: +55-11-4335-2200

Fax: +55-11-4335-3888

ROSS

Cakemore Road, Rowley Regis,

Warley, West Midlands, B65 OQW

United Kingdom

Phone: +44-121 559 4900

Fax: +44-121 559 5309

www.rossuk.com

UK Ltd.

ROSS

10209-5 Tana, Sagamihara-shi

Kanagawa-pref. 229-11, Japan

Phone: +81-427-78-7251

Fax: +81-427-78-7256

www.rossasia.co.jp

ASIA K.K.

ROSS ASIA K.K.-

CHINA LIAISON OFFICE

ROSS CONTROLS INDIA Pvt. Ltd.

Plot 113, Industrial Estate

Ambattur

Chennai 600 058, India

Phone: +91-44-8413136

Fax: +91-44-8413137

www.rossindia.com

Room 701, Taiji Building,

No. 33.1249 Street

Xikang Road

Shanghai, China

Phone: +86-21-6296-5123

Fax: +86-21-6299-0529

W ARRANTY

Products manufactured by ROSS are warranted to be free of defects in material and workmanship for a period of one year

from the date of purchase. ROSS' obligation under this warranty is limited to repair or replacement of the product or refund

of the purchase price paid solely at the discretion of ROSS and provided such product is returned to ROSS freight prepaid

and upon examination by ROSS is found to be defective. This warranty shall be void in the event that product has been

subject to misuse, misapplication, improper maintenance, modification or tampering. The warranty expressed above is in

lieu of and exclusive of all other warranties and ROSS expressly disclaims all other warranties either expressed or implied with respect to merchantability or fitness for a particular purpose. ROSS makes no warranty with respect to its products meeting the provisions of any governmental occupational safety and/or health laws or regulations. In no event shall

ROSS be liable to purchaser, user, their employees or others for incidental or consequential damages which may result

from a breach of the warranty described above or the use or misuse of the products. No statement of any representative

or employee of ROSS shall extend the liability of ROSS as set forth herein.

Printed in Germany 11-2003 Form No. RE-E-A 10200

12www.rosseuropa.com

Page 13

PRODUCT DATA SHEET INFORMATION

environment

safety

e

technology

productivity

5/2 CROSSMIRROR® Series 77

Solenoid Pilot Controlled Pneumatic Double Valve

Control Reliable Energy Isolation

• Self-contained dynamic monitoring system requires no additional valve

monitoring controls

• Base mounted, stainless steel spool valve construction

• Status indication switch (ready-to-run) to inform machine controller of valve

condition; MUST be integrated into machine controls in order to prevent run

signal until fault is cleared in valve

• Applications include small size pneumatic cylinder-operated presses, valve

operators, and safety latches

ISO 13849-1:2006 Category 4

PL e applications

• Base mounted, stainless steel spool valve construction

• Sistema library data available (consult ROSS or visit the Safety industry page at

www.rosscontrols.com)

• Explosion proof solenoid pilot available, for more information consult ROSS

Cylinder Return to

Ordering Information

Valve Size 2

Model* Port Sizes CV Pressure Dimensions inches (mm) Weight Replacements*

Number 1 2, 3 , 4 , 5 1-2 1-4 2-3 4-5 Switch A B C lb (kg) Valve No. Base No.

7776A3410 1/2 3/8 2.0 1.6 1.6 2.8 Without 11.1 (282) 4.1 (104) 3.2 (81) 7.6 (3.4) 7776A3400 996C91

7776A3411 1/2 3/8 2.0 1.6 1.6 2.8 With• 11.1 (282) 6.7 (170) 3.2 (81) 8.4 (3.8) 7776A3401 996C91

* Model number includes base supplied with NPT threads. For BSPP threads, order model or base with a “D” prefix, e.g., D7776A3410, D996C91.

• For pressure switch option, order model or v alve with a “Z” suffix for 110 volts AC or “W” suffix for 24 volts DC , e.g., 7786A3411Z, 7776A3401Z.

Valve Size 4

7776A4420 3/4 1/2 3.2 3.4 2.7 7.2 Without 12.1 (307) 4.3 (109) 4.1 (104) 10.2 (4.6) 7776A4400 1049C91

7776A4421 3/4 1/2 3.2 3.4 2.7 7.2 With• 12.1 (307) 6.9 (175) 4.1 (104) 11.2 (5.1) 7776A4401 1049C91

7776A5410 3/4 3/4 3.2 3.4 2.7 7.2 Without 12.1 (307) 4.3 (109) 4.1 (104) 10.2 (4.6) 7776A4400 1153C91

7776A5411 3/4 3/4 3.2 3.4 2.7 7.2 With• 12.1 (307) 6.9 (175) 4.1 (104) 11.2 (5.1) 7776A4401 1153C91

* Model number includes base supplied with NPT threads. For G threads, order model or base with a “D” prefix, e.g., D7776A4420, D1049C91.

• For pressure switch option, order model or valve with a “Z” suffix for 110 volts AC or “W” suffix for 24 volts DC, e.g., 7776A4421W, 7776A4401W.

Valve Size 4 SAE

S7776A4H10 SAE 12 SAE 12 3.2 3.4 2.7 7.2 Without 12.1 (307) 4.3 (109) 4.1 (104) 10.2 (4.6) 7776A4400 1159G91

S7776A4H11 SAE 12 SAE 12 3.2 3.4 2.7 7.2 With• 12.1 (307) 6.9 (175) 4.1 (104) 11.2 (5.1) 7776A4401 1159G91

* Model number includes base. • For pressure switch option, order model or valve with a “Z” suffix for 110 volts AC or “W” suffix for 24 volts DC, e.g.,

S7776A4H11Z, 7776A4401Z.

B

Standard Specifications

Pilot

Pilot Solenoids: Rated for continuous duty.

A

Standard Voltages: 100-110 volts, 50 Hz; 100-120 volts, 60 Hz;

24 volts DC; 110 volts DC. For other voltages, consult ROSS.

Power Consumption: Each solenoid, 18 VA inrush, 14 VA

holding on 50 or 60 Hz; 6 watts on DC.

Electrical Connections: Uses cord-grip connectors at solenoids.

Order connectors separately, see accessories.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Flow Media: Filtered air; 5 micron recommended.

Inlet Pressure: 40 to 150 psig (2.5 to 10 bar).

Media Temperature: 40° to 175°F (4° to 80°C).

This valve is not designed for use in power press clutch/brake applications.

C

Base

Valve

Chambers

1

Air Supply

5

2

Home Position

Pressure

Switch

Pilot

Valve

Base

4

3

Designing toward

Zero-Harm.

Designing to

maximize return

on investment.

Designing to save

energy and reduce

greenhouse gases.

Designing to optimiz

reduction processes

and applications.

Page 14

PRODUCT DATA SHEET INFORMATION

5/2 CROSSMIRROR® Series 77

Two-Hand Pressure Controlled Pneumatic Double Valve

Control Reliable Energy Isolation

This Series 77 5/2 CrossMirror® valve is a control reliable, two hand pressure controlled 4-way

double valve that is controlled by two separate pneumatic signals essentially providing “AND”

gate control for the output ports. Both pilot signals must be provided within approximately 500

milliseconds of each other to actuate the valve.

Proper actuation shifts output pressure to port 4. If the valve is not actuated, not provided

appropriate pneumatic signals within the discordance window or if the valve actuates abnormally,

inlet pressure will only be passed to port 2 - cylinder retracted.

This valve is constructed with precision, stainless steel spools as the main valve elements, and

is designed to offer added safety to the operation of many pneumatically controlled machines.

• Requires two inputs within 500 ms

• Self-contained dynamic monitoring system requires no additional valve monitoring controls

• Senses asynchronous inputs via status indicator switch

• Status indication switch available to be integrated with electrical safety control system where

available

• Applications include small size pneumatic cylinder-operated presses, valve operators,

and safety latches

• Base mounted, stainless steel spool valve construction

• Sistema library data available (consult ROSS or visit the Safety industry page at

www.rosscontrols.com)

ISO 13849-1:2006 Category 4

PL e applications

APPLICATIONS: Pneumatic cylinder applications.

• Tw o hand control EN574 Type III C

• Pinch point applications

• Shearing equipment

• Forming applications

• Cutting applications

• Clamping applications

Cylinder Return to

Home Position

VALVE OPERATION

Normal Operation:

After installation the valve is operated by pressurizing both pilot supply ports (S1 and S2) simultaneously. This causes both main

valve elements to be actuated so that air from inlet port 1 flows to outlet port 4. Air downstream of port 2 is exhausted through port 3.

When the pilot supply ports are de-pressurized, both valve elements are de-actuated, and air then flows from inlet port 1 to outlet

port 2. Air downstream of port 4 is exhausted through port 5.

Safety Function:

If the two main valve elements are not actuated or de-actuated synchronously, within 500ms , the v alve def aults so that outlet port

2 receives full inlet pressure, and outlet port 4 is exhausted through port 5. If this abnormal operation is the result of a temporary

circumstance, the valve will be ready to resume normal operation as soon as both pilot signal ports have been de-pressurized and

both main valve elements hav e returned to their normal ready-to-run position. Applying pressure to both signal ports simultaneously

will resume normal operation.

If the cause of the abnormal operation is still present, the valve will either remain in the default position (pressure on port 2 and

not port 4) or will again go into this position on the next actuation attempt. The source of the abnormality must be investigated

and corrected before further operation.

Pressure Switch:

Valv es with model numbers ending in the n umber 1 hav e a pressure s witch to provide user f eedback when mo vement of the main

valve elements was asynchronous.

This valve is not designed for use in power press clutch/brake applications.

www.rosscontrols.com

Page 15

Ordering Information

A

Valve Size 2

Model* Port Sizes CV Pressure Dimensions inches (mm) Weight Replacements*

Number 1 2, 3, 4, 5 1-2 1-4 2-3 4-5 Switch A B C lb (kg) Valve No. Base No.

7786A3410 1/2 3/8 2.0 1.6 1.6 2.8 Without 10.9 (277) 4.1 (104) 3.2 (81) 7.6 (3.4) 7786A3400 996C91

7786A3411 1/2 3/8 2.0 1.6 1.6 2.8 With• 10.9 (277) 6.7 (170) 3.2 (81) 8.4 (3.8) 7786A3401 996C91

* Model number includes base supplied with NPT threads. For G threads, order model or base with a “D” prefix, e.g., D7786A3410, D996C91

• For pressure switch option, order model or v alve with a “Z” suffix for 110 volts AC or “W” suffix for 24 volts DC , e.g., 7786A3411Z, 7786A3401Z .

Valve Size 4

7786A4420 3/4 1/2 3.2 3.4 2.7 7.2 Without 12.1 (307) 4.3 (109) 4.1 (104) 10.6 (4.6) 7786A4400 1049C91

7786A4421 3/4 1/2 3.2 3.4 2.7 7.2 With• 12.1 (307) 6.9 (175) 4.1 (104) 11.6 (5.1) 7786A4401 1049C91

7786A5410 3/4 3/4 3.2 3.4 2.7 7.2 Without 12.1 (307) 4.3 (109) 4.1 (104) 10.6 (4.6) 7786A4400 1153C91

7786A5411 3/4 3/4 3.2 3.4 2.7 7.2 With• 12.1 (307) 6.9 (175) 4.1 (104) 11.6 (5.1) 7786A4401 1153C91

* Model number includes base supplied with NPT threads. For G threads, order model or base with a “D” prefix, e.g., D7786A4420, D1049C91.

• For pressure switch option, order model or valve with a “Z” suffix for 110 volts AC or “W” suffix for 24 volts DC, e.g., 7786A4421W, 7786A4401W.

Valve Size 4 SAE

S7786A4H10 SAE 12 SAE 12 3.2 3.4 2.7 7.2 Without 12.1 (307) 4.3 (109) 4.1 (104) 10.6 (4.6) 7786A4400 1159G91

S7786A4H11 SAE 12 SAE 12 3.2 3.4 2.7 7.2 With• 12.1 (307) 6.9 (175) 4.1 (104) 11.6 (5.1) 7786A4401 1159G91

* Model number includes base.

• For pressure switch option, order model or valve with a “Z” suffix for 110 volts AC or “W” suffix for 24 volts DC, e.g.,S7786A4H11Z, 7786A4401Z.

B

C

Standard Specifications

Ambient Temperature:

Typical 2-Hand-Anti-Tie-Down Application

Customer

Supplied

3/2 Valve

Customer

Supplied

3/2 Valve

40° to 120°F (4° to 50°C).

Media Temperature:

40° to 175°F (4° to 80°C).

Flow Media:

Filtered air; 5 micron recommended.

Inlet Pressure:

40 to 100 psig (2.5 to 7 bar).

Pilot Pressure:

Must be equal or greater than inlet pressure, but should not

exceed maximum inlet pressure.

CROSSMIRROR

Control Reliable

Pneumatic 5/2 “AND” Gate

®

S1 S2

5

1

3

Customer

Supplied

4

2

Cylinder

Pressure Switch Rating:

Max Current 4A, Max 250 volts AC .

Max Current 50 mA, Max 24 volts DC.

Pressure Switch: Pressure Switch signal indicates when

the input signals or parts movement is asynchronous.

Status Indicator (pressure switch)

Terminals 1 and 4 are connected when air pressure is

present and the valve is “Ready-to-Run”. If an abnormal

operation has occured or pressure is removed from the

valve inlet, terminals 1 and 2 are connected.

Note: DC voltage pressure switches do not have a

ground terminal.

Pin 1: Common

Pin 2: Normally Closed

Pin G: Not used

Pin 4 : Normally Open

www.rosscontrols.com

Page 16

ACCESSORIES

ELECTRICAL CONNECTORS

Electrical connectors are required to connect the valve solenoids to the drop cords supplying electrical

power.

Each connector can be positioned so that the cord exits upward or to the side. Cords of 6 mm to 10 mm

diameter can be used. Connectors with a light in a translucent housing are also available to serve as

indicator lights. Order connectors by the part numbers given in the chart below.

WIRED CONNECTORS have a 2 meter (6½ ft) cord with three 18 gauge conductors. Cord exits upw ard,

and is available in either 6 mm or 10 mm diameter.

CONNECTORS for THREADED CONDUIT accept 1/2 inch electrical conduit fittings.

Model Numbers of Electrical Connectors

Connector Type Without Light With Light*

For use with dropcord

(Cord not included)

Wired with 6-mm cord 721K77 720K77*

Wired with 10-mm cord 371K77 383K77*

937K87 936K87*

CAUTION:

Do not use electrical connectors with surge suppressors, as

this may increase valve response time when de-actuating

the solenoids.

For use with threaded conduit 723K77 724K77*

Service Kits for Two-Hand Pressure Controlled Valves

Valve Valve Body Valve Body Base Pressure Switch Pressure Pressure

Valve Model Seal and Gasket Service Kit Service Kit Assembly Service Switch Switch Connector

Size Number Kit Model Number Model Number Model Number Kit Model Number Model Number Model Number

7786A3400 2216K77 2218K77 1694K77 N/A N/A N/A

2

7786A3401 2216K77 2218K77 1694K77 1696K77 AC - 518E30 522E30

DC - 798E30

7786A4400 2217K77 2219K77 1695K77 N/A N/A N/A

4

7786A4401 2217K77 2219K77 1695K77 1696K77 AC - 518E30 522E30

DC - 798E30

COMPANY INFORMATION

Your local ROSS distributor is:

In 1954 ROSS patented the first double valve for

the most demanding of safety applications: metal

forming press clutch and brake control. Since that

time, ROSS has patented several improved versions

of the double valve and expanded its safety product

offering. ROSS has become recognized as the

premier supplier of high-quality pneumatic and

hydraulic safety components for various applications

in metal forming and other industries.

ROSS CONTROLS

Customer Svs. 1-800-GET-ROSS

Technical Svs. 1-888-TEK-ROSS

ROSS EUROPA GmbH

Germany

Fax: 49-6103-74694

info@rosseuropa.com

Printed in the U.S.A. – Rev. 12/12 © 2012 ROSS CONTROLS®. All Rights Reserved. Form NPS005

ROSS ASIA

Fax: 81-427-78-7256

custsvc@rossasia.co.jp

U.S.A.

www.rosscontrols.com

®

K.K.

Japan

®

ROSS UK Ltd.

United Kingdom

Fax: 44-121-559-5309

sales@rossuk.co.uk

ROSS CONTROLS

India

Fax: 91-44-2625-8730

rossindia@airtelmail.in

WARRANTY and CAUTIONS

Standard ROSS warranty and cautions apply, available upon

request or at www.rosscontrols.com

®

INDIA Pvt. Ltd.

ROSS SOUTH AMERICA Ltda.

Brazil

Fax: 55-11-4335-3888

vendas@ross-sulamerica.com.br

DIMAFLUID s.a.s.

France

Fax: 33-01-4945-6530

dimafluid@dimafluid.com

ROSS CONTROLS

(CHINA) Ltd.

China

Fax: 86-21-6915-7960

alvinzhurong@vip.163.com

Loading...

Loading...