Page 1

BULLETIN 505

BULLETIN 505

2

®

2

DM

DM

3/2 Double Valves

3/2 Double Valves

with Dynamic Monitoring &

Dynamic Memory

Kupplung/Bremse

Embreagem/Freio

®

Series D

Series D

クラッチ/ブレーキ

Iaktk@ xfrjks/kd

离合器/制动器

• Manufacturers of Premium Pneumatic Controls since 1921 •

Page 2

DM

Table of Contents

2®

Series D Double Valves

General Information

Page 3 - 4

Ordering Information

Valve Dimensions

Overview of DM2® Series D

Double Valve

Flow Information

Operating Instructions

Repair Kits

Accessories

Cautions/Warranty

Page 5

Page 6 - 7

Page 8 - 9

Page 10 - 11

Page 12

Page 13

Page 14

Page 15

The Leader in Double Valve Design

ROSS has long been in the forefront of

double valve research and development.

For over 60 years ROSS has been responding to the needs of press manufacturers and

users by progressively improving double

valve technology. Internal flow patterns of

double valves developed by ROSS have

included series flow, parallel flow, combined

series-parallel tandem flow, and combined

series-parallel Crossflow

Monitoring devices have also been offered

in a variety of designs to satisfy differing

requirements. Traditionally, in order to

achieve complete monitoring capability,

it has been necessary to add devices or

components to the valve or to the control

system.

2 © 2010, ROSS CONTROLS. All Rights Reserved.

TM

.

The DM

monitor and the main valve components

into two identical piston-poppet assemblies.

Two piston-poppet assemblies provide

a redundant 3/2 normally closed air flow

pattern and the patented internal design

provides dynamic monitoring as well as

complete memory.

During valve operation air pressure acting

on changing combinations of assembly

surfaces cause the assemblies to move

to the required position. Force balances

in the valve assure positive shifting forces

during normal operation as well as a

positive force to hold the assemblies in a

locked-out position.

2®

Series D valve combines the

Page 3

DM2® Series D Double Valves

The ROSS DM2® Series D double valves provide significant

features in response to the changing demands of the

mechanical press industry and its associated standards and

regulations regarding the control of pneumatically controlled

clutch and brake applications. The consensus requirements

of the regulations and good practices require that, in case of

a failure within the valve, the clutch and brake mechanisms be

quickly exhausted, a monitor takes action to prevent further

operation, and a method to alert personnel is incorporated.

These features also make the valve suitable for use in other

Category 3 & 4 safety-related applications.

2®

A ROSS DM

Series D double valve has two valve elements

independently controlled by two solenoid pilots. The two

valve elements share common inlet, outlet, and exhaust ports.

When the pilot valves are simultaneously energized, the valve

elements operate so that the valve functions as a 3/2 normally

closed valve.

If one of the valve elements does not open or close synchronously

with the other, the valve goes into a faulted condition, exhausts

downstream air and keeps residual outlet pressure to less than

1% of inlet supply. This is an important safety characteristic of

2®

the ROSS DM

Series D design.

DM2® Monitoring:

The DM

intermediate, lockout position) distinguished by CrossflowTM

passages with poppet and spool valving on the main valve

stems. This arrangement provides the valve’s outstanding

flow characteristics and an integrated monitoring capability

with total memory. The valve provides dynamic monitoring

and dynamic memory.

2®

is a patented 3/2 normally closed valve (with an

Valve element redundancy provides an additional safety factor,

as the likelihood of a malfunction in both valve elements in the

same cycle is considered extremely remote.

2®

valves also have an internal monitor that is integrated

DM

into the valve elements. Should the valve operate abnormally,

the monitor will lock-out the valve and prevent further operation

until corrective action is taken.

IMPORTANT NOTE:

Standards, regulations, and good practice all require that

mechanical power presses or other hazardous machines using

a pneumatically-controlled clutch and brake mechanism be

equipped with a double valve with a self-contained monitoring

device and/or an external monitoring system, which inhibits

further operation of the valve and machine in the event of a

failure within the valve. Of course, a double valve is just one

of the components in a press control system, and all other

elements of the system should be planned with safety as a

primary consideration.

Dynamic Monitoring means that all monitoring components

change state on every valve cycle. Should the valve elements

cycle asynchronously, the valve will exhaust downstream air

and lock-out, prohibiting further operation.

Dynamic Memory within a monitoring system indicates that

when a valve lock-out occurs, the valve will retain the fault

information regardless of air or electrical changes. The DM

2®

system can only be reset by a defined operation/procedure, and

will not self-reset (turning the valve off and on) or reset when

inlet air supply is removed and re-applied. Such automatic

resetting would conceal potential hazards from the operator.

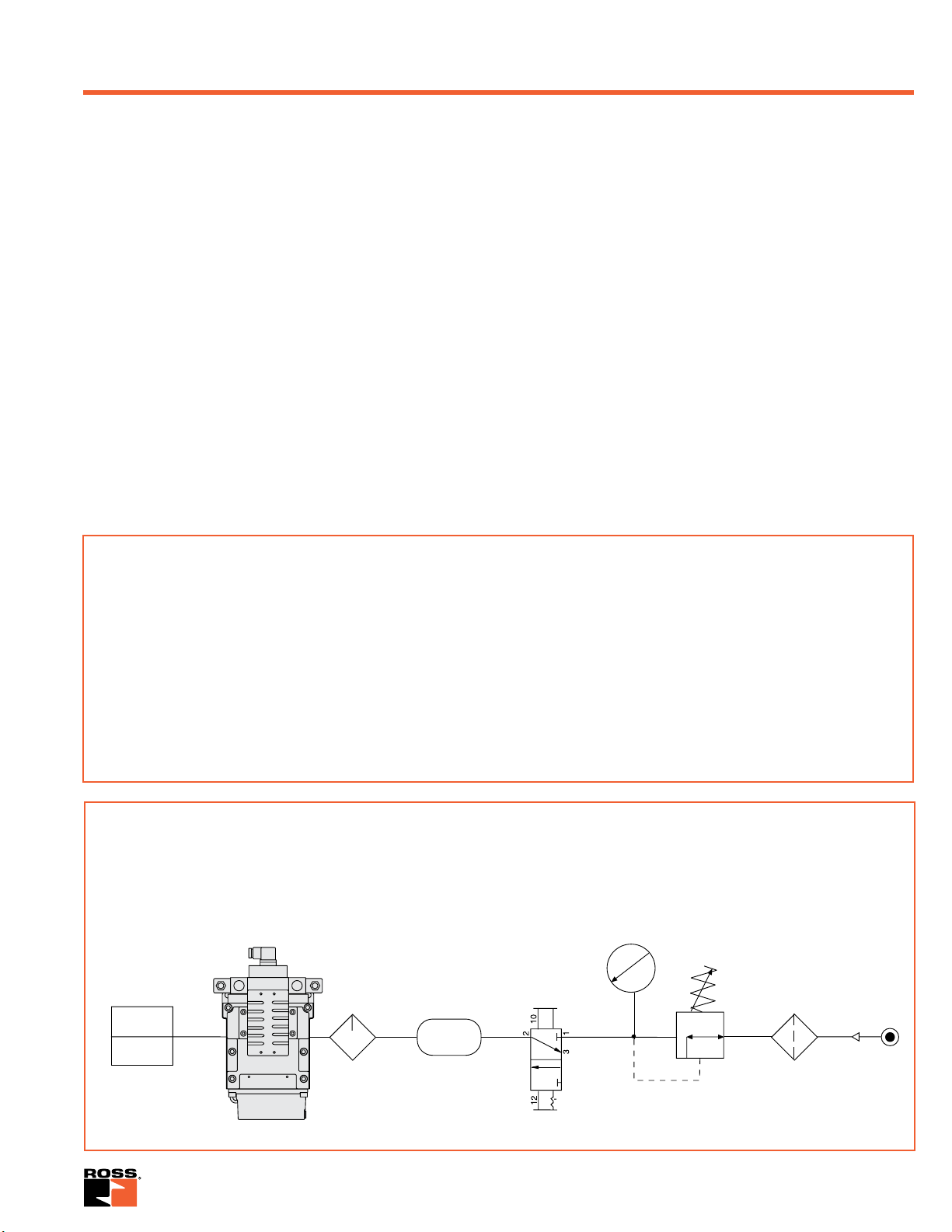

Installation Example

2®

DM

Series D Double Valve

(Status indicator – optional)

Clutch and brake

combination

Lubricator

Volume

L-O-X

www.rosscontrols.com 3

Pressure gauge

®

- Valve

Filter and

water separator

Pressure regulator

Page 4

DM

2®

Series D

Self Monitored - Clutch/Brake Control

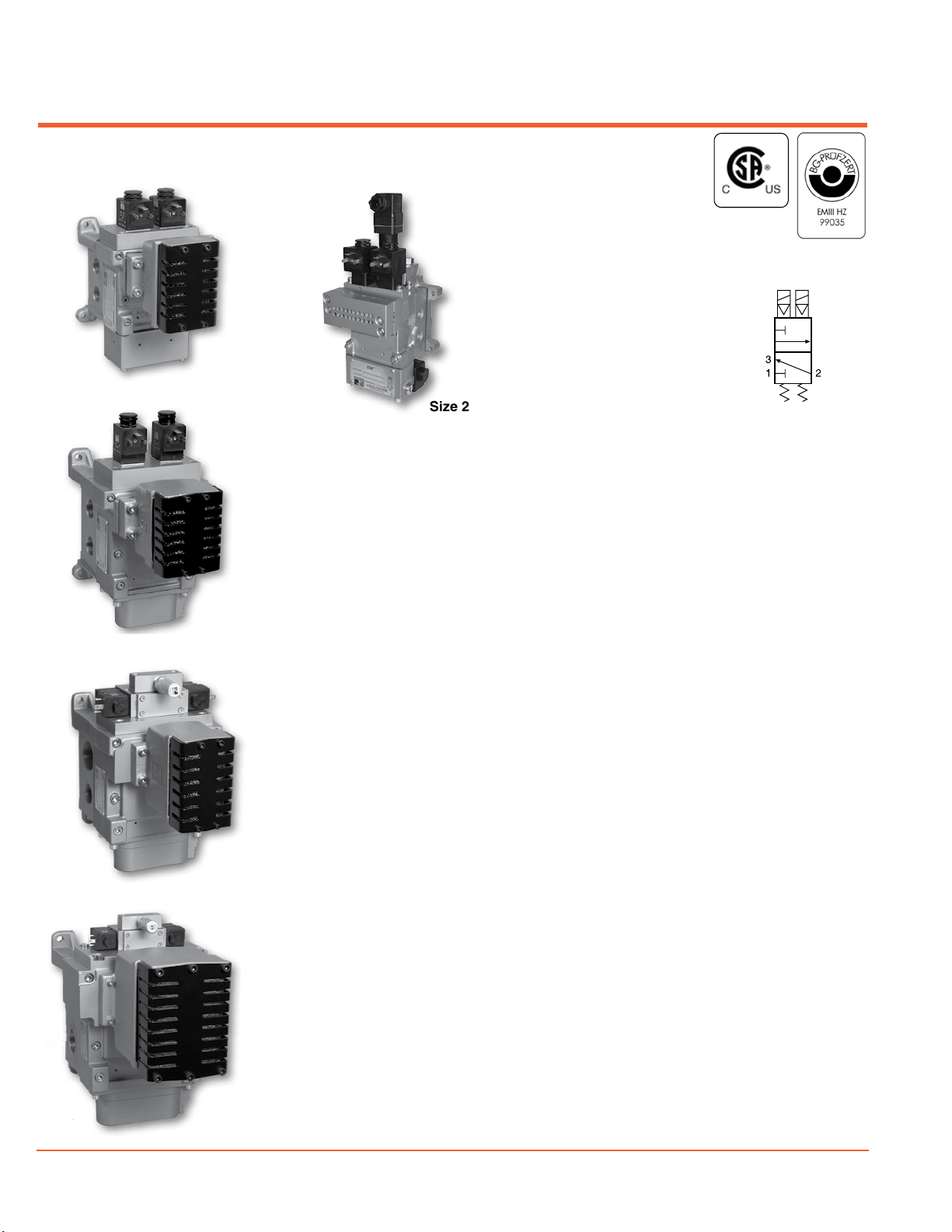

Size 4

Double Valves with Total Dynamic

Monitoring & Complete Memory

For Size 2 Certifications

Approval Pending

Size 8

Size 12

Size 2

Valve Sizes: DM2® Series D double valves are available in 5 sizes, providing a

broad range of flow capabilities to meet your needs. For convenience, valves

are designated by the nominal sizes 2, 4, 8, 12, and 30 with outlet ports ranging

from 1/4” to 2”.

Simplified Schematic

Size 2, 4, 8, 12 and 30

• Dynamic Monitoring With Complete Memory: Memory, monitoring, and air

flow control functions are simply integrated into two identical valve elements.

Valves lock-out due to asynchronous movement of valve elements during

actuation or de-actuation, resulting in a residual outlet pressure of less than

1% of supply. Overt action is required for reset – cannot be reset by removing

and re-applying supply pressure. Reset can only be accomplished by remote

air signal, optional electrical solenoid reset signal, or optional manual reset.

• Basic 3/2 Normally Closed Valve Function: Dirt tolerant, wear compensating

poppet design for quick response and high flow capacity. Teflon back-up rings on

pistons to enhance valve endurance – operates with or without inline lubrication.

• Status Indicator (Optional): Includes a pressure switch with both normally

open and normally closed contacts to provide status feedback to the press

control system indicating whether the valve is in the lockout or ready-to-run

condition. The Status Indicator can be ordered installed or purchased separately

and added to any DM2® base.

• Silencers: All models include high flow, clog resistant silencers.

• Mounting: Base mounted – with BSPP or NPT pipe threads. Inlet and outlet

ports on both sides provide for flexible piping (plugs for unused ports included).

Captive valve-to-base mounting screws.

Size 12 and 30

• Intermediate Pilots: Increases pilot air flow for fast valve response, making it

possible to use the same size solenoids as valve sizes 2, 4 & 8, thereby reducing

electrical power requirements for these larger valves.

Size 30

4 © 2010, ROSS CONTROLS.

All Rights Reserved.

Page 5

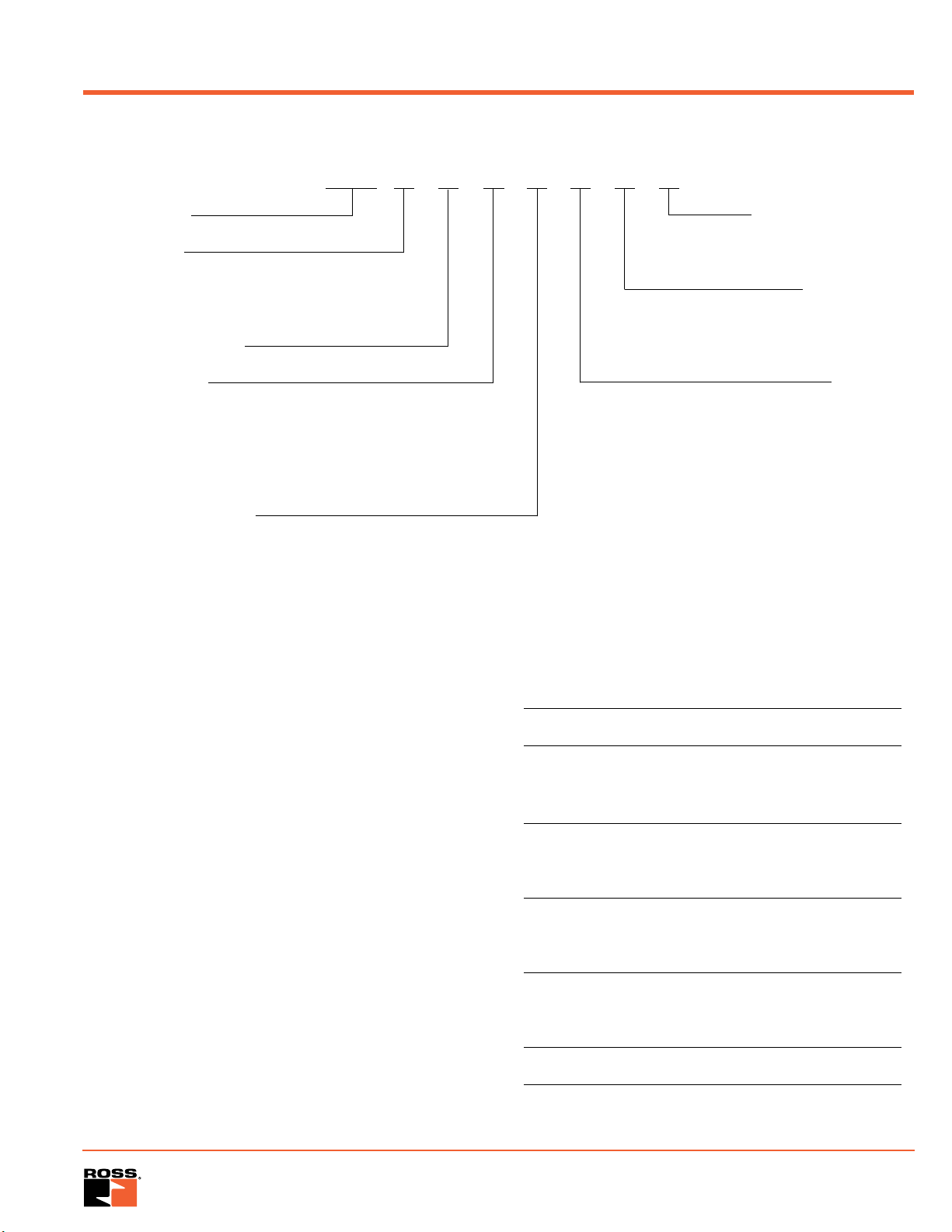

DM2® Series D Double Valves

HOW TO ORDER

(Choose your options (in red) to configure your valve model number.)

DM2D D A 4 2 A 1 1

PRODUCT

THREAD

BSPP ............................................. D

NPT ............................................... N

N/A (no base) ................................ X

REVISION LEVEL

BASIC SIZE

2......................................................2

4......................................................4

8......................................................5

12....................................................6

30....................................................8

BASE PORT SIZE

Size 2

1/4 inlet – 1/4 outlet ........................0

3/8 inlet – 3/8 outlet ........................1

Size 4

1/2 inlet – 1/2 outlet ........................2

1/2 inlet – 3/4 outlet ........................3

Size 8

3/4 inlet – 3/4 outlet ........................4

1 inlet – 1 outlet ..............................5

Size 12

1inlet – 1outlet ................................6

1inlet – 1½ outlet ............................7

Size 30

1½ inlet – 2 outlet ...........................8

Valve only (less base) ................. X

Valve Weight: Valve and base assembly

with status indicator and solenoid reset.

Size 2: 5.0 lb (2.3 kg).

Size 4: 6.0 lb (2.8 kg).

Size 8: 9.1 lb (4.2 kg).

Size 12: 15.5 lb (7.1 kg).

Size 30: 32.6 lb (14.8 kg).

STATUS INDICATOR

1......................................... YES

X ...........................................N O

RESET TYPE

1..................................REMOTE

2.............................. SOLENOID

4.................................. MANUAL

VOLTAGE

A ............................. 24 volts DC

B ........... 110 volts AC, 50/60 Hz

C** ........ 220 volts AC, 50/60 Hz

** 220 VAC not available in the U.S.

(OSHA regulations limit press control

voltage to no more than 120 volts AC).

BASE MODEL NUMBERS and

BASE SPECIFIC INFORMATION

Valve

Port Size Base Status Weight

Size Inlet Outlet Model Number*

2 1/4 1/4 1872C91 No 1.7 (0.8)

2 1/4 1/4 1873C91 Yes 2.1 (1.0)

2 3/8 3/8 1874C91 No 1.7 (0.8)

2 3/8 3/8 1875C91 Yes 2.1 (1.0)

4 1/2 1/2 1697C91 No 1.7 (0.8)

4 1/2 1/2 1698C91 Yes 2.3 (1.1)

4 1/2 3/4 1699C91 No 1.7 (0.8)

4 1/2 3/4 1700C91 Yes 2.3 (1.1)

8 3/4 3/4 1701C91 No 3.6 (1.6)

8 3/4 3/4 1702C91 Yes 4.2 (1.9)

8 1 1 1703C91 No 3.6 (1.6)

8 1 1 1704C91 Yes 4.2 (1.9)

12 1 1 1705C91 No 6.2 (2.8)

12 1 1 1706C91 Yes 6.8 (3.1)

12 1 1½ 1707C91 No 6.2 (2.8)

12 1 1½ 1708C91 Yes 6.8 (3.1)

30 1½ 2 1709C91 No 12.0 (5.4)

30 1½ 2 1710C91 Yes 12.6 (5.7)

*NPT port threads. For BSPP threads add a “D“ prefix to the

model number, e.g., D1872C91.

Indicator

lb (kg)

www.rosscontrols.com 5

Page 6

DM2® Series D Double Valves

SIZE 2

CV :

1 to 2: 2.17

2 to 3: 3.66

SIZE 4

10.63

(270.0)

With Status

Indicator &

Solenoid Reset

0.64

(16.2)

4.79 (121.6)

1.37

(34.9)

1.19

(30.2)

0.82

(20.9)

9.99

(253.8)

With Status

Indicator

4.50 (114.3)

4.00 (101.6)

2.99

(75.9)

2.04

(51.9)

7.73

(196.4)

0.25

(6.4)

DIMENSIONS – inches (mm)

(Base mounting hole pattern)

(Base mounting hole pattern)

(Based in overall hole dimnsions at left.)

View X

Valve envelope

(Based in overall hole dimnsions at left.)

0.22 (5.6)

(4 places)

4.00 (101.6)

2.99

(75.9)

4.00 (101.6)

2.04

(51.9)

0.64 (16.3)

with Solenoid Reset

View X

Valve envelope

0.25

(6.4)

:

C

V

1 to 2: 2.80

2 to 3: 6.70

SIZE 8

C

:

V

1 to 2: 4.63

2 to 3: 12.55

6 © 2010, ROSS CONTROLS.

All Rights Reserved.

(Base mounting hole pattern)

View X

Valve envelope

(Based in overall hole dimnsions at left.)

Page 7

DM2® Series D Double Valves

DIMENSIONS – inches (mm)

SIZE 12

CV :

1 to 2: 8.86

2 to 3: 20.78

SIZE 30

with Pressure

11.27

(286.26)

12.61

(320.23)

Switch

(Base mounting hole pattern)

(Base mounting hole pattern)

(Based in overall hole dimnsions at left.)

View X

Valve envelope

(Based in overall hole dimnsions at left.)

View X

Valve envelope

C

:

V

1 to 2: 20.22

2 to 3: 53.68

STANDARD SPECIFICATIONS: For DM2® Series D double valves.

Pilot Solenoids: According to VDE 0580. Enclosure rating

according to DIN 40050, IEC 60529 IP65. Two solenoids, rated

for continuous duty (

additional solenoid on optional reset).

Standard Voltages: 110 volts, 50/60 Hz; 220** volts, 50/60 Hz;

24 volts DC. For other voltages, consult ROSS.

** 220 volts AC not available in the U.S. (OSHA regulations limit

press control voltage to no more than 120 volts AC. Specify voltage

and frequency on order.

Power Consumption (each solenoid):

Size 2, 4, 12, 30:

For primary and reset solenoids:

6.0 watts on DC; 15.8 VA inrush and 10.4 VA holding on AC.

Size 8:

Primary solenoids:

15 watts on DC; 36 VA inrush and 24.6 VA holding on AC.

Reset solenoid:

6.0 watts on DC; 15.8 VA inrush and 10.4 VA holding on AC.

Electrical connection:

Size 2, 4, 8, 12, 30: DIN 43650, Form A. Order connectors separately.

15.48

(393.14)

with Pressure

Switch

14.25

(361.98)

Ambient Temperature: 15° to 120°F (-10° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered, lubricated or unlubricated (mineral oils

according to DIN 51519, viscosity classes 32-46); 5-micron

recommended.

Inlet Pressure:

Size 2: 45 to 150 psig (3.1 to 10.3 bar).

Size 4, 8, 12, 30: 30 to 120 psig (2.1 to 8.3 bar).

Reset Pressure: For remote air reset option – must be equal to

inlet pressure.

Manual Pressure: Encapsulated, push button actuation.

Pressure Switch (Status Indicator) Rating: Contacts - 5 amps

at 250 volts AC, or 5 amps at 30 volts DC.

Monitoring: Dynamically, cyclically, internally during each actuating

and de-actuating movement. Monitoring function has memory and

requires an overt act to reset unit after lockout.

Mounting orientation: Preferably horizontally (valve on top of base)

or vertically (with pilot solenoids on top).

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

www.rosscontrols.com 7

Page 8

Overview of DM

EXH

U

S

TTT

N

EXH

U

S

TTT

N

O

U

TLE

T

EXHAUST

OUTLET

INLET

AB

EXH

U

S

TTT

N

O

U

TLE

T

2®

Series D Double Valve Function

Valve de-actuated:

The flow of inlet air pressure

into the crossover passages

AB

is restricted by the size of the

passage between the stem and

the valve body opening. Flow is

A

EXHAUST

sufficient to quickly pressurize

pilot supply/timing chambers A

OUTLET

and B. The inlet poppets prevent

air flow from crossover passages

into the outlet chamber. Air pres-

INLET

sure acting on the inlet poppets

and return pistons securely hold

the valve elements in the closed

position. (Air passages shown

out of position and reset adapter

Valve ready-to-run

omitted for clarity.)

Valve actuated:

Energizing the pilot valves

AB

simultaneously applies pressure to both pistons, forcing the

internal parts to move to their

actuated (open) position, where

A

EXHAUST

OUTLET

OUTLET

inlet air flow to crossover passages is fully open, inlet poppets

are fully open and exhaust poppets are fully closed. The outlet

is then quickly pressurized, and

INLET

pressure in the inlet, crossovers,

outlet, and timing chambers are

quickly equalized.

De-energizing the pilots quickly

Valve actuated

causes the valve elements

to return to the ready-to-run

position.

Valve loked-out:

Whenever the valve elements

operate in a sufficiently asynchronous manner, either on actuation

AB

or de-actuation, the valve will

move to a locked-out position.

In the locked-out position, one

crossover and its related timing

chamber will be exhausted, and

A

EXHAUST

OUTLET

the other crossover and its related

timing chamber will be fully pressurized. The valve element (side

B) that is partially actuated has

INLET

pilot air available to fully actuate

it, but no air pressure on the

return piston to fully de-actuate

the valve element. Air pressure

Valve locked out

in the crossover acts on the differential of side B stem diameters

creating a latching force.

Side A is in a fully closed position, and has no pilot air available to

actuate, but has full pressure on the inlet poppet and return piston

to hold the element in the fully closed position.

Inlet air flow on side A into its crossover is restricted, and flows

through the open inlet poppet on side B, through the outlet into the

exhaust port, and from the exhaust port to atmosphere. Residual

pressure in the outlet is less than 1% of inlet pressure.

The return springs are limited in travel, and can only return the valve

elements to the intermediate (locked-out) position. Sufficient air

pressure acting on the return pistons is needed to return the valve

elements to a fully closed position.

Resetting the valve:

The valve will remain in the lockedout position, even if the inlet air

supply is removed and re-applied. A

remote reset signal (air or electric),

or a manual push button actuation

must be applied to reset the valve.

Reset is accomplished by momentarily pressurizing the reset

port. Actuation of the reset piston

physically pushes the main valve elements to their closed position. Inlet

air fully pressurizes the crossovers

and holds the inlet poppets on seat.

Actuation of the reset piston opens

the reset poppet, thereby, immedi-

Valve being reset

ately exhausting pilot supply air, thus, preventing valve operation

during reset. (Reset adapter added to illustration.)

De-actuation of reset pistons

causes the reset poppets to

close and pilot supply to fully

pressurize.

Reset air pressure can be

applied by a remote 3/2 normally

closed valve, or from an optional

3/2 normally closed solenoid, or

a manual push button mounted

Status indicator (optional)

in normal ready-to-run position

on the reset adapter.

Status indicator:

The status indicator pressure switch will

actuate when the main valve is operating

normally, and will de-actuate when the

main valve is in the locked-out position

AB

or inlet pressure is removed. This device

is not part of the valve lockout function,

but, rather, only reports the status of

the main valve.

Size 12 and 30 valves require relatively

large pilots to actuate and de-actuate

the main valve elements. In order to

achieve extremely quick valve response

for such large pilots, a 2-stage solenoid

pilot system is incorporated into the

design. This keeps the electrical

current required to operate the pilots,

to a minimum.

Size 12 & 30 pilots

8 © 2010, ROSS CONTROLS. All Rights Reserved.

Page 9

EXHAUST

OUTLET

INLET

AB

Overview of DM

MAIN VALVE INTERNALS

2®

Series D Double Valve

VALVE SCHEMATIC

Pilot Valve B

Piston

Exhaust chamber

Exhaust poppet

Crossover passages

Inlet chamber

Spring stop

Return spring

Pilot Valve A

Pilot supply/timing chamber A

Outlet chamber

Inlet poppet

Timing orifice

Flow restrictor

Reset poppet

Reset piston

www.rosscontrols.com 9

Page 10

Valve Response Charts

The charts below represent the fill and exhaust times for each of the various sizes of DM2® Series D

double valves. The “fill” times were measured while raising (filling) the pressure in a volume from 0 to

30, 60, & 80 psi (0 to 2.1, 4.1, & 5.5 bar) with a 90 psi (6.2 bar) inlet pressure. Conversely, the “exhaust”

times were measured while lowering the pressure (exhausting) in a volume from 90 psi (6.2 bar) down

to 90 to 60, 30, & 9 psi (4.1, 2.1, & 0.6 bar). Exhausting tests performed with silencer installed.

ExhaustingFilling

Size 2

0.25 (15.25) 0.5 (30.5) 0.75 (45.75) 1 (61)

Volume litres (cubic inches)

Volume litres (cubic inches)

0.25 (15.25) 0.5 (30.5) 0.75 (45.75) 1 (61)

Volume litres (cubic inches)

Size 4

Volume litres (cubic inches)

Size 8

Volume litres (cubic inches)

10 © 2010, ROSS CONTROLS. All Rights Reserved.

Volume litres (cubic inches)

Page 11

Valve Response Charts

Size 12

ExhaustingFilling

Volume litres (cubic inches)

Size 30

Volume litres (cubic inches)

Application & Safety Category

1. General

2®

The design features of the DM

importance to users of double valves, such as on mechanical

power press applications and other critical applications. This

is because the DM

2®

Series D is designed to meet the latest

standards requiring “control reliable”, “Category-3 & -4”, or

“dynamic monitoring” capability.

Both the monitoring and memory capabilities of the DM

D valve are built in to the two piston-poppet stem assemblies.

During normal operation, the assemblies move between two

extreme positions. The 3rd, or intermediate, position occurs only

during valve lock-out. The valve will lock out whenever there is

sufficiently asynchronous motion between the two piston-poppet

stem assemblies. No additional external or internal devices

are needed to provide monitoring and memory. When the inlet

air supply is removed and re-applied, the valve “remembers”

whether it was in the ready-to-run or locked-out position prior

to the removal of the air supply. Resetting the valve after it has

gone in to “locked out” mode requires a momentary application

of a reset signal. Should the reset signal be inadvertently left on

(permanent signal), the valve will nevertheless go back in to lockout mode.

2. Description

The three way valve with DM

valve systems and two pilot valve systems. The air flow paths

within the main valve systems are a proven combination of both

SERIES and PARALLEL paths.

Both pilot valves and both main valve elements are interconnected

with each other pneumatically. The main valve elements control the

air via Crossflow™ air passages from inlet (port 1) to outlet (port 2).

Series D are of considerable

2®

Series

2®

capability consists of two main

Volume litres (cubic inches)

Volume litres (cubic inches)

Air flows first through a control element on one side of the valve

to a control element on the second side of the valve, hence a

series flow path. A parallel flow path starts on the second side

of the valve and flows to the first side of the valve. A total of four

elements control air flow from inlet to outlet. Air flow from outlet

(port 2) to exhaust port (port 3) occurs in parallel via the exhaust

poppets of both main valve elements.

In normal operation, pilot air supply is maintained as long as the

two main elements operate in a synchronous manner. Whenever

there is asynchronous motion, however, one of the pilot air supplies

will be exhausted.

Sufficient pilot pressure is necessary to move the main valve

elements to their fully actuated or de-actuated positions.

Lack of sufficient pilot pressure will prevent a valve element from

fully shifting, resulting in the element stopping in the intermediate,

locked-out position.

3. Application

Uncontrolled movements of cylinders or rotary drives risks harm

to personnel and machinery. In order to reduce risk of injuries

and damage, pneumatic controls should ideally meet strict safety

requirements.

2®

ROSS developed the DM

Series D double valves for controlling

pneumatic clutch and brake mechanisms on mechanical power

presses. However, the features and functions built in to the

valve make it an ideal product to meet the specifications and

standards associated with other critical applications. Because

of its redundant design and the fact that the air is directed in a

Crossflow™ and SERPAR

®

pattern, the DM

2®

valve provides a

very high level of safety.

www.rosscontrols.com 11

Page 12

Operating Instructions

Start-up

Before start-up, the installation must be checked thoroughly by persons trained and experienced in the operation of pneumatic

equipment. Make sure that specifications given on the valve label (e.g. “max. operating pressure” and “electrical characteristics”)

will be in accordance with the operating specifications of the press. When operating pressure is initially applied, it may be

necessary to actuate the reset valve momentarily to move the main valve into the ready-to-run condition. Make sure that the

inlet supply and the exhaust path are not restricted. Operating pressure must comply with the minimum and maximum limits.

Functional test

Test Result

1. Solenoid “A” actuated Valve moves into lock-out mode, slight leakage at exhaust port 3

2. Solenoid “B” actuated Valve moves into lock-out mode, slight leakage at exhaust port 3

3. Solenoids “A” and “B” actuated with Valve operates properly

∆t < 0.1 s

4. Solenoids “A” and “B” actuated with Valve moves into lock-out mode, slight leakage at exhaust port 3

∆t > 0.1 s

5. After lock-out, permanent signal on Valve cannot be moved into ready-to-run mode

reset valve - solenoids “A” and “B”

or only “A” / only “B” actuated

Pressure test

After a valve lock-out, the double valve must be moved into the readyto-run position by using the reset valve. In general, if the valve is in

the lock-out mode and one or both of the solenoids are energized,

the valve should not reset with application or application and removal

of the reset signal. If the valve is in the ready-to-run mode after

the reset solenoid valve has been actuated momentarily, the valve

will function normally with application and removal of pilot solenoid

signal. However, if the valve elements cycle asynchronously, the

valve will go to the lock-out mode. Provided that both solenoids

are de-energized, removal of reset signal will return the valve to

the ready-to-run mode.

An additional test to perform:

• With the valve in the ready-to-run mode, exhaust and re-pressurize

the inlet port. The valve should remain in the ready-to-run mode.

• With the valve in the lock-out mode, exhaust and re-pressurize

the inlet port. The valve should remain in the lock-out mode.

Lock-outs

Any asynchronous movement between both piston elements for a

time period > 0.1 s will result in a lock-out of the valve. This can be

due to various causes, for instance:

• worn piston seals

• delayed response of the main valve elements due to dirt or

varnished lubricant

• electrical signals to solenoid incomplete or unable to maintain

proper voltage

• independent electrical signals to solenoids are not received

concurrently

• delayed response of solenoid pilots or booster pilots due to

damaged components, dirt, or varnished lubricant

• collection of excessive water or lubrication

Maintenance, Testing

Maintenance and testing procedures must follow the rules and

regulations set by the respective national work-safety institutions.

These procedures should only be performed by persons trained

and experienced in the use of pneumatic equipment. Regulations

generally require that maintenance and test procedures be performed

at least once a year.

Repair

ROSS would be happy to service this specialized double valve for you

at its factory repair center. Call your local ROSS office or distributor

(in the U.S. 1-800-GET-ROSS or +1-706-356-3708 outside the U.S.)

for information. If you service the valve yourself, be sure to turn off

electrical power to the valve, shut off the air supply, exhaust the air

in the system, and lock-out all power sources before beginning any

disassembly operation. Customers maintaining their own valves

should make sure that only original spare parts (as specified in the

ROSS parts lists) are used.

Pneumatic equipment should be repaired only by persons trained

and experienced in the repairing of such equipment, guided by

these operating instructions. Information about valve repair and/

or the exchange of a valve must be written down in the machine

operation documentation.

12 © 2010, ROSS CONTROLS. All Rights Reserved.

Page 13

Repair Kits

Item Description Size 2 Size 4 Size 8 Size 12 Size 30

A Valve body service kit 2101K77 2102K77 2103K77 2104K77 2105K77

B* Complete primary solenoid pilot 1480C79 1403H79 1404H79 1391K79 1391K79

C* Complete reset solenoid pilot 859C79 851C79 851C79 851C79 851C79

D* Solenoid coil - pilots 306K33 306K33 360K33 306K33 306K33

E* Solenoid coil reset 306K33 306K33 306K33 306K33 306K33

F* Pilot booster service kit – – – 2106K77 2106K77

* Specify solenoid voltage and Hz when ordering.

Kits for optional items Status indicator assembly kit – 2151H77

(not shown in the drawings): Replacement pressure switch – 1104A30

Sizes 2, 4 & 8

Sizes 12 & 30

DB

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

D

B

F

A

A

A

A

Reset port - 1/8

(remote reset models)

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Reset port - 1/8

A A

A

A

C E

A

A

A

C

E

A

(remote reset models)

www.rosscontrols.com 13

Page 14

Accessories

STATUS INDICATOR

The Status Indicator pressure switch

actuates when the valve is in a ready-torun condition and de-actuates when the

valve is in a lock-out condition or when

the inlet air pressure has been removed.

Although the valves can be purchased

with this option already installed, the

Statu s In dic ato r can be purc hased

separately by ordering part number:

670B94

RESET VALVES for MODELS with REMOTE RESET

On valve models with solenoid reset, a solenoid on the valve

is actuated to perform the reset function. Models for remote

reset, however, require a small reset valve and the installation

of a 1/8 line from the reset valve to the reset port on the double

valve. ROSS offers 3/2 normally closed valves with either

manual or electric control that are suitable for this purpose.

The valves, pictured below, are suggested.

Model Numbers of Reset Valves

Description Valve Model Numbers**

Pushbutton: Green 1223A1005

Direct Solenoid Control 1613B1020*

for line mounting

Direct Solenoid Control W1413A1409*

for base mounting (Base: 516B91)

**For BSPP threads, add a D prefix to the model number, e.g.,

D1223A1005. In the case of the W1413A1409, the prefix

should be added to the base model instead of the valve,

e.g., D516B91.

* Specify solenoid voltage and Hz when ordering.

ELECTRICAL CONNECTORS

Electrical connectors are required

to connect the valve solenoids to

the drop cords supplying electrical

power.

Each connector can be positioned

so that the cord exits upward or to

the side. Cords of 6-mm to 10-mm

diameter can be used. Connectors

with a light in a translucent housing are also available to

serve as indicator lights. Order connectors by the part

numbers given in the chart below.

WIRED CONNECTORS have a 2-meter (6-1/2 ft.) cord

with three 18-gauge conductors. Cord exits upward, and is

available in either 6-mm or 10-mm diameter.

Part Numbers of Form A Electrical Connectors

Connector Type Without Light With Light*

For use with dropcord

(Cord not included)

Wired with 6-mm cord 721K77 720K77*

Wired with 10-mm cord 371K77 383K77*

For use with threaded conduit** 723K77 724K77*

*Specify solenoid voltage when ordering.

**Accept 1/2-inch electrical conduit fitting.

CAUTION: Do not use electrical connectors with surge

suppressors, as this may increase valve response time

when de-actuating the solenoids.

937K87 936K87*

Pushbutton Models

Green button: 1223A1005

Direct Solenoid Model

for Line Mounting

1613B1020*

* Specify solenoid voltage and Hz when ordering.

14 © 2010, ROSS CONTROLS. All Rights Reserved.

Direct Solenoid Model

for Base Mounting

Valve: W1413A1409*

Sub-Base: 516B91

Page 15

CAUTIONS

PRE-INSTALLATION or SERVICE

1. Before servicing a valve or other pneumatic component, be

sure that all sources of energy are turned off, the entire pneumatic

system is shut off and exhausted, and all power sources are locked

out (ref: OSHA 1910.147, EN 1037).

2. All ROSS products, including service kits and parts, should

be installed and/or serviced only by persons having training and

experience with pneumatic equipment. Because any installation

can be tampered with or need servicing after installation, persons

responsible for the safety of others or the care of equipment must

check every installation on a regular basis and perform all necessary

maintenance.

3. All applicable instructions should be read and complied with

before using any fluid power system in order to prevent harm to

persons or equipment. In addition, overhauled or serviced valves

must be functionally tested prior to installation and use.

4. Each ROSS product should be used within its specification limits.

In addition, use only ROSS parts to repair ROSS products. Failure

to follow these directions can adversely affect the performance of

the product or result in the potential for human injury or damage

to property.

FILTRATION and LUBRICATION

5. Dirt, scale, moisture, etc. are present in virtually every air system.

Although some valves are more tolerant of these contaminants than

others, best performance will be realized if a filter is installed to clean

the air supply, thus preventing contaminants from interfering with

the proper performance of the equipment. ROSS recommends a

filter with a 5-micron rating for normal applications.

6. All standard ROSS filters and lubricators with polycarbonate

plastic bowls are designed for compressed air applications only.

Do not fail to use the metal bowl guard, where provided, to

minimize danger from high pressure fragmentation in the event of

bowl failure. Do not expose these products to certain fluids, such

as alcohol or liquefied petroleum gas, as they can cause bowls to

rupture, creating a combustible condition, hazardous leakage, and

the potential for human injury or damage to property. Immediately

replace a crazed, cracked, or deteriorated bowl. When bowl gets

dirty, replace it or wipe it with a clean dry cloth.

7. Only use lubricants which are compatible with materials used

in the valves and other components in the system. Normally,

compatible lubricants are petroleum based oils with oxidation

inhibitors, an aniline point between 180°F (82°C) and 220°F (104°C),

and an ISO 32, or lighter, viscosity. Avoid oils with phosphate type

additives which can harm polyurethane components, potentially

leading to valve failure which risks human injury, and/or damage

to property.

AVOID INTAKE/EXHAUST RESTRICTION

8. Do not restrict the air flow in the supply line. To do so could reduce

the pressure of the supply air below the minimum requirements for

the valve and thereby cause erratic action.

9. Do not restrict a valve’s exhaust port as this can adversely affect

its operation. Exhaust silencers must be resistant to clogging and

must have flow capacities at least as great as the exhaust capacities

of the valves. Contamination of the silencer can result in reduced

flow and increased back pressure.

ROSS expressly disclaims all warranties and responsibility for any

unsatisfactory performance or injuries caused by the use of the

wrong type, wrong size, or an inadequately maintained silencer

installed with a ROSS product.

POWER PRESSES

10. Mechanical power presses and other potentially hazardous

machinery using a pneumatically controlled clutch and brake

mechanism must use a press control double valve with a monitoring

device. A double valve without a self-contained monitoring device

should be used only in conjunction with a control system which

assures monitoring of the valve. All double valve installations

involving hazardous applications should incorporate a monitoring

system which inhibits further operation of the valve and machine

in the event of a failure within the valve mechanism.

ENERGY ISOLATION/EMERGENCY STOP

®

11. Per specifications and regulations, ROSS L-O-X

L-O-X® valves with EEZ-ON® operation are defined as energy

isolation devices, NOT AS EMERGENCY STOP DEVICES.

valves and

STANDARD WARRANTY

All products sold by ROSS CONTROLS are warranted for a one-year period [with the exception of all Filters, Regulators and

Lubricators (“FRLs”) which are warranted for a period of seven years] from the date of purchase to be free of defects in material

and workmanship. ROSS’ obligation under this warranty is limited to repair or replacement of the product or refund of the purchase

price paid solely at the discretion of ROSS and provided such product is returned to ROSS freight prepaid and upon examination

by ROSS is found to be defective. This warranty becomes void in the event that product has been subject to misuse, misapplication,

improper maintenance, modification or tampering.

THE WARRANTY EXPRESSED ABOVE IS IN LIEU OF AND EXCLUSIVE OF ALL OTHER WARRANTIES AND ROSS EXPRESSLY

DISCLAIMS ALL OTHER WARRANTIES EITHER EXPRESSED OR IMPLIED WITH RESPECT TO MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. ROSS MAKES NO WARRANTY WITH RESPECT TO ITS PRODUCTS MEETING

THE PROVISIONS OF ANY GOVERNMENTAL OCCUPATIONAL SAFETY AND/OR HEALTH LAWS OR REGULATIONS. IN NO

EVENT IS ROSS LIABLE TO PURCHASER, USER, THEIR EMPLOYEES OR OTHERS FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES WHICH MAY RESULT FROM A BREACH OF THE WARRANTY DESCRIBED ABOVE OR THE USE OR MISUSE OF

THE PRODUCTS. NO STATEMENT OF ANY REPRESENTATIVE OR EMPLOYEE OF ROSS MAY EXTEND THE LIABILITY OF

ROSS AS SET FORTH HEREIN.

www.rosscontrols.com 15

Page 16

GLOBAL Reach with a LOCAL Touch

sm

ROSS CONTROLS

Troy, MI., U.S.A.

Telephone: + 1-248-764-1800

Fax: + 1-248-764-1850

In the United States:

Customer Service: 1-800-GET ROSS

(438-7677)

Technical Service: 1-888-TEK-ROSS

(835-7677)

www.rosscontrols.com

ROSS EUROPA GmbH

Langen, Germany

Telephone: + 49-6103-7597-0

Fax: + 49-6103-74694

Email: info@rosseuropa.com

www.rosseuropa.com

ROSS ASIA K.K.

Kanagawa, Japan

Telephone: + 81-427-78-7251

Fax: + 81-427-78-7256

www.rossasia.co.jp

ROSS SOUTH AMERICA Ltda.

São Paulo, Brazil CEP 09725-020

Telephone: + 55-11-4335-2200

Fax: + 55-11-4335-3888

Email: vendas@ross-sulamerica.com.br

DIMAFLUID s.a.s.

Saint Ouen, France

Telephone: + 33-01-49-45-65-65

Fax: + 33-01-49-45-65-30

Email: dimafluid@dimafluid.com

www.dimafluid.com

ROSS CONTROLS (CHINA) Ltd.

Shanghai, China

Telephone: + 86-21-6915-7951

Fax: + 86-21-6915-7960

www.rosscontrolschina.com

ROSS UK Ltd.

Birmingham, United Kingdom

Telephone: + 44-121-559-4900

Fax: + 44-121-559-5309

Email: sales@rossuk.co.uk

Your local ROSS distributor is:

ROSS CONTROLS INDIA Pvt. Ltd.

Chennai, India

Telephone: + 91-44-2624-9040

Fax: + 91-44-2625-8730

Email: rossindia@airtelbroadband.in

There are ROSS Distributors Throughout the World

To meet your requirements across the globe, ROSS distributors are located throughout the world. Through ROSS or its

distributors, guidance is available for the selection of ROSS products, both for those using pneumatic components for

the first time and those designing complex pneumatic systems.

This catalog presents an overview of the extensive ROSS product line. Other literature is available for engineering,

maintenance, and service requirements. If you need products or specifications not shown here, please contact ROSS

or your ROSS distributor. They will be happy to assist you in selecting the best product for your application.

Printed in the U.S.A. - Rev. 10/10 © 2010, ROSS CONTROLS. All Rights Reserved.

Form A10295

Supersedes all previous

editions of 505 bulletins.

Loading...

Loading...