Page 1

DM

1

Series E

New Product

Introduction

Simplified

Schematic

Port Size C

Model Number* In-Out Exh. In-Out Out-Exh. lb (Kg)

DM1ENA20**31 1/4 1/2 1.34 2.43 5.0 (2.27)

DM1ENA21**31 3/8 1/2 1.92 2.43 5.0 (2.27)

* NPT port threads. For BSPP threads , replace “N” in the model

number with a “D”.

** Insert voltage code: “A” = 24 volts DC, “B” = 110 volts AC,

“C” = 220 volts AC, “D” = 12 volts DC.

V

Weight

Control Reliable

Double Valve

with Dynamic Monitoring

Size 2

This valve is not designed for controlling clutch/brake mechanisms on mechanical power presses.

FEATURES:

Dynamic Monitoring:• Monitoring and air flow control functions are integrated into two identical valve elements

for CAT 3 applications. The valve exhausts downstream air if asynchronous movement of valve elements occurs

during actuation or de-actuation, resulting in a residual outlet pressure of less than 1% of supply. If the abnormality

clears itself, the valve will return to the ready-to-run state; there is no memory of the abnormal behavior, as in

ROSS’ DM

Basic 3/2 Normally Closed Valve Function:• Dirt tolerant, wear compensating poppet design for quick response

and high flow capacity. Teflon back-up rings on pistons to enhance valve endurance – operates with or without

inline lubrication.

Ready-to-run:• If an abnormality clears itself upon the removal of electricity to both solenoids, it will be ready-to-

run again. It does not remember the abnormality & stay in a locked-out state until intentionally reset. Therefore,

cumulative abnormalities may go undetected.

Status Indicator:• The above products include a pressure switch with both NO & NC contacts to provide status

feedback to the control system indicating whether the valve is in the “ready-to-run” condition or has experienced

abnormal function. This indicator only reports status it is not part of a lockout function.

Silencers:• All models include high flow, clog resistant silencers.

Mounting:• Inline mounted – with BSPP or NPT pipe threads. Inlet and outlet ports on both sides provide for

flexible piping (plugs for unused ports included).

2®

Series E and DM

2®

Series C products that require an intentional reset following lockout.

APPLICATIONS:

Category 3 applications - e.g. Air Dump/Release.

www.rosscontrols.com

Page 2

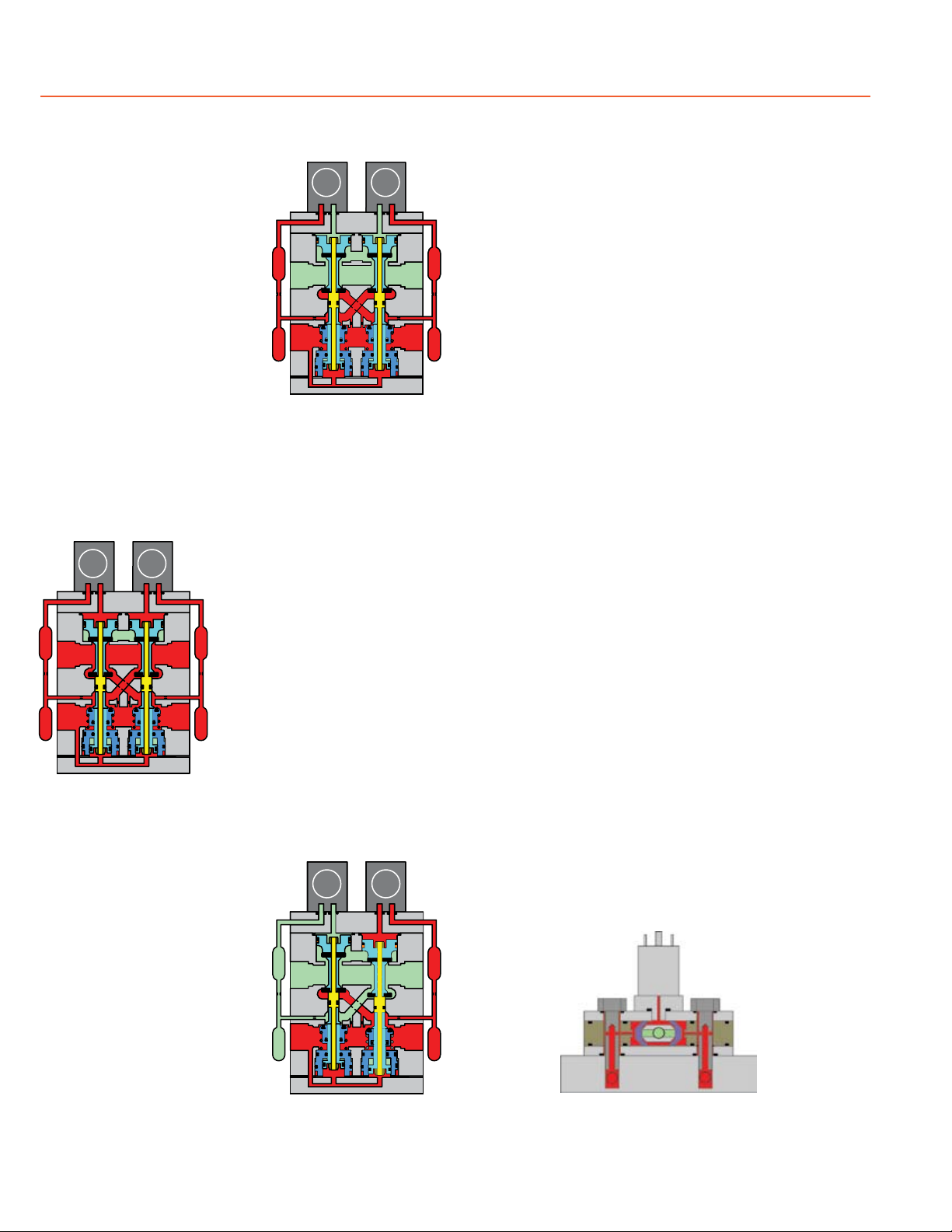

Overview of DM1 Series E Double Valve Function

.004

.004

.004

B

A

EXHAUST

OUTLET

INLET

B

A

EXHAUST

OUTLET

INLET

B

A

EXHAUST

OUTLET

INLET

Valve de-actuated

(ready-to-run):

The flow of inlet air pressure

into the crossover passages

fr om the i nlet cha mber is

restricted by orifices that allow

air pressure to bypass the lower

inlet poppets. Flow is sufficient

to quickly pressurize the pilot

supply/timing chambers on both

sides A and B. The upper inlet

poppets prevent air flow from

the crossover passages into the

outlet chamber. Air pressure

acting on the inlet poppets and

return pistons securely hold

the valve elements in the deactuated position. (Internal air

passages shown out of the valve

body for clarity.)

Valve actuated:

Energizing the pilot solenoids

simultaneously applies pressure

to both pistons, forcing the

internal parts to move to their

actuated position, where inlet

air flow to outlet is open and

both exh aust poppets are

closed. The outlet is then quickly

pressurized, and pressure in

the inlet, crossovers, outlet, and

timing chambers are quickly

equalized. De-energizing the

main solenoids causes the valve

Valve actuated.

elements to return to the readyto-run (de-actuated) position.

Asynchronous operation:

If the valve elements operate

in a sufficiently asynchronous

manner on ACTUATION, the

valve will shift into a position

where one crossover and its

related timing chambers will

be exhausted, and the other

crossover and its related timing

chambers will be pressurized.

In the illustration, side B is in the

de-actuated position, but has

no pilot air available to actuate

with and has full pressure on its

Valve ready-to-run.

Valve in restricted outlet

to exhaust state.

upper and lower inlet poppets and return piston to hold it in

place. Inlet air flow on side B into its crossover is restricted

and flows through the open upper inlet poppet on side A,

through the outlet into the the exhaust port, and from the

exhaust port to atmosphere. Residual pressure in the outlet

is less than 1% of inlet pressure.

Once the main solenoids are de-energized, actuating pressure

is removed from the top of the main pistons and then the

lower inlet poppet return spring along with inlet air pressure

acting on the side A return piston will push side A back into

the de-actuated position. Inlet air pressurizes the crossovers

and volume chambers. Pressure in the crossovers helps

hold the upper inlet poppets on seat. The valve will then be

in the ready-to-run position. On the next attempt to actuate

normally, if side B is still unable to actuate synchronously

with side A, the same sequence of events described above

will occur again.

WARNING:

If asynchronous operation occurs while DE-ACTUATING,

the pilot supply/timing chambers on one side will still be

exhausted as described above. However, this could be a

temporary situation because the cause of the asynchronous

operation may be able to correct itself allowing the stuck or

slow acting side of the valve to eventually move back into

the de-actuated position. Once the slow or stuck side has

de-actuated, the pilot supply/timing chambers that were

exhausted will then repressurize. If an external monitoring

system is only checking the status indicator periodically this

fault signal could be missed. The machine’s safety system

must be designed to ensure that this does not cause a

hazardous situation.

Status indicator:

The status indicator pressure switch will actuate when the

main valve is operating normally, and will de-actuate when

the main valve operation is sufficiently asynchronous or inlet

pressure is removed. This device is not part of the valve

lock-out function, but, rather, only reports the status of the

main valve.

Status indicator in normal

ready-to-run position.

ROSS CONTROLS

®

Page 3

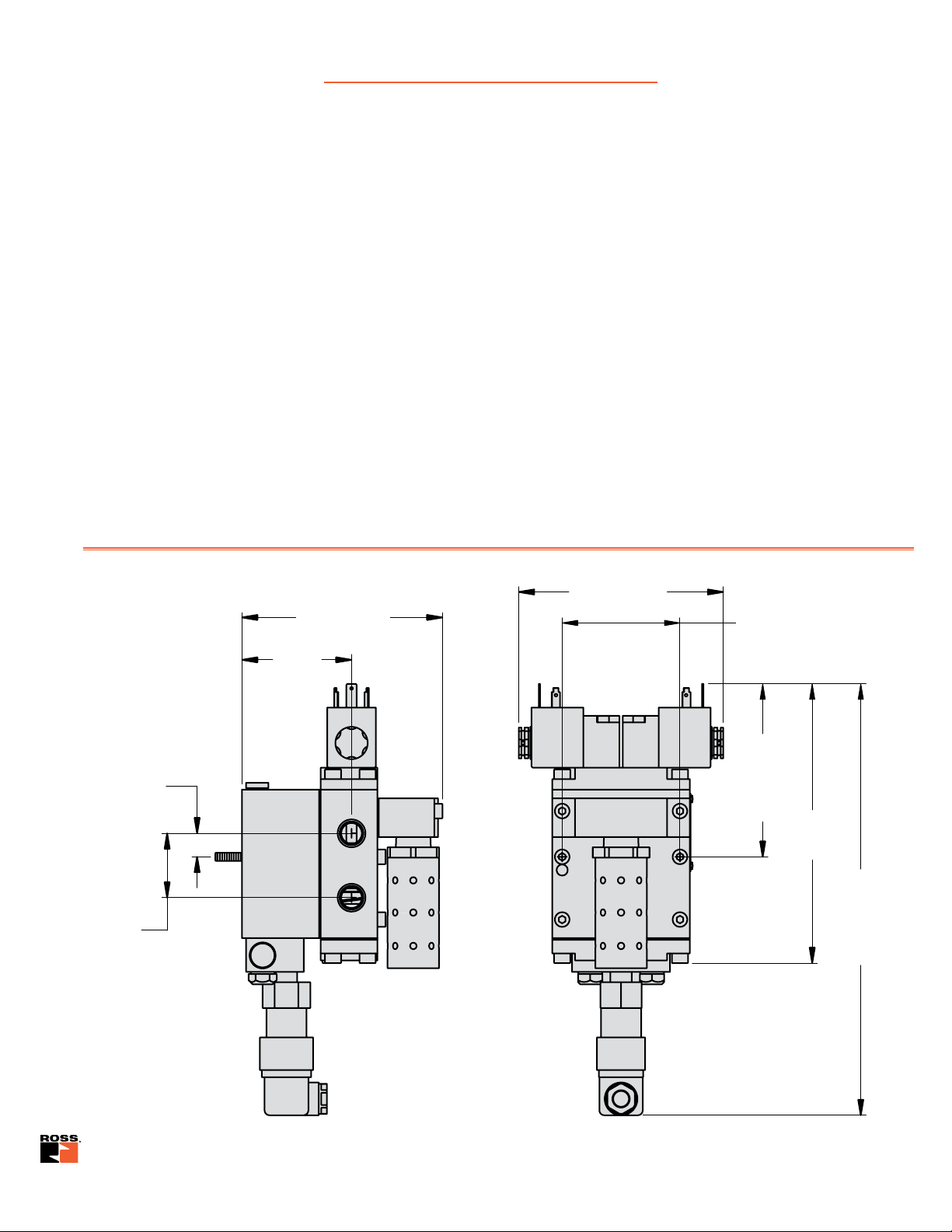

STANDARD SPECIFICATIONS

1

2

4.87 (123.6)

2.66

(67.6)

.57

(14.5)

1.56

(40.0)

4.96 (126.1)

2.87 (72.6)

Valve Mounting Pattern

4.20

(106.6)

Valve

Mounting

Pattern

6.77

(172.0)

10.46

(265.7)

with

Status

Indicator

Pilot Solenoid Power Consumption (each solenoid): 6.0 watts on DC; 15.8 VA inrush and

10.4 VA holding on AC.

Solenoids: According to VDE 0580. Enclosure rating according to DIN 400 50 IP 65.

Connector socket according to DIN 43650 Form A. Three solenoids, rated for continuous duty.

Standard Voltages: 110 volts AC, 50/60 Hz; 24 volts DC.

Temperature Range:

Ambient: 15° to 122°F (4° to 50°C).

Media: 40° to 175°F (4° to 80°C).

Flow Media: Filtered (5 micron recommended), lubricated or unlubricated air (mineral oils

according to DIN 51519, viscosity classes 32-46).

Inlet Pressure: 30 to 116 psig (2 to 8 bar).

Pressure Switch (Status Indicator) Rating: Contacts - 5 amps at 250 volts AC, or 5 amps at

30 volts DC.

DIMENSIONS – inches (mm)

www.rosscontrols.com

Page 4

ACCESSORIES

ELECTRICAL CONNECTORS

Wired connectors have a 2-meter (6½ ft) cord with three

18-gauge conductors. Cord is available in either 6-mm

or 10-mm diameter and with or without indicator light.

Without Light With Light 24 VDC With Light 110 VAC

Wired with 6-mm cord 721K77 720K77-W 720K77-Z

Wired with 10-mm cord 371K77 383K77-W 383K77-Z

For threaded conduit 723K77 724K77-W 724K77-Z

For use with drop cord 937K87 936K87-W 936K87-Z

(cord not included)

For additional wiring kit accessories, please see Form NPS011 available at

www.rosscontrols.com.

Company Information

STATUS INDICATOR

The Status Indicator pressure switch

actuates when the valve is in a ready-to-run

condition and de-actuates

when the valve is in a

lockout condition or when

the inlet air pressure has

been removed.

Although, the valves can

be purchased with this

option already installed,

the Status Indicator can

be purchased separately

by ordering part number:

Y670B94.

ROSS EUROPA GmbH

Germany

Fax: 49-6103-74694

info@rosseuropa.com

Since 1921 ROSS CONTROLS® has been manufacturing the highest quality

pneumatic valves. Founded by three families and still privately held, Ross has

grown from a small Michigan valve company into a company with global subsidiaries

and distribution throughout the world. It is this global presence that allows Ross

to focus on specific industries and provide the support required in our integrated

world. Ross continues to lead in industries such as safety by providing products to

meet or exceed the specific requirements of those industries as well as the global

standards.

Our global safety team can assist with system and product selection and provide

solutions that help customers standardize globally.

ROSS CONTROLS

Customer Svs. 1-800-GET-ROSS

Technical Svs. 1-888-TEK-ROSS

ROSS ASIA

Fax: 81-427-78-7256

custsvc@rossasia.co.jp

U.S.A.

www.rosscontrols.com

®

K.K.

Japan

®

ROSS UK Ltd.

United Kingdom

Fax: 44-121-559-5309

sales@rossuk.co.uk

WARRANTY and CAUTIONS

Standard ROSS warranty and cautions apply, available upon request or at

www.rosscontrols.com.

®

ROSS CONTROLS

Fax: 91-44-2625-8730

rossindia@airtelbroadband.in

INDIA Pvt. Ltd.

India

ROSS SOUTH AMERICA Ltda.

Brazil

Fax: 55-11-4335-3888

vendas@ross-sulamerica.com.br

DIMAFLUID s.a.s.

France

Fax: 33-01-4945-6530

dimafluid@dimafluid.com

ROSS CONTROLS

Fax: 86-21-6915-7960

alvinzhurong@vip.163.com

(CHINA) Ltd.

China

Printed in the U.S.A. – Rev. 05/09 © 2009 ROSS CONTROLS®. All Rights Reserved. Form NPS006

Loading...

Loading...